IoT Based Electric Vehicle Application Using Boosting Algorithm for Smart Cities

Abstract

1. Introduction

1.1. Literature Survey

1.2. Research Gap and Motivation

1.3. Objectives

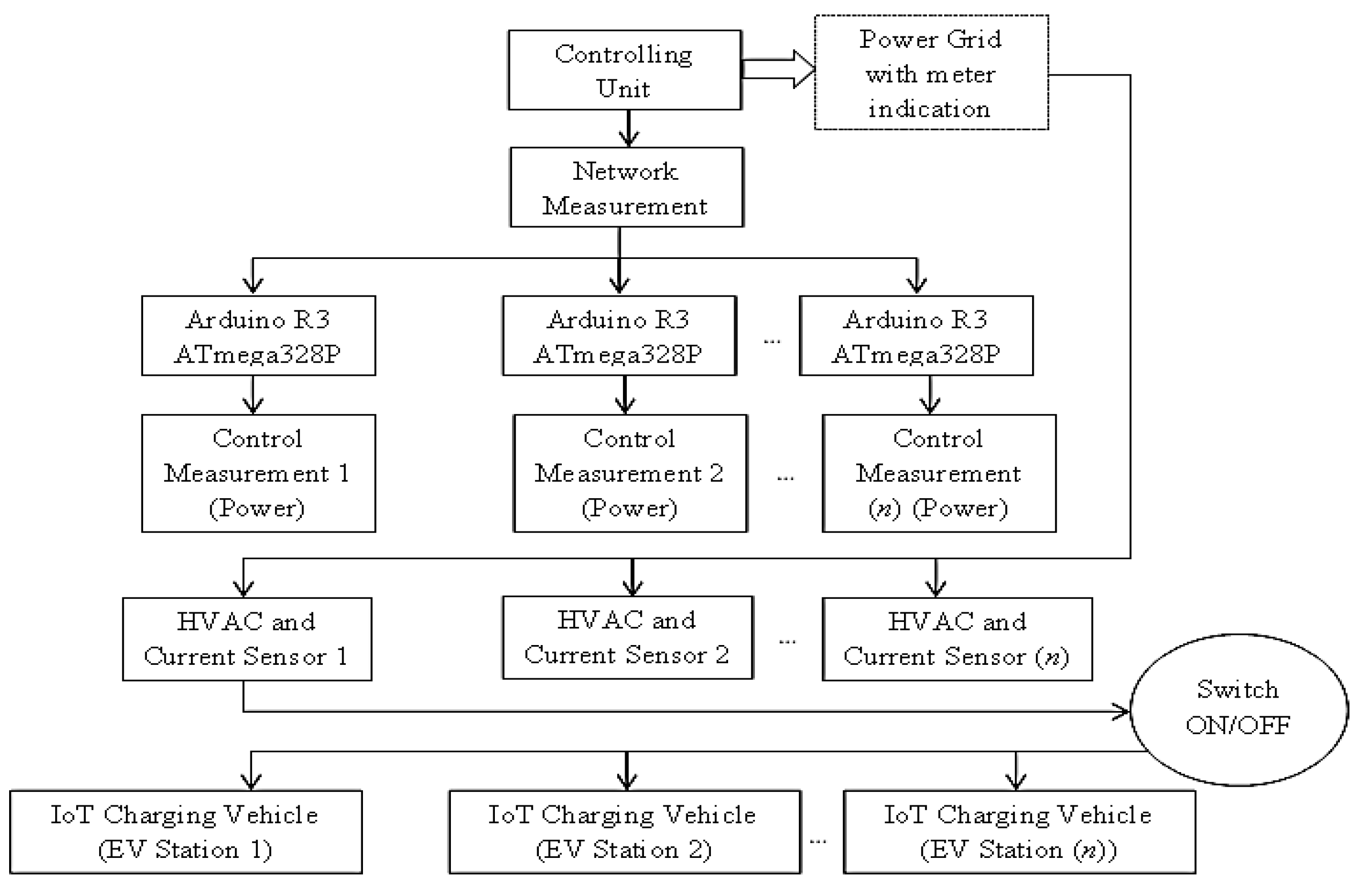

2. Problem Formation

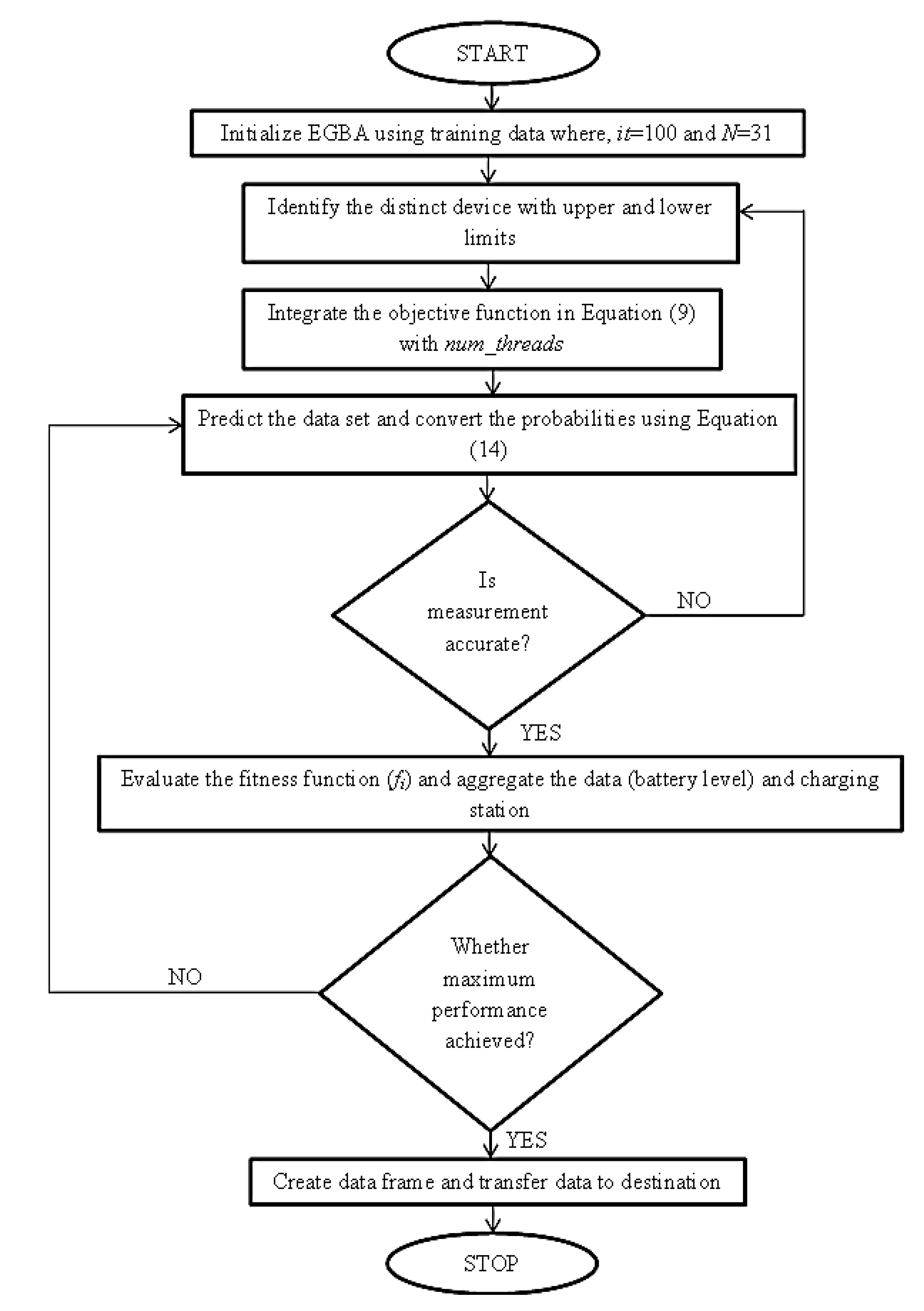

3. Optimization Algorithm

