Research Progress and Prospects of Multi-Stage Centrifugal Pump Capability for Handling Gas–Liquid Multiphase Flow: Comparison and Empirical Model Validation

Abstract

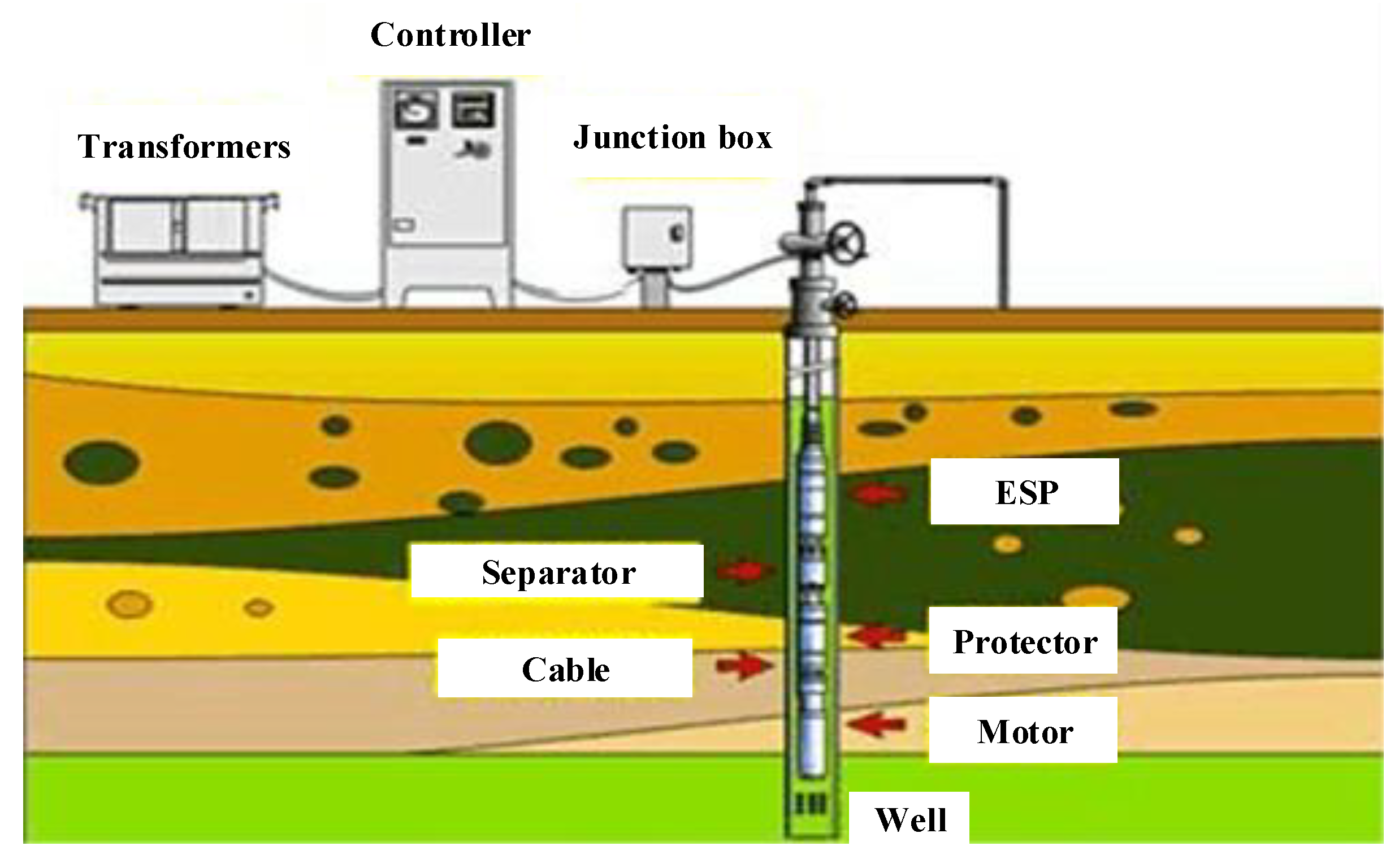

1. Introduction

2. Flow Mechanism in Multi-Stage Centrifugal Pump

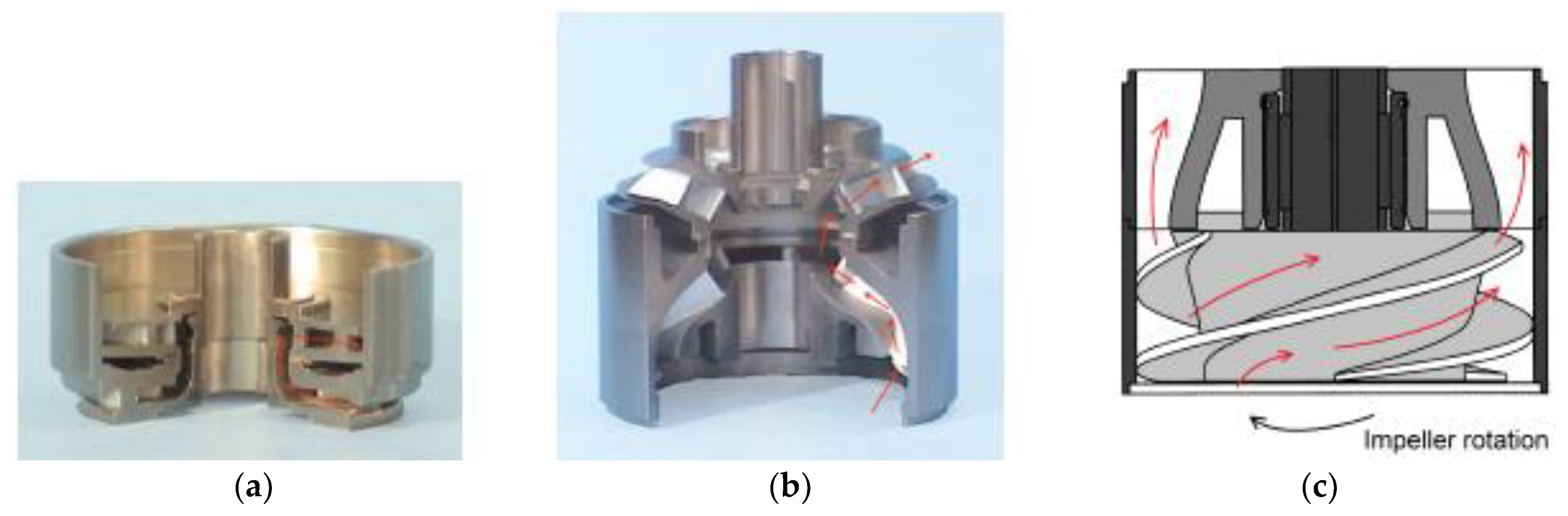

2.1. Types of ESP Based on Stage Geometry and Specific Speed

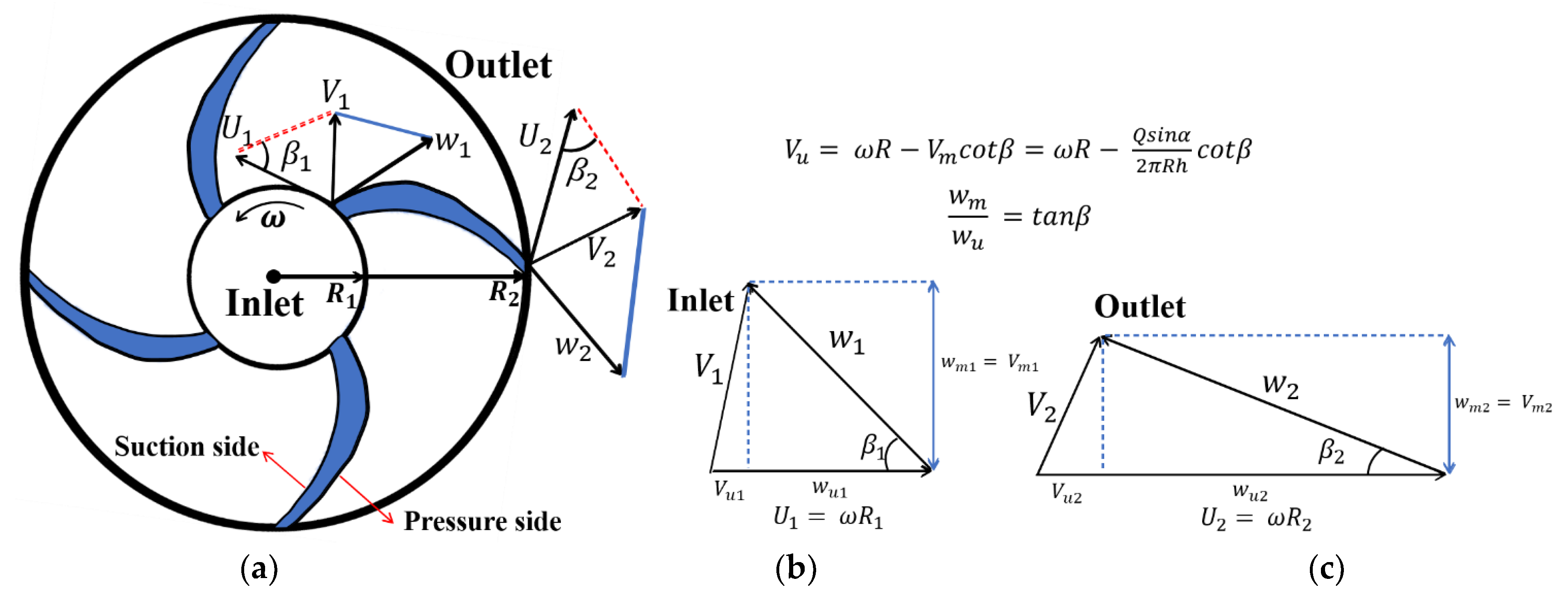

2.2. Flow Velocity Triangles

3. Experimental Analysis

3.1. Empirical Approach

- ▪

- The influence of free gas on pump performance is more dangerous at lower intake pressures and lower inlet GVFs. However, it decreases with the increase in intake pressure.

- ▪

- Mixed-flow pumps are better than the radial flow pumps while handling gas–liquid two-phase flow.

- ▪

- The pumps perform better with diesel–CO2 mixtures than the air–water mixtures.

