Some Aspects of the Modelling of Thin-Layer Drying of Sawdust

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Drying Equipment and Experimental Procedure

2.2.1. Drying in Memmert UFP400 (v: 0.01 and 0.15 m/s)

2.2.2. Drying in Laboratory Dryer (v: 1.5 m/s)

2.2.3. Moisture Content

2.3. Mathematical Modelling of Drying Curves

- for an infinite plane of thickness 2s,

- for a sphere of radius s,

3. Results and Discussion

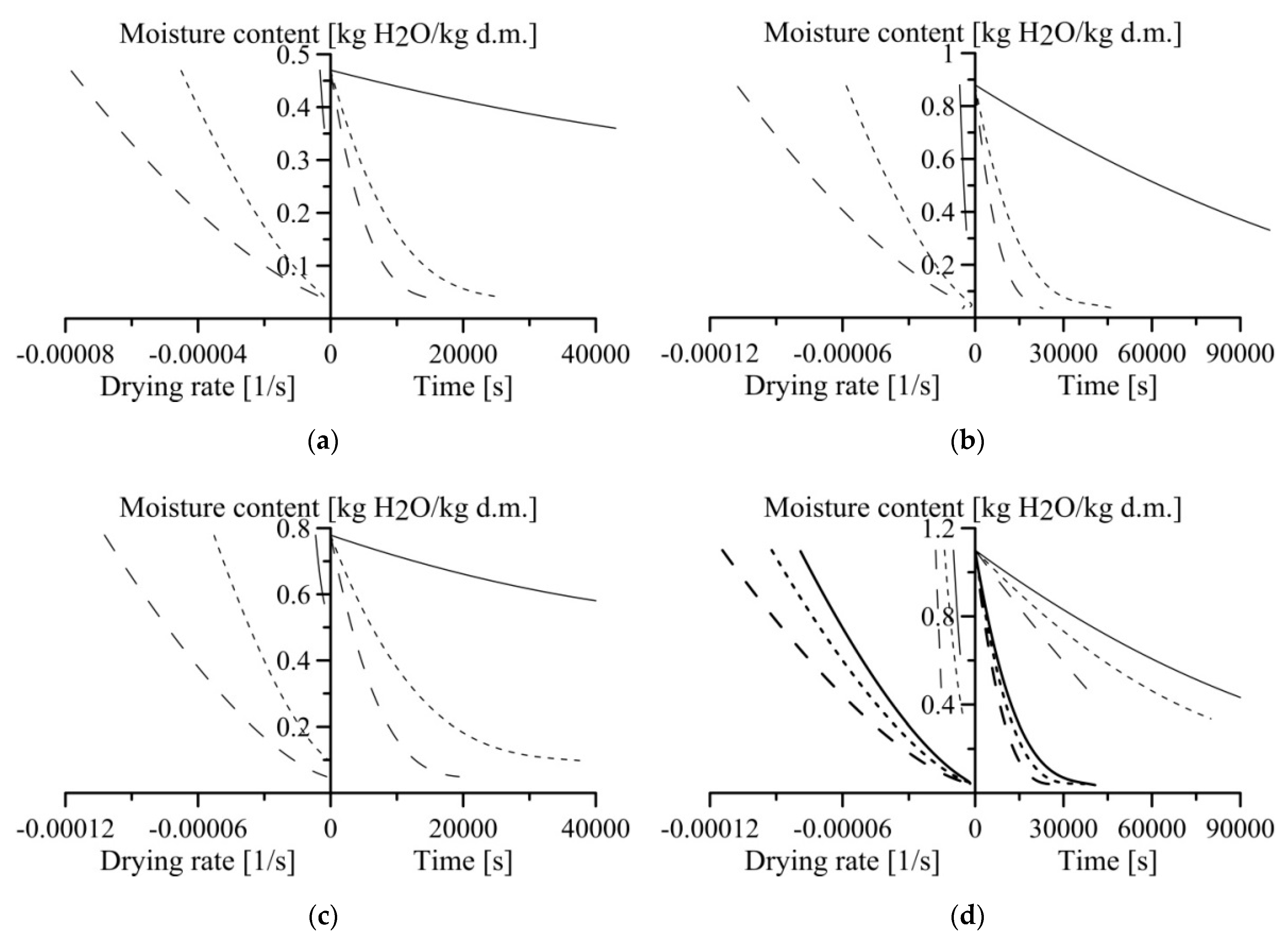

3.1. Drying Characteristics

3.2. Evaluation of the Models

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Demirbaş, A. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- Demirbas, A. Waste management, waste resource facilities and waste conversion process. Energy Convers. Manag. 2011, 52, 1280–1287. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, C.; Champagne, P. Overview of recent advances in thermo–chemical conversion of biomass. Energy Convers. Manag. 2010, 51, 969–982. [Google Scholar] [CrossRef]

