1. Introduction

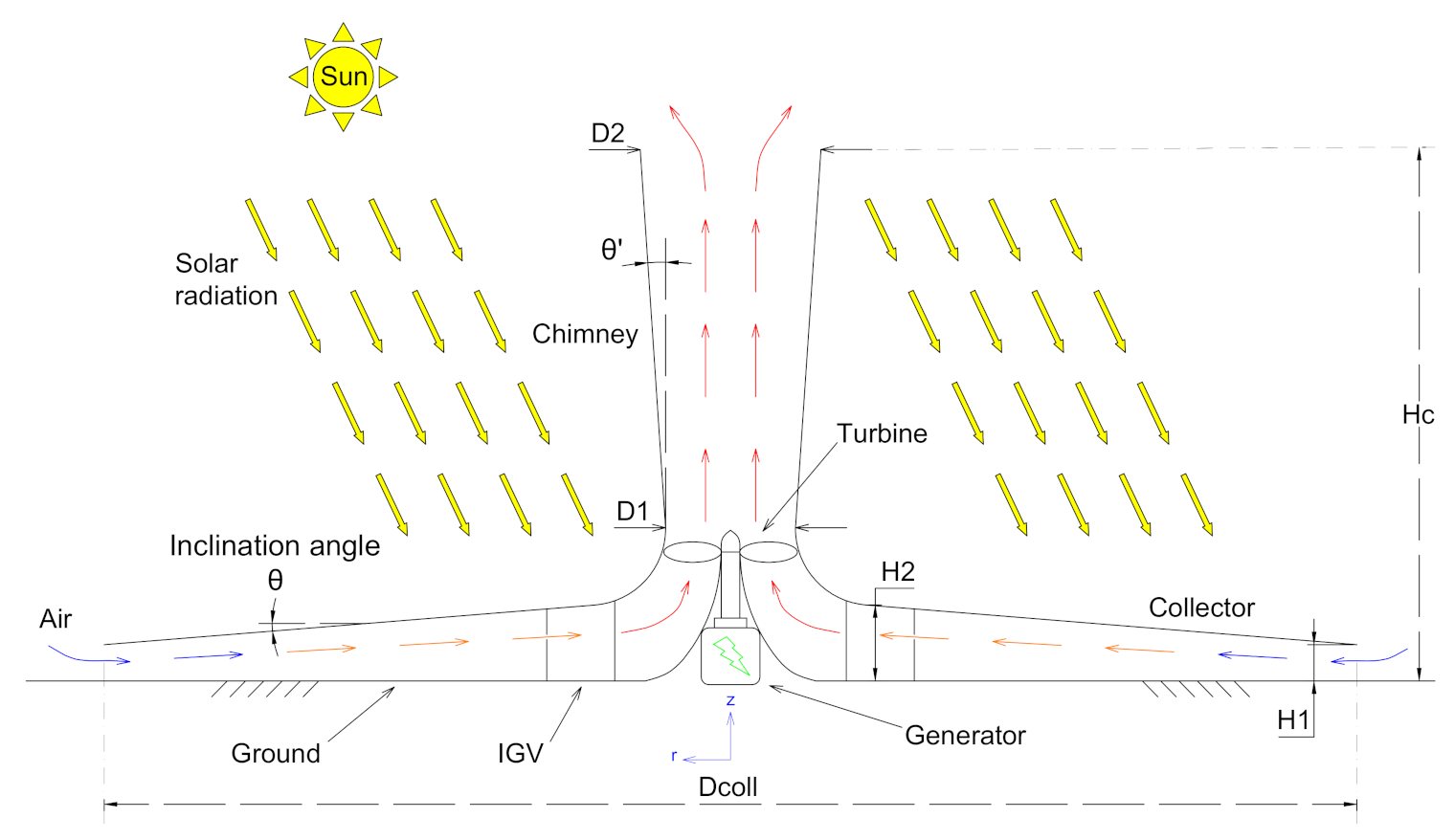

Solar chimney power plants (SCPPs) use solar radiation to increase the temperature of the air collected over a large area of ground, as shown in

Figure 1. The resulting airflow drives one or more turbines shown at the base of the chimney. Only one large-scale SCPP demonstration prototype has been built, at Manzanares, Spain [

1]. The mean collector radius was 122 m, the chimney height was 194.6 m, and the maximum output power was 37 kW. Due to its uniqueness, most of the literature on SCPP is based on analysis of, or comparisons to the Manzanares design.

The power conversion unit (PCU) comprises the turbine(s), power electronics, grid interface, and the flow passage from the collector exit to the chimney inlet [

2]. The main component of the PCU studied in this paper is the turbine.

Previous SCPP prototypes have used axial turbines in different configurations. Gannon and Von Backström ([

3,

4]) designed and tested a turbine for a SCPP. A free vortex method was used to determine the main dimensions; then a matrix throughflow method (MTM) predicted the flow trough the inlet guide vanes (IGVs) and rotor; and finally, an optimization scheme coupled to a surface vortex method generated blades of minimum chord and low drag. The authors concluded that a total-to-total efficiency of 85–90% and a total-to-static efficiency of 77–80% could be expected in a full-scale turbine. From here on, this paper considers only the total-to-total efficiency. Von Backström and Gannon [

5] presented an analytical method to find the influences of turbine flow, load coefficient, and degree of reaction on turbine efficiency for an SCPP. These characteristics were measured on a 720 mm diameter axial turbine model with 12 blades and 18 IGVs.

