Testing Selected Personal Protection Items of Firefighters in Combined Conditions of Mechanical Loads and Temperatures Occurring during Gas LNG Leaks

Abstract

1. Problem Description

2. Use of Personal Protection by Firefighters

3. General Characteristics of Risks Associated with the Use of LNG

4. Basic Requirements for Selected Firefighter’s Personal Protective Equipment

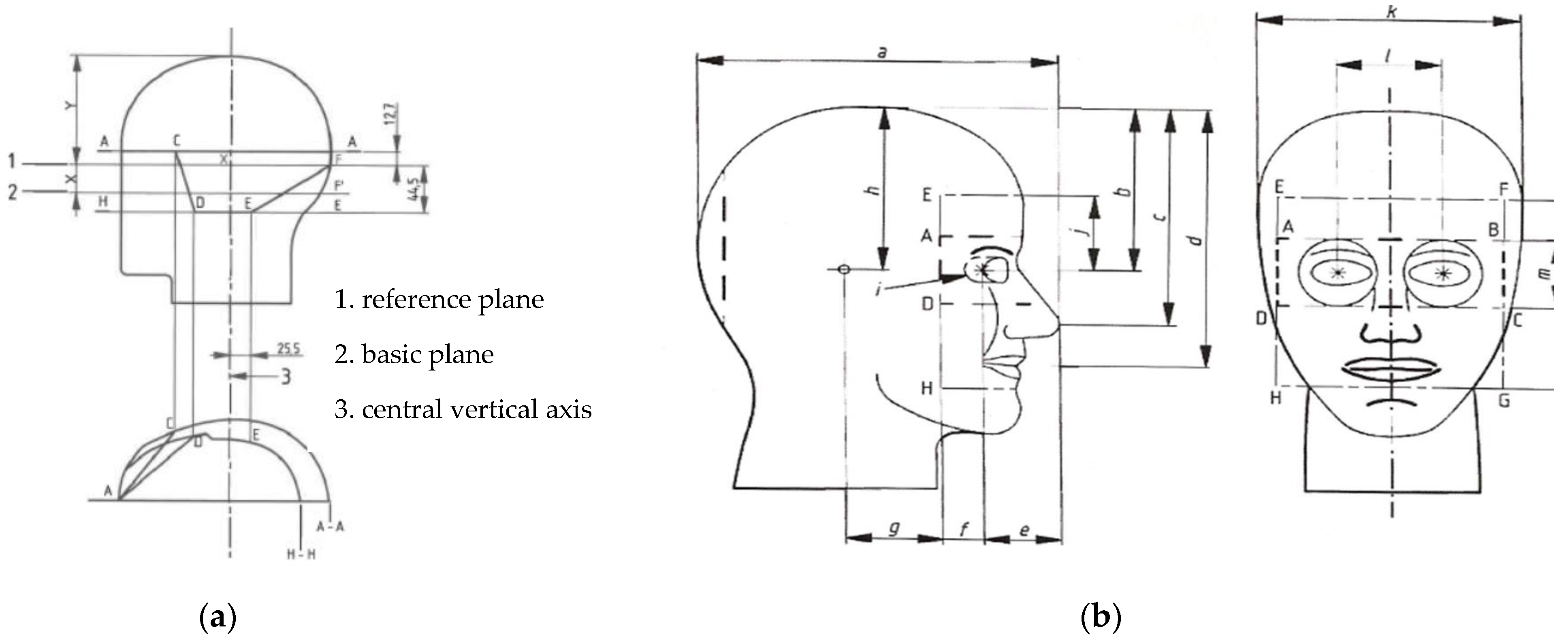

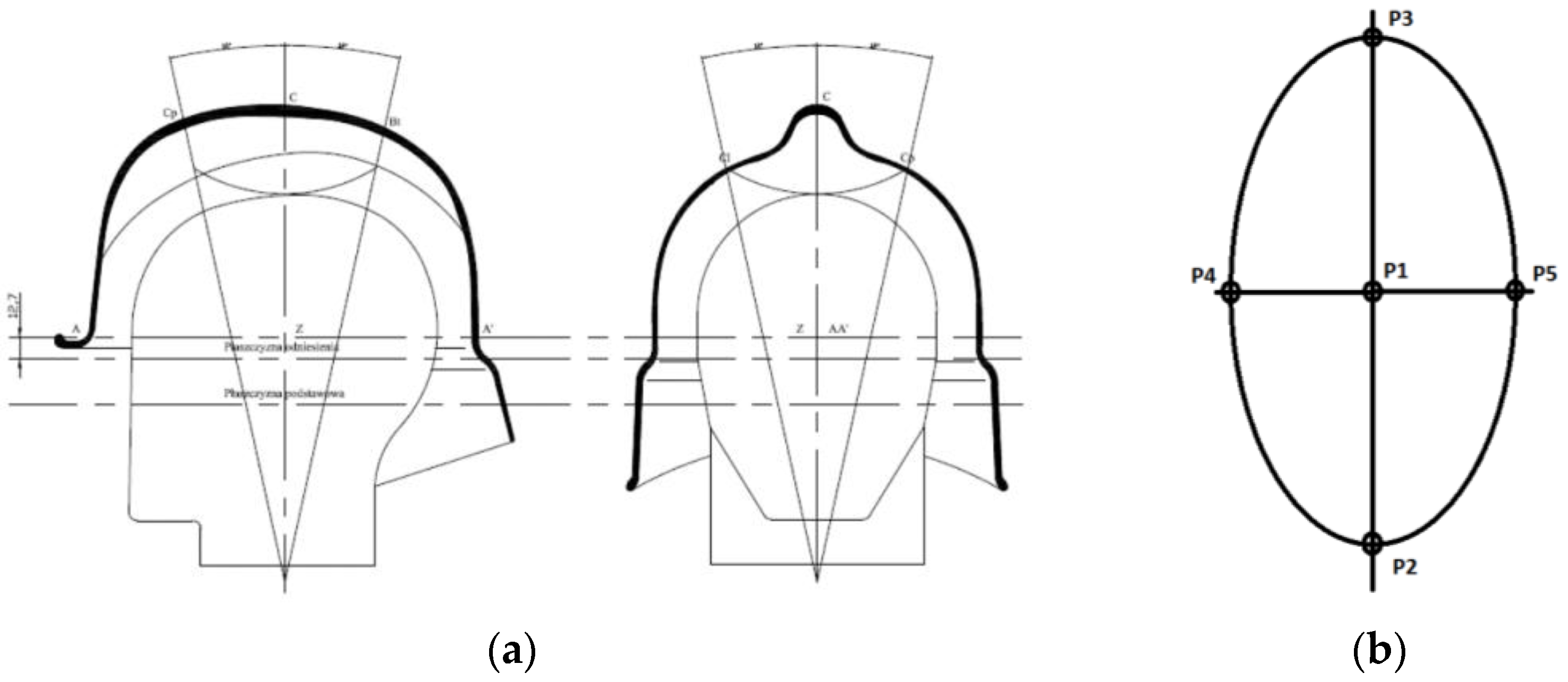

4.1. Helmets

4.2. Special Footwear

- Safety shoes (S),

- Protective shoes (P),

- Occupational shoes (O).

- good thermal insulation with the possibility of vapour transmission to the outside;

- protection against heat radiation;

- protection against mechanical damage by metal reinforcements of the heel, sole, toe, Achilles’ tendon and ankle joint;

- dielectric properties of the boot;

- energy-absorbing sole;

- anti-slip properties of the boot sole;

- use of zippers and laces allowing to adjust and fit the shoe profile to almost every leg;

- high resistance of the sole to contact with hot ground.

