Abstract

Electrification of powertrain systems offers numerous advantages in the global trend in vehicular applications. A wide range of energy sources and zero-emission propulsion in the tank to wheel significantly add to electric vehicles’ (EV) attractiveness. This paper presents analyses of the energy balance between micro-photovoltaic (PV) installation and small electric vehicle in real conditions. It is based on monitoring PV panel’s energy production and car electricity consumption. The methodology included energy data from real household PV installation (the most common renewable energy source in Poland), electric vehicle energy consumption during real driving conditions, and drivetrain operating parameters, all collected over a period of one year by indirect measuring. A correlation between energy produced by the micro-PV installation and small electric car energy consumption was described. In the Winter, small electric car energy consumption amounted to 14.9 kWh per 100 km and was 14% greater than summer, based on test requirements of real driving conditions. The 4.48 kW PV installation located in Poznań produced 4101 kWh energy in 258 days. The calculation indicated 1406 kWh energy was available for EV charging after household electricity consumption subtraction. The zero-emission daily distance analysis was done by the simplified method.

1. Introduction

The introduction of environmentally friendly and highly efficient energy conversion systems represents one of the biggest challenges in the development of vehicle drivetrain systems [1]. Considering global energy consumption, 44% of global transport energy is consumed by light-duty vehicles, the next 26% by heavy-duty vehicles [2], and 30% by others [3]. Over 99.8% of transport means are still powered by combustion engines, impeding fast transport decarbonization [3,4].

The mechanical energy generated by petroleum product’s combustion processes produces problematic carbon dioxide and other toxic exhaust compounds [5,6]. The EU legislation pays special attention to CO2 emission and, starting in 2021, has limited it to 95 g/km [7,8]. The CO2 emission is tightly bound with fuel consumption and related directly to engine efficiency in tank to wheel (TTW) calculations. A wide variety of powertrains systems, including internal combustion engines (ICE) and electric vehicles (EV), dedicated to vehicles demand not only tank to wheel analysis but also life cycle assessment (LCA). It provides detailed information about the environment’s energetic impacts [9]. LCA analysis carried out by Message et al. [10] shows the most significant climate change, expressed in gram CO2/km, for conventional vehicles using fossil fuels, particularly Petrol Euro 4, and the lowest for EVs, highlighting the significance of energy source. The elementary difference in LCA between conventional and electric powertrain relies on Well-to-Tank (WTT) and TTW share. EV characterizes the majority of the WTT energy conversion share compared to conventional ICE, where TTW is dominant [10]. Respectively, other studies indicate EV lifetime relevance [11]. The attractiveness of EVs in terms of global warming potential increases with its lifetime.

An electric vehicle’s advantage is that it consumes energy from various energy sources, such as fossil fuels, renewable energy (RES), bioenergy, or nuclear [12]. The trends in EV technology field development provide a necessity for energy market analysis. The study presented by Xu et al., 2020 [13] discusses four different charging strategies, and how they will influence greenhouse gas (GHG) emissions in 2050, i.e., when high decarbonization levels and large RES shares are expected. The analysis included electricity mix type and reduced energy consumption from gas-fired power stations, and increased energy share from RES by controlling the charging process. Other predictions, up to 2040, indicate the benefits of implementing the ClimPol scenario. It significantly increases energy sharing from RES, reducing kilogram carbon dioxide equivalence per kWh to just above 0.2, from the global case of slightly more than 0.8 [14]. The trend is primarily influenced by an increased share of wind, solar biomass, and nuclear power in energy generation and EV battery charging, with results depending on the EU country [15]. Overall, the lowest charging effect has been achieved in France in 2015. Forecasting shows a 19% increasing RES share in 28 EU countries, along with a 17% decrease of share of electricity from solid fuels between 2020–2050.

Rising demand for RES energy led to fast photovoltaic infrastructure development, which became competitive in terms of low cost and high efficiency. The flexibility of the design of PV systems allows energy production in a wide range of voltage, from systems with power above 100 MWp to household applications, most often below 15 kWp [16,17]. Integration of household PV systems and electric vehicle use are a promising solution for global GHG reduction and locally lower fuel costs [17,18]. Energy analysis from Kyoto, with limited areas intended for RES, indicated 74% CO2 emission and 37% cost reduction from the power and transport sectors by applying photovoltaic rooftop systems and electric vehicles [19]. Results from 12 stands at an EV charging station equipped with photovoltaic panels (48 kW) and Li-ion 100 kW battery energy storage show the possibility of achieving 100% renewable electricity using appropriate control modes [20]. Modeling [21] of 400 combinations shows an attractive solution: cooperation of stationary battery (EV) with household PV infrastructure. The electric vehicle, being mobile energy storage, can effectively replace traditional battery storage. Using the battery in an EV as energy storage in such vehicle to grid (V2G) combinations, the self-sufficiency of solar self-consumption of household residentials increases [22]. In relation to V2G Technology, Wu Y. et al. proposes a real-time energy management system (EMS), that allows for a 29–55% reduction of the total cost of a Photovoltaic assisted charging station [23].

Energy stored in lithium-ion batteries has many advantages [24]. However, significant limitations are the dependence of the distance range on charging infrastructures, battery capacity, and drive quality [25,26]. Hence, it is important to monitor the high voltage battery state of charge to better understand energy flow phenomena and distance range prediction [27]. The range–distance prediction can be estimated based on various data collection methods. Zhang J. et al. obtained data from fifty EV taxis driving in Beijing [28]. In another study, testing was carried out by 32 electric busses traveling four routes under different working conditions [29]. Many studies about energy consumption prediction used data from experimental tests to validate new approaches [30,31,32]. In order to determine energy consumption by an electric vehicle, some researchers [33,34] used the real driving emission (RDE) test procedure as a suitable method to compare results with conventional ICE vehicles.

In recent years, Poland has noticed a rapid growth in interest in photovoltaic energy development [35]. The installed generated power increased by approximately 30% between the end of 2019 and May 2020 and achieved more than 1950 MW. The high growth rate places Poland in the top five EU countries in terms of new power. Most solar energy is produced by PV micro installations, representing more than 70% of all Polish PV markets in 2019. New regulations and supporting programs cause changes in the Polish renewable energy market [36]. The number of new registered battery electric vehicles has grown parallel to the number of household PV installations. Within a year, Poland’s quantity of EVs increased by 80% to almost 7300 vehicles [37]. In effect, electric energy consumption will constantly be rising [38].

In the analysis of electric vehicle research, some major fields of experimental study can be quoted:

- Energy consumption by electric vehicle [28,39],

- Energy production by household photovoltaic installations [40,41],

- EV charging process analysis and optimization with reference to PV source of electricity [42,43,44].

