2.2. The Power Plant

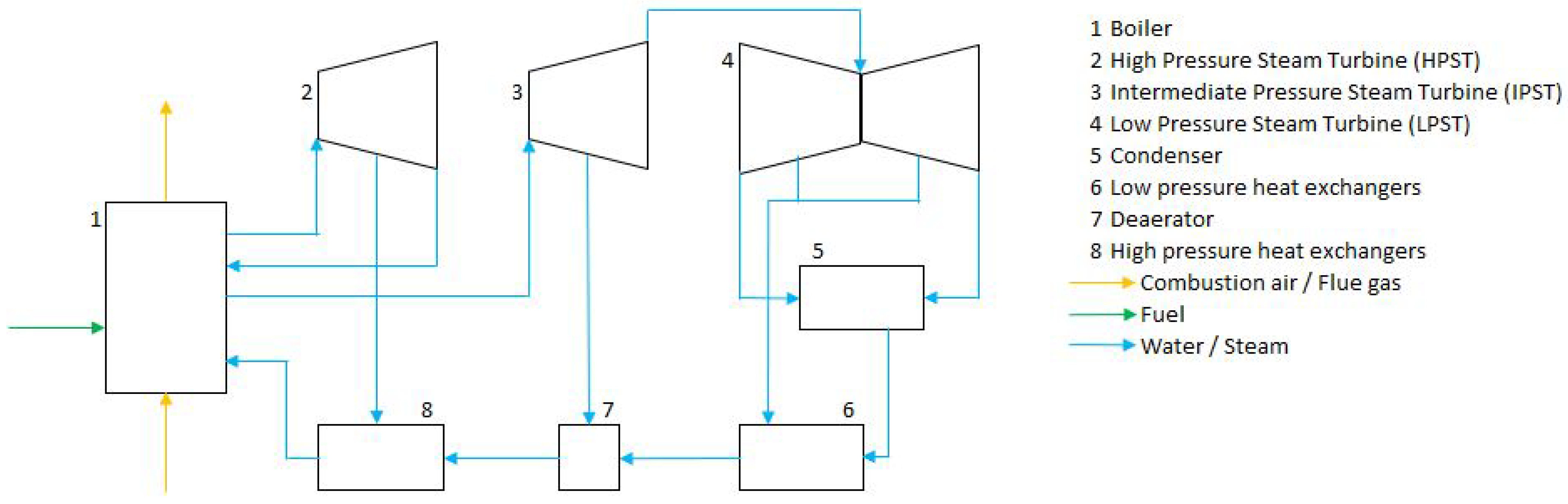

The power plant studied in this work is a modern ultra-super-critical (USC), coal-fired, 730 MW

power plant. Its nominal, net electrical efficiency is 45%. The plant was commissioned in 2015. The generator is driven by a steam turbine composed of one high-pressure, one intermediate-pressure and two diabolo-type, low-pressure steam turbines. The expanded steam is then condensed in two water-cooled condensors, and the feedwater then flows through five low-pressure preheaters, a deaerator, and three high-pressure preheaters, driven by several pumps. The 1550 MW

, USC boiler features an economiser, an evaporator (“Evaporator” is the customary term for the radiative heat exchanger in the furnace, although the cycle is supercritical in this case and, therefore, does not present an evaporation phase as such), three superheaters, and two reheaters. The live steam parameters at the outlet of the superheaters are 252.2 bar and 600 °C. At the outlet of the reheaters, they are reduced to 61 bar and 620 °C. The combustion air, pressurised by two forced draught (FD) fans, flows through a rotating air preheater. An induced draught (ID) fan entrains the flue gas through state-of-the-art flue gas treatment (FGT) systems: a selective catalytic reduction (SCR) denitrification system, an electrostatic precipitator for dust removal, and a wet scrubber to reduce the SO

emissions. Coal is pulverised in four roller mills, each of them feeding a row of four low-NO

burners in an opposed-type arrangement. The boiler is also equipped with an over fire air (OFA) system for the further reduction of NO

production in the furnace through global air staging.

Figure 2 presents a simplified schematic of the steam cycle.