- Głowacki, S.; Tulej, W.; Sojak, M.; Bryś, A.; Jaros, M.; Szulc, D. Ultrasonic impact on the drying process of wood biomass. In Renewable Energy Sources: Engineering, Technology, Innovation; Springer: Cham, Switzerland, 2020; pp. 89–98. [Google Scholar] [CrossRef]

- Chih, Y.K.; Chen, W.H.; Ong, H.C.; Show, P.L. Product Characteristics of Torrefied Wood Sawdust in Normal and Vacuum Environments. Energies 2019, 12, 3844. [Google Scholar] [CrossRef]

- Gigler, J.K.; van Loon, W.K.P.; Sonneveld, C. Experiment and modelling of parameters influencing natural wind drying of willow chunks. Biomass Bioenergy 2004, 26, 507–514. [Google Scholar] [CrossRef]

- Rupar, K.; Santini, M. The release of organic compounds during biomass drying depends upon the feedstock and/or altering drying heating medium. Biomass Bioenergy 2003, 25, 615–622. [Google Scholar] [CrossRef]

- Hektor, B. Cost effectiveness of measures for the reduction of net accumulation of carbon dioxide in the atmosphere. Biomass Bioenergy 1998, 15, 299–309. [Google Scholar] [CrossRef]

- Rösch, C.; Kaltschmitt, M. Energy from biomass–do non–technical barriers prevent an increased use? Biomass Bioenergy 1999, 16, 347–356. [Google Scholar] [CrossRef]

- Głowacki, S.; Tulej, W.; Jaros, M.; Sojak, M.; Bryś, A.; Kędziora, R. Kinetics of drying silver birch (Betula pendula Roth) as an alternative source of energy. In Renewable Energy Sources: Engineering, Technology, Innovation; Springer: Cham, Switzerland, 2018; pp. 433–442. [Google Scholar]

- Bilandžija, N.; Krička, T.; Matin, A.; Leto, J.; Grubor, M. Effect of harvest season on the fuel properties of sida hermaphrodita (L.) rusby biomass as solid biofuel. Energies 2018, 11, 3398. [Google Scholar] [CrossRef]

- Križan, P.; Matú, M.; Šooš, L.; Beniak, J. Behavior of beech sawdust during densification into a solid biofuel. Energies 2015, 8, 6382–6398. [Google Scholar] [CrossRef]

- Arce, M.E.; Saavedra, A.; Míguez, J.L.; Granada, E.; Cacabelos, A. Biomass fuel and combustion conditions selection in a fixed bed combustor. Energies 2013, 6, 5973–5989. [Google Scholar] [CrossRef]

- Holmberg, H.; Ahtila, P. Comparison of drying costs in biofuel drying between multi–stage and single–stage drying. Biomass Bioenergy 2004, 26, 515–530. [Google Scholar] [CrossRef]

- Rensrőm, R. The potential of improvements in the energy systems of sawmills when coupled dryers are used for drying of wood fuels and wood products. Biomass Bioenergy 2006, 30, 452–460. [Google Scholar] [CrossRef]

- Reddy, B.S. Biomass energy for India: An overview. Energy. Convers. Manag. 1994, 35, 341–361. [Google Scholar] [CrossRef]

- Ståhl, M.; Granstrőm, K.; Berghel, J.; Renstrőm, R. Industrial process for biomass drying and their effects on the quality properties of wood pellets. Biomass Bioenergy 2004, 27, 621–628. [Google Scholar] [CrossRef]

- Sheikholeslami, R.; Watkinson, A.P. Drying of wood residues in a fixed bed. In Convective Heat and Mass Transfer in Porous Media; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1991; pp. 673–693. [Google Scholar]

- Moreno, R.; Rios, R. Study on sawdust drying techniques in fluidized bed. Biosyst. Eng. 2002, 82, 321–329. [Google Scholar] [CrossRef]

- Di Blasi, C.; Branca, C.C.; Speranoi, S.; La Manita, B. Drying characteristics of wood cylinders for conditions pertinent to fixed–bed countercurrent gasification. Biomass Bioenergy 2003, 25, 45–58. [Google Scholar] [CrossRef]

- Hansson, L.; Antti, A.L. The effect of microwave drying on Norway spruce wood strength: A comparison with conventional drying. J. Mater. Process. Technol. 2003, 141, 41–50. [Google Scholar] [CrossRef]

- Hansson, L.; Antti, A.L. The effect of drying method and temperature level on the hardness of wood. J. Mater. Process. Technol. 2006, 171, 467–470. [Google Scholar] [CrossRef]

- Karlsson, E.; Truedsson, I.; Stenstrőm, S. Construction of a Flexible Pilot Dryer for Products Such as Biofuels and Iron Ore Pellets; Värmerforsk: Stockholm, Sweden, 2007; Report No. 1087. [Google Scholar]

