1. Introduction

Battery electric drives are nowadays intensively developed for road vehicles. In aerospace, they are commonly used in unmanned aerial vehicles. Similar technologies in some range can be taken into consideration for light manned aircrafts such as motor gliders, training aircrafts, or others in which the mission is short. Due to the limited energy density of presently available electrochemical cells, the range of flight can be increased by hydrogen fuel cell systems [

1,

2,

3] for which energy density, including the weight and volume of fuel cell, hydrogen storage, and supplementary equipment, is higher. However, to avoid the fuel cell system sizing for peak power needed during take-off and climbing, and to design it only for the low power during horizontal flight, it is highly recommended to use a fuel cell as part of a hybrid energy source supported by additional energy storage. The energy storage provides boost power during take-off and climbing and should be sized considering both energy and power demand. In academic research the specific energy of lithium-ion cells reaches 300 Wh/kg [

4]. From among commercially available Li-Ion cells specific energy of 100–220 Wh/kg is available, but those of higher specific energy have lower power density. Due to relatively short time of energy storage usage during mission profile, high energy density but low power density cells may not meet the requirements. Even taking into account Li-Ion cells with specific energy value in the mid-range, it is still one order higher than commercially available supercapacitor cells (4–6 Wh/kg).

The hybrid-electric drive system with a fuel cell has been described in a few papers, mainly in terms of fuel cell behavior. As the fuel cell system is the most expensive component in the entire hybrid drive system, its design and optimization is the most challenging [

5] issue. Possible direct hybridization without a fully controlled power electronic converter [

6] may be considered for small unmanned aerial vehicles. Direct connection of fuel cell and battery terminals does not allow fully controlled energy management, which may cause problems in higher power ranges. In a directly connected fuel cell and battery in a converter-less drive system, load sharing between the fuel cell and battery depends on the battery discharge level, and depending on the battery voltage level, the fuel cell operates at a different point, one not necessarily optimal in a specific stage of the aircraft mission.

Some of the developed hybrid drive systems with fuel cells for light aircrafts contain DC/DC power electronic converters for both fuel cell and battery [

7]. Depending on the power of both devices, such a solution provides voltage matching of the supply devices to the DC bus voltage required by the motor inverter. However, in the case of motor glider, the fuel cell power demanded only for horizontal flight is much smaller than the demanded power of the battery serving as a boosting energy source. At the same time, the battery energy demand makes it possible to design the battery so that the voltage is high enough to connect directly to the DC bus. This way, a relatively large bidirectional DC/DC converter between the battery and the DC bus is avoided. However, if done this way, there is no direct regulation of the battery current and its control is indirect through the use of battery current signal in the fuel cell converter control structure.

The superior control structure (energy management) can be made outside the power converters controllers in the on-board computer, or another external controller which collects the necessary data from the fuel cell, fuel cell DC/DC converter, battery, and load [

8]. However, the signal transmission delays and possible faults of the communication network prompted us to find solutions that allow energy management without communication system engagement. This is one of the ways hybrid system reliability increases (elimination of communication system problems as a reason for hybrid drive faults generation). This way, the on-board computer applied in the designed system is responsible for sending starting commands only and is not involved in further control of power converters. It is also used to visualize hybrid drive operation to give some necessary information to the pilot, and for data collection from the experiments, but this does not influence the hybrid drive system operation.

Fault prevention can be achieved in a different way, such as through over-sizing of components, additional protections, redundancy, etc. [

9,

10]. The proposed solution of communication-less energy management can be treated as a redundant solution to the communication-based system. It must be noted that a communication-based system can have wider functionalities due to the fact that it collects data from all devices simultaneously, but in the case of the communication system fault, an additional energy management method which provides safe control of power converters and assures the demanded power may be of interest during the design of hybrid-electric propulsion not only with a fuel cell system, but also with other types of energy sources.

The paper presents the structure of a power electronics-based energy conversion system and its control for a hybrid drive composed of a 10 kW fuel cell and 30 kW of battery power for a motor glider.

Section 2 presents the assumed profile of propeller torque and speed related to the stationary conditions and braking power assumed for different stages of flight. This is followed by the selection of the fuel cell, battery, and motor parameters, meeting the requirements in terms of energy and power demands. Propeller characteristics are also provided.

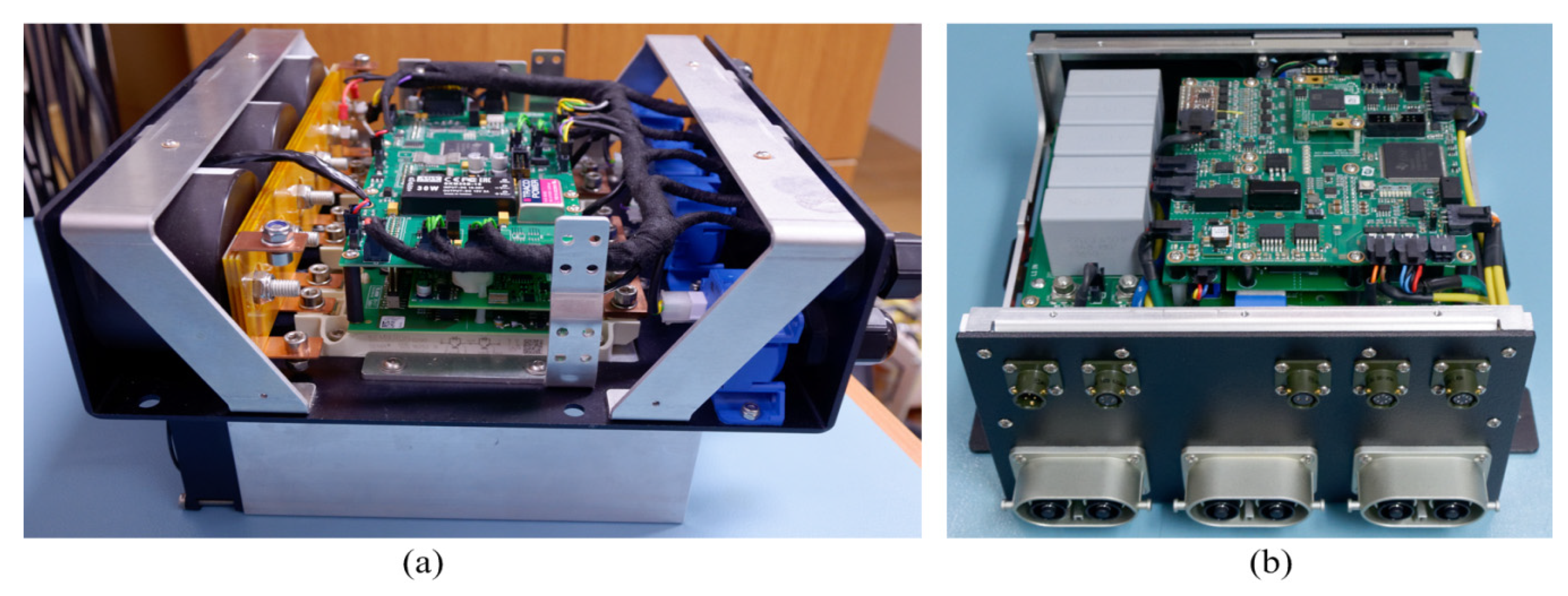

Section 3 presents the selected topologies of DC/DC and DC/AC power converters and their parameters, as well as some discussion about the efficiency of electrical energy conversion depending on the braking power demand.