2.3. Thermodynamic Modelling and Validation

Thermoflex®, the most flexible and adaptable package of the Thermoflow® software, is an energy and mass balance engineering tool performing static simulations of power production facilities, such as coal-fired power plants, gas-fired power plants, or solar power plants. The thermodynamic design of a power plant is based on the combination of predefined components. If the system components are carefully defined and connected, Thermoflex® computes the full heat and mass balance and the performances of the system, based on a series of thermodynamic design assumptions. A second step consists of switching to engineering design mode. In this mode, Thermoflex® translates the initial, basic thermodynamic design assumptions into equipment design assumptions. These assumptions can be adapted by the user in order to fit actual data. After computation, it results in physical equipment design, including technical specifications and costs, as well as in updated heat and mass balance, and plant performances that are consistent with the defined equipment design. The last step of the detailed modelling of a power plant is performed in the off-design mode. In this mode, the equipment physical design and technical specifications are locked. Set points that differ from the base case are then defined, and the final heat and mass balance, plant performances and costs are calculated. This mode therefore allows for the simulation of various loads. A very useful feature of Thermoflex® for this last phase is the possibility to create a functional interface between the model and a spreadsheet (Elink). It allows the computation of various cases by defining specific inputs to be varied and outputs of interest.

In order to investigate the impact of the retrofit of the studied coal-fired power plant into a large-scale, biomass-fired CHP plant, a detailed and representative model of the existing power plant needs to be developed. Thermoflex

® models were first developed based on the original design and operational data of the power plant. As all loads cannot be covered by a single model, several parameters have to be adapted and fine-tuned for lower loads to get representative results. The obtained models were validated against field data from the acceptance tests performed during the commissioning of the power plant; see

Section 2.3.1. Since the commissioning in 2015, component aging has, however, led to a slow degradation of the plant performances. Using recent operational data, the developed models were therefore fine-tuned to reproduce the current performances of the plant, leading to new versions of the models taking aging into account; see

Section 2.3.2. As a last step of the thermodynamic modelling of the existing plant, biomass co-firing was modelled and validated against tests performed in the framework of the Arbaheat project for a 22% biomass share; see

Section 2.3.3. These results will then be extrapolated to 100% biomass firing, together with the addition of the internal and external heat clients, see

Section 2.4.

2.3.1. Original Performances

A base-case model has been developed using the original technical information and operational data from the power plant. Its purpose is to reproduce the net performances of the power plant after its commissioning, for various loads. In order to accurately reproduce them, the base-case model is comprehensive: it covers all systems of the power plant, including the flue gas treatment systems, and all auxiliary equipment, such as auxiliary pumps, fans and heat exchangers. Overall, it consists of more than 180 components, 285 links and 1500 variables.

This model was validated against the data from the official acceptance test performed in December 2014 by an accredited third party, using a combination of available measurements retrieved from the power plant’s control system and specific, additional measurements. All measurement tools were calibrated before the test. The performance tests covered the following loads: maximum continuous rating (MCR) and boiler maximum continuous rate (BMCR). MCR is defined as the maximum rating of the plant under normal and continuous operations in natural sliding pressure mode, with steam generator and steam turbine being ready to provide primary frequency control as required, and with boiler in normal operating mode including blowdown and auxiliary steam consumption. BMCR is defined at reference conditions as the maximum rating at which the boiler is able to operate under normal, continuous operating conditions for any coal from the design range. It is defined as 103% of the MCR.

During such an acceptance test, the power plant is operated in well-reported conditions, which never perfectly match the standard conditions for which the expected performances were assessed. The tests results are therefore adapted using correction curves provided by the manufacturer. For the power plant studied here, corrections are available for the following variables:

Modelling a large power plant never results in a perfect match between the simulation results and the field data, due to an unavoidable discrepancy between the modelled components and their actual behaviour. The limited accuracy of the performed measurements also introduces additional uncertainty. In addition, choices need to be made in terms of the main parameters of interest, for which the discrepancy between the model and the field data is minimised during the fine tuning and validation process. A (relatively) larger discrepancy is tolerated for other, secondary parameters. It is of course important to take this into account when interpreting the simulation results, by avoiding drawing firm conclusions on the variations of secondary parameters. The main parameters used here to validate the developed thermodynamic models are:

