Monolithic Perovskite/Silicon-Heterojunction Tandem Solar Cells with Nanocrystalline Si/SiOx Tunnel Junction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Perovskite Solar Cells Fabrication

2.2. SHJ Solar Cells Fabrication

2.3. Tandem Solar Cells Fabrication

- c-Si wafer cleaning and removal of native oxides;

- c-Si wafer processing for the realization of the SHJ device (without front electrode) and the tunnel junction by vacuum techniques (PECVD, sputtering, evaporation);

- cutting of the processed wafer into smaller square pieces for further processing;

- UV-ozone treatment of the top surface and subsequent fabrication by spin coating of the main layers forming the perovskite top cell (ETL, absorber, HTL);

- realization of the transparent front contact stack and metal grid by evaporation and sputtering;

- application of front antireflection coating by evaporation (on selected samples).

2.4. Characterization of Materials and Devices

3. Results and Discussion

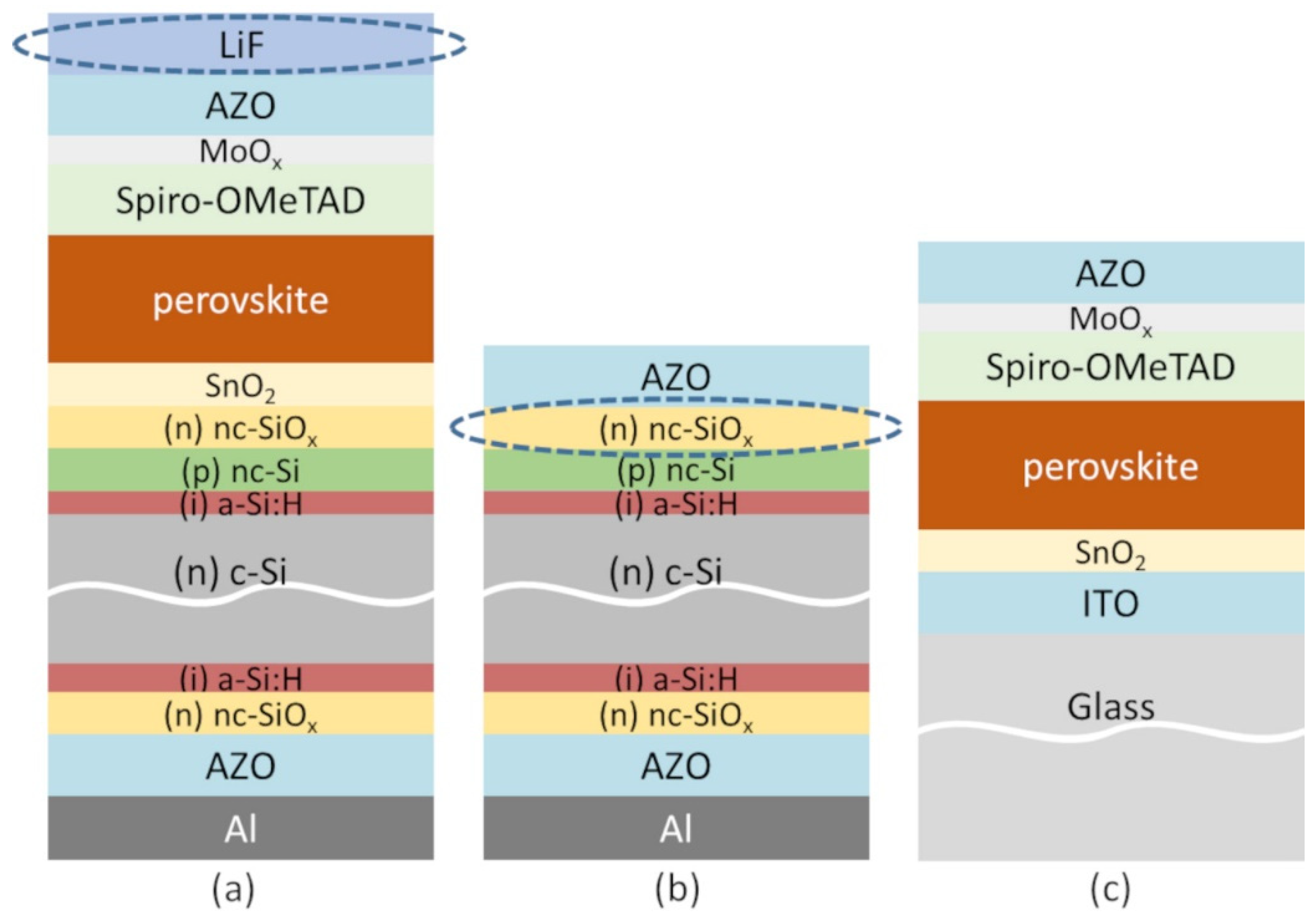

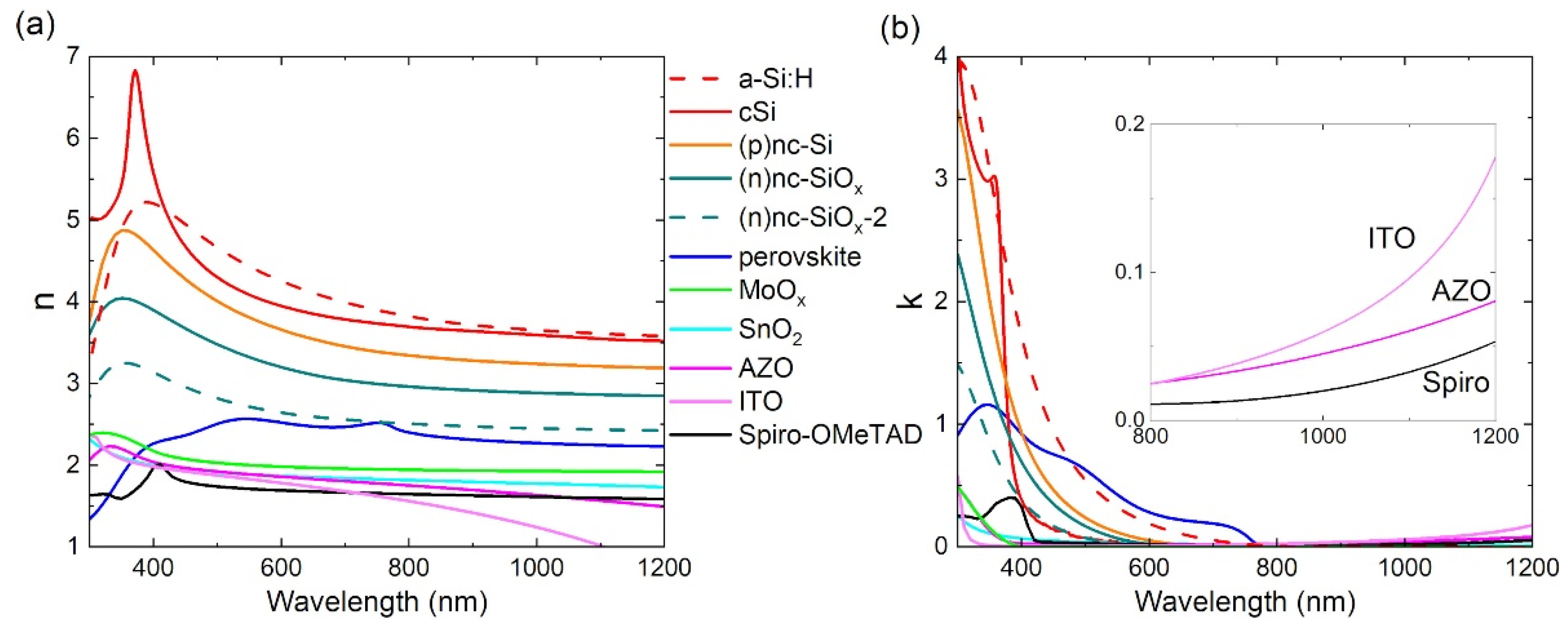

3.1. Device Design and Optical Simulations

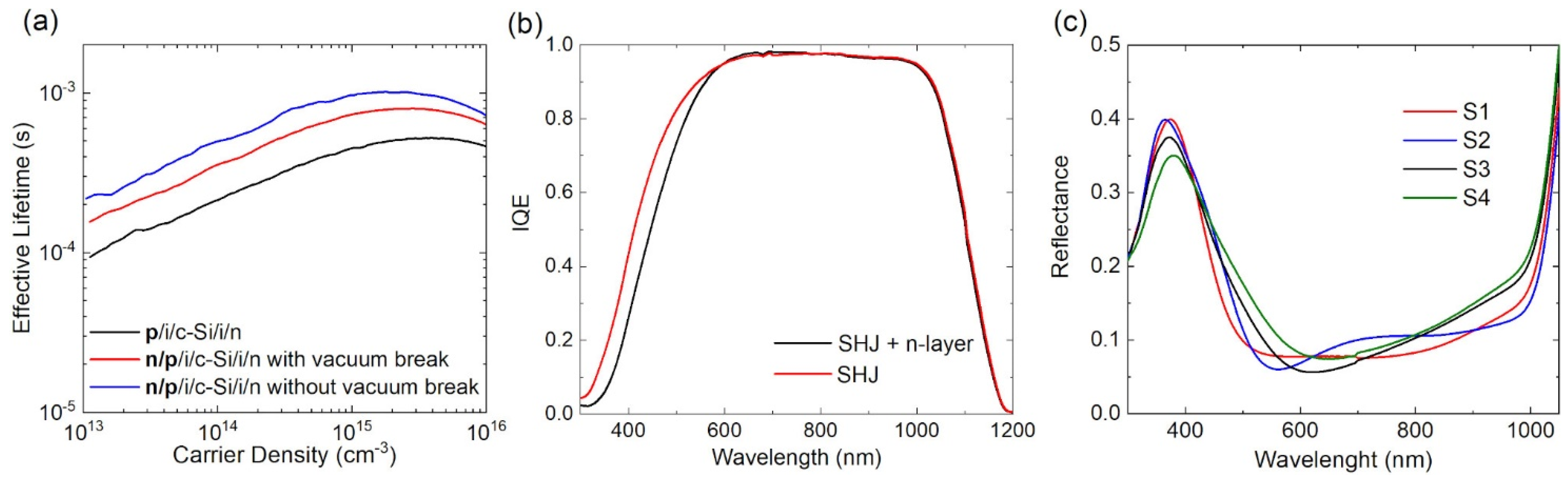

3.2. Tunnel Recombination Junction

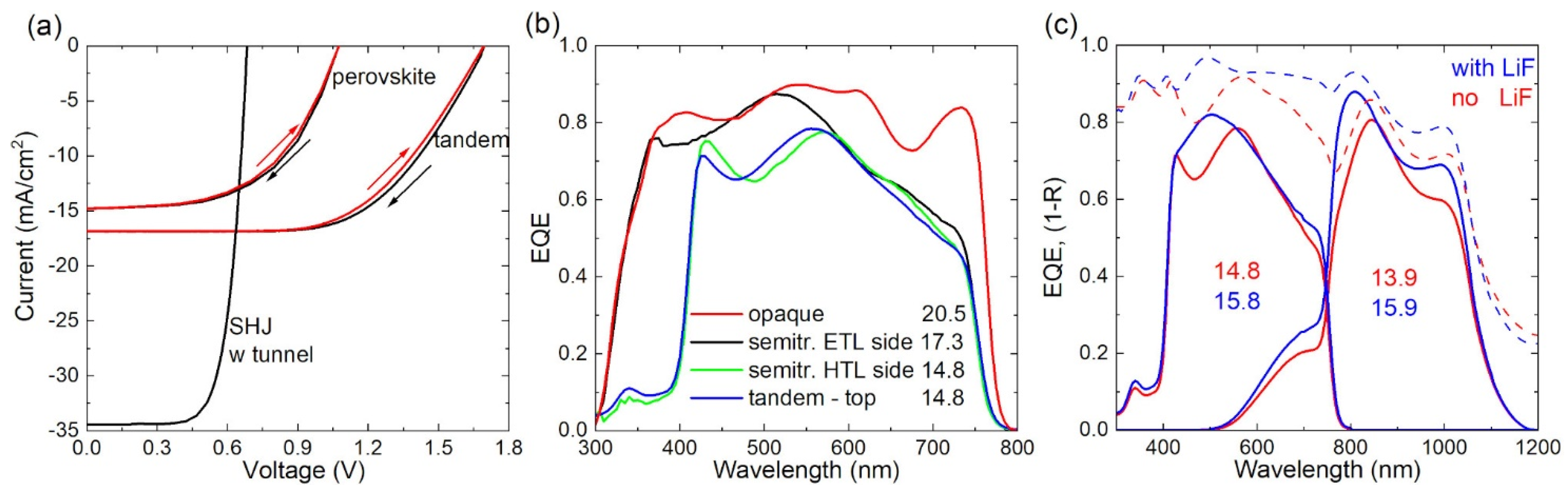

3.3. Semitransparent Perovskite Solar Cells and Perovskite/SHJ Tandem Solar Cells

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Kim, M.; Wang, L.; Verlinden, P.; Hallam, B. Design Considerations for Multi-Terawatt Scale Manufacturing of Existing and Future Photovoltaic Technologies: Challenges and Opportunities Related to Silver, Indium and Bismuth Consumption. Energy Environ. Sci. 2021, 14, 5587–5610. [Google Scholar] [CrossRef]

