Analysis of the Long-Term Mass Balance and Efficiency of Waste Recovery in a Municipal Waste Biodrying Plant

Abstract

:1. Introduction

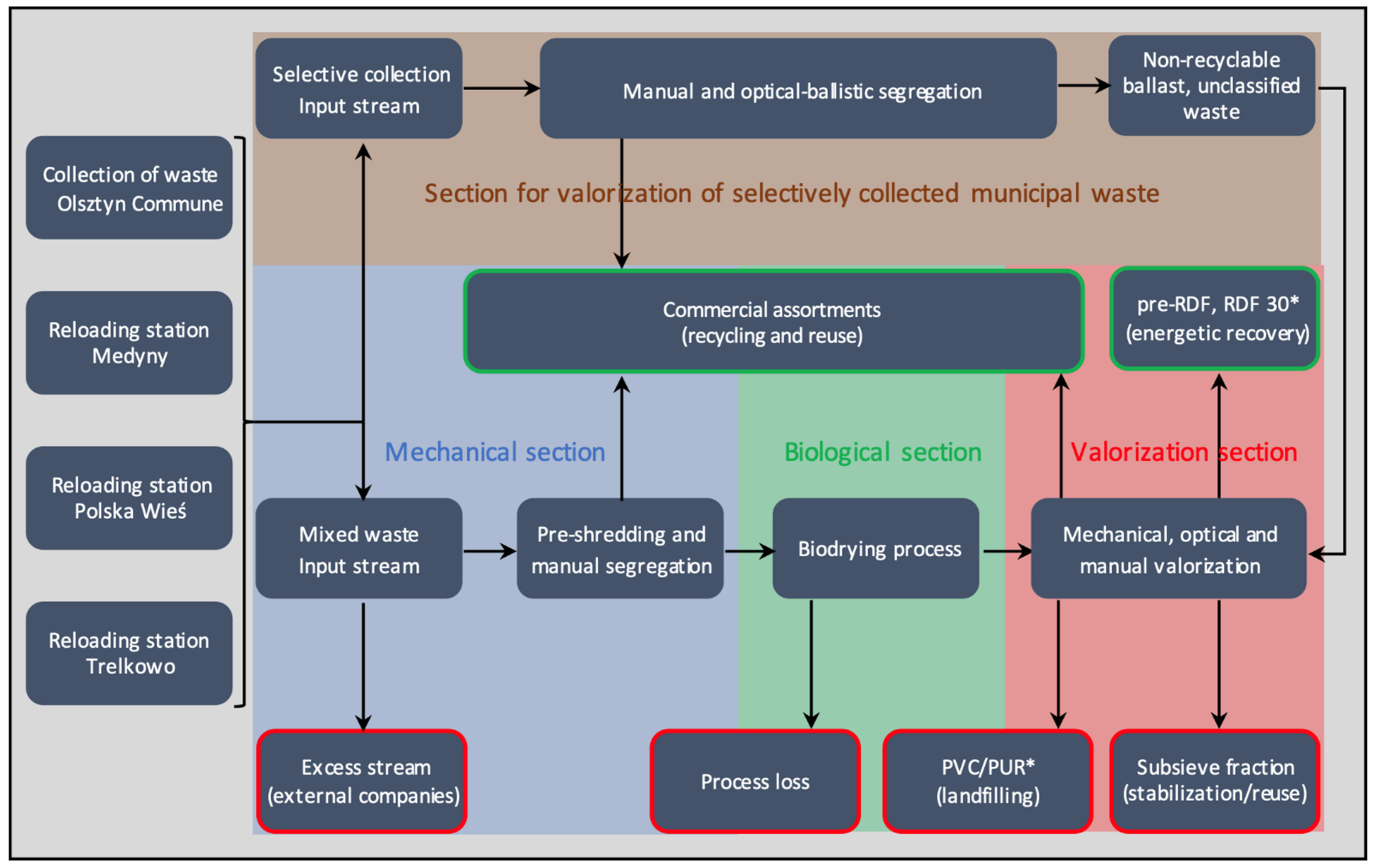

2. Materials and Methods

2.1. Subject of the Case Study

2.2. Scope of the Research

2.3. Calculation Methods

3. Results