When these parameters are within the acceptable deviations described in the standard DIN1943 dedicated to thermal acceptance tests of steam turbines, a model is considered as validated. These acceptable deviations vary with the measured parameters. The fine-tuning of the model was carried through careful adjustment of the technical parameters of the key pieces of equipment, resulting in light deviations from their design values (order of magnitude lower than 1%), see the results in

Table 2. The main parameters that were adjusted were nominal flows, cleanliness factors, fouling factors, pump characteristics, mechanical losses, rotor angles, leakage flows, heat transfer coefficients, or heat exchanger surfaces, among others. This of course represents a labour-intensive and time-consuming task, that can only be achieved with a deep understanding of the operation of the plant. In the future, the use of uncertainty quantification (UQ) [

17,

18] techniques should be investigated to automatically reconcile the model parameters with the field measurements, taking into account the related uncertainties. To the best knowledge of the authors, the application of these techniques to models featuring such a high number of parameters (>1000) requires further research.

In addition to the acceptance tests performed at MCR and BMCR, the base-case model was also validated against operational data retrieved during normal operation after the commissioning, at various loads: 100%, 75%, 50%, 30% and 25%. The deviations for the main parameters for the lower loads were less then 1%.

2.3.2. Current Performances: Steam Turbine Aging

With time, processes such as fouling, erosion or wear lead to a decrease of the performances of some pieces of equipment. This overall slow degradation process is often referred to as aging. In particular, steam turbine aging has a significant impact on the overall plant performances [

19]. Other pieces of equipment, such as heat exchangers, are also submitted to variations of their performances with time, but these are also strongly impacted by the operational conditions of the plant, especially in solid fuel-fired boilers. Variations of the fuel characteristics (properties of the inorganic compounds, among others), variable soot blowing system operations, or acceptable, temporary leakages can impact the heat and mass balance of the boiler.

In the frame of this study, steam turbine aging was assessed and integrated into the thermodynamic model of the plant to match recent field data. To do so, the heat exchange parameters in the boiler also had to be adjusted, although it is not considered as resulting from an aging process, strictly speaking.

Base load tests are performed at the power plant on a regular basis. These so-called P tests are carried out during stable runs of at least 15 min. All the data necessary for the assessment of the plant performances are then gathered from the control system. The P test used in the frame of this work was carried out during winter 2019, as it presented the highest reliability among the most recent tests. It must therefore be considered that the performances of the plant are predicted at this moment. The extrapolation of the aging process is out of the scope of this study, but will be subject to future works.

In order to assess the decrease of the steam turbine performances for a given lifetime, the model first needs to accurately predict the corresponding inlet steam parameters. The boiler heat and mass balance parameters were therefore adjusted to reach a discrepancy lower than 1% between the model prediction and the considered P

test. The steam turbine dry stage efficiencies were then adjusted to reproduce their performances for the measured input steam parameters, which lead to a quantification of an aging factor for each turbine. The resulting factors are given in

Table 3. The final deviation between the full model and the P

test results is less than 1% for the key parameters (

Table 4).

2.3.3. Biomass Co-Firing

In the beginning of the project, one of the four roller mills was adapted to carry out co-firing tests and gather information about the impact of a full switch. During these tests, an overall share of 22% of steam-exploded pellets (mass-based) was reached. The co-firing tests took place during summer 2019. They aimed at testing several systems: fuel handling, fuel milling, combustion and flue gas treatment, among others. It was also an opportunity to assess the impact of biomass co-firing on the performances of the power plant. The key information retrieved from these tests in this regard concerns the impact of biomass co-firing on the overall, radiative heat transfer in the furnace, that cannot be predicted based on the fuel characteristics. In Thermoflex, the parameter ruling the amount of radiant heat flux from the furnace directly transferred to the radiant superheaters was adjusted to match the overall performances of the plant with the same accuracy as for coal-firing. The observed evolution of this parameter was extrapolated to predict the performances of the plant for 100% steam-exploded pellets firing; see

Section 3.

2.4. The Biomass-Fired CHP

The main objective of the present study is to predict the energetic and exergetic performances of the plant after its retrofit into a biomass-fired CHP coupled to three different heat clients: a steam-explosion plant used for the pre-treatment of the biomass, a biorefinery process extracting valuable chemical compounds from the produced condensate, and an external, large-scale heat network. In this Section, a way in which live steam can be extracted from the turbine to deliver high-temperature heat is described. The heat clients considered in this study and the related heat demands are also defined. Finally, the methodology that will be used to optimise the steam extraction in function of various heat demand scenarios is presented.