Regarding the high rate of changes in the energy market and non-ICE vehicle development, the authors decided to investigate the energy balance between energy production from the micro photovoltaic system and the energy consumption by small passenger cars equipped with a battery electric powertrain system. The approach of combining real objects (vehicle, residential building) in the energy balance consideration, as proven in the literature, is a commonly analyzed issue. In terms of the studied field, the novelty is the connection between the following approaches: annual balance, changing of ambient conditions, and road approved electric vehicle energy consumption evaluation based on a real driving conditions (RDC) test.

This study’s aim is to assess household micro-photovoltaic systems’ self-sufficiency in connection with battery electric vehicle use. The research goals are:

- How much energy does a city electric vehicle consume during its intended operation?

- Is the 4.48 kW photovoltaic installation capable of satisfying the energy demand in the assumed scenarios of driving an electric vehicle?

The extent of this study included the energy flow analysis from a PV system, then charging, followed by RDC testing to discover the amount of energy consumed by an electric vehicle. It covered a one-year period with energy generation analysis from photovoltaic panels being carried out during the same periods as the vehicle tests, with average energy consumption during driving estimated for both winter and summer measurements.

2. Methods of Analysis

The aim of this study was to evaluate the energy flow generated by the solar panels, followed by analysis of the energy flow during vehicle’s charging and the energy consumption in the RDC test. The analysis of energy generation from photovoltaic panels was carried out during the same periods as the vehicle tests, i.e., in winter and summer periods in 2020 on the territory of Poznan city in Poland. In the same periods, the average driving energy consumption was also estimated. The following questions were posed: How much energy does a city electric vehicle consume during its intended operation periods? Is the applied 4.48 kW photovoltaic installation able to guarantee an electric vehicle’s energy demand in the assumed driving scenarios? The scope of the research included two test runs compliant with the RDC test procedure in urban, rural, and motorway cycles in winter and summer conditions of 2020. The measurements were made in the ECO driving mode, which in earlier studies [34] showed a beneficial reduction in energy consumption by the vehicle. The measurements made in the same driving mode allowed the estimation of the impact of weather conditions on the overall energy consumption of the vehicle on selected road sections. The data from the test run were recorded in real-time based on the information pulled from the vehicle controller area network (CAN) by a dedicated on-board diagnostics system (OBD) scan tool. The main parameters that were recorded during the measurements in the actual traffic conditions of the vehicle were those describing the operation of the electric motor (rotational speed, value of the current and voltage, and torque and vehicle speed) and the parameters concerning the accumulation of energy in the battery (state of charge (SOC), and power).

The characteristics of the electric vehicle used in road tests are shown in Table 1. The vehicle used in the tests—ŠKODA CITIGOe iV—is supplied with an electric drive, allowing different driving modes and variable intensity of regenerative braking. The 61 kW ŠKODA CITIGOe iV powertrain used a Li-Ion battery of 36.8 kWh full capacity and 32.3 kWh useable capacity. The location of the batteries have also been shown in Table 1.

Table 1.

Technical data of the analyzed powertrain fitted in ŠKODA CITIGOe iV [34].

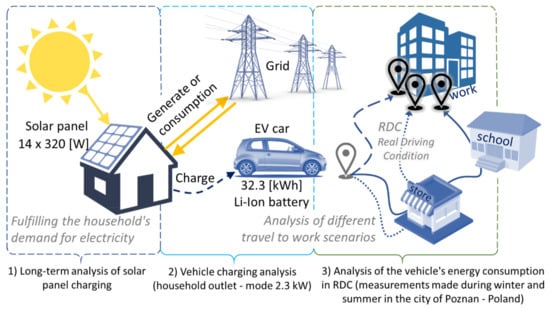

This article presents an analysis of three stages of energy conversion with emphasis on the vehicle’s energy consumption under real traffic conditions (Figure 1). The comparison of the stages of energy conversion from the PV energy generation to vehicle charging, allowed us to develop a compilation of the possibility of driving the vehicle using energy from renewable sources only.

Figure 1.

Division of analysis carried out in the discussed studies.

2.1. Long-term Analysis of Solar Panel Household Power Generation

Long term analysis of producing electric energy has been based on monitoring working the parameters of household micro-PV installation located in the northern part of Poznan and in service since February 2020. The system has been working in on-grid mode with solar electric power used by household and the surplus sold to the grid. The PV installation contains fourteen monocrystalline rooftop PV panels, DC/AC inverter, fuses, and assembly parts. The 320 W panels’ total power output is 4.48 kW. The installation also includes three-phase 5.2 kW inverter SMA Sunny Tripower 5.0 and a two-way energy meter. The real-time view of the energy data (±1 Wh) is possible through dedicated web and mobile apps.

The daily average energy consumption has been calculated using Equation (1) below.

The calculation was based on 258 days with 2293 kWh of energy taken from the grid and 402 kWh of energy supplied by PV installation.

Available energy dedicated to an electric vehicle charging has been estimated using Equation (2).

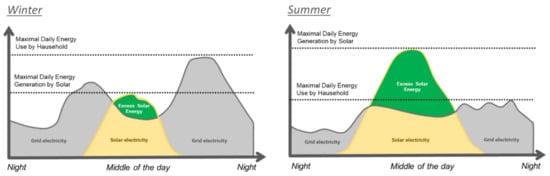

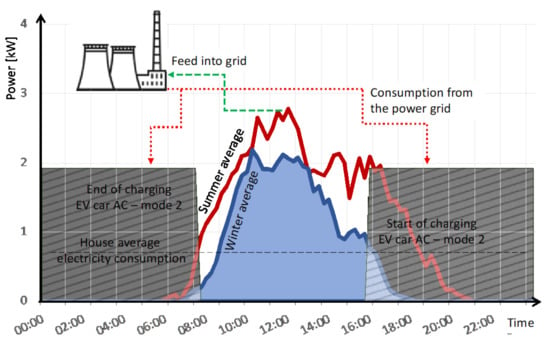

This additional energy of 1406 kWh is available for EV charging (taking into account the billing period of 258 days). Due to the analyses carried out in different periods of the year, it is possible to change the flow of energy from the source in the form of photovoltaic panels and the power plant. The trending differences are shown in Figure 2.

Figure 2.

Characteristic correlations in electricity production from photovoltaic panels in the summer and winter months (based on [45]).

2.2. Electrical Vehicle Charging Modes

Small passenger EV used in this investigation could be charged following the modes below:

- 2.3 kW (AC) Type 2 from the household grid with dedicated converter supplied by the manufacturer,

- 7.2 kW (AC) Type 2 from the wall outlet or a public charging station,

- 40.0 kW (AC/DC) combined charging system (CCS) from the rapid charging station.

The combined charging system (CSS) can, within one hour, charge up to 80% of the car battery capacity.

