Thermal Performance of a Cylindrical Lithium-Ion Battery Module Cooled by Two-Phase Refrigerant Circulation

Abstract

:1. Introduction

2. Experimental

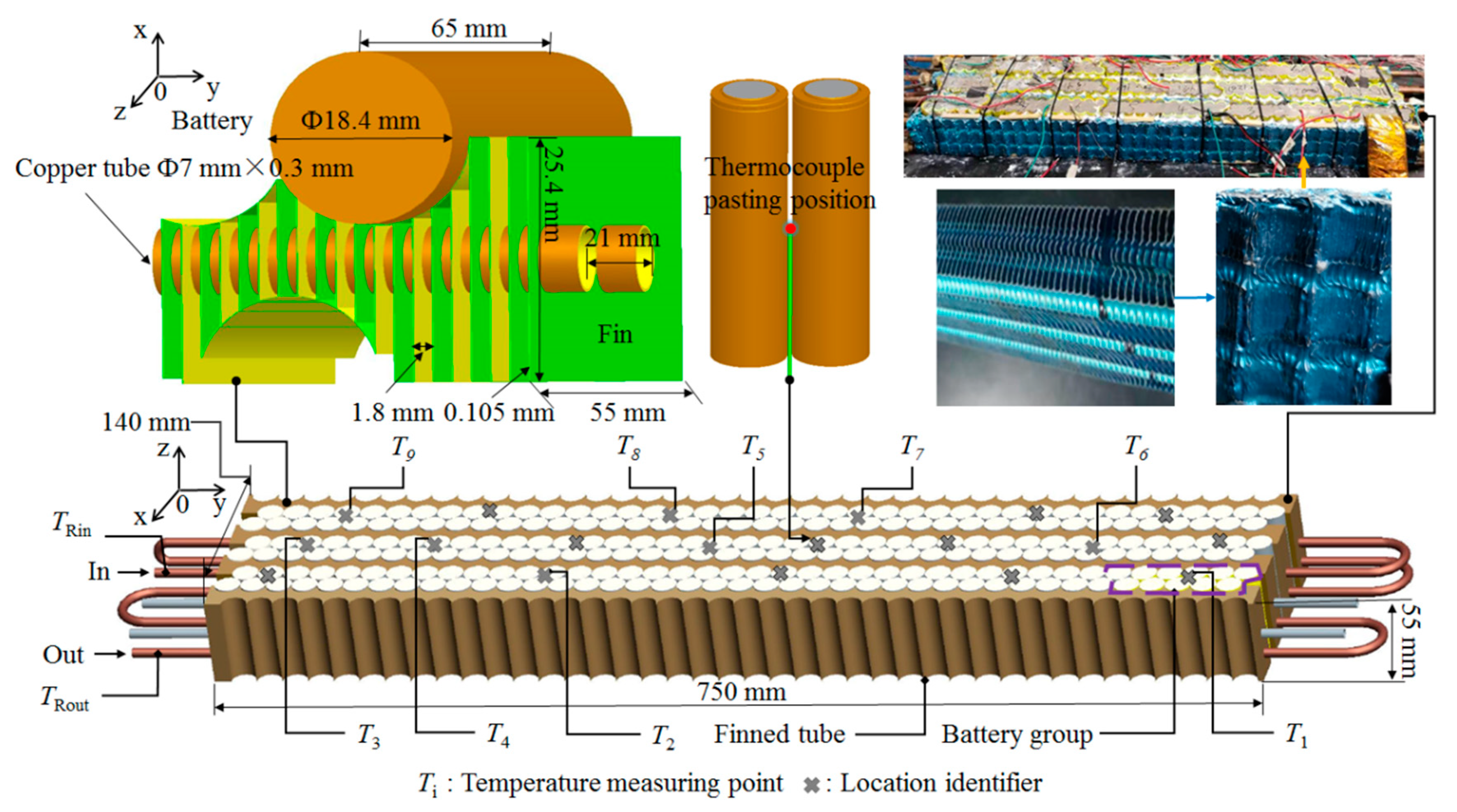

2.1. Battery Module Structure

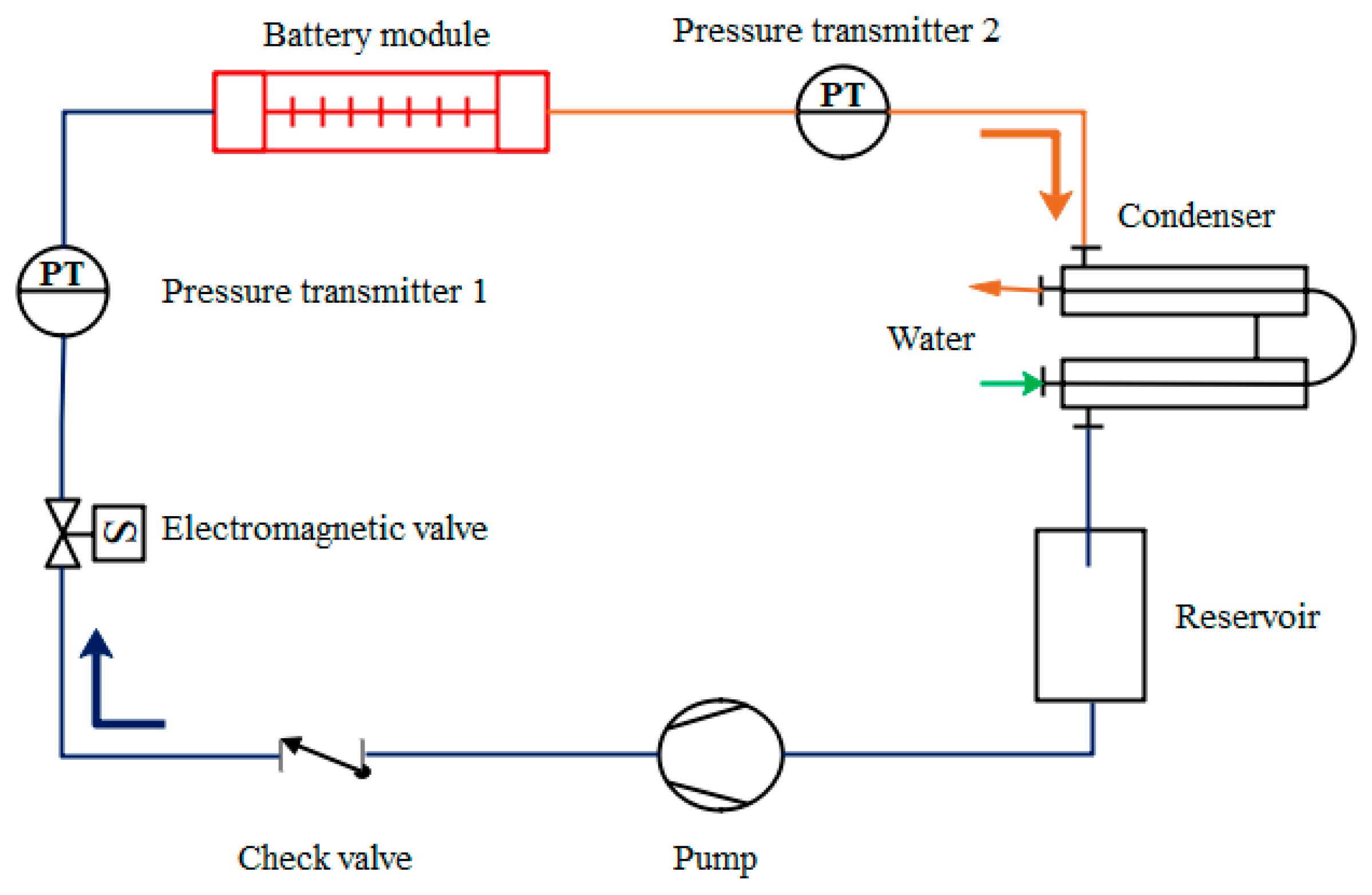