2.4.1. Steam Extraction Points

The steam turbine was originally designed to allow steam extraction for district heating (DH) purposes. Three extraction points are available: from the HP turbine outlet (cold reheat line), from the IP turbine outlet, and from the LP turbine. The latter extraction point is specifically designed for large flow rates, unlike the four other, conventional steam extraction points from the LP turbine delivering heat to the feedwater preheaters, in order to increase the efficiency of the steam cycle. The turbine manufacturer predicts that the turbine could deliver 150 MW of thermal power to a DH network at MCR, assuming a supply temperature to the network of 180 °C and a return temperature of 80 °C. The delivered thermal power and the related energy and exergy efficiencies are of course very much dependant on the power plant load, as well as on the heat demand and the temperature levels required by the heat clients. This design value can therefore not be generalised, and detailed simulations must be carried out to assess the performances of the CHP in the conditions of interest for this project, which is precisely the purpose of this study.

The maximum steam extraction flow rates from the turbines are a function of the turbine inlet flow rates. Although the blades located upstream of the tapping points are reinforced, the relative extraction flow rates are limited by the acceptable loading of the turbine stages, especially at high loads. This results in maximum extraction flow values which correspond to a boiler load around 80%. These maximum extraction rates will have a strong impact on the predicted performances of the CHP in the scenarios studied in

Section 2.5. In the lower unit load range, the steam velocity at the extraction tapping point must be considered, as well as the minimum necessary steam flow through the last part of the LP turbine.

2.4.2. The Heat Clients

In this Section, the heat clients considered in this studied for the CHP operation of the plant are described.