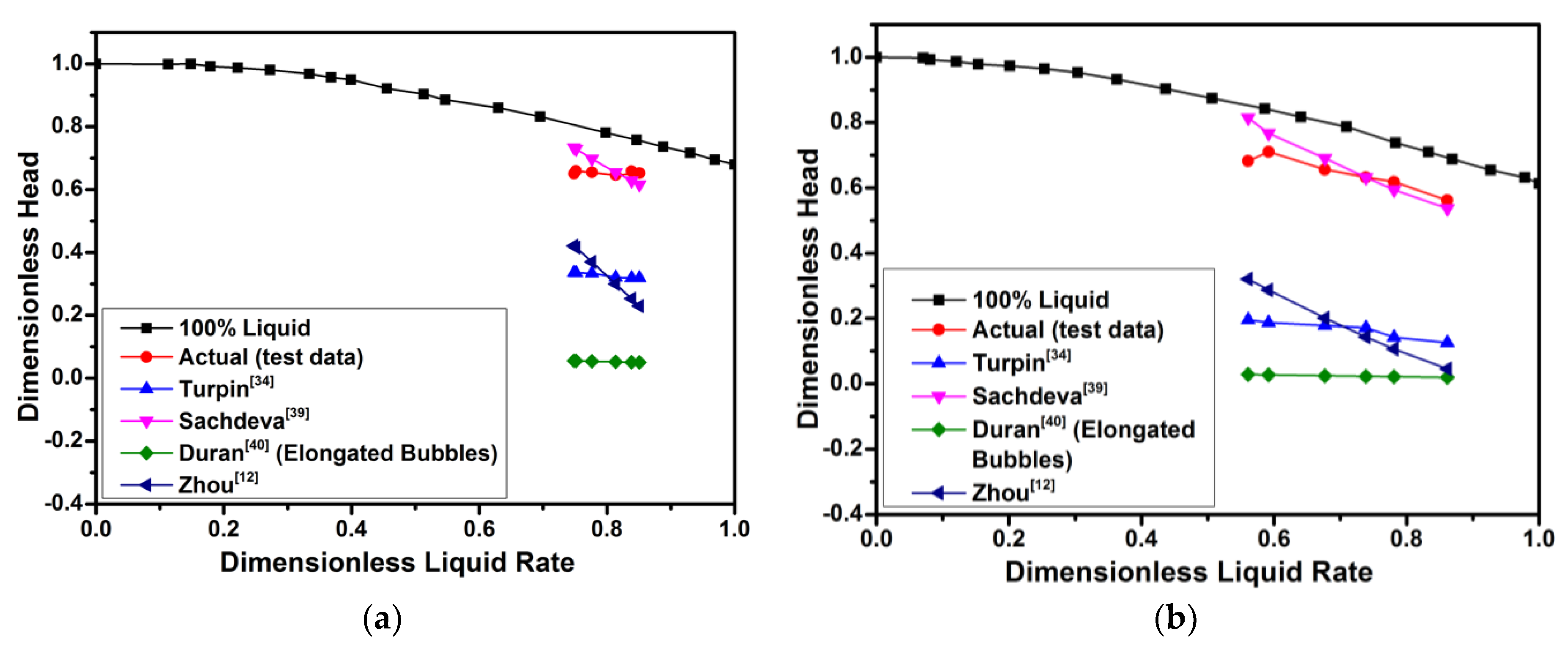

3.1.1. Comparison of Different Correlation Models

3.1.2. Comparison of Different Surging Correlations

3.2. Flow Visualization and Bubble Size Measurement

- ▪

- Impeller blade tip should be left open to reduce bubble accumulation by leakage.

- ▪

- Impeller should have some recirculation holes in order to burst the bubbles.

- ▪

- The use of higher outlet blade angle should be effective.

- ▪

- Diffuser vanes have to be near the impeller outlet.