- Kobayashi, J.; Itaya, Y.; Tsukada, S.; Mizuno, K.; Ueda, M.; Morikawa, H.; Sugimoto, T.; Ueda, Y.; Oshika, Y.; Kobayashi, N.; et al. Drying technology of woody biomass for fine grinding by vibration mills. Asia Pac. J. Chem. Eng. 2007, 2, 83–89. [Google Scholar] [CrossRef]

- Bengtsson, P. Experimental analysis of low–temperature bed drying of wooden biomass particles. Dry Technol. 2008, 26, 602–610. [Google Scholar] [CrossRef]

- Kowalski, S.J.; Pawłowski, A. Drying of wood with air of variable parameters. Chem. Process. Eng. 2010, 31, 135–147. [Google Scholar] [CrossRef]

- Lerman, P.; Wennberg, O. Experimental method for designing a biomass bed dryer. Biomass Bioenergy 2011, 35, S31–S35. [Google Scholar] [CrossRef]

- Fagernäs, L.; Brammer, J.; Wilén, C.; Lauer, M.; Verhoeff, F. Drying of biomass for second generation synfuel production. Biomass Bioenergy 2010, 34, 1267–1277. [Google Scholar] [CrossRef]

- Motevali, A.; Minaei, S.; Banakar, A.; Ghobadian, B.; Khoshtaghaza, M.H. Comparison of energy parameters in various dryers. Energy Convers. Manag. 2014, 87, 711–725. [Google Scholar] [CrossRef]

- Şevik, S. Desing, experimental investigation and analysis of a solar drying system. Energy Convers. Manag. 2013, 68, 227–234. [Google Scholar] [CrossRef]

- Falade, K.O.; Solademi, O.J. Modelling of air drying of fresh and blanched sweet potato slices. Int. J. Food Sci. Tech. 2010, 45, 278–288. [Google Scholar] [CrossRef]

- Afriyie, J.K.; Rajakaruna, H.; Nazha, M.A.A.; Forson, F.K. Mathematical modelling and validation of the drying process in a Chimney—Dependent Solar Crop Dryer. Energy Convers. Manag. 2013, 67, 103–116. [Google Scholar] [CrossRef]

- Colak, N.; Hepbasli, A. A review of heat pump drying: Part 1—Systems, models and studies. Energy Convers. Manag. 2009, 50, 2180–2186. [Google Scholar] [CrossRef]

- Sopade, P.A.; Xun, P.Y.; Halley, P.J.; Hardin, M. Equivalence of the Peleg, Pilosof and SinghKulshrestha models for water absorption in food. J. Food Eng. 2007, 78, 730–734. [Google Scholar] [CrossRef]

- Kaleta, A.; Górnicki, K. Some remarks on evaluation of drying models of red beet particles. Energy Convers. Manag. 2010, 51, 2967–2978. [Google Scholar] [CrossRef]

- Reuss, M.; Benkert, S.; Aeberhard, A.; Martina, P.; Raush, G.; Rentzell, B.V.; Sogari, N. Modelling and experimental investigation of a pilot plant for solar wood drying. Sol. Energy 1997, 59, 259–270. [Google Scholar] [CrossRef]

- TRNSYS; University of Wisconsin—Madison, Solar Energy Laboratory: Madison, VI, USA, 1994.

- Fyhr, C.; Rasmuson, A. Some aspects of the modelling of wood chips drying in superheated steam. Int. J. Heat Mass. Tran. 1997, 40, 2825–2842. [Google Scholar] [CrossRef]

- Johansson, A.; Fyhr, C.; Rasmuson, A. High temperature convective drying of wood chips with air and superheated steam. Int. J. Heat Mass Transf. 1997, 40, 2843–2858. [Google Scholar] [CrossRef]

- Gigler, J.K.; van Loon, W.K.P.; van den Berg, J.V.; Sonneveld, C.; Meerdink, G. Natural wind drying of willow stems. Biomass Bioenergy 2000, 19, 153–163. [Google Scholar] [CrossRef]

- Gigler, J.K.; van Loon, W.K.P.; Vissers, M.M.; Bot, G.P.A. Forced convective drying of willow chips. Biomass Bioenergy 2000, 19, 259–270. [Google Scholar] [CrossRef]

- Dincer, I. Moisture transfer analysis during drying of slab woods. Heat Mass Transf. 1998, 34, 317–320. [Google Scholar] [CrossRef]

- Weres, J.; Olek, W.; Guzenda, R. Identification of mathematical model coefficients in the analysis of the heat and mass transport in wood. Dry. Technol. 2000, 18, 1697–1708. [Google Scholar] [CrossRef]

- Awadalla, H.S.F.; El–Dib, A.F.; Mohamad, M.A.; Reuss, M.; Hussein, H.M.S. Mathematical modelling and experimental verification of wood drying process. Energy Convers. Manag. 2004, 45, 197–207. [Google Scholar] [CrossRef]

