Multi-Channel Profile Based Artificial Neural Network Approach for Remaining Useful Life Prediction of Electric Vehicle Lithium-Ion Batteries

Abstract

:1. Introduction

- The proposed method considers input parameters from the charging profiles such as voltage, current, and temperature along with discharge capacity degradation profile.

- In addition, the method employs systematic sampling to obtain critical sample values of input parameters from each charging cycle at equal intervals. Due to the inclusion of systematic sampling, it is easy to reconstitute or redesign the prediction curve while training the algorithm.

- The novelty of the proposed work lies in the development of an intelligent framework for RUL prediction of lithium-ion batteries as well as training the algorithm with various dataset combinations provided by NASA. The performance of the system is evaluated using various statistical error terms. The effectiveness of the presented algorithm is verified by training the model with various dataset combinations.

2. Battery Data Preparation

2.1. Lithium-Ion Battery Dataset

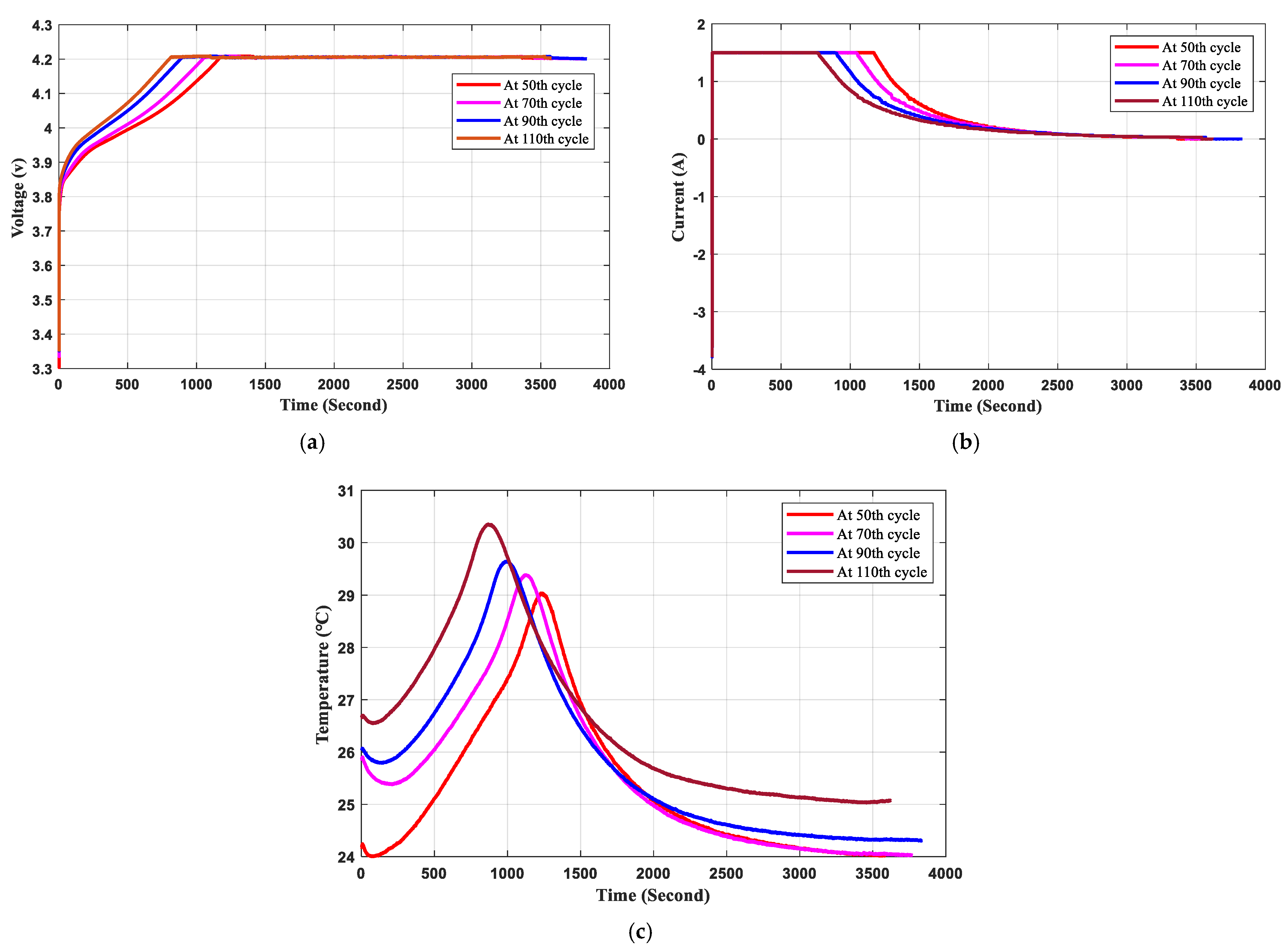

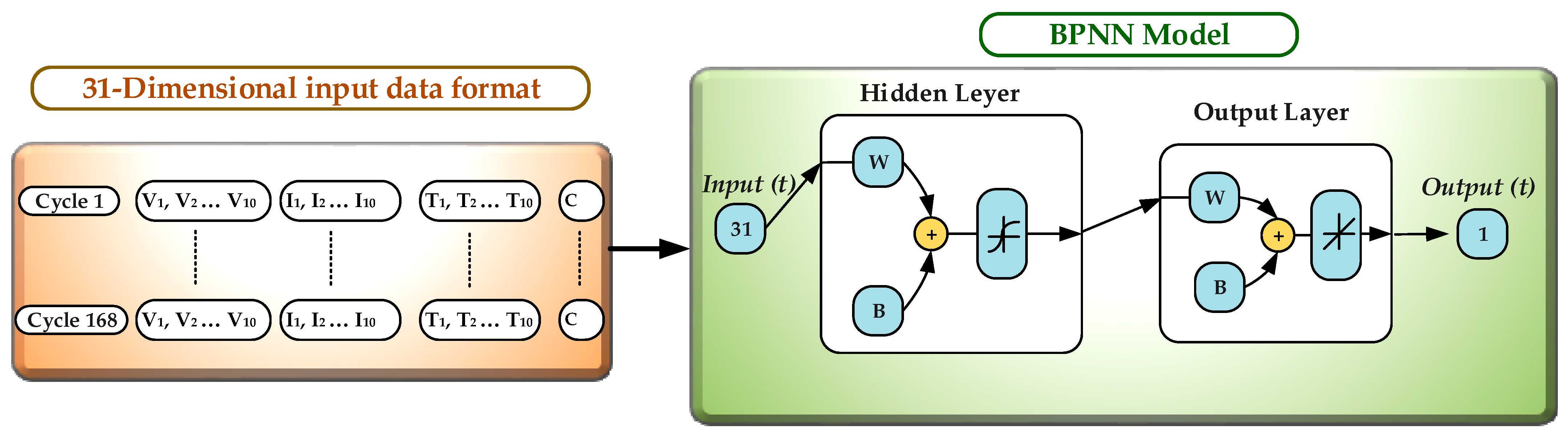

2.2. Data Extraction from the Charging Profile

2.3. Importance of Capacity Regeneration Phenomena

3. RUL Prediction Algorithm Based on BPNN with MCI Profile

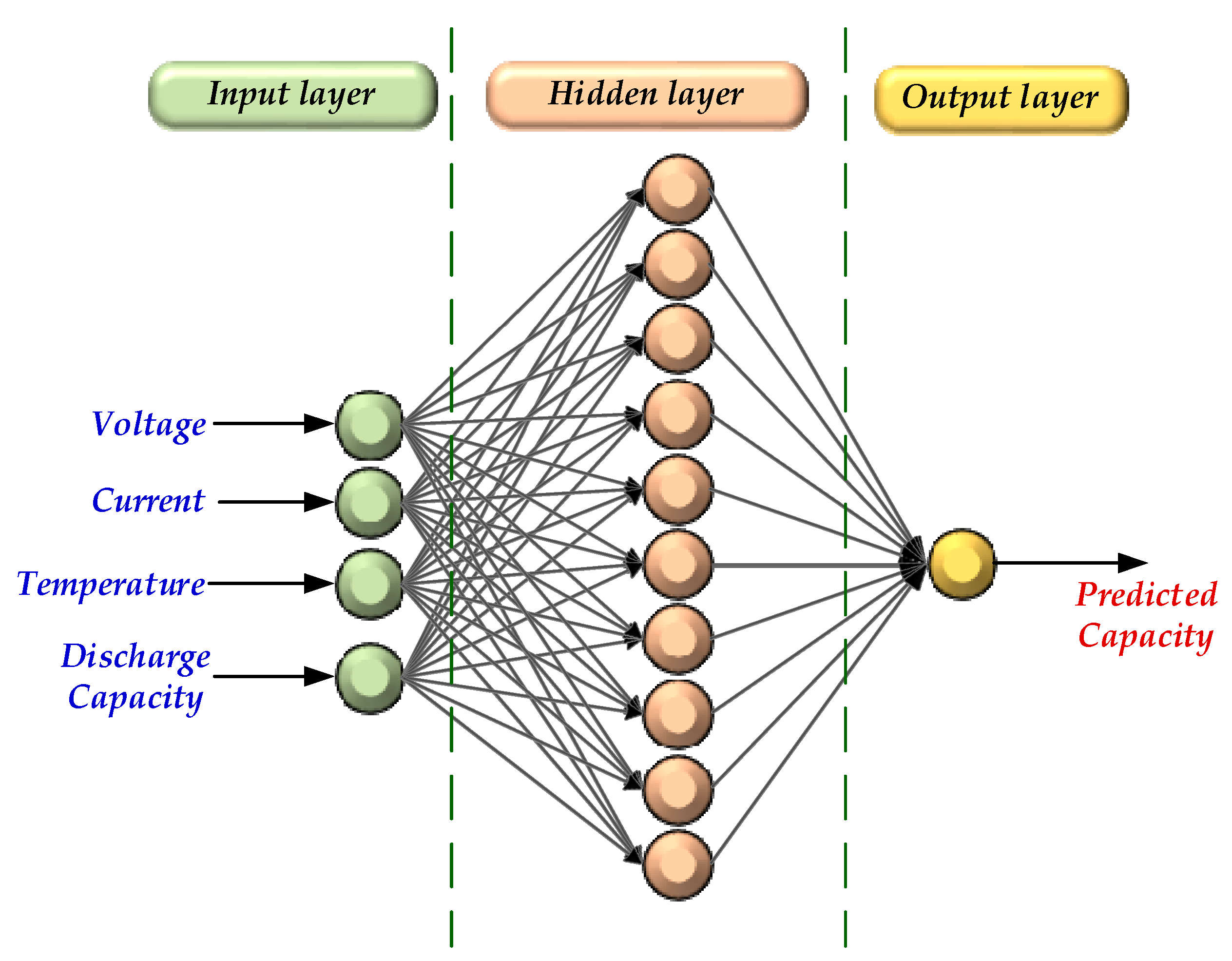

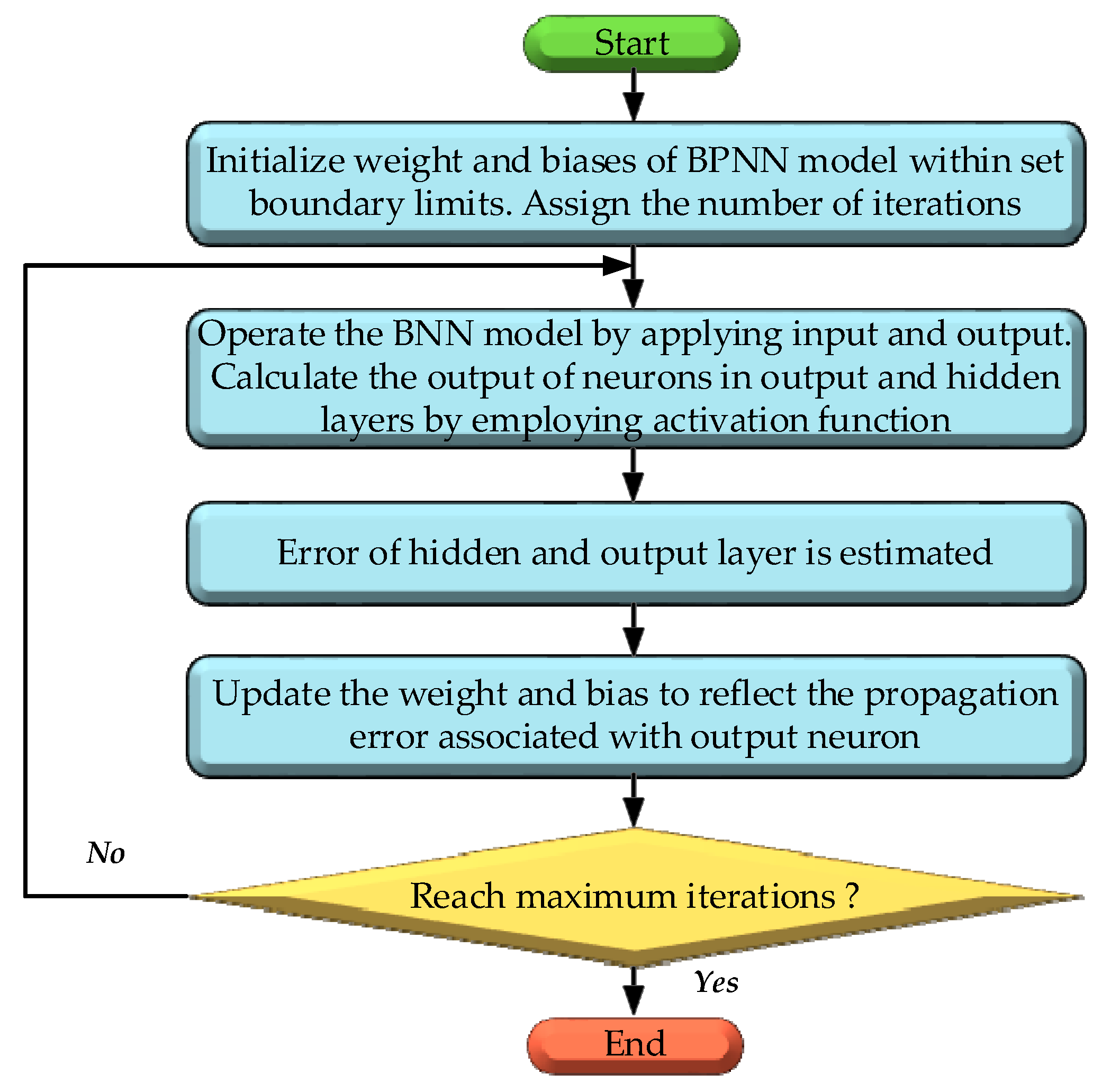

3.1. Back Propagation Neural Network Algorithm