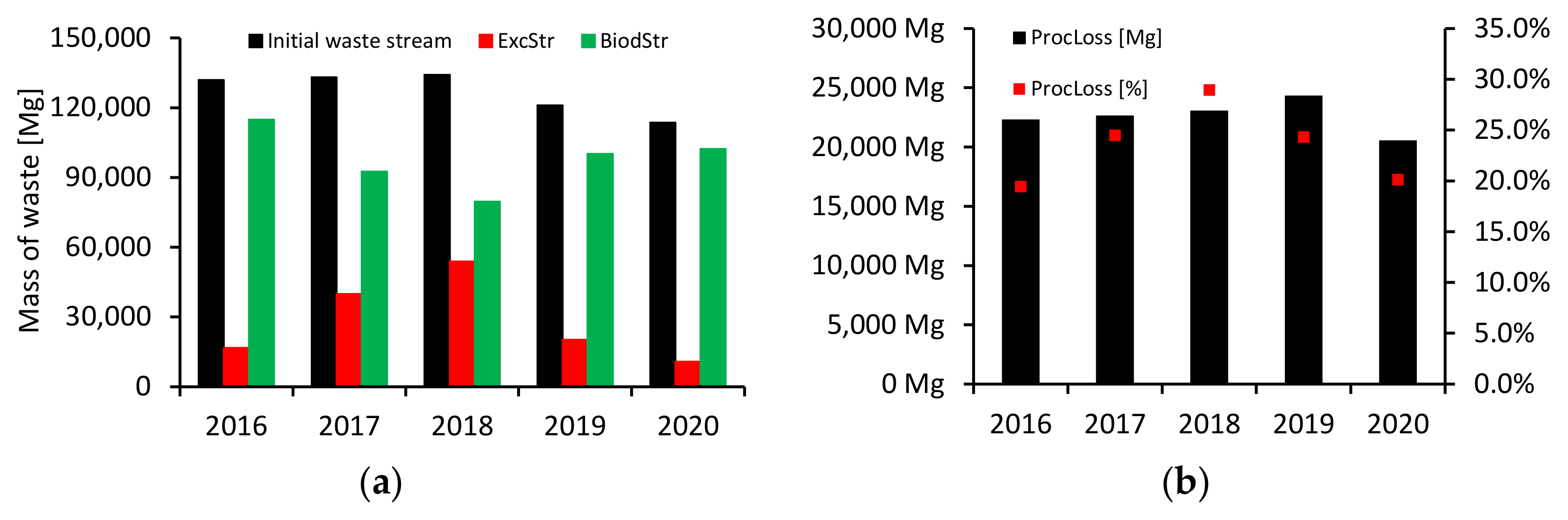

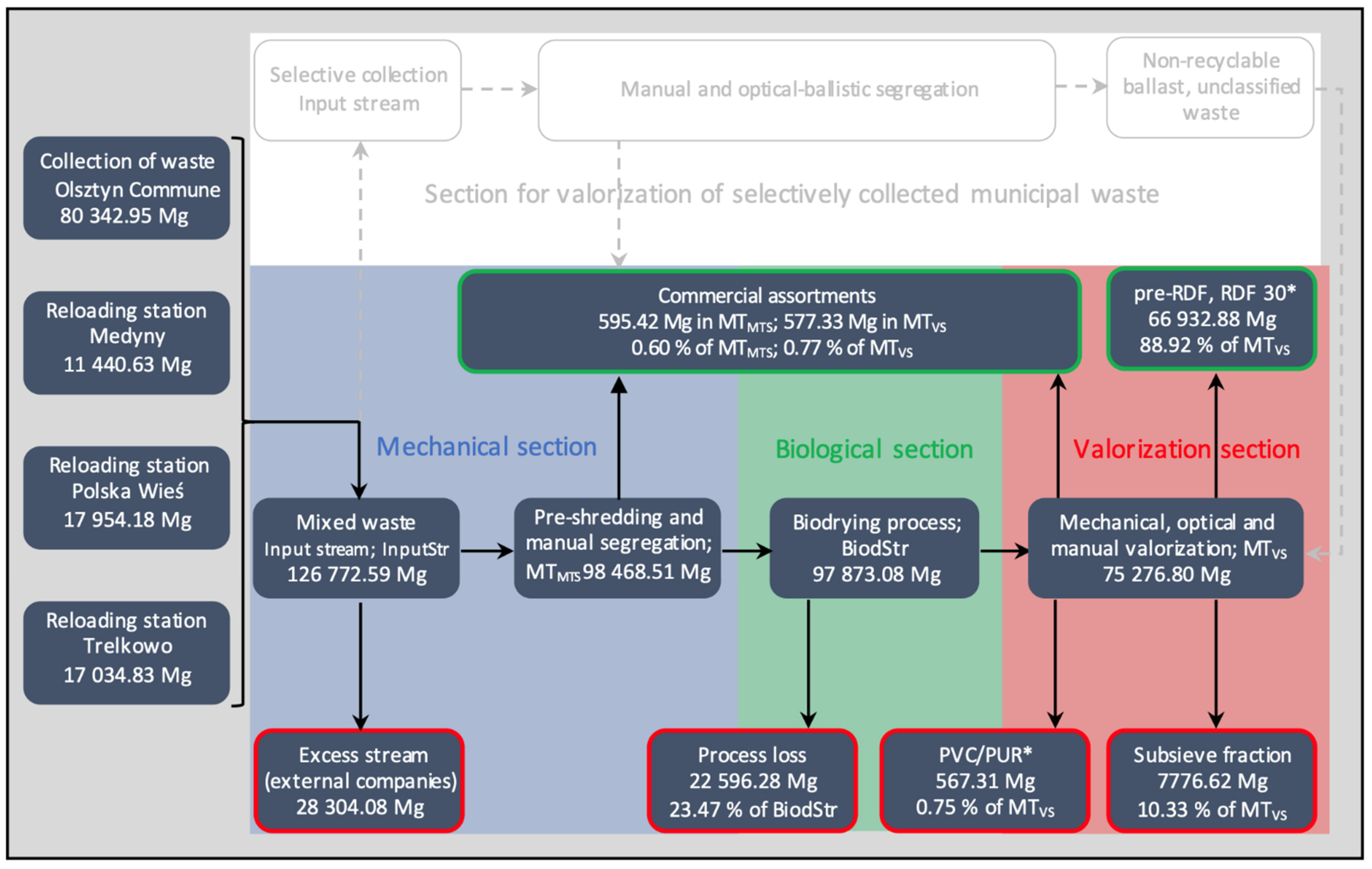

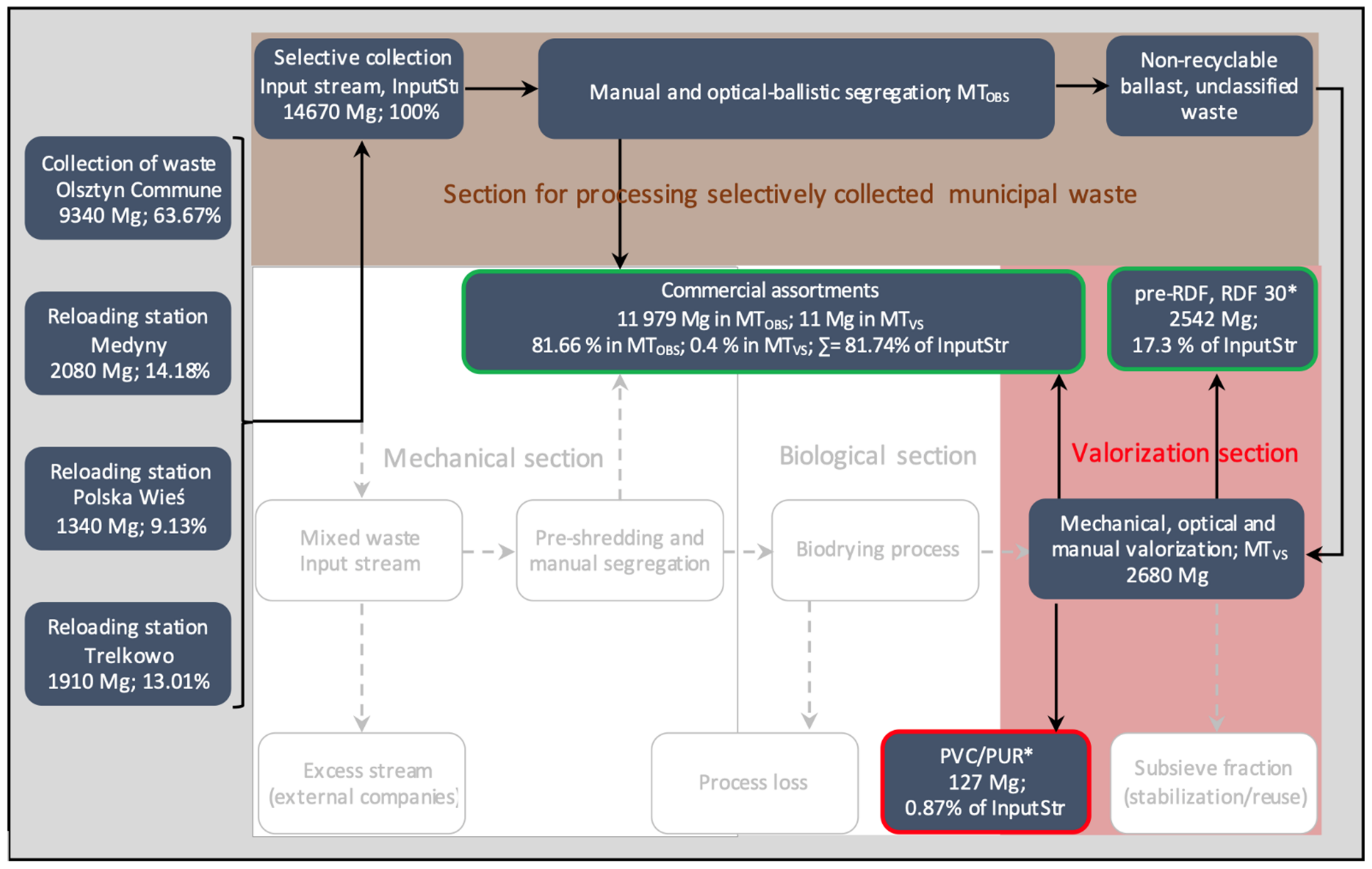

3.1. Mechanical-Biological Treatment Line

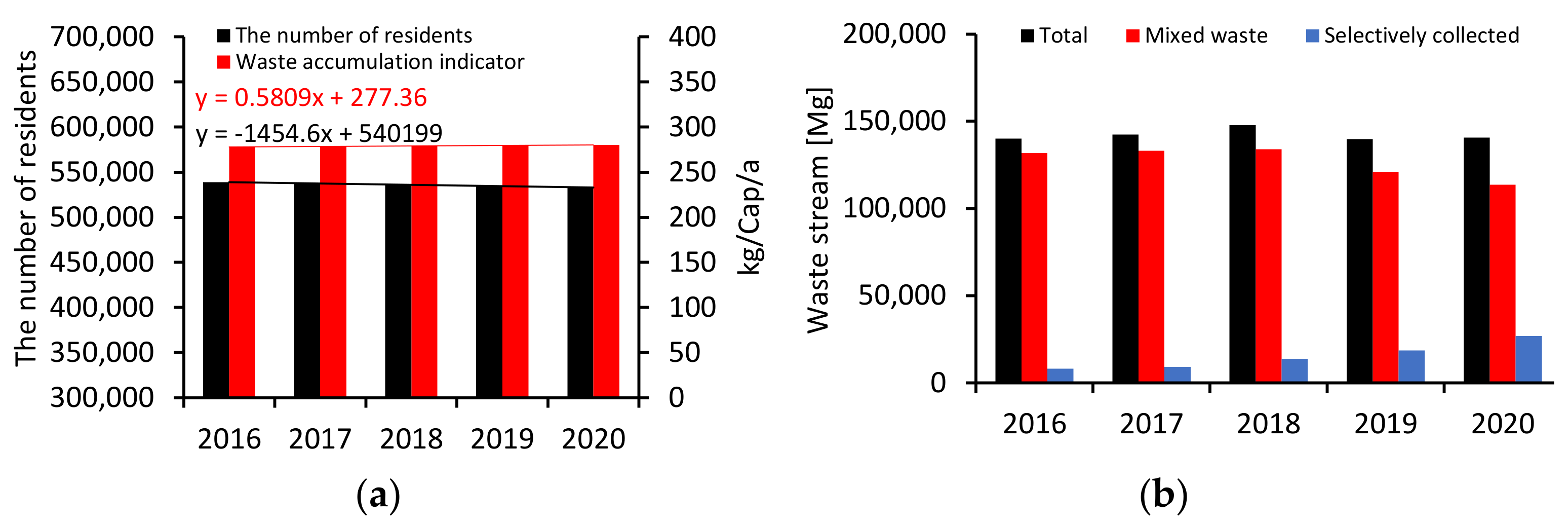

3.1.1. Primary Mass Flow of The Raw Waste Stream in The Municipal Waste Management Plant

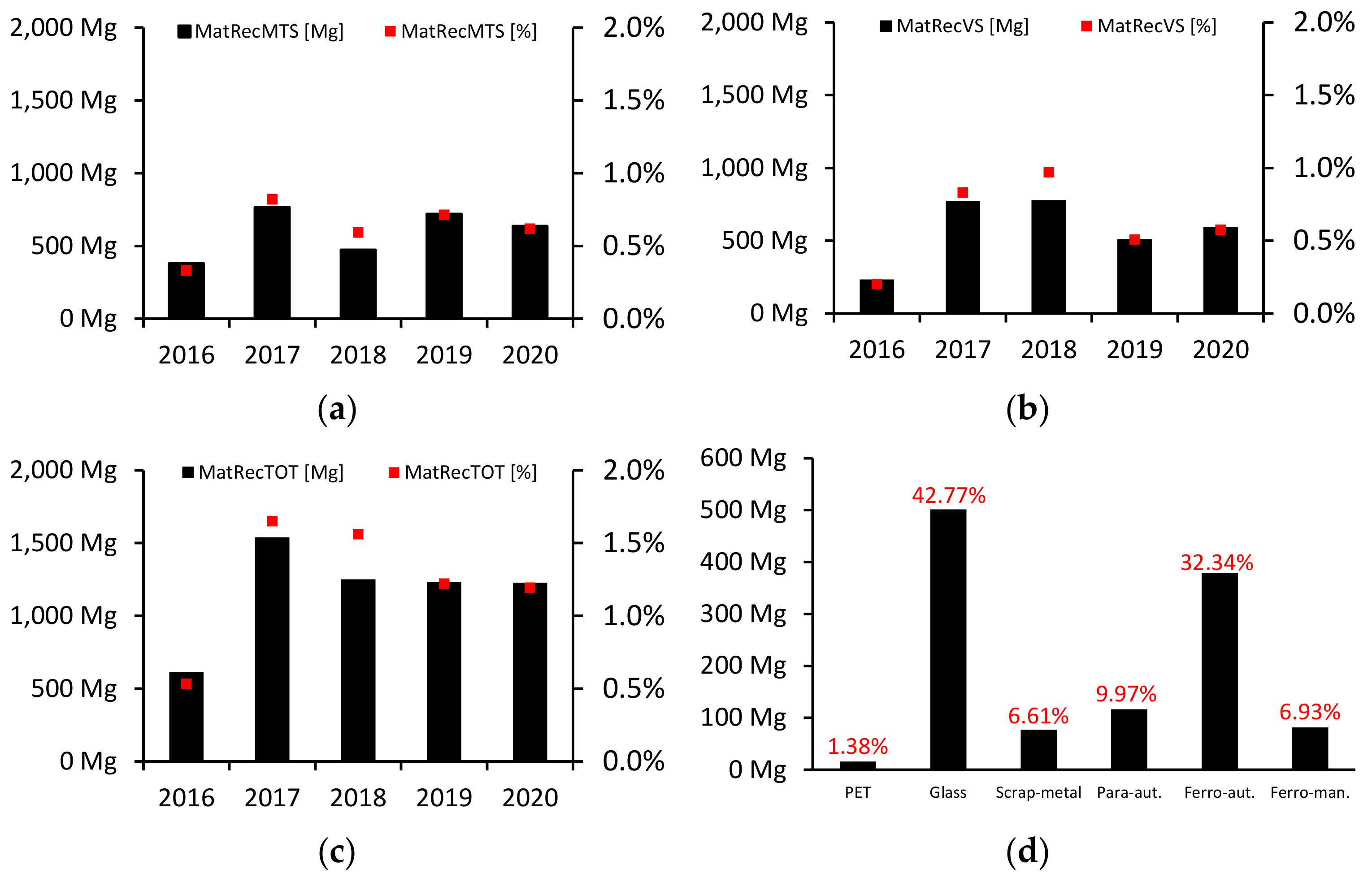