- Reyes-Belmonte, M.A. Quo Vadis Solar Energy Research? Appl. Sci. 2021, 11, 3015. [Google Scholar] [CrossRef]

- Almansouri, I.; Ho-Baillie, A.; Bremner, S.P.; Green, M.A. Supercharging Silicon Solar Cell Performance by Means of Multijunction Concept. IEEE J. Photovolt. 2015, 5, 968–976. [Google Scholar] [CrossRef]

- Green, M.A.; Dunlop, E.D.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Hao, X. Solar Cell Efficiency Tables (Version 58). Prog. Photovolt. Res. Appl. 2021, 29, 657–667. [Google Scholar] [CrossRef]

- Al-Ashouri, A.; Köhnen, E.; Li, B.; Magomedov, A.; Hempel, H.; Caprioglio, P.; Márquez, J.A.; Vilches, A.B.M.; Kasparavicius, E.; Smith, J.A.; et al. Monolithic Perovskite/Silicon Tandem Solar Cell with >29% Efficiency by Enhanced Hole Extraction. Science 2020, 370, 1300–1309. [Google Scholar] [CrossRef] [PubMed]

- Jošt, M.; Kegelmann, L.; Korte, L.; Albrecht, S. Monolithic Perovskite Tandem Solar Cells: A Review of the Present Status and Advanced Characterization Methods Toward 30% Efficiency. Adv. Energy Mater. 2020, 10, 1904102. [Google Scholar] [CrossRef]

- Jeong, J.; Kim, M.; Seo, J.; Lu, H.; Ahlawat, P.; Mishra, A.; Yang, Y.; Hope, M.A.; Eickemeyer, F.T.; Kim, M.; et al. Pseudo-Halide Anion Engineering for α-FAPbI3 Perovskite Solar Cells. Nature 2021, 592, 381–385. [Google Scholar] [CrossRef]

- Hörantner, M.T.; Leijtens, T.; Ziffer, M.E.; Eperon, G.E.; Christoforo, M.G.; McGehee, M.D.; Snaith, H.J. The Potential of Multijunction Perovskite Solar Cells. ACS Energy Lett. 2017, 2, 2506–2513. [Google Scholar] [CrossRef]