3.3. Viscosity Analysis

4. Numerical Simulation

4.1. One-Dimensional (1-D) Two-Phase Modeling

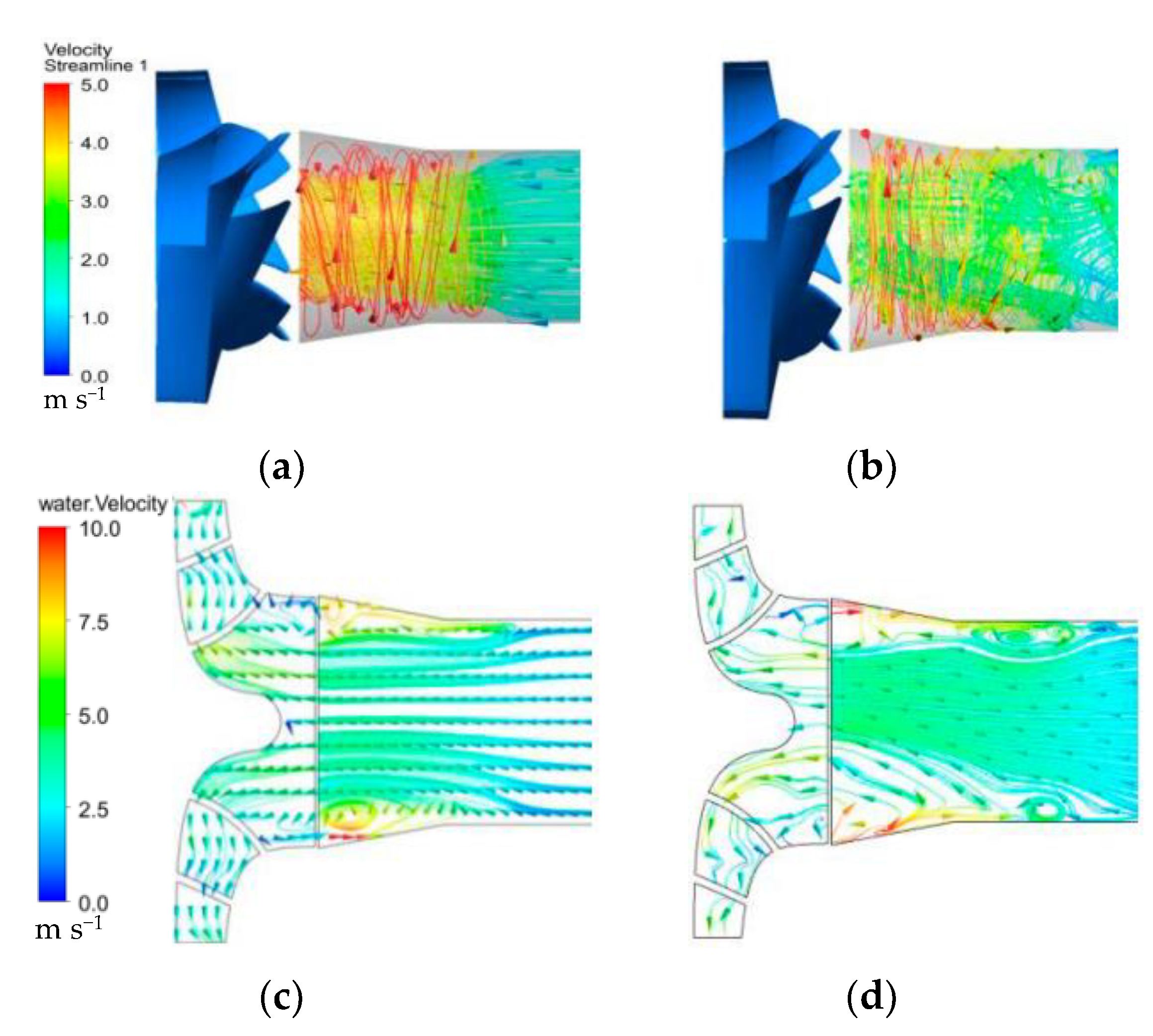

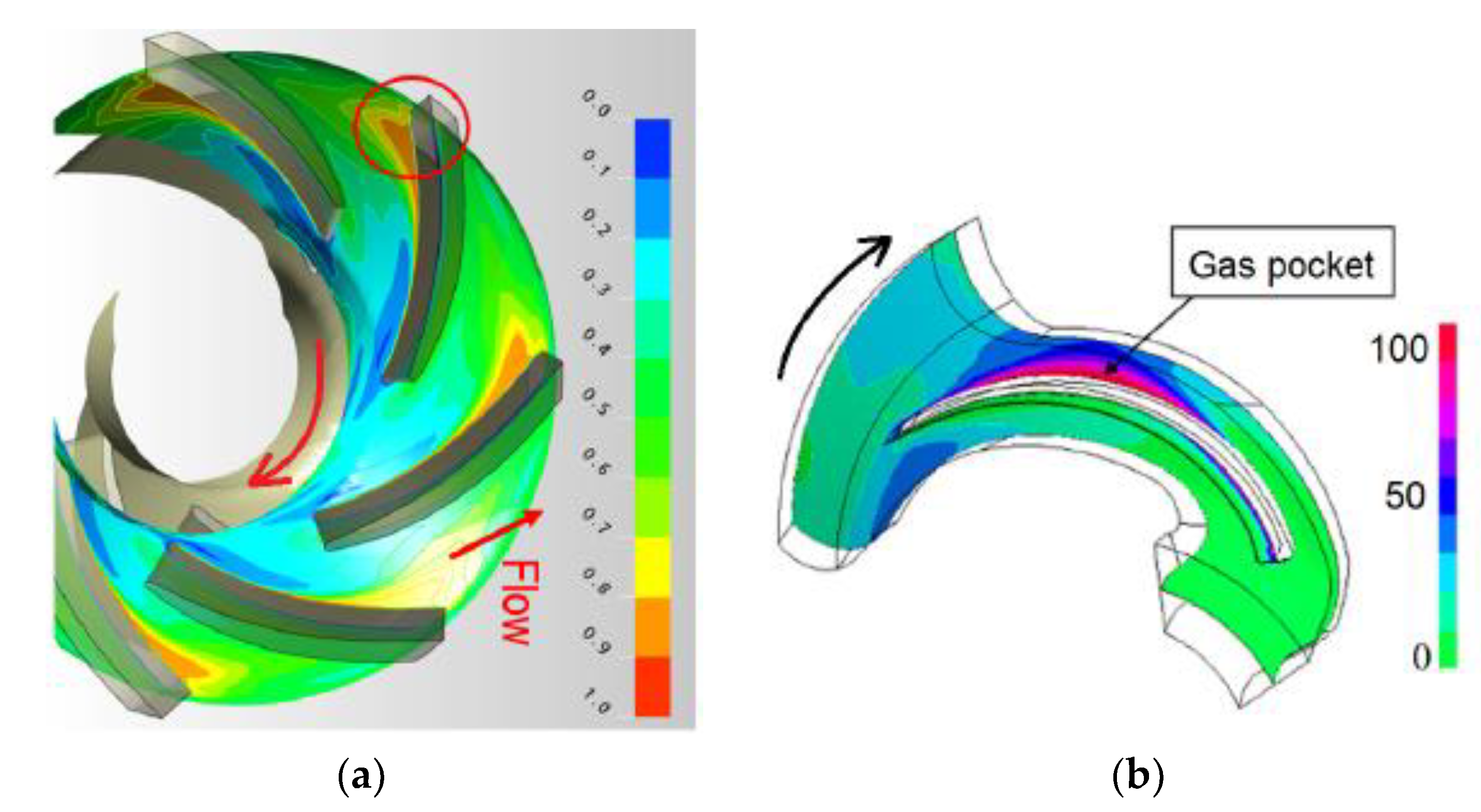

4.2. Three-Dimensional (3-D) Two-Phase Flow Modeling

4.3. Bubble Diameter Effect on Gas-Handling Capability of Pump

4.4. Influence of Viscosity on Two-Phase Performance

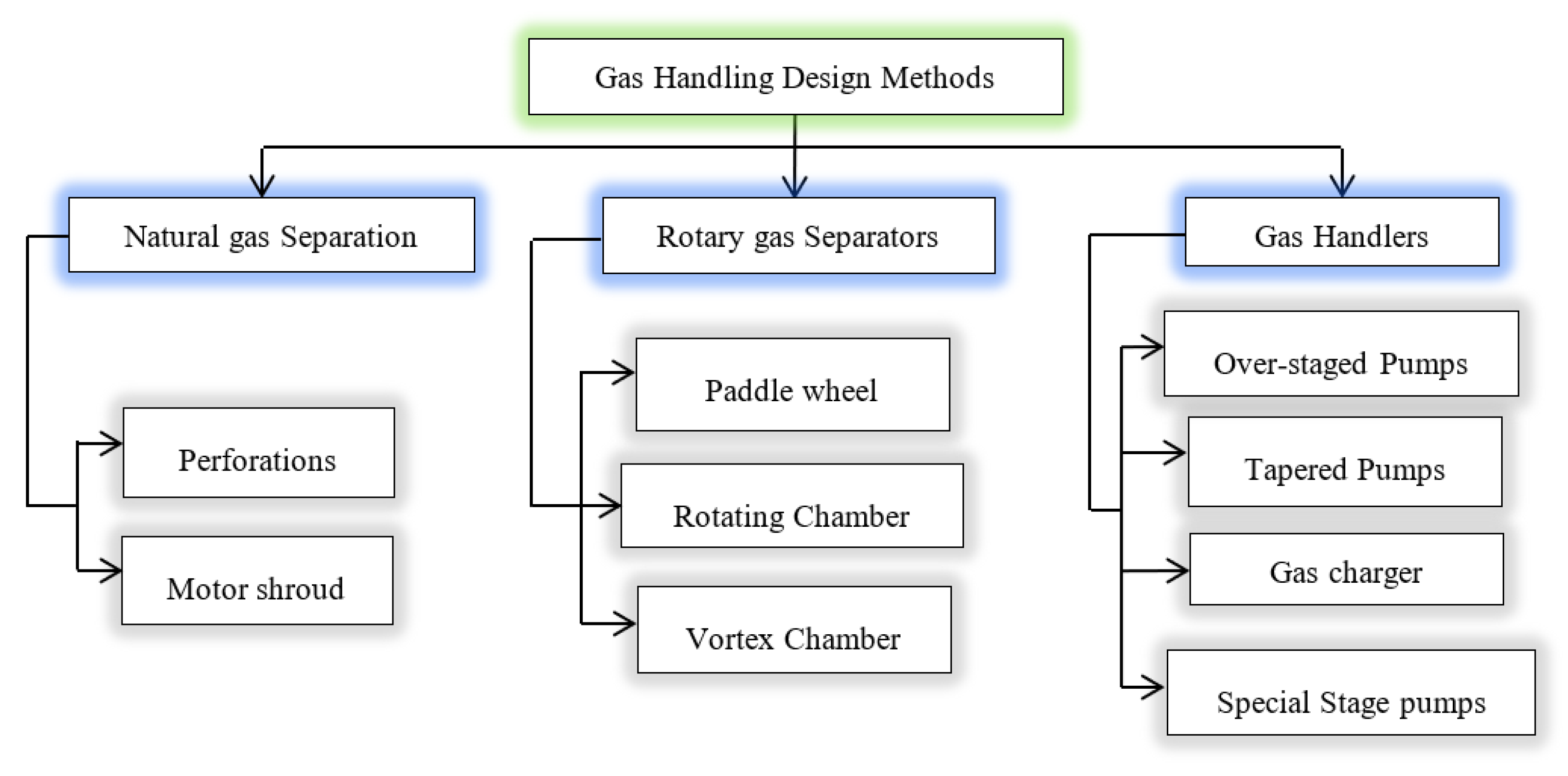

5. Design Methods to Increase Two-Phase Flow-Handling Ability of Pumps

- i.

- Natural gas separation: The entrance of free gas into the ESP system handling gas–liquid two-phase mixtures should be stopped using natural gas separation techniques.

- ii.

- Rotary gas separation: If the natural gas separation is not sufficient in handling the free gas entrainment into the ESP system, then rotary gas separators (RGSs) should be applied to separate the entered gas before entering into pump.

- iii.

- Gas handlers: If the separation of free gas inside the ESP system is not possible using the aforementioned methods, then gas handlers, alone or in combination with RGS, should be applied, which can carry higher volumes of free gas together with liquid phase without effecting the pump performance.

6. Conclusions

- (1)