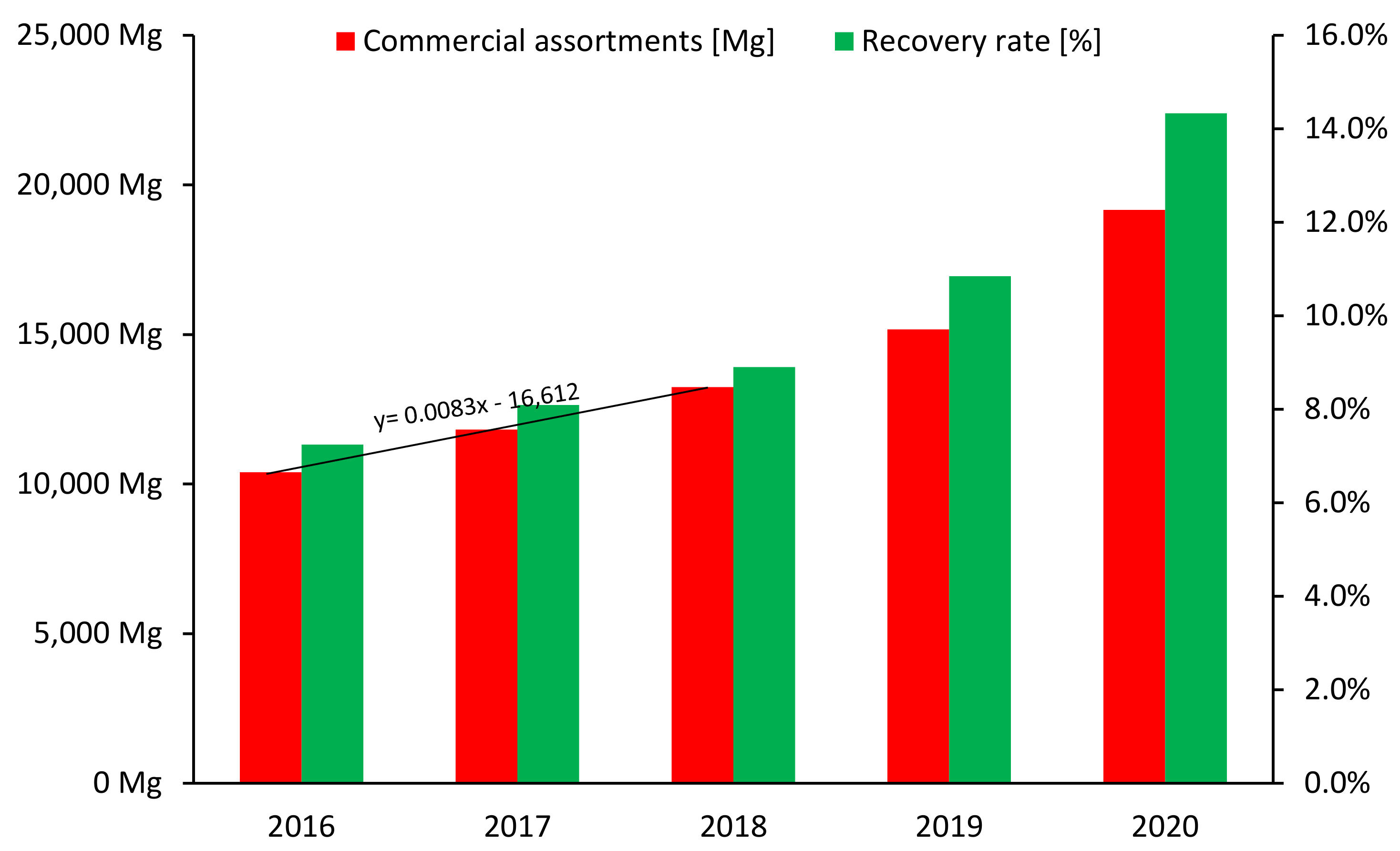

3.1.2. Recovery of Commercial Assortments during the Mechanical-Biological Treatment of Municipal Solid Waste

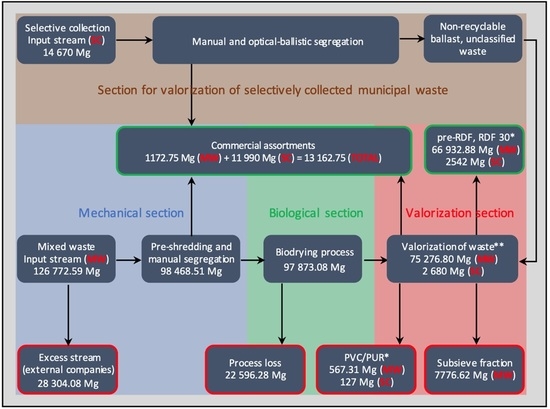

3.1.3. Mass balance of the Mechanical-Biological Treatment Line

3.2. Selectively Collected Waste Valorization Line