Section 4 presents the communication structure and control method, allowing safe operation in case of communication system fault, followed by some results related to the fuel cell system protection against overload and its intentional short circuiting. Some discussion related to other types of possible faults and concepts of how the conversion system should assist in these states is given.

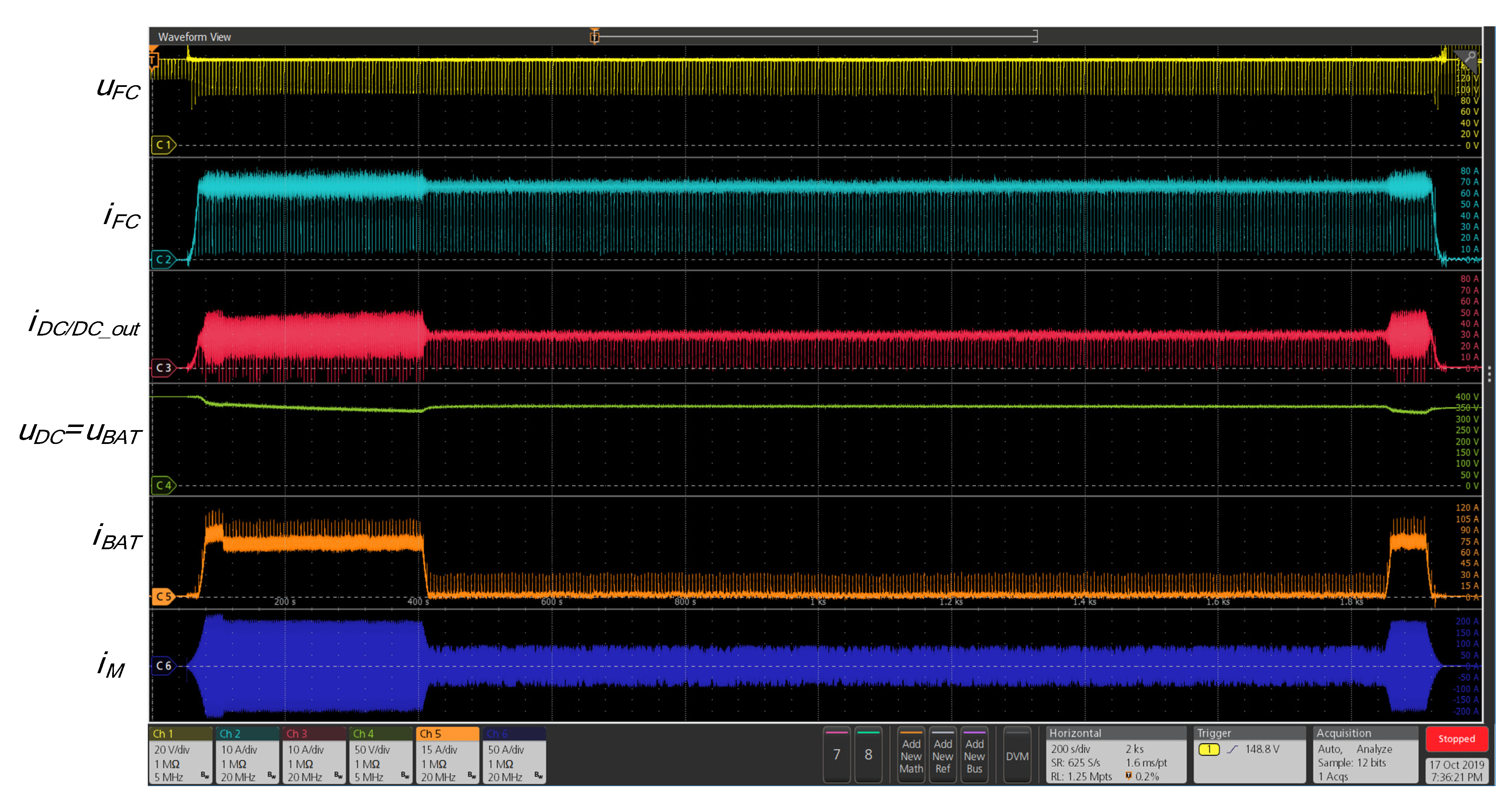

Section 5 presents the experimental tests results for a full profile in stationary conditions using a fuel cell simulator instead of the real unit.