2.2. Experimental System

2.3. Experimental Conditions

3. Results and Analysis

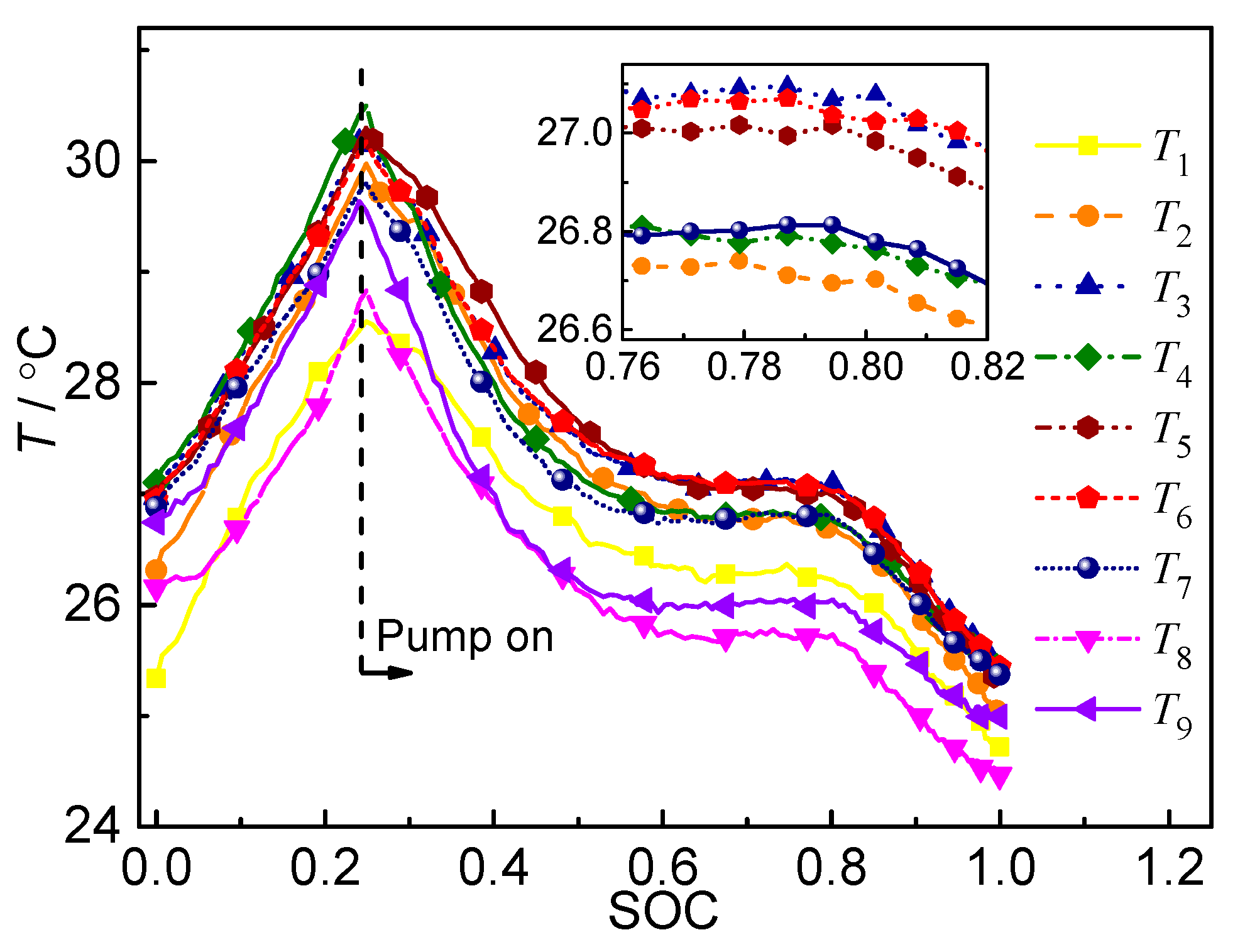

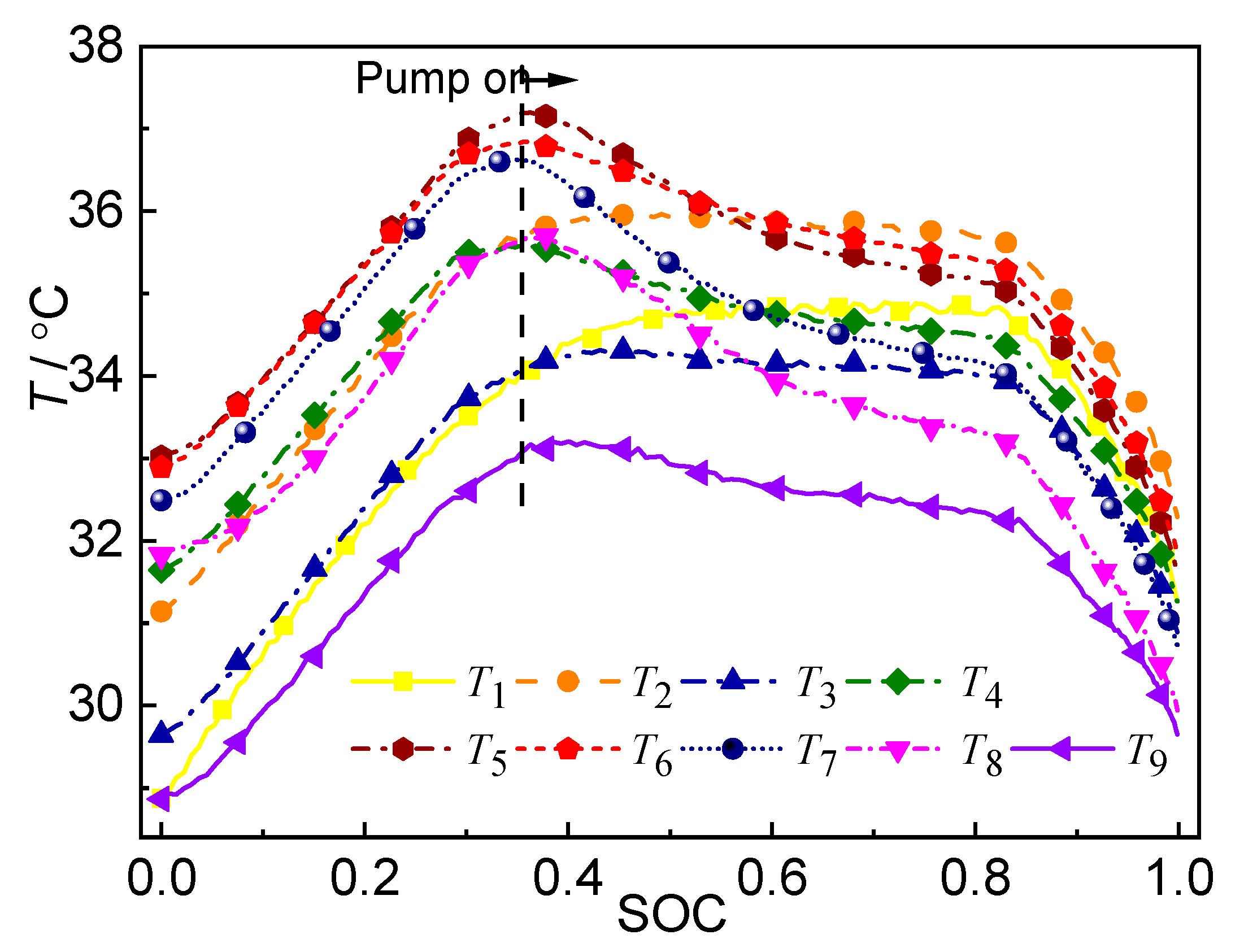

3.1. Constant Pump Frequency Mode

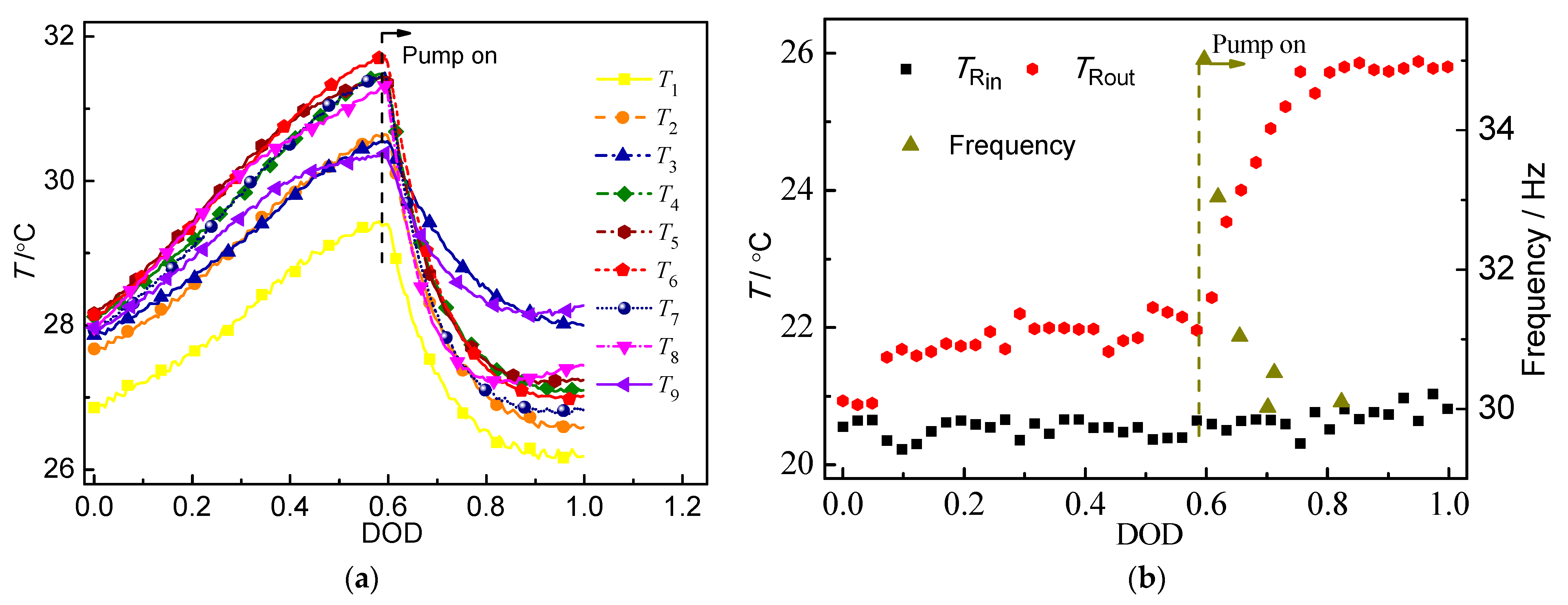

3.2. Variable Pump Frequency Mode