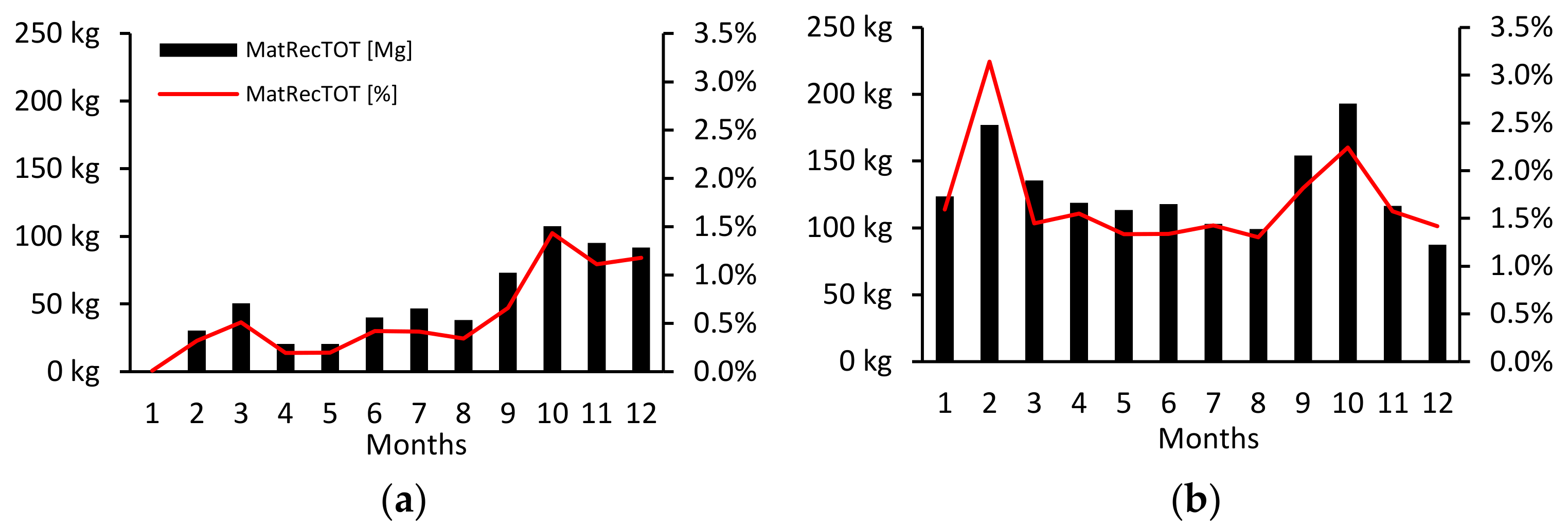

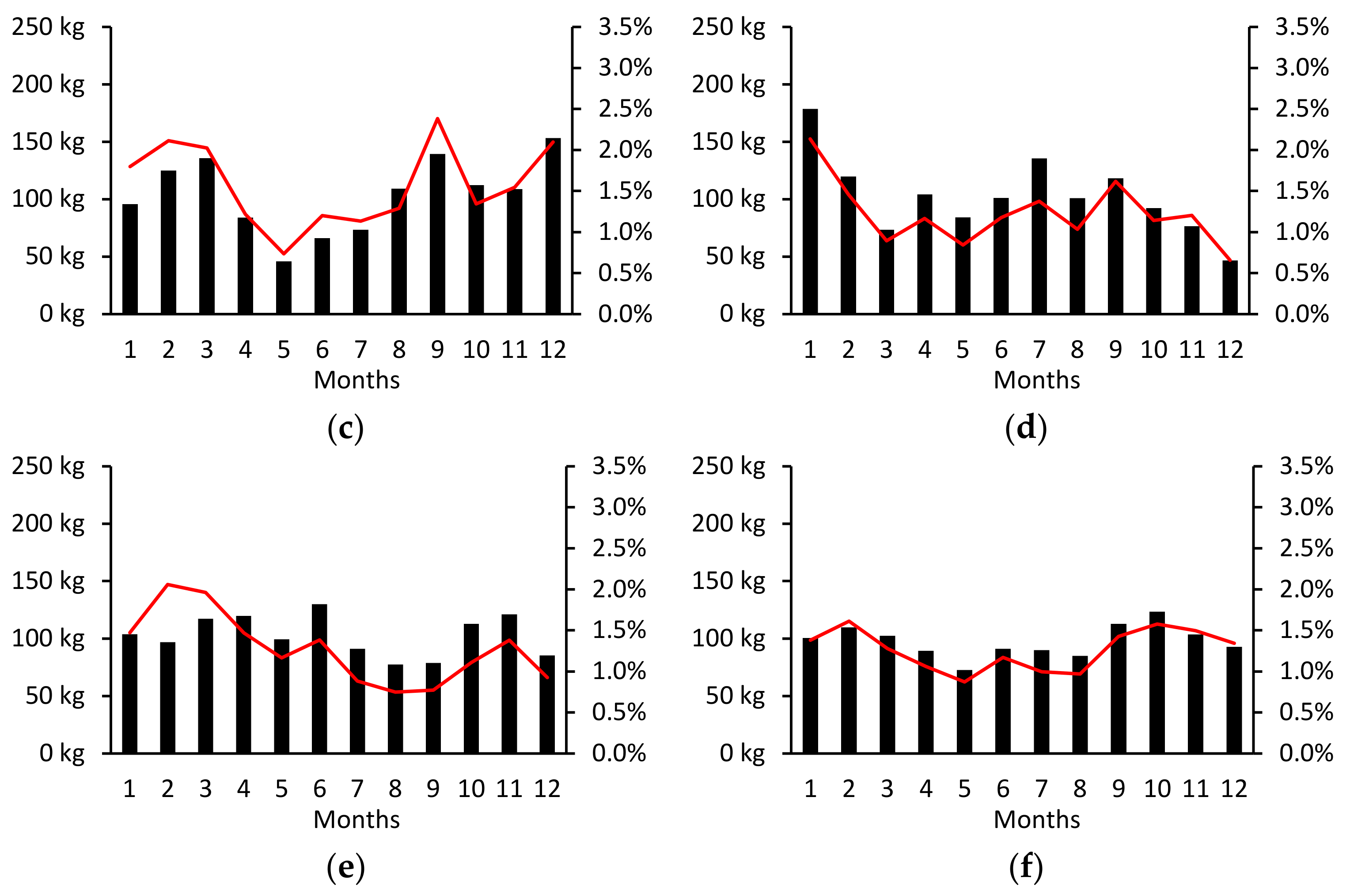

3.2.1. Characteristics of the Generated Stream of Selectively Collected Waste

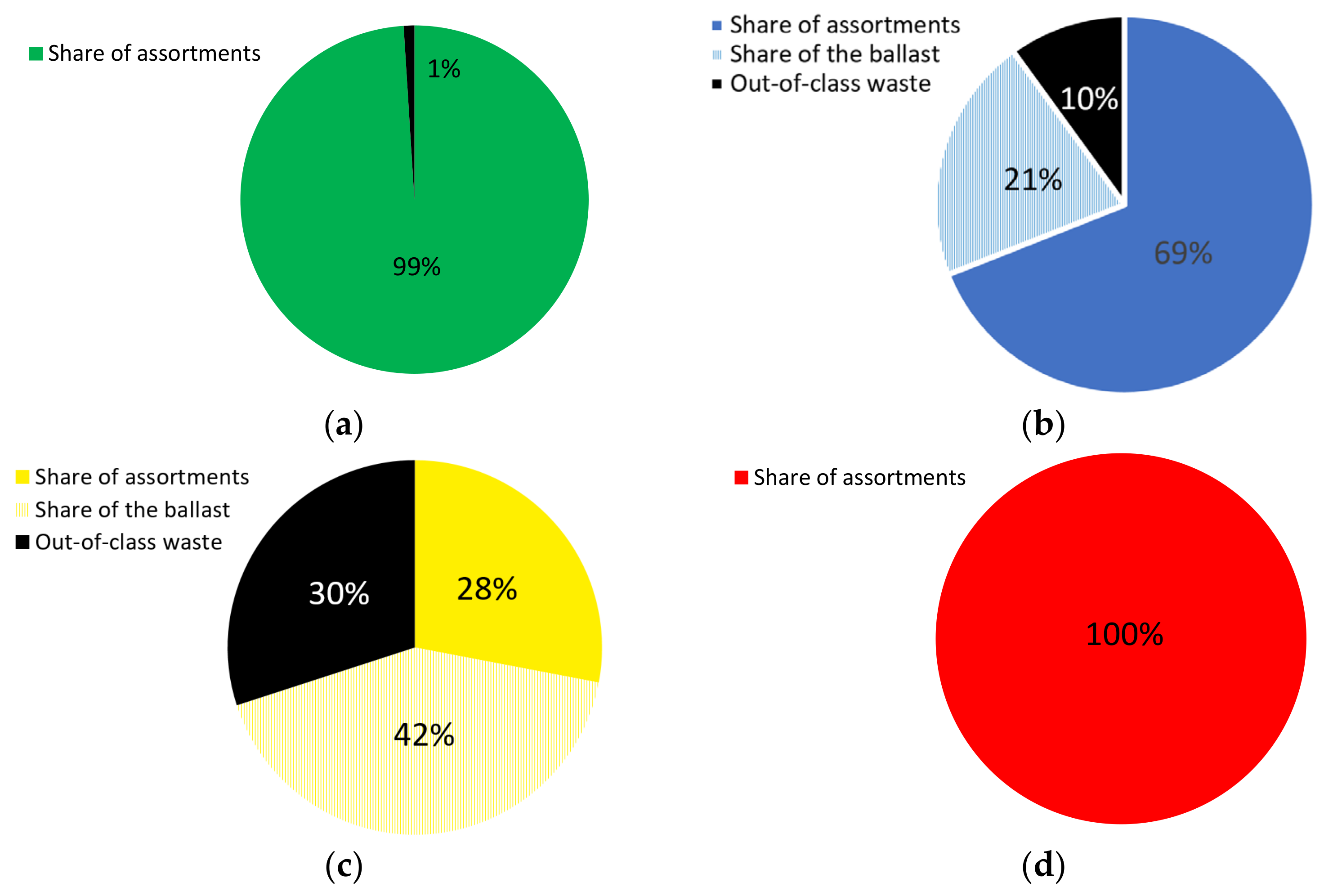

3.2.2. Recovery of Individual Commercial Assortments from Selectively Collected Waste

- -

