3.1. Rotational Speeds and Power of Closely Spaced VAWTs

Figure 8 shows the variation in the rotational speed

N [rpm] with the gap between the two rotors,

g. The results for the CO, CU, and CD configurations are presented in

Figure 8a–c, respectively. We define the average rotational speed of rotors (Rotor 1 and Rotor 2) as

Nave. In the experimental rotor, the achieved rotational speed depended on subtle differences in alignment between the turbine rotor and the direct current motor. The free rotational speed in the case of the single-rotor

NSI was carefully adjusted 2720 ± 10 rpm at

y = 0 mm (see

Figure 4), just before each double-rotor experiment. This is the most difficult task for the experiment, and it usually takes half a day. The rotational direction of each rotor is the same as in

Figure 2. The values of

Nave were 2763 rpm, 2733 rpm, and 2770 rpm at

g/

D = 2.0 for CO, CU, and CD, respectively. The rotational speed of the isolated rotor obtained in the experiments was lower than the value (3153 rpm) expected from the results presented in

Figure 3. This may be attributed to differences in the turbulent intensities of the wind tunnels in different institutes, in addition to the subtle differences in alignment. Since the turbulent intensity (

T.I.) in the freestream has a possibility to improve the blade aerodynamic efficiency by increasing the lift-to-drag ratio (as suggested by Ahmadi-Baloutaki et al. [

13] based on Devinant et al. [

18]), the isolated model rotor may rotate at higher speed with the wind tunnel at the Tottori university (

T.I. < 5%) compared with the experiments at the Kagawa college (

T.I. < 2%).

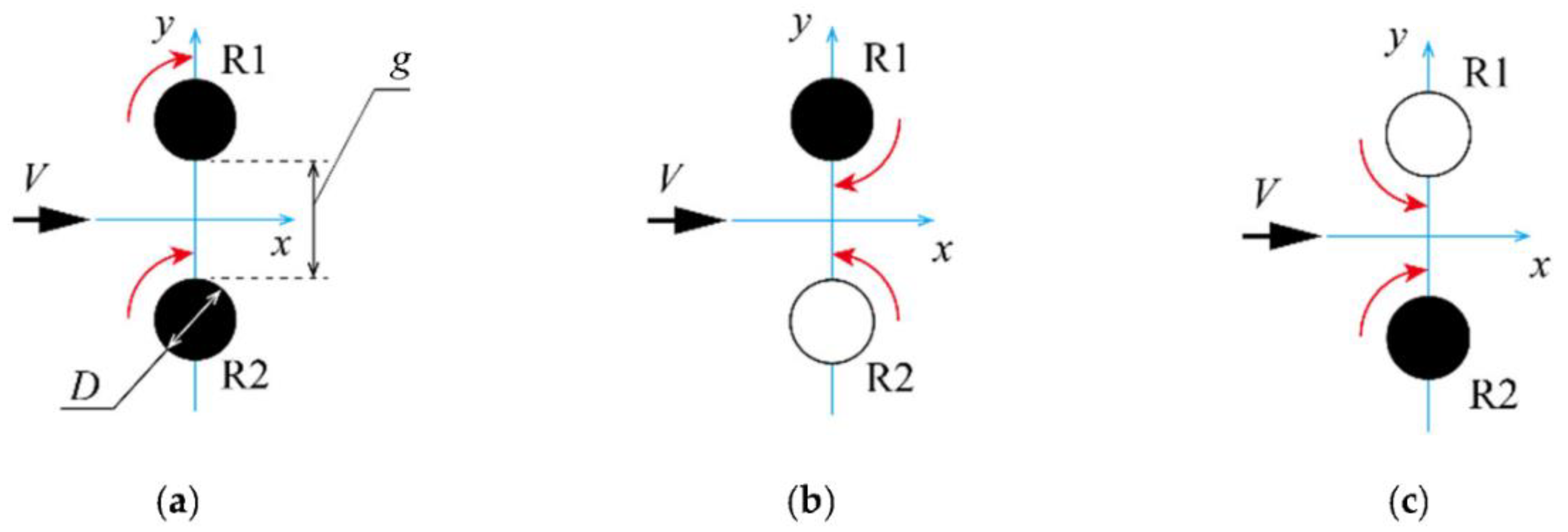

First, in the CO configuration in

Figure 8a, the rotational speed of Rotor 1 (R1) increased as the gap decreased. An increase in the power of Rotor 1 was indicated by acceleration. The maximum increase in the rotational speed reached 6.3% of