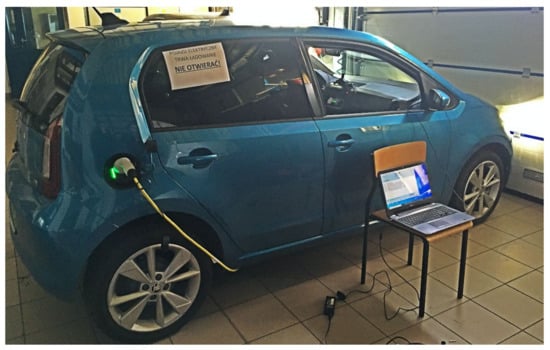

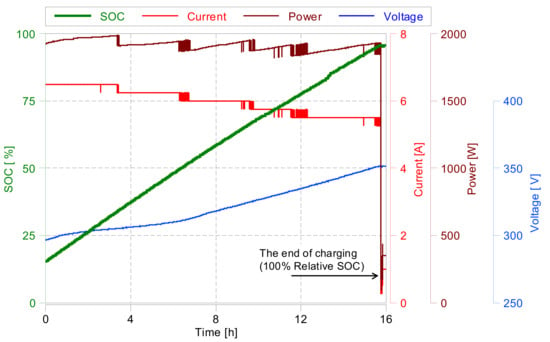

The full charge time increases with decreased charging power. Charging profile of the first mode—2.3 kW (AC)—was observed over one full cycle. The charging level (±0.1%), voltage (±1 V), and current (±0.01 A) were sampled with 1.3 Hz and were registered from vehicle’s CAN in real time. The observation setup is shown below in Figure 3.

Figure 3.

Vehicle charging setup.

2.3. Vehicle Energy Consumption in RDC Test

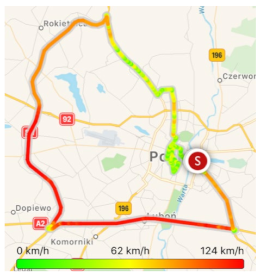

The test route was proposed in [34,46] and determined to lead through the city of Poznań and its surrounding areas. It covered urban, rural, and motorway conditions. The maximum motorway legal speed is 140 km/h. Selected test requirements related to the course of the test run have been presented in Table 2. The duration of all the test runs exceeded 90 min, and the total length of the track did not change.

Table 2.

Real driving conditions test requirements with map of the route traveled during the measurements [34].

The main problem of constantly developing industry is its negative impact on the environment. One of the most dynamically changing sectors of industry is transport, which significantly affects the concentration of hazardous substances in the air. In order to reduce the impact of vehicles on the environment, increasingly restrictive emission standards are being introduced, and solutions are being sought to minimize the emission of exhaust fumes from vehicles. Exhaust emission standards are set to control the pollutants emitted from automotive vehicles around the world. Exhaust emission values are measured under conditions in an established type approval test. This part of the vehicle certification process is responsible for the environmental performance of the vehicle and is the same for all passenger cars. The course of the test corresponds to the most likely road conditions, and the tests performed, which are the same for all vehicles, authorize the comparison of emission results between them. However, currently, more and more attention is paid to road tests, i.e., tests performed in real driving conditions. At present, these tests have been included in the European Union regulations under the name RDE (real driving emissions) [47,48]. They are performed in order to best reflect the actual vehicle operation conditions in terms of ecological aspects. Such tests must be performed with specific requirements, the main assumptions of which are presented in Table 2. The winter and summer runs performed in this research met the requirements specified in the RDE test directive (Table 3). However, due to the lack of exhaust emission measurement, these tests are named RDC.

Table 3.

Meeting real driving emissions (RDE) test requirements for summer and winter performed measurements [47,48].

2.4. Energy Supply and Demand for Selected Driving Scenarios

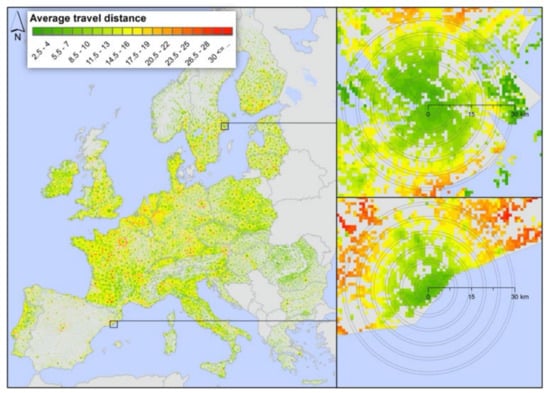

The choice of a means of transport for many users is motivated by economic factors (total cost of vehicle use). Literature sources of daily commutes provided average distances in the EU. Commutes within cities ranged between 4–25 km. Commutes from suburban areas can be significantly longer (Figure 4). In the next part of this section, we analyzed and presented three scenarios of daily commute.

Figure 4.

Average travel distances (km) in Europe, with focus on Stockholm and Barcelona, showing the dependence of the average distance on the distance from the metropolitan area [49].

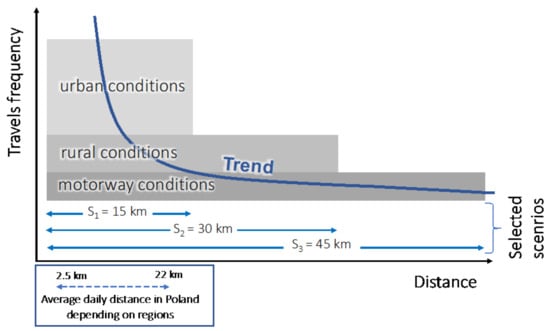

Based on described trends [50] of dependency of distance and travel frequency and information about average distances covered in Poland [49], three different distances have been selected to analyze (Figure 5). Scenario 1 assumes a 15 km distance per day focusing on an urban area. Consequently, scenarios 2 and 3 concern the suburban areas where the residence is a farther distance from the workplace.

Figure 5.

Typical distribution of frequency of trips vs. distance covered in Italy [50], supplemented by proposed scenarios and statistical data on average distances covered in Poland [49].

3. Results

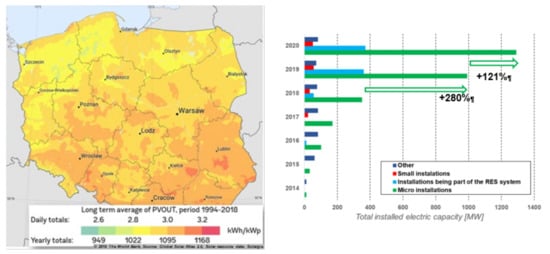

3.1. Long Term Analysis of PV Energy Production

In Poland, the solar radiation falls consistently within 1050–1160 kWh/m2/year, with highest values observed in the central part (Poznan or Warsaw) and in the south of the country (Krakow), as shown in Figure 6. The photovoltaic systems produce similar amounts of energy throughout the country. The Institute of Renewable Energy report shows that, in Poland, about 70% of currently installed photovoltaic sources are micro installations with an increasing trend. In 2019, there were 640 MW of new power installed, three times more than in 2018. Such a rapidly growing branch of power industry presents real possibilities for power self-sufficient households with excess energy to be dedicated to zero-emission transport.