4. Results and Discussion

4.1. Scenario 1—Analysis of Capacity

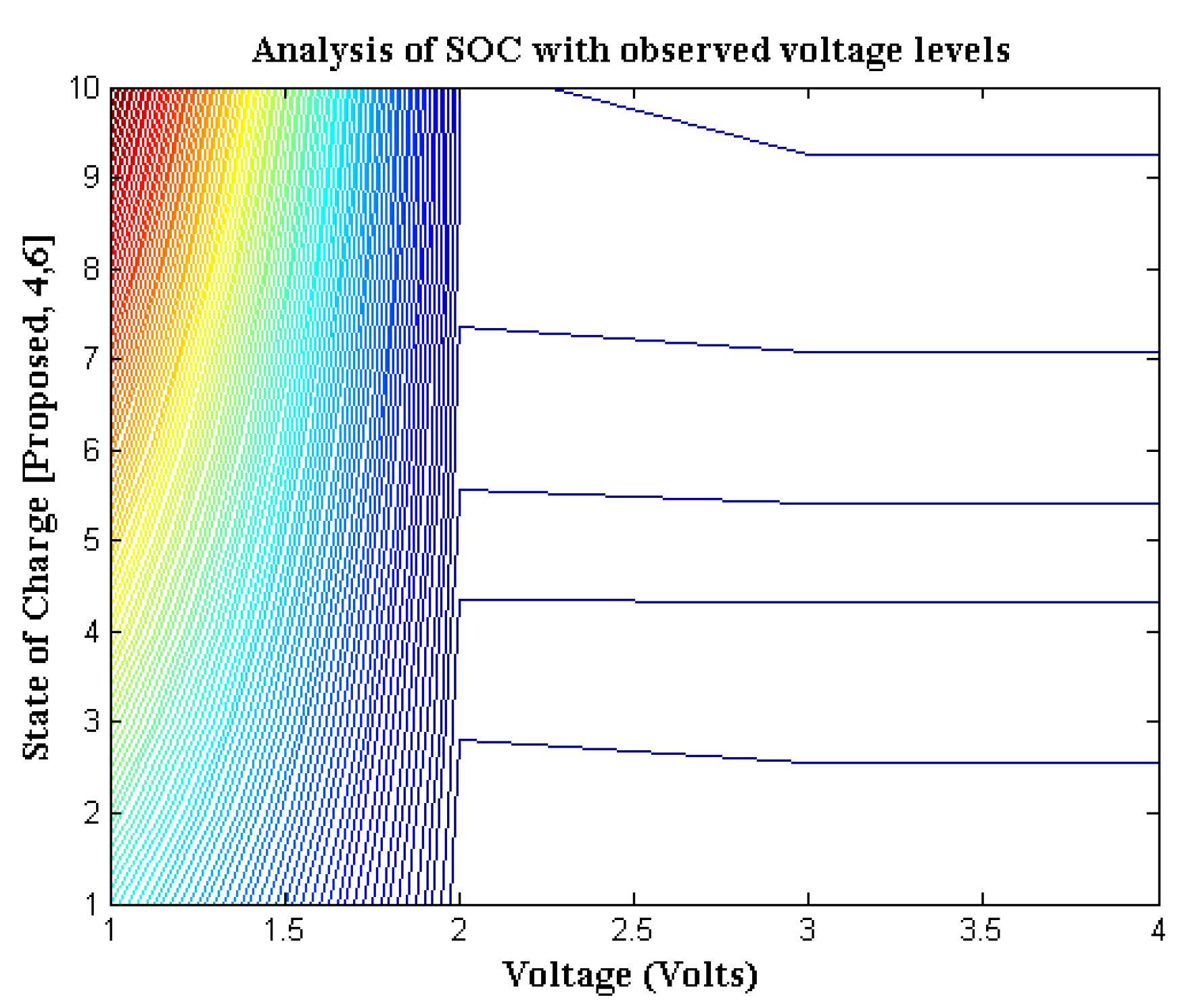

4.2. Scenario 2—Design of Voltage Sets

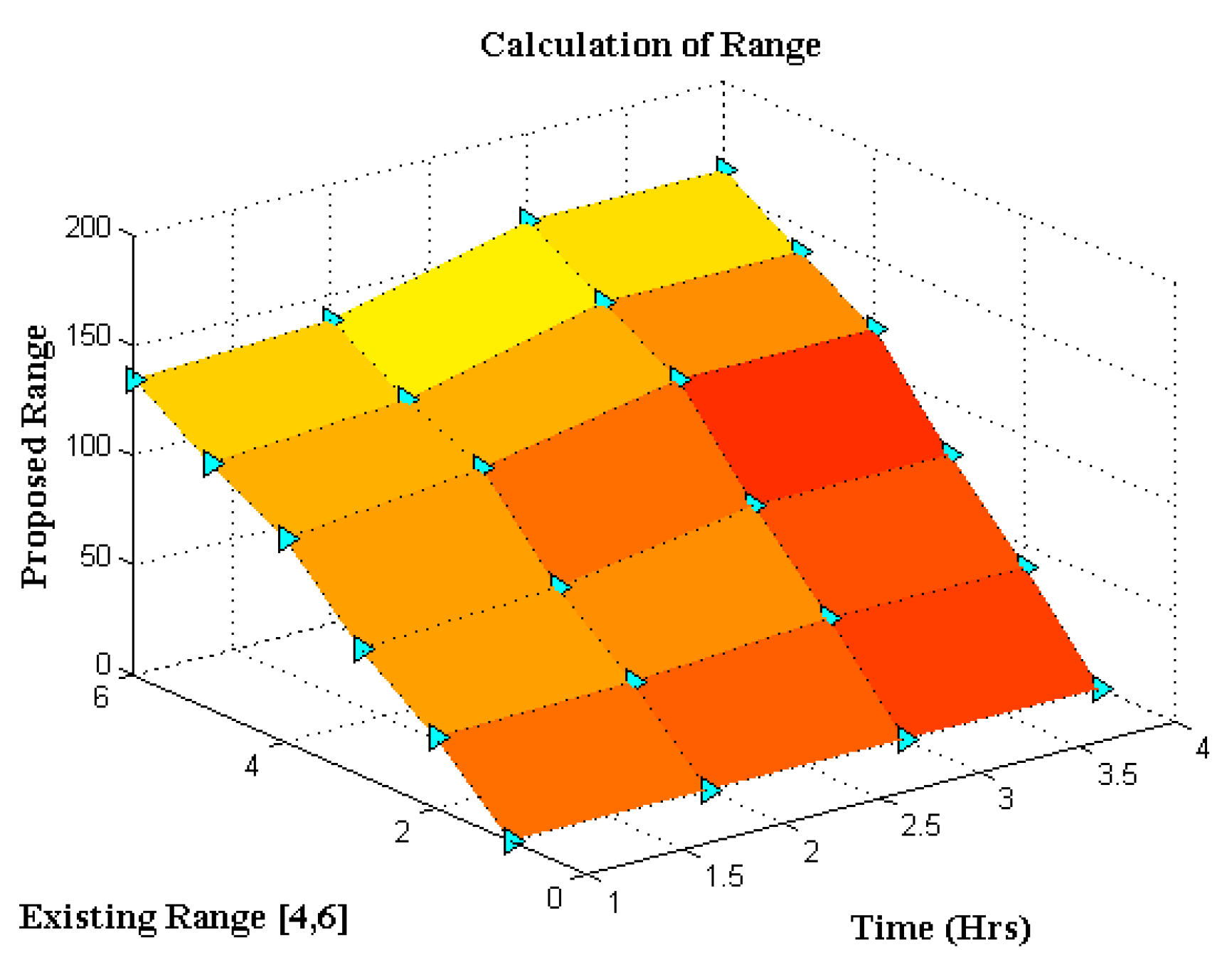

4.3. Scenario 3—Measurement on Range

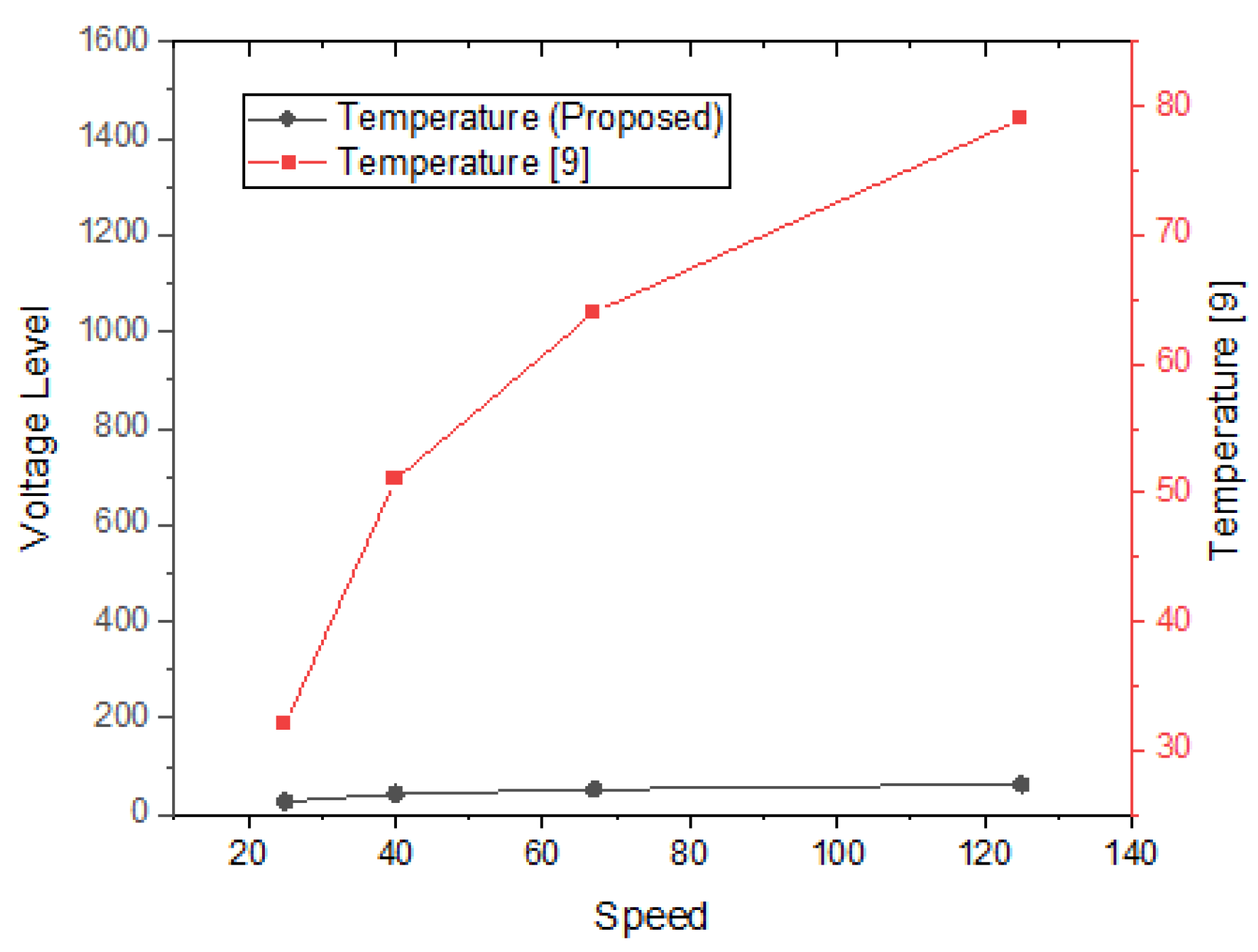

4.4. Scenario 4—Expanse of Temperature

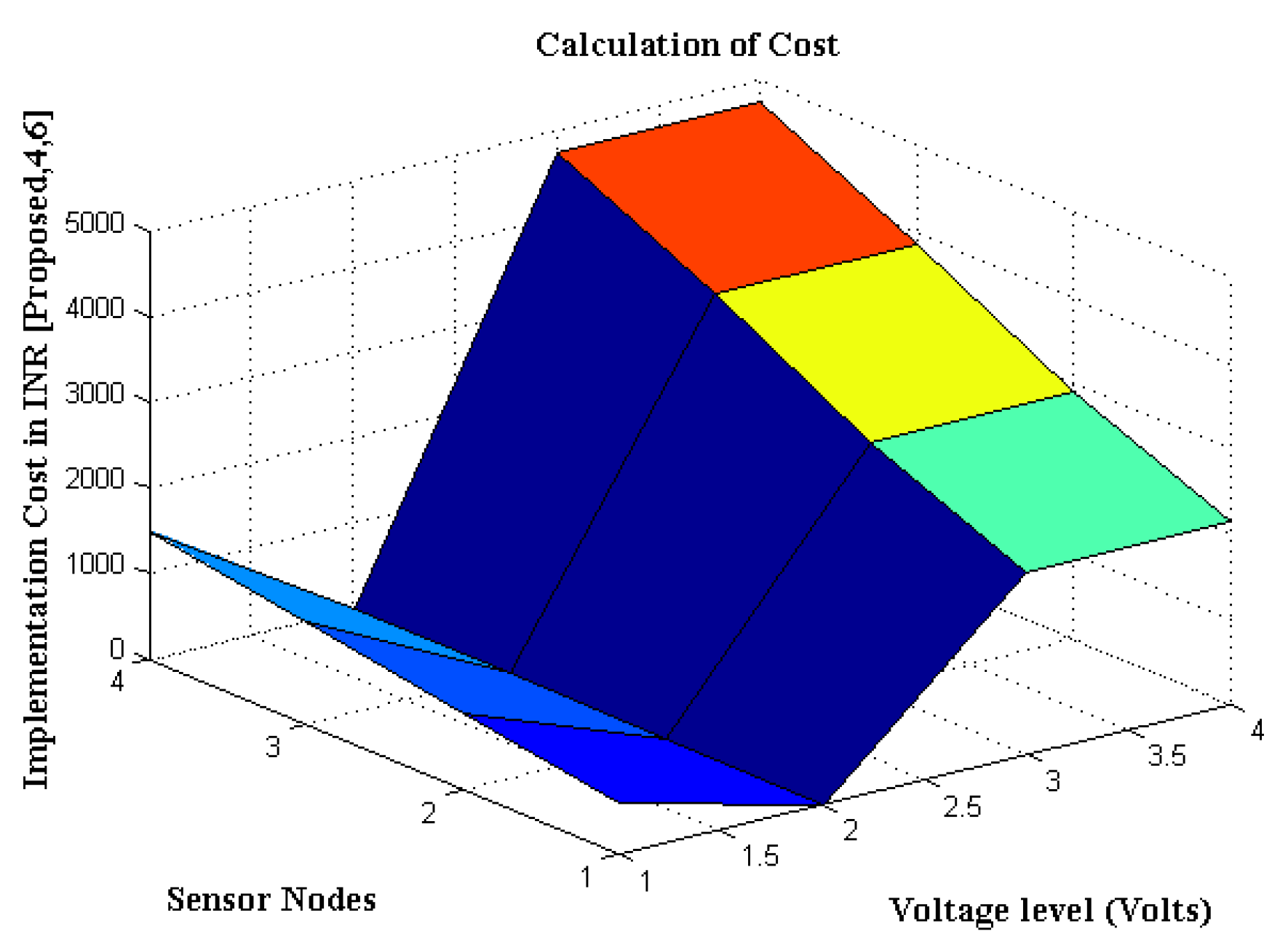