NSI. Meanwhile, in Rotor 2 (R2), there was little change in the rotational speed with a decreased gap, except in the case of the smallest gap. The maximum decrease in the rotational speed of Rotor 2 reached 1.5% of

NSI. Note that the speed of Rotor 1 is always higher than that of Rotor 2. This is in good agreement with the CFD results obtained by Hara et al. [

5]. Between the two VAWTs, the blades of Rotor 1 proceed in the opposite direction (negative

x-direction) to the gap flow (

x-direction), whereas the rotational direction of the blades of Rotor 2 is the same as the gap flow. The higher rotational speed of Rotor 1 can be explained by the strong induced velocity caused by Rotor 2 (see reference De Tavernier et al. [

3]). The sharp reduction in the rotational speed of Rotor 2 at the minimum gap is attributed to the induced velocity of Rotor 1. The increase in the average rotational speed of the two turbines corresponds to the power density, which is defined as the power output per unit land area.

Second, in the CU configuration in

Figure 8b, the rotational speeds of both Rotor 1 and Rotor 2 slightly increase with the decreasing gap until it reaches

g = 25–50 mm. Conversely, with a reduction in the gap of less than 25 mm, both rotors start to decelerate. As a whole in the CU configuration, compared with the cases of CO and CD, the rotational speeds of Rotor 1 and Rotor 2 do not change much with a decrease in gap until the smallest gap examined. This indicates the insensitivity of the rotational speed of the CU configuration against gap variation. Note that the almost constant difference in rotational speeds between Rotor 1 and 2 is attributed to the individual difference of rotors and slight miss-alignment.

Last, in the CD configuration presented in

Figure 8c, both Rotor 1 and 2 demonstrate a significant increase in the rotational speed with a decrease in gap until the smallest gap tested is reached. The most interesting finding is the “

phase-synchronized rotation” (Jodai et al. [

19]; Hara et al. [

20]; Hara and Jodai [

21]) between both rotors when the gap is equal to or less than 15 mm (

g/

D ≤ 0.3), as a result of the dynamic interaction between VAWTs. The synchronized rotation has also been reported by Vergaerde et al. [

15] based on an experiment at

g/

D = 0.3 using two-bladed Darrieus turbines with NACA 0018 airfoil. Vergaerde et al. [

15] explained the synchronization that the rotational speeds equalize, and the phase difference between both rotors converges consistently to a mean value. In our experiments, the maximum rotational speed at

g/

D = 0.1 reached 113% of

NSI. To the best of our knowledge, this is the first experiment to show a steep rise in the rotational speed in the extreme gap of

g/

D = 0.1 accompanied by the phase-synchronization. Note that this synchronism automatically occurs after 30–120 s (the rotational speeds of both Rotor 1 and 2 increase gradually during the time period), depending on the gap and the initial rotor speeds. This suggests that a relatively long simulation time is necessary to replicate the synchronistic effect in an unsteady CFD for solving dynamic interaction.

Recently, the CFD results obtained by Hara et al. [

5] revealed a relatively large fluctuation in the rotational speeds of both rotors with the ‘opposite phase’ (the blades move downwind in the gap region simultaneously) in the case of CD configuration with a short gap of

g/

D = 0.2. These are the first reproduction of the phase-synchronization of two VAWT rotors via CFD analysis. They also demonstrated phase-synchronization in the case of

g/

D = 0.3 of the CU layout, though phase-synchronization was not observed in the CD layout with

g/

D = 0.3. More details of the mechanism of phase-synchronization generation are given in the paper by Hara et al. [

5].

Next, we examine the normalized rotational speed

Nnorm and the normalized power

Pnorm based on the average rotational speed

Nave and the average power

Pave, and clarify the effects of the double rotor configuration. Here,

Nnorm and

Pnorm are defined in Equations (3) and (4), respectively. Note that

Pave and the power in the case of the single-rotor

PSI are obtained using Equation (2).