Denantes and Bilgen [

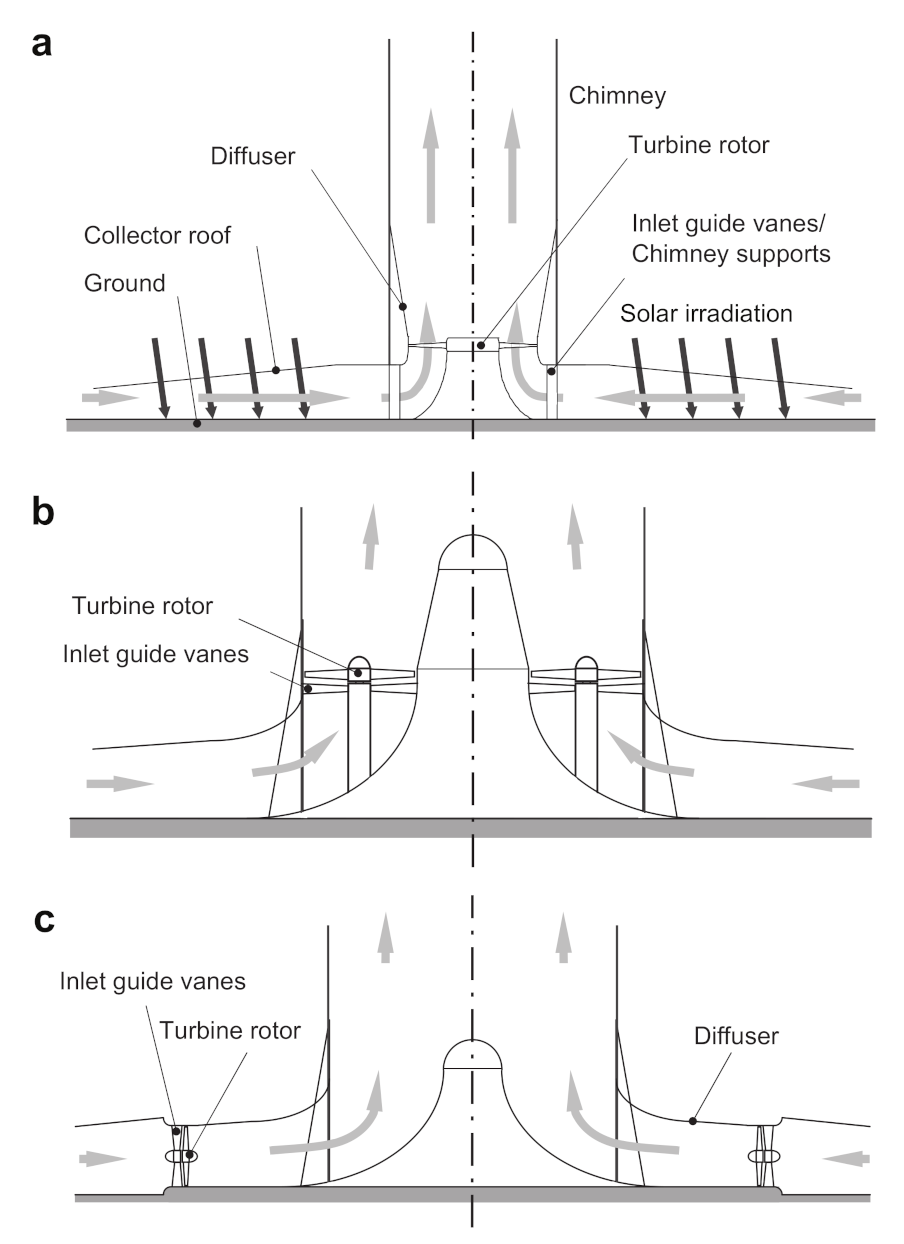

7] compared three different turbine layouts using an efficiency model: single vertical axis (VA), six VA, and 36 horizontal axes (HA), as shown in

