Stochastic Drift Counteraction Optimal Control of a Fuel Cell-Powered Small Unmanned Aerial Vehicle

Abstract

:1. Introduction

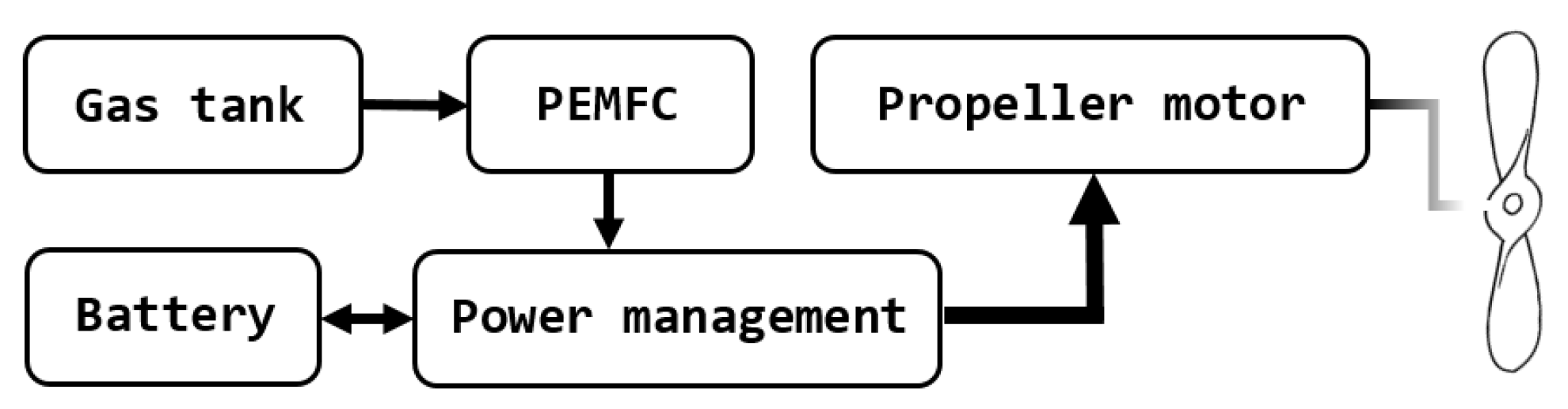

2. Physical Description of the Systems and Model

2.1. sUAV Dynamics

2.2. Propeller Model

2.3. Electric Motor Model

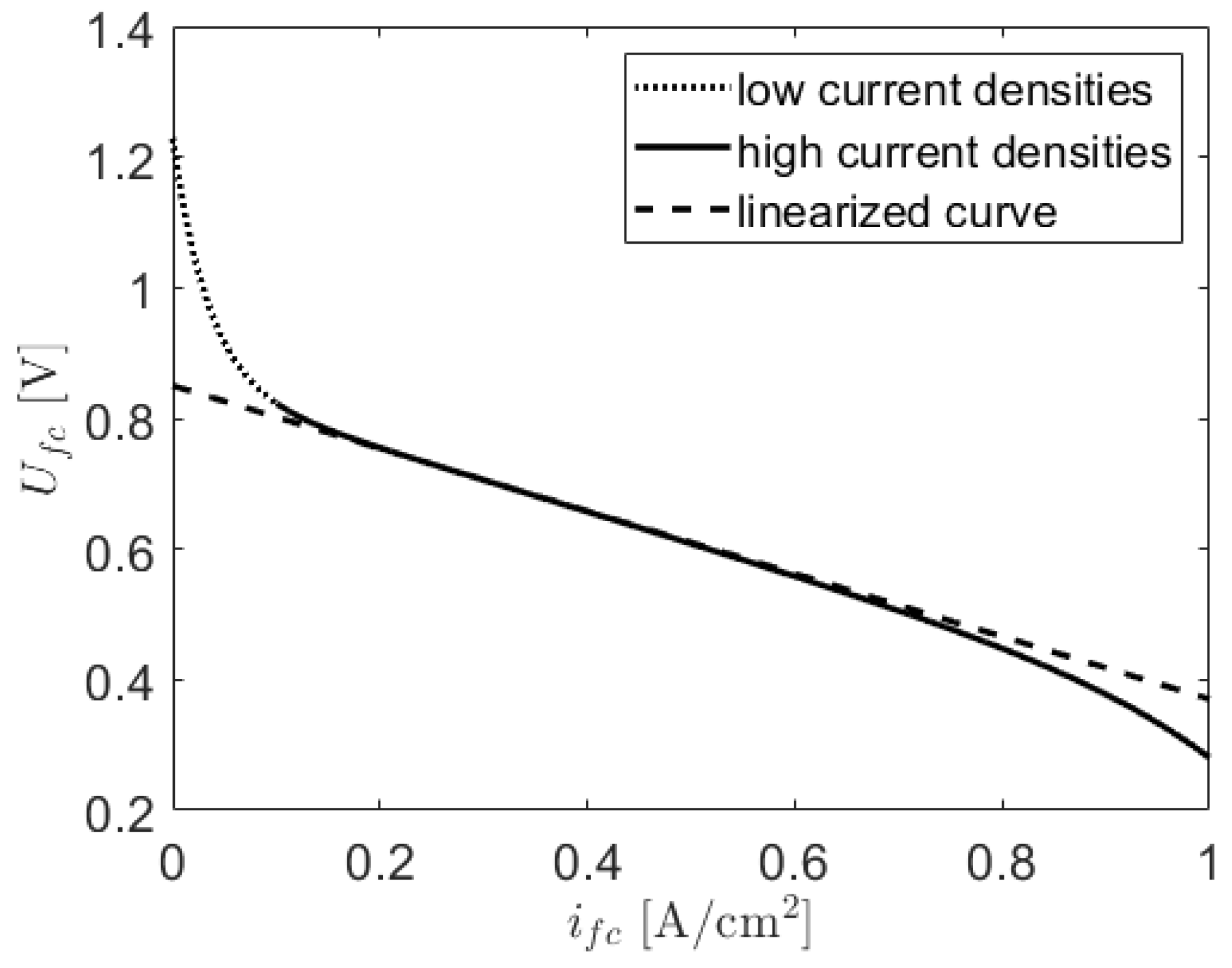

2.4. Fuel Cell Model

2.5. Battery Model

3. Hybrid System Model and Problem Formulation

3.1. Hybrid System

3.2. Problem Formulation

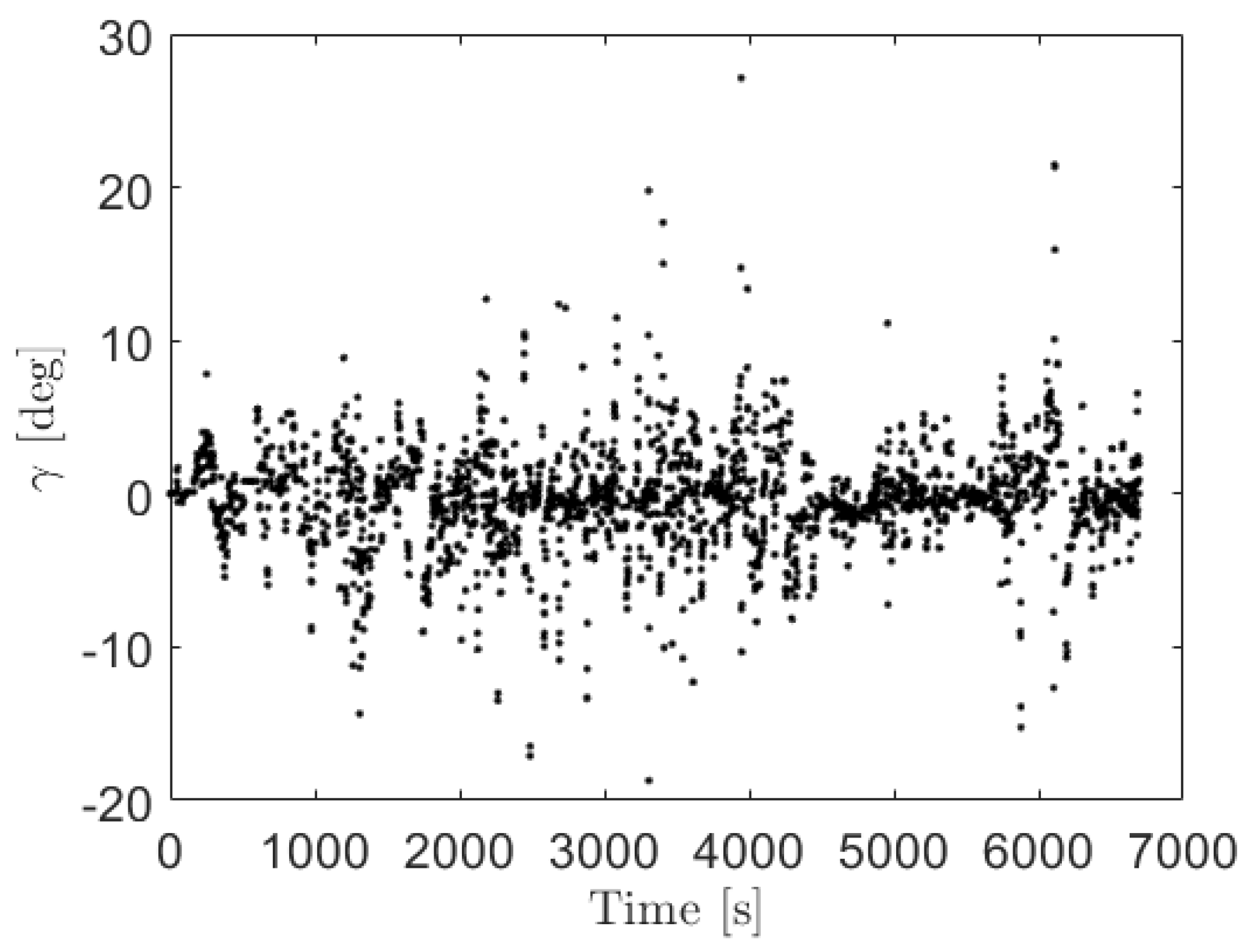

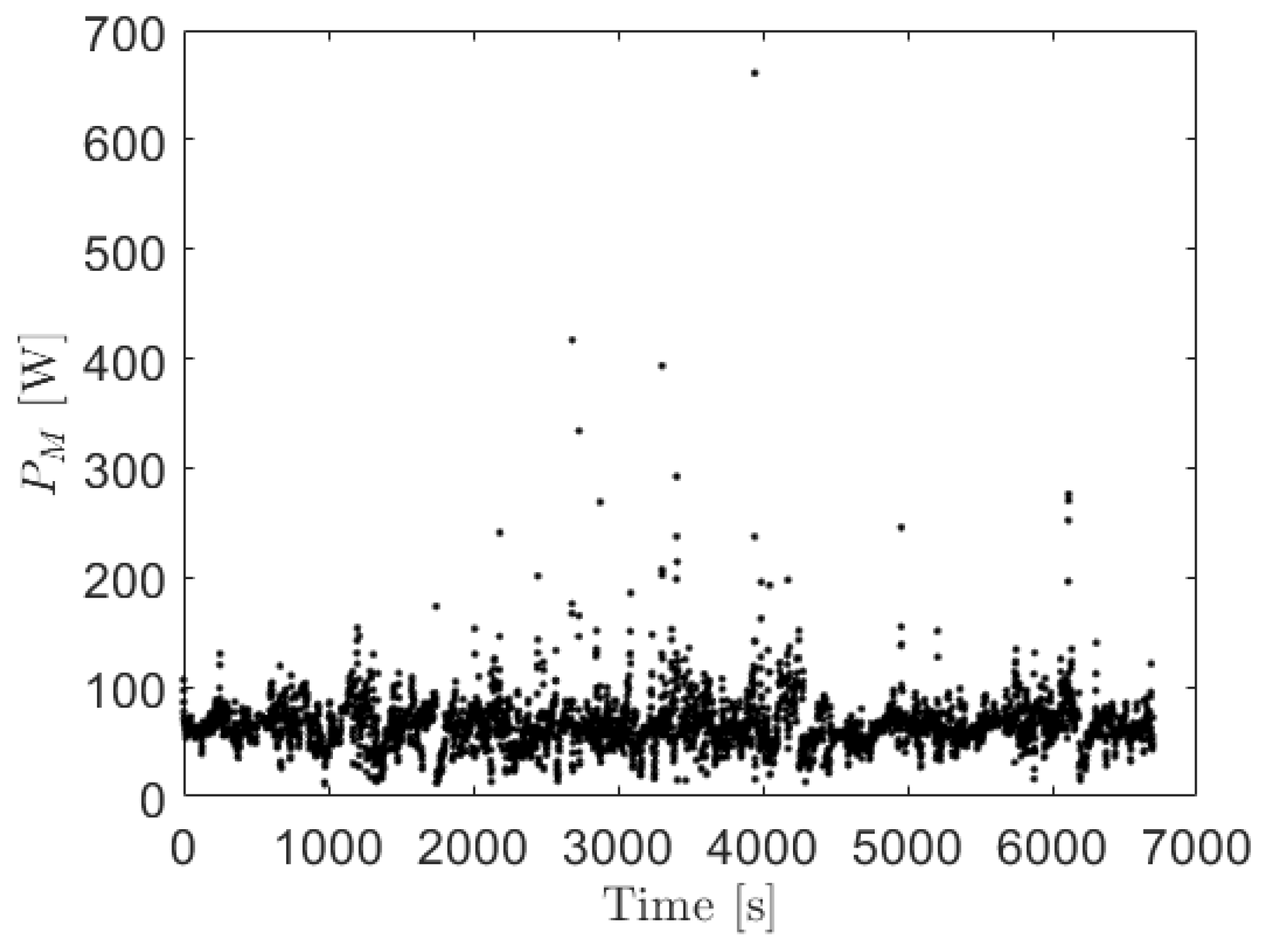

3.3. Markov Chain Modeling

4. Control Law Construction

5. Control Law Computations and Results

5.1. sUAV Configuration and Model Parameters

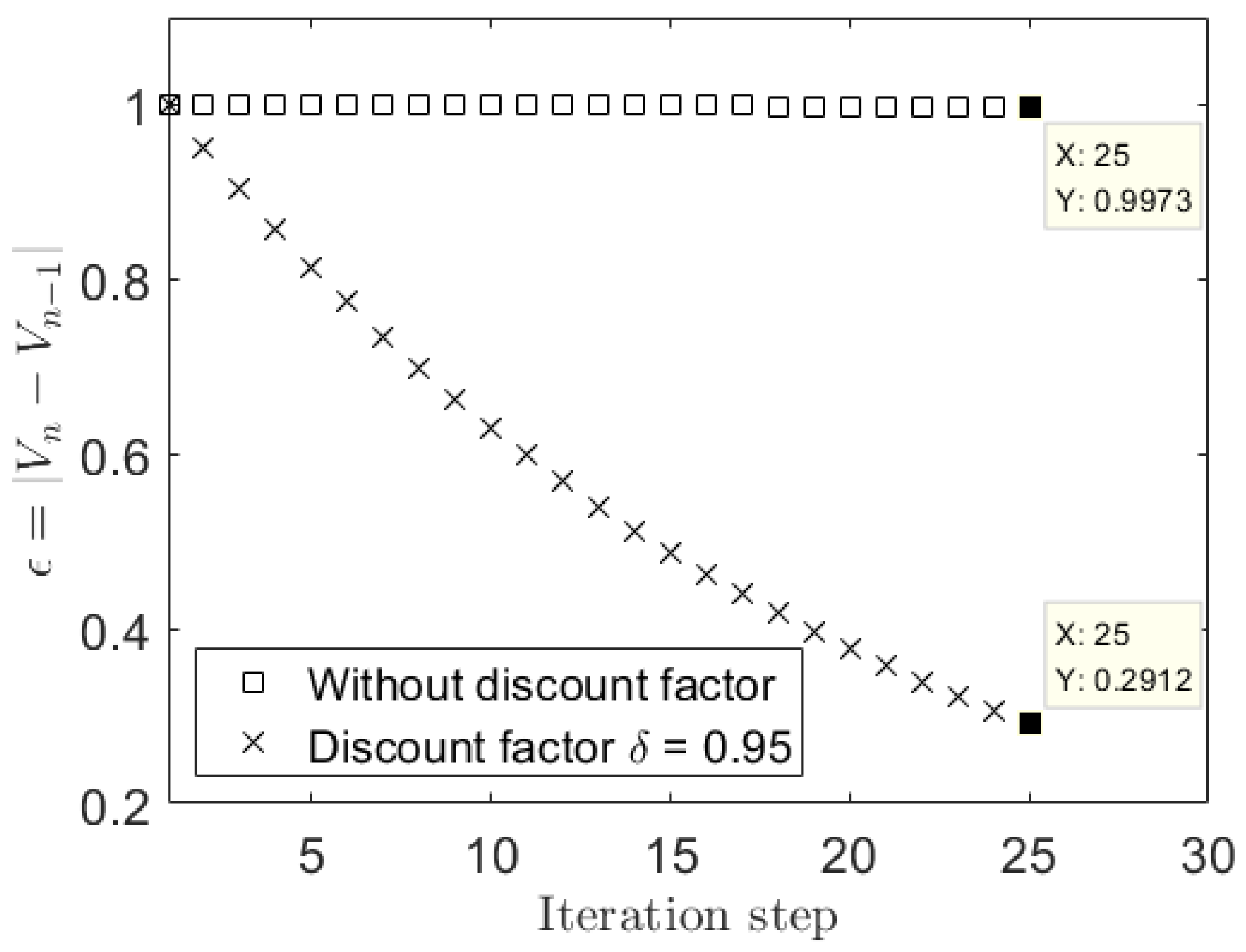

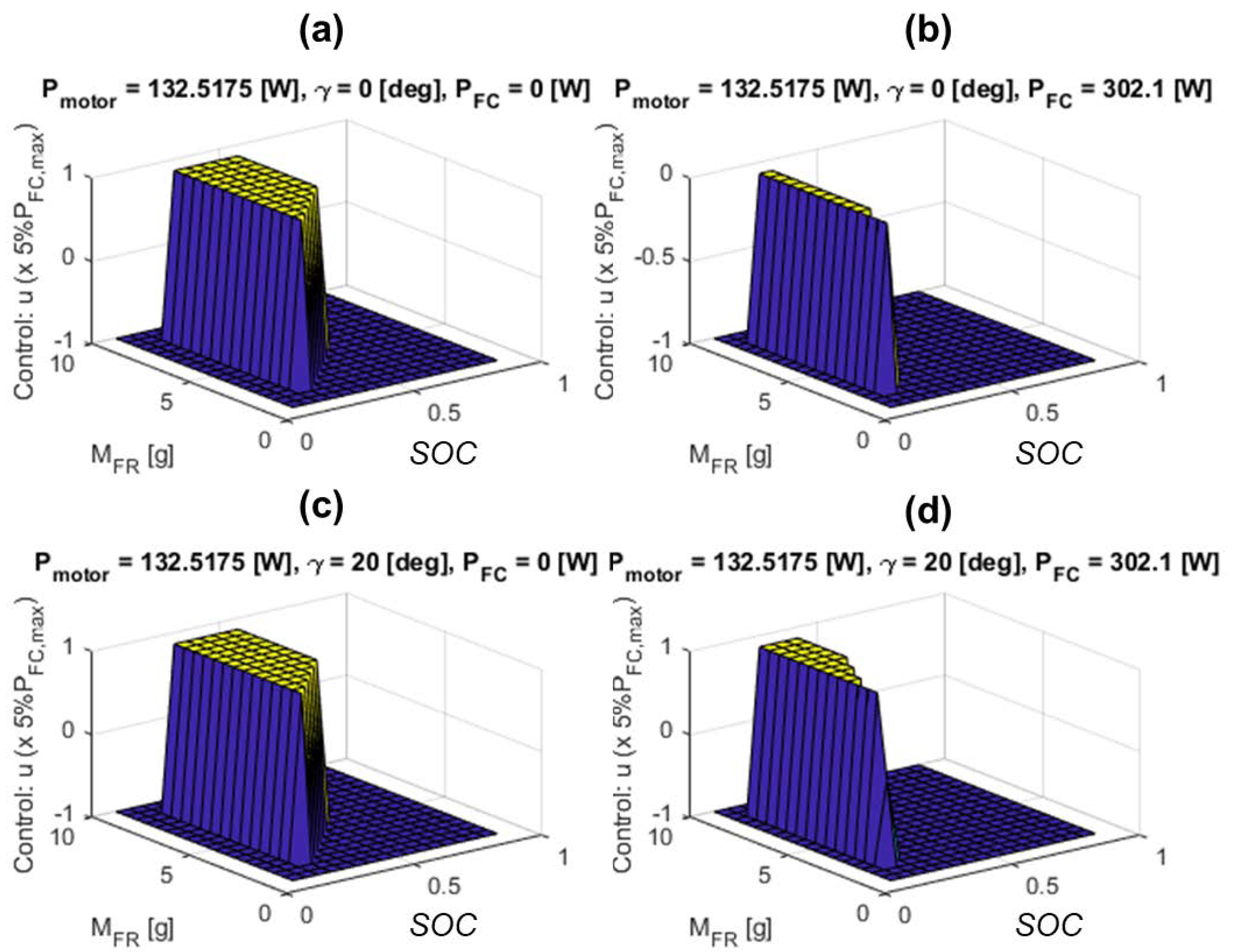

5.2. Control Law Computation