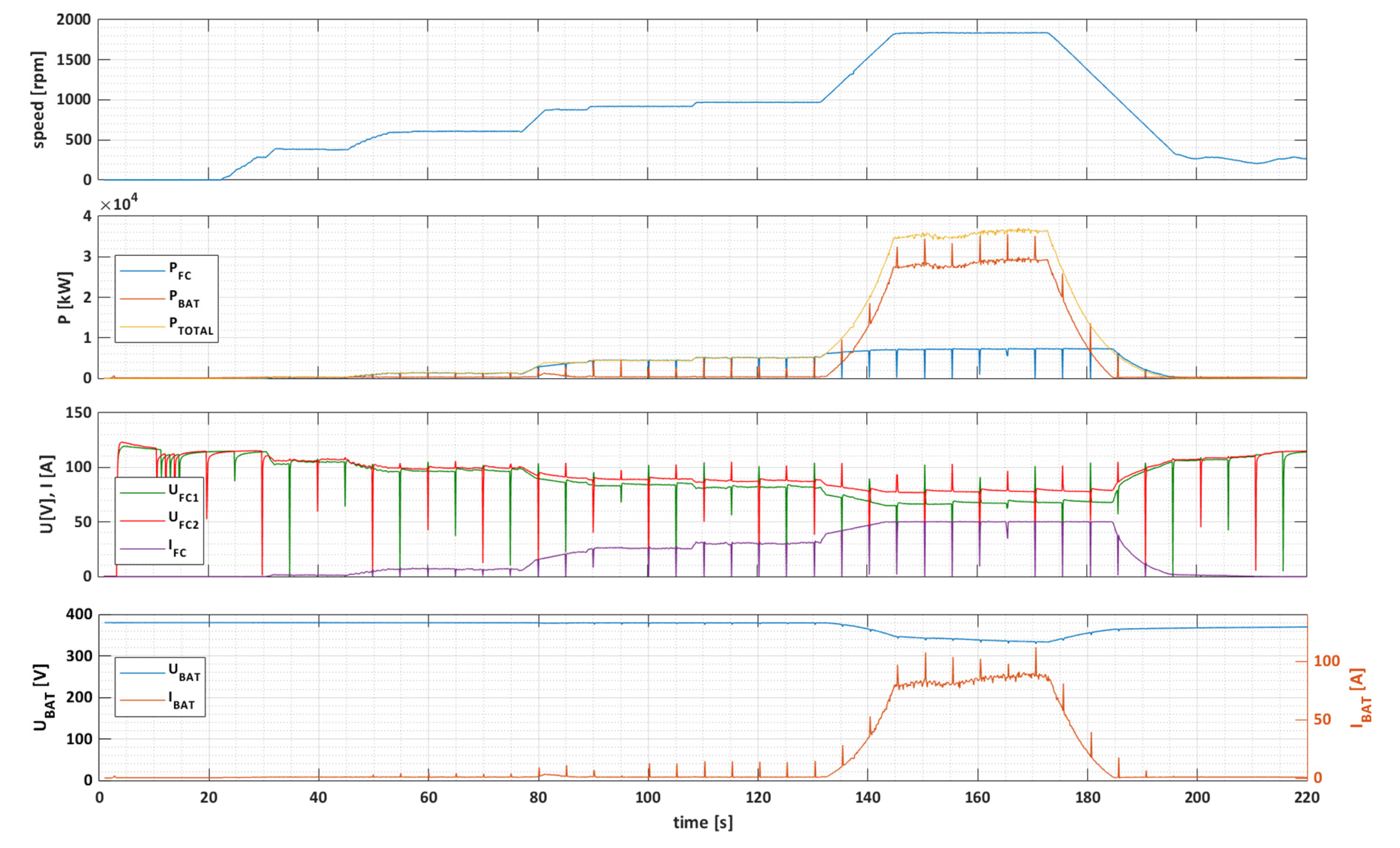

Section 6 presents the selected results of experimental tests of the fuel cell and battery-based hybrid drive system in a real motor-glider on a runway.

The main scope of the paper is an alternative control method not involving a communication system in the entire process of the energy conversion unit, which can be used after any used CAN bus communication faults between the fuel cell controller or between power conversion units.

2. Power System Demands and Components Selection

2.1. Loading Profile

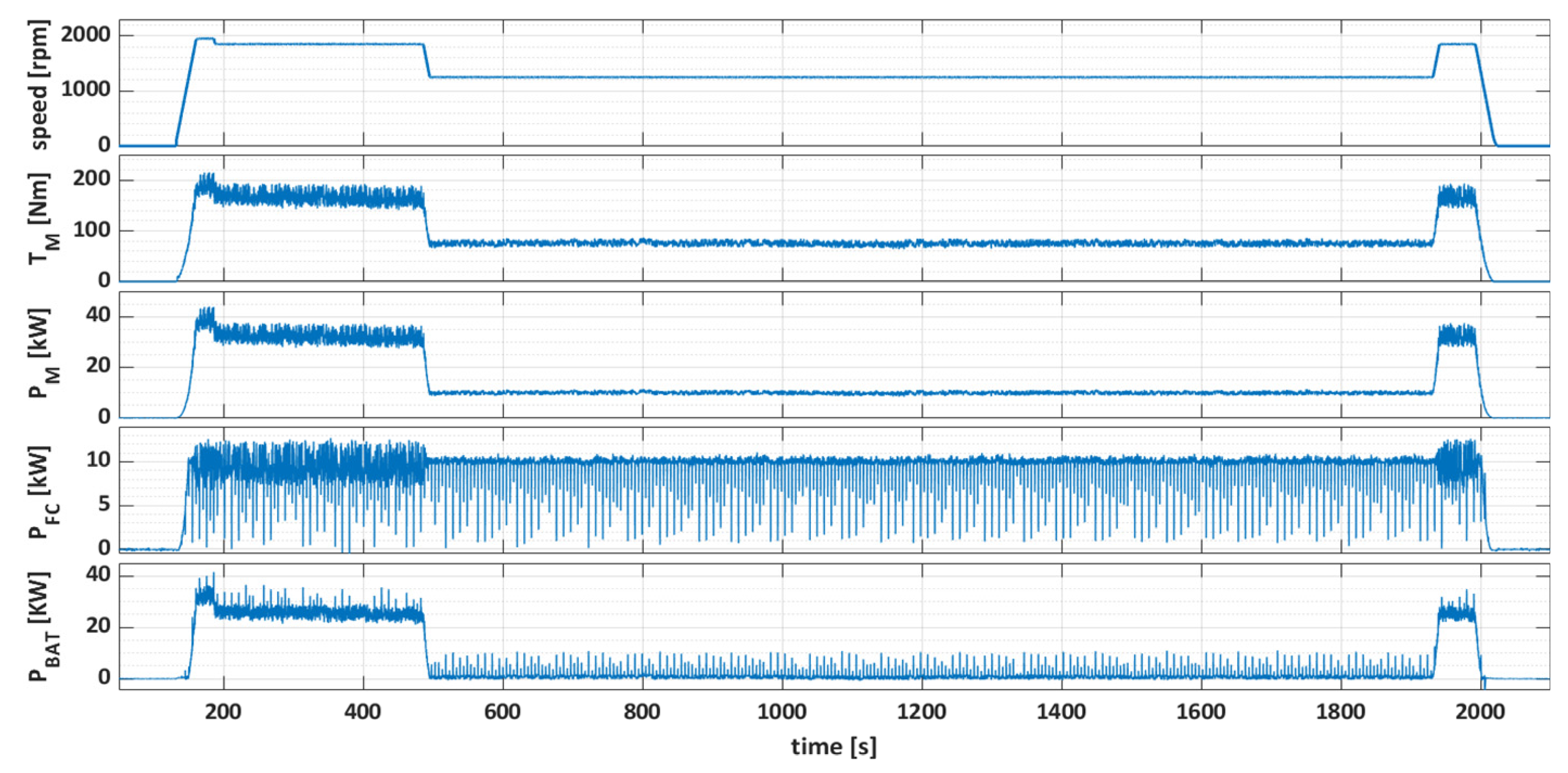

The power electronics converter and its control for a hybrid-electric drive system described in this paper are developed for a motor glider of assumed max. take-off weight 660 kg. Mission profile is divided into the following stages:

Start-up of the power system (0–30 s)–30 s ramp used

Taking-off of the motor glider (30–60 s)–maximum mechanical power 37 kW

Climbing (60–330 s)–mechanical power equal to 33 kW

Horizontal flight (15 min)–mechanical power equal to 9 kW

Maneuvering before landing (1 min)–optional

Landing

Due to the fact that the considered AOS-H2 light aircraft is a glider with relatively high aerodynamic performance, the horizontal flight power demand is significantly smaller than the power demand during take-off and climbing.