3.3. Severe Operation with Large Initial Temperature Difference

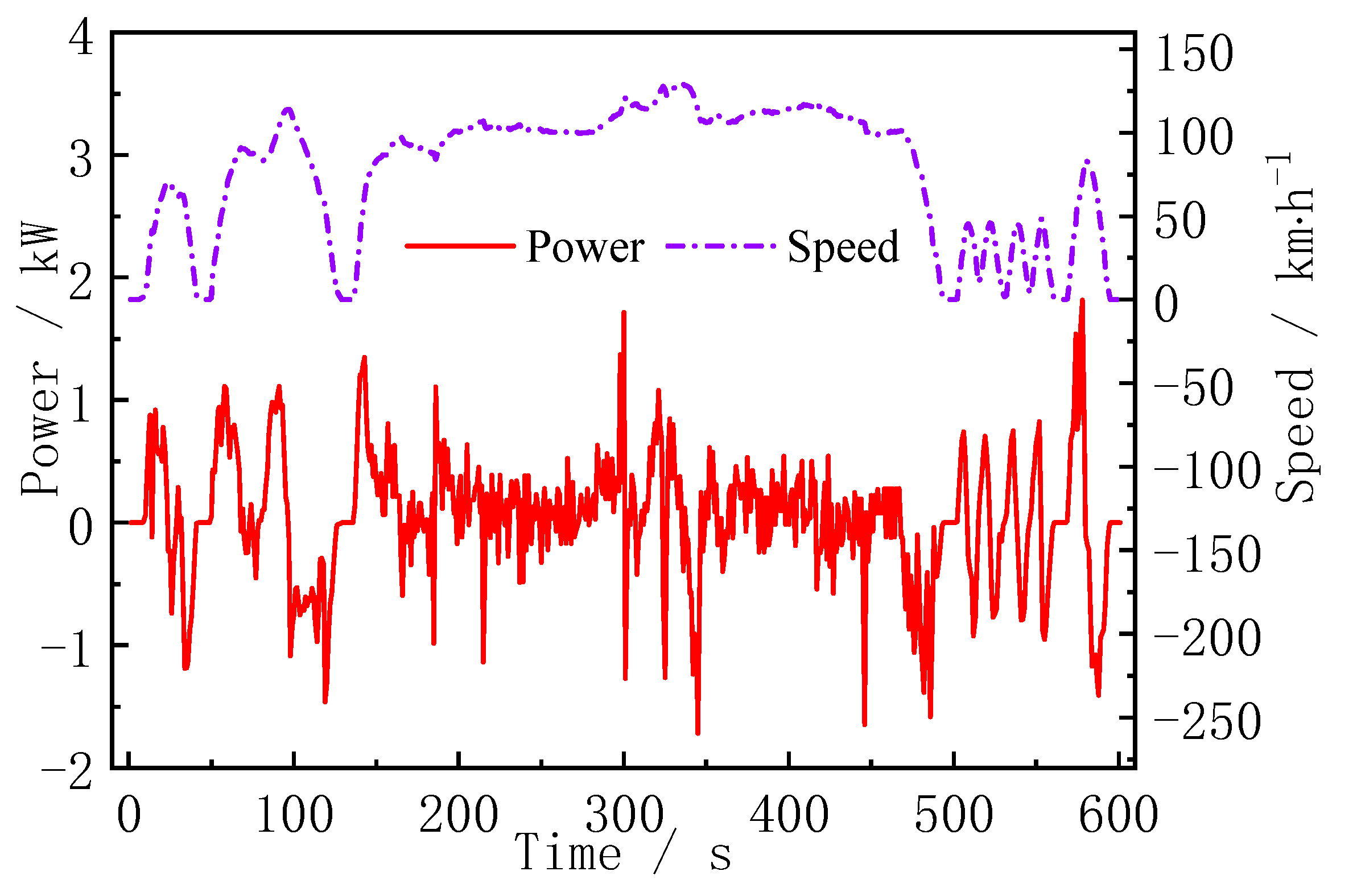

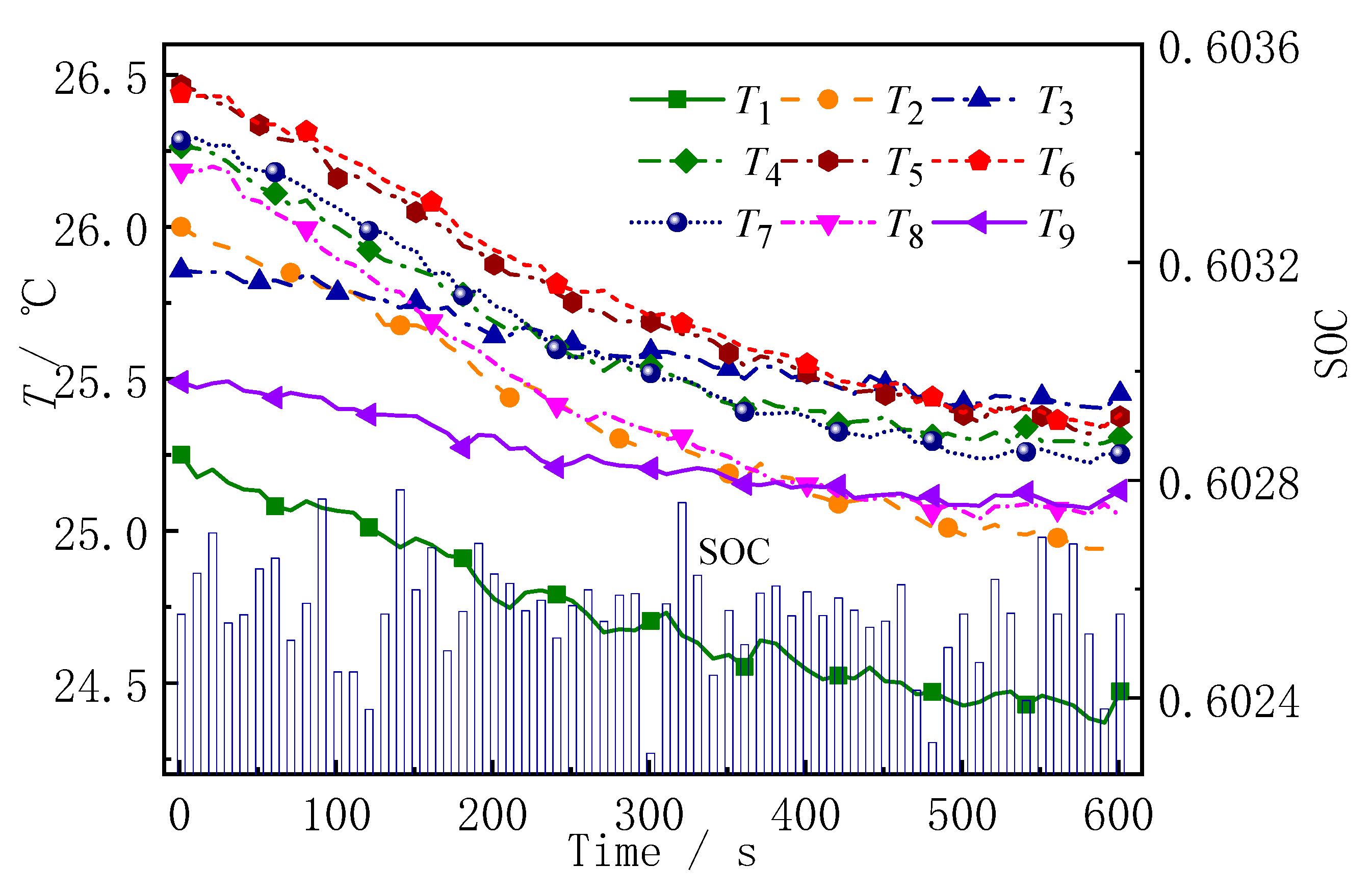

3.4. Discharge with Simulated Road Driving Conditions

4. Conclusions

- (1)

- When the battery module was charged and discharged at the C-rates considered, the refrigerant circulating cooling system could maintain the battery module within the optimum temperature range. Compared with the 0.5 °C charge process, the 1 °C discharge process, which generates more heat, showed a greater temperature uniformity. Nevertheless, the temperature difference in the battery module remained about 2.0–2.5 °C during the tested 1 °C discharge process.

- (2)

- During the tested 0.6 C discharge process, the temperature of the battery module was approximately constant when gradually reducing the pump frequency from the initial 35 Hz to 30.1 Hz.

- (3)

- In the tested battery charging case with severe working conditions (i.e., a large initial temperature difference), the refrigerant cooling system could effectively control the rise in battery temperature and also reduce the temperature difference.