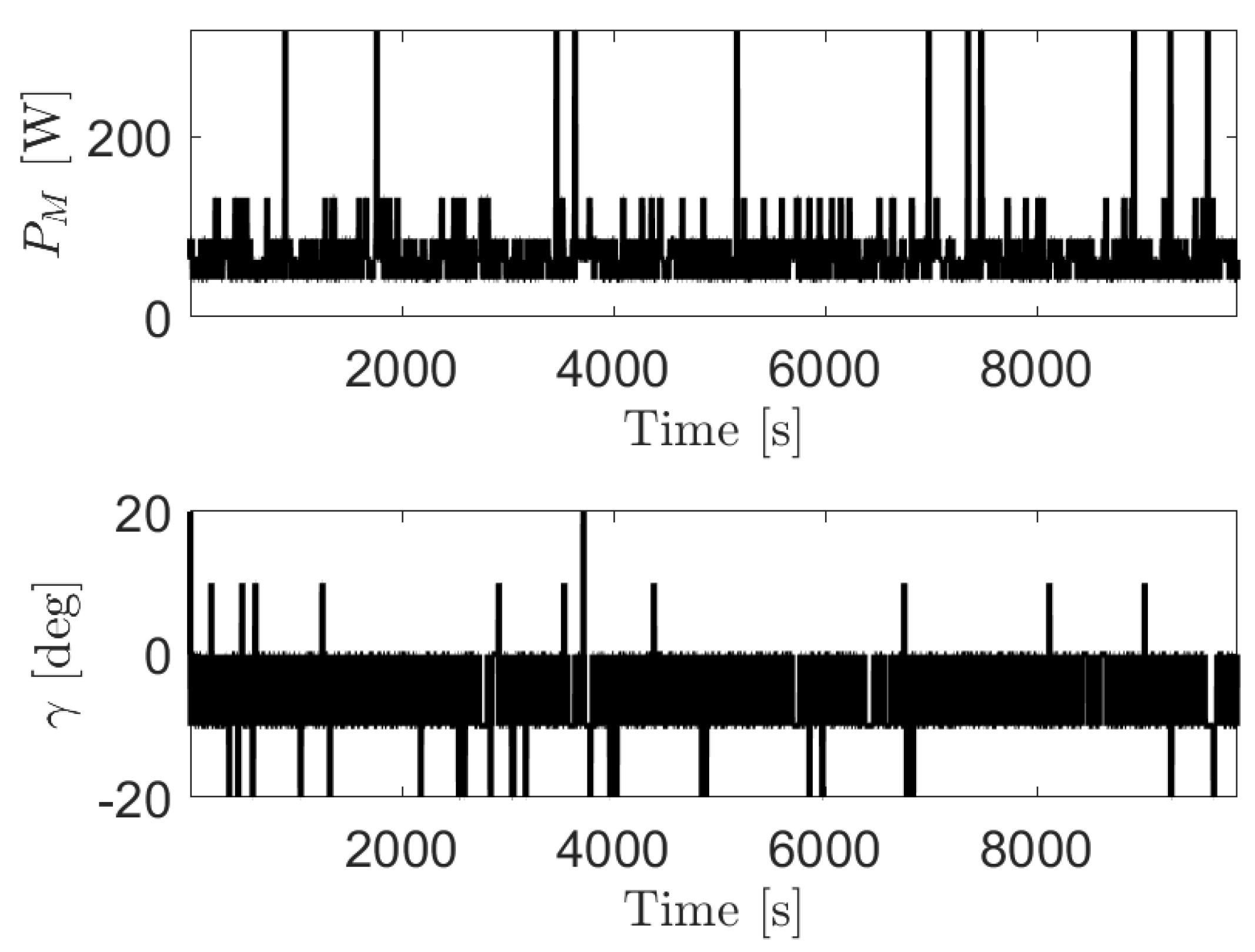

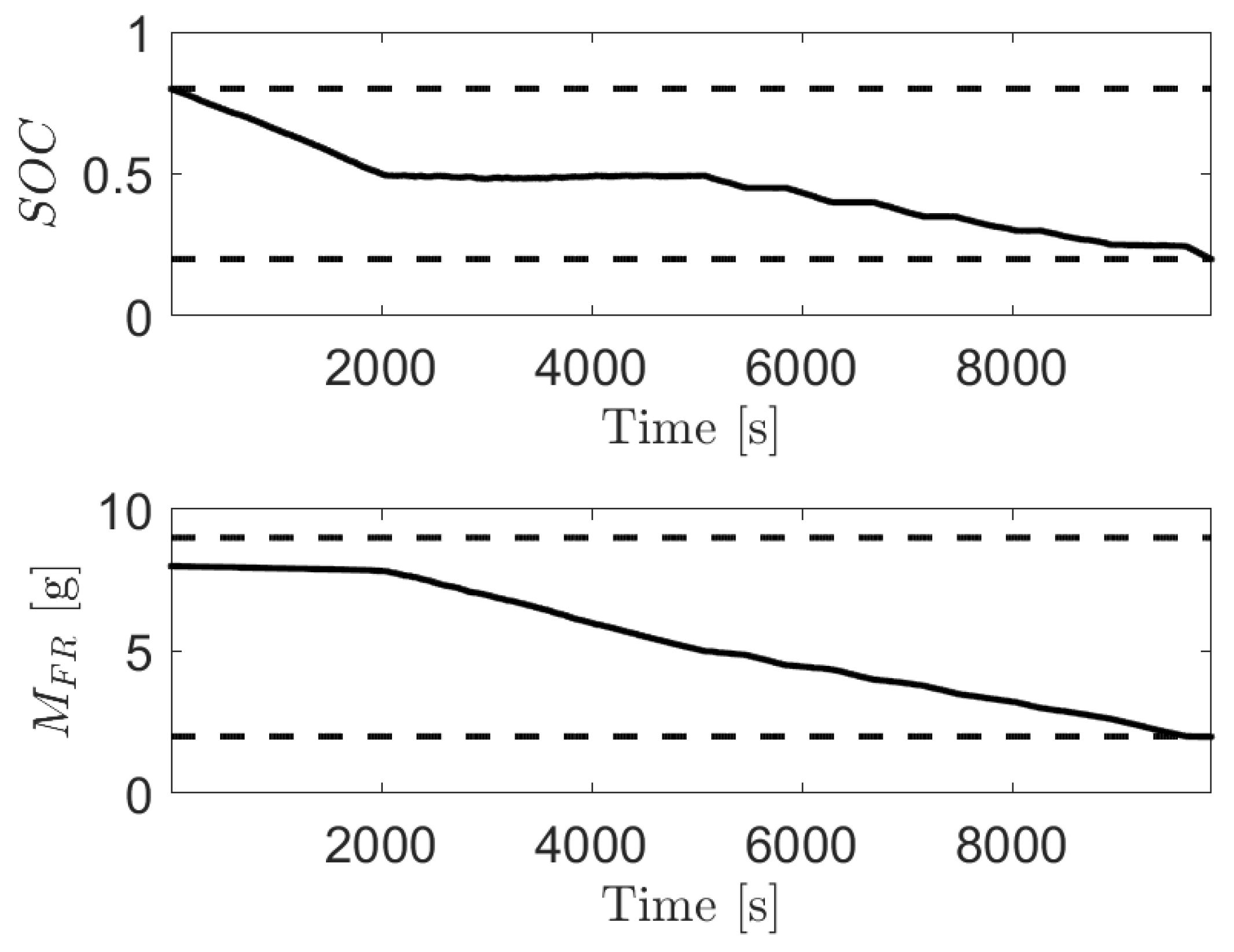

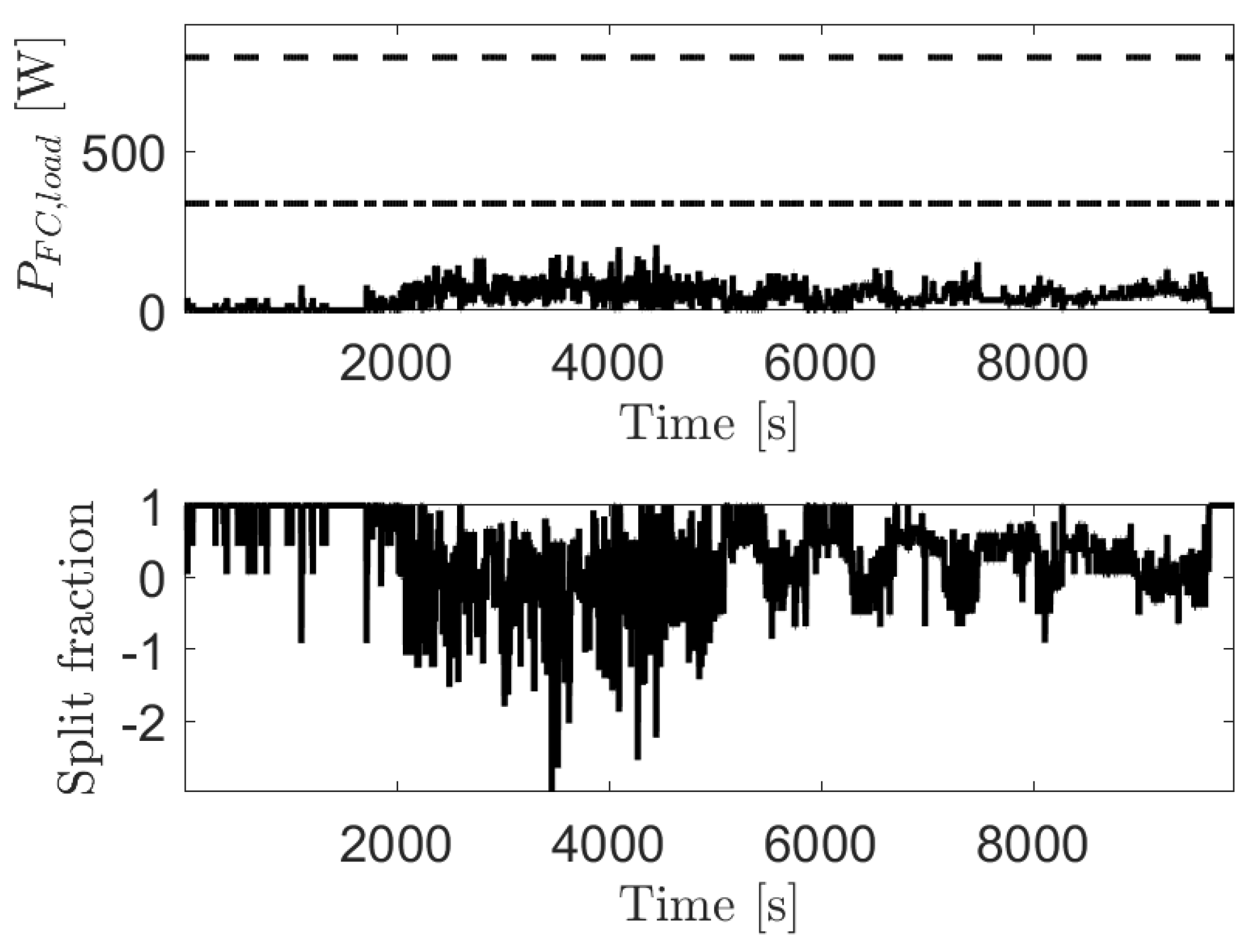

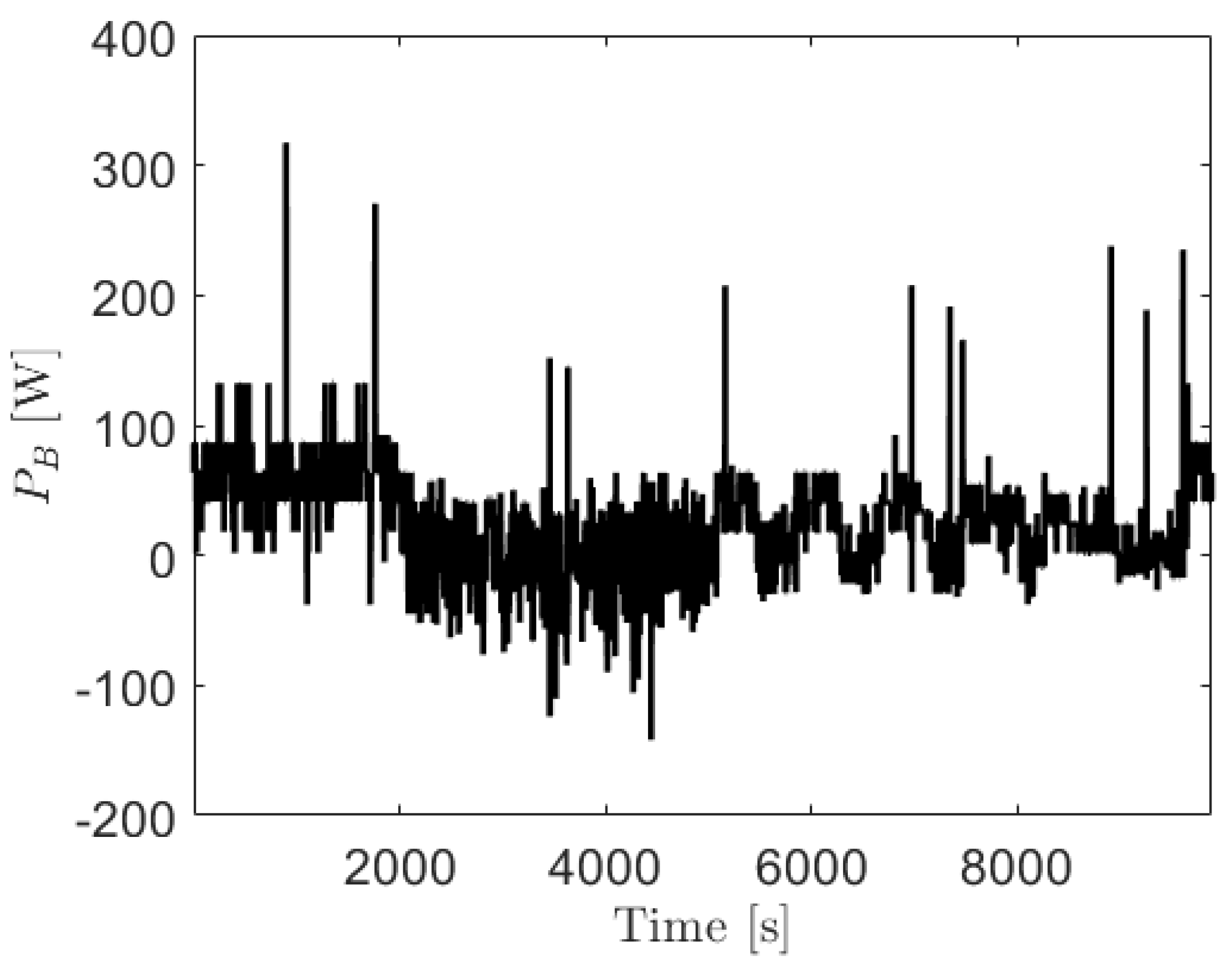

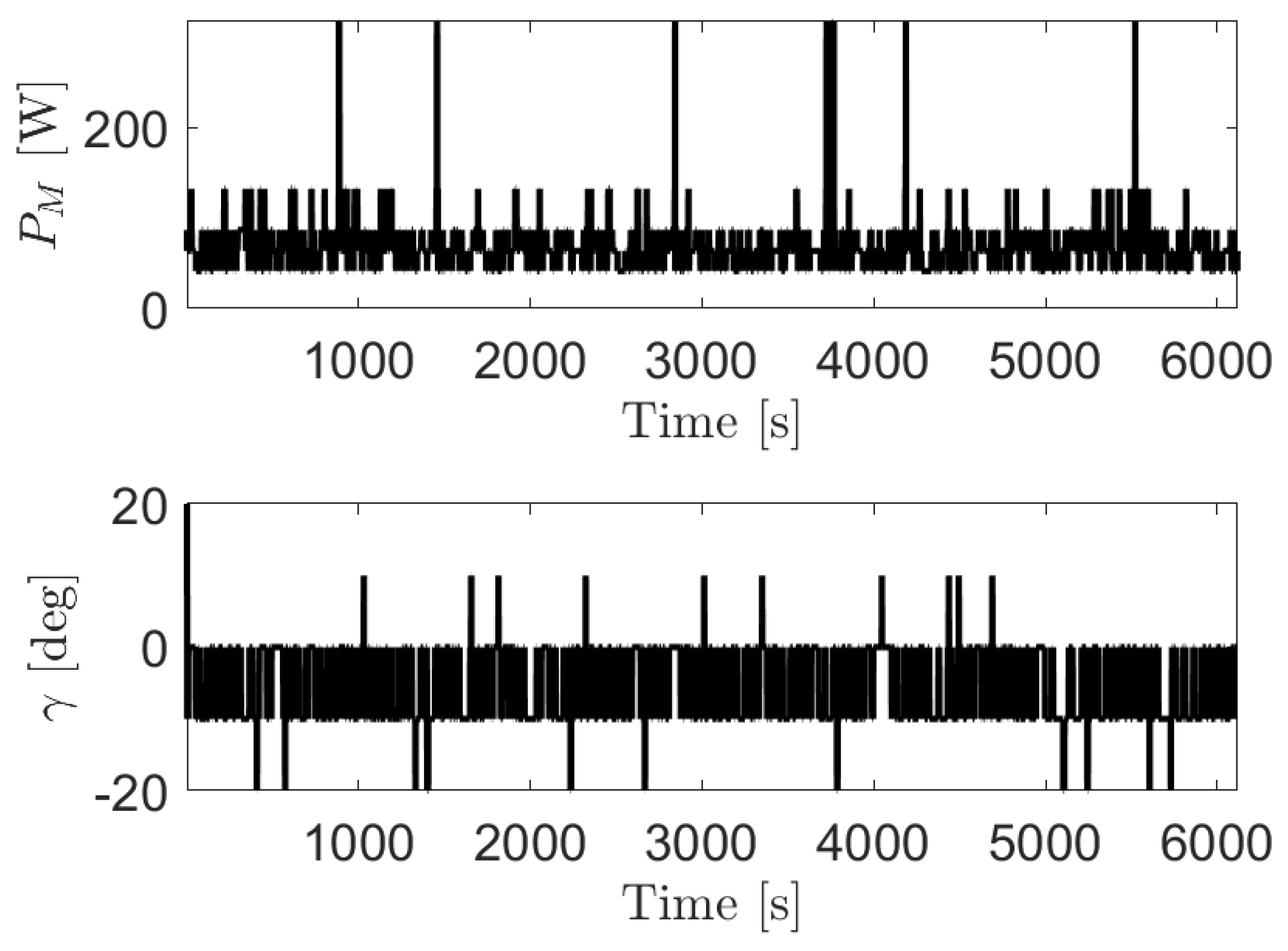

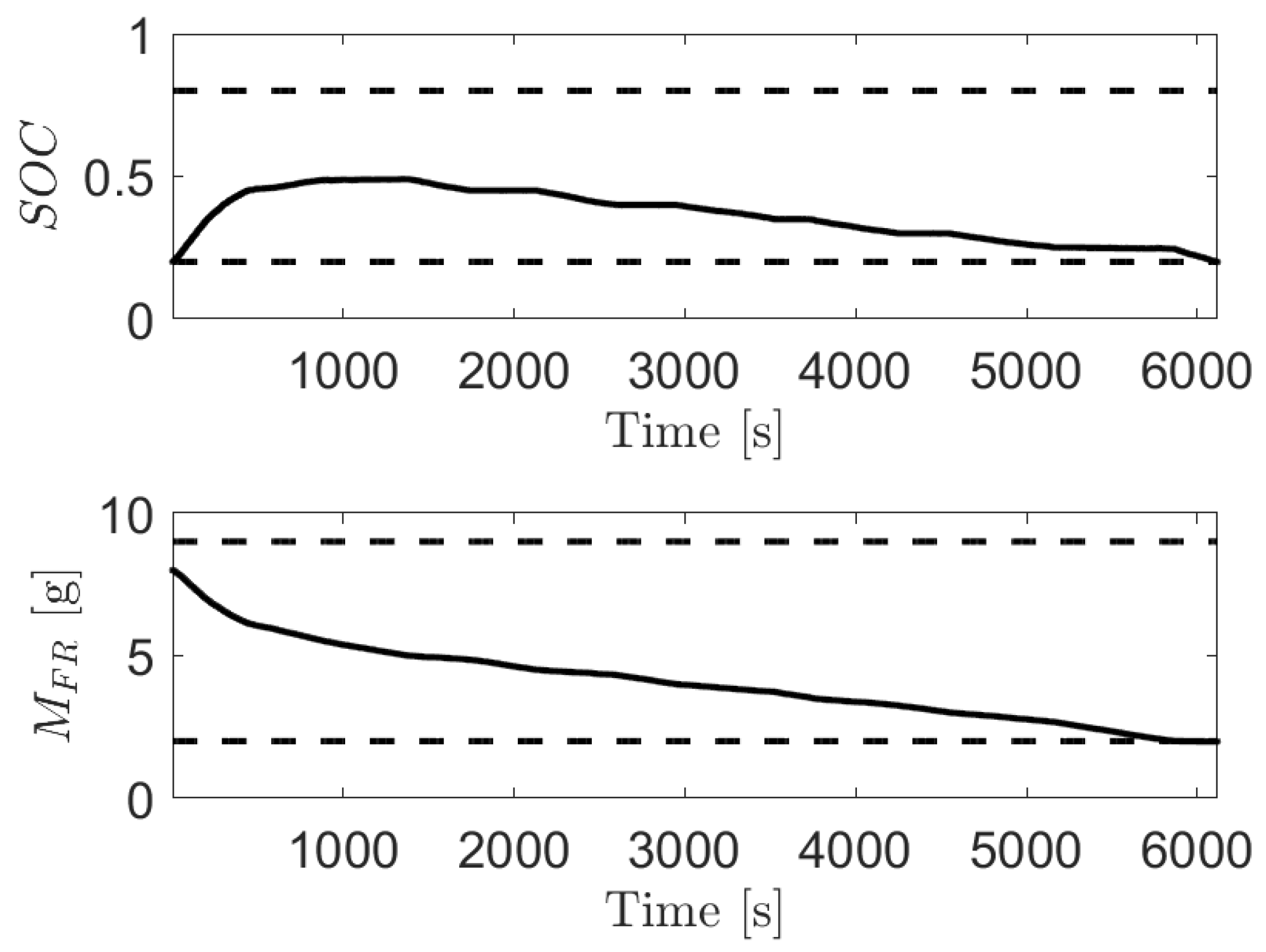

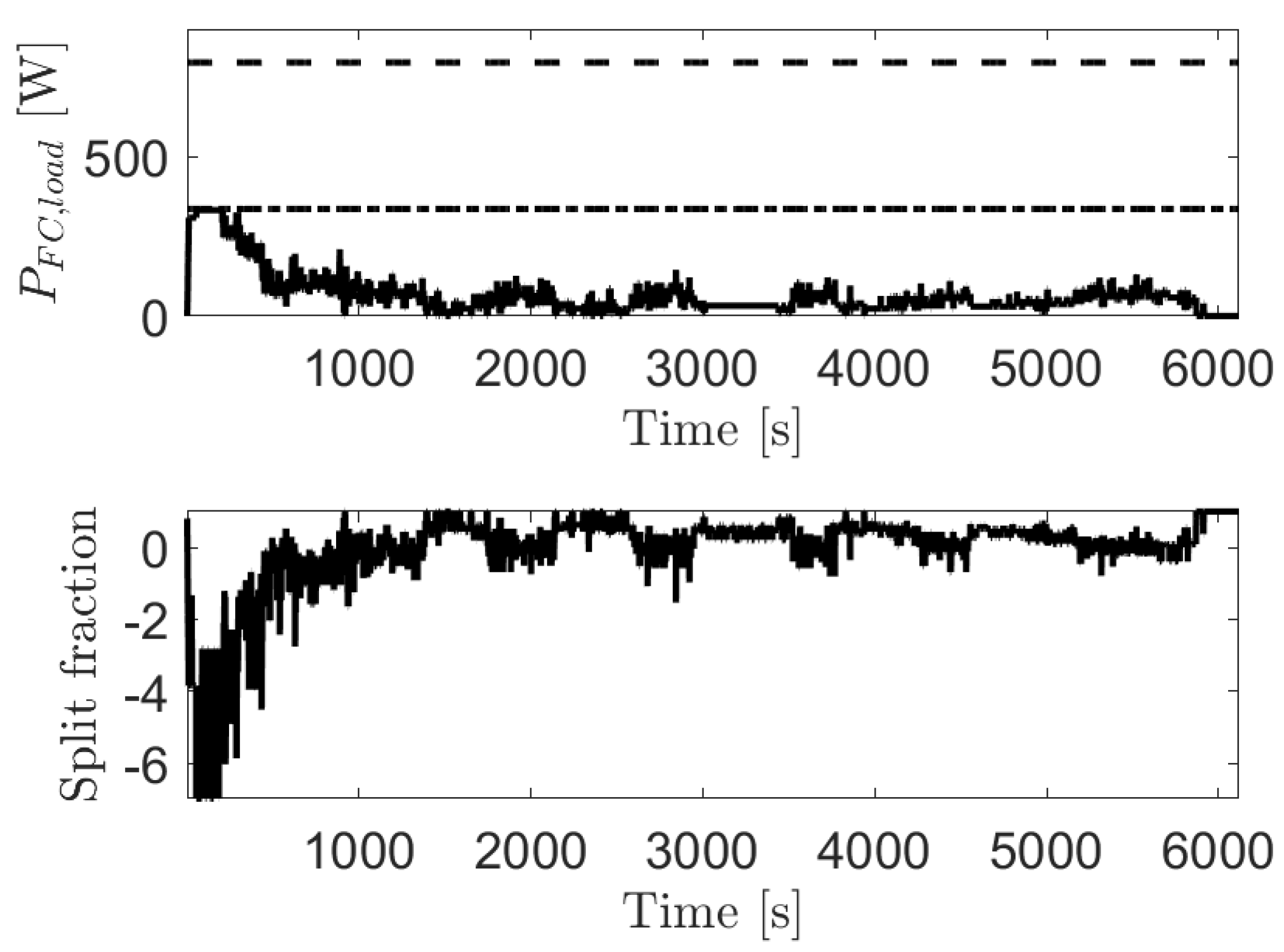

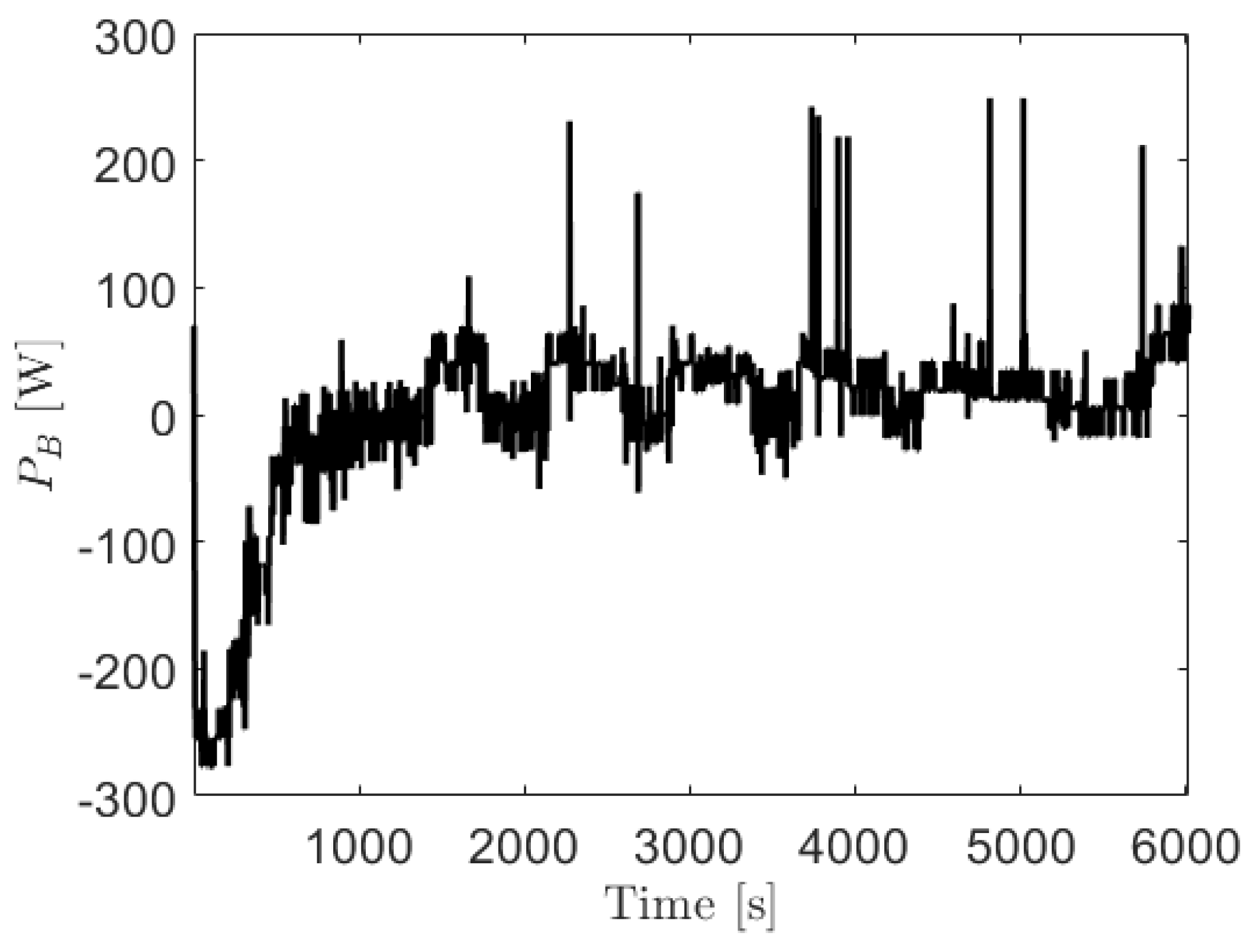

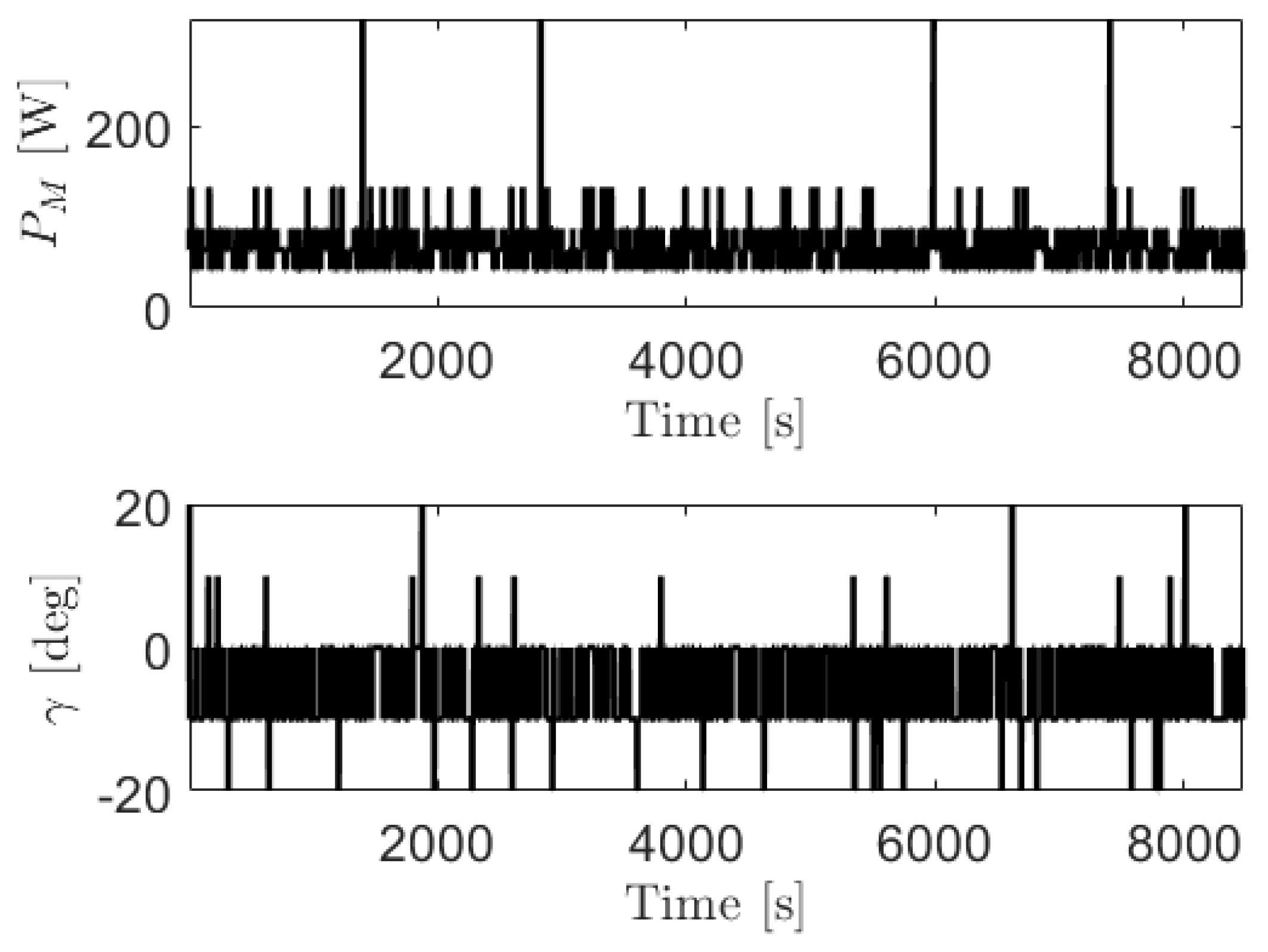

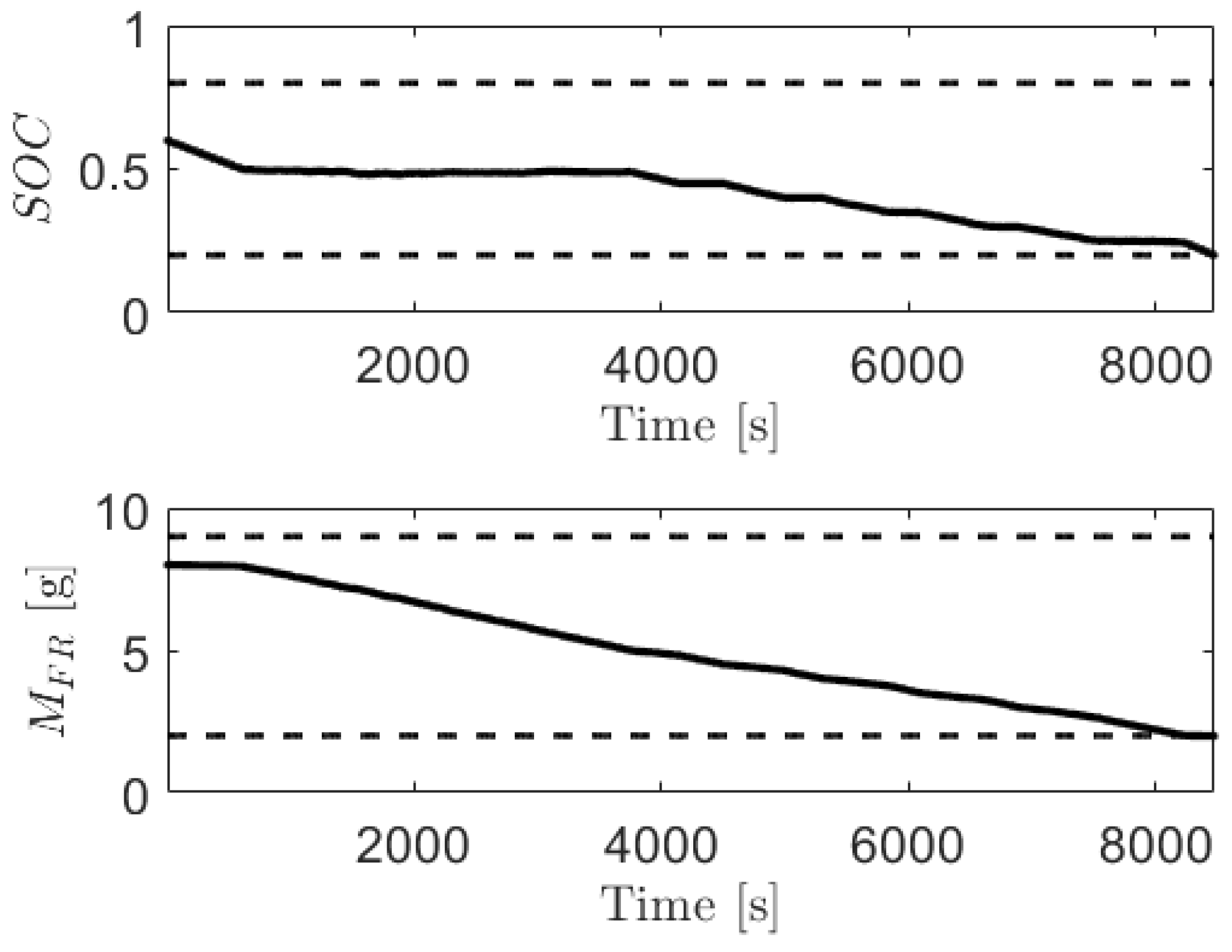

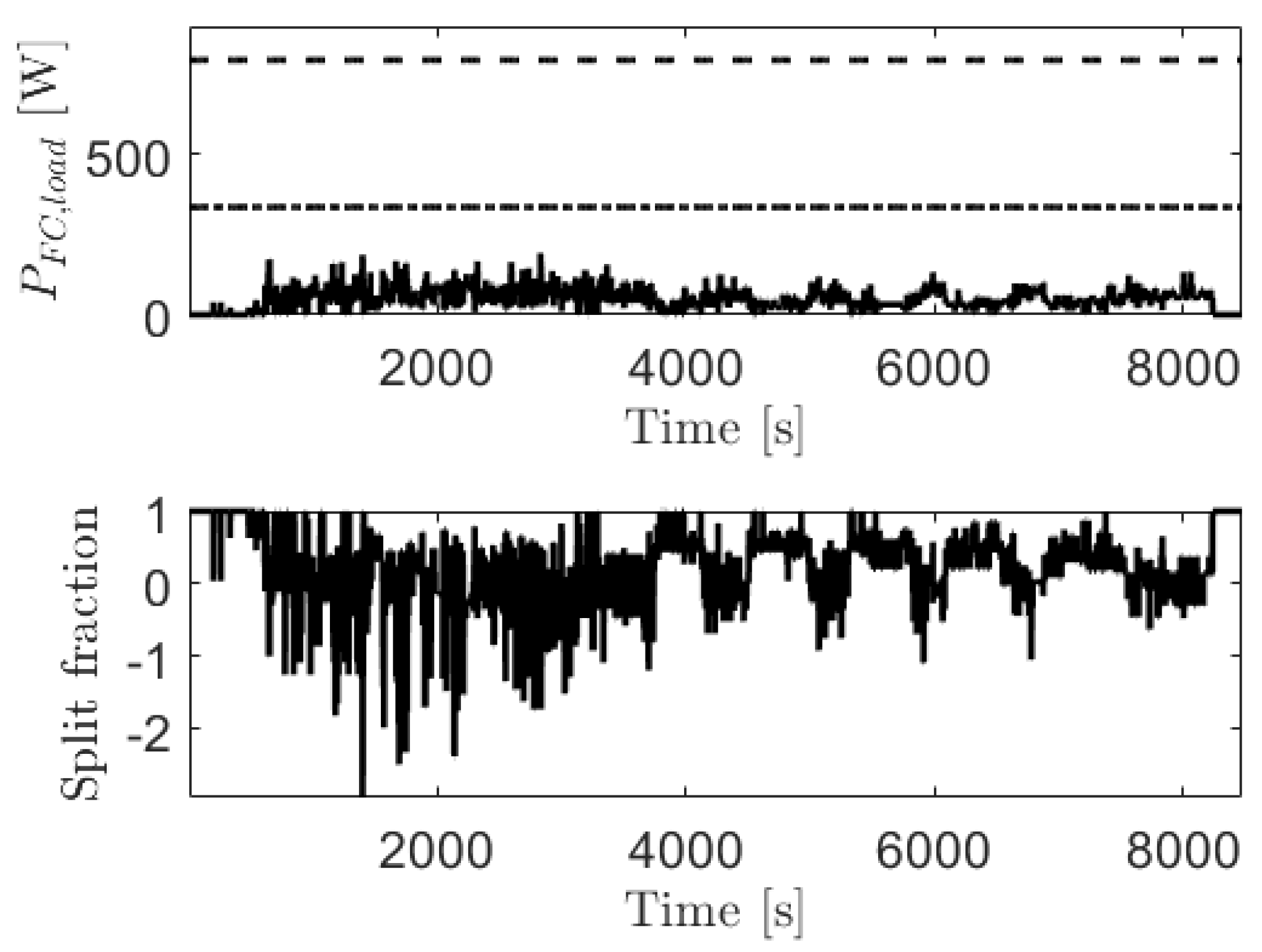

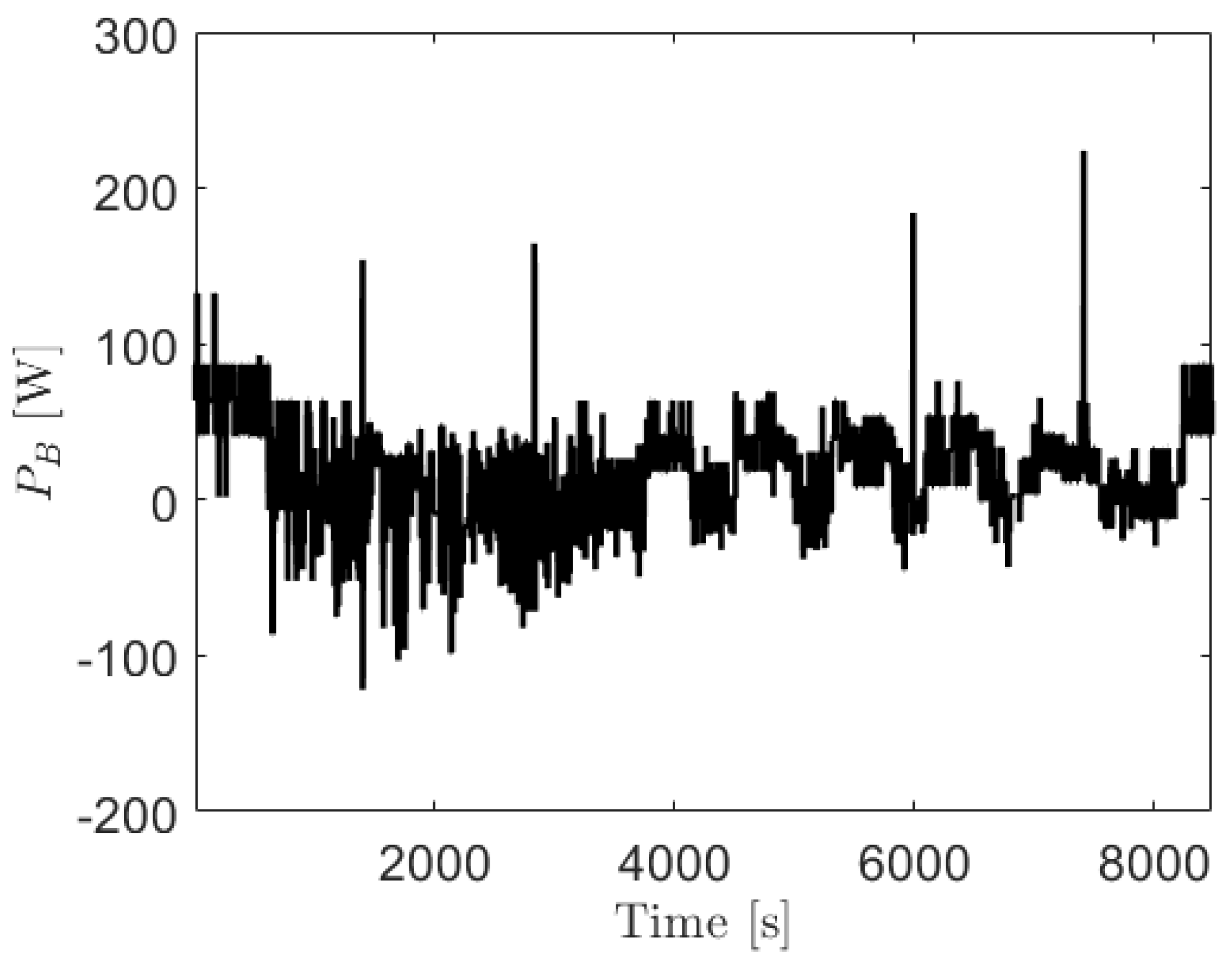

5.3. Endurance Maximization Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| EPA | Environmental Protection Agency |

| DMFC | Direct methanol fuel cell |

| sUAV | Small unmanned aerial vehicle |

| MPC | Model predictive control |

| PEMFC | Polymer electrolyte membrane fuel cell |