Figure 6.

Average annual sum of photovoltaic (PV) power potential [51] and the development of micro installations in Poland [35].

Measurements of an existing single-family building with a 4.48 kWp photovoltaic installation were made. The Sunny Tripower 5.0 model STP5.0–3AV–40 424 inverter enabled real-time measurement of the generated power by the photovoltaic system, with monitoring performed by a dedicated application (SMA Smart Connected) and data archiving by the Sunny Portal service. The inverter’s parameters are shown in Table 4 and the values of the energy obtained are presented in Figure 7.

Table 4.

Characteristics of the inverter Sunny Tripower 5.0 used in the tested home installation [52].

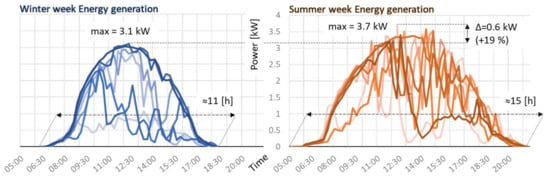

Figure 7.

The data from 4.48 kWp solar energy installation located in Poznan city in Poland—energy generated during the winter and summer weeks, collected by the Sunny Tripower 5.0 data acquisition system.

The differences between energy generation in the summer and winter months were significant. Shortening the time of solar radiation of the panels by 30% reduced the maximum power generated by 19% (Figure 7), resulting in a total reduction in the share of accumulated energy by about 40% (energy gain in June was 664.5 kWh while in March only 406.7 kWh). Such large differences in the total values of energy produced raises doubts about the ability to meet the energy demand for both the power supply to the building and the electric vehicle.

The compiled daily electricity production characteristics (Figure 7) were averaged and presented in relation to the daily usage pattern of the electric vehicle (Figure 8). Part of the energy produced during the day (around the afternoon hours) was transferred to the power plant, because at this point, the energy was not used for the household’s needs. The graph shows the maximum vehicle charging time with a discharged battery. Charging time, in this case, is long also because of the choice of basic charging technology. In the absence of energy production by photovoltaic panels, the energy needed to charge the vehicle (as well as other home usage) was drawn back from the power plant.

Figure 8.

Electric vehicle charging scenario (using charging mode 2) in relation to the average generation of electricity from the photovoltaic installation (red—summer, blue—winter).

3.2. Vehicle Charging Analysis

The charging profiles, represented by SOC, power, and voltage, are shown in Figure 9. The authors did not optimize the charging process. Algorithms implemented by the vehicle manufacturer controlled the charging. Battery charging from 15.2% to 95.6% lasted almost sixteen hours. The charging process was carried out by constant current (CC) mode, i.e., with approximate constant current and variable voltage using the original manufacturer household charger. The voltage rose from 296.25 V to 351.75 V at the end of charging. At the same time, the current value was changing significantly. At 96% of SOC, current reduced to slightly above 0, and with it, large voltage variations were observed. When the car was not being used and had a full battery, the charger ensured stand by energy consumption. The battery delivered 30.16 kWh energy after one charging cycle.

Figure 9.

Single cycle charging profile carried out by household dedicated converter in constant current (CC) mode.

3.3. The Impact of Atmospheric Conditions on the Energy Consumption of an Electric Vehicle

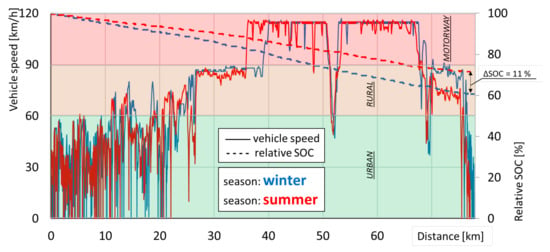

The driving cycles, realized in compliance with the RDC procedures, were started at 100% battery SOC level (software readout). The test runs were performed by a single driver to assure consistency in the driving style. Compared to the previous analysis results of the driving energy consumption in the RDC test [34], this article focuses on the determination of the total energy consumption by route sections: urban, rural, and motorway under different atmospheric conditions. The vehicle velocity and relative SOC profile during the RDC tests are shown in Figure 10. Presented curves marked in blue and red colors represent different ambient conditions. Vehicle speed and state of charge are represented by solid and dotted lines, respectively. In the tests with similar conditions achieved during the measurement journeys, the indications of the vehicle speed in relation to the distance travelled showed a high similarity to the journey, both in the urban part and in the sections with increased speeds. Some differences in the speed on the suburban and highway routes were dictated by road conditions, and there was no possibility to repeat them.

Figure 10.

Comparison of the real driving conditions (RDC) test for the performed test runs in winter and summer conditions.

The driving cycles, realized in compliance with the RDC procedures, were started at battery level SOC 100% (software readout). The test runs were performed by a single driver to avoid inconsistency in the driving style. During the test run, the vehicle speed and battery level were recorded. Due to running the vehicle in ECO mode, the maximum speed was limited by the drivetrain controller; both runs were comparable speeds in the given test intervals, and nevertheless, the energy consumption was about 11% more in the winter period. For this reason, further work identifies the intervals of route split and vehicle speed affecting the increased energy consumption.

The flow of the energy ΔE was determined based on the flow of current (IBAT) and voltage (UBAT) of the battery as a result of its discharge and regenerative braking charge during driving of the car:

- discharging:

- energy recovery (regenerative braking):

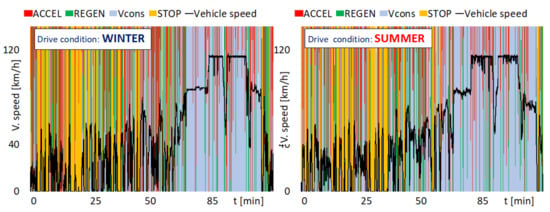

In order to determine the individual electric powertrain operating conditions, road portions were specified where the system operated in these individual conditions. On this basis, the operating modes were divided into individual phases: driving, acceleration, standstill, and braking, during operation of the electric drive. The adopted criteria have been shown in Table 5 and Figure 11.

Table 5.

Vehicle motion phase criteria.

Figure 11.

Distribution of motion phases in winter and summer conditions.

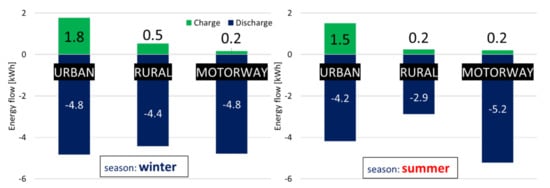

The energy balance as a function of the type of the road is shown below (Figure 12). Regardless of the weather conditions, similar energy recovery values were recorded. However, due to more vehicle stops during winter measurements, higher energy recovery was achieved in both the urban and suburban parts during winter measurements. The greatest amount of energy was recovered in the urban cycle due to the high number of brakings, compared to the smooth traffic road portions.