- Sahli, F.; Kamino, B.A.; Werner, J.; Bräuninger, M.; Paviet-Salomon, B.; Barraud, L.; Monnard, R.; Seif, J.P.; Tomasi, A.; Jeangros, Q.; et al. Improved Optics in Monolithic Perovskite/Silicon Tandem Solar Cells with a Nanocrystalline Silicon Recombination Junction. Adv. Energy Mater. 2018, 8, 1701609. [Google Scholar] [CrossRef]

- Mazzarella, L.; Lin, Y.-H.; Kirner, S.; Morales-Vilches, A.B.; Korte, L.; Albrecht, S.; Crossland, E.; Stannowski, B.; Case, C.; Snaith, H.J.; et al. Infrared Light Management Using a Nanocrystalline Silicon Oxide Interlayer in Monolithic Perovskite/Silicon Heterojunction Tandem Solar Cells with Efficiency above 25%. Adv. Energy Mater. 2019, 9, 1803241. [Google Scholar] [CrossRef]

- Saliba, M.; Matsui, T.; Seo, J.-Y.; Domanski, K.; Correa-Baena, J.-P.; Nazeeruddin, M.K.; Zakeeruddin, S.M.; Tress, W.; Abate, A.; Hagfeldt, A.; et al. Cesium-Containing Triple Cation Perovskite Solar Cells: Improved Stability, Reproducibility and High Efficiency. Energy Environ. Sci. 2016, 9, 1989–1997. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yoshikawa, K.; Kawasaki, H.; Yoshida, W.; Irie, T.; Konishi, K.; Nakano, K.; Uto, T.; Adachi, D.; Kanematsu, M.; Uzu, H.; et al. Silicon Heterojunction Solar Cell with Interdigitated Back Contacts for a Photoconversion Efficiency over 26%. Nat. Energy 2017, 2, 1–8. [Google Scholar] [CrossRef]

- Ru, X.; Qu, M.; Wang, J.; Ruan, T.; Yang, M.; Peng, F.; Long, W.; Zheng, K.; Yan, H.; Xu, X. 25.11% Efficiency Silicon Heterojunction Solar Cell with Low Deposition Rate Intrinsic Amorphous Silicon Buffer Layers. Sol. Energy Mater. Sol. Cells 2020, 215, 110643. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Wu, Y.; Yang, G.; Mazzarella, L.; Procel-Moya, P.; Tamboli, A.C.; Weber, K.; Boccard, M.; Isabella, O.; et al. High-Efficiency Silicon Heterojunction Solar Cells: Materials, Devices and Applications. Mater. Sci. Eng. R Rep. 2020, 142, 100579. [Google Scholar] [CrossRef]

- Bastiani, M.D.; Subbiah, A.S.; Aydin, E.; Isikgor, F.H.; Allen, T.G.; Wolf, S.D. Recombination Junctions for Efficient Monolithic Perovskite-Based Tandem Solar Cells: Physical Principles, Properties, Processing and Prospects. Mater. Horiz. 2020, 7, 2791–2809. [Google Scholar] [CrossRef]

- Albrecht, S.; Saliba, M.; Baena, J.P.C.; Lang, F.; Kegelmann, L.; Mews, M.; Steier, L.; Abate, A.; Rappich, J.; Korte, L.; et al. Monolithic Perovskite/Silicon-Heterojunction Tandem Solar Cells Processed at Low Temperature. Energy Environ. Sci. 2016, 9, 81–88. [Google Scholar] [CrossRef]

- Bush, K.A.; Palmstrom, A.F.; Yu, Z.J.; Boccard, M.; Cheacharoen, R.; Mailoa, J.P.; McMeekin, D.P.; Hoye, R.L.Z.; Bailie, C.D.; Leijtens, T.; et al. 23.6%-Efficient Monolithic Perovskite/Silicon Tandem Solar Cells with Improved Stability. Nat. Energy 2017, 2, 1–7. [Google Scholar] [CrossRef]