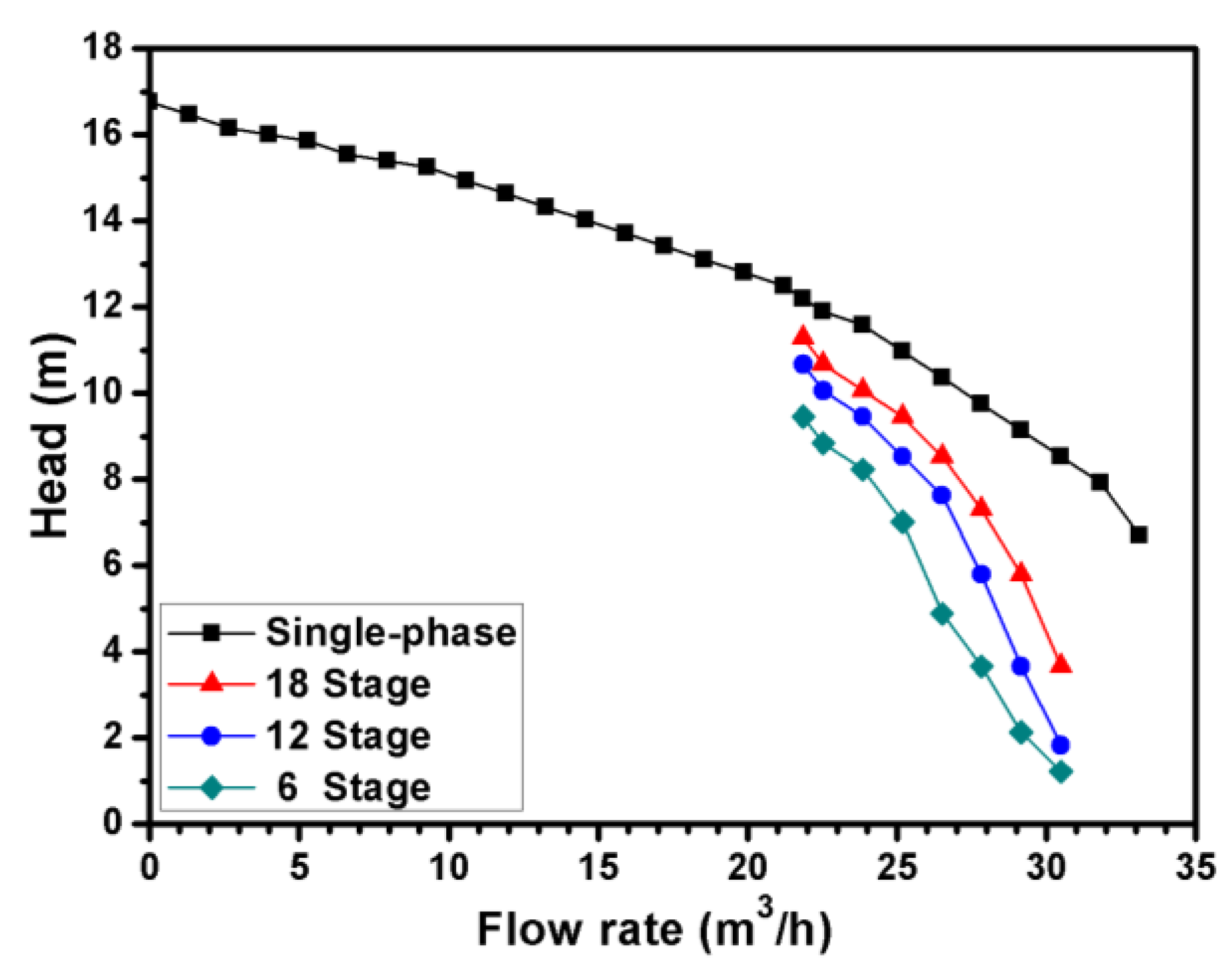

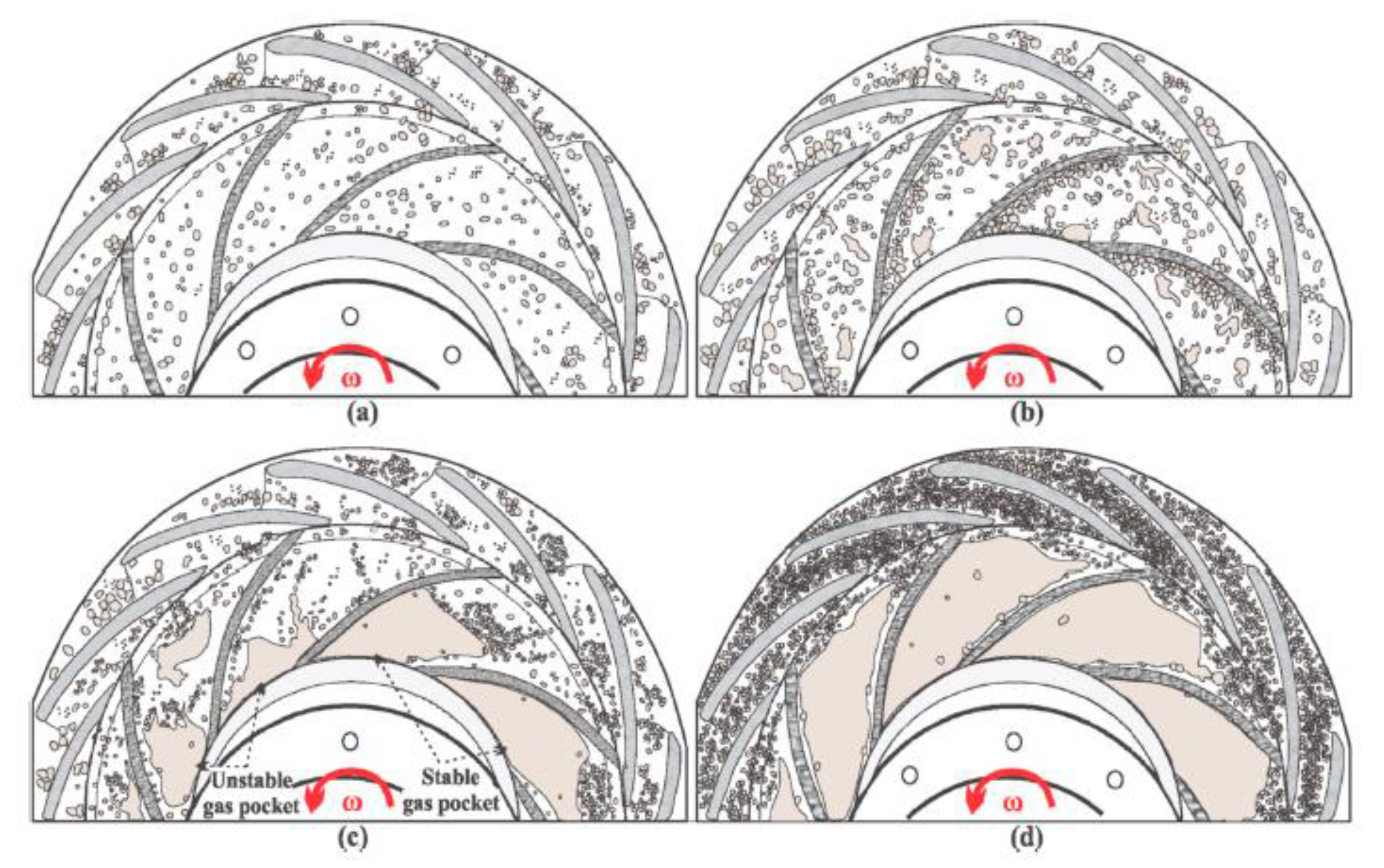

- The recent experimental analysis on ESPs handling multiphase flow (consisting of empirical model and their comparison, flow visualization, bubble size measurements and viscosity analysis) has helped in identifying some major parameters and difficulties that are accountable for pump performance degradation. The gas accumulation, gas-pocket formation and surging initiation mechanism are strongly dependent on the bubble size and trajectories. Bubble size has claimed to be the main parameter responsible for the two-phase performance degradation of ESPs. However, the increase in rotational speed has a positive effect on the pump performance, because the bubble diameter decreased at higher rotational speed, which makes the impeller flow channel more stable.

- (2)

- The comparison among different correlations with our data sets has shown different trends regarding pump performance prediction and surging mechanism. Some empirical models offer good simulation of the data sets in Table 4. However, some of them did not produce any outcomes for our data set, because most of their models were established for high inlet pressure (for example, in the case of Turpin, 344.73 kpa, 689.47 kpa and 1378.95 kpa), no water, but oil and CO2, multistage arrangement, different rotational speed (compared with our experimental data) and different pump geometries. Therefore, these empirical models become specific and valid for the pump types evaluated. This is the reason why most researchers performed more specific research using much simpler arrangements, such as centrifugal or mixed-flow single stages, in order to get more local flow features.

- (3)

- The visualization techniques have played a satisfactory role in examining the unsteady internal flow behavior of the fluid and different flow patterns inside the rotating ESPs. However, the complete two-phase flow phenomena, responsible for pump performance degradation, are still difficult to visualize because of the complex geometry of ESP stages having several impeller and diffusers. Although the CFD-based numerical simulations, alone or in combination with experimental studies, have been used as an alternate to analyze the two-phase flow, its reliability and accuracy are still questioned.

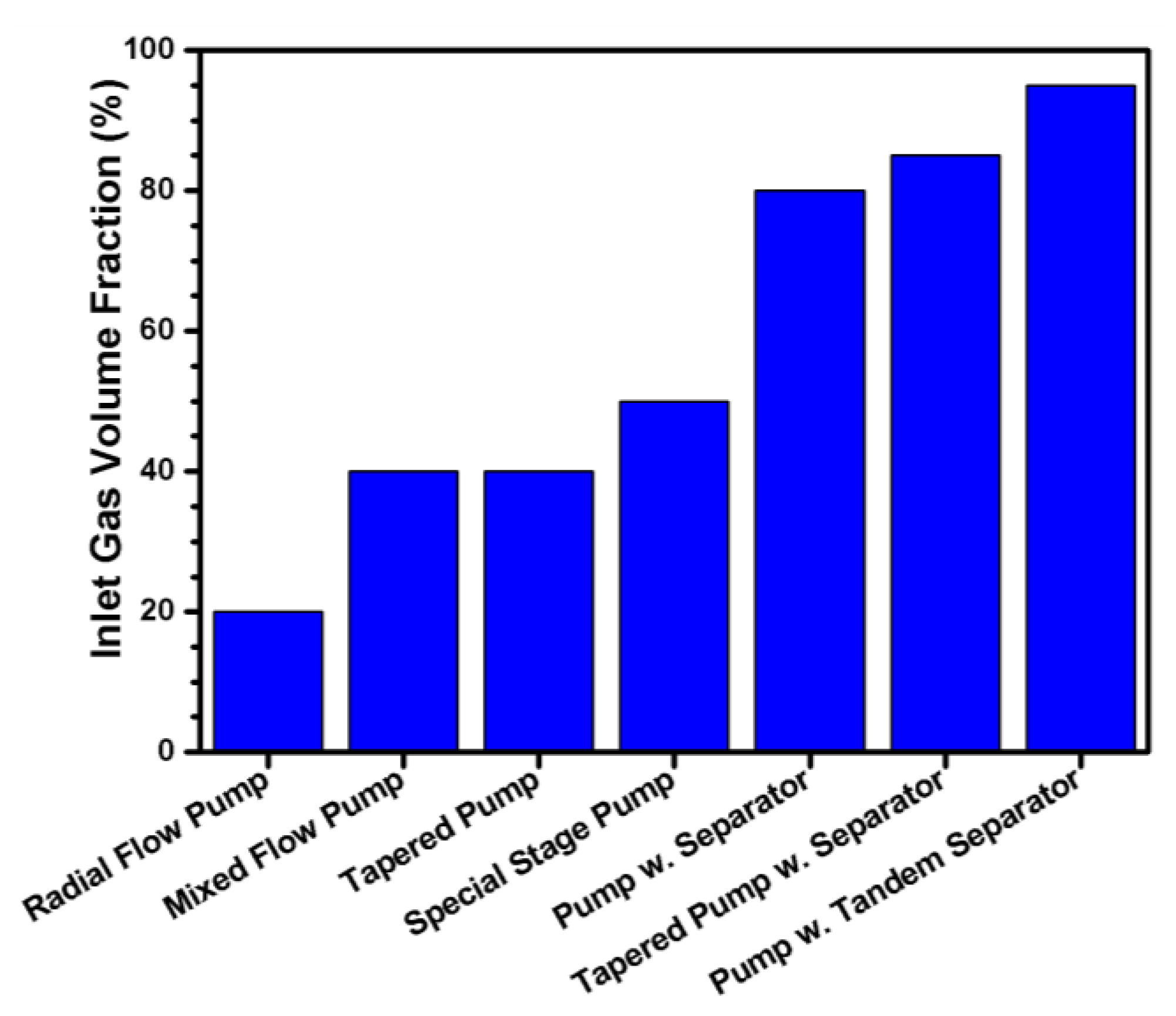

- (4)

- Gas-handling design methods have successfully increased the two-phase handling ability of ESPs either by stopping the entrance of free gas into the pump system (natural gas separation) or removing the entered gas with the help of RGSs alone or combined with gas handlers. The application of gas handlers combined with RGSs has proven to be very useful for increasing the gas-handling capability of the ESP system up to 95%. This paper has an individuality in describing the complete mechanism of all the gas-handling techniques.

7. Future Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Takacs, G. Chapter 1—Introduction. In Electrical Submersible Pumps Manual, 2nd ed.; Takacs, G., Ed.; Gulf Professional Publishing: Houston, TX, USA, 2017; pp. 1–10. [Google Scholar]

- Brookbank, E. Electric Submersible Pumps—The First Sixty Years; European ESP Workshop: London, UK, 1988. [Google Scholar]

- Barrios, L.J. Visualization and Modeling of Multiphase Performance Inside an Electrical Submersible Pump. Ph.D. Thesis, The University of Tulsa, Tulsa, OK, USA, 2007. [Google Scholar]

- Barrios, L.; Rojas, M.; Monteiro, G.; Sleight, N. Brazil field experience of ESP performance with viscous emulsions and high gas using multi-vane pump MVP and high power ESPs. In Proceedings of the SPE Electric Submersible Pump Symposium: The Woodlands, Richardson, TX, USA, 24–28 April 2017; Society of Petroleum Engineers: Richardson, TX, USA, 2017. [Google Scholar]

- Ladopoulos, E. Four-dimensional Petroleum Exploration & Non-linear ESP Artificial Lift by Multiple Pumps for Petroleum Well Development. Univ. J. Hydr. 2015, 1, 14. [Google Scholar]

- Zhu, J.; Zhang, H.-Q. CFD simulation of ESP performance and bubble size estimation under gassy conditions. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014; Society of Petroleum Engineers: Richardson, TX, USA, 2014. [Google Scholar]

- Banjar, H.; Gamboa, J.; Zhang, H.-Q. Experimental study of liquid viscosity effect on two-phase stage performance of electrical submersible pumps. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013; Society of Petroleum Engineers: Richardson, TX, USA, 2013. [Google Scholar]

- Takacs, G. Chapter 4—Use of ESP Equipment in Special Conditions. In Electrical Submersible Pumps Manual; Takacs, G., Ed.; Gulf Professional Publishing: Boston, MA, USA, 2009; pp. 119–186. [Google Scholar]

- Pessoa, R.; Prado, M. Two-phase flow performance for electrical submersible pump stages. SPE Prod. Facil. 2003, 18, 13–27. [Google Scholar] [CrossRef]

- Estevam, V. A Phenomenological Analysis about Centrifugal Pump in Two-Phase Flow Operation. Ph.D. Thesis, Universidade Estadual de Campinas, Campinas, Brazil, 2002. [Google Scholar]

- Gamboa, J. Prediction of the Transition in Two-Phase Performance of an Electrical Submersible Pump. Ph.D. Dissertation, University of Tulsa, Tulsa, OK, USA, 2008. [Google Scholar]

- Zhou, D.; Sachdeva, R. Simple model of electric submersible pump in gassy well. J. Pet. Sci. Eng. 2010, 70, 204–213. [Google Scholar] [CrossRef]

- Camilleri, L.A.; Brunet, L.; Segui, E. Poseidon Gas Handling Technology: A Case Study of Three ESP Wells in the Congo. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 25–28 September 2011. [Google Scholar]

- Rahime, F.; Sakr, K.; Areekat, M.; Suryadi, R. Application of the Gas Handlers in KOC. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 10–13 March 2013. [Google Scholar]

- Murakami, M.; Minemura, K. Effects of entrained air on the performance of a centrifugal pump: 1st report, performance and flow conditions. Bull. JSME 1974, 17, 1047–1055. [Google Scholar] [CrossRef]

- Sekoguchi, K.; Takada, S.; Kanemori, Y. Study of air-water two-phase centrifugal pump by means of electric resistivity probe technique for void fraction measurement: 1st report, measurement of void fraction distribution in a radial flow impeller. Bull. JSME 1984, 27, 931–938. [Google Scholar] [CrossRef]