3.2. Input Selection for RUL Prediction

4. Research Framework and Execution of MCI Profile Based BPNN Algorithm for RUL Prediction

4.1. Feature Selection and Data Pre-Processing

4.2. Data Split Method

4.3. RUL Prediction and Analysis

5. RUL Experimental Results and Validation

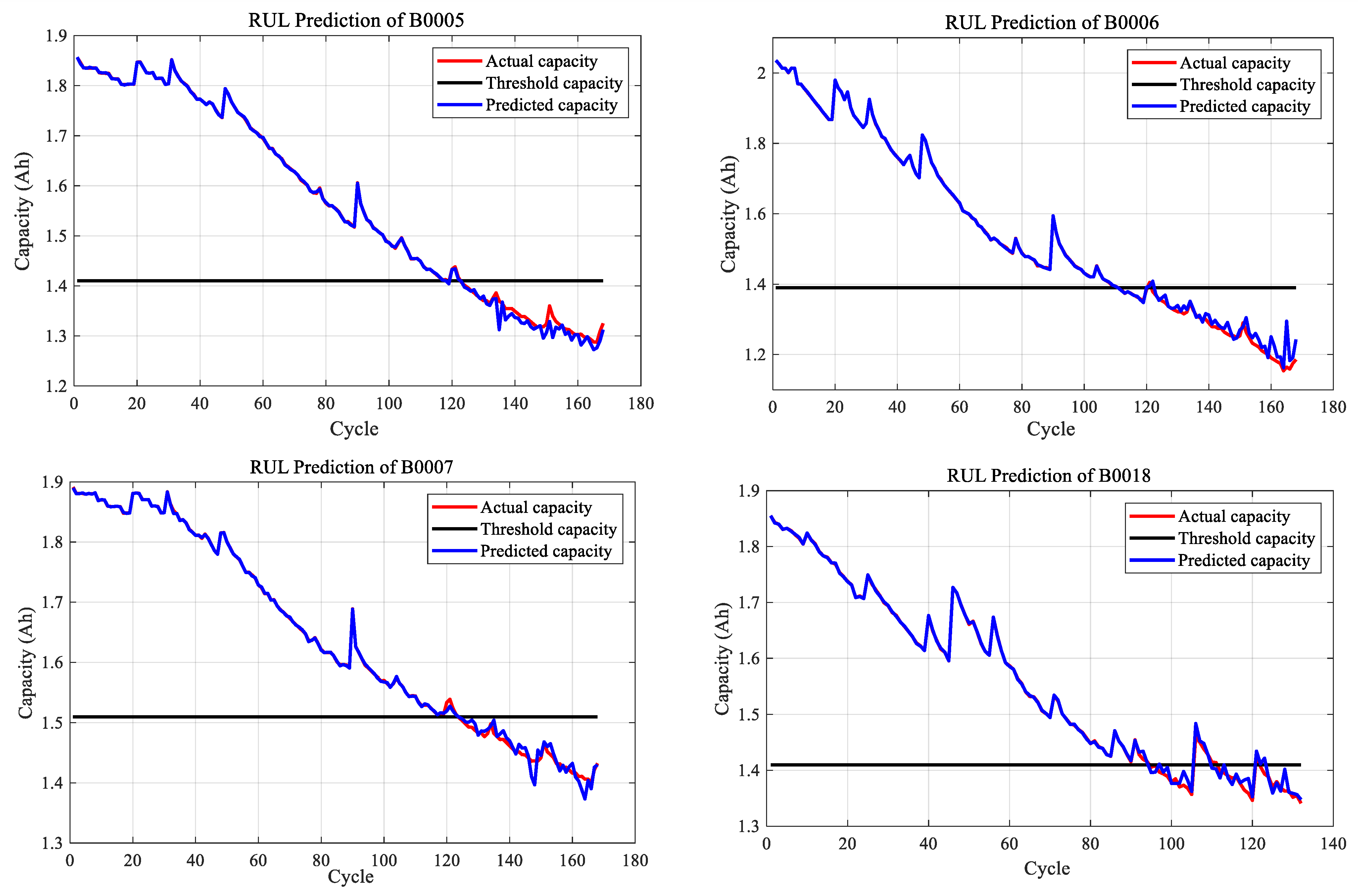

5.1. RUL Prediction by SCI Profile

5.2. RUL Prediction by MCI Profile

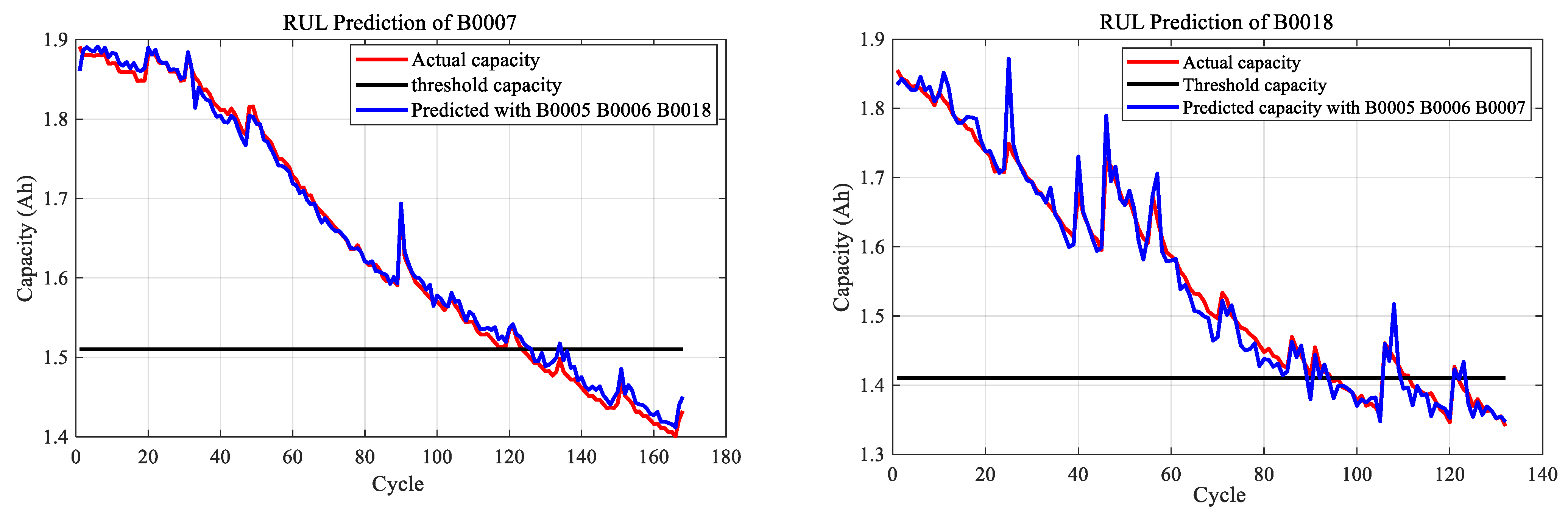

5.2.1. Prediction When Trained with Three Datasets

5.2.2. RUL Prediction When Trained with Two Datasets

5.2.3. RUL Prediction When Trained with One Dataset

5.3. Comparative Validation with the Existing Works

6. Conclusions

- The proposed model delivers accurate results with regard to RMSE while training with MCI based technique with three datasets as compared to the training with two datasets and one dataset, respectively. For B0005, the RMSE is calculated to be 0.0819 while training with three datasets, however, the RMSE decreases to 0.1746, 0.1669, and 1.2866 when trained with three combinations of two datasets.

- The effect of capacity regeneration phenomena was also assessed while training the model with B0006 and B0018 which lowers the prediction accuracy of the model. While training the MCI model with three datasets for B0005, the RMSE is estimated to be 0.0819 while that for B0006 is 0.4247. The same pattern of prediction error was studied in other cases of battery as well.