- Shruti, V.; Das, S.; Ting, Y.-P. Predictive modeling and response analysis of spent catalyst bioleaching using artificial neural network. Bioresour. Technol. Rep. 2020, 9, 100389. [Google Scholar] [CrossRef]

- Omari, A.; Behroozi-Khazaei, N.; Sharifian, F. Drying kinetic and artificial neural network modeling of mushroom drying process in microwave-hot air dryer. J. Food Process Eng. 2018, 41, e12849. [Google Scholar] [CrossRef]

- Özdemir, M.B.; Aktaş, M.; Şevik, S.; Khanlari, A. Modeling of a convective-infrared kiwifruit drying process. Int. J. Hydrog. Energy 2017, 42, 18005–18013. [Google Scholar] [CrossRef]

- Balbay, A.; Şahin, Ö.; Karabatak, M. An investigation of drying process of shelled pistachios in a newly designed fixed bed dryer system by using Artificial Neural Network. Dry. Technol. 2011, 29, 1685–1696. [Google Scholar] [CrossRef]

- Nadi, F.; Górnicki, K.; Winiczenko, R. A novel optimization algorithm for Echium amoenum petals drying. Appl. Sci. 2020, 10, 8387. [Google Scholar] [CrossRef]

- Kaveh, M.; Chayjan, R.A. Mathematical and neural network modelling of terebinth fruit under fluidized bed drying. Res. Agric. Eng. 2016, 61, 55–65. [Google Scholar] [CrossRef]

- Yüzgeç, U.; Türker, M. Comparison of different modeling concepts for drying process of baker’s yeast. IFAC Proc. Vol. 2009, 42, 816–821. [Google Scholar] [CrossRef]

- Alara, O.R.; Abdurahman, N.H.; Olalere, O.A. Mathematical modelling and morphological properties of thin layer oven drying of Vernonia amygdalina leaves. J. Saudi Soc. Agric. Sci. 2017, 18, 309–315. [Google Scholar] [CrossRef]

- Kaleta, A.; Górnicki, K.; Winiczenko, R.; Chojnacka, A. Evaluation of drying models of apple (var. Ligol) dried in a fluidized bed dryer. Energy Convers. Manag. 2013, 67, 179–185. [Google Scholar] [CrossRef]

- Mghazli, S.; Ouhammou, M.; Hidar, N.; Lahnine, L.; Idlimam, A.; Mahrouz, M. Drying characteristics and kinetics solar drying of Moroccan rosemary leaves. Renew. Energy 2017, 108, 303–310. [Google Scholar] [CrossRef]

- Hosseinabadi, H.Z.; Doosthoseini, K.; Layeghi, M. Drying kinetics of poplar (Populus Deltoides) wood particles by a convective thin layer dryer. Drv. Ind. 2012, 63, 169–176. [Google Scholar] [CrossRef][Green Version]

- Kaleta, A.; Górnicki, K. Evaluation of drying models of apple (var. McIntosh) dried in a convective dryer. Int. J. Food Sci. Technol. 2010, 45, 891–898. [Google Scholar] [CrossRef]

- Lutovska, M.; Mitrevski, V.; Pavkov, I.; Babic, M.; Mijakovski, V.; Geramitcioski, T.; Stamenkovic, Z. Different methods of equilibrium moisture content determination. J. Process. Energy Agric. 2017, 21, 91–96. [Google Scholar] [CrossRef]

- Srivastava, V.K.; John, J. Deep bed grain drying modeling. Energy Convers. Manag. 2002, 43, 1689–1708. [Google Scholar] [CrossRef]

- Courtois, F. Dynamic Modelling of Drying to Improve Processing Quality of Corn. Ph.D. Thesis, ENSIA, Massy, France, 1997. [Google Scholar]

- Lopez, A.; Pique, M.T.; Romero, A. Simulation on deep bed drying of hazelnuts. Dry. Technol. 1998, 16, 651–665. [Google Scholar] [CrossRef]

- Pabis, S.; Jayas, D.S.; Cenkowski, S. Grain drying. Theory and Practice; John Wiley & Sons: New York, NY, USA, 1998. [Google Scholar]

- Sitompul, J.P.; Istadi; Widiasa, I.N. Modeling and simulation of deep-bed grain dryers. Dry. Technol. 2001, 19, 269–280. [Google Scholar] [CrossRef][Green Version]

- Ertekin, C.; Firat, M.Z. A Comprehensive review of thin layer drying models used in agricultural products. Crit. Rev. Food Sci. Nutr. 2015, 57, 701–717. [Google Scholar] [CrossRef]

- Lewis, W.K. The rate of drying of solid materials. J. Ind. Eng. Chem. 1921, 13, 427–432. [Google Scholar] [CrossRef]

