Classification of Geomembranes as Raw Material for Defects Reduction in the Manufacture of Biodigesters Using an Artificial Neuronal Network

Abstract

:1. Introduction

2. Materials and Methods

2.1. Definition of Material Requirements

- Thickness (Tk). This feature refers to the width of the geomembranes. The ranges between which Tk oscillates are 0.75 to 3.0 mm. It is necessary to have an adequate Tk that preferably facilitates the thermofusion process.

- Density (De). This characteristic helps to know the flexibility in geomembranes. It also indicates if the material is suitable for direct exposure to the sun. For the construction of a biodigester, the De must be greater than 0.94 g/.

- Breaking Strength (BS). The BS is the measure of force that a material opposes before a crack occurs. Common ranges in geomembranes are between 17 and 84 kN/m. These values indicate the maximum tenseness of the geomembranes.

- Tear Resistance (TR). Measurement of maximum strength of the geomembranes to resist the effects of tearing. Ranges for this feature are from 69 to 342 N.

- Yield Strength (YS). It is the point that indicates when a geomembrane undergoes a deformation when it is subjected to constant stress and temperature. Values range from 8 to 44 kN/m.

- Punching Resistance (PR). Maximum force to which the geomembrane is subjected before being perforated. Ranges are between 235 and 835 N.

- 7.

- Composition (Co). This feature refers to geomembrane components. Polyethylene geomembranes are manufactured with virgin polyethylene resins and carbon black. The geomembrane is composed of 97–98% polyethylene, leaving the rest for other components. It is important to have the correct Co that allows to guarantee a long duration, even under outdoor conditions. A geomembrane that is not in the correct percentage will decrease its resistance to UV rays and will start to get harder. If these percentages are not suitable, they tend to crystallize over time due to sun exposure, causing cracks and degradation of the geomembranes.

- 8.

- Geomembrane Type (T): This characteristic refers to whether the geomembrane is GM13 or nominal. The first fully comply with the American GM13 standard. While the nominal geomembranes do not comply with this requirement.

- 9.

- Biodigester Size (S): For this study, S was divided into two sizes: those that measure less than 80 m wide and 150 m long will be considered medium, and those that fulfill those measurements or more will be considered large.

2.2. Conceptualization of the Variables

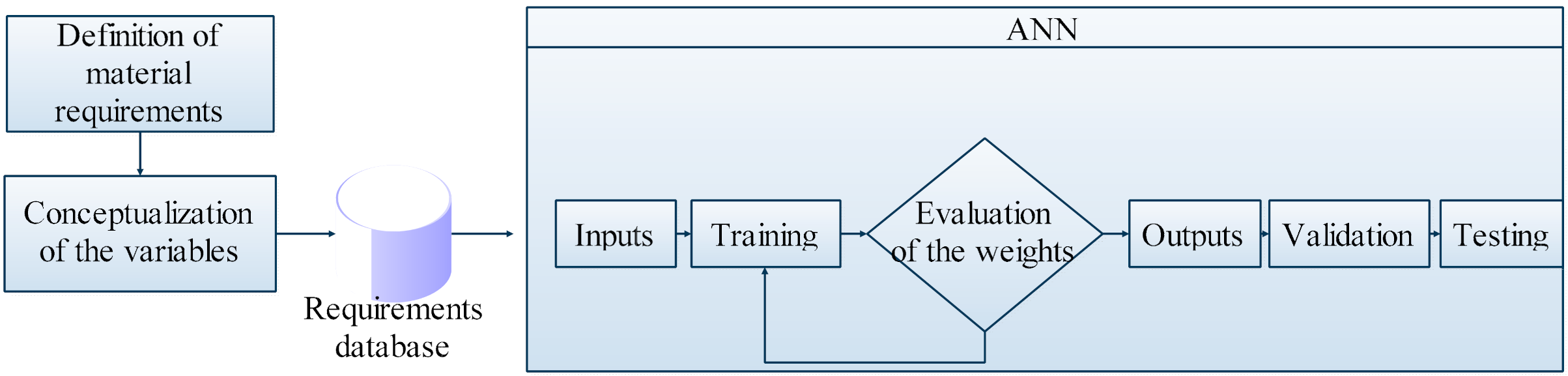