- Additionally, the average value of various error metrics is the lowest when the model is trained with large training data, i.e., three datasets. While training with SCI, the average error for RMSE is 1.5018. When the MCI profile is used, the error declines to 0.2917 and 0.9848 with three and two datasets, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANN | Artificial Neural Network |

| ARIMA | Auto-Regressive Integrated Moving Average |

| BCT | Box-Cox transformation |

| BPNN | Back Propagation Neural Network |

| EEMD | Ensemble Empirical Mode Decomposition |

| EV | Electric Vehicle |

| FFNN | Feed Forward Neural Network |

| HI | Health Indicator |

| LMA | Lavenberg Marquardt Algorithm |

| MAE | Mean Average Error |

| MAPE | Mean Absolute Percentage Error |

| MC | Monte Carlo |

| MCI | Multi-Channel Input |

| MSE | Mean Square error |

| NARX | Nonlinear Autoregressive Network |

| Probability Density Function | |

| PF | Particle Filtering |

| PSO | Particle Swarm Optimization |

| RMSE | Root Mean Square Error |

| RNN | Recurrent Neural Network |

| RUL | Remaining Useful Life |

| RVM | Relevance Vector Machine |

| SCI | Single Channel Input |

| SD | Standard Deviation |

| SI | Single Input |

| SOH | State of Health |

| SVM | Support Vector Machine |

References

- Venugopal, P. State-of-Health Estimation of Li-ion Batteries in Electric Vehicle Using IndRNN under Variable. Energies 2019, 12, 4338. [Google Scholar] [CrossRef] [Green Version]

- Tu, R.; Gai, Y.J.; Farooq, B.; Posen, D.; Hatzopoulou, M. Electric vehicle charging optimization to minimize marginal greenhouse gas emissions from power generation. Appl. Energy 2020, 277, 115517. [Google Scholar] [CrossRef]

- Wróblewski, P.; Drożdż, W.; Lewicki, W.; Dowejko, J. Total cost of ownership and its potential consequences for the development of the hydrogen fuel cell powered vehicle market in poland. Energies 2021, 14, 2131. [Google Scholar] [CrossRef]

- Wróblewski, P.; Kupiec, J.; Drożdż, W.; Lewicki, W.; Jaworski, J. The Economic Aspect of Using Different Plug-In Hybrid Driving Techniques in Urban Conditions. Energies 2021, 14, 3543. [Google Scholar] [CrossRef]

- Wróblewski, P.; Drożdż, W.; Lewicki, W.; Miązek, P. Methodology for assessing the impact of aperiodic phenomena on the energy balance of propulsion engines in vehicle electromobility systems for given areas. Energies 2021, 14, 2314. [Google Scholar] [CrossRef]

- Thorgeirsson, A.T.; Scheubner, S.; Funfgeld, S.; Gauterin, F. Probabilistic Prediction of Energy Demand and Driving Range for Electric Vehicles with Federated Learning. IEEE Open J. Veh. Technol. 2021, 2, 151–161. [Google Scholar] [CrossRef]

- Zhu, J.; Tan, T.; Wu, L.; Yuan, H. RUL prediction of lithium-ion battery based on improved DGWO-ELM method in a random discharge rates environment. IEEE Access 2019, 7, 125176–125187. [Google Scholar] [CrossRef]

- He, W.; Williard, N.; Osterman, M.; Pecht, M. Prognostics of lithium-ion batteries based on Dempster-Shafer theory and the Bayesian Monte Carlo method. J. Power Sources 2011, 196, 10314–10321. [Google Scholar] [CrossRef]

- Potrykus, S.; Kutt, F.; Nieznanski, J.; Morales, F.J.F. Advanced lithium-ion battery model for power system performance analysis. Energies 2020, 13, 2411. [Google Scholar] [CrossRef]

- Hu, X.; Zou, C.; Zhang, C.; Li, Y. Technological Developments in Batteries: A Survey of Principal Roles, Types, and Management Needs. IEEE Power Energy Mag. 2017, 15, 20–31. [Google Scholar] [CrossRef]

- Gong, X.; Xiong, R.; Mi, C.C. A Data-Driven Bias-Correction-Method-Based Lithium-Ion Battery Modeling Approach for Electric Vehicle Applications. IEEE Trans. Ind. Appl. 2016, 52, 1759–1765. [Google Scholar] [CrossRef]

- Swornowski, P.J. Destruction mechanism of the internal structure in Lithium-ion batteries used in aviation industry. Energy 2017, 122, 779–786. [Google Scholar] [CrossRef]

- Orrù, P.F.; Zoccheddu, A.; Sassu, L.; Mattia, C.; Cozza, R.; Arena, S. Machine learning approach using MLP and SVM algorithms for the fault prediction of a centrifugal pump in the oil and gas industry. Sustainability 2020, 12, 4776. [Google Scholar] [CrossRef]

- Lipu, M.S.H.; Faisal, M.; Ansari, S.; Hannan, M.A.; Karim, T.F.; Ayob, A.; Hussain, A.; Miah, M.S.; Saad, M.H.M. Review of electric vehicle converter configurations, control schemes and optimizations: Challenges and suggestions. Electronics 2021, 10, 477. [Google Scholar] [CrossRef]

- Hossain Lipu, M.S.; Hannan, M.A.; Karim, T.F.; Hussain, A.; Saad, M.H.M.; Ayob, A.; Miah, M.S.; Indra Mahlia, T.M. Intelligent algorithms and control strategies for battery management system in electric vehicles: Progress, challenges and future outlook. J. Clean. Prod. 2021, 292, 126044. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, R.; He, H.; Pecht, M.G. Long Short-Term Memory Recurrent Neural Network for Remaining Useful Life Prediction of Lithium-Ion Batteries. IEEE Trans. Veh. Technol. 2018, 67, 5695–5705. [Google Scholar] [CrossRef]

- Wu, Y.I.; Li, W.E.I.; Wang, Y.; Zhang, K.A.I. Remaining Useful Life Prediction of Lithium-Ion Batteries Using Neural Network and Bat-Based Particle Filter. IEEE Access 2019, 7, 54843–54854. [Google Scholar] [CrossRef]