- A stream of correctly segregated waste (commercial assortments);

- -

- A waste stream that is correctly segregated, but not suitable for recycling (ballast);

- -

- A waste stream that is incorrectly segregated (out-of-class waste stream).

3.2.3. Mass Balance of the Selectively Collected Waste Valorization Line

4. Discussion

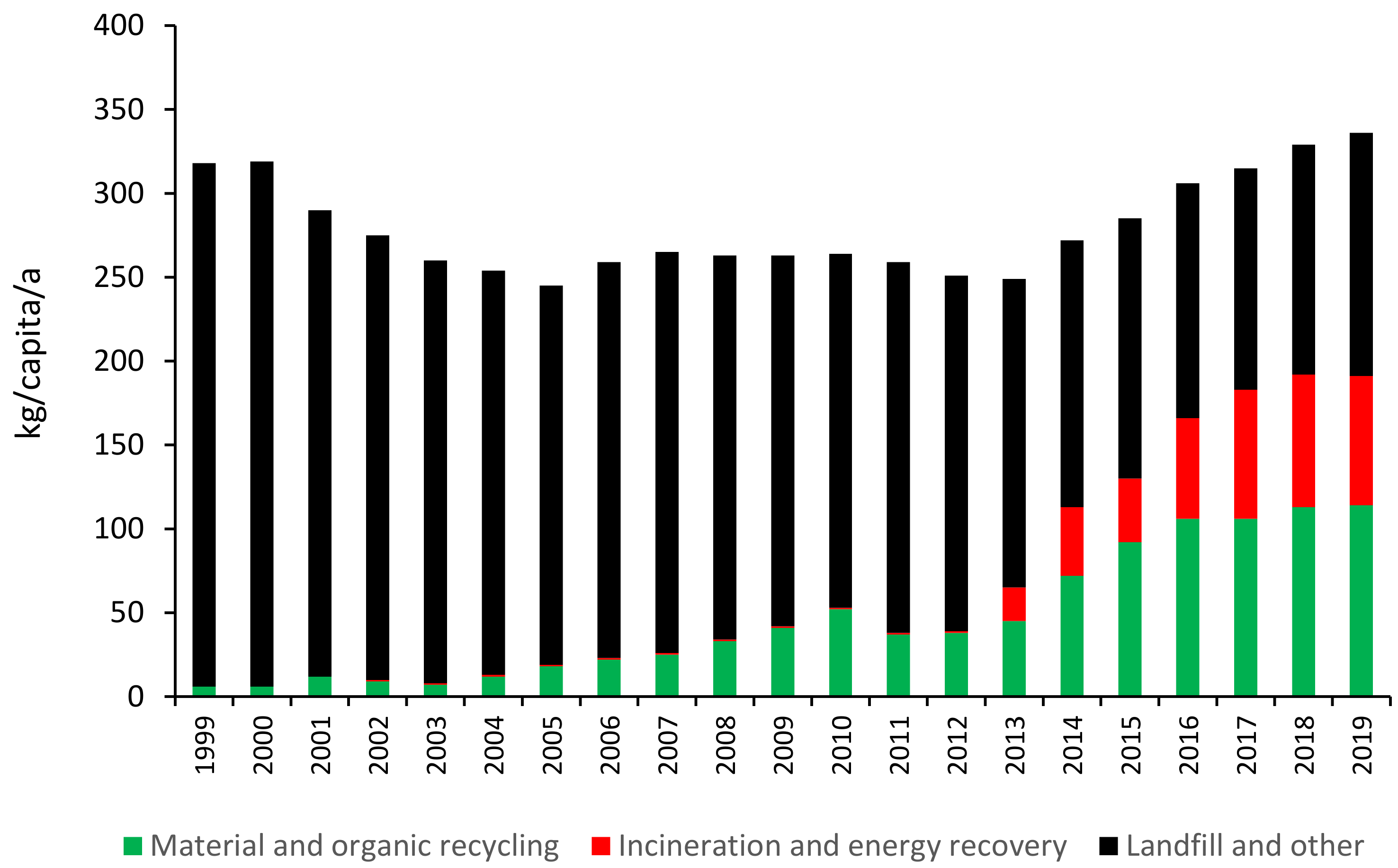

4.1. Change Trends in Municipal Waste Stream

4.2. Selective Waste Collection and a Circular Economy

4.3. Biodrying and the Achievement of a Circular Economy

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment; Harvester Wheatsheaf: London, UK, 1990. [Google Scholar]