5. Studies of Selected Personal Protection Equipment of Firefighters at Reduced Temperatures

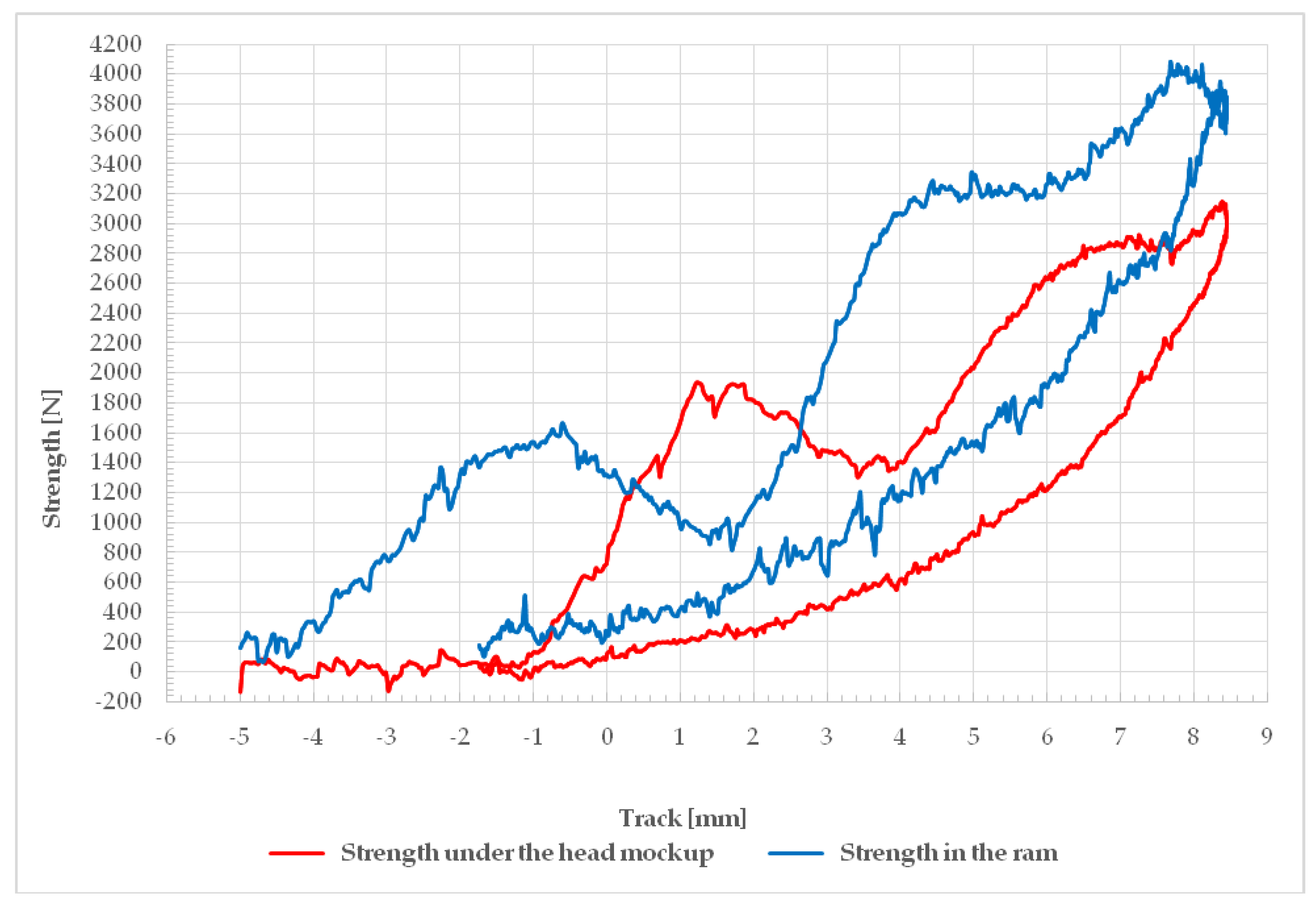

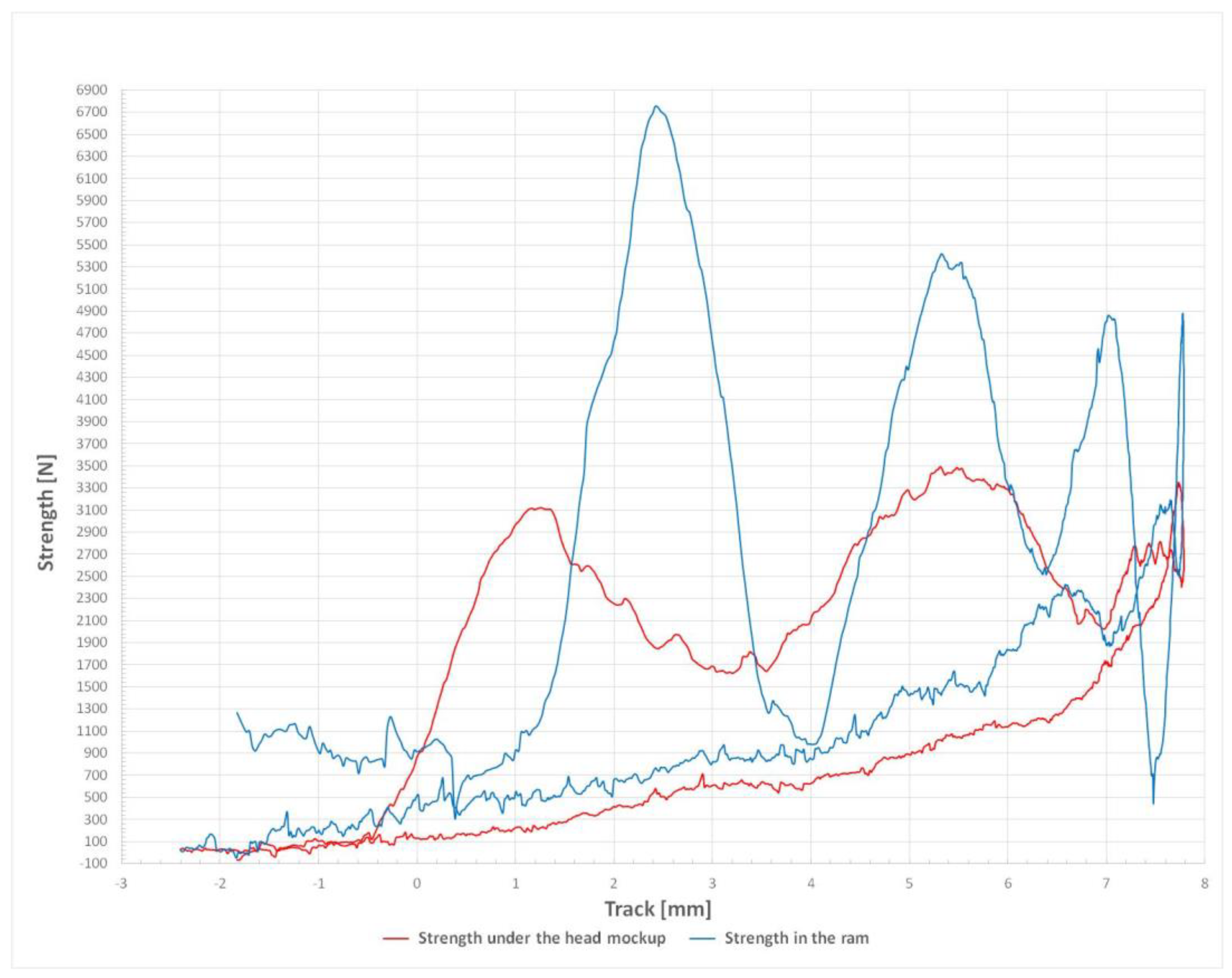

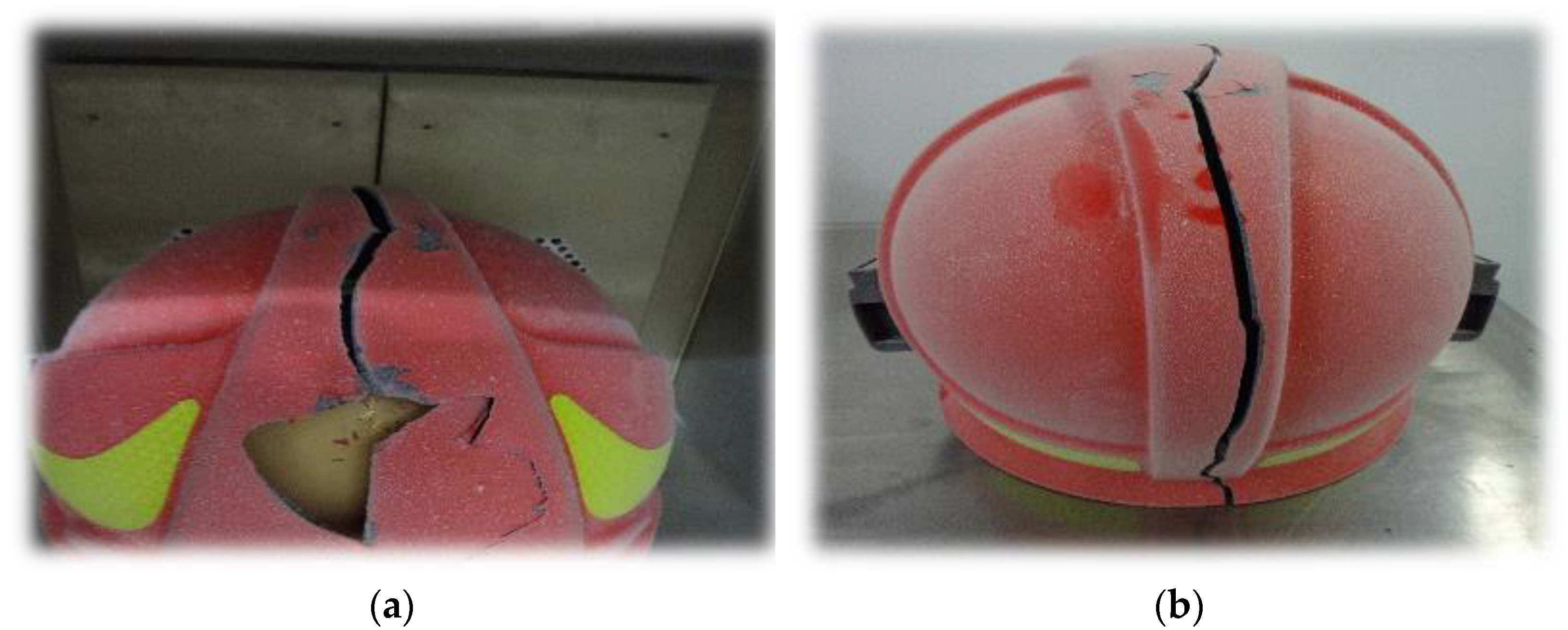

5.1. Helmets

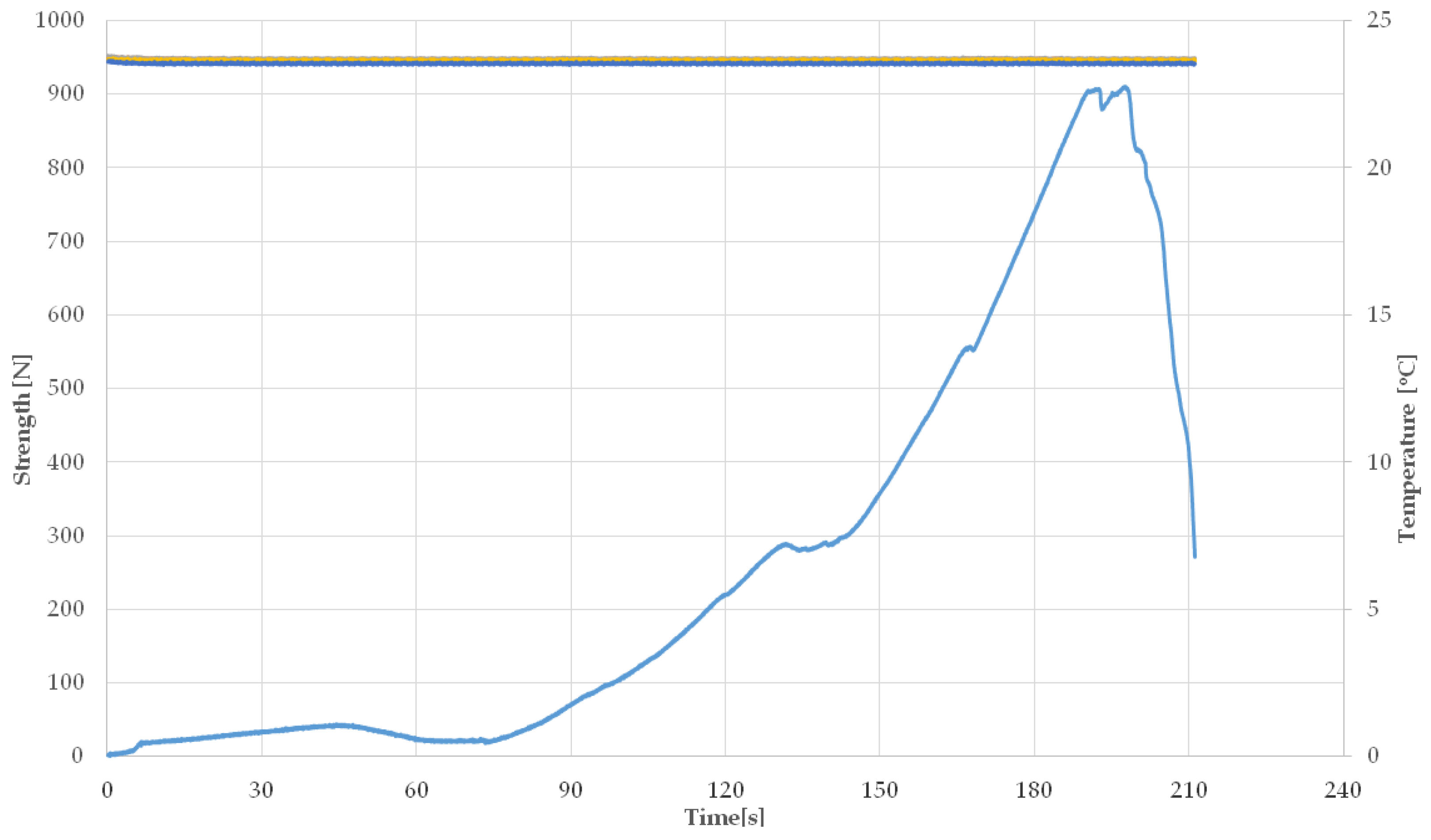

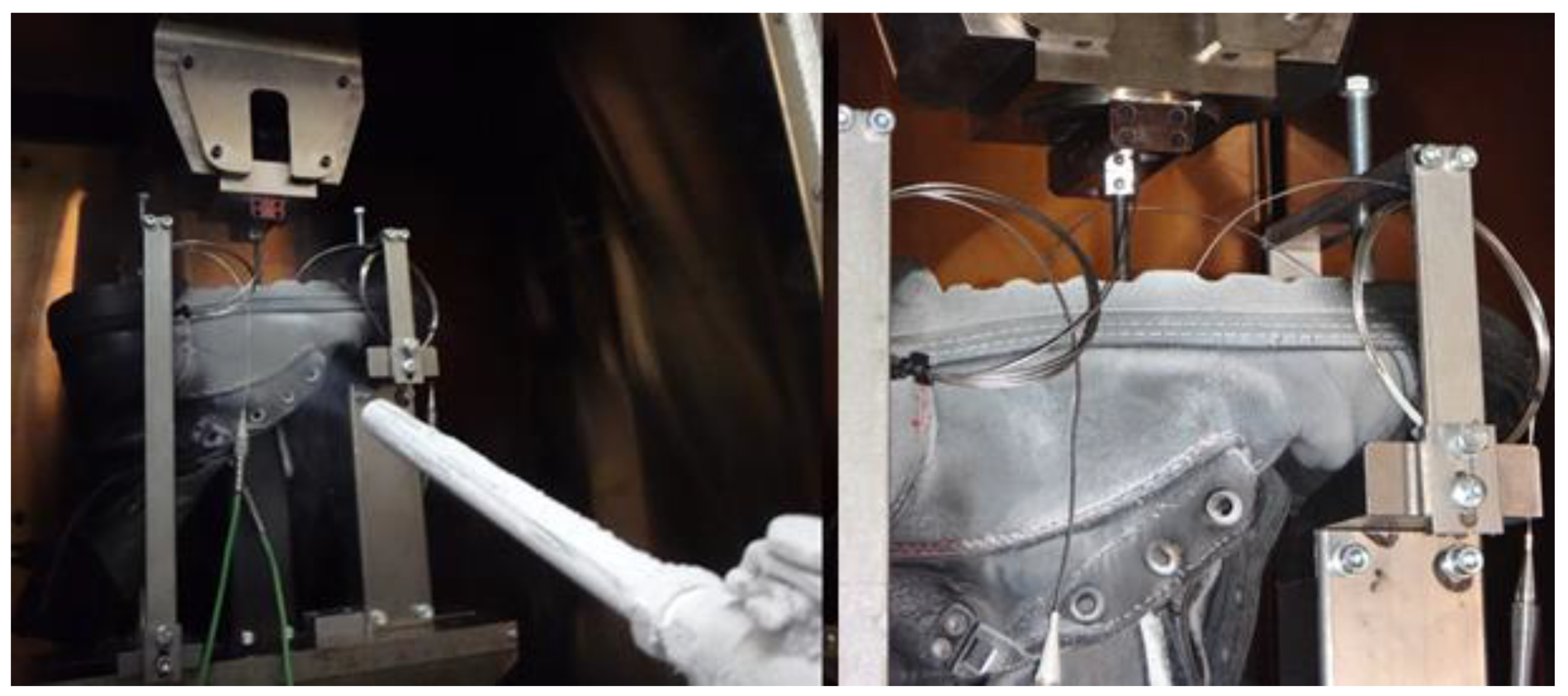

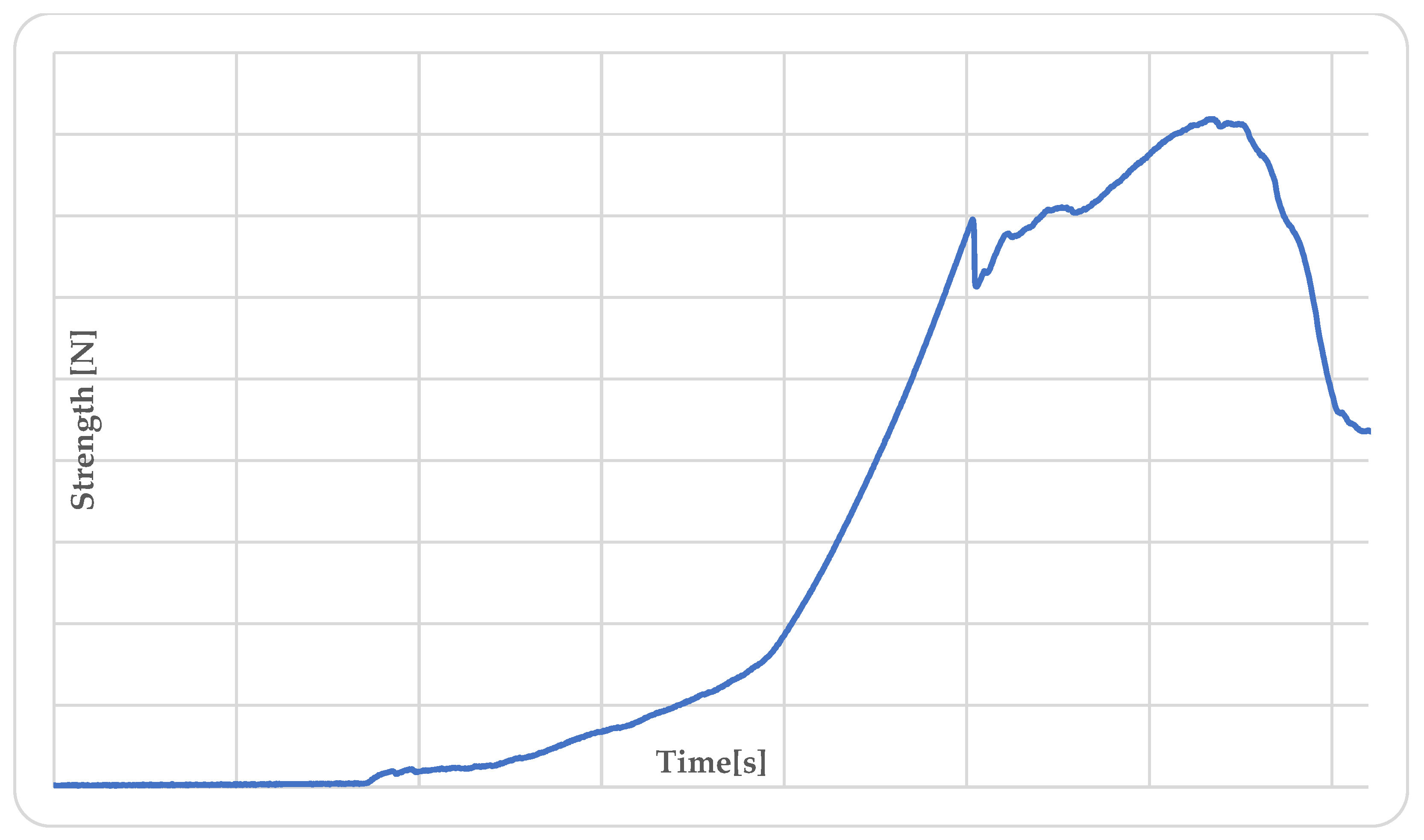

5.2. Special Footwear

6. Discussion

7. Conclusions

- Impact tests of firefighter helmets have shown that as regards the temperature of 20 °C, the value of the maximum force under the mock-up head was uniformly dependent on selected points. The situation changed completely when the chamber was cooled to −80 °C. In general, when