- (4)

- The refrigerant circulating battery cooling system could meet the cooling requirements of the battery pack operating under the US06 cycle.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Rao, Z.; Wang, S. A review of power battery thermal energy management. Renew. Sustain. Energy Rev. 2011, 15, 4554–4571. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, Q.; Ping, P.; Zhao, X.; Sun, J.; Lin, Z. Heat transfer in the dynamic cycling of lithium–titanate batteries. Int. J. Heat Mass Transf. 2016, 93, 896–905. [Google Scholar] [CrossRef]

- Qian, L. A thermal-structure coupled optimization study of lithium-ion battery modules with mist cooling. Int. J. Energy Res. 2020, 44, 12295–12311. [Google Scholar] [CrossRef]

- Wilke, S.; Schweitzer, B.; Khateeb, S.; Al-Hallaj, S. Preventing thermal runaway propagation in lithium ion battery packs using a phase change composite material: An experimental study. J. Power Source 2017, 340, 51–59. [Google Scholar] [CrossRef]

- Wang, Q.; Ping, P.; Zhao, X.; Chu, G.; Sun, J.; Chen, C. Thermal runaway caused fire and explosion of lithium ion battery. J. Power Source 2012, 208, 210–224. [Google Scholar] [CrossRef]

- Chiu, K.-C.; Lin, C.-H.; Yeh, S.-F.; Lin, Y.-H.; Huang, C.-S.; Chen, K.-C. Cycle life analysis of series connected lithium-ion batteries with temperature difference. J. Power Source 2014, 263, 75–84. [Google Scholar] [CrossRef]

- Fleckenstein, M.; Bohlen, O.; Roscher, M.A.; Bäker, B. Current density and state of charge inhomogeneities in Li-ion battery cells with LiFePO4 as cathode material due to temperature gradients. J. Power Source 2011, 196, 4769–4778. [Google Scholar] [CrossRef]

- Zhao, R.; Zhang, S.; Liu, J.; Gu, J. A review of thermal performance improving methods of lithium ion battery: Electrode modification and thermal management system. J. Power Source 2015, 299, 557–577. [Google Scholar] [CrossRef]

- Bandhauer, T.M.; Garimella, S.; Fuller, T.F. A critical review of thermal issues in Lithium-Ion batteries. J. Electrochem. Soc. 2011, 158, R1. [Google Scholar] [CrossRef]

- Waldmann, T.; Wilka, M.; Kasper, M.; Fleischhammer, M.; Wohlfahrt-Mehrens, M. Temperature dependent ageing mechanisms in Lithium-ion batteries–A Post-Mortem study. J. Power Source 2014, 262, 129–135. [Google Scholar] [CrossRef]

- Chung, Y.; Kim, M.S. Thermal analysis and pack level design of battery thermal management system with liquid cooling for electric vehicles. Energy Convers. Manag. 2019, 196, 105–116. [Google Scholar] [CrossRef]

- Greco, A.; Jiang, X.; Cao, D. An investigation of lithium-ion battery thermal management using paraffin/porous-graphite-matrix composite. J. Power Source 2015, 278, 50–68. [Google Scholar] [CrossRef]

- Panchal, S.; Khasow, R.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Thermal design and simulation of mini-channel cold plate for water cooled large sized prismatic lithium-ion battery. Appl. Therm. Eng. 2017, 122, 80–90. [Google Scholar] [CrossRef]

- Lai, Y.; Wu, W.; Chen, K.; Wang, S.; Xin, C. A compact and lightweight liquid-cooled thermal management solution for cylindrical lithium-ion power battery pack. Int. J. Heat Mass Transf. 2019, 144, 118581. [Google Scholar] [CrossRef]

- Chen, D.; Jiang, J.; Kim, G.-H.; Yang, C.; Pesaran, A. Comparison of different cooling methods for lithium ion battery cells. Appl. Therm. Eng. 2016, 94, 846–854. [Google Scholar] [CrossRef] [Green Version]

- Temel, U.N. Passive thermal management of a simulated battery pack at different climate conditions. Appl. Therm. Eng. 2019, 158, 113796. [Google Scholar] [CrossRef]

- Chen, F.; Huang, R.; Wang, C.; Yu, X.; Liu, H.; Wu, Q.; Qian, K.; Bhagat, R. Air and PCM cooling for battery thermal management considering battery cycle life. Appl. Therm. Eng. 2020, 173, 115154. [Google Scholar] [CrossRef]

- Smith, J.; Singh, R.; Hinterberger, M.; Mochizuki, M. Battery thermal management system for electric vehicle using heat pipes. Int. J. Therm. Sci. 2018, 134, 517–529. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, S.; Wu, M.; Lin, Z.; Li, F. Experimental investigation on thermal management of electric vehicle battery with heat pipe. Energy Convers. Manag. 2013, 65, 92–97. [Google Scholar] [CrossRef]