4.5. Scenario 5—Minimization of Cost

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kabalci, Y.; Kabalci, E.; Padmanaban, S.; Holm-Nielsen, J.B.; Blaabjerg, F. Internet of things applications as energy internet in smart grids and smart environments. Electronics 2019, 8, 972. [Google Scholar] [CrossRef]

- Farmanbar, M.; Parham, K.; Arild, O.; Rong, C. A widespread review of smart grids towards smart cities. Energies 2019, 12, 4484. [Google Scholar] [CrossRef]

- Yao, L.; Chen, Y.Q.; Lim, W.H. Internet of Things for Electric Vehicle: An Improved Decentralized Charging Scheme. In Proceedings of the 2015 IEEE International Conference on Data Science and Data Intensive Systems, Sydney, Australia, 11–13 December 2015; pp. 651–658. [Google Scholar] [CrossRef]

- Benedetto, M.; Ortenzi, F.; Lidozzi, A.; Solero, L. Design and Implementation of Reduced Grid Impact Charging Station for Public Transportation Applications. World Electr. Veh. J. 2021, 12, 28. [Google Scholar] [CrossRef]

- Sousa, R.A.; Melendez, A.A.N.; Monteiro, V.; Afonso, J.L.; Ferreira, J.C.; Afonso, J.A. Development of an IoT system with smart charging current control for electric vehicles. In Proceedings of the IECON 2018-44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 4662–4667. [Google Scholar] [CrossRef]