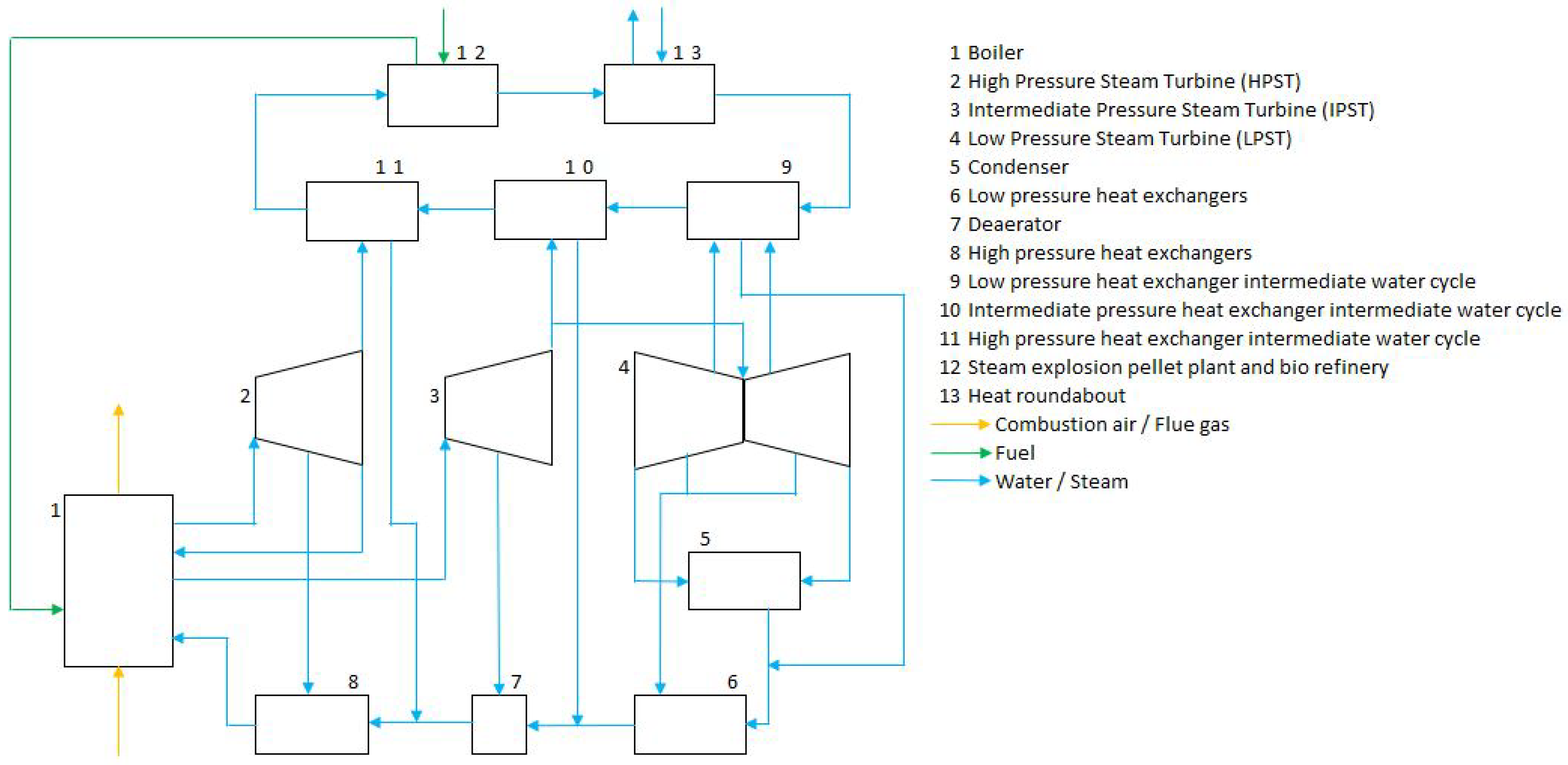

Figure 1 shows the general layout of the CHP system. Three heat exchangers (9, 10, 11) transfer heat from the steam extracted from the three tapping points (outlet HP, outlet IP and LP turbines) to an intermediate closed loop. This intermediate loop in turns delivers heat to internal heat clients (12) and to an external heat network (13).

The condensates flow back to the power plant. The return points were chosen very carefully, in order to guarantee that the pressure and temperature of the condensates are adequate at all loads. The following points were selected based on a worst case scenario (lowest load):

High pressure condensate flows back into the system between the booster pumps and the feed water pumps;

Intermediate pressure condensate flows back to the deaerator;

Low pressure condensate flows back in the feedwater stream behind the gland steam condensors.