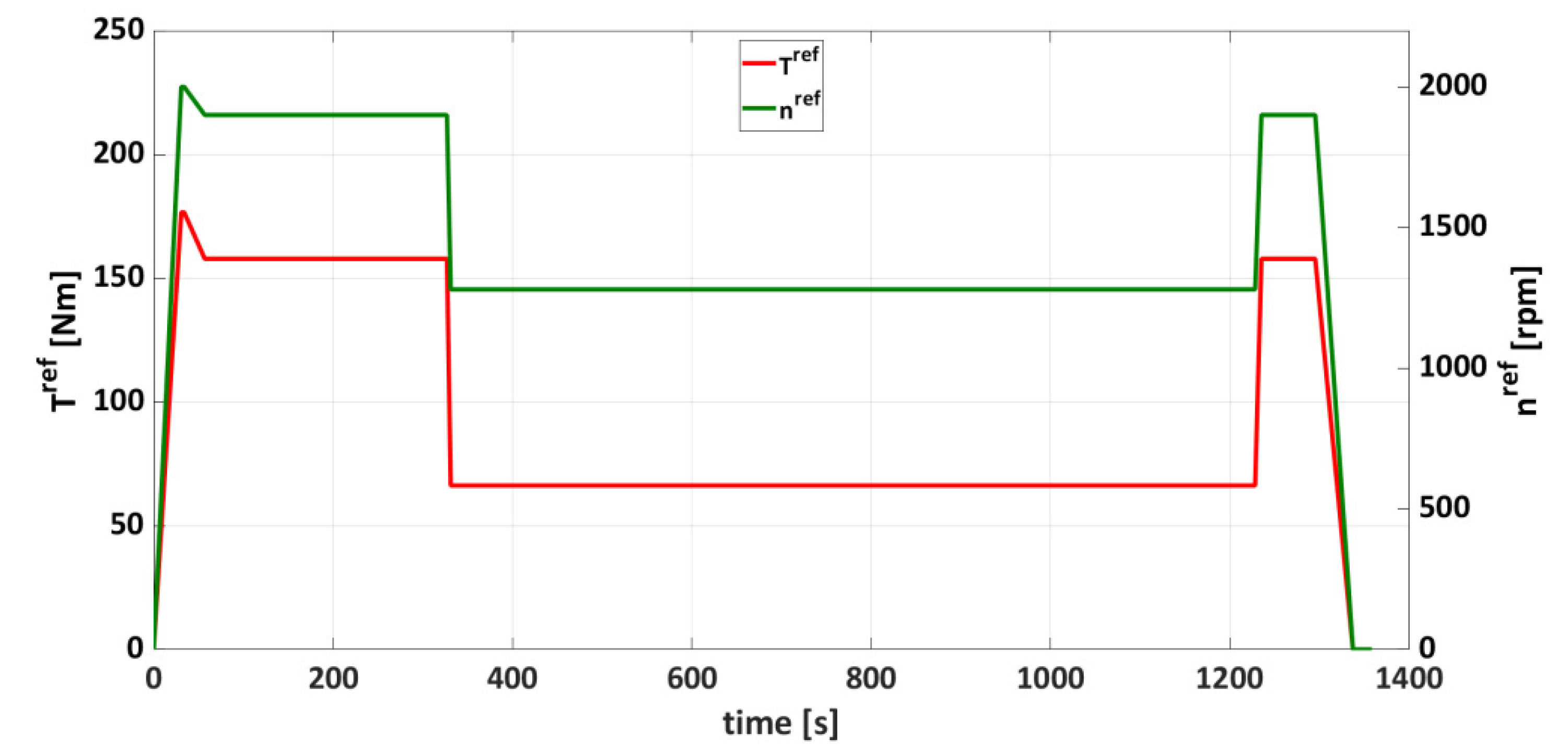

Figure 1 presents the profile of the demanded torque and rotational speed related to the stationary conditions to obtain the profile of demanded power. It must be noted that the referenced rotational speed for a given propeller characteristic does not take into consideration the characteristic change for different velocities of the aircraft, because most tests have been made in stationary conditions.

2.2. Fuel Cell Parameters

A 10 kW fuel cell system used in the designed platform suffices to keep the horizontal flight without the use of a battery. The fuel cell unit comprises two H-5000 Horizon’s stacks whose construction has been adapted to the airframe. The main parameters of the selected single stack are provided in

Table 1. Details of the single original stack are available in the datasheet [

11].

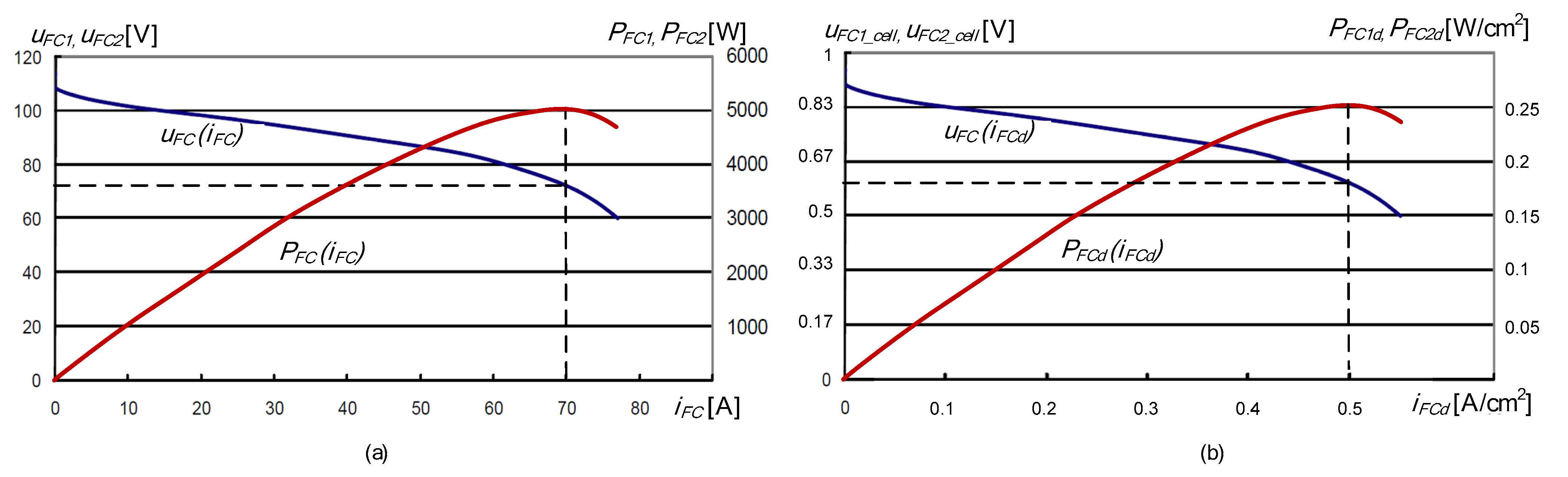

Figure 2 presents voltage-current and power-current output characteristics of the single stack.

Detailed properties of the fuel cell system, composed of two series connected stacks designed for this aircraft, can be found in [

12]. Total weight of the fuel cell system equals ~65 kg. Fuel cell stacks are periodically short-circuited for tens of milliseconds to improve humidification of membranes [

13]. In these conditions, the stack does not provide energy to the load due to the zeroed voltage on the stack terminals, so the energy at this state is consumed from a battery used in a hybrid system.

2.3. Battery Parameters

Taking into account that the fuel cell system is designed for the power range needed to obtain safe horizontal flight, during any other state requiring higher power (e.g., during climbing or maneuvering), the battery set providing boosting energy has to be used. The selected battery pack comprises 96 Lithium-Polymer cells, model SLPB78205130H from Kokam, which is dedicated for automotive, military, and aviation applications. According to [

14], the estimated resistance of a single cell equals 4 mΩ. The energy required for five minutes of take-off and climbing and for one minute of maneuvering equals 3 kWh. Additional 2.5 kWh is stored in case of energy deficit from the fuel cell during horizontal flight if the demanded power is higher than the assumed 10 kW and in case of fuel cell system emergency stop, to provide the energy necessary to assure time to find a safe place for landing. The battery system is equipped with its own battery management system BMS (responsible for monitoring each battery cell voltage and temperature, battery voltage, and battery current) and common DC-bus precharging. Parameters of the battery pack are provided in

Table 2.