Figure 9 shows the gap dependence of

Nnorm and

Pnorm of a pair of VAWT models arranged side-by-side. The gap between the two rotors (

g on the abscissa) is also nondimensionalized with the diameter of each rotor

D. Regardless of the layout type, as the gap decreased, the normalized rotational speed (

Figure 9a) and the normalized power (

Figure 9b) increased gradually until

g/

D reached 0.5–1.0. This supports the findings obtained by Hara et al. [

5] via CFD analysis (normalized power is shown in

Figure 9c). For CO, the maximum increase in the normalized rotational speed

Nnorm occurs at

g/

D = 0.2–0.5, which is 4–5% of the

NSI (

Figure 9a). For CU, the maximum increase in

Nnorm is only 2% of the

NSI. The decreasing tendency of

Nnorm and

Pnorm at a narrower gap for CU is important, which is also consistent with the CFD result by Hara et al. [

5]. On the other hand,

Nnorm for CD shows a significant increase at

g/

D < 0.5 and the maximum increase in

Nnorm or in

Pnorm occurs at

g/

D = 0.1, which is 13% of the

NSI or 15% of the

PSI.

Therefore, in order to obtain higher power generation using the acceleration of the closely arranged VAWTs, the gaps of

g/

D ≤ 0.5 for CO and CD are recommended. Comparing the values of the normalized rotational speeds or the normalized power shown in

Figure 9a,b, the relation CD > CO > CU is evident, which is in agreement with the CFD result at the narrowest gap by Hara et al. [

5] shown in

Figure 9c. Zanforlin and Nishino [

2] obtained the same relation (CD > CU) via CFD analysis using 2-D rotors with a medium solidity

σ = 0.102 (

Table 1).

This differs significantly from the result reported by De Tavernier et al. [

3] with a small solidity (

σ = 0.032), where CU was identified as best configuration (see

Figure 8 in De Tavernier et al. [

3]; at

g/

D = 0.2, the power coefficient for CU was the highest, and that for CD was the lowest). Our result, showing higher rotational speeds for CD than for CU at

g/

D < 0.5, is also in opposition to the result obtained by Vergaerde et al. [

15], in which the power coefficient for CU was higher than that for CD at

g/

D = 0.3 (see their

Figure 7). Note that Vergaerde et al. [

15] reported only the case of

g/

D = 0.3, which may not be sufficiently small to realize a strong synchronization for their experiments. The discrepancy could be attributed to the differences in solidity. According to the references (Ahmadi-Baloutaki et al. [

13]; Thomas [

22]), high solidity wind turbines (such as

σ = 0.382 in our study compared to a small solidity, whose value is unknown, of Vergaerde et al. [

15]) can increase the duration that blades spend in the gap region between two counter-rotating turbines. This may explain the aforementioned significant increase in

Nnorm for CD in our study. The solidity

σ =

Bc/(

πD) in Vergaerde et al. [

16] is 0.064, though they do not cite their earlier study (Vergaerde et al. [

15]). In future, our experimental results should be validated by using larger turbine models with low solidity.

Incidentally, it is worth noting that the power of CO is higher than the averaged power of CU and CD as shown in

Figure 9b, except for the case of

g/

D = 0.1. This supports the finding of our recent CFD results that the co-rotating pair yielded a higher output power than the counter-rotating pair under ideal bidirectional wind conditions (

Table 1 in Hara et al. [

5]). Therefore, we propose using a low-cost CO configuration in the field in cases of bidirectional wind, such as strong accelerated flow between high-rise buildings, rather than CD or CU configurations.

In summary for unidirectional wind, a clearance of g/D = 0.2 is recommended on VAWTs in a side-by-side arrangement, if significant deceleration or acceleration due to misalignment in the field of wind-power generation at g/D = 0.1 for CO or CD is undesired. Here, the values of Nnorm (corresponding Pnorm) by the VAWTs at g/D = 0.2 are 1.047 (1.054) and 1.063 (1.073) for CO and CD, respectively. Consequently, one of the best configurations is CO at g/D = 0.2 using the same two rotors rotating in the same direction if reducing engineering costs is the first priority (reducing the manufacturing and installation costs while maintaining a raised power of more than 5%).

Among some related studies on the interaction between two Savonius turbines (drag-type, e.g., Shigetomi et al. [

23]; Shaheen et al. [

24]), Ogawa et al. [

25] experimentally reported an increase in turbine power in the order of CD > CO > CU.