Figure 12.

Energy consumption balance in terms of road and weather conditions.

The specification of the assumptions used in the energy flow summation (Figure 12) are specified in Table 6. The assumptions for the urban, rural, and motorway segmentation of the route are consistent with the RDC test assumptions presented earlier (Table 2 and Table 3). The value of power delivered or generated from/to the battery was recorded during the measurements, with the following assumptions, the summed energy flows presented earlier were determined. These assumptions also apply to the energy consumption totals in Figure 14.

Table 6.

Vehicle motion phase criteria [34,35].

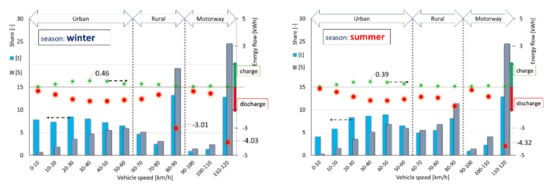

During the RDC test, the vehicle’s energy consumption was dependent on the road conditions. Increased energy consumption of the vehicle was noticeable in the higher speed ranges. The bar charts of Figure 13 show the energy flow and the share of energy consumption for different speed ranges. The marked points represent the total energy flow of both recovered (green) and consumed (red) energy in a specific speed range. The largest amount of energy was recovered in the 20–50 km/h range. The amount of energy recovered in the urban speed range allowed us to increase the vehicle range. However, the energy consumption in each speed range was higher than the recovered energy. The highest energy consumption was recorded in the intervals of increased vehicle speed, both during summer and winter driving conditions; in the speed range 110–120 km/h, the vehicle consumes more than 4 kWh (the distance covered at this speed is almost 25% of the entire RDC test). The shares of each speed interval in the test indicate nearly identical driving conditions in the urban route speed range (0–60 km/h) and in the motorway route range (v > 90 km/h).

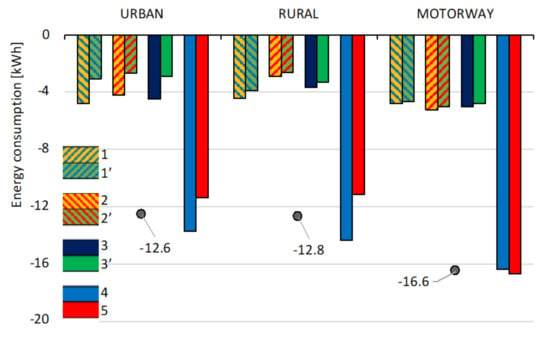

Figure 13.

Energy flow characteristic and the share of energy consumption for different speed ranges in the RDC tests.

A summary of the vehicle’s energy consumption during the RDC test for sections of the route (urban, rural, and motorway) is shown below in Figure 14 and Table 7 (1, 2 and 3). It compares both the energy consumption without recovery and the reduction of energy consumption after taking into account the recovery of energy from braking, which is shown in Table 7 (1′, 2′ and 3′). The graph shows the energy flow characteristics for both winter and summer conditions. The energy consumption was then calculated for 100 km of the sections under consideration (urban, rural, and motorway), thus obtaining the total energy consumption of the vehicle in winter conditions (14.9 kWh/100 km) and in summer conditions (13.1 kWh/100 km). Averaging the total energy consumption of a vehicle, without division into sections of the route and weather conditions, gives 14 kWh/100 km. The assumptions presented below are affected by some simplifications, but the paper is intended to undertake a preliminary analysis of the possibility of supplying an electric vehicle from a renewable source. Due to the variety of drivers and routes taken, these calculations are not applicable to every type of vehicle or every road with their own unique characteristics; nevertheless, the authors estimated the average energy consumption for a small urban vehicle, which was then compiled together with the assumed travel scenarios of the electric vehicle user.

Figure 14.

Energy flow characteristics and the share of energy consumption for different speed intervals in the RDC tests.

Table 7.

Energy consumption of an electric vehicle in the RDC test of Figure 13.

The above average values, without division into atmospheric conditions, were used for the analysis of the electric vehicle driving scenarios and are presented below.

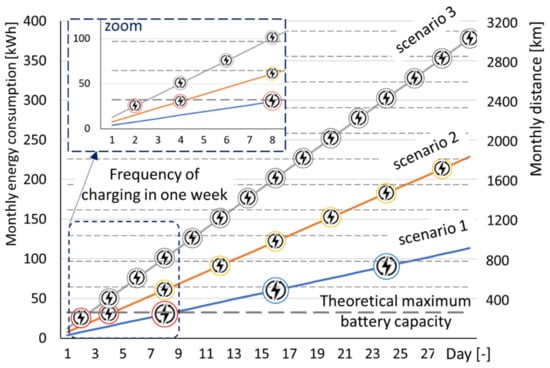

3.4. Energy Supply and Demand for Selected Scenarios of Driving a Vehicle

The analysis of the average distance travelled by passenger vehicles in 2.4 has been used to develop a theoretical list of three scenarios (Table 8) in which the distance, together with the share of individual route sections, is a variable. Scenario (S1)—the minimum analyzed commuting distance is 15 km and covers urban driving conditions only. Scenario (S2) assumes a one-way distance of 30 km with 15 km in urban and 15 km in suburban driving conditions. Scenario (S3) assumes the participation of all three sections of the route and is 45 km total in one direction. Increasing the distance makes it necessary to charge the vehicle more often. This frequency was estimated based on calculations of the distance of a particular route compared with the energy consumption of the vehicle presented in the previous sections. According to the investigation’s assumptions about charging, the vehicle must ensure an adequate charge to cover the entire route planned during the day. An overview of the charging frequency is presented in Figure 15.

Table 8.

Analyzed scenarios of distances covered by an electric vehicle.

Figure 15.

Frequency of charging an electric vehicle in the presented scenarios depending on the distance covered by a user.

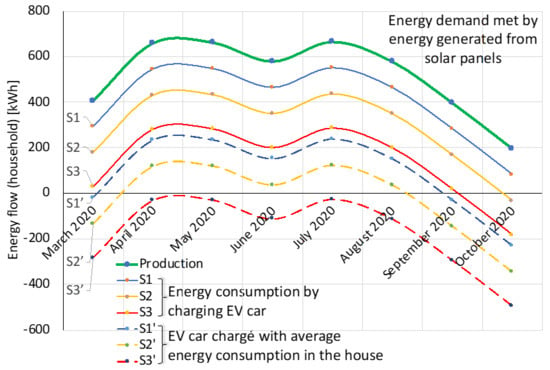

The summary of energy production to power an electric vehicle, Figure 16, shows the energy produced by the photovoltaic installations in the months from March to October, marked as green. The calculated energy consumption of the vehicle in all scenarios shows it can be met by the production of electricity from solar panels in all months except October. However, if we also consider the current average electricity consumption of household appliances, Scenario 3 is not possible in any month. In such cases, the energy to power the vehicle in scenario 3 would come directly from the power plant. The solution to reduce electricity costs in such cases should be increasing the number of photovoltaic panels.