The minimum voltage for selected cells declared by the manufacturer equals 2.7 V, but to increase the battery lifetime, such deep discharge is avoided by setting the minimum voltage for a single cell at 3 V in a BMS system. Depending on the demanded power, a few percent of energy stored in the battery will not be used (e.g., 7% at 5 C of discharging current and 10% at 8 C of discharging current). According to short-circuiting of fuel cell stacks, the battery must be resistant to temporarily increased current. This is solved by average current calculation per each 100 ms period, and the battery is disconnected if the current five consecutive samples calculated this way exceed the limit.

2.4. Selection of Electric Motor for Propeller

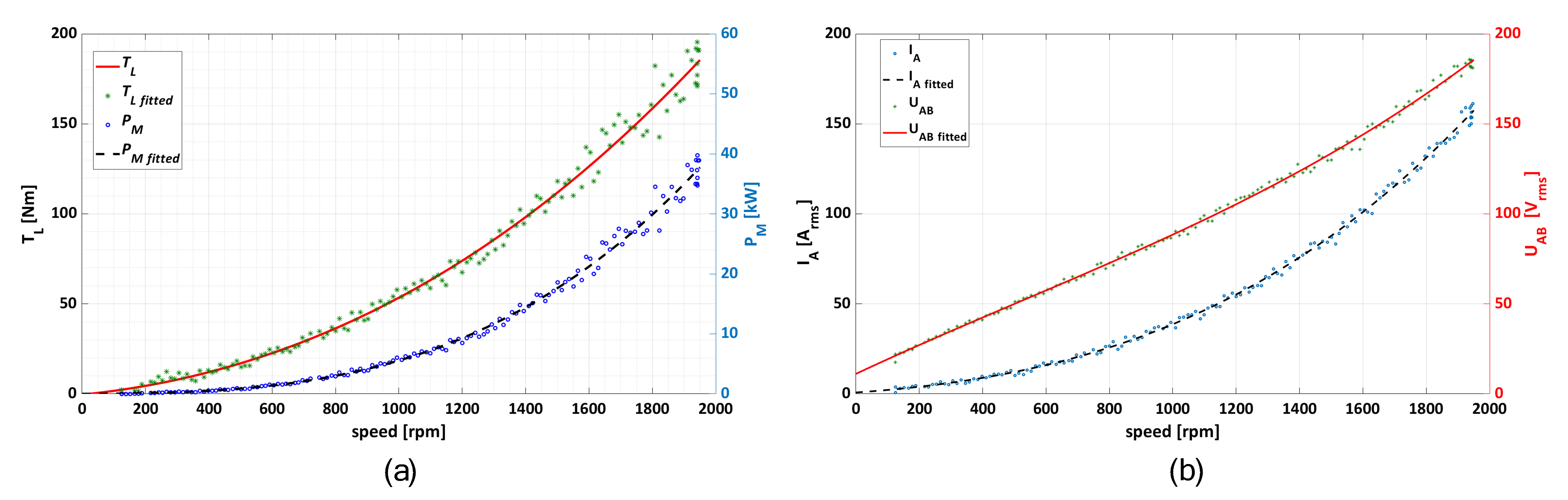

From the point of view of aircraft design, propeller characteristics of thrust vs. rotational speed and vs. aircraft velocity are the most important issues. However, from the point of view of electric drive system design and control, the power/torque vs. rotational speed characteristics are crucial because they determine energy consumption from both the battery and the fuel cell. The motor-propeller set characteristics obtained in the stationary tests are shown in

Figure 3. Maximum mechanical power 38 kW in stationary conditions is available at 1950 rpm of rotational speed. The propeller of 1.85 m diameter is designed in such a way to provide higher thrust for climbing velocity 80–100 km/h (1.7 kN) than in stationary conditions (1kN) at full rotational speed 1950 rpm. Real thrust has not been measured because the aircraft was not equipped with a thrust sensor.

In horizontal flight, the propeller speed is considerably lower than the maximum speed (1300 rpm vs. 1950 rpm respectively), so even a slight change to 1400 rpm or even 1500 rpm is possible. Thus, the voltage required in the DC bus by a DC/AC converter is much lower than battery voltage connected directly to the DC bus. Please note that at the end of the profile, we assumed the optional maneuvering stage before landing, and at this stage, the speed is maximal. Of course, the possibility depends not only on the battery terminal voltage but on the energy available in the battery as well.

The selected motor was EMRAX 268 VHML MVAC, which according to the motor datasheet [

15], can provide 40 kW at 2000 rpm. Maximum motor rms line to line voltage for maximum speed equals 180 V and the rms current equals 160 A. It is visible that at low speed (so low mechanical torque), the voltage linearly depends on the speed, while at higher speed, the torque increases according to the speed square function and the stator resistance voltage drop increases; thus, the stator terminal voltage is slightly higher than the one resulting from the linear speed function.

The electric motor has to provide the required torque at a given speed without exceeding the maximum temperature in different ambient conditions.