- Barrios, L.; Prado, M.G. Experimental visualization of two-phase flow inside an electrical submersible pump stage. J. Energy Resour. Technol. 2011, 133. [Google Scholar] [CrossRef]

- Schobeiri, M. Turbomachinery Flow Physics and Dynamic Performance; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Gülich, J.F. Pump types and performance data. In Centrifugal Pumps; Springer: Berlin/Heidelberg, Germany, 2014; pp. 43–78. [Google Scholar]

- Zhu, J.; Zhang, H.-Q. Numerical study on electrical-submersible-pump two-phase performance and bubble-size modeling. SPE Prod. Oper. 2017, 32, 267–278. [Google Scholar] [CrossRef]

- Shi, Y.; Zhu, H.; Zhang, J.; Zhang, J.; Zhao, J. Experiment and numerical study of a new generation three-stage multiphase pump. J. Pet. Sci. Eng. 2018, 169, 471–484. [Google Scholar] [CrossRef]

- De Salis, J.; De Marolles, C.; Falcimaigne, J.; Durando, P. Multiphase pumping-operation & control. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 6–9 October 1996. [Google Scholar] [CrossRef]

- Dupoiron, M.A.N. The Effect of Gas on Multi-Stage Mixed-Flow Centrifugal Pumps. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 2018. [Google Scholar]

- Truesdell, C.; Euler, L. The Rational Mechanics of Flexible or Elastic Bodies, 1638–1788: Introduction to Leonhardi Euleri Opera Omnia Vol X Et XI Seriei Secundae; Orell Füssli: Zürich, Switzerland, 1960; Volume 11. [Google Scholar]

- Si, Q.; Ali, A.; Yuan, J.; Fall, I.; Muhammad Yasin, F. Flow-Induced Noises in a Centrifugal Pump: A Review. Sci. Adv. Mater. 2019, 11, 909–924. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, H.-Q. A review of experiments and modeling of gas-liquid flow in electrical submersible pumps. Energies 2018, 11, 180. [Google Scholar]

- Si, Q.; Bois, G.; Zhang, K.; Yuan, J. Air-water two-phase flow experimental and numerical analysis in a centrifugal pump. In Proceedings of the 12th European Conference on Turbomachinery, Fluid Dynamics and Thermodynamics, Stockholm, Sweden, 3–7 April 2017; pp. 3–7. [Google Scholar]

- Si, Q.; Cui, Q.; Zhang, K.; Yuan, J.; Bois, G. Investigation on centrifugal pump performance degradation under air-water inlet two-phase flow conditions. La Houille Blanche 2018, 41–48. [Google Scholar] [CrossRef]

- Si, Q.; Bois, G.; Jiang, Q.; He, W.; Ali, A.; Yuan, S. Investigation on the Handling Ability of Centrifugal Pumps under Air–Water Two-Phase Inflow: Model and Experimental Validation. Energies 2018, 11, 3048. [Google Scholar] [CrossRef]

- Si, Q.; Cui, Q.; Shouqi, Y.U.A.N.; Zhang, K.; Cao, R.; Tang, Y. Influence of inlet gas volume fraction on similarity law in centrifugal pumps under gas-liquid Two-phase Condition. In Transactions of the Chinese Society for Agricultural Machinery; Editorial Office of Transactions of the Chinese Society of Agricultural Engineering: Beijing, China, 2018. [Google Scholar]

- Jiang, Q.; Heng, Y.; Liu, X.; Zhang, W.; Bois, G.; Si, Q. A review of design considerations of centrifugal pump capability for handling inlet gas-liquid two-phase flows. Energies 2019, 12, 1078. [Google Scholar] [CrossRef]

- Lea, J.F.; Bearden, J. Effect of gaseous fluids on submersible pump performance. J. Pet. Technol. 1982, 34, 2922–2930. [Google Scholar] [CrossRef]

- Turpin, J.L.; Lea, J.F.; Bearden, J.L. Gas-liquid flow through centrifugal pumps-Correlation of data. In Proceedings of the 3rd International Pump Symposium, Houston, TX, USA, 20–22 May 1986. [Google Scholar] [CrossRef]

- Cirilo, R. Air-Water Flow through Electric Submersible Pumps. Ph.D. Thesis, University of Tulsa, Department of Petroleum Engineering, Tulsa, OK, USA, 1998. [Google Scholar]

- Pessoa, R.; Machado, M.; Robles, J.; Escalante, S.; Henry, J. Tapered Pump Experimental Tests with Light and Heavy Oil in PDVSA INTEVEP Field Laboratory. In Proceedings of the SPE-ESP Workshop (April 1999), Houston, TX, USA, 28–30 April 1999. [Google Scholar]

- Romero, M. An Evaluation of an Electrical Submersible Pumping System for High GOR Wells. Ph.D. Thesis, University of Tulsa, Tulsa, OK, USA, 1999. [Google Scholar]

- Sachdeva, R. Two-Phase Flow through Electric Submersible Pumps. Ph.D. Thesis, University of Tulsa, Tulsa, OK, USA, 1988. [Google Scholar]

- Sachdeva, R.; Doty, D.; Schmidt, Z. In Performance of Axial Electric Submersible Pumps in a Gassy Well. In Proceedings of the SPE Rocky Mountain Regional Meeting, Casper, Wyoming, 18–21 May 1992. [Google Scholar]

- Duran, J.; Prado, M.G. ESP stages air-water two-phase performance—Modeling and experimental data. SPE 120628. In Proceedings of the 2004 SPE ESP Workshop, Houston, TX, USA, 28–30 April 2004. [Google Scholar]

- Salehi, E. ESP Performance in Two-Phase FLOW through Mapping and Surging Tests at Various Rotational Speeds and Intake Pressures. Master’s Thesis, University of Tulsa, Tulsa, OK, USA, 2012. [Google Scholar]

- Mohammadzaheri, M.; Tafreshi, R.; Khan, Z.; Franchek, M.; Grigoriadis, K. In Modelling of Petroleum Multiphase Fluids in ESP an Intelligent Approach. In Proceedings of the Offshore Mediterranean Conference and Exhibition, Ravenna, Italy, 25–27 March 2015. [Google Scholar]

- Mohammadzaheri, M.; Tafreshi, R.; Khan, Z.; Ziaiefar, H.; Ghodsi, M.; Franchek, M.; Grigoriadis, K. Modelling of electrical submersible pumps for petroleum multiphase fluids, an intelligent approach supported by a critical review and experimental results. J. Eng. Res. 2019, 16, 77–86. [Google Scholar] [CrossRef]

- Zhu, J.; Guo, X.; Liang, F.; Zhang, H.-Q. Experimental study and mechanistic modeling of pressure surging in electrical submersible pump. J. Nat. Gas Sci. Eng. 2017, 45, 625–636. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, J.; Cao, G.; Zhao, Q.; Peng, J.; Zhu, H.; Zhang, H.-Q. Modeling flow pattern transitions in electrical submersible pump under gassy flow conditions. J. Pet. Sci. Eng. 2019, 180, 471–484. [Google Scholar] [CrossRef]

- Mohammadzaheri, M.; Tafreshi, R.; Khan, Z.; Ghodsi, M.; Franchek, M.; Grigoriadis, K. Modelling of petroleum multiphase flow in electrical submersible pumps with shallow artificial neural networks. Ships Offshore Struct. 2020, 15, 174–183. [Google Scholar] [CrossRef]

- Si, Q.; Zhang, H.; Bois, G.; Zhang, J.; Cui, Q.; Yuan, S. Experimental investigations on the inner flow behavior of centrifugal pumps under inlet air-water two-phase conditions. Energies 2019, 12, 4377. [Google Scholar] [CrossRef]

- Gamboa, J.; Prado, M. Review of electrical-submersible-pump surging correlation and models. SPE Prod. Oper. 2011, 26, 314–324. [Google Scholar] [CrossRef]

- Murakami, M.; Minemura, K. Effects of entrained air on the performance of centrifugal pumps: 2nd report, effects of number of blades. Bull. JSME 1974, 17, 1286–1295. [Google Scholar] [CrossRef]

- Patel, B. Investigations into the two-phase flow behavior of centrifugal pumps. Proc. Polyph. Flow Turbomach. ASME 1978, 79–100. [Google Scholar]

- Kim, J.; Duffey, R.; Belloni, P. On centrifugal pump head degradation in two-phase flow. In Design Methods for Two-Phase Flow in Turbomachinery; ASME: New York, NY, USA, 1985. [Google Scholar]

- Furukawa, A.; Shirasu, S.-I.; Sato, S. Experiments on air-water two-phase flow pump impeller with rotating-stationary circular cascades and recirculating flow holes. JSME Int. J. Ser. B Fluids Therm. Eng. 1996, 39, 575–582. [Google Scholar] [CrossRef]

- Sato, S.; Furukawa, A.; Takamatsu, Y. Air-water two-phase flow performance of centrifugal pump impellers with various blade angles. JSME Int. J. Ser. B Fluids Therm. Eng. 1996, 39, 223–229. [Google Scholar] [CrossRef]

- Andras, E. Two Phase Flow Centrifugal Pump Performance. Ph.D. Thesis, Idaho State University, Pocatello, ID, USA, 1997. [Google Scholar]

- Takemura, T.; Kato, H.; Kanno, H.; Okamoto, H.; Aoki, M.; Goto, A.; Egashira, K.; Shoda, S. Development of rotordynamic multiphase pump: The first report. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Vancouver, BC, Canada, 13–17 April 1997; pp. 201–208. [Google Scholar]

- Thum, D.; Hellmann, D.; Sauer, M. Influence of the Patterns of Liquid-Gas Flows on Multiphase-Pumping of Radial Centrifugal Pumps. In Proceedings of the 5th North American Conference on Multiphase Technology, Banff, AB, Canada, 31 May–2 June 2006; pp. 79–90. [Google Scholar]

- Izturitz, D.L.; Kenyery, F. Effect of Bubble Size on an ESP Performance Handling Two-Phase Flow Conditions; UBS-LABCEM Publication: Caracas, Venezuela, 2007; pp. 931–939. [Google Scholar]

- Schäfer, T.; Bieberle, A.; Neumann, M.; Hampel, U. Application of gamma-ray computed tomography for the analysis of gas holdup distributions in centrifugal pumps. Flow Meas. Instrum. 2015, 46, 262–267. [Google Scholar] [CrossRef]

- Schäfer, T.; Neumann-Kipping, M.; Bieberle, A.; Bieberle, M.; Hampel, U. Ultrafast X-Ray Computed Tomography Imaging for Hydrodynamic Investigations of Gas–Liquid Two-Phase Flow in Centrifugal Pumps. J. Fluids Eng. 2020, 142. [Google Scholar] [CrossRef]