- Van Buren, N.; Demmers, M.; Van der Heijden, R.; Witlox, F. Towards a Circular Economy: The Role of Dutch Logistics Industries and Governments. Sustainability 2016, 8, 647. [Google Scholar] [CrossRef] [Green Version]

- Kazimierowicz, J.; Dzienis, L.; Dębowski, M.; Zieliński, M. Optimisation of methane fermentation as a valorisation method for food waste products. Biomass Bioenergy 2021, 144, 105913. [Google Scholar] [CrossRef]

- Kazimierowicz, J. Depletion Efficiency of Selected Expired Food Products in the Process of Methane Fermentation. J. Ecol. Eng. 2019, 20, 132–137. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Zieliński, M.; Dębowski, M. Influence of the Heating Method on the Efficiency of Biomethane Production from Expired Food Products. Fermentation 2021, 7, 12. [Google Scholar] [CrossRef]

- Dajian, Z. Background, Pattern and Policy of China for Developing Circular Economy. Chin. J. Popul. Resour. Environ. 2008, 6, 3–8. [Google Scholar] [CrossRef]

- Pesce, M.; Tamai, I.; Guo, D.; Critto, A.; Brombal, D.; Wang, X.; Cheng, H.; Marcomini, A. Circular Economy in China: Translating Principles into Practice. Sustainability 2020, 12, 832. [Google Scholar] [CrossRef] [Green Version]

- Eurostat Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Municipal_waste_statistics#Municipal_waste_treatment (accessed on 10 November 2021).

- Wang, W.; Themelis, N.J.; Sun, K.; Bourtsalas, A.C.; Huang, Q.; Zhang, Y.; Wu, Z. Current influence of China’s ban on plastic waste imports. Waste Dispos. Sustain. Energy 2019, 1, 67–78. [Google Scholar] [CrossRef] [Green Version]

- Marks, D. Southeast Asia’s Plastic Waste Problem. In East Asia Forum, June 2019. Available online: https://www.eastasiaforum.org/2019/06/26/southeast-asias-plastic-waste-problem (accessed on 10 November 2021).

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F.; Kendall, A. A Taxonomy of Circular Economy Indicators. J. Clean. Prod. 2019, 207, 542–559. [Google Scholar] [CrossRef] [Green Version]

- Kasztelan, A. How circular are the European economies? A taxonomic analysis based on the INEC (index of national economies’ circularity). Sustainability 2020, 12, 7613. [Google Scholar] [CrossRef]

- Competition in the Market of Communal Waste. Report of UOKiK, Warsaw, 2012. Available online: http://uokik.gov.pl/publikacje (accessed on 10 November 2021).

- Estimation of Investment Costs in the Field of Installations and Facilities for Municipal Waste Management in Poland in 2011–2020; Ministry of the Environment: Warsaw, Poland, 2010.

- Kepys, W.; Jaszczura, K. Waste Thermal Treatment Installations in Poland. Inżynieria Miner. 2020, 1, 47–50. [Google Scholar] [CrossRef]

- Council Directive 1999/31/EC of 26 April 1999 on the landfill of waste. Off. J. L 1999, 182, 1–19.

- Ecoprog GmbH. Waste to Energy 2019/2020: Technologies, Plants, Projects, Players and Backgrounds of the Global Thermal Waste Treatment Business. Extract. 12th ed. Cologne. 2019. Available online: https://www.ecoprog.com/fileadmin/user_upload/extract_market_report_WtE_2020-2021_ecoprog.pdf (accessed on 10 November 2021).

- Ragazzi, M.; Rada, E.C.; Panaitescu, V.; Apostol, T. Municipal solid waste pre-treatment: A comparison between two dewatering options. WIT Trans. Ecol. Environ. 2007, 102, 7. [Google Scholar] [CrossRef] [Green Version]

- Psaltis, P.; Komilis, D. Environmental and economic assessment of the use of biodrying before thermal treatment of municipal solid waste. Waste Manag. 2019, 83, 95–103. [Google Scholar] [CrossRef]

- Database of Waste Management Technologies. Available online: http://www.epem.gr/waste-c-control/database/html/case_study-20.htm (accessed on 10 November 2021).

- Hood, P.; Smith, S.R.; Skourides, I. A Method and System for Treating Mixed Municipal and Selected Commercial Waste; International Publication Number: WO 2008/065452 A2, 5-06-08; World Intellectual Property Organisation: Geneva, Switzerland, 2008; p. 17. [Google Scholar]

- Archer, E.; Baddeley, A.; Klein, A.; Schwager, J.; Whiting, K. Mechanical-Biological Treatment: A Guide for Decision Makers, Processes, Policies and Markets; Juniper Consultancy Services Ltd.: März, Austria, 2005. [Google Scholar]

- Velis, C.A.; Longhurst, P.J.; Drew, G.H.; Smith, R.; Pollard, S.J. Biodrying for mechanical–biological treatment of wastes: A review of process science and engineering. Bioresour. Technol. 2009, 100, 2747–2761. [Google Scholar] [CrossRef] [Green Version]

- Adani, F.; Baidoa, D.; Calcaterrab, E.; Genevini, P. The influence of biomass temperature on biostabilization—Biodrying of municipal solid waste. Bioresour. Technol. 2002, 83, 173–179. [Google Scholar] [CrossRef]

- Tambone, F.; Scaglia, B.; Scotti, S.; Adani, F. Effects of biodrying process on municipal solid waste properties. Bioresour. Technol. 2011, 102, 7443–7450. [Google Scholar] [CrossRef]

- Evangelou, A.; Gerassimidou, S.; Mavrakis, N.; Komilis, D. Monitoring the performances of a real scale municipal solid waste composting and a biodrying facility using respiration activity indices. Environ. Monit. Assess. 2016, 188, 302. [Google Scholar] [CrossRef]

- Rada, E.C.; Ragazzi, M.; Zardi, D.; Laiti, L.; Ferrari, A. PCDD/F enviromental impact from municipal solid waste bio-drying plant. Chemosphere 2011, 84, 289–295. [Google Scholar] [CrossRef]

- Malinauskaite, J.; Jouhara, H.; Czajczyńska, D.; Stanchev, P.; Katsou, E.; Rostkowski, P.; Thorne, R.J.; Colon, J. Ponsa, S.; Al.-Mansour, F.; et al. Municipal solid waste management and waste-to-energy in the context of a Circular Economy and energy recycling in Europe. Energy 2017, 141, 2013–2044. [Google Scholar] [CrossRef]

- Leal Filho, W.; Voronova, V.; Kloga, M.; Paço, A.; Minhas, A.; Salvia, A.L.; Ferreira, C.D.; Sivapalan, S. COVID-19 and waste production in households: A trend analysis. Sci. Total Environ. 2021, 777, 145997. [Google Scholar] [CrossRef]