hitting the first point (according to the experimental plan), the value of the maximum force was similar to the force at 20 °C and was 3489.99. However, the impact itself significantly damaged the helmet shell. This made it necessary to discontinue further testing;

- After lowering the temperature, the testing of the puncture force of firefighters’ special footwear resulted in the hardness of the sole increasing and, consequently, in the puncture force increasing by approx. 50%;

- The breakthrough time increased by approximately 100 s at a temperature of −60 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Occupational Safety and Health Administration. OSHA Issues Emergency Temporary Standard on COVID-19 Vaccination and Testing; United States Department of Labor: Washington, DC, USA, 2019. Available online: https://www.osha.gov/ (accessed on 20 October 2020).

- Radkowski, R.; Zwęgliński, T. Organizational Aspects of the Rescue System in Poland. In Security and Law in the Cognitive and Utilitarian Context; Wiśniewski, B., Kobes, P., Sander, G., Eds.; Verlag Dr. Kovač: Hamburg, Germany, 2015; Volume 17, pp. 145–158. [Google Scholar]

- Zwęgliński, T.; Radkowski, R. Jednostki ochrony przeciwpożarowej podczas epidemii COVID-19. Funkcjonowanie i zadania w pierwszych miesiącach aktywności wirusa SARS-CoV-2. Zesz. Nauk. SGSP 2020, 76, 93–114. [Google Scholar] [CrossRef]