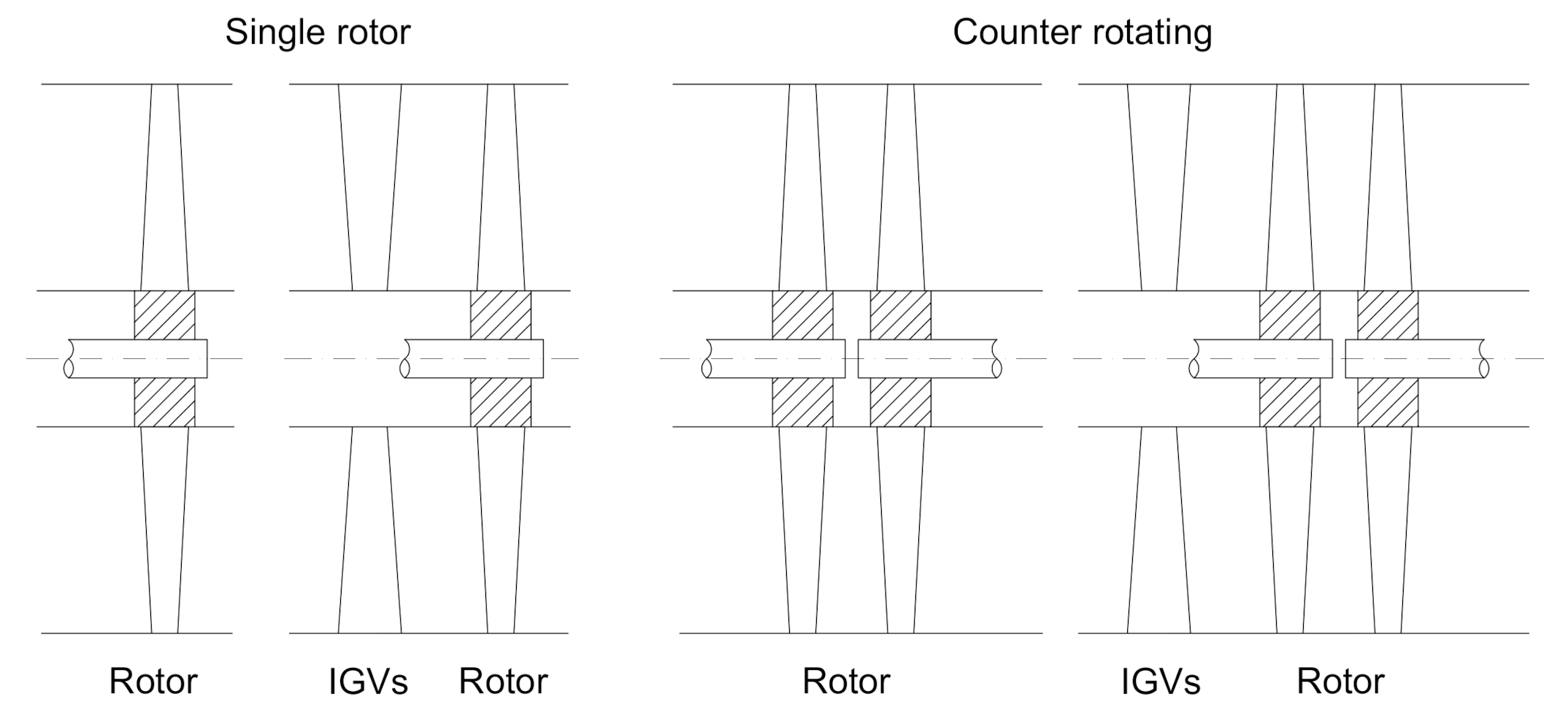

Figure 2. Two different types of turbines are shown in

Figure 3: a single runner turbine and a counter-rotating turbine with and without IGVs. The counter-rotating turbines had better performance at higher loads than the single runner turbines, but the latter showed better efficiency at solar radiation greater than 800 W/m

; SCPPs, however, work most of the time with solar radiation less than 800 W/m

. Another advantage for a counter-rotating turbine is that it can be designed without IGVs, which reduce the turbine efficiency.

Tingzhen et al. [

8] numerically simulated a 3-bladed axial turbine for the Manzanares prototype, and a 5-bladed axial turbine for another 10 MW SCPP. The 3-bladed turbine had higher rotational speed than the 4-blade axial turbine installed in the Manzanares prototype for the same power output of 50 kW. Additionally, they found that a 2-bladed turbine could not extract the same power. They concluded that a 5-bladed turbine would have a maximum power output and efficiency of 10 MW and 50%, respectively. Fluri and Von Backström [

2] analyzed the PCU in the three configurations of

Figure 2. Configuration (a) generated the highest yearly energy yield; however, the peak torque was 474.3 MNm, making its drive train costly and its feasibility doubtful. The advantage of having more turbines is the distribution of the torque over the individual generators. Each of the six vertical axis turbines operated at a peak torque of 31.3 MNm, and each of the 32 horizontal axis turbines at 2.63 MNm. It is likely that multiple turbines would be more expensive than a single turbine for the same total power.

Rangel et al. [

9] compared the VA and the HA turbines in [

2,

5] respectively to maximize the power in both configurations for the SCPP. CFD simulations showed that a VA turbine produced a maximum power of 78 kW at 58 rpm, and HA turbines produced 58 kW at 86 rpm. Zhou et al. [

10] designed an axial turbine for a SCPP with vertical collector using the NACA 63-215 airfoil; they tested the performance of a scale model of the turbine in a wind tunnel where the maximum power was around 11 W at a wind speed of 8 m/s approximately. The conclusion was that the optimum number of blades was six, and the optimum tip speed ratio, defined as the ratio between the tangential speed of the tip of a blade and the actual speed of the wind, was 1.9.

Elmagid and Keppler [

12] used the geometry of the chimney and collector of the Manzanares SCPP to design an axial turbine using free vortex analysis to find a first approximation of the blade shape. Then an MTM was used to calculate the airflow inflow and outflow angles; this method is able to simulate the radial inflow and axial outflow. A CFD simulation using ANSYS-CFX gave results in good agreement with the experimental data from [

13].

Gholamalizadeh and Chung [

14] compared three CFD models of an axial turbine in an SCPP. Two models used the standard

k-

turbulence model, and [

15] used RNG

k-

with scalable wall functions and full buoyancy effects for the flow inside the SCPP. The authors claimed that the main reason for selecting the

k-

turbulence model is to reduce the mesh resolution at the wall because the computational cost for simulations is high. There are no previous turbulence studies for radial turbines in similar applications. Zhang et al. [

16] used RNG

k-

in a mixed flow pump with guide vanes because it can accurately predict the flow separation, secondary flow, and vortex behavior in the wall region. It is a comparable study to the present one because both involve incompressible flow that changes direction, guide vanes, and curved blades.

Liu et al. [

17] used wind turbine blade design methodology to increase the efficiency of axial turbines for SCPPs. Unfortunately, they chose a 1930s airfoil, the NACA 4418, when a more modern section may have led to higher efficiency. Blade element theory was applied to determine the blade airfoil chord and pitch.