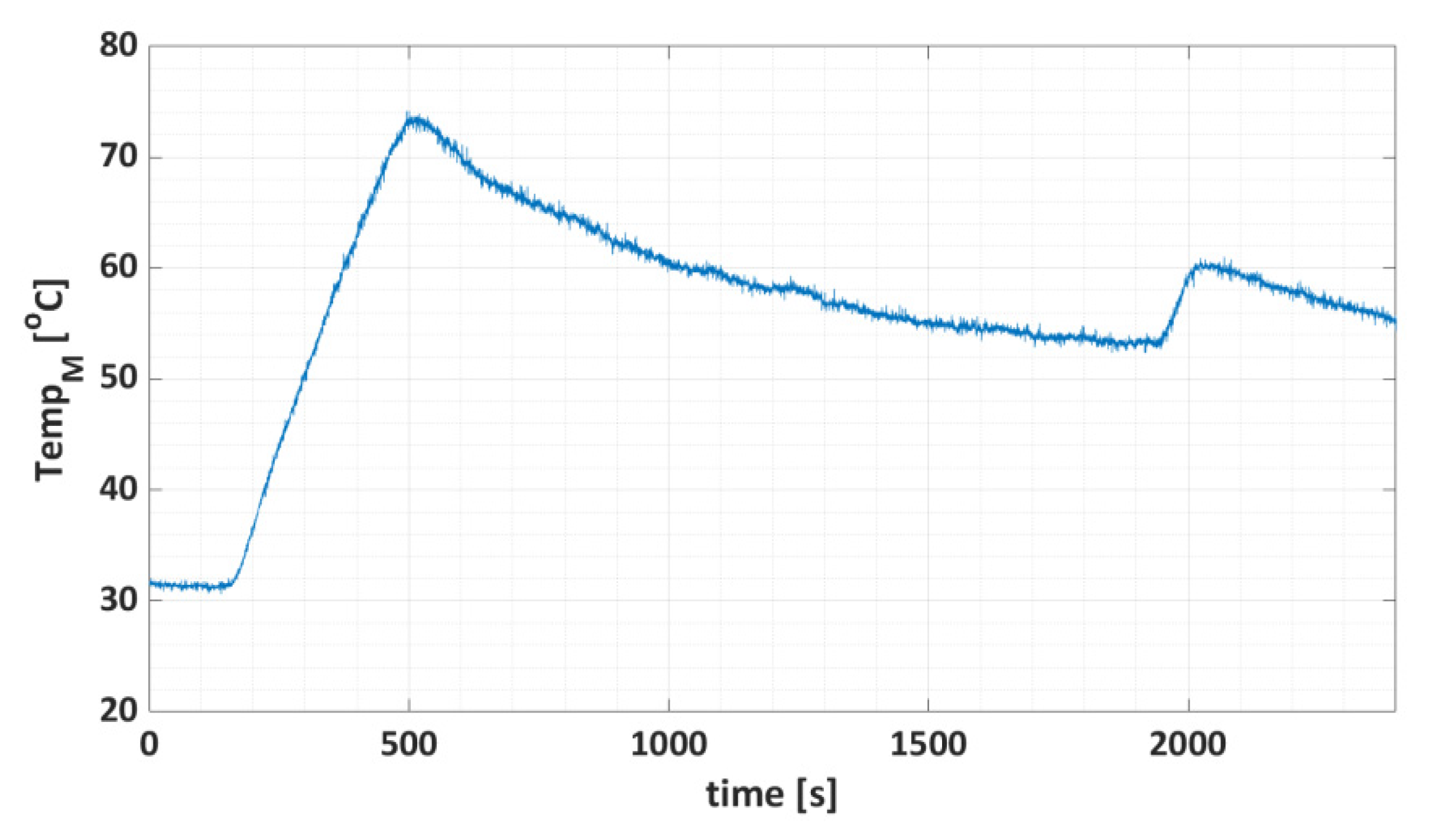

Figure 4 presents the motor temperature measured using a KTY 81/210 embedded winding temperature sensor during the testing profile.

It can be seen that the temperature margin allows take-off of the aircraft even after a longer stay on the runway in case of high solar radiation, which may increase significantly the initial temperature of the uncovered motor.

The main parameters of the selected electric motor are provided in

Table 3. According to

kω [rpm/1Vudc) the minimum dc voltage required to obtain 2000 rpm of rotational speed equals 285 V, so it is close to the minimum battery voltage and it makes it possible to almost fully use the energy stored in the battery up to the minimum level of dc (battery) voltage (3 V/cell).

4. CAN Communication System and Control Structure

4.1. Communication System

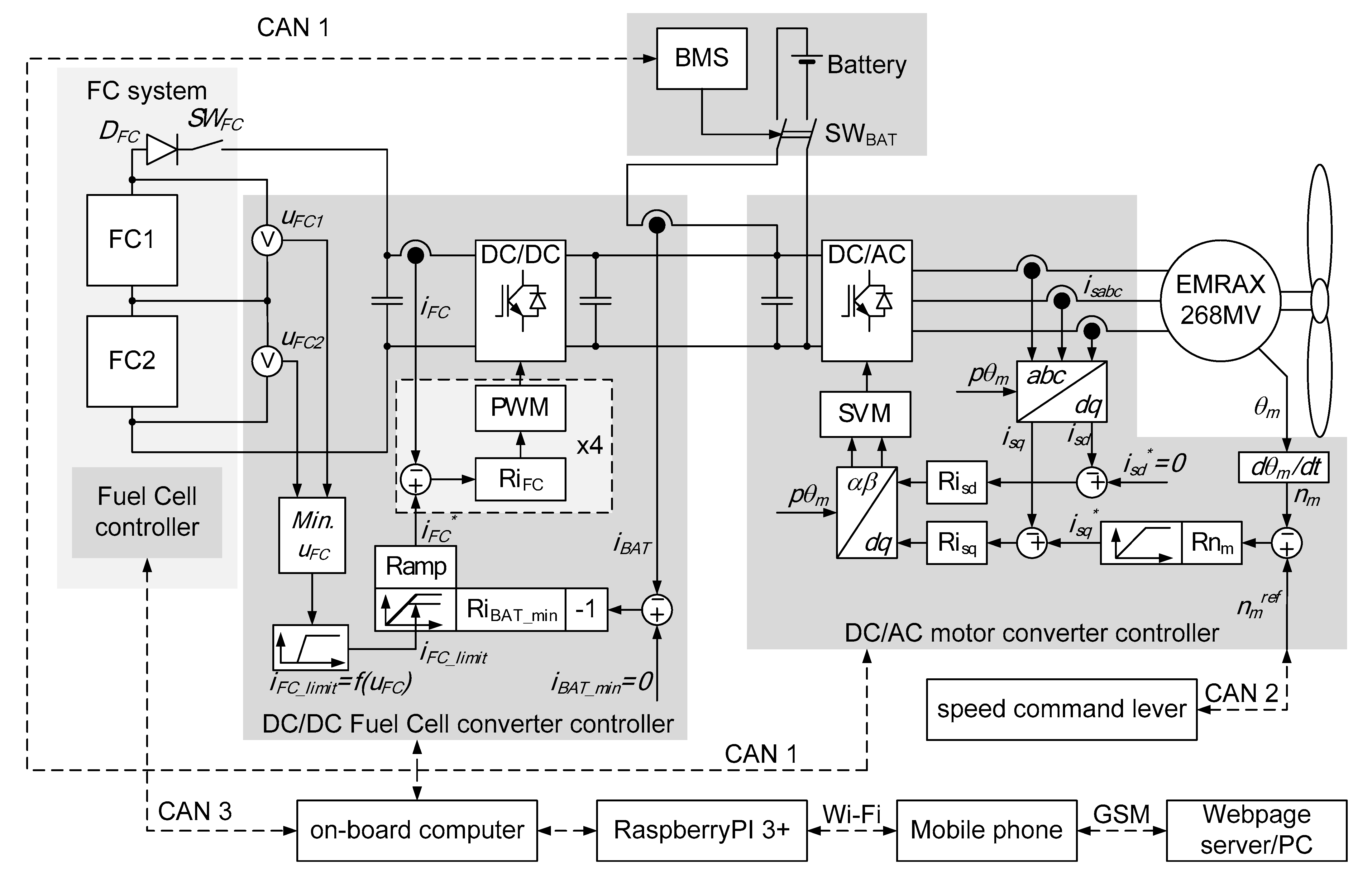

The scheme of communication between components is shown in the next

Section 4.2 together with the control structure. The communication system comprises three isolated CAN-buses. The first one (CAN1) integrates the battery, DC/AC and DC/DC power converters, and on-board computer, and this communication is matched to the CAN protocol of the battery management system. The second communication bus (CAN2) is completely independent and it integrates the DC/AC converter with a speed command lever. This is to avoid any influence of other components on the speed commanded from the lever as well as introduce a kind of redundancy in speed commanding. Simply, any failure in CAN1 does not influence speed commanding. Additionally, when CAN2 communication permanent failure is detected between the speed lever and power converter, CAN1 can be used for speed commanding from the on-board computer as an alternative commanded speed source.