Table 2 compares the normalized power

Pnorm by Ogawa et al. [

25] with our studies using a Butterfly Wind Turbine (BWT). The values of

Pnorm in

Table 2 for CU at

g/

D = 0.5 fit well with each other. Shigetomi et al. [

23] reported extra power production using particle image velocimetry and explained the mechanism in connection with the pressure coupling or change in mean velocity. The error in the free rotational speeds of their models with 40 mm diameter was 180 rpm (13.6% of the average speed of 1327 rpm). Note that our corresponding difference of 10 rpm (0.36% of mean velocity, see

Section 2.1) was strictly imposed on our model with a 50 mm diameter. Although Shaheen et al. [

24] concluded that the optimum gap distance is 0.2

D in a CO arrangement based on CFD, counter-rotating configurations have not been reported.

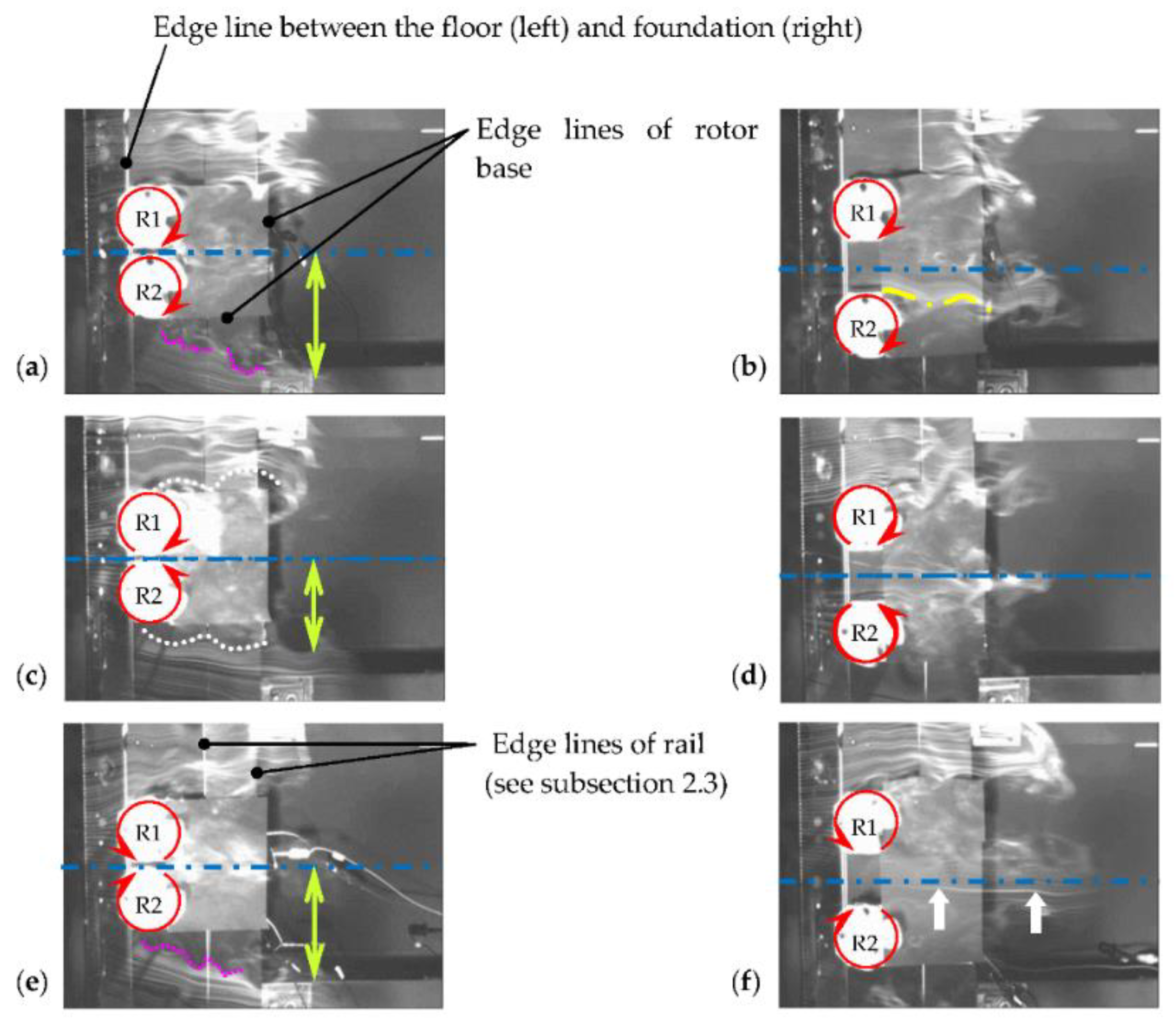

3.2. Flow Pattern around the VAWTs

Figure 10 shows the photographs taken by the smoke-wire method around the two rotors without rotation. The gap between Rotor 1 (above in

Figure 10) and Rotor 2 (below in

Figure 10) is

g = 10 mm. The dotted curves indicate the cross section of the turbine blades at the equatorial plane (these curves are not precisely represented in scale and angle). This arrangement corresponds to the CD configuration, although the rotational speed is zero. The black area marked by a letter A at

t = 0.15 s (streak fronts are slightly left) in

Figure 10a shows the flow separation at the blade painted out in red.

Figure 10a also includes an enlarged inset that shows the area in which A is contained. Here,

t = 0 s is recorded as the time when streaks left the wire. The area marked by a letter B at

t = 0.21 s (the streak fronts are in the middle) in

Figure 10b is the domain that corresponds to A, which has been flown down. The large vortex-like areas marked by letters C and D at

t = 0.27 and 0.33 s, respectively (the streak fronts are slightly right and right, respectively), in

Figure 10c,d are the areas that correspond to B, but are enlarged toward the lower right. The appearance period of area A is about 0.03–0.04 s (around 30 Hz). Since the Strouhal number based on the blade chord length (

c = 20 mm) and the uniform wind velocity (