- Henderson, S.M.; Pabis, S. Grain drying theory. I. Temperature effect on drying coefficient. J. Agric. Eng. Res. 1961, 6, 169–174. [Google Scholar]

- Yagcioglu, A.; Degirmencioglu, A.; Cagatay, F. Drying characteristics of laurel leaves under different drying conditions. In Proceedings of the 7th International Congress on Agricultural Mechanization and Energy, Adana, Turkey, 26–27 May 1999; pp. 565–569. [Google Scholar]

- Henderson, S.M. Progress in developing the thin–layer drying equation. Trans. ASAE 1974, 17, 72. [Google Scholar] [CrossRef]

- Noomhorm, A.; Verma, L.R. A Generalized Single-Layer Rice Drying Model; ASAE Paper No: 86-3057; ASAE: St. Joseph, MI, USA, 1986. [Google Scholar]

- Karathanos, V.T. Determination of water content of dried fruits by drying kinetics. J. Food Eng. 1999, 39, 337–344. [Google Scholar] [CrossRef]

- Sharaf–Eldeen, Y.I.; Blaisdell, J.L.; Hamdy, M.Y. A model for ear corn drying. Trans. ASAE 1980, 23, 71. [Google Scholar] [CrossRef]

- Verma, L.R.; Bucklin, R.A.; Endan, J.B.; Wratten, F.T. Effect of drying air parameters on rice drying models. Trans. ASAE 1985, 28, 296–301. [Google Scholar] [CrossRef]

- Page, G.E. Factors Influencing the Maximum Rates of Air Drying Shelled Corn in Thin Layers. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 1949. [Google Scholar]

- Hii, C.L.; Law, C.L.; Cloke, M. Modelling of thin layer drying kinetics of cocoa beans during artificial and natural drying. J. Food Sci. Tech. 2008, 3, 1–10. [Google Scholar]

- Overhults, D.G.; White, H.E.; Hamilton, H.E.; Ross, I.J. Drying soybean with heated air. Trans. ASAE 1973, 16, 112–113. [Google Scholar] [CrossRef]

- Ademiluyi, T.; Oboho, E.O.; Owudogu, M. Investigation into the thin layer drying models of Nigerian popcorn varieties. Leonardo Electr. J. Pract. Technol. 2008, 13, 47–62. [Google Scholar]

- Demir, V.; Gunhan, T.; Yagcioglu, A.K. Mathematical modelling of convection drying of green table olives. Biosyst. Eng. 2007, 98, 47–53. [Google Scholar] [CrossRef]

- Wang, C.Y.; Singh, R.P. A Single Layer Drying Equation for Rough Rice; ASAE Paper No: 78-3001; ASAE: St. Joseph, MI, USA, 1978. [Google Scholar]

- Midilli, A.; Kucuk, H.; Yapar, Z. A new model for single-layer drying. Dry. Technol. 2002, 20, 1503–1513. [Google Scholar] [CrossRef]

- STATISTICA (Data Analysis Software System); (StatSoft2011); version 10, StatSoft Polska Sp. z o.o., Krakow, Poland. Available online: www.statsoft.pl (accessed on 30 January 2021).

- Gómez-de la Cruz, F.J.; Casanova-Pelaez, P.J.; López-Garcia, R.; Cruz-Peragón, F. Review of the drying kinetics of olive oil mill wastes: Biomass recovery. BioResources 2015, 10, 6055–6080. [Google Scholar] [CrossRef]

- Doymaz, I. Evaluation of some thin–layer drying models of persimmon slices (Diospyros kaki L.). Energy Convers. Manag. 2012, 56, 199–205. [Google Scholar] [CrossRef]

- Cunningham, S.E.; McMinn, W.A.M.; Magee, T.R.A.; Richardson, P.S. Modelling water absorption of pasta during soaking. J. Food Eng. 2007, 82, 600–607. [Google Scholar] [CrossRef]

- Kaymak-Ertekin, F. Drying and rehydrating of green and red peppers. J. Food Sci. 2002, 67, 168–175. [Google Scholar] [CrossRef]

- Bauer, K. Development and Optimisation of a Low-Temperature Drying Schedule for Eucalyptus Grandis (Hill) ex Maiden in a Solar-Assisted Timber Dryer. Ph.D. Thesis, Hohenheim University, Stuttgart, Germany, 2003. [Google Scholar]

- Kashaninejad, M.; Motrazavi, A.; Safekȯrdi, A.; Tabil, L.G. Thin-layer drying characteristics and modeling of pistachio nuts. J. Food Eng. 2007, 78, 98–108. [Google Scholar] [CrossRef]

- Shi, Q.; Zheng, Y.; Zhao, Y. Mathematical modeling on thin-layer heat pump drying of yacon (Smallanthus sonchifolius) slices. Energy Convers. Manag. 2013, 71, 208–216. [Google Scholar] [CrossRef]