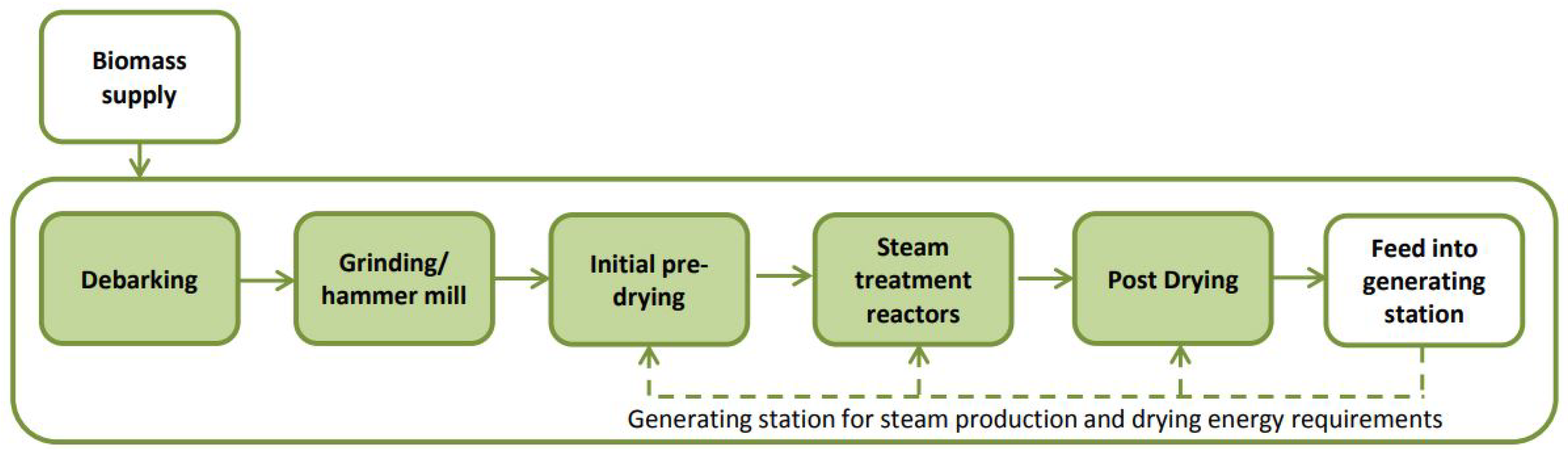

2.4.2.1. Steam-Explosion Plant and Biorefinery

A state-of-the-art, full-scale steam-explosion plant designed by Arbaflame is coupled to the CHP to take advantage of the available steam. All the heat streams are studied in detail and integrated to make the plant as energy-efficient as possible. The various steps of the steam-explosion process are illustrated in

Figure 3. The steam-explosion plant requires three different streams of saturated steam, at different temperature levels: for the steam-explosion process as such (222 °C), to heat up the reactor vessels jackets (165 °C), and for the post-drying step (198 °C).

The condensate released by the steam-explosion process can be valorized by extracting high-added value, bio-sourced chemical compounds such as furfural [

15]. The studied biorefinery process leading to the production of such compounds is also considered here as an internal heat client for the CHP plant. It consists of several distillation columns, extractors, heat exchangers, pumps, among others. The required steam is saturated, at a temperature of 120 °C.

As its future purpose will most probably be to contribute to the grid stability while providing high-temperature heat with a high efficiency, the CHP plant is not expected to run continuously at full load. A realistic design for a full-scale pre-treatment plant installed on the selected site leads to an annual production of steam-exploded pellets around 700,000 t/y. It corresponds to a continuous steam demand of 29.6 kg/s, including the biorefinery process.

2.4.2.2. Heat Roundabout

The surplus of heat that is not consumed by the internal heat clients can be delivered to external clients through a heat network. As a first step of the Arbaheat project, potential clients were identified in the surrounding industrial and urban areas, and several scenarios were investigated for the development of such a network. Industrial processes as well as tertiary and residential buildings are the main potential clients. The furthest point of the network could be 40 km away from the plant. In summer conditions, a temperature of 100 °C would be required, with a return temperature of 60 °C. In winter conditions, a temperature of 120 °C should be reached, while the return temperature should be 70 °C. In the mid term, the total thermal power demand could reach 400 MWth peak, while it could increase to 2400 MWth peak in the long term. Local heat production plants installed along the network could support the CHP in fulfilling heat demand. The detailed operation of the network is, however, out of the scope of this paper. Our main purpose is to assess the efficiency of the CHP plant when it faces various heat demands from external clients, while running at various loads. This information is key to the evaluation of the various opportunities in terms of development and future extension of the heat network. We will therefore assess the maximum thermal power that can be provided to the network in various scenarios, providing it does exceed the maximum demand that was identified. The winter conditions are considered, i.e., supply and return temperatures of 120 °C and 70 °C, respectively.

2.4.3. Steam Extraction Optimisation

As explained in

Section 2.4.1, the potential steam extraction points in the power plant are fixed by design: outlet HP, outlet IP and LP turbines. Determining the optimal extraction flow rates from these three points for a given scenario is not straightforward. A cascading principle was used: in order to maximise the exergetic efficiency of the plant, steam extraction from the LP turbine is favoured, provided that it meets the requirements in terms of temperature level in the heat exchangers of the intermediate loop, until the maximum allowable flow rate is reached. IP and HP steam flows are then subsequently used to fulfill the remaining demand.