- Aydin, E.; Liu, J.; Ugur, E.; Azmi, R.; Harrison, G.T.; Hou, Y.; Chen, B.; Zhumagali, S.; Bastiani, M.D.; Wang, M.; et al. Ligand-Bridged Charge Extraction and Enhanced Quantum Efficiency Enable Efficient n–i–p Perovskite/Silicon Tandem Solar Cells. Energy Environ. Sci. 2021, 14, 4377–4390. [Google Scholar] [CrossRef]

- Puaud, A.; Ozanne, A.-S.; Senaud, L.-L.; Muñoz, D.; Roux, C. Microcrystalline Silicon Tunnel Junction for Monolithic Tandem Solar Cells Using Silicon Heterojunction Technology. IEEE J. Photovolt. 2021, 11, 58–64. [Google Scholar] [CrossRef]

- Mercaldo, L.V.; Usatii, I.; Veneri, P.D. Advances in Thin-Film Si Solar Cells by Means of SiOx Alloys. Energies 2016, 9, 218. [Google Scholar] [CrossRef] [Green Version]

- Despeisse, M.; Bugnon, G.; Feltrin, A.; Stueckelberger, M.; Cuony, P.; Meillaud, F.; Billet, A.; Ballif, C. Resistive Interlayer for Improved Performance of Thin Film Silicon Solar Cells on Highly Textured Substrate. Appl. Phys. Lett. 2010, 96, 073507. [Google Scholar] [CrossRef]

- Čampa, A.; Meier, M.; Boccard, M.; Mercaldo, L.V.; Ghosh, M.; Zhang, C.; Merdzhanova, T.; Krč, J.; Haug, F.-J.; Topič, M. Micromorph Silicon Solar Cell Optical Performance: Influence of Intermediate Reflector and Front Electrode Surface Texture. Sol. Energy Mater. Sol. Cells 2014, 130, 401–409. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, L.; Wang, H.; Yang, X.; Meng, J.; Liu, H.; Yin, Z.; Wu, J.; Zhang, X.; You, J. Enhanced Electron Extraction Using SnO2 for High-Efficiency Planar-Structure HC(NH2)2PbI3-Based Perovskite Solar Cells. Nat. Energy 2016, 2, 1–7. [Google Scholar] [CrossRef]

- Jeon, N.J.; Noh, J.H.; Kim, Y.C.; Yang, W.S.; Ryu, S.; Seok, S.I. Solvent Engineering for High-Performance Inorganic–Organic Hybrid Perovskite Solar Cells. Nat. Mater. 2014, 13, 897–903. [Google Scholar] [CrossRef]

- La Ferrara, V.; De Maria, A.; Rametta, G.; Delli Veneri, P. The Effect of Storage Cycle on Improvement in the Photovoltaic Parameters of Planar Triple Cation Perovskite Solar Cells. Mater. Adv. 2021, 2, 5396–5405. [Google Scholar] [CrossRef]

- Mercaldo, L.V.; Bobeico, E.; Usatii, I.; Della Noce, M.; Lancellotti, L.; Serenelli, L.; Izzi, M.; Tucci, M.; Delli Veneri, P. Potentials of Mixed-Phase Doped Layers in p-Type Si Heterojunction Solar Cells with ZnO:Al. Sol. Energy Mater. Sol. Cells 2017, 169, 113–121. [Google Scholar] [CrossRef]

- Demaurex, B.; De Wolf, S.; Descoeudres, A.; Charles Holman, Z.; Ballif, C. Damage at Hydrogenated Amorphous/Crystalline Silicon Interfaces by Indium Tin Oxide Overlayer Sputtering. Appl. Phys. Lett. 2012, 101, 171604. [Google Scholar] [CrossRef] [Green Version]

- Palik, E.D. (Ed.) Handbook of Optical Constants of Solids; Academic Press: Boston, MA, USA, 1998; ISBN 978-0-12-544422-4. [Google Scholar]

- Raoult, E.; Bodeux, R.; Jutteau, S.; Rives, S.; Yaiche, A.; Coutancier, D.; Rousset, J.; Collin, S. Optical Characterizations and Modelling of Semitransparent Perovskite Solar Cells for Tandem Applications. Eur. Photovolt. Sol. Energy Conf. Exhib. 2019, 757–763. [Google Scholar] [CrossRef]