Figure 16.

Energy balance of the presented scenarios of driving an electric vehicle in relation to the energy produced and consumed by a household with a 4.48 kW photovoltaic installation.

4. Discussion

This paper focused on an experimental assessment of the energy flow between household PV installation and a small size battery electric vehicle. Karkosiński et al., 2018 [53] conducted a similar approach without RDC test requirements and household energy consumption. The results indicated a significant impact of the sun’s shining state during the day for energy generation, obtaining 100 W/m2 sun irradiance on a cloudy day and almost 250 W/m2 on a clear day in January. In effect, 11.4 kWh energy was obtained on an average sunny day in January. The study of [54], with polycrystalline and monocrystalline PV modules, showed an 80% difference between the amount of energy produced in summer and winter over a three year period. The results of this study confirmed the above trends through detailed analyses of PV energy production during the week of ride test cycles. In addition, a 19% increase in peak power has been observed in summer with the effective energy production time during the day raised by approximately 4 h.

EV energy consumption was examined with RDC tests. The average energy consumption in considered cases was 13.1 kWh/100 km in summer and 14.9 kWh/100 km in winter. The elevated energy consumption was likely caused by interior comfort system energy demand. For reference, in [33] where energy consumption was determined also with the RDC test, the average energy consumption was 19.6 kWh/100 km, calculated from two repeated rides with the difference between the rides of 1.3 kWh.

Comparison of three types of powertrain: gasoline, hybrid, and electric, in terms of an RDC test, was performed by Pielecha J. et al., 2020 [55]. During the RDE test, the lowest accumulated energy demand was achieved for the electric vehicle, approximately 30% lower than the combustion engine and 10% lower than a plug-in hybrid powertrain. In the research presented, like in [55], energy consumption was analyzed separately for each road type and in terms of ambient climate conditions, not powertrain type. In [36], the influence of drive mode and braking strategy on energy flow in small-sized EV was investigated within the RDC test requirements.

During the summer, smaller energy consumption was observed, 17% for urban conditions and 22% for rural residents, including braking energy recovery. The result of another investigation [56] shows decrease of possible driving range from 150 km at 20 °C to 85 km at 0 °C. Doyle A. et al., 2019 [57] indicated that interior thermal comfort systems consume an average of 14% of the total trip’s energy by the cooling system and 18% by a heating operation.

The last part of the investigation included analyses of energy balance between household PV installation and EV. To assess sufficiency of PV installations, three scenarios of distance covered by EV were considered. In effect, it was possible to use an EV car charged by surplus energy from PV installation. The mentioned aspect of cooperation between electric vehicles and renewable energy sources is key to effective electric powertrain future developments.

5. Conclusions

The article presents an analysis of energy flow from the stage of production of electricity from a renewable source in the form of solar energy (PV panels), through the charging of the electrical vehicle, and the subsequent consumption of this energy while driving. Charging of electric vehicles, especially in areas with limited access to charging points, can be difficult. Therefore, the estimates of both the energy consumption of the vehicle and the necessary frequency of charging the vehicle are shown here. The energy consumption of the vehicle has been recorded for driving conditions during both winter and summer periods. The influence of the type of route (urban, rural, or motorway) and distance covered have significant impact on the vehicle’s energy consumption. The presented scenarios are a stage of preliminary elaboration by the authors of the mechanism of simulating the energy consumption of electric vehicles considering various road conditions. In addition, oversupply of energy produced by the residential PV system used in this study indicates the possibility of reliance of charging of the EV from that source only.

The study specific conclusions:

- The electric vehicle’s (urban type) consumed energy during the RDC test:

- ◦

- In winter conditions: 11.39 kWh/RDC test (estimated at 100 km = 14.9 kWh)

- ◦

- In summer conditions: 10.35 kWh/RDC test (estimated at 100 km = 13.1 kWh)

- The 4.48 kW PV installation can guarantee sufficient EV energy demand:

- ◦

- For all three scenarios in March–September period without energy demand by household appliances

- ◦

- For Scenario 1 and 2 in April–August period with household appliances

- For Scenario 3, the PV installation cannot guarantee the total energy demand while also powering household appliances. This case will be the subject of further research by the authors.

Author Contributions

Conceptualization, W.C., F.S., W.G., and A.B.; methodology, W.C., F.S., W.G., and A.B.; formal analysis, W.C., F.S., W.G., and A.B.; investigation, W.C. and F.S.; writing—original draft preparation, W.C., F.S., W.G., and A.B.; writing—review and editing, W.C., F.S., and W.G.; visualization, W.C. and F.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

This work was supported by the Volkswagen Group Polska Sp. z o.o.

Conflicts of Interest

Authors declare no conflict of interest.

Abbreviations

| EV | Electric Vehicle |

| CAN | Controller Area Network |

| CC | Constant Current |

| CSS | Combined Charging System |

| GHG | Greenhouse Gas |

| GWP | Global Warming Potential |

| HEV | Hybrid Electric Vehicle |

| ICE | Internal Combustion Engines |

| LCA | Life Cycle Assessment |

| OBD | On Board Diagnostics System |

| PV | Photovoltaic |

| RES | Renewable Energy Source |

| RDC | Real Driving Conditions |

| RDE | Real Driving Emissions |

| SOC | State of Charge |

| TTW | Tank to Wheel |

| V2G | Vehicle to Grid |

| WTT | Well to Tank |

References

- Van Mierlo, J.; Maggetto, G.; Lataire, P. Which energy source for road transport in the future? A comparison of battery, hybrid and fuel cell vehicles. Energy Convers. Manag. 2006, 47, 2748–2760. [Google Scholar] [CrossRef]

- Final Energy Consumption by Fuel Type and Sector. Available online: https://www.eea.europa.eu/ (accessed on 1 November 2020).