| RPM | Rotations per minute |

| UAV | Unmanned aerial vehicle |

Appendix A

| Variable | Description | Value | Unit |

|---|---|---|---|

| m | Mass of the sUAV | 1.5 | |

| g | Gravitational acceleration | 9.81 | |

| Wing area | 0.09 | ||

| sUAV coefficient of drag at | 0.1038 | ∖ | |

| K | Coefficient in Equation (3) | 0.0637 | ∖ |

| Diameter of the propeller | 0.24 | ||

| J | Advance ratio | 0.37 | ∖ |

| Motor resistance | 0.105 | ||

| Motor current at zero load | 1.3 | ||

| Motor speed constant | 1490 | ||

| Number of single cells in series | 12 | ∖ | |

| Bias power of the fuel cell | 5 | ||

| Coefficient in Equation (12) | 0.05 | ||

| Fuel cell area | 200 | ||

| Molar specific Gibbs free energy | 237.3 | ||

| Number of ions passed in reaction | 2 | ∖ | |

| F | Faraday constant | 96,485 | |

| Temperature of the reaction | 333.15 | ||

| Charge transfer coefficient | 0.5 | ∖ | |

| R | Universal gas constant | 8.314 | |

| Ohmic resistance defined in Equation (15) | 0.0024 | ||

| Coefficient in Equation (16) | 3e-5 | ||

| Coefficient in Equation (16) | 8 | ||

| Coefficient in Equation (18) | 4 | ∖ | |

| Coefficient in Equation (18) | 1 | ∖ | |

| Molecular weight of | 2 | ||

| Number of batteries in series | 8 | ∖ | |

| Open circuit voltage when | 2.5 | ||

| Open circuit voltage when | 4.2 | ||

| Battery internal resistance | 0.012 | ||

| Standard discharge capacity | 14400 | ||

| Maximum discharge current | 35 |

References

- Unmanned Aerial Vehicle (UAV) Market by Component (Hardware, Software), Class (Mini UAVs, Micro UAVs), End User (Military, Commercial, Agriculture), Type (Fixed Wing, Rotary-Wing UAVs), Capacity, and Mode of Operation—Global Forecast to 2027. Available online: https://www.meticulousresearch.com/product/unmanned-aerial-vehicle-UAV-market-5086 (accessed on 16 February 2021).

- Kasliwal, A.; Furbush, N.J.; Gawron, J.H.; McBride, J.R.; Wallington, T.J.; De Kleine, R.D.; Kim, H.C.; Keoleian, G.A. Role of flying cars in sustainable mobility. Nat. Commun. 2019, 10, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goyal, R. Urban Air Mobility (uam) Market Study; NASA: Washington, DC, USA, 2018.

- Samy, I.; Postlethwaite, I.; Gu, D.W.; Green, J. Neural-network-based flush air data sensing system demonstrated on a mini air vehicle. J. Aircr. 2010, 47, 18–31. [Google Scholar] [CrossRef]

- Ma, S.; Lin, M.; Lin, T.E.; Lan, T.; Liao, X.; Maréchal, F.; Yang, Y.; Dong, C.; Wang, L. Fuel cell-battery hybrid systems for mobility and off-grid applications: A review. Renew. Sustain. Energy Rev. 2020, 135, 110119. [Google Scholar] [CrossRef]

- Lapeña-Rey, N.; Blanco, J.; Ferreyra, E.; Lemus, J.; Pereira, S.; Serrot, E. A fuel cell powered unmanned aerial vehicle for low altitude surveillance missions. Int. J. Hydrogen Energy 2017, 42, 6926–6940. [Google Scholar] [CrossRef]

- Oh, T.H. Conceptual design of small unmanned aerial vehicle with proton exchange membrane fuel cell system for long endurance mission. Energy Convers. Manag. 2018, 176, 349–356. [Google Scholar] [CrossRef]

- Bradley, T.; Moffitt, B.; Fuller, T.; Mavris, D.; Parekh, D. Design studies for hydrogen fuel cell powered unmanned aerial vehicles. In Proceedings of the 26th AIAA Applied Aerodynamics Conference, Honolulu, HI, USA, 18–21 August 2008; p. 6413. [Google Scholar]

- Bradley, T.H.; Moffitt, B.A.; Mavris, D.N.; Parekh, D.E. Development and experimental characterization of a fuel cell powered aircraft. J. Power Sources 2007, 171, 793–801. [Google Scholar] [CrossRef]

- Citroni, R.; Di Paolo, F.; Livreri, P. A novel energy harvester for powering small UAVs: Performance analysis, model validation and flight results. Sensors 2019, 19, 1771. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hochgraf, C.G.; Ryan, M.J.; Wiegman, H.L. Engine Control Strategy for a Series Hybrid Electric Vehicle Incorporating Load-Leveling and Computer Controlled Energy Management; SAE Technical Paper No. 1996–02-01; SAE: Detroit, MI, USA, 1996. [Google Scholar]