V = 1 m/s) is about 0.6, the vortex shedding from A is not the result of roll-up shedding from a bluff body (lower turbine, Rotor 2) with a diameter of

D = 50 mm (expecting 4.2 Hz), considering that the Strouhal number of a circular cylinder is about 0.21 at the Reynolds number (e.g., Schlichting [

26]). Now, we call the outside of B, C, and D areas as ‘undulating shear layers’. On the other hand, the streaks that pass between the two turbines seem relatively smooth.

Figure 11 presents the flow pattern captured by the smoke-wire method around the two rotors with rotation. The flow (

V = 1 m/s) is the same as that in

Figure 10, from left to right. The pitch between the streaks when they left the wire was carefully set to be sufficiently small (less than 0.1

D) by using kinked wire (

Figure 7) to capture the flow pattern in detail. An edge line between the floor (left, far below) and foundation (right, supporting rotors), the edge lines of the rail (see explanation of

Figure 6), and the edge line of the rotor base are shown as white/black lines in each photograph in addition to electric wires (far below, see

Figure 10). The gaps between Rotor 1 (above) and Rotor 2 (below) are

g = 10 and 50 mm. For the CO, CU, and CD configurations, the results are shown in

Figure 11a–f, respectively. The red curved arrows indicate the rotational directions of the turbine rotors, whereas the blue dash–dotted lines represent the center lines between the two rotors. In all cases, since the streaks flowing outside the turbines (upward and downward in

Figure 11) are strongly bent in front of the rotors and the volumetric flow rate per unit width normal to a stream is increased, the acceleration of fluid flow occurs there as in

Figure 4 of Zanforlin and Nishino [

2]. First, we explore the flow pattern at a narrower gap of

g/

D = 0.2. A yellow-green arrow shows the wake half-width, the distance from the center line to the concentrated region of streaks inside the outer shear layers. Apparently, the wake width in the case of CU is remarkably narrower than those obtained for CO and CD. This is consistent with the result of Zanforlin and Nishino [

2] (though the CO case was not examined), where a narrower wake width can be confirmed in the case of CU by the contour of streamwise velocity (see

Figure 4b,c in Zanforlin and Nishino [

2] and

Figure 6b,c in Hara et al. [

5]).