Caicedo [

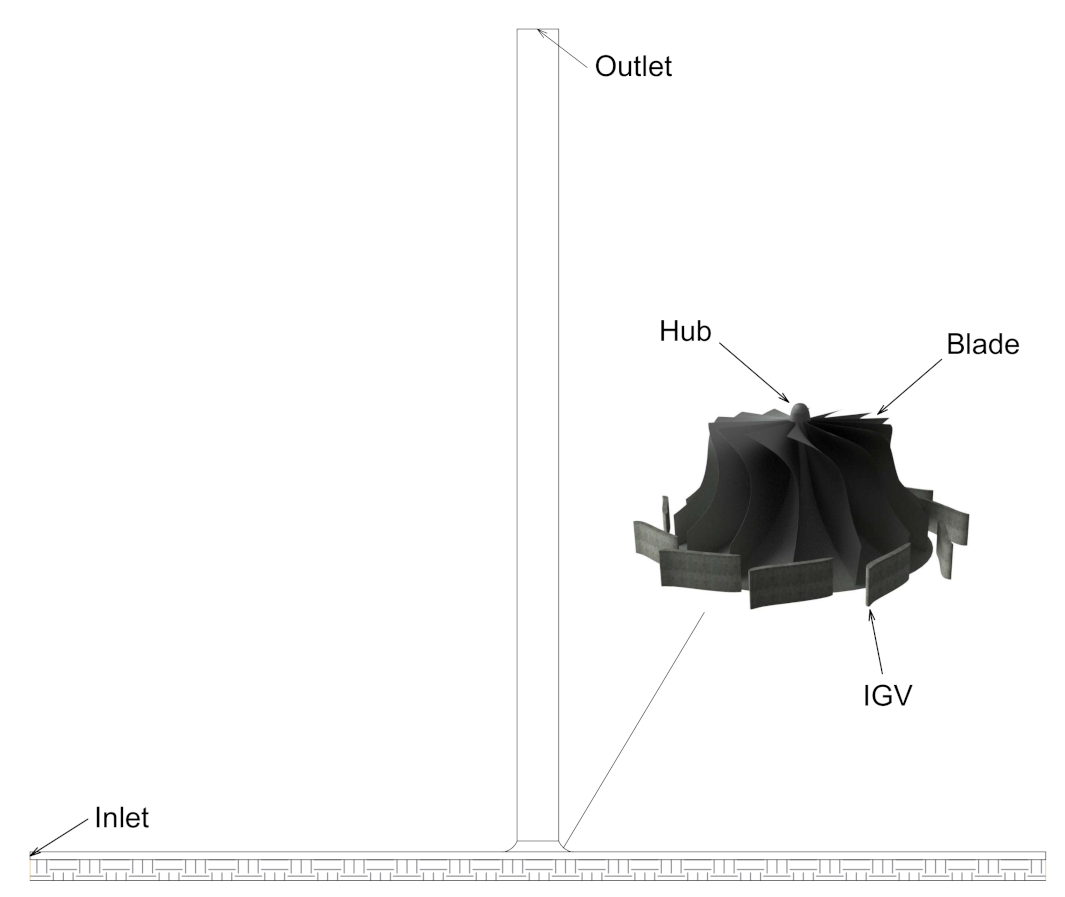

18] estimated the lifetime cost of electricity from SCPPs and summarized the findings in his Table 2.2. This shows the average cost of an SCPP turbine is 15% of the total SCPP investment, and is therefore significant. All the turbines described in this review require blade shapes that are specific to the SCPP being designed. Blades are normally made using molds so that changing the design requires making new molds. Molds, in turn, are expensive, so to improve the cost effectiveness of SCPPs, a turbine type that is new to this application and does not require expensive blade molds is proposed. This is the radial inflow (RIF) turbine shown conceptually in

Figure 4. The blades have constant thickness and so can be rolled from a metal sheet or made using thin composite material. In addition, the blades would not require the high dimensional tolerance, as is necessary for efficient blades made from airfoil sections. As the turbine is located at the base of the chimney, the installation of the generator should be easier and cheaper than for some of the axial turbines shown above. The manufacturing and installation issues are not considered any further because the radial turbine can only be cost-effective if it has high efficiency. The paper concentrates, therefore, on using CFD with models for the turbulence, buoyancy effects, heat transfer, and solar radiation, to determine the performance of the turbine that is designed using a much simpler analysis. It is not feasible to use CFD for turbine design because of the large computational cost. The interested reader can find more general aspects of SCPP design in the extensive reviews by [

10,

19].

Previous designs considered axial turbines only. The main objective of this work was to assess the performances of several radial turbine designs for the Manzanares SCPP. CFD simulations were used to predict important parameters such as efficiency, power output, rotational speed, and torque. These performance parameters are compared to those of the axial flow turbine used at Manzanares and the axial turbines reviewed above. The feasibility of implementing custom-designed, low-cost radial turbines for SCPP applications in general is discussed.

The following section documents the governing equations that are applied to the whole system.

Section 3 describes the turbine design, followed by a description of the CFD methodology. The results are presented in

Section 5 and the conclusions in

Section 6.