The third bus (CAN3) is implemented between the on-board computer and the fuel cell controller. The fuel cell controller requires only starting and stopping commands, and besides these two signals, the fuel cell controller independently tackles the fuel cell state. However, the on-board computer is involved in some data collection of the whole system during the experiment, including some parameters of the fuel cell. CAN3 is established separately from CAN1 and CAN2 because the fuel cell system has been elaborated by another team in the project [

12]. In such a case it is easier to coordinate the data transfer when only two devices are communicated in the same bus.

The on-board computer is responsible for the devices switching on before take-off, collection of all data during profile realization, visualization, and device switching off after profile ending. Control of energy transfers from the fuel cell and battery to the electric motor is made in the power converter controllers without intervention of the on-board computer. The on-board computer was additionally connected to a single-chip computer RaspberryPi 3B+, to send the data by Wi-Fi to the mobile phone placed on-board, and further by GSM to the webpage. It allows for observation of the waveforms on-line on a PC computer during testing of the motor glider on the runway.

4.2. Scheme of the Control System for Power Converters

A detailed scheme of the control and communication structure of power electronic converters set for the hybrid energy system with a fuel cell and battery is shown in

Figure 7. The DC/AC converter feeding motor is equipped with stator current vector control, in which the

d component of the current vector is set to zero, because the machine does not require field strengthening to obtain the maximum demanded power. The

q component of the current vector responsible for torque creation is referenced from the outer speed controller. This part is a classical rotor flux-oriented control. The reference speed is commanded from the CAN communicated speed command lever. All controllers are proportional-integral type. A saturation block joined with a mechanical speed controller Rn

m is a reference current limiter and also serves as the anti-wind-up structure for the speed controller.

The basic control of the fuel cell converter is composed of four current regulators, each for a single branch of the DC/DC interleaved converter. The reference value iFC* of the fuel cell current is divided by four to obtain the same reference for each single current regulator. Four independent current sensors are also used to measure the currents in each inductor of the interleaved converter.

4.3. Battery Charging Current Regulator

Charging of the battery during flight is not taken into consideration for the elaborated alternative communication-less method even if the power possible from the fuel cell is higher than the instantaneous power consumption by the motor drive. This is because the charging process is less efficient and higher thermal losses occur in a considerably high charging current. When the propeller is not used during flight of the glider, the full power of the fuel cell (10 kW) can be used for battery charging. This is equivalent to 1.5C of charging current. Taking into account that in the initial stage of the profile, we have 30 kW of battery power discharge, and the temperature of cells increases by 14 °C, further charging may increase the cells temperature to over 45 °C. According to the cells specification in the temperature range 35–45 °C the charging current should be limited to 1C, whereas above 45 °C charging is prohibited at all. As during CAN communication fault no information from battery BMS can be received by other devices, the temperature of cells is unknown. Thus, we decided to resign from the charging process when the presented alternative communication-less control method is used. To avoid charging during energy surplus in the fuel cell, the reference fuel cell current iFC* is reduced by the battery charging current controller RiBAT_min in the DC/DC converter control structure. Implementation of battery charging is simply possible by a change of the minimum current value iBAT_min to some allowed level (negative value).

4.4. Fuel Cell Undervoltage Protection

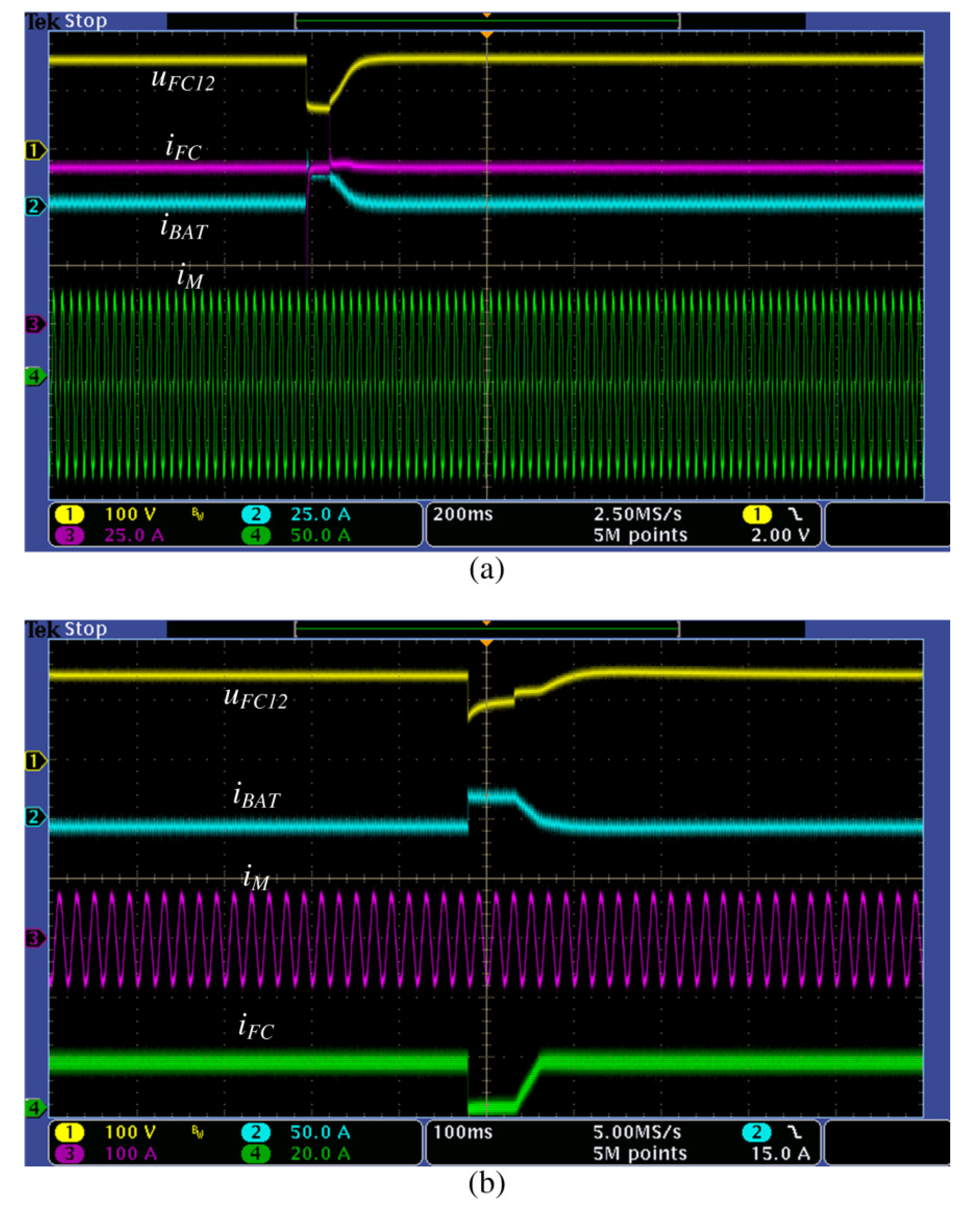

Series connected fuel cell stacks are periodically short-circuited to improve the humidification of the cell, which positively influences stacks performances and consequently increases the available power. Short circuits are made through additional switches SW1 and SW2 (

Figure 5) during ten milliseconds with ten seconds intervals at each stack. Due to the series connection of two stacks, the total voltage on the fuel cell terminals during short circuit drops by half. Thus, energy flow is possible from the non short-circuited stack during this process. The other solution is to bring the fuel cell current to zero. Both manners are possible in DC/DC converter control, as shown in

Figure 8.