- Cheevitsopon, E.; Noomhorm, A. Effect of paraboiling and fluidized bed drying on the physicochemical properties of germinated brow rice. Int. J. Food Sci. Tech. 2011, 46, 2498–2504. [Google Scholar] [CrossRef]

- Akpimar, E.; Midilli, A.; Bicer, Y. Single layer drying behaviour of potato slices on a convective cyclone dryer and mathematical modelling. Energy Convers. Manag. 2003, 44, 1689–1705. [Google Scholar] [CrossRef]

- Pangavhane, D.R.; Sawhney, R.L.; Sarsavadia, P.N. Drying kinetics studies on single layer Thompson seedless grapes under controlled heated air conditions. J. Food Process. Pres. 2000, 24, 335–352. [Google Scholar] [CrossRef]

- Toğrul, I.T.; Pehlivan, D. Modelling of drying kinetics of single apricot. J. Food Eng. 2003, 58, 23–32. [Google Scholar] [CrossRef]

- Garcia-Pascual, P.; Sanjuán, N.; Bon, J.; Carreres, J.E.; Mulet, A. Rehydration process of Boletus edulis mushroom: Characteristic and modeling. J. Sci. Food Agric. 2005, 85, 1397–1404. [Google Scholar] [CrossRef]

- Garcia-Pascual, P.; Sanjuán, N.; Melis, R.; Mulet, A. Marchella esculenta (morel) rehydration process modelling. J. Food Eng. 2006, 72, 346–353. [Google Scholar] [CrossRef]

- Zielińska, M.; Markowski, M. Drying behaviour of carrots dried in spout-fluidized bed dryer. Dry. Technol. 2007, 25, 261–270. [Google Scholar] [CrossRef]

| Model No. | Model Equation | Model Name | References |

|---|---|---|---|

| 1 | MR = exp(−kt) | Lewis (Newton) | [64] |

| 2 | MR = aexp(−kt) | Henderson and Pabis | [65] |

| 3 | MR = aexp(−k1t) + b | Logarithmic | [66] |

| 4 | MR = aexp(−k1t) + bexp(−k2t) | Two-term | [67] |

| 5 | MR = aexp(−k1t) + bexp(−k2t) + c | Noomhorm and Verma | [68] |

| 6 | MR = aexp(−k1t) + bexp(−k2t) + cexp(−k3t) | Modified Henderson and Pabis | [69] |

| 7 | MR = aexp(−kt) + (1 − a)exp(−akt) | Two-term exponential | [70] |

| 8 | MR = aexp(−kt) + (1 − a)exp(−gt) | Verma et al. | [71] |

| 9 | MR = exp(−ktn) | Page | [72] |

| 10 | MR = aexp(−ktn) | Kaleta et al. I | [53] |

| 11 | MR = aexp(−ktn) + bexp(−gtn) | Hii et al. | [73] |

| 12 | MR = aexp(−ktn) + (1 − a)exp(−gtn) | Kaleta et al. II | [53] |

| 13 | MR = exp[−(kt)n] | Modified Page | [74] |

| 14 | MR = aexp[−(kt)n] | Ademiluyi | [75] |

| 15 | MR = aexp[−(kt)n] + b | Demir et al. | [76] |

| 16 | MR = aexp[−(kt)n] + bexp[−(gt)n] | Kaleta et al. III | [53] |

| 17 | MR = 1 + at + bt2 | Wang and Singh | [77] |

| 18 | MR = aexp(−ktn) + bt | Midilli et al. | [78] |

| Material | Conditions of Drying | Time (h) | |||

|---|---|---|---|---|---|

| 1 | 2 | 4 | 8 | ||

| Spruce | 25 °C, 0.01 m/s | 0.45 ± 0.04bc | 0.44 ± 0.04b | 0.42 ± 0.04e | 0.39 ± 0.04b |

| 60 °C, 0.01 m/s | 0.32 ± 0.03ab | 0.22 ± 0.03a | 0.09 ± 0.03a | ||

| 80 °C, 0.01 m/s | 0.24 ± 0.03a | 0.11 ± 0.03a | 0.04 ± 0.03a | ||

| Beech | 25 °C, 0.01 m/s | 0.85 ± 0.05f | 0.83 ± 0.05ef | 0.78 ± 0.05fg | 0.69 ± 0.05c |

| 60 °C, 0.01 m/s | 0.68 ± 0.05de | 0.52 ± 0.04bc | 0.29 ± 0.03d | 0.08 ± 0.03a | |

| 80 °C, 0.01 m/s | 0.69 ± 0.04de | 0.42 ± 0.03b | 0.13 ± 0.03ab | ||

| Willow | 25 °C, 0.01 m/s | 0.75 ± 0.05def | 0.73 ± 0.05de | 0.69 ± 0.05f | 0.62 ± 0.04c |