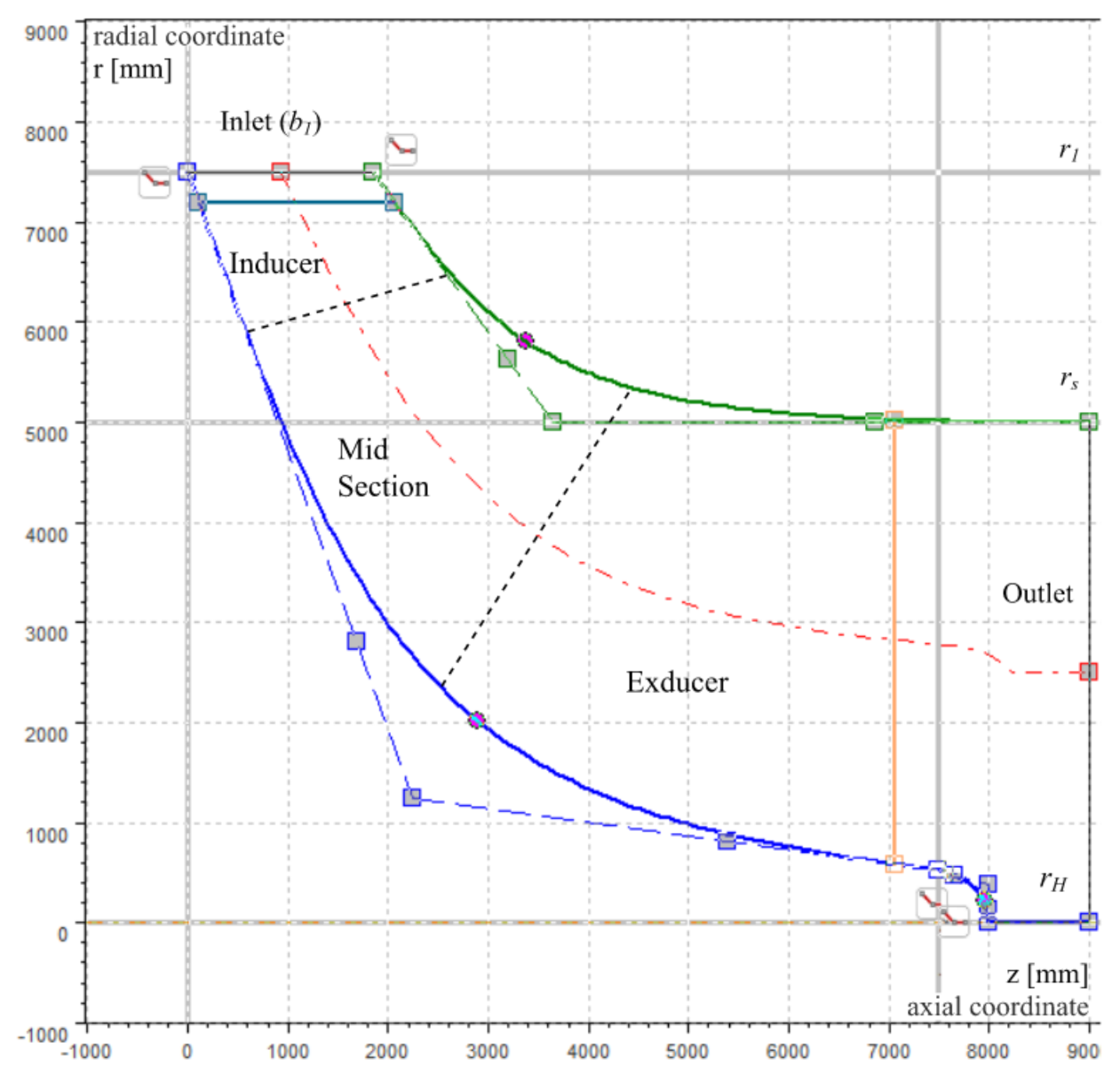

3. Turbine Design

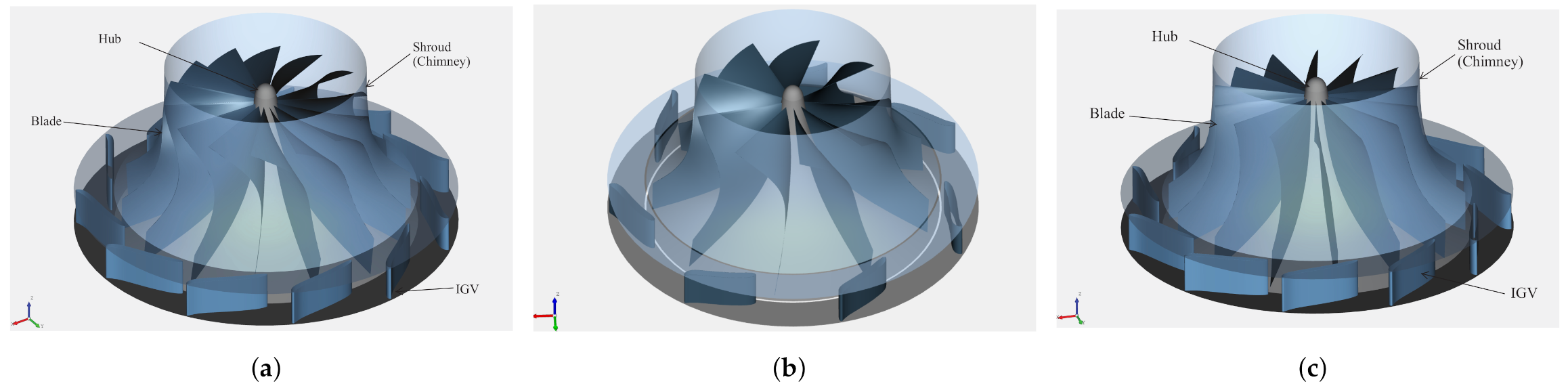

Caicedo [

18] presents the detailed design for the radial turbine, of which the following is a summary. The turbomachinery design software CFturbo 10.3 [

26] was used to design radial turbines with IGVs. This code uses simplified versions of the conservation equations to determine a parametric design for stators, rotors, and volutes. Optimizing a turbine design using CFD is not feasible due to the large computational costs, but it is necessary to use CFD to assess the design produced from CFturbo within the SCPP considering the solar model, buoyancy, and radiation. The present design considers the stator (IGVs) and rotor only because the flow enters radially to the turbine. There are two empirical equations available to determine the number of blades,

N. In the present case, they give significantly different values:

N = 14 and 9. Since

N is likely to have a big impact on turbine cost, both designs were analyzed for efficiency. The third design considered is a modification of the first (with

N = 14) to improve its efficiency.

Table 1 shows the common parameters for the three turbines. The rotor radius of the turbine was calculated from [

27], where

< 0.7 (see

Figure 5). The air density

was taken at 698 m, which is the elevation of Manzanares. A corresponding dry bulb temperature of 23

C and relative humidity of 22% were based on weather data for the month of September, 2008, at noon [

28].