- Zwęgliński, T.; Smolarkiewicz, M. Exercising in a Radioactive Environment—A Case Study from CBRNE Exercise in Chernobyl Exclusion Zone. Saf. Fire Technol. 2019, 54, 160–166. [Google Scholar] [CrossRef]

- Kahn, S.A.; Patel, J.H.; Lentz, C.W.; Bell, D.E. Firefighter Burn Injuries. J. Burn. Care Res. 2012, 33, 152–156. [Google Scholar] [CrossRef]

- Kunadharaju, K.; Smith, T.D.; DeJoy, D.M. Line-of-duty deaths among U.S. firefighters: An analysis of fatality investigations. Accid. Anal. Prev. 2011, 43, 1171–1180. [Google Scholar] [CrossRef]

- Maglio, M.A.; Scott, C.; Davis, A.L.; Allen, J.; Taylor, J.A. Situational Pressures that Influence Firefighters’ Decision Making about Personal Protective Equipment: A Qualitative Analysis. Am. J. Health Behav. 2016, 40, 555–567. [Google Scholar] [CrossRef] [PubMed]

- Kelloway, E.K.; Mullen, J.; Francis, L. Divergent effects of transformational and passive leadership on employee safety. J. Occup. Health Psychol. 2006, 11, 76–86. [Google Scholar] [CrossRef]

- Smith, T.D.; Eldridge, F.; DeJoy, D.M. Safety-specific transformational and passive leadership influences on firefighter safety climate perceptions and safety behavior outcomes. Saf. Sci. 2016, 86, 92–97. [Google Scholar] [CrossRef]

- Karter, M.J. Patterns of Firefighter Fire Ground Injuries; National Fire Protection Association: Quincy, MA, USA, January 2012.