- Leach, F.; Kalghatgi, G.; Stone, R.; Miles, P. The scope for improving the efficiency and environmental impact of internal combustion engines. Transp. Eng. 2020, 1, 100005. [Google Scholar] [CrossRef]

- González Palencia, J.C.; Nguyen, V.T.; Araki, M.; Shiga, S. The Role of Powertrain Electrification in Achieving Deep Decarbonization in Road Freight Transport. Energies 2020, 13, 2459. [Google Scholar] [CrossRef]

- Moreno, J.C.; Stenlaas, O.; Tunestal, P. Multi-Cylinder Adaptation of In-Cycle Predictive Combustion Models. SAE Int. J. Adv. Curr. Pract. Mobility 2021, 3, 299–311. [Google Scholar]

- Balawender, K.; Ustrzycki, A.; Lejda, K.; Jakubowski, M.; Jaworski, A.; Kuszewski, H.; Siedlecka, S.; Zielińska, E. Modeling of Unburned Hydrocarbon Emission in a Di Diesel Engine Using Neural Networks. In SAE Technical Papers, Proceedings of the SAE 2020 International Powertrains, Fuels and Lubricants Meeting, Krakow, Poland, 22–24 September 2020; Society of Automotive Engineers: Warrendale, PA, USA, 2020. [Google Scholar]

- Sitnik, L.J. Energy Demand Assessment for Long Term Operation of Vehicles. In SAE Technical Papers, Proceedings of the SAE 2020 International Powertrains, Fuels and Lubricants Meeting, Krakow, Poland, 22–24 September 2020; Society of Automotive Engineers: Warrendale, PA, USA, 2020. [Google Scholar]

- Pielecha, J.; Merkisz, J.; Kurtyka, K.; Skobiej, K. Cold start emissions of passenger cars with gasoline and diesel engines in Real Driving Emissions tests. Combust. Engines 2019, 179, 160–168. [Google Scholar]

- Del Pero, F.; Delogu, M.; Pierini, M. Life Cycle Assessment in the automotive sector: A comparative case study of Internal Combustion Engine (ICE) and electric car. Procedia Struct. Integr. 2018, 12, 521–537. [Google Scholar] [CrossRef]

- Messagie, M.; Boureima, F.-S.; Coosemans, T.; Macharis, C.; Mierlo, J.V. A Range-Based Vehicle Life Cycle Assessment Incorporating Variability in the Environmental Assessment of Different Vehicle Technologies and Fuels. Energies 2014, 7, 1467–1482. [Google Scholar] [CrossRef]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2012, 17, 53–64. [Google Scholar] [CrossRef]

- Chau, K.; Wong, Y.; Chan, C. An overview of energy sources for electric vehicles. Energy Convers. Manag. 1999, 40, 1021–1039. [Google Scholar] [CrossRef]

- Xu, L.; Yilmaz, H.Ü.; Wang, Z.; Poganietz, W.-R.; Jochem, P. Greenhouse gas emissions of electric vehicles in Europe considering different charging strategies. Transp. Res. Part D Transp. Environ. 2020, 87, 102534. [Google Scholar] [CrossRef]

- Cox, B.; Bauer, C.; Beltran, A.M.; Van Vuuren, D.P.; Mutel, C.L. Life cycle environmental and cost comparison of current and future passenger cars under different energy scenarios. Appl. Energy 2020, 269, 115021. [Google Scholar] [CrossRef]

- Burchart-Korol, D.; Jursova, S.; Folęga, P.; Pustejovska, P. Life cycle impact assessment of electric vehicle battery charging in European Union countries. J. Clean. Prod. 2020, 257, 120476. [Google Scholar] [CrossRef]

- Yang, Y.; Lian, C.; Ma, C.; Zhang, Y. Research on Energy Storage Optimization for Large-Scale PV Power Stations under Given Long-Distance Delivery Mode. Energies 2019, 13, 27. [Google Scholar] [CrossRef]

- Khuong, P.M.; McKenna, R.; Fichtner, W. A Cost-Effective and Transferable Methodology for Rooftop PV Potential Assessment in Developing Countries. Energies 2020, 13, 2501. [Google Scholar] [CrossRef]

- Coffman, M.; Bernstein, P.; Wee, S. Integrating electric vehicles and residential solar PV. Transp. Policy 2017, 53, 30–38. [Google Scholar] [CrossRef]

- Kobashi, T.; Yoshida, T.; Yamagata, Y.; Naito, K.; Pfenninger, S.; Say, K.; Takeda, Y.; Ahl, A.; Yarime, M.; Hara, K. On the potential of “Photovoltaics + Electric vehicles” for deep decarbonization of Kyoto’s power systems: Techno-economic-social considerations. Appl. Energy 2020, 275, 115419. [Google Scholar] [CrossRef]

- Novoa, L.; Brouwer, J. Dynamics of an integrated solar photovoltaic and battery storage nanogrid for electric vehicle charging. J. Power Sources 2018, 399, 166–178. [Google Scholar] [CrossRef]

- Gudmunds, D.; Nyholm, E.; Taljegard, M.; Odenberger, M. Self-consumption and self-sufficiency for household solar producers when introducing an electric vehicle. Renew. Energy 2020, 148, 1200–1215. [Google Scholar] [CrossRef]

- Falvo, M.C.; Graditi, G.; Siano, P. Electric Vehicles integration in demand response programs. In Proceedings of the 2014 International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Ischia, Italy, 18–20 June 2014; pp. 548–553. [Google Scholar]

- Wu, Y.; Zhang, J.; Ravey, A.; Chrenko, D.; Miraoui, A. Real-time energy management of photovoltaic-assisted electric vehicle charging station by markov decision process. J. Power Sources 2020, 476, 228504. [Google Scholar] [CrossRef]

- Raza, W.; Ko, G.S.; Park, Y.C. Induction Heater Based Battery Thermal Management System for Electric Vehicles. Energies 2020, 13, 5711. [Google Scholar] [CrossRef]

- Vaz, W.; Nandi, A.K.; Landers, R.G.; Koylu, U.O. Electric vehicle range prediction for constant speed trip using multi-objective optimization. J. Power Sources 2015, 275, 435–446. [Google Scholar] [CrossRef]

- Rhode, S.; Van Vaerenbergh, S.; Pfriem, M. Power prediction for electric vehicles using online machine learning. Eng. Appl. Artif. Intell. 2020, 87, 103278. [Google Scholar] [CrossRef]

- Liu, X.; Deng, X.; He, Y.; Zheng, X.; Zeng, G. A Dynamic State-of-Charge Estimation Method for Electric Vehicle Lithium-Ion Batteries. Energies 2019, 13, 121. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Liu, P.; Zhang, Z. Energy consumption analysis and prediction of electric vehicles based on real-world driving data. Appl. Energy 2020, 275, 115408. [Google Scholar] [CrossRef]

- Gong, J.; He, J.; Cheng, C.; King, M.; Yan, X.; He, Z.; Zhang, H. Road Test-Based Electric Bus Selection: A Case Study of the Nanjing Bus Company. Energies 2020, 13, 1253. [Google Scholar] [CrossRef]

- Donkers, A.; Yang, D.; Viktorović, M. Influence of driving style, infrastructure, weather and traffic on electric vehicle performance. Transp. Res. Part D Transp. Environ. 2020, 88, 102569. [Google Scholar] [CrossRef]