- Shirayama, M.; Kadowaki, H.; Miyadera, T.; Sugita, T.; Tamakoshi, M.; Kato, M.; Fujiseki, T.; Murata, D.; Hara, S.; Murakami, T.N.; et al. Optical Transitions in Hybrid Perovskite Solar Cells: Ellipsometry, Density Functional Theory, and Quantum Efficiency Analyses for CH3NH3PbI3. Phys. Rev. Appl. 2016, 5, 014012. [Google Scholar] [CrossRef] [Green Version]

- IMD Can Be Run as an Extension to the Free XOP Software Package, Available at ESRF. Available online: Esrf.fr/Instrumentation/software/data-analysis/xop2.4 (accessed on 19 October 2021).

| Cell | VOC (V) | JSC (mA/cm2) | FF (%) | η (%) | Area (cm2) | p/n (nm/nm) |

|---|---|---|---|---|---|---|

| SHJ | ||||||

| S1-ref | 0.641 | 34.6 | 71.5 | 15.8 | 4 | 19/-- |

| SHJ with tunnel junction | ||||||

| S1 | 0.684 | 34.4 | 71.1 | 16.7 | 4 | 19/37 |

| S2 | 0.680 | 33.2 | 72.1 | 16.2 | 4 | 22/55 |

| S3 | 0.711 | 34.0 | 62.4 | 15.1 | 4 | 21/15 |

| S4 | 0.702 | 33.3 | 66.4 | 15.5 | 4 | 31/19 |

| Perovskite | ||||||

| Opaque | 1.045 | 20.5 | 79.2 | 17.0 | 0.11 | --/-- |

| Semitransp. | 1.082 | 14.8 | 55.1 | 8.8 | 0.63 | --/-- |

| Tandem | ||||||

| A 1 | 1.660 | 16.8 | 63.4 | 17.7 | 1 | 19/37 |

| B | 1.795 | 12.8 | 71.5 | 16.5 | 1 | 31/19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mercaldo, L.V.; Bobeico, E.; De Maria, A.; Della Noce, M.; Ferrara, M.; La Ferrara, V.; Lancellotti, L.; Rametta, G.; Sannino, G.V.; Usatii, I.; et al. Monolithic Perovskite/Silicon-Heterojunction Tandem Solar Cells with Nanocrystalline Si/SiOx Tunnel Junction. Energies 2021, 14, 7684. https://doi.org/10.3390/en14227684

Mercaldo LV, Bobeico E, De Maria A, Della Noce M, Ferrara M, La Ferrara V, Lancellotti L, Rametta G, Sannino GV, Usatii I, et al. Monolithic Perovskite/Silicon-Heterojunction Tandem Solar Cells with Nanocrystalline Si/SiOx Tunnel Junction. Energies. 2021; 14(22):7684. https://doi.org/10.3390/en14227684

Chicago/Turabian StyleMercaldo, Lucia V., Eugenia Bobeico, Antonella De Maria, Marco Della Noce, Manuela Ferrara, Vera La Ferrara, Laura Lancellotti, Gabriella Rametta, Gennaro V. Sannino, Iurie Usatii, and et al. 2021. "Monolithic Perovskite/Silicon-Heterojunction Tandem Solar Cells with Nanocrystalline Si/SiOx Tunnel Junction" Energies 14, no. 22: 7684. https://doi.org/10.3390/en14227684

APA StyleMercaldo, L. V., Bobeico, E., De Maria, A., Della Noce, M., Ferrara, M., La Ferrara, V., Lancellotti, L., Rametta, G., Sannino, G. V., Usatii, I., & Delli Veneri, P. (2021). Monolithic Perovskite/Silicon-Heterojunction Tandem Solar Cells with Nanocrystalline Si/SiOx Tunnel Junction. Energies, 14(22), 7684. https://doi.org/10.3390/en14227684