Figure 12 shows a significant difference in wake width by the rotor arrangements (in the order of CD > CO > CU) obtained using CFD results (Hara et al. [

5]) in our research group at a narrower of

g/

D = 0.2. Here, the wake width

b is determined as the full range at which the streamwise time-averaged velocity attains a value of 10 m/s. It is quite interesting that the wake width in the case of CU (doublet-like configuration,

Figure 6a in Chan et al. [

27]) is also narrower than that in the case of CD (reverse doublet-like configuration, Figure 17b in Chan et al. [

27]), for

g/

D = 3.0,

λ = 1 (close to our

λ~0.8) and

ReD~200, as an example for a pair of counter-rotating cylinders. Zanforlin and Nishino [

2] highlighted important features, such as “

flow acceleration between the two turbines is less pronounced for CU” and “

more flow tends to go outside of the two turbines for CU than for CD”. This agrees with an explanation by Zheng et al. [

28] for CD that a wake constraint effect helps accelerate the flow through the rotor path and thus improves the power coefficient.

In contrast to the CU configuration, in the cases of CO and CD, much momentum seems to be transferred between the gap, as seen in

Figure 11a,e, in which dense streaks can be clearly observed downstream of the gap flow region. As for the difference of CO and CD, an investigation of successive images with an interval of 0.01 s confirms that intermittent fluid injection (corresponding to the “

phase-synchronized rotation”) between the rotors only occurs in the case of CD and not CO. The decrease in wake width for the CU configuration is also clearly confirmed by the evidence of a gentle downward (outward) slope of the shear layers just below the bottom turbine (Rotor 2) in

Figure 11c.

The second interesting finding of the present experimental study is that the “

nominal front-stagnation point” of each rotor moved toward the center of the rotor pair (

x-axis) based on the flow visualization in the CU arrangement. Since the streak line toward the stagnation point was considerably inclined to the outside in that configuration, the outer streak lines around the stagnation point are bent along with the circle made by the rotation of the rotor-blades. There are similarities to the increase in streamline curvature around a rotational circular cylinder, which dominate the Magnus effect. Maruyama [

29] explained the physical mechanisms of the Magnus effect, based on both Bernoulli’s theorem and the momentum theorem including discussions on the streamline curvature theorem and the shift of the stagnation points. Moreover, the streamwise-spatial interval of the ‘undulating shear layers’ in the CU arrangement (white rounded dotted lines in

Figure 11c, where the blades move along the mainstream) is longer than that in either the CO or CD (purple jagged dotted lines in

Figure 11a,e, where the blades move against the mainstream).

In the CU configuration, the clear (undisturbed) shear layers occur because the direction of flow and the direction of movement of the blades are the same at the outsides of the VAWTs; consequently, the shear layers are not affected by strong disturbance from the turbine blades. Here, the frequency of the undulation corresponds to the passing period of each blade, which is about 0.07 s (6–7 frames at a speed of 100 fps). Similar undulation can be confirmed by the contour of streamwise velocity reported by Hara et al. [

5]. In all cases with a small clearance of

g/

D = 0.2, the wake behind VAWTs seems to behave as one. Though further investigation is required, this seems similar to the behavior of the wake flow behind two parallel circular cylinders at rest as reported by Alam et al. [

30] (

g/

D = 0.1) and Yoon et al. [

31] (

g/

D = 0.2). In addition, a vortex street seen in the flow behind two parallel rotating cylinders in the CU configuration in

Figure 6c of Yoon et al. [

31] (

g/

D = 0.7) is also similar to that of a single bluff body flow. It is well known that a pair of counter-rotating cylinders can suppress vortex shedding (e.g., Chan et al. [

27]). It should be noted that there is a completely different regime called ‘bistable’ (Alam et al. [

30]), ‘flip-flopping’ (Yoon et al. [

31]) or ‘gross unsteadiness’ (Bearman and Wadcock [

32]) in the 0.1–0.2 <

g/

D < 1–1.2, according to the references, for the flow around two parallel stationary cylinders.