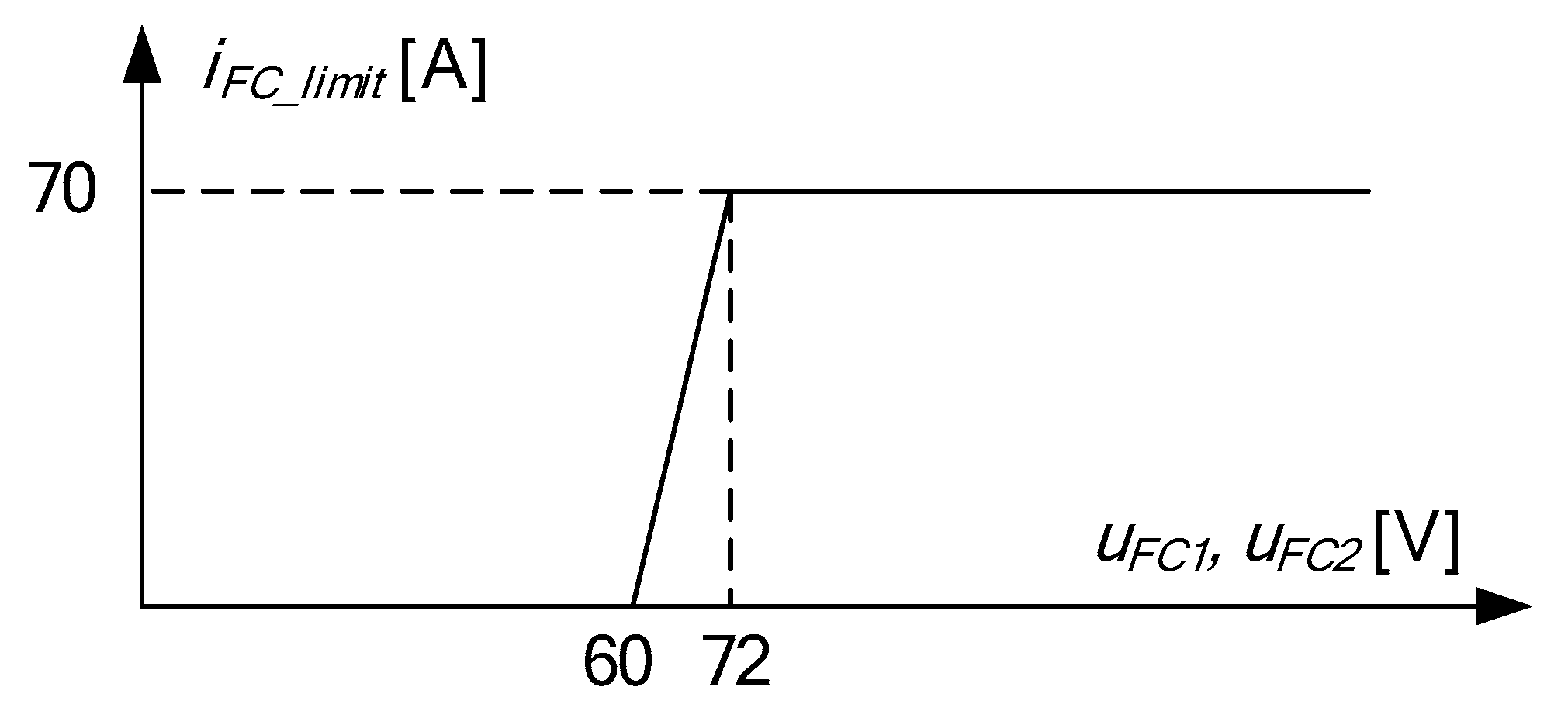

Finally, to avoid additional loading of the fuel cell during short circuit in further research, the second solution has been taken into consideration, and this is realized by an additional function

iFC_limit = f(uFC) in the DC/DC converter control structure (

Figure 7). The function is implemented for additional reduction of the fuel cell current limit, and the function details are shown in

Figure 9. Periodical drop of the fuel cell current to zero causes increased current consumption by the battery. To avoid disconnection of the battery during fuel cell periodical short-circuiting, the battery over-current protection is realized in such a way that five consecutive average values of battery current calculated in 100ms periods are compared with the current limit.

The fuel cell under-voltage function serves as additional protection. The fuel cell current is reduced not only during short-circuit, but also in the case in which fuel cell operates above nominal point, and the fuel cell voltage dangerously drops below nominal value. To avoid fuel cell overload, this function is responsible for unloading the fuel cell system. This way, even if it is impossible to reach the rated power from the fuel cell, it operates with partial power, which is better than fuel cell system disconnection or even possible degradation of cells. A small supercapacitor bank can be of interest as additional storage assisting in the fuel cell short circuits. A supercapacitor bank connected in parallel to the input terminals of the DC/DC converter can be used to avoid battery current peaks during fuel cell short circuit. However, this requires an additional small power converter for charging of the supercapacitors bank in the intervals between short circuits and increases the weight of the conversion system by ca. 3 kg.

4.5. Discussion on Other Possible Faults in the Energy Conversion System

Possible faults may happen in all devices. It is quite difficult to find a solution giving DC/AC converter postfault or motor postfault operation in the used configuration. This is why the motor is sized with some margin, avoiding overheating during take-off and climbing, and the same is true of the DC/AC converter power modules selection. Some protections to avoid faults, such as prevention against motor or DC/AC converter temperature increase, can be done by reducing maximum torque in the DC/AC converter controller. To obtain higher reliability, multiphase (more than three phases) machines with DC/AC converter redundant legs may be used, or two independent machines clutched on the same shaft and fed from two independent DC/AC converters. However, taking into account that the system is designed for a glider, such issues are not critical.

Possible fuel cell system faults cause reduction of available electric power, and the battery only provides energy in this state. Its ability depends on the available energy in a battery, which depends on the stage of flight. In the case of fuel cell system fault, the information from the fuel cell controller or DC/DC converter controller is provided to the on-board computer by one of the CAN communication channels and the available power for the DC/AC converter can be recalculated to the maximum possible torque/speed on the motor shaft. The information of recalculated maximum torque/speed is updated in the DC/AC converter controller. The new maximum torque/speed may be available up to the total discharge of the battery.

Battery faults can be assisted in a similar way. Battery fault detection and its disconnection from the DC bus through the battery switch SWBAT is done by BMS. After disconnection of the battery by BMS, information about it can be sent to the on-board computer and the maximum torque/speed is updated by an on-board computer in the DC/AC converter controller. In such a case, additionally, action is needed related to the DC bus maximum voltage control in the case in which the propeller energy demand is lower than the energy fed from the fuel cell. In such a case, the adaptive current limitation of the fuel cell must be enabled to limit the fuel cell instantaneous power when DC voltage reaches 400V. These issues are part of further research.