| 60 °C, 0.01 m/s | 0.60 ± 0.04cd | 0.46 ± 0.04b | 0.27 ± 0.03cd | ||

| 80 °C, 0.01 m/s | 0.46 ± 0.04bc | 0.26 ± 0.03a | 0.07 ± 0.03a | ||

| Alder | 25 °C, 0.01 m/s | 1.06 ± 0.06g | 1.03 ± 0.06g | 0.96 ± 0.05h | 0.83 ± 0.05d |

| 25 °C, 0.15 m/s | 1.05 ± 0.06g | 1.00 ± 0.06g | 0.91 ± 0.05gh | 0.74 ± 0.05cd | |

| 25 °C, 1.5 m/s | 1.03 ± 0.06g | 0.97 ± 0.05fg | 0.84 ± 0.05gh | 0.61 ± 0.04c | |

| 60 °C, 0.01 m/s | 0.83 ± 0.05ef | 0.62 ± 0.04cd | 0.32 ± 0.03de | ||

| 60 °C, 0.15 m/s | 0.80 ± 0.05ef | 0.56 ± 0.04bc | 0.25 ± 0.03bcd | ||

| 60 °C, 1.5 m/s | 0.73 ± 0.05def | 0.47 ± 0.04b | 0.15 ± 0.03abc | ||

| Model No. | Type of Parameter Equation | Parameter Equation Coefficients | Parameter | R | RMSE | χ2 | ||

|---|---|---|---|---|---|---|---|---|

| A | B | C | ||||||

| 4 | L | −0.47612 −0.01618 −0.10423 −0.01521 | 0.03182 0.00017 −0.03171 0.00014 | −72.40853 1.02927 230.99235 1.13035 | a = 0.70887 k1 = 0.00425 b = 0.30290 k2 = 0.00457 | 0.998 | 0.091 | 0.008 |

| R | 0.52554 0.02222 5.97768 0.06247 | −95.75608 −0.46294 95.18170 −0.38511 | −72.40853 1.02927 230.99235 1.13035 | a = 1.52489 k1 = 0.00849 b = −0.50984 k2 = 0.00810 | 0.978 | 0.100 | 0.010 | |

| Ln | 3.00751 0.01312 −2.11214 0.01678 | 2.04886 0.01083 −2.03906 0.00905 | 0.02595 −0.00006 −0.08074 −0.00048 | a = 1.13719 k1 = 0.00654 b = −0.12426 k2 = 0.00647 | 0.995 | 0.040 | 0.002 | |

| Lc | −9.22934 0.00942 −1.09934 −0.01197 | 4.71767 0.02495 −4.69511 0.02083 | 2.22772 0.01106 −2.24454 0.01028 | a = 1.13719 k1 = 0.00654 b = −0.12426 k2 = 0.00647 | 0.995 | 0.040 | 0.002 | |

| 5 | L | 1.18054 −0.01414 2.37032 −0.04351 −0.02425 | 0.02686 0.00013 −0.03477 0.00005 0.00788 | −244.23485 1.19220 59.89724 4.51495 −66.74356 | a = 0.34993 k1 = 0.00532 b = 0.88299 k2 = 0.00486 c = −0.21868 | 0.999 | 0.109 | 0.012 |

| R | 1.08304 0.00585 −2.52352 −0.01468 −0.19371 | −78.70977 −0.40595 105.44911 −0.23236 −27.15350 | 0.01263 0.00010 0.00755 0.00025 0.00638 | a = 1.03397 k1 = 0.00860 b = −0.01063 k2 = 0.00640 c = −0.00864 | 0.978 | 0.104 | 0.011 | |

| Ln | −2.02610 −0.04502 3.08442 0.00825 −0.76611 | 1.77418 0.00874 −2.33462 0.00439 0.56400 | 0.98370 −0.00351 −1.49768 0.00450 0.36053 | a = 0.70789 k1 = 0.00696 b = 0.42275 k2 = 0.00551 c = −0.11718 | 0.996 | 0.103 | 0.011 | |

| Lc | −3.10616 −0.01181 2.70636 0.00700 −0.34452 | 4.08520 0.02013 −5.37567 0.01011 1.29866 | 1.72503 0.00852 −3.63758 0.00974 1.04094 | a = 0.70789 k1 = 0.00696 b = 0.42275 k2 = 0.00551 c = −0.11718 | 0.996 | 0.103 | 0.011 | |

| 7 | L | 2.70189 0.01411 | −0.00751 0.00011 | −54.25145 −1.20281 | a = 1.70857 k = 0.00893 | 0.994 | 0.044 | 0.002 |

| R | 0.88426 0.02428 | 19.42966 −0.38425 | 0.00315 −0.00006 | a = 1.52317 k = 0.01195 | 0.961 | 0.133 | 0.018 | |