- Lipu, M.S.H.; Hannan, M.A.; Hussain, A.; Ayob, A.; Saad, M.H.M.; Muttaqi, K.M. State of Charge Estimation in Lithium-Ion Batteries: A Neural Network Optimization Approach. Electronics 2020, 9, 1546. [Google Scholar] [CrossRef]

- Khelif, R.; Chebel-Morello, B.; Zerhouni, N. Experience based approach for Li-ion batteries RUL prediction. IFAC PapersOnLine 2015, 28, 761–766. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, J.; Li, K.; Lv, C. The Remaining Useful Life Prediction by Using Electrochemical Model in the Particle Filter Framework for Lithium-Ion Batteries. IEEE Access 2020, 8, 126661–126670. [Google Scholar] [CrossRef]

- Sun, T.; Xia, B.; Liu, Y.; Lai, Y.; Zheng, W.; Wang, H.; Wang, W.; Wang, M. A novel hybrid prognostic approach for remaining useful life estimation of lithium-ion batteries. Energies 2019, 12, 3678. [Google Scholar] [CrossRef] [Green Version]

- Khelif, R.; Malinowski, S.; Chebel-Morello, B.; Zerhouni, N. RUL prediction based on a new similarity-instance based approach. In Proceedings of the 2014 IEEE 23rd International Symposium on Industrial Electronics (ISIE), Istanbul, Turkey, 1–4 June 2014; pp. 2463–2468. [Google Scholar] [CrossRef] [Green Version]

- Liao, L.; Köttig, F. Review of hybrid prognostics approaches for remaining useful life prediction of engineered systems, and an application to battery life prediction. IEEE Trans. Reliab. 2014, 63, 191–207. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, M. Lithium-ion batteries remaining useful life prediction based on a mixture of empirical mode decomposition and ARIMA model. Microelectron. Reliab. 2016, 65, 265–273. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, R.; He, H.; Pecht, M.G. Lithium-Ion Battery Remaining Useful Life Prediction with Box-Cox Transformation and Monte Carlo Simulation. IEEE Trans. Ind. Electron. 2019, 66, 1585–1597. [Google Scholar] [CrossRef]

- Nuhic, A.; Terzimehic, T.; Soczka-Guth, T.; Buchholz, M.; Dietmayer, K. Health diagnosis and remaining useful life prognostics of lithium-ion batteries using data-driven methods. J. Power Sources 2013, 239, 680–688. [Google Scholar] [CrossRef]

- Qin, X.; Zhao, Q.; Zhao, H.; Feng, W.; Guan, X. Prognostics of remaining useful life for lithium-ion batteries based on a feature vector selection and relevance vector machine approach. In Proceedings of the 2017 IEEE International Conference on Prognostics and Health Management (ICPHM), Dallas, TX, USA, 19–21 June 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Wu, J.; Zhang, C.; Chen, Z. An online method for lithium-ion battery remaining useful life estimation using importance sampling and neural networks. Appl. Energy 2016, 173, 134–140. [Google Scholar] [CrossRef]

- Ansari, S.; Ayob, A.; Lipu, M.S.H.; Hussain, A.; Hanif, M.S. A Comparative Analysis of Lithium Ion Battery Input Profiles for Remaining Useful Life Prediction by Cascade Forward Neural Network. In Proceedings of the IEEE World AI IoT Congress 2021, Seattle, WA, USA, 10–13 May 2021; pp. 181–186. [Google Scholar]

- Małek, A.; Marciniak, A. The use of deep recurrent neural networks to predict performance of photovoltaic system for charging electric vehicles. Open Eng. 2021, 11, 377–389. [Google Scholar] [CrossRef]

- Khumprom, P.; Yodo, N. A Data-Driven Predictive Prognostic Model for Lithium-ion Batteries based on a Deep Learning Algorithm. Energies 2019, 12, 660. [Google Scholar] [CrossRef] [Green Version]

- Liu, D.; Zhou, J.; Liao, H.; Peng, Y.; Peng, X. A health indicator extraction and optimization framework for lithium-ion battery degradation modeling and prognostics. IEEE Trans. Syst. Man Cybern. Syst. 2015, 45, 915–928. [Google Scholar]

- Ma, G.; Zhang, Y.; Cheng, C.; Zhou, B.; Hu, P.; Yuan, Y. Remaining useful life prediction of lithium-ion batteries based on false nearest neighbors and a hybrid neural network. Appl. Energy 2019, 253, 113626. [Google Scholar] [CrossRef]

- Pang, X.; Huang, R.; Wen, J.; Shi, Y.; Jia, J.; Zeng, J. A lithium-ion battery rul prediction method considering the capacity regeneration phenomenon. Energies 2019, 12, 2247. [Google Scholar] [CrossRef] [Green Version]

- Xiong, R.; Zhang, Y.; Wang, J.; He, H.; Peng, S.; Pecht, M. Lithium-Ion Battery Health Prognosis Based on a Real Battery Management System Used in Electric Vehicles. IEEE Trans. Veh. Technol. 2019, 68, 4110–4121. [Google Scholar] [CrossRef]

- NASA Prognostics Center of Excellence—Data Repository. Available online: https://ti.arc.nasa.gov/tech/dash/groups/pcoe/prognostic-data-repository/ (accessed on 18 October 2020).