- Al-Zareer, M.; Dincer, I.; Rosen, M.A. Heat and mass transfer modeling and assessment of a new battery cooling system. Int. J. Heat Mass Transf. 2018, 126, 765–778. [Google Scholar] [CrossRef]

- Wu, W.; Wang, S.; Wu, W.; Chen, K.; Hong, S.; Lai, Y. A critical review of battery thermal performance and liquid based battery thermal management. Energy Convers. Manag. 2019, 182, 262–281. [Google Scholar] [CrossRef]

- Lu, M.; Zhang, X.; Ji, J.; Xu, X.; Zhang, Y. Research progress on power battery cooling technology for electric vehicles. J. Energy Storage 2020, 27, 101155. [Google Scholar] [CrossRef]

- Liu, H.; Chika, E.; Zhao, J. Investigation into the effectiveness of nanofluids on the mini-channel thermal management for high power lithium ion battery. Appl. Therm. Eng. 2018, 142, 511–523. [Google Scholar] [CrossRef]

- Zhang, W.; Liang, Z.; Wu, W.; Ling, G.; Ma, R. Design and optimization of a hybrid battery thermal management system for electric vehicle based on surrogate model. Int. J. Heat Mass Transf. 2021, 174, 121318. [Google Scholar] [CrossRef]

- Bandhauer, T.M.; Garimella, S. Passive, internal thermal management system for batteries using microscale liquid–vapor phase change. Appl. Therm. Eng. 2013, 61, 756–769. [Google Scholar] [CrossRef]

- Park, S.; Jang, D.S.; Lee, D.; Hong, S.H.; Kim, Y. Simulation on cooling performance characteristics of a refrigerant-cooled active thermal management system for lithium ion batteries. Int. J. Heat Mass Transf. 2019, 135, 131–141. [Google Scholar] [CrossRef]

- Hong, S.H.; Jang, D.S.; Park, S.; Yun, S.; Kim, Y. Thermal performance of direct two-phase refrigerant cooling for lithium-ion batteries in electric vehicles. Appl. Therm. Eng. 2020, 173, 115213. [Google Scholar] [CrossRef]

- Cen, J.; Li, Z.; Jiang, F. Experimental investigation on using the electric vehicle air conditioning system for lithium-ion battery thermal management. Energy Sustain. Dev. 2018, 45, 88–95. [Google Scholar] [CrossRef]

- Kim, J.; Oh, J.; Lee, H. Review on battery thermal management system for electric vehicles. Appl. Therm. Eng. 2019, 149, 192–212. [Google Scholar] [CrossRef]

- Hamut, H.S.; Dincer, I.; Naterer, G.F. Performance assessment of thermal management systems for electric and hybrid electric vehicles. Int. J. Energy Res. 2012, 37, 1–12. [Google Scholar] [CrossRef]

- Hayes, J.G.; de Oliveira, R.P.R.; Vaughan, S.; Egan, M.G. Simplified electric vehicle power train models and range estimation. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011; pp. 1–5. [Google Scholar]

| Parameter Name | Diameter /mm | Height /mm | Rated Capacity /mA·h | Operating Voltage /V |

|---|---|---|---|---|

| Value | Φ18.4 | 65 | 2600 | 3.0~4.2 |

| Pump | Frequency Converter |

|---|---|

| Power: 120 W | Rated capacity: 1.9 kVA |

| Flow: 130~218 L/h | Input current: 12.8 A |

| Head: 90~310 kPa | Rated output current: 5 A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, B.; Cen, J.; Jiang, F. Thermal Performance of a Cylindrical Lithium-Ion Battery Module Cooled by Two-Phase Refrigerant Circulation. Energies 2021, 14, 8094. https://doi.org/10.3390/en14238094

Lin B, Cen J, Jiang F. Thermal Performance of a Cylindrical Lithium-Ion Battery Module Cooled by Two-Phase Refrigerant Circulation. Energies. 2021; 14(23):8094. https://doi.org/10.3390/en14238094

Chicago/Turabian StyleLin, Bichao, Jiwen Cen, and Fangming Jiang. 2021. "Thermal Performance of a Cylindrical Lithium-Ion Battery Module Cooled by Two-Phase Refrigerant Circulation" Energies 14, no. 23: 8094. https://doi.org/10.3390/en14238094

APA StyleLin, B., Cen, J., & Jiang, F. (2021). Thermal Performance of a Cylindrical Lithium-Ion Battery Module Cooled by Two-Phase Refrigerant Circulation. Energies, 14(23), 8094. https://doi.org/10.3390/en14238094