- Savari, G.F.; Krishnasamy, V.; Sathik, J.; Ali, Z.M. Abdel Aleem SHE. Internet of Things based real-time electric vehicle load forecasting and charging station recommendation. ISA Trans. 2020, 97, 431–447. [Google Scholar] [CrossRef] [PubMed]

- Gao, D.; Zhang, Y.; Li, X. The internet of things for electric vehicles: Wide area charging-swap information perception, transmission and application. Adv. Mater. Res. 2013, 608, 1560–1565. [Google Scholar] [CrossRef]

- Asaad, M.; Ahmad, F.; Alam, M.S.; Rafat, Y. IoT enabled Electric Vehicle’s Battery Monitoring System. EAI SGIOT 2017, 8. [Google Scholar] [CrossRef]

- Helmy, M.; Wahab, A.; Imanina, N.; Anuar, M.; Ambar, R.; Baharum, A.; Shanta, S.; Sulaiman, M.S.; Fauzi, S.S.M.; Hanafi, H.F. IoT-Based Battery Monitoring System for Electric Vehicle. Int. J. Eng. Technol. 2018, 7, 505–510. [Google Scholar]

- Divyapriya, S.; Amudha, A.; Vijayakumar, R. Design and Implementation of Grid Connected Solar/Wind/Diesel Generator Powered Charging Station for Electric Vehicles with Vehicle to Grid Technology Using IoT. Curr. Signal Transduct. Ther. 2018, 13, 59–67. [Google Scholar] [CrossRef]

- Muralikrishnan, P.; Kalaivani, M.; College, K.R. IOT based electric vehicle charging station using Arduino Uno. Int. J. Sci. Technol. 2020, 29, 4101–4106. [Google Scholar]

- Ayob, A.; Wan Mahmood, W.M.F.; Mohamed, A.; Wanik, M.Z.C.; Siam, M.F.M.; Sulaiman, S.; Azit, A.H.; Mohamed Ali, M.A. Review on electric vehicle, battery charger, charging station and standards. Res. J. Appl. Sci. Eng. Technol. 2014, 7, 364–372. [Google Scholar] [CrossRef]

- Motlagh, N.H.; Mohammadrezaei, M.; Hunt, J.; Zakeri, B. Internet of things (IoT) and the energy sector. Energies 2020, 13, 494. [Google Scholar] [CrossRef]

- Kong, P.Y.; Karagiannidis, G.K. Charging Schemes for Plug-In Hybrid Electric Vehicles in Smart Grid: A Survey. IEEE Access 2016, 6846–6875. [Google Scholar] [CrossRef]

- Phadtare, K.S. A Review on IoT based Electric Vehicle Charging and Parking System. Int. J. Eng. Res. 2020, V9, 831–835. [Google Scholar] [CrossRef]

- Vaidya, B.; Mouftah, H.T. IoT Applications and Services for Connected and Autonomous Electric Vehicles. Arab. J. Sci. Eng. 2020, 45, 2559–2569. [Google Scholar] [CrossRef]

- Florea, B.C.; Taralunga, D.D. Blockchain IoT for smart electric vehicles battery management. Sustainability 2020, 12, 3984. [Google Scholar] [CrossRef]

- Sun, Y.; Jin, K.; Guo, Z.; Zhang, C.; Wang, H. Research on Intelligent Guidance Optimal Path of Shared Car Charging in the IOT Environment. Wirel. Commun. Mob. Comput. 2020, 2020. [Google Scholar] [CrossRef]

- Elakya, R.; Seth, J.; Ashritha, P.; Namith, R. Smart parking system using IoT. Int. J. Eng. Adv. Technol. 2019, 9, 6091–6095. [Google Scholar]

- Issrani, D.; Bhattacharjee, S. Smart Parking System Based on Internet of Things: A Review. In Proceedings of the 2018 Fourth International Conference on Computing Communication Control and Automation (ICCUBEA), Pune, India, 16–18 August 2018; pp. 10281–10285. [Google Scholar]

- Bajaj, R.K.; Rao, M.; Agrawal, H. Internet of Things (IoT) In The Smart Automotive Sector: A Review. J. Comput. Eng. 2018, 36–44. [Google Scholar]