- Choi, Y.; Ryu, S.; Park, K.; Kim, H.; Member, S. Machine Learning-Based Lithium-Ion Battery Capacity Estimation Exploiting Multi-Channel Charging Profiles. IEEE Access 2019, 7, 75143–75152. [Google Scholar] [CrossRef]

- Park, K.; Choi, Y.; Choi, W.J.; Ryu, H.Y.; Kim, H. LSTM-Based Battery Remaining Useful Life Prediction with Multi-Channel Charging Profiles. IEEE Access 2020, 8, 20786–20798. [Google Scholar] [CrossRef]

- Ren, L.; Zhao, L.; Hong, S.; Zhao, S.; Wang, H.; Zhang, L. Remaining Useful Life Prediction for Lithium-Ion Battery: A Deep Learning Approach. IEEE Access 2018, 6, 50587–50598. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.S.H.; Hussain, A.; Saad, M.H.; Ayob, A. Neural Network Approach for Estimating State of Charge of Lithium-Ion Battery Using Backtracking Search Algorithm. IEEE Access 2018, 6, 10069–10079. [Google Scholar] [CrossRef]

- Jain, A.; Nandakumar, K.; Ross, A. Score normalization in multimodal biometric systems. Pattern Recognit. 2005, 38, 2270–2285. [Google Scholar] [CrossRef]

- Qin, W.; Lv, H.; Liu, C.; Nirmalya, D.; Jahanshahi, P. Remaining useful life prediction for lithium-ion batteries using particle filter and artificial neural network. Ind. Manag. Data Syst. 2019, 120, 312–328. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.S.H.; Hussain, A.; Ker, P.J.; Mahlia, T.M.I.; Mansor, M.; Ayob, A.; Saad, M.H.; Dong, Z.Y. Toward Enhanced State of Charge Estimation of Lithium-ion Batteries Using Optimized Machine Learning Techniques. Sci. Rep. 2020, 10, 4687. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, L.; Saldivar, A.A.F.; Bai, Y.; Li, Y. Battery remaining useful life prediction with inheritance particle filtering. Energies 2019, 12, 2784. [Google Scholar] [CrossRef] [Green Version]

- Gao, D.; Huang, M. Prediction of remaining useful life of lithium-ion battery based on multi-kernel support vector machine with particle swarm optimization. J. Power Electron. 2017, 17, 1288–1297. [Google Scholar] [CrossRef]

- Liu, D.; Zhou, J.; Pan, D.; Peng, Y.; Peng, X. Lithium-ion battery remaining useful life estimation with an optimized Relevance Vector Machine algorithm with incremental learning. Measurement 2015, 63, 143–151. [Google Scholar] [CrossRef]

- Ali, M.U.; Zafar, A.; Nengroo, S.H.; Hussain, S.; Park, G.S.; Kim, H.J. Online remaining useful life prediction for lithium-ion batteries using partial discharge data features. Energies 2019, 12, 4366. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; He, Y.; Yuan, L.; Xiang, S. Capacity Prognostics of Lithium-Ion Batteries using EMD Denoising and Multiple Kernel RVM. IEEE Access 2017, 5, 12061–12070. [Google Scholar] [CrossRef]

| Battery No. | Charging | Discharging | Operating Condition | ||||

|---|---|---|---|---|---|---|---|

| Constant Current (A) | Upper Voltage Limit (V) | Cut off Current (mA) | Constant Current (A) | Cut off Voltage (V) | Initial Capacity (Ah) | Capacity Retention | |