- Shao, C.; Li, C.; Zhou, J. Experimental investigation of flow patterns and external performance of a centrifugal pump that transports gas-liquid two-phase mixtures. Int. J. Heat Fluid Flow 2018, 71, 460–469. [Google Scholar] [CrossRef]

- Cubas, J.M.; Stel, H.; Ofuchi, E.M.; Neto, M.A.M.; Morales, R.E. Visualization of two-phase gas-liquid flow in a radial centrifugal pump with a vaned diffuser. J. Pet. Sci. Eng. 2020, 187, 106848. [Google Scholar] [CrossRef]

- Stel, H.; Ofuchi, E.M.; Sabino, R.H.; Ancajima, F.C.; Bertoldi, D.; Marcelino Neto, M.A.; Morales, R.E. Investigation of the motion of bubbles in a centrifugal pump impeller. J. Fluids Eng. 2019, 141. [Google Scholar] [CrossRef]

- Zhang, J.; Cai, S.; Li, Y.; Zhu, H.; Zhang, Y. Visualization study of gas–liquid two-phase flow patterns inside a three-stage rotodynamic multiphase pump. Exp. Therm. Fluid Sci. 2016, 70, 125–138. [Google Scholar] [CrossRef]

- Verde, W.M.; Biazussi, J.L.; Sassim, N.A.; Bannwart, A.C. Experimental study of gas-liquid two-phase flow patterns within centrifugal pumps impellers. Exp. Therm. Fluid Sci. 2017, 85, 37–51. [Google Scholar] [CrossRef]

- Trevisan, F.E. Modeling and Visualization of Air and Viscous Liquid in Electrical Submersible pump. Ph.D. Thesis, University of Tulsa, Tulsa, OK, USA, 2009. [Google Scholar]

- Ippen, A.T. The influence of viscosity on centrifugal pump performance. Trans. ASME 1946, 68, 823–848. [Google Scholar]

- Institute, H. Tentative Standards of Hydraulic Institute: Charts for the Determination of Pump Performance when Handling Viscous Liquids; The Institute: New York, NY, USA, 1948. [Google Scholar] [CrossRef]

- Stepanoff, A.J. Centrifugal and Axial Flow Pumps. Theory, Design, and Application; John Wiley & Sons: Hoboken, NJ, USA, 1957. [Google Scholar]

- Gülich, J. Pumping highly viscous fluids with centrifugal pumps—Part 1. World Pumps 1999, 1999, 30–34. [Google Scholar] [CrossRef]

- Gülich, J. Pumping highly viscous fluids with centrifugal pumps—Part 2. World Pumps 1999, 1999, 39–42. [Google Scholar] [CrossRef]

- Añez, D.; Kenyery, F.; Escalante, S.I.; Teran, V.M. ESP’s Performance with Two-Phase and Viscous Flow. Proc. ETCE 2001, 5–7. [Google Scholar]

- Turzo, Z.; Takacs, G.; Zsuga, J. Equations correct centrifugal pump curves for viscosity. Oil Gas J. 2000, 98, 57. [Google Scholar]

- Amaral, G.; Estevam, V.; Franca, F.A. On the influence of viscosity on ESP performance. SPE Prod. Oper. 2009, 24, 303–311. [Google Scholar] [CrossRef]

- Solano, E.A. Viscous Effects on the Performance of Electro Submersible Pumps (ESP’s). Master’s Thesis, University of Tulsa, Tulsa, OK, USA, 2009. [Google Scholar]

- Trevisan, F.E.; Prado, M. Experimental Investigation of the Viscous Effect on Two-Phase-Flow Patterns and Hydraulic Performance of Electrical Submersible Pumps. J. Can. Pet. Technol. 2011, 50, 45–52. [Google Scholar] [CrossRef]

- Bannwart, A.C.; Estevam, V.; Paternost, G.M. Experimental Study of Centrifugal Pump Handling Viscous Fluid and Two-Phase Flow. In Proceedings of the SPE Artificial Lift Conference-Americas, Cartagena, Colombia, 21–22 May 2013. [Google Scholar]

- Paternost, G.M.; Bannwart, A.C.; Estevam, V. Experimental study of a centrifugal pump handling viscous fluid and two-phase flow. SPE Prod. Oper. 2015, 30, 146–155. [Google Scholar] [CrossRef]

- Zhu, J.; Banjar, H.; Xia, Z.; Zhang, H.-Q. CFD simulation and experimental study of oil viscosity effect on multi-stage electrical submersible pump (ESP) performance. J. Pet. Sci. Eng. 2016, 146, 735–745. [Google Scholar] [CrossRef]

- Zhang, J. Experiments, CFD Simulation and Modeling of ESP Performance under Viscous Fluid Flow Conditions. Master’s Thesis, The University of Tulsa, Tulsa, OH, USA, 2017. [Google Scholar]

- Valdés, J.P.; Becerra, D.; Rozo, D.; Cediel, A.; Torres, F.; Asuaje, M.; Ratkovich, N. Comparative analysis of an electrical submersible pump’s performance handling viscous Newtonian and non-Newtonian fluids through experimental and CFD approaches. J. Pet. Sci. Eng. 2020, 187, 106749. [Google Scholar] [CrossRef]

- Anderson, J.D.; Wendt, J. Computational Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 1995; Volume 206. [Google Scholar]

- Li, W.; Awais, M.; Ru, W.; Shi, W.; Ajmal, M.; Uddin, S.; Liu, C. Review of Sensor Network-Based Irrigation Systems Using IoT and Remote Sensing. Adv. Meteorol. 2020, 2020. [Google Scholar] [CrossRef]

- Si, Q.; Shen, C.; Ali, A.; Cao, R.; Yuan, J.; Wang, C. Experimental and numerical study on gas-liquid two-phase flow behavior and flow induced noise characteristics of radial blade pumps. Processes 2019, 7, 920. [Google Scholar] [CrossRef]

- Mikielewicz, J.; Wilson, D.G.; Chan, T.-C.; Goldfinch, A.L. A method for correlating the characteristics of centrifugal pumps in two-phase flow. J. Fluids Eng. 1978, 100, 395–409. [Google Scholar] [CrossRef]

- Wilson, D.G.; Chan, T.; Manzano-Ruiz, J. Analytical Models and Experimental Studies of Centrifugal-Pump Performance in Two-Phase Flow; Report No. EPRI NP-677; MIT: Cambridge, MA, USA, 1979. [Google Scholar]

- Zakem, S. Determination of gas accumulation and two-phase slip velocity ratio in a rotating impeller. In ASME, Polyphase Flow and Transportation Technology; ASME: New York, NY, USA, 1980; Volume 167–173. [Google Scholar]

- Furuya, O. An analytical model for prediction of two-phase (noncondensable) flow pump performance. J. Fluids Eng. 1985, 107, 139–147. [Google Scholar] [CrossRef]

- Sachdeva, R.; Doty, D.; Schmidt, Z. Performance of electric submersible pumps in gassy wells. SPE Prod. Facil. 1994, 9, 55–60. [Google Scholar] [CrossRef]

- Minemura, K.; Uchiyama, T.; Shoda, S.; Egashira, K. Prediction of air-water two-phase flow performance of a centrifugal pump based on one-dimensional two-fluid model. J. Fluids Eng. 1998, 120, 327–334. [Google Scholar] [CrossRef]

- Sun, D.; Prado, M. Modeling gas-liquid head performance of electrical submersible pumps. In Proceedings of the ASME Pressure Vessels and Piping Conference, San Diedo, CA, USA, 25–29 July 2004; pp. 63–71. [Google Scholar]

- Minemura, K.; Uchiyama, T. Three-dimensional calculation of air-water two-phase flow in a centrifugal pump based on a bubbly flow model with fixed cavity. JSME Int. J. Ser. B Fluids Therm. Eng. 1994, 37, 726–735. [Google Scholar] [CrossRef]

- Pak, E.; Lee, J. Performance and pressure distribution changes in a centrifugal pump under two-phase flow. Proc. Inst. Mech. Eng. Part A J. Power Energy 1998, 212, 165–171. [Google Scholar] [CrossRef]

- Caridad, J.; Kenyery, F. CFD analysis of electric submersible pumps (ESP) handling two-phase mixtures. J. Energy Resour. Technol. 2004, 126, 99–104. [Google Scholar] [CrossRef]

- Ossia, S.; Godeluck, J. Gas-Liquid Flow CFD Study of SN8500; Internal Report: GeMS 100318644; Schlumberger Ltd.: Houston, TX, USA, 2006. [Google Scholar]

- Caridad, J.; Asuaje, M.; Kenyery, F.; Tremante, A.; Aguillón, O. Characterization of a centrifugal pump impeller under two-phase flow conditions. J. Pet. Sci. Eng. 2008, 63, 18–22. [Google Scholar] [CrossRef]

- Barrios, L.; Prado, M.G.; Kenyery, F. CFD Modeling Inside an Electrical Submersible Pump in Two-Phase Flow Condition. In Proceedings of the Fluids Engineering Division Summer Meeting, Vail, CO, USA, 2–6 August 2009; pp. 457–469. [Google Scholar]

- Tillack, P. Förderverhalten von Kreiselpumpen bei viskosen, gasbeladenen Flüssigkeiten. Phd Diss. Tu Kaiserslaut. 1998. [Google Scholar]

- Gonzalez, J.; Fernandez, J.N.; Blanco, E.; Santolaria, C. Numerical simulation of the dynamic effects due to impeller-volute interaction in a centrifugal pump. J. Fluids Eng. 2002, 124, 348–355. [Google Scholar] [CrossRef]

- González, J.; Santolaria, C. Unsteady flow structure and global variables in a centrifugal pump. J. Fluids Eng. 2006, 128, 937–946. [Google Scholar] [CrossRef]

- Marsis, E.; Pirouzpanah, S.; Morrison, G. CFD-based design improvement for single-phase and two-phase flows inside an electrical submersible pump. In Proceedings of the Fluids Engineering Division Summer Meeting, Incline Village, NV, USA, 7–11 July 2013. [Google Scholar]

- Zhu, J.; Zhu, H.; Zhang, J.; Zhang, H.-Q. A numerical study on flow patterns inside an electrical submersible pump (ESP) and comparison with visualization experiments. J. Pet. Sci. Eng. 2019, 173, 339–350. [Google Scholar] [CrossRef]

- SHOJAEIFARD, M.; Boyaghchi, F.; Ehghaghi, M. Experimental study and three-dimensional numerical flow simulation in a centrifugal pump when handling viscous fluids. IUST Int. J. Eng. Sci. 2006, 17, 53–60. [Google Scholar]

- Shojaeefard, M.; Tahani, M.; Ehghaghi, M.; Fallahian, M.; Beglari, M. Numerical study of the effects of some geometric characteristics of a centrifugal pump impeller that pumps a viscous fluid. Comput. Fluids 2012, 60, 61–70. [Google Scholar] [CrossRef]