- Xie, Y.; Li, Y.; Zhao, Z.; Dong, H.; Wang, S.; Liu, J.; Guan, J.; Duan, X. Microsimulation of electric vehicle energy consumption and driving range. Appl. Energy 2020, 267, 115081. [Google Scholar] [CrossRef]

- Guo, J.; Jiang, Y.; Yu, Y.; Liu, W. A novel energy consumption prediction model with combination of road information and driving style of BEVs. Sustain. Energy Technol. Assess. 2020, 42, 100826. [Google Scholar] [CrossRef]

- Gis, W.; Merkisz, J. The development status of electric (BEV) and hydrogen (FCEV) passenger cars park in the world and new research possibilities of these cars in real traffic conditions. Combust. Engines 2019, 178, 144–149. [Google Scholar]

- Cieślik, W.; Szwajca, F.; Golimowski, J. The possibility of energy consumption reduction using the ECO driving mode based on the RDC test. Combust. Engines 2020, 182, 59–69. [Google Scholar]

- PV Market in Poland, Institute for Renewable Energy. Available online: https://ieo.pl/en/pv-report (accessed on 24 November 2020).

- PV Market in Poland. 2020. Available online: https://ieo.pl/ (accessed on 24 November 2020).

- Number of Electric Passenger Cars in Poland from 2019 to 2020, by Type of Vehicle. Available online: https://www.statista.com/ (accessed on 24 November 2020).

- Gis, W.; Waśkiewicz, J.; Menes, M. Experts forecasts on the demand for energy carriers in motor vehicle transport in Poland up to year 2035. Combust. Engines 2019, 178, 162–165. [Google Scholar]

- Chłopek, Z.; Lasocki, J.; Wójcik, P.; Badyda, A.J. Experimental investigation and comparison of energy consumption of electric and conventional vehicles due to the driving pattern. Int. J. Green Energy 2018, 15, 773–779. [Google Scholar] [CrossRef]

- Wang, F.; Zhu, Y.; Yan, J. Performance of solar PV micro-grid systems: A comparison study. Energy Procedia 2018, 145, 570–575. [Google Scholar] [CrossRef]

- Monna, S.; Juaidi, A.; Abdallah, R.; Itma, M. A Comparative Assessment for the Potential Energy Production from PV Installation on Residential Buildings. Sustainability 2020, 12, 10344. [Google Scholar] [CrossRef]

- Fachrizal, R.; Shepero, M.; Van Der Meer, D.; Munkhammar, J.; Widén, J. Smart charging of electric vehicles considering photovoltaic power production and electricity consumption: A review. eTransportation 2020, 4, 100056. [Google Scholar] [CrossRef]

- Mohammad, A.; Zamora, R.; Lie, T.T. Integration of Electric Vehicles in the Distribution Network: A Review of PV Based Electric Vehicle Modelling. Energies 2020, 13, 4541. [Google Scholar] [CrossRef]

- Savio, D.A.; Juliet, V.A.; Chokkalingam, B.; Padmanaban, S.; Holm-Nielsen, J.B.; Blaabjerg, F. Photovoltaic Integrated Hybrid Microgrid Structured Electric Vehicle Charging Station and Its Energy Management Approach. Energies 2019, 12, 168. [Google Scholar] [CrossRef]

- UNISON GROUP. Energy Self-Sufficiency. Available online: https://www.unison.co.nz/ (accessed on 1 November 2020).

- Cieslik, W.; Zawartowski, J.; Fuc, P. The Impact of the Drive Mode of a Hybrid Drive System on the Share of Electric Mode in the RDC Test. In SAE Technical Papers, Proceedings of the SAE 2020 International Powertrains, Fuels and Lubricants Meeting, Krakow, Poland, 22–24 September 2020; Society of Automotive Engineers: Warrendale, PA, USA, 2020. [Google Scholar]

- The European Commision Regulation 2017/1154 Amending Regulation (EU) 2017/1151 Supplementing Regulation (EC) No 715/2007 of the European Parliament and of the Council on Type-Approval of Motor Vehicles with Respect to Emissions from Light Passenger and Commercial Vehicles (Euro 5 and Euro 6) and on Access to Vehicle Repair and Maintenance Information, Amending Directive 2007/46/EC of the European Parliament and of the Council, Commission Regulation (EC) No 692/2008 and Commission Regulation (EU) No 1230/2012 and repealing Regulation (EC) No 692/2008 and Directive 2007/46/EC of the European Parliament and of the Council as Regards Real-Driving Emissions from Light Passenger and Commercial Vehicles (Euro 6) (Text with EEA Relevance); Official Journal of the European Union: Brussels, Belgium, 7 June 2017.

- Pielecha, J.; Skobiej, K. Evaluation of ecological extremes of vehicles in road emission tests. Arch. Transp. 2020, 56, 33–46. [Google Scholar] [CrossRef]

- Jacobs-Crisioni, C.; Kompil, M.; Baranzelli, C.; Lavalle, C. Indicators of Urban form and Sustainable Urban Transport. Introducing Simulation-Based Indicators for the LUISA Modelling Platform; JRC Technical Reports; Joint Research Centre: Ispra, Italy, 2015; pp. 1–33. [Google Scholar]

- Chiara, B.D.; Deflorio, F.; Pellicelli, M.; Castello, L.; Eid, M. Perspectives on Electrification for the Automotive Sector: A Critical Review of Average Daily Distances by Light-Duty Vehicles, Required Range, and Economic Outcomes. Sustainability 2019, 11, 5784. [Google Scholar] [CrossRef]

- Solar Resource Map. Available online: https://solargis.com/ (accessed on 20 November 2020).

- SMA Solar Technology. Available online: https://www.sma-solar.pl (accessed on 10 December 2020).

- Karkosiński, D.; Pacholczyk, M.; Sienkiewicz, Ł. Experimental study of the use of electric car powered with stationary solar and electrochemical batteries in Northern Poland. MATEC Web Conf. 2018, 180, 0209. [Google Scholar] [CrossRef]

- Sarniak, M. Analysis of energy efficiency of photovoltaic installation in central Poland. E3S Web Conf. 2018, 46, 00002. [Google Scholar] [CrossRef]

- Pielecha, J.; Skobiej, K.; Kurtyka, K. Exhaust Emissions and Energy Consumption Analysis of Conventional, Hybrid, and Electric Vehicles in Real Driving Cycles. Energies 2020, 13, 6423. [Google Scholar] [CrossRef]

- Iora, P.; Tribioli, L. Effect of Ambient Temperature on Electric Vehicles’ Energy Consumption and Range: Model Definition and Sensitivity Analysis Based on Nissan Leaf Data. World Electr. Veh. J. 2019, 10, 2. [Google Scholar] [CrossRef]

- Doyle, A.; Muneer, T. Energy consumption and modelling of the climate control system in the electric vehicle. Energy Explor. Exploit. 2018, 37, 519–543. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).