- Bakri, I.; Lee, J.-Y.; Nakao, K.; Wakabayashi, H.; Tochihara, Y. Effects of firefighters’ self-contained breathing apparatus’ weight and its harness design on the physiological and subjective responses. Ergonomics 2012, 55, 782–791. [Google Scholar] [CrossRef] [PubMed]

- Plat, M.-C.J.; Frings-Dresen, M.H.; Sluiter, J.K. Clinimetric quality of the fire fighting simulation test as part of the Dutch fire fighters Workers’ Health Surveillance. BMC Health Serv. Res. 2010, 10, 32. [Google Scholar] [CrossRef]

- Williford, H.N.; Duey, W.J.; Olson, M.S.; Howard, R.; Wang, N. Relationship between fire fighting suppression tasks and physical fitness. Ergonomics 1999, 42, 1179–1186. [Google Scholar] [CrossRef]

- Alderman, J.A. Introduction to LNG safety. Process. Saf. Prog. 2005, 24, 144–151. [Google Scholar] [CrossRef]

- Bernatik, A.; Šenovský, P.; Pitt, M. LNG as a potential alternative fuel—Safety and security of storage facilities. J. Loss Prev. Process. Ind. 2011, 24, 19–24. [Google Scholar] [CrossRef]

- Bubbico, R.; Di Cave, S.; Mazzarotta, B. Preliminary risk analysis for LNG tankers approaching a maritime terminal. J. Loss Prev. Process. Ind. 2009, 22, 634–638. [Google Scholar] [CrossRef]

- Chamberlain, G.A. Management of Large LNG Hazards. In Proceedings of the 23rd World Gas Conference, Amsterdam, The Netherlands, 5–9 June 2006. [Google Scholar]

- Chan, S. Numerical simulations of LNG vapor dispersion from a fenced storage area. J. Hazard. Mater. 1992, 30, 195–224. [Google Scholar] [CrossRef]

- Project DOB-BIO9/15/02/2018 Entitled Innovative Research and Training Station “LNG Trainer” for the Development of Tactics for Operations with Equipment at the Disposal of the PSP during LNG Incidents. Available online: https://archiwum.ncbr.gov.pl/fileadmin/Obronnosc/9_2018/Lista_wnioskow_pozytywnie_ocenionych_pod_wzgledem_formalnym_BIO9.pdf (accessed on 12 December 2018).

- Zwęgliński, T. Rationalization of an emergency response measures for haz-mat incidents involving LNG in road transport. In Internal Security and Public Security. Law and Organization; Sander, G., Wiśniewski, B., Kobes, P., Eds.; Verlag Dr. Kovač: Hamburg, Germany, 2020; Volume 25, pp. 137–158. [Google Scholar]

- Available online: https://e-raports-ext.llnl.gov/pdf/195030.pdf (accessed on 9 November 2021).

- Nedelka, D.; Moorhouse, D.J.; Tucker, R.F. The Montoir 35 m Diameter LNG Pool Fire Experiments. In Proceedings of the 9th International Conference & Exhibition on Liquefied Natural Gas (LNG 9), Nice, France, 17–20 October 1989. [Google Scholar]

- Nicholson, P. Evolving Risks in the LNG Supply Chain. Public Utilities Fortnightly, January 2006; pp. 20–23. [Google Scholar]

- Maradikazeroini, A.; Shoele, K. Computational study of Rayleigh-Bernard convection in a cylindrical pressurized cryogenic tank. In Proceedings of the 74th Annual Meeting of the APS Division of Fluid Dynamics, Phoenix Convention Centre, Phoenix, Arizona, 21–23 November 2021. [Google Scholar]

- Liu, Y.; Banerjee, S.; Lian, Y. A Low Mach Number, Adaptive Mesh Method for Simulating Multiphase Flows in Cryogenic Fuel Tanks. In Proceedings of the SIAM Conference on Computational Science and Engineering, Virtual, 1–5 March 2021. [Google Scholar]

- Livingston, M.; Gustafson, R. Minimize Risks from Cryogenic Exposure on LNG Facilities Hydrocarbon. Processing 2009, 88, 51–58. [Google Scholar]

- Melhem, G.A. Managing LNG Rollover. Mosaic Corporation Quarterly News, March 2005; p. 1. [Google Scholar]

- Er, I.D. Safety and Environmental concern analysis for LNG carriers. Int. J. Mar. Navig. Saf. Sea Transp. 2007, 1, 421–426. [Google Scholar]

- Tanabe, M.; Miyake, A. Risk reduction concept to provide design criteria for Emergency Systems for onshore LNG plants. J. Loss Prev. Process. Ind. 2011, 24, 383–390. [Google Scholar] [CrossRef]