| Ln | 0.42531 −0.00316 | −0.46806 0.00814 | −0.67255 0.00429 | a = 1.60614 k = 0.01040 | 0.980 | 0.094 | 0.009 | |

| Lc | 2.86410 −0.00824 | −1.07774 0.01875 | −0.32922 0.00734 | a = 1.60614 k = 0.01040 | 0.980 | 0.0948 | 0.009 | |

| Kind of Sawdust | Model | Coefficients of Parameter Equation | R | RMSE | χ2 | |

|---|---|---|---|---|---|---|

| A | B | |||||

| Spruce | Ip | −0.0012 | 7 × 10−5 | 0.912–0.970 | 0.132–0.280 | 0.004–0.050 |

| S | −0.0002 | 10−5 | 0.876–0.950 | 0.167–0.301 | 0.030–0.070 | |

| Beech | Ip | −0.0026 | 8 × 10−5 | 0.900–0.974 | 0.066–0.2405 | 0.004–0.054 |

| S | −0.0005 | 2 × 10−5 | 0.627–0.953 | 0.159–0.451 | 0.026–0.157 | |

| Willow | Ip | −0.0026 | 8 × 10−5 | 0.937–0.972 | 0.075–0.250 | 0.006–0.013 |

| S | −0.0006 | 2 × 10−5 | 0.754–0.956 | 0.160–0.334 | 0.026–0.112 | |

| Alder | Ip | −0.0008 | 5 × 10−5 | 0.907–0.974 | 0.127–0.238 | 0.007–0.057 |

| S | −0.0002 | 10−5 | 0.741–0.964 | 0.155–0.340 | 0.024–0.121 | |

| Kind of Sawdust | Drying Variables | Infinite Plane | Sphere | |||||

|---|---|---|---|---|---|---|---|---|

| v (m/s) | T (°C) | R | RMSE | χ2 | R | RMSE | χ2 | |

| Spruce | 0.01 | 25 | 0.926 | 0.115 | 0.013 | 0.836 | 0.361 | 0.130 |

| 60 | 0.969 | 0.125 | 0.016 | 0.887 | 0.242 | 0.059 | ||

| 80 | 0.965 | 0.192 | 0.037 | 0.929 | 0.202 | 0.041 | ||

| 0.15 | 25 | 0.926 | 0.186 | 0.025 | 0.668 | 0.402 | 0.133 | |

| 60 | 0.972 | 0.141 | 0.020 | 0.912 | 0.179 | 0.032 | ||

| 1.5 | 25 | 0.930 | 0.118 | 0.012 | 0.782 | 0.390 | 0.150 | |

| 60 | 0.969 | 0.208 | 0.043 | 0.943 | 0.175 | 0.031 | ||

| Alder | 0.01 | 25 | 0.913 | 0.120 | 0.014 | 0.814 | 0.389 | 0.151 |

| 60 | 0.973 | 0.070 | 0.005 | 0.814 | 0.260 | 0.068 | ||

| 80 | 0.976 | 0.136 | 0.018 | 0.929 | 0.202 | 0.041 | ||

| 0.15 | 25 | 0.909 | 0.222 | 0.033 | 0.641 | 0.435 | 0.149 | |

| 60 | 0.974 | 0.089 | 0.008 | 0.912 | 0.179 | 0.032 | ||

| 1.5 | 25 | 0.928 | 0.121 | 0.013 | 0.782 | 0.390 | 0.150 | |

| 60 | 0.969 | 0.138 | 0.019 | 0.943 | 0.175 | 0.031 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bryś, A.; Kaleta, A.; Górnicki, K.; Głowacki, S.; Tulej, W.; Bryś, J.; Wichowski, P. Some Aspects of the Modelling of Thin-Layer Drying of Sawdust. Energies 2021, 14, 726. https://doi.org/10.3390/en14030726

Bryś A, Kaleta A, Górnicki K, Głowacki S, Tulej W, Bryś J, Wichowski P. Some Aspects of the Modelling of Thin-Layer Drying of Sawdust. Energies. 2021; 14(3):726. https://doi.org/10.3390/en14030726

Chicago/Turabian StyleBryś, Andrzej, Agnieszka Kaleta, Krzysztof Górnicki, Szymon Głowacki, Weronika Tulej, Joanna Bryś, and Piotr Wichowski. 2021. "Some Aspects of the Modelling of Thin-Layer Drying of Sawdust" Energies 14, no. 3: 726. https://doi.org/10.3390/en14030726

APA StyleBryś, A., Kaleta, A., Górnicki, K., Głowacki, S., Tulej, W., Bryś, J., & Wichowski, P. (2021). Some Aspects of the Modelling of Thin-Layer Drying of Sawdust. Energies, 14(3), 726. https://doi.org/10.3390/en14030726