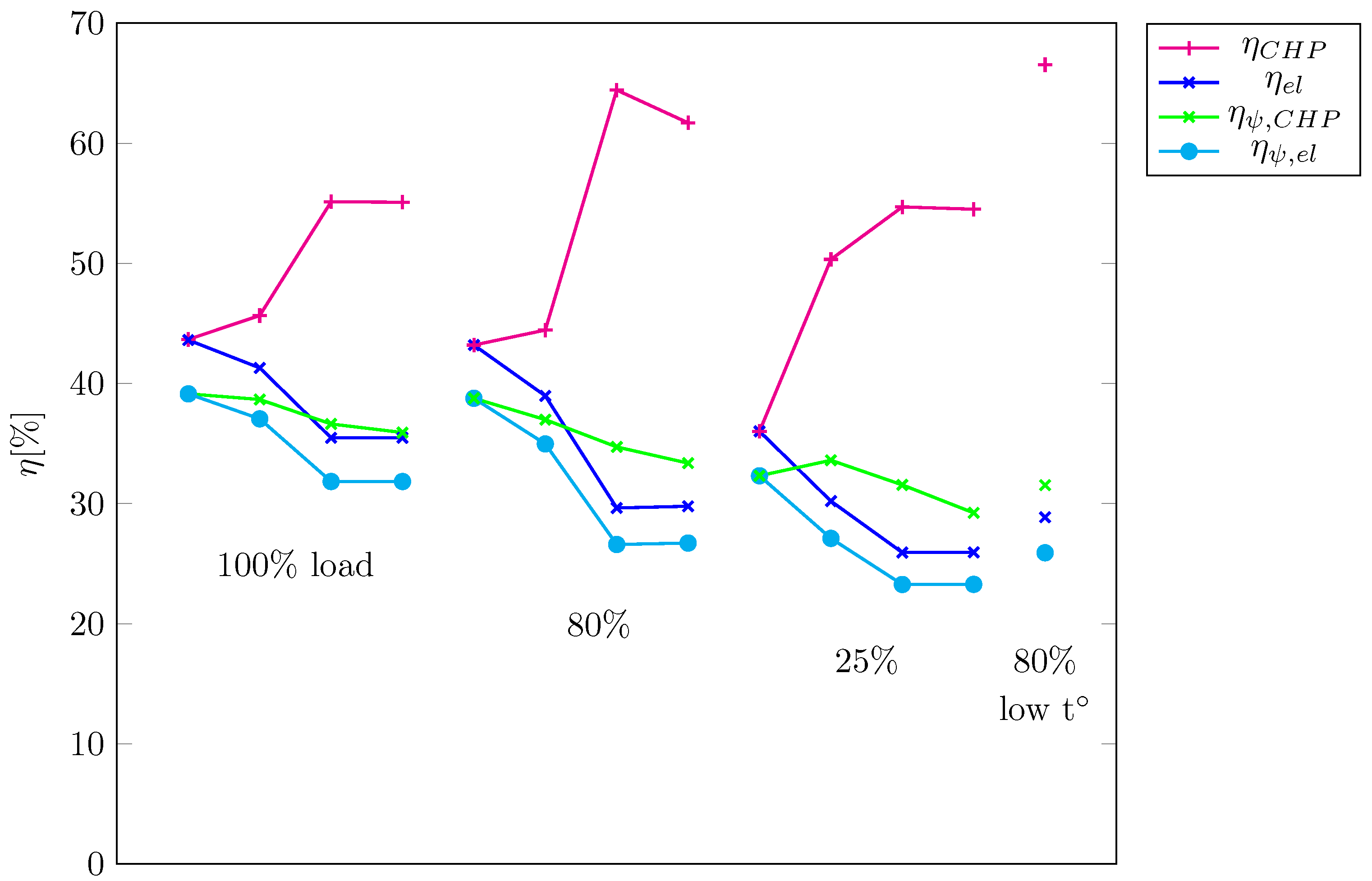

2.5. Scenarios

The main objective of this paper is to assess the impact of the proposed retrofit on the energy and exergy efficiencies of the plant. To do so, a finite number of relevant scenarios were defined, both in terms of total load and thermal power demand. They are representative of the typical operation modes expected after the retrofit. The defined scenarios are summarised in

Table 5.

In these scenarios, the plant runs at three different loads in terms of thermal input in the boiler: 100% (full load), 80% (maximum steam extraction load) and 25% (minimum load). The 80% load was selected because it corresponds to the maximum steam extraction flow rates from the turbines; see

Section 2.4.1. All cases are based on 100% biomass firing.

The base cases correspond to pure electrical power production at each load. They will be used as references. Cases a to c are variants of the base cases, with 100% internal heat demand and no external demand, 100% internal heat demand and the highest possible external demand, and no internal demand with the highest possible external demand, respectively.

The last case is a variant of case , with lower requirements in terms of heat network temperatures, in order to reach a higher energy efficiency. The supply and return temperature for the external heat client are reduced to 70 °C and 30 °C, respectively.