- Sirino, T.; Stel, H.; Morales, R.E. Numerical study of the influence of viscosity on the performance of an electrical submersible pump. In Proceedings of the Fluids Engineering Division Summer Meeting, Incline Village, NV, USA, 7–11 July 2013; American Society of Mechanical Engineers Digital Collection: Incline Village, NV, USA, 2013. [Google Scholar]

- Stel, H.; Sirino, T.; Prohmann, P.R.; Ponce, F.; Chiva, S.; Morales, R.E. CFD investigation of the effect of viscosity on a three-stage electric submersible pump. In Proceedings of the 4th Joint US-European Fluids Engineering Division Summer Meeting Collocated with the ASME 2014 12th International Conference on Nanochannels, Microchannels, and Minichannels, Chicago, IL, USA, 3–7 August 2014. [Google Scholar]

- Stel, H.; Sirino, T.; Ponce, F.J.; Chiva, S.; Morales, R.E. Numerical investigation of the flow in a multistage electric submersible pump. J. Pet. Sci. Eng. 2015, 136, 41–54. [Google Scholar] [CrossRef]

- Basaran, B. CFD Simulation for the Erosion on Electrical Submersible Pump Due to Viscosity and Air presence. Master’s Thesis, Texas A & M University, College Station, TX, USA, 2017. [Google Scholar]

- Ofuchi, E.M.; Stel, H.; Sirino, T.; Vieira, T.S.; Ponce, F.J.; Chiva, S.; Morales, R.E. Numerical investigation of the effect of viscosity in a multistage electric submersible pump. Eng. Appl. Comput. Fluid Mech. 2017, 11, 258–272. [Google Scholar] [CrossRef]

- Ofuchi, E.; Stel, H.; Vieira, T.; Ponce, F.; Chiva, S.; Morales, R. Study of the effect of viscosity on the head and flow rate degradation in different multistage electric submersible pumps using dimensional analysis. J. Pet. Sci. Eng. 2017, 156, 442–450. [Google Scholar] [CrossRef]

- Ofuchi, E.; Cubas, J.; Stel, H.; Dunaiski, R.; Vieira, T.; Morales, R. A new model to predict the head degradation of centrifugal pumps handling highly viscous flows. J. Pet. Sci. Eng. 2020, 187, 106737. [Google Scholar] [CrossRef]

- Awais, M.; Li, W.; Arshad, A.; Haydar, Z.; Yaqoob, N.; Hussain, S. Evaluating removal of tar contents in syngas produced from downdraft biomass gasification system. Int. J. Green Energy 2018, 15, 724–731. [Google Scholar] [CrossRef]

- Bagci, A.S.; Kece, M.M.; Rivero, N.; Delida, J. Challenges of Using Electrical Submersible Pump (ESP) in High Free Gas Applications. In Proceedings of the International Oil and Gas Conference and Exhibition in China, Beijing, China, 8–10 June 2010; Society of Petroleum Engineers: Beijing, China, 2010; p. 131760. [Google Scholar]

- Wilson, B. There’s No Free Lunch, Pumping Two Phase Fluids with ESP. In Proceedings of the SPE Gulf Coast Section Electric Submersible Pump Workshop, Houston, TX, USA, 30 April–2 May 2003. [Google Scholar]

- Bedrin, V.; Khasanov, M.; Khabibullin, R.; Krasnov, V.; Pashali, A.; Litvinenko, K.; Elichev, V.; Prado, M. High GLR ESP Technologies Comparison, Field Test Results (Russian). In Proceedings of the SPE Russian Oil and Gas Technical Conference and Exhibition, Moscow, Russia, 28–30 October 2008; p. 117414. [Google Scholar]

- Wilson, B.; Mack, J.; Foster, D. Operating electrical submersible pumps below the perforations. SPE Prod. Facil. 1998, 13, 141–145. [Google Scholar] [CrossRef]

- Kallas, P.; Way, K. An Electrical Submergible Pumping System for High GOR Wells. In Proceedings of the SPE Electrical Submergible Pump Workshop, Houston, TX, USA, 26 April 1995. [Google Scholar]

- Lee, L.C.; Tyagi, M.K.; Furnas, M.W.; Traylor, F.T. Liquid-Gas Separator Apparatus. U.S. Patent 4,481,020, 6 November 1984. [Google Scholar]

- Bunnelle, P.R. Liquid-Gas Separator Unit. U.S. Patent 3,887,342, 3 June 1975. [Google Scholar]

- Tuzson, J.J. Separator. U.S. Patent 4,088,459, 9 May 1978. [Google Scholar]

- Enegess, D.N. Vortex Gas Separator. U.S. Patent 4,162,901, 31 July 1979. [Google Scholar]

- Kobylinski, L.; Taylor, F.; Brienan, J. Development and field test results of an efficient downhole centrifugal gas separator. J. Pet. Technol. 1985, 37, 1295–1304. [Google Scholar] [CrossRef]

- Darbani, S.; Riasi, A.; Nejat, A. The parametric study of an electrical submersible pump rotary gas separator under two-phase flow condition. Energy Equip. Syst. 2015, 3, 33–44. [Google Scholar]

- Alhanati, F.J.S. Bottomhole Gas Separation Efficiency in Electrical Submersible Pump Installations. Ph.D. Thesis, University of Tulsa, Tulsa, OK, USA, 1993. [Google Scholar]

- Alhanati, F.; Doty, D. A simple model for the efficiency of rotary separators. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 25–28 September 1994. [Google Scholar]

- Sambangi, S.R. Gas Separation Efficiency in Electrical Submersible Pump Installations with Rotary Gas Separators. Ph.D. Thesis, University of Tulsa, Tulsa, OK, USA, 1994. [Google Scholar]

- Lackner, G. The Effect of Viscosity on Downhole Gas Separation in a Rotary Gas Separator. Ph.D. Thesis, Tulsa University, Tulsa, OK, USA, 1997. [Google Scholar]

- Harun, A.F. The Effect of Inducer Performance on the Efficiency of the ESP Rotary Gas Separator. Ph.D. Dissertation, Tulsa University, Tulsa, OK, USA, 2000. [Google Scholar]

- Awais, M.; Li, W.; Munir, A.; Omar, M.M.; Ajmal, M. Experimental investigation of downdraft biomass gasifier fed by sugarcane bagasse and coconut shells. Biomass Convers. Biorefinery 2020, 1–16. [Google Scholar] [CrossRef]

- Yanez, R.; Escalante, S.I.; Pessoa, R.; Pena, M. Experimental Test to Obtain Inducer Curve of Rotary Gas Separators; Technical Report Intevep, INT-3967; Intevep: Los Teques, Venezuela, 1997. [Google Scholar]

- Harun, A.; Prado, M.; Doty, D. Design Optimization of a Rotary Gas Separator in ESP Systems. In Proceedings of the SPE Production and Operations Symposium, Oklahoma City, OH, USA, 23–25 March 2003. [Google Scholar]

- Suarez, L.; Kenyery, F.; Azuaje, M.; Pena, M.A. 3D CFD Simulation of ESP Rotary Gas-Separator Performance Under Two-Phase-Flow Condition. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference; Intevep: Los Teques, Miranda, Venezuela, 2005. [Google Scholar]

- Derakhshan, S.; Riahi, F.; Bashiri, M. Efficiency improvement of a rotary gas separator by parametric study and gas/liquid-flow analysis. SPE Prod. Oper. 2018, 33, 320–335. [Google Scholar] [CrossRef]

- Lackner, G.; Doty, D.; Shirazi, S.; Schmidt, Z. Effect of viscosity on downhole gas separation in a rotary gas separator. SPE Prod. Facil. 2002, 17, 184–191. [Google Scholar] [CrossRef]

- Swetnam, J.; Sackash, M. Performance Review of Tapered Submergible Pumps in the Three Bar Field. J. Pet. Technol. 1978, 30, 1781–1787. [Google Scholar] [CrossRef]

- Camilleri, L.; Segui, E.; Valette, P.; Brunet, L. Poseidon gas handling technology: A case study of two ESP wells in congo. In Proceedings of the Gulf Coast Section Electric Submersible Pump Workshop, Manama, Bahrain, 25–28 September 2011. [Google Scholar]

- Lea, J.; Nickens, H.; Wells, M. Chapter 12—Electric Submersible Pumps. In Gas Well Deliquification; Gulf Professional Publishing: Burlington, VT, USA, 2003; pp. 239–250. [Google Scholar]

- Lea, J.F.; Nickens, H.V.; Wells, M.R. Chapter 12—electric submersible pumps. In Gas Well Deliquification (Second Edition); Lea, J.F., Nickens, H.V., Wells, M.R., Eds.; Gulf Professional Publishing: Burlington, VT, USA, 2008; pp. 361–382. [Google Scholar]

- Lea, J.F.; Rowlan, L. 12—Electrical submersible pumps. In Gas Well Deliquification (Third Edition); Lea, J.F., Rowlan, L., Eds.; Gulf Professional Publishing: Burlington, VT, USA, 2019; pp. 237–308. [Google Scholar]

- Marsis, E. CFD Simulation and Experimental Testing of Multiphase Flow inside the MVP Electrical Submersible Pump. Ph.D. Thesis, A&M University, College Station, TX, USA, 2012. [Google Scholar]

- Hua, G.; Falcone, G.; Teodoriu, C.; Morrison, G. Comparison of multiphase pumping technologies for subsea and downhole applications. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 30 October–2 November 2011. [Google Scholar]

- Müller-Link, D.; Rohlfing, G. Grown-up twin-screw multiphase pumps–from marginal to full size applications. In Proceedings of the 14th International Conference on Multiphase Production Technology, Cannes, France, 17–19 June 2009; BHR Group, 2009. [Google Scholar]

- MacNeil, D.; Dass, P. Replacing ESP and Gas Lift with ESTSP (Electric Submersible Twin Screw Pumps). In Proceedings of the SPE Artificial Lift Conference and Exhibition, Manama, Bahrain, 27–28 November 2012; Society of Petroleum Engineers, 2012. [Google Scholar]

- Centrilift, Inc. Comparison of Free Gas Handling Abilities of ESP Systems; Centrilift, lnc.: Claremore, OK, USA; Wharley End, UK; Available online: https://www.wwdmag.com/company/centrilift (accessed on 31 December 2020).