Next, we investigate the flow pattern at a wider gap of

g/

D = 1.0. The white region, which consists of a bundle of streaks near the wake center line, reaches further downstream at

t = 0.25 s, compared with that in a narrower gap. In the cases of CO and CU in

Figure 11b,d, the white region meanders downstream, which is probably due to the passing of each turbine blade. As seen in

Figure 11b, a clear ‘undulating shear layer’ in the CO (yellow dash–dotted line) is observable only on the inner side of the bottom turbine (Rotor 2), where the direction of flow and the direction of movement of the blades between the VAWTs are identical. Conversely, in the case of CD in

Figure 11f, there is a long straight streak (indicated by white arrows) along the wake center line, which implies the existence of a high-momentum zone without transverse mixing between the turbines. In all the cases with a large clearance of

g/

D = 1.0, the following wake seems to be roughly in the form of two vortex streets. Again, this has similarities with the wake flow behind two parallel circular cylinders at rest discussed by Alam et al. [

30] (

g/

D > 1.5), Bearman and Wadcock [

32] (

g/

D = 2.0), and Yoon et al. [

31] (

g/

D = 1.5).

The narrower wake width for CU than for CD at a wider gap of

g/

D = 1.0 is also reported by Lam and Peng [

14] based on wake measurements with a tip speed ratio of

λ = 1.01 and a solidity of

σ = 0.371 (close to

λ ~ 0.8 and

σ = 0.382 obtained in our study), as presented in

Table 1. They explained the reason for the narrower wake for CU using two pairs of stationary counter-rotating streamwise vortices. This concurs well with our latest additional visualizations with a wire set behind rotors (not shown here) using a smoke-wire method at the span center (

z/

D = 0) and above the pair of rotors (

z/

D = 1.0).

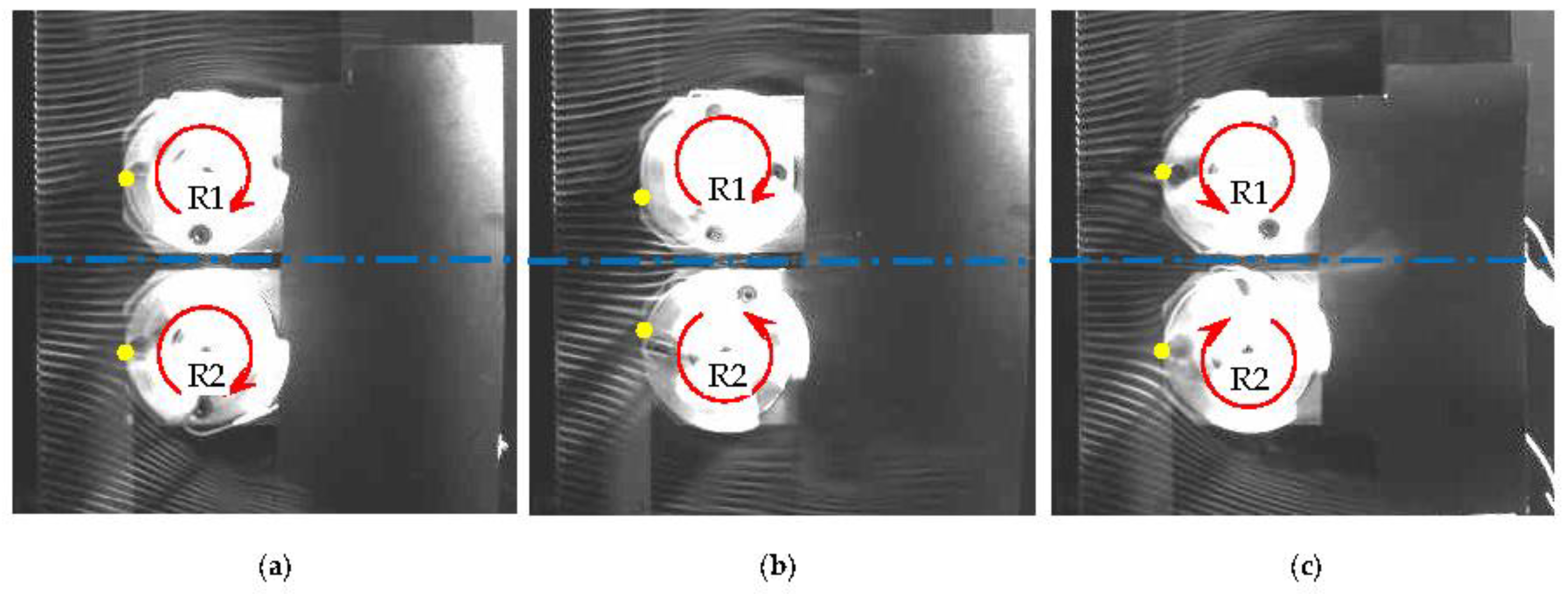

Figure 13 shows the flow pattern captured by the smoke-wire method around the two rotors with rotation at a narrower gap of

g/

D = 0.2. The uniform wind velocity

V is 2 m/s. The flow direction, red curved arrows, and the blue dash–dotted lines are the same as those in