- EN 443. Helmets for Firefighting in Buildings and Other Structures; BSI: London, UK, 2008. [Google Scholar]

- EN 14458. Personal Eye-Equipment. High Performance Visors Intended Only for Use with Protective Helmets; BSI: London, UK, 2018. [Google Scholar]

- EN ISO 20345. Personal Protective Equipment—Safety Footwear; BSI: London, UK, 2012. [Google Scholar]

- EN ISO 20344. Personal Protective Equipment. Test Methods for Footwear; BSI: London, UK, 2012. [Google Scholar]

- Li, N.-N.; Liu, Y.-B.; Liu, K. Primary Discussion on LNG Terminal Fire Prevention System Design. Procedia Eng. 2013, 52, 181–185. [Google Scholar] [CrossRef][Green Version]

- Holmér, I. TLV in cold environments. J. Therm. Biol. 1993, 18, 643–646. [Google Scholar] [CrossRef]

- Williamson, D.; Chrenko, F.; Hamley, E. A study of exposure to cold in cold stores. Appl. Ergon. 1984, 15, 25–30. [Google Scholar] [CrossRef]

- Dyck, W. A review of Footwear for Cold/Wet Scenarios. Part I: The Boot (U), AD-A264 870; Defence Research Establishment: Ottawa, ON, Canada, 1992. [Google Scholar]

- Gavhed, D. Thermal Responses in Man to Combinations of Work Protocols and Clothing in Cold Air. Bachelor’s Thesis, Karolinska Institute, Division of Physiology and Pharmacology, Stockholm, Sweden, 1996. [Google Scholar]

- Nguyen-Tri, P.; Triki, E.; Nguyen, T.A. Butyl Rubber-Based Composite: Thermal Degradation and Prediction of Service Lifetime. J. Compos. Sci. 2019, 3, 48. [Google Scholar] [CrossRef]

- Jaunich, M.; Stark, W.; Wolff, D. Low Temperature Properties of Rubber Seals. Results of Component Tests. Raw Mater. Appl. 2013, 66, 26–30. [Google Scholar]

- Grelle, T.; Wolff, D.; Jaunich, M. Leakage behaviour of elastomer seals under dynamic unloading conditions at low temperatures. Polym. Test. 2017, 58, 219–226. [Google Scholar] [CrossRef]

| Item | Maximum Force under Head Mock-Up (N) | Tit Deflection of Shock Absorbing System (mm) | Transfer Energy (J) | Dissipation Energy (J) | Time (s) |

|---|---|---|---|---|---|

| Point P1 (20 °C) | 3144.84 | 8.46 | 17.0 | 12.9 | 0.025 |

| Point P2 (20 °C) | 2079.11 | 17.39 | 21.4 | 8.6 | 0.062 |

| Point P3 (20 °C) | 2875.78 | 18.65 | 21.3 | 8.7 | 0.034 |

| Point P4 (20 °C) | 2382.32 | 17.91 | 25.0 | 5.1 | 0.035 |

| Point P5 (20 °C) | 2665.28 | 16.34 | 26.2 | 3.7 | 0.034 |

| Point P1 (−80 °C) | 3489.99 | 7.78 | 12.4 | 17.7 | 0.028 |

| Point P2 (−80 °C) | 1778.42 | 36.02 | 15.1 | 14.8 | 0.062 |

| Puncture Force (−60 °C) (N) | Puncture Force (20 °C) (N) |

|---|---|

| 1776.6 | 912.7 |

| 1820.7 | 896.7 |

| 1685.4 | 910.4 |

| 1764.2 | 900.7 |

| 1764.2 | 922.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogrodnik, P.; Powęzka, A.; Piec, R.; Zwęgliński, T.; Smolarkiewicz, M.; Gromek, P.; Wróbel, R.; Węsierski, T.; Majder-Łopatka, M.; Wąsik, W. Testing Selected Personal Protection Items of Firefighters in Combined Conditions of Mechanical Loads and Temperatures Occurring during Gas LNG Leaks. Energies 2021, 14, 7698. https://doi.org/10.3390/en14227698

Ogrodnik P, Powęzka A, Piec R, Zwęgliński T, Smolarkiewicz M, Gromek P, Wróbel R, Węsierski T, Majder-Łopatka M, Wąsik W. Testing Selected Personal Protection Items of Firefighters in Combined Conditions of Mechanical Loads and Temperatures Occurring during Gas LNG Leaks. Energies. 2021; 14(22):7698. https://doi.org/10.3390/en14227698

Chicago/Turabian StyleOgrodnik, Paweł, Aleksandra Powęzka, Robert Piec, Tomasz Zwęgliński, Marcin Smolarkiewicz, Paweł Gromek, Rafał Wróbel, Tomasz Węsierski, Małgorzata Majder-Łopatka, and Wiktor Wąsik. 2021. "Testing Selected Personal Protection Items of Firefighters in Combined Conditions of Mechanical Loads and Temperatures Occurring during Gas LNG Leaks" Energies 14, no. 22: 7698. https://doi.org/10.3390/en14227698

APA StyleOgrodnik, P., Powęzka, A., Piec, R., Zwęgliński, T., Smolarkiewicz, M., Gromek, P., Wróbel, R., Węsierski, T., Majder-Łopatka, M., & Wąsik, W. (2021). Testing Selected Personal Protection Items of Firefighters in Combined Conditions of Mechanical Loads and Temperatures Occurring during Gas LNG Leaks. Energies, 14(22), 7698. https://doi.org/10.3390/en14227698