- Besagni, G.; Inzoli, F. Bubble size distributions and shapes in annular gap bubble column. Exp. Therm. Fluid Sci. 2016, 74, 27–48. [Google Scholar] [CrossRef]

| Reference | Analysis | Pump Model Type and Fluid |

|---|---|---|

| Lea (1982) [32] | Multi-phase flow performance of 3 distinct ESPs handling gaseous fluids | Two radial pumps, I-42B and C-72, and K-70, a mixed-flow pump; water–air and diesel–CO2, two-phase mixture |

| Turpin (1986) [33] | Development of empirical correlation for predicting centrifugal pump’s performance working under two-phase flow conditions | Same as Lea [32] |

| Cirilo (1998) [34] | Two-phase flow performance comparison among three different submersible pumps | Two mixed-flow pumps and one radial flow design; water–air |

| Pessoa (1999) [35] | Investigates gas-handling capability of tapered pump working with light/heavy oil and gas | Axial-flow pump with mixed-flow geometry; crude-oil/gas |

| Romero (1999) [36] | Two-phase flow performance evaluation of an ESP working with gas-handling device with slotted rotor | Mixed-flow pump with slotted impeller; water–air |

| Sachdeva (1988) [37] | Evaluates the working capability of ESPs (used in petroleum industry) under two-phase flow conditions | Same as Lea [32] |

| Sachdeva (1992) [38] | Correlates two-phase performance of ESPs working under gaseous conditions | Same as Lea [32] |

| Duran (2003) [39] | Correlation development for ESP two-phase performance prediction | Commercial ESP (series 513 having 6100 B/D at BEP); air–water |

| Zhou (2010) [12] | Improves and modifies Sachdeva’s correlation for gas–liquid performance prediction of ESPs in gassy well | Same as Lea [32] and Sachdeva [37,38] |

| Salehi (2012) [40] | Analyzes two-phase performance of the ESP using modelling of surging mechanism | ESP (TE2700); water–air |

| Mohammadzaheri (2015, 2019) [41,42] | Introduces artificial neural network (ANN) for two-phase head predication in ESPs, as a substitute of existing empirical models | Radial (I-42B) ESP used in Lea’s [32] experiments; two-phase petroleum fluids |

| Zhu (2017–18) [26,43] | Investigates the liquid–gas two-phase flow behavior in ESP by conducting experiments and modelling | Commercial ESP; liquid–gas |

| Zhu (2019) [44] | Development of a new mechanistic model to examine the gas–liquid flow patterns in ESP | ESP with capacity of 5000 B/D; air–water |

| Mohammadzaheri (2020) [45] | Proposes a shallow ANN model for the prediction of two-phase head and pressure increase in ESPs, as a replacement of existing empirical models | Radial (I-42B) ESP used in Lea’s [32] test; two-phase petroleum fluids |

| Reference | Empirical Correlation | Related Parameters | Application Range |

|---|---|---|---|

| Turpin (1986) [33] | = single-phase head (m) = intake pressure (kpa) = flow rates of gas and liquid at inlet (m3/d) | Pump performance prediction | |

| Sachdeva (1992) [38] | = pressure increment (kpa/stage) α = free gas content (stage intake) | Pressure rise in ESP and pump performance prediction | |

| Romero (1999) [36] | = dimensionless liquid flow rate (manufacturer’s catalog curve)) = dimensionless two-phase head | Less degradation in ESP performance or dispersed bubbly flow | |

| Duran (2003) [39] | Bubbly flow, Elongated bubbly flow, | α = in-situ GVFs = normalized gas flow rate a = −0.47075 b = −0.21626 | Slight and severe head degradation |

| Zhou (2010) [12] | = dimensionless two-phase head | Low and high head degradation or bubbly flow and churn flow | |

| Mohammadzaheri (2015, 2019) [41,42] | ANN fully connected cascade (FCC) model, | W and T = first and second-layer weights; C = matrix of cascade connection weights; and b = biases | Pressure rise and head prediction, two-phase flow in ESP |

| Mohammadzaheri (2020) [45] | Shallow ANN model, | , qm and α, represented as ui, i = 1–3; Wij and Tj = first and second-layer weights; bj and b = biases | Pressure rise and head prediction, two-phase flow in ESP |

| Study | Pump Type | K | Kc | E1 | E2 | E3 | E4 | E5 |

|---|---|---|---|---|---|---|---|---|

| Sachdeva (1992) [38] | Mixed (K-70) | 0.0936583 | _ | 0.622180 | −1.350338 | −0.31704 | _ | _ |

| Radial (I-42B) | 1.154562 | _ | 0.943308 | −1.175596 | −1.30009 | _ | _ | |

| Radial (C-72) | 0.1531026 | _ | 0.875192 | −1.764939 | −0.91870 | _ | _ | |

| Zhou (2010) [12] | Mixed (K-70) | 1.236426 | 7.497750 | 2.570713 | 12.66051 | 0.75505 | −0.34870 | 0.86709 |

| Radial (I-42B) | 1.971988 | 1.418884 | 1.987836 | 9.659564 | 0.90591 | −0.07244 | 0.31854 | |

| Radial (C-72) | 1.401067 | 2.173723 | 3.100355 | 14.93852 | 1.30836 | −0.05253 | 0.83359 |

| Rotational Speed | Gas Void Ratio (%) | Mixture Rate (m3/d) | Pump Intake Pressure (kpa) | Mixture Density (kg/m3) | Pressure Increase (kpa) |

|---|---|---|---|---|---|

| 1000 rpm | 4.2 | 338.2 | 132.70 | 957.20 | 22.70 |

| 4.2 | 343.22 | 132.65 | 957.20 | 22.49 | |

| 4.2 | 328.18 | 133.00 | 957.20 | 22.28 | |

| 4.2 | 313.15 | 133.44 | 957.20 | 22.58 | |

| 4.2 | 303.13 | 133.62 | 957.20 | 22.73 | |

| 4.2 | 301.88 | 133.71 | 957.20 | 22.44 | |

| 1450 rpm | 5 | 562.86 | 125.90 | 949.21 | 41.01 |

| 5 | 510.32 | 127.39 | 949.21 | 45.12 | |

| 5 | 482.53 | 128.96 | 949.21 | 46.15 | |

| 5 | 442.11 | 130.15 | 949.21 | 47.89 | |

| 5 | 386.53 | 132.05 | 949.21 | 51.84 | |

| 5 | 366.32 | 133.61 | 949.21 | 49.76 |

| Study | Empirical Correlation | Related Parameters |

|---|---|---|

| Turpin (1986) [33] | = Criterion to predict pump stability and instability | |

| Cirilo (1998) [34] | = Critical gas volume content | |

| Romero (1999) [36] | = 0.145 | |

| Duran (2003) [39] | and = normalized gas and liquid rate at surging point, respectively | |

| Zhou (2010) [12] | ||

| Gamboa (2011) [47] | = pump rotational speed (rpm) = fluid kinematic viscosity D = impeller outlet diameter (m) | |

| Zhu (2017–19) [26,43,44] | = surface tension (N/m) = angular speed (rad/s) = liquid flow rate (m3/s) = impeller volume (m3) = representative rotor radius (m) |

| Study | Analysis | Experimental Methodology and Observation |

|---|---|---|

| Ippen (1946) [65] | Single-phase flow | More than 200 experiments were performed at different rotational speeds and for oil viscosities around 10,000 SSU (303.03 centistokes) to predict the viscosity effects on pump performance |

| Hydraulic institute (1948) [66] | Single-phase flow | Based on water data, correction factors were developed for centrifugal pump performance working under viscous fluids conditions |

| Stepanoff (1957) [67] | Single-phase flow | Developed correction factors similar to the Hydraulic institute [66] in addition to Reynolds correlation |

| Gülich (1999) [68,69] | Single-phase flow | Analyzed the accuracy of correlations developed by the Hydraulic institute [66] |

| Añez (2001) [70] | Two-phase flow | Influence of free-gas entrainment and fluid viscosity on working capability of an ESP using gas, water and oil (375 Cp) |

| Turzo (2001) [71] | Single-phase flow | Developed equations on the basis of the Hydraulic institute [66] data, in order to examine the pump performance |

| Amaral (2009) [72] | Single-phase flow | Evaluate the correlations and charts developed by the Hydraulic institute [66] |

| Solano (2009) [73] | Single-phase flow | Similar observation as Amaral [72] |

| Trevisan (2009) [64] | Two-phase flow | Flow pattern analysis on ESP handling viscous fluids under two-phase flow condition |

| Trevisan and Prado (2010) [74] | Two-phase flow | Flow pattern analysis on ESP handling viscous fluids under two-phase flow condition |

| Bannwart (2013) [75] | Two-phase flow | Analyzed the effect of free-gas fraction and different liquid viscosities on the pump performance |

| Banjar (2013) [7] | Two-phase flow | Similar experiments as Trevisan [64,74] were observed |

| Paternost (2015) [76] | Two-phase flow | Free-gas entrainment effect on pump performance with an increase in liquid viscosity |

| Zhu (2016) [77] | Single-phase flow | Effect of oil with different viscosities on the pump performance at different flow rates and rotational speeds |

| Zhang (2017) [78] | Single-phase flow | Examined the pump performance parameters with the increase in fluid viscosity; pipe viscometer was used to measure viscosity |

| Valdes (2020) [79] | Single-phase flow | Pioneer study to investigate the influence of Newtonian and non-Newtonian viscous fluids on ESP performance |

| IAVF | Scale | Flow Rate = 0.6 Qd | Flow Rate = 0.8 Qd | Flow Rate = Qd |

|---|---|---|---|---|

| 1% |  |  |  |  |

| 5% |  |  |  |  |

| 7% |  |  |  |  |

| Pump Type | Pumping Mechanism | Max. GVF | Max. Capacity (Gas–liquid) | Max. Pressure | Max. Temperature |

|---|---|---|---|---|---|

| Helico-Axial (Poseidon) | Rotating | 75% | 9000 B/D | - | 450 °F |

| Multi-Vane (Baker Hughes-MVP) | Rotating | 70% | 18,000 B/D | - | 410 °F |

| Twin-Screw (CAN-K) | Positive displacement | 98% | Around 450,000 B/D | Around 3500 psi | 662 °F |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, A.; Yuan, J.; Deng, F.; Wang, B.; Liu, L.; Si, Q.; Buttar, N.A. Research Progress and Prospects of Multi-Stage Centrifugal Pump Capability for Handling Gas–Liquid Multiphase Flow: Comparison and Empirical Model Validation. Energies 2021, 14, 896. https://doi.org/10.3390/en14040896

Ali A, Yuan J, Deng F, Wang B, Liu L, Si Q, Buttar NA. Research Progress and Prospects of Multi-Stage Centrifugal Pump Capability for Handling Gas–Liquid Multiphase Flow: Comparison and Empirical Model Validation. Energies. 2021; 14(4):896. https://doi.org/10.3390/en14040896

Chicago/Turabian StyleAli, Asad, Jianping Yuan, Fanjie Deng, Biaobiao Wang, Liangliang Liu, Qiaorui Si, and Noman Ali Buttar. 2021. "Research Progress and Prospects of Multi-Stage Centrifugal Pump Capability for Handling Gas–Liquid Multiphase Flow: Comparison and Empirical Model Validation" Energies 14, no. 4: 896. https://doi.org/10.3390/en14040896

APA StyleAli, A., Yuan, J., Deng, F., Wang, B., Liu, L., Si, Q., & Buttar, N. A. (2021). Research Progress and Prospects of Multi-Stage Centrifugal Pump Capability for Handling Gas–Liquid Multiphase Flow: Comparison and Empirical Model Validation. Energies, 14(4), 896. https://doi.org/10.3390/en14040896