- Antczak, E. Regionally Divergent Patterns in Factors Affecting Municipal Waste Production: The Polish Perspective. Sustainability 2020, 12, 6885. [Google Scholar] [CrossRef]

- Grodzińska-Jurczak, M. Management of industrial and municipal solid wastes in Poland. Resour. Conserv. Recycl. 2001, 32, 85–103. [Google Scholar] [CrossRef]

- Dennison, G.; Dodd, V.; Whelan, B. A socio-economic based survey of household waste characteristics in the city of Dublin, Ireland. I & II. Waste composition. Resour. Conserv. Recycl. 1996, 17, 227–257. [Google Scholar] [CrossRef]

- Daskalopoulos, E.; Badr, O.; Probert, S. Municipal solid waste: A prediction methodology for the generation rate and composition in the European Union countries and the United States of America. Resour. Conserv. Recycl. 1998, 24, 155–166. [Google Scholar] [CrossRef]

- Bandara, N.J.; Hettiaratchi, J.P.A.; Wirasinghe, S.; Pilapiiya, S. Relation of waste generation and composition to socio-economic factors: A case study. Environ. Monit. Assess. 2007, 135, 31–39. [Google Scholar] [CrossRef]

- Gellynck, X.; Jacobsen, R.; Verhelst, P. Identifying the key factors in increasing recycling and reducing residual household waste: A case study of the Flemish region of Belgium. J. Environ. Manag. 2011, 92, 2683–2690. [Google Scholar] [CrossRef]

- Zaleski, P.; Chawla, Y. Circular Economy in Poland: Profitability analysis for two methods of waste processing in small municipalities. Energies 2020, 13, 5166. [Google Scholar] [CrossRef]

- Beigl, P.; Lebersorger, S.; Salhofer, S. Modelling municipal solid waste generation: A review. Waste Manag. 2008, 28, 200–214. [Google Scholar] [CrossRef]

- Oribe-Garcia, I.; Kamara-Esteban, O.; Martin, C.; Macarulla-Arenaza, A.M.; Alonso-Vicario, A. Identification of influencing municipal characteristics regarding household waste generation and their forecasting ability in Biscay. Waste Manag. 2015, 9, 26–34. [Google Scholar] [CrossRef] [Green Version]

- Ramachandra, T.; Bharath, H.; Kulkarni, G.; Han, S.S. Municipal solid waste: Generation, composition and GHG emissions in Bangalore, India. Renew. Sustain. Energy Rev. 2018, 82, 1122–1136. [Google Scholar] [CrossRef]

- Hage, O.; Söderholm, P. An econometric analysis of regional differences in household waste collection: The case of plastic packaging waste in Sweden. Waste Manag. 2008, 28, 1720–1731. [Google Scholar] [CrossRef]

- Waste Management Plan for the Warmian-Masurian Voivodeship for 2016–2022 (Polish). Available online: https://bip.warmia.mazury.pl/114/plan-gospodarki-odpadami-dla-wojewodztwa-warminsko-mazurskiego-na-lata-2016-2022.html (accessed on 10 November 2021).

- Latosińska, J.; Miłek, D.; Komór, A.; Kowalik, R. Selective Collection of Municipal Waste in a Residential District with Multi-Family Buildings—Case Study from Poland. Resources 2021, 10, 83. [Google Scholar] [CrossRef]

- Abis, M.; Bruno, M.; Kuchta, K.; Simon, F.G.; Grönholm, R.; Hoppe, M.; Fiore, S. Assessment of the Synergy between Recycling and Thermal Treatments in Municipal Solid Waste Management in Europe. Energies 2020, 13, 6412. [Google Scholar] [CrossRef]

- Meyer, B. Macroeconomic Modelling of Sustainable Development and the Links between the Economy and the Environment; Final Report of the MacMod project (ENV. F. 1/ETU/2010/0033) to the European Commission; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- MacArthur, E. Towards the circular economy. J. Ind. Ecol. 2013, 2, 23–44. [Google Scholar]

- Economopoulos, A.P. Technoeconomic aspects of alternative municipal solid wastes treatment methods. Waste Manag. 2010, 30, 707–715. [Google Scholar] [CrossRef]

- Rolewicz-Kalińska, A.; Lelicińska-Serafin, K.; Manczarski, P. The Circular Economy and organic fraction of municipal solid waste recycling strategies. Energies 2020, 13, 4366. [Google Scholar] [CrossRef]

- Rada, E.C.; Ragazzi, M.; Badea, A. MSW Bio-drying: Design criteria from a 10 years research. UPB Sci. Bull. Ser. D 2012, 74, 209–216. [Google Scholar]

- Kazimierowicz, J. Legal Regulations and Methods Neutralising Expired Food Products. J. Ecol. Eng. 2018, 19, 217–224. [Google Scholar] [CrossRef]

- glass,

- glass,  - paper,

- paper,  - plastic,

- plastic,  - metal.

- metal.

- glass,

- glass,  - paper,

- paper,  - plastic,

- plastic,  - metal.

- metal.

| Component | Location | ||

|---|---|---|---|

| Larger City | Small Communities | Analyzed Region | |

| A | B | 63%·A + 37%·B | |

| Paper and carboard | 19.10% | 9.70% | 15.62% |

| Glass | 10.00% | 10.20% | 10.07% |

| Metals | 2.60% | 1.50% | 2.19% |

| Plastics | 15.10% | 11.00% | 13.58% |

| Tetra Pak | 2.50% | 4.00% | 3.06% |

| Kitchen/garden waste | 28.90% | 36.70% | 31.79% |

| Green waste | 5.30% | 5.30% | 5.30% |

| Total | 81.61% | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kasiński, S.; Dębowski, M.; Olkowska, M.; Rudnicki, M. Analysis of the Long-Term Mass Balance and Efficiency of Waste Recovery in a Municipal Waste Biodrying Plant. Energies 2021, 14, 7711. https://doi.org/10.3390/en14227711

Kasiński S, Dębowski M, Olkowska M, Rudnicki M. Analysis of the Long-Term Mass Balance and Efficiency of Waste Recovery in a Municipal Waste Biodrying Plant. Energies. 2021; 14(22):7711. https://doi.org/10.3390/en14227711

Chicago/Turabian StyleKasiński, Sławomir, Marcin Dębowski, Maria Olkowska, and Marcin Rudnicki. 2021. "Analysis of the Long-Term Mass Balance and Efficiency of Waste Recovery in a Municipal Waste Biodrying Plant" Energies 14, no. 22: 7711. https://doi.org/10.3390/en14227711

APA StyleKasiński, S., Dębowski, M., Olkowska, M., & Rudnicki, M. (2021). Analysis of the Long-Term Mass Balance and Efficiency of Waste Recovery in a Municipal Waste Biodrying Plant. Energies, 14(22), 7711. https://doi.org/10.3390/en14227711