Figure 10 and

Figure 11. For the CO, CU, and CD configurations, the results are shown in

Figure 13a–c. The movement of the “

nominal front-stagnation point” of each rotor towards the center of the rotor pair (mentioned in relation to

Figure 11c) can be clearly confirmed in

Figure 13b for the CU arrangement, as indicated by the closed-yellow circles. This is consistent with the numerical result of Zanforlin and Nishino [

2] (see their

Figure 4c), although they do not mention it.

Figure 14 shows the flow patterns around the two rotating turbines arranged side-by-side at

g/

D = 1.0. Photographs of smoke flow under a uniform velocity of

V = 2 m/s and the corresponding binarization images are placed in the left and middle columns, respectively. The right column contains the time-averaged streamlines based on the CFD results (Hara et al. [

5]) obtained by our research group. As illustrated by the green arrows, the deflected gap flow towards the bottom side of the image can be clearly confirmed in

Figure 14a,c for the CO arrangement. For the CU arrangement, significant movement of the nominal front-stagnation point indicated by the closed yellow circle of each rotor toward the center of the rotor pair in

Figure 14d can be clearly substantiated by the CFD result in

Figure 14f. In this case, the gentle outward flows indicated by blue arrows can be confirmed outside the turbines, as shown in

Figure 14d,f.

This leads to the narrowest wake width for the arrangement as quantitatively shown in

Figure 12 for

g/

D = 0.2. Note that a slight downward shift of the front-stagnation point can also be confirmed in the CO arrangement in

Figure 14a–c only for the upper rotor R1, which rotates at a higher speed (see

Figure 8a) as a result of the induced velocity by the lower rotor R2. For the CD arrangement, steep outward flows are illustrated by lavender arrows outside the turbines in

Figure 14g,i, leading to a wide wake behind the turbines. The area in the lavender broken frame in

Figure 14h shows long straight streak lines along the wake center line (explained in

Figure 11f), supporting the high-speed region shown in

Figure 14i obtained by CFD (Hara et al. [

5]).

Figure 15 shows the binarized images of smoke flow around two turbines arranged side-by-side at

g/

D = 1.0, rotating at 600 rpm under

V = 2 m/s. Orange circles indicate the movement of a particular blade in each rotor for convenience, but are not precisely represented in angle.

Figure 15a–e shows a series of images at

t = 0–0.08 s of the CO arrangement,

Figure 15f–j shows those of the CU arrangement, and

Figure 15k–o shows those of the CD arrangement, with a temporal interval of 0.02 s corresponding to 1/5 rotation (72°). The far-left column corresponds to the time of smoke generation at

t = 0 s. It is important that the flow pattern in each arrangement is not largely deformed owing to the rotation of the blades. As a conclusion of flow visualization in this study,

Figure 15 corroborates our findings supported by Computational Fluid Dynamics (CFD) adopting the dynamic fluid-body interaction (DFBI) method reported by Hara et al. [

5].

Figure 16 illustrates the effect of the movement of the stagnation point, indicated by the closed-yellow circle, on the relative velocity

W and the angle of attack

α of the model blade.

U is the flow velocity approaching the rotor and

rω is the peripheral velocity due to the rotation of the blade. The above movement (‘without shift’ to ‘with shift’ in

Figure 16) towards the centerline of the rotor pair results in a decrease in

W and an increase in

α. According to the properties of the NACA 0018 airfoil (Kumar et al. [

11]) in the range of a blade-chord-based Reynolds number of ~10

4, a decrease in

W leads to a decrease in the lift and an increase in

α beyond 5° reduces the lift to drag ratio. This translates to a reduction in the wind turbine torque and the rotational speed. This agrees with

Figure 8 and

Figure 9, where the rotational speeds of both Rotor 1 and Rotor 2 decrease for a narrow gap only in the case of CU.