- Rupanr, S.; Doshi, N. A review of smart parking using internet of things (IoT). Procedia Comput. Sci. 2019, 160, 706–711. [Google Scholar] [CrossRef]

- Mukadam, Z.; Logeswaran, R. A cloud-based smart parking system based on IoT technologies. J. Crit. Rev. 2020, 7, 105–109. [Google Scholar]

- Rajbhandari, S.; Thareja, B.; Deep, V.; Mehrotra, D. IoT based smart parking system. In Proceedings of the 2016 International Conference on Internet of Things and Applications (IOTA), Pune, India, 22–24 January 2018; pp. 121–136. [Google Scholar]

- Chandran, M.; Mahrom, N.F.; Sabapathy, T.; Jusoh, M.; Osman, M.N.; Yasin, M.N.; Hambali, N.A.M.; Jamaluddin, R.; Ali, N.; Wahab, Y.A. An IoT Based Smart Parking System. J. Phys. Conf. Ser. 2019, 1339, 266–270. [Google Scholar] [CrossRef]

- Sivaraman, P.; Sharmeela, C. IoT-Based Battery Management System for Hybrid Electric Vehicle. Artif. Intell. Tech. Electr. Hybrid Electr. Veh. 2020, 1–16. [Google Scholar] [CrossRef]

- Lekshmi, M.; Mayur, P.; Manjunatha, B.; Kavya, U.; Anil Kumar, J.H. IoT based Smart Car Parking with Wireless Charging Feature for Electric Car. Int. Res. J. Eng. Technol. 2020, 7, 2188–2191. [Google Scholar]

- Girish, B.G.; Gowda, A.D.; Amreen, H.; Singh, K.M.A. IoT based security system for smart vehicle. Int. Res. J. Eng. Technol. 2018, 5, 2869–2874. [Google Scholar]

- Sun, S.; Zhang, J.; Bi, J.; Wang, Y.; Moghaddam, M.H.Y. A Machine Learning Method for Predicting Driving Range of Battery Electric Vehicles. J. Adv. Transp. 2019, 2019. [Google Scholar] [CrossRef]

| Parameters | Battery Type for Real Test Drive | |||

|---|---|---|---|---|

| Li-Ion | Na-NiCl2 | Ni-MH | Li-S | |

| Consumption of electricity (kW/h) | 15.6 | 13.5 | 16.2 | 12.4 |

| Self-sufficiency | 146 | 153 | 138 | 193 |

| Input energy (kJ) | 9546 | 8692 | 7854 | 8235 |

| Output energy (kJ) | 193 | 182 | 169 | 165 |

| Features | Data Source | Thing Speak | GMap |

|---|---|---|---|

| Directions | Nearest Location of charging station | Y | Y |

| Travel path | Shortest path for travel | Y | Y |

| Charging time | Limits of charging | Y | N |

| State of charge | Health of battery | Y | N |

| Charging ID | Identification of battery type | Y | N |

| Enclosed Temperature | Limits of Temperature | Y | N |

| Speed | Acceleration | Y | N |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urooj, S.; Alrowais, F.; Teekaraman, Y.; Manoharan, H.; Kuppusamy, R. IoT Based Electric Vehicle Application Using Boosting Algorithm for Smart Cities. Energies 2021, 14, 1072. https://doi.org/10.3390/en14041072

Urooj S, Alrowais F, Teekaraman Y, Manoharan H, Kuppusamy R. IoT Based Electric Vehicle Application Using Boosting Algorithm for Smart Cities. Energies. 2021; 14(4):1072. https://doi.org/10.3390/en14041072

Chicago/Turabian StyleUrooj, Shabana, Fadwa Alrowais, Yuvaraja Teekaraman, Hariprasath Manoharan, and Ramya Kuppusamy. 2021. "IoT Based Electric Vehicle Application Using Boosting Algorithm for Smart Cities" Energies 14, no. 4: 1072. https://doi.org/10.3390/en14041072

APA StyleUrooj, S., Alrowais, F., Teekaraman, Y., Manoharan, H., & Kuppusamy, R. (2021). IoT Based Electric Vehicle Application Using Boosting Algorithm for Smart Cities. Energies, 14(4), 1072. https://doi.org/10.3390/en14041072