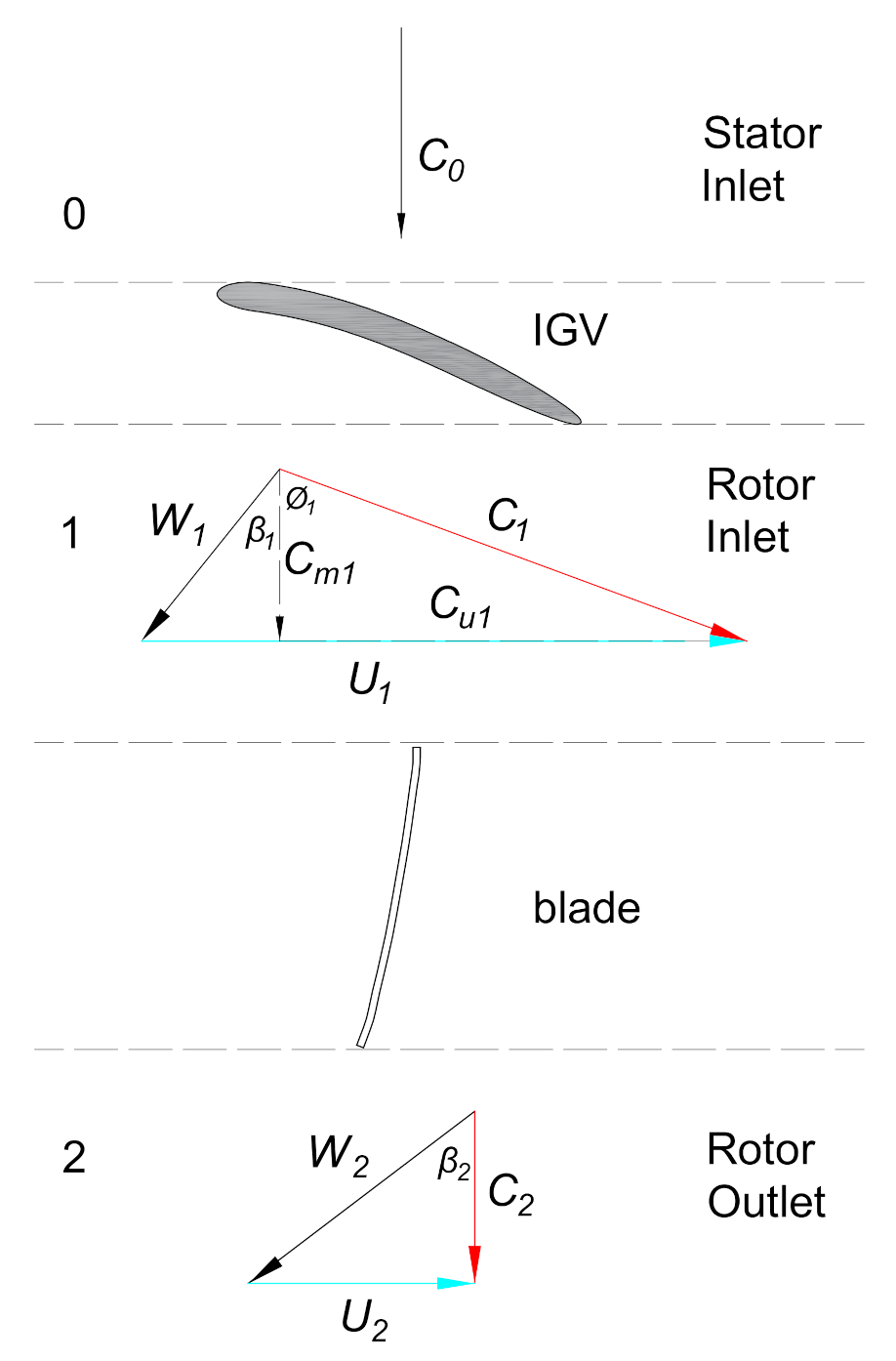

3.1. Velocity Triangles

The velocity triangles of a RIF turbine are plotted in

Figure 6, where

is the absolute velocity of the air,

U is the tangential velocity of the rotor, and

W the relative velocities of the fluid. The horizontal projection of

is

and

1 is the exit flow angle from the stator. The exit swirl is normally small due to the curvature in the blades at the rotor exit.

Two turbines are designed based on different equations to obtain the number of blades and a third one to reduce the bending stress on the blade. In the first turbine design,

1 = 74

gave maximum efficiency according to [

27];

N was calculated using the empirical relationship by Glassman from [

30]:

The equations to calculate the velocity components are obtained from the user manual for CFturbo 10.3 [

26]. The inlet velocity at the inlet of the IGVs is found using the mass flow rate given in

Table 1 whose value is set in

Section 5.1:

Once

N is set, the number of IGVs,

n, has to be chosen carefully to minimize pressure pulsations [

16], caused by the proximity of the leading edge of the rotor blades passing the trailing edge of the IGVs. This can generate mechanical load and noise which is maximized when

. The interference of the IGVs and blades cannot be calculated exactly. Instead, the design is based on

M, the difference between the periodicities, which is calculated by

where

and

are the impeller and stator periodicities, respectively, and

and

are integer multipliers. The minimum periodicity for

is 0, which is not acceptable. When 11 IGVs are specified, the optimum periodicity is

M = 3. Knowing

n, the inlet meridional velocity at the blades is calculated as

where

1 is the blockage of the flow by the IGVs in Section 1 (see

Figure 6), which depends on

t1 = 5.43 m, the circular sector of the stator, and

σ1 = 1.1 m, the blockage due to the thickness of the IGV given in

Table 1. The blockage and velocities for the IGVs are as follows:

Gholamalizadeh and Chung [

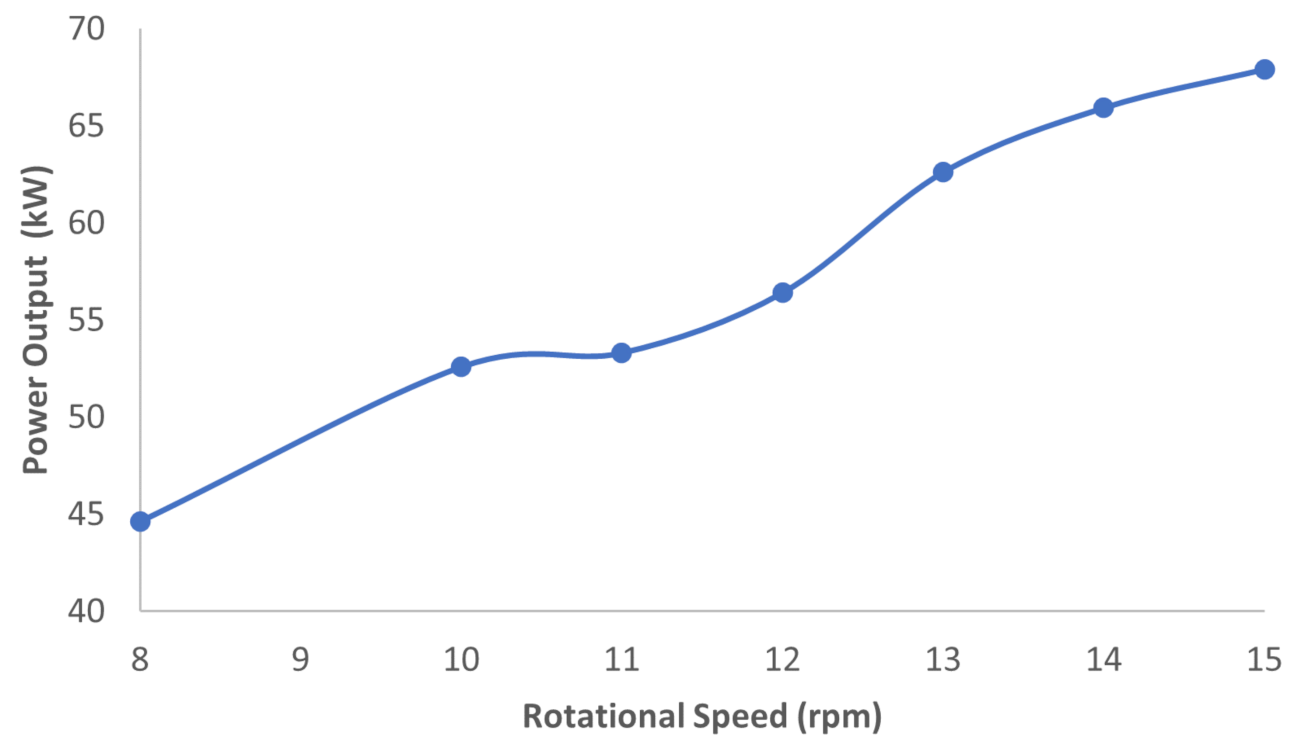

31] assessed CFD models of an axial turbine in an SCPP. The calculations were performed for a rotational velocity in the range from 80 to 180 rpm. For the RIF turbine, the rotational velocity is limited by the specific speed Ω

s and the maximum allowed value in CFturbo is

= 14 rpm. The specific speed is a dimensionless parameter that is used to determine the point of high efficiency at the design condition. A turbine can be scaled by maintaining its specific speed to different flow rates. The maximum efficiency in a radial turbine could be more than 80% within the recommended specific speed range, between 0.45 and 0.75. The value of Ω

s is calculated using equation (8.47b) from [

32] for a RIF turbine

which gives

as

At maximum efficiency there is no circumferential velocity component at the rotor outlet (

= 0). In the current work, the hub radius

= 0.6 m to maximize the opening according the geometric restrictions. The axial velocity (

=

) is calculated using the outlet area and the mass flow rate through the turbine:

The velocity components and vary with the radius. Those components are calculated iteratively by the software. The blade angles are controlled to avoid a highly twisted profile which could increase the complexity of the manufacturing process.

3.2. Stator and Rotor Geometry Design

An SCPP needs columns to support the chimney, which it is assumed to be integrated with the IGVs as was assumed in [

5]. These structural elements should be aerodynamic to minimize their effect on the turbine efficiency. This design considers IGVs with elliptical shapes at the leading and trailing edge to have low drag. Their thickness and length are 0.3 m and 1.9 m, respectively; these are default values recommended by the software. CFturbo allows modification of the curvature of the blades in the hub and shroud with Bezier curves as shown in the meridional contour in

Figure 5. It is assumed that the blades are made from metal sheet whose thickness is too small to influence the velocities. The required thickness was calculated using a stress analysis by Caicedo [

18].