- Bradley, T.; Moffitt, B.; Parekh, D.; Fuller, T.; Mavris, D. Energy management for fuel cell powered hybrid-electric aircraft. In Proceedings of the 7th International Energy Conversion Engineering Conference, Denver, CO, USA, 2–5 August 2009; p. 4590. [Google Scholar]

- Doff-Sotta, M.; Cannon, M.; Bacic, M. Optimal energy management for hybrid electric aircraft. arXiv 2020, arXiv:2004.02582. [Google Scholar]

- Anatone, M.; Cipollone, R.; Donati, A.; Sciarretta, A. Control-Oriented Modeling and Fuel Optimal Control of a Series Hybrid Bus; SAE Technical Paper No. 2005–04-11; SAE: Detroit, MI, USA, 2005. [Google Scholar]

- Dobrokhodov, V.; Jones, K.D.; Walton, C.; Kaminer, I.I. Achievable Endurance of Hybrid UAV Operating in Time-Varying Energy Fields. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 2197. [Google Scholar]

- Kolmanovsky, I.V.; Lezhnev, L.; Maizenberg, T.L. Discrete-time drift counteraction stochastic optimal control: Theory and application-motivated examples. Automatica 2008, 44, 177–184. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Kolmanovsky, I.; Saha, B. Range maximization of a direct methanol fuel cell powered Mini Air Vehicle using Stochastic Drift Counteraction Optimal Control. In Proceedings of the 2012 American Control Conference (ACC), Fairmont Queen Elizabeth, MO, USA, 27–29 June 2012; pp. 3272–3277. [Google Scholar]

- Guzzella, L.; Sciarretta, A. Vehicle Propulsion Systems: Introduction to Modeling and Pptimization; Springer: Berlin, Germany, 2013; Chapter 6; pp. 207–208. [Google Scholar] [CrossRef]

- Guida, D.; Minutillo, M. Design methodology for a PEM fuel cell power system in a more electrical aircraft. Appl. Energy 2017, 192, 446–456. [Google Scholar] [CrossRef]

- Wipke, K.; Sprik, S.; Kurtz, J.; Ramsden, T.; Ainscough, C.; Saur, G. All Composite Data Products: National FCEV Learning Demonstration with Updates through January 18, 2012; Technical Report, NREL/TP-5600-54021; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2012. [Google Scholar]

- Kolmanovsky, I.; Siverguina, I.; Lygoe, B. Optimization of powertrain operating policy for feasibility assessment and calibration: Stochastic dynamic programming approach. In Proceedings of the 2002 American Control Conference (ACC), Anchorage, AK, USA, 8–10 May 2002; Volume 2, pp. 1425–1430. [Google Scholar]

- Roskam, J.; Lan, C. Airplane Aerodynamics and Performance; DARcorporation: Lawrence, KS, USA, 2003. [Google Scholar]

- Hrad, P.M. Conceptual Design Tool for Fuel-Cell Powered Micro Air Vehicles; Technical Report; Air Force Institute of Technology: Dayton, OH, USA, 2010. [Google Scholar]

- Rodatz, P.H. Dynamics of the polymer electrolyte fuel cell: Experiments and model-based analysis. Ph.D. Thesis, ETH, Zurich, Switzerland, 2003. [Google Scholar]

- Specification of Product INR21700-40T. Available online: https://www.dnkpower.com/wp-content/uploads/2019/02/SAMSUNG-INR21700-40T-Datasheet.pdf (accessed on 16 February 2021).

- Bronz, M.; Moschetta, J.M.; Brisset, P.; Gorraz, M. Towards a long endurance MAV. Int. J. Micro Air Veh. 2009, 1, 241–254. [Google Scholar] [CrossRef] [Green Version]

- Murphy, O.J.; Cisar, A.; Clarke, E. Low-cost light weight high power density PEM fuel cell stack. Electrochim. Acta 1998, 43, 3829–3840. [Google Scholar] [CrossRef]

- Quattrochi, D. Performance of Propellers. Available online: https://web.mit.edu/16.unified/www/FALL/thermodynamics/notes/node86.html (accessed on 16 February 2021).

- Gur, O.; Rosen, A. Optimizing electric propulsion systems for UAVs. In Proceedings of the 12th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Victoria, BC, Canada, 10–12 September 2008; p. 5916. [Google Scholar]

- Guzzella, L.; Amstutz, A. CAE tools for quasi-static modeling and optimization of hybrid powertrains. IEEE Trans. Veh. Technol. 1999, 48, 1762–1769. [Google Scholar] [CrossRef]

- Mann, R.F.; Amphlett, J.C.; Hooper, M.A.; Jensen, H.M.; Peppley, B.A.; Roberge, P.R. Development and application of a generalised steady-state electrochemical model for a PEM fuel cell. J. Power Sources 2000, 86, 173–180. [Google Scholar] [CrossRef]

- Maxoulis, C.N.; Tsinoglou, D.N.; Koltsakis, G.C. Modeling of automotive fuel cell operation in driving cycles. Energy Convers. Manag. 2004, 45, 559–573. [Google Scholar] [CrossRef]

- Amphlett, J.; Baumert, R.; Mann, R.; Peppley, B.; Roberge, P.; Rodrigues, A. Parametric modelling of the performance of a 5-kW proton-exchange membrane fuel cell stack. J. Power Sources 1994, 49, 349–356. [Google Scholar] [CrossRef]

- Pukrushpan, J.T.; Peng, H.; Stefanopoulou, A.G. Control-oriented modeling and analysis for automotive fuel cell systems. J. Dyn. Syst. Meas. Control 2004, 126, 14–25. [Google Scholar] [CrossRef]

- Bansal, D.; Rajagopalan, S.; Choi, T.; Guezennec, Y.; Yurkovich, S. Pressure and air fuel ratio control of pem fuel cell system for automotive traction. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Gijón, Spain, 26–29 September 2004. [Google Scholar]

- El-Emam, S.H.; Mousa, A.A.; Awad, M.M. Effects of stack orientation and vibration on the performance of PEM fuel cell. Int. J. Energy Res. 2015, 39, 75–83. [Google Scholar] [CrossRef]

- Zhang, R.; Xia, B.; Li, B.; Cao, L.; Lai, Y.; Zheng, W.; Wang, H.; Wang, W.; Wang, M. A study on the open circuit voltage and state of charge characterization of high capacity lithium-ion battery under different temperature. Energies 2018, 11, 2408. [Google Scholar] [CrossRef] [Green Version]

- Vahidi, A.; Greenwell, W. A decentralized model predictive control approach to power management of a fuel cell-ultracapacitor hybrid. In Proceedings of the 2007 American Control Conference (ACC), New York, NY, USA, 9–13 July 2007; pp. 5431–5437. [Google Scholar]

- Dynkin, E.B.; Yushkevich, A.A. Markov Processes: Theorems and Problems; Plenum: New York, NY, USA, 1969. [Google Scholar]

- Ross, S.M. Introduction to Stochastic Dynamic Programming; Academic Press: Cambridge, MA, USA, 2014. [Google Scholar]

- U.S. Department of Energy—Fuel Economy. Detailed Test Information. Available online: http://fueleconomy.gov/feg/fe_test_schedules.shtml (accessed on 16 February 2021).

- Schneider, A. GPS Visualizer. Available online: http://www.gpsvisualizer.com/ (accessed on 16 February 2021).

- Wang, Y.; Zou, Y.; Henrickson, K.; Wang, Y.; Tang, J.; Park, B.J. Google Earth elevation data extraction and accuracy assessment for transportation applications. PLoS ONE 2017, 12, e0175756. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Variable | Description | Unit |

|---|---|---|

| v | Velocity of the sUAV | |

| Climb angle | ||

| T | Thrust force | |

| Angle of attack | ||

| L | Lift force | |

| D | Drag force | |

| sUAV coefficient of lift | ∖ | |

| sUAV coefficient of drag | ∖ | |

| Air density | ||

| Power required by the sUAV | ||

| N | Angular speed of the electric motor | |

| Power generated by the propeller | ||

| Ideal propeller power | ||

| Propulsive efficiency | ∖ | |

| Electric motor driver’s input voltage | ||

| Electric motor driver’s input current | ||

| Elector motor driver’s input power | ||

| Motor efficiency | ∖ | |

| Total power of the fuel cell | ||

| Load demand power of the fuel cell | ||

| Power required by the auxiliaries | ||

| Single cell voltage | ||

| Single cell current | ||

| Single cell current density | ||

| Activation polarization | ||

| Ohmic losses | ||

| Concentration polarization | ||

| Equivalent open circuit voltage of a single fuel cell | ||

| Modified single fuel cell resistance | ||

| Variable defined in Equation (18) | ||

| Open circuit voltage of the battery | ||

| Battery’s state of charge | ∖ | |

| Power of the battery | ||

| Initial SOC | ∖ | |

| Split fraction | ∖ | |

| u | Control input | ∖ |

| Defined in Equation (25) | ||

| Mass of fuel remaining |

| Number of Iteration | Computing Time (min) | Exit Time with 20% Initial (s) | Exit Time with 80% Initial (s) | |

|---|---|---|---|---|

| 0.99 | 2258 | 830.02 | 6358.44 | 9742.99 |

| 0.97 | 753 | 100.69 | 6276.18 | 9716.86 |

| 0.95 | 448 | 58.27 | 6221.37 | 9640.24 |

| 0.93 | 317 | 39.22 | 6186.50 | 9610.22 |

| 0.91 | 244 | 30.55 | 6159.65 | 9602.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Kolmanovsky, I.; Amini, M.R. Stochastic Drift Counteraction Optimal Control of a Fuel Cell-Powered Small Unmanned Aerial Vehicle. Energies 2021, 14, 1304. https://doi.org/10.3390/en14051304

Zhang J, Kolmanovsky I, Amini MR. Stochastic Drift Counteraction Optimal Control of a Fuel Cell-Powered Small Unmanned Aerial Vehicle. Energies. 2021; 14(5):1304. https://doi.org/10.3390/en14051304

Chicago/Turabian StyleZhang, Jiadi, Ilya Kolmanovsky, and Mohammad Reza Amini. 2021. "Stochastic Drift Counteraction Optimal Control of a Fuel Cell-Powered Small Unmanned Aerial Vehicle" Energies 14, no. 5: 1304. https://doi.org/10.3390/en14051304