| B0005 | 1.5 | 4.2 | 20 | 2 | 2.7 | 1.86 | 70.5 |

| B0006 | 1.5 | 4.2 | 20 | 2 | 2.5 | 2.04 | 57.7 |

| B0007 | 1.5 | 4.2 | 20 | 2 | 2.2 | 1.89 | 75.2 |

| B0018 | 1.5 | 4.2 | 20 | 2 | 2.5 | 1.86 | 73.0 |

| Battery | Error Metrics | ||||

|---|---|---|---|---|---|

| RMSE | MSE | MAPE | MAE | SD | |

| B0005 | 0.5130 | 0.0028 | 0.2153 | 0.3007 | 0.5131 |

| B0006 | 2.4247 | 0.0588 | 0.8352 | 1.0869 | 2.2040 |

| B0007 | 0.7091 | 0.0050 | 0.2552 | 0.3812 | 0.6881 |

| B0018 | 2.6604 | 0.0708 | 0.7300 | 0.1849 | 2.3292 |

| Average error | 1.5018 | 0.0343 | 6.0357 | 0.4884 | 1.4336 |

| Testing Battery Dataset | Training Battery Dataset | Error Metrics | ||||

|---|---|---|---|---|---|---|

| RMSE | MSE | MAPE | MAE | SD | ||

| B0005 | B0006, B0007, B0018 | 0.0819 | 6.7114 × 10−5 | 0.0423 | 0.0681 | 0.0717 |

| B0006 | B0005, B0007, B0018 | 0.4247 | 0.0018 | 0.1247 | 0.2066 | 0.4219 |

| B0007 | B0005, B0006, B0018 | 0.0995 | 9.8968 × 10−5 | 0.0451 | 0.0451 | 0.0968 |

| B0018 | B0005, B0006, B0007 | 0.5608 | 0.0031 | 0.2423 | 0.3894 | 0.5558 |

| Average error | 0.2917 | 2.5 × 10−3 | 0.1136 | 0.1679 | 0.2865 | |

| Testing Battery Dataset | Training Battery Dataset | Error Metrics | ||||

|---|---|---|---|---|---|---|

| RMSE | MSE | MAPE | MAE | SD | ||

| B0005 | B0006, B0007 | 0.1746 | 1.0154 × 10−4 | 0.0913 | 0.1423 | 0.1348 |

| B0007, B0018 | 0.1669 | 2.7843 × 10−4 | 0.0836 | 0.1306 | 0.1550 | |

| B0006, B0018 | 1.2866 | 0.0169 | 0.7790 | 1.1782 | 0.5885 | |

| B0006 | B0005, B0007 | 0.4651 | 0.0022 | 0.1736 | 0.2714 | 0.4665 |

| B0007, B0018 | 0.4771 | 0.0023 | 0.2134 | 0.3032 | 0.4669 | |

| B0005, B0018 | 1.5211 | 0.0231 | 0.5998 | 0.9371 | 1.5092 | |

| B0007 | B0005, B0007 | 0.2440 | 5.9554 × 10−4 | 0.1127 | 0.1821 | 0.2289 |

| B0006, B0018 | 2.4424 | 0.0597 | 1.2529 | 2.0233 | 2.4482 | |

| B0005, B0018 | 1.3147 | 0.0173 | 0.5669 | 0.9532 | 1.2805 | |

| B0018 | B0005, B0006 | 1.1827 | 0.0140 | 0.4154 | 0.6576 | 1.1867 |

| B0006, B0007 | 2.5091 | 0.0630 | 1.2325 | 1.8611 | 2.2680 | |

| B0005, B0007 | 2.2096 | 0.0488 | 0.9112 | 1.4495 | 2.2022 | |

| Average error | 0.9848 | 0.0157 | 0.4408 | 0.6878 | 0.8937 | |

| Testing Battery Dataset | Training Battery Dataset | Error Metrics | ||||

|---|---|---|---|---|---|---|

| RMSE | MSE | MAPE | MAE | SD | ||

| B0005 | B0006 | 3.7092 | 0.1376 | 1.8156 | 2.8964 | 3.7077 |

| B0007 | 3.3678 | 0.1140 | 2.0337 | 3.0532 | 3.3228 | |

| B0018 | 3.9373 | 0.1550 | 2.1278 | 3.4206 | 2.2033 | |

| B0006 | B0005 | 2.6744 | 0.0715 | 1.5379 | 2.3424 | 1.3287 |

| B0007 | 3.6120 | 0.1305 | 1.8588 | 2.9353 | 3.4052 | |

| B0018 | 3.4729 | 0.1206 | 0.9298 | 1.5688 | 3.4528 | |

| B0007 | B0005 | 2.4065 | 0.0579 | 1.0860 | 1.8607 | 1.9955 |

| B0006 | 4.3247 | 0.1870 | 1.8260 | 3.0315 | 4.2578 | |

| B0018 | 4.9495 | 0.2450 | 2.4701 | 4.0452 | 4.9640 | |

| B0018 | B0005 | 1.9564 | 0.0383 | 0.9709 | 1.5528 | 1.5764 |

| B0006 | 4.5414 | 0.2062 | 2.3562 | 3.6030 | 3.9198 | |

| B0007 | 3.9374 | 0.2255 | 2.5342 | 3.9374 | 4.6883 | |

| Average error | 3.5714 | 0.1407 | 1.7955 | 2.8539 | 3.2272 | |

| Reference | Algorithm | Input Feature and Output | Battery Type | Validation | Performance Metrics | Research Gap |

|---|---|---|---|---|---|---|

| [44] | Linear PF | -[Input] = Impedance, aging, number of charging cycle -[output] = Capacity | -18650 lithium ion battery | NASA battery dataset | RMSE 0.2902 | -Charging and discharging profile parameters can be considered for better predictability |

| [45] | Hybrid PSO and SVM | -[Input] = Discharge cycle data -[output] = Capacity | -18650 lithium ion battery | NASA battery dataset | MSE 0.0213 | -Increased computational burden, variability in the outcomes during optimization |

| [47] | SVM | -[Input] = Voltage, current, temperature, capacity and time -[output] = RUL | -18650 lithium ion battery | NASA battery dataset | RMSE 0.2159, 0.3108 | The validation of the technique could be performed with data-driven models |

| [48] | EMD and RVM | -[Input] = Capacity -[output] = RUL | -18650 lithium ion battery | NASA battery dataset | MSE 4.4972 × 10−5, 1.6437 × 10−5 (battery 5 and 18) | -Employment of low volume of training data, validation with other model-based technique is needed |

| [28] | FFNN | -[Input] = Voltage -[output] = RUL | -18650 lithium ion battery | NASA battery dataset | MAE 29.4218 | -Very high error, requires hyperparameter adjustment |

| [31] | Deep neural network | -[Input] = Voltage, current, temperature, capacity -[output] = RUL | -18650 lithium ion battery | NASA battery dataset | RMSE 3.427 | -Computational burden and high error |

| Proposed method | BPNN | -[Input] = Voltage, current, temperature, capacity -[output] = RUL | -18650 lithium ion battery | NASA battery dataset | RMSE 0.0819 MSE 6.7114 × 10−5 | -The accuracy of the model can be further improved by utilizing optimization techniques. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ansari, S.; Ayob, A.; Hossain Lipu, M.S.; Hussain, A.; Saad, M.H.M. Multi-Channel Profile Based Artificial Neural Network Approach for Remaining Useful Life Prediction of Electric Vehicle Lithium-Ion Batteries. Energies 2021, 14, 7521. https://doi.org/10.3390/en14227521

Ansari S, Ayob A, Hossain Lipu MS, Hussain A, Saad MHM. Multi-Channel Profile Based Artificial Neural Network Approach for Remaining Useful Life Prediction of Electric Vehicle Lithium-Ion Batteries. Energies. 2021; 14(22):7521. https://doi.org/10.3390/en14227521

Chicago/Turabian StyleAnsari, Shaheer, Afida Ayob, Molla Shahadat Hossain Lipu, Aini Hussain, and Mohamad Hanif Md Saad. 2021. "Multi-Channel Profile Based Artificial Neural Network Approach for Remaining Useful Life Prediction of Electric Vehicle Lithium-Ion Batteries" Energies 14, no. 22: 7521. https://doi.org/10.3390/en14227521

APA StyleAnsari, S., Ayob, A., Hossain Lipu, M. S., Hussain, A., & Saad, M. H. M. (2021). Multi-Channel Profile Based Artificial Neural Network Approach for Remaining Useful Life Prediction of Electric Vehicle Lithium-Ion Batteries. Energies, 14(22), 7521. https://doi.org/10.3390/en14227521