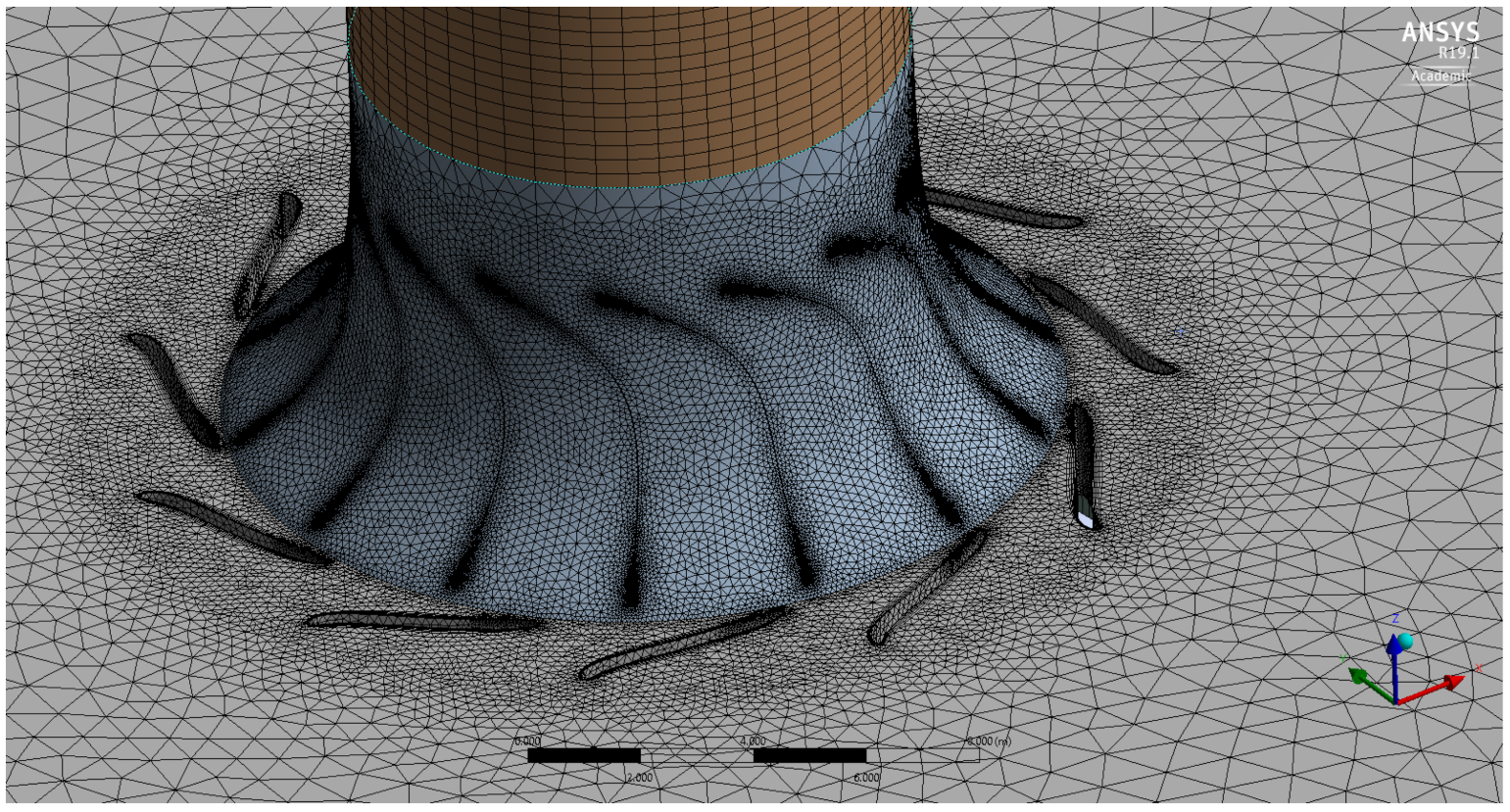

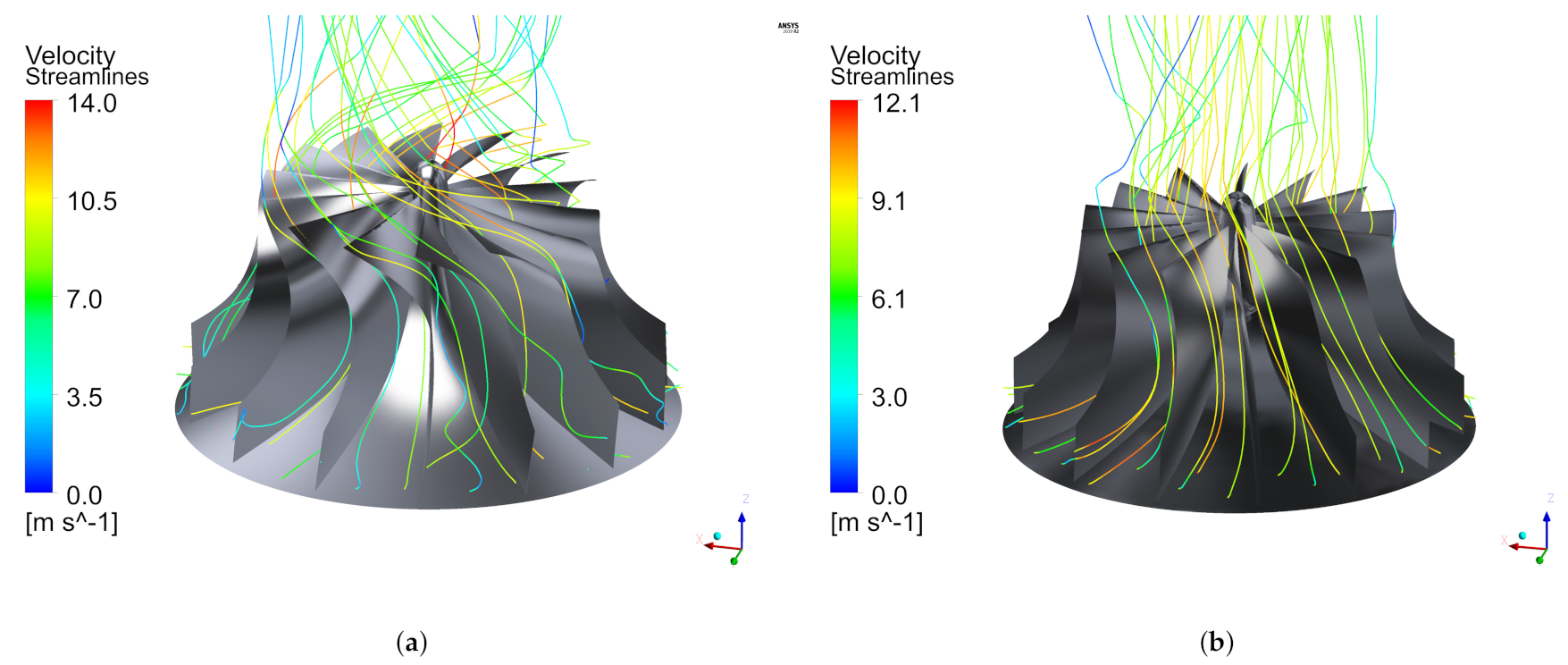

A CAD rendering of the first turbine model is shown in

Figure 7a. The resulting CAD geometry was exported to ANSYS for meshing in preparation of CFD analysis as shown in

Figure 8. The easiest way to reduce turbine and installation costs is to minimize

N. The second design used an inlet angle as defined in

Figure 6 of

ϕ1 = 70

.

N was calculated using Whitfield’s relationship which is Equation (8.31c) from [

32]. The result was

The number of IGVs in the stator was found using Equation (

12) and

M = 2, the lowest recommended value.

The third design considers an approximately straight blade profile at the exducer that reduces the stress due to the bending moment caused in large turbines by their own weight.

Figure 7c shows that turbine design with 14 blades. The trailing edge has a minimum curvature to reduce the circumferential velocity.

N = 14 was used for the first and third turbines to lower the impeller-stator interference as calculated by

M compared to

. CFD simulations will determine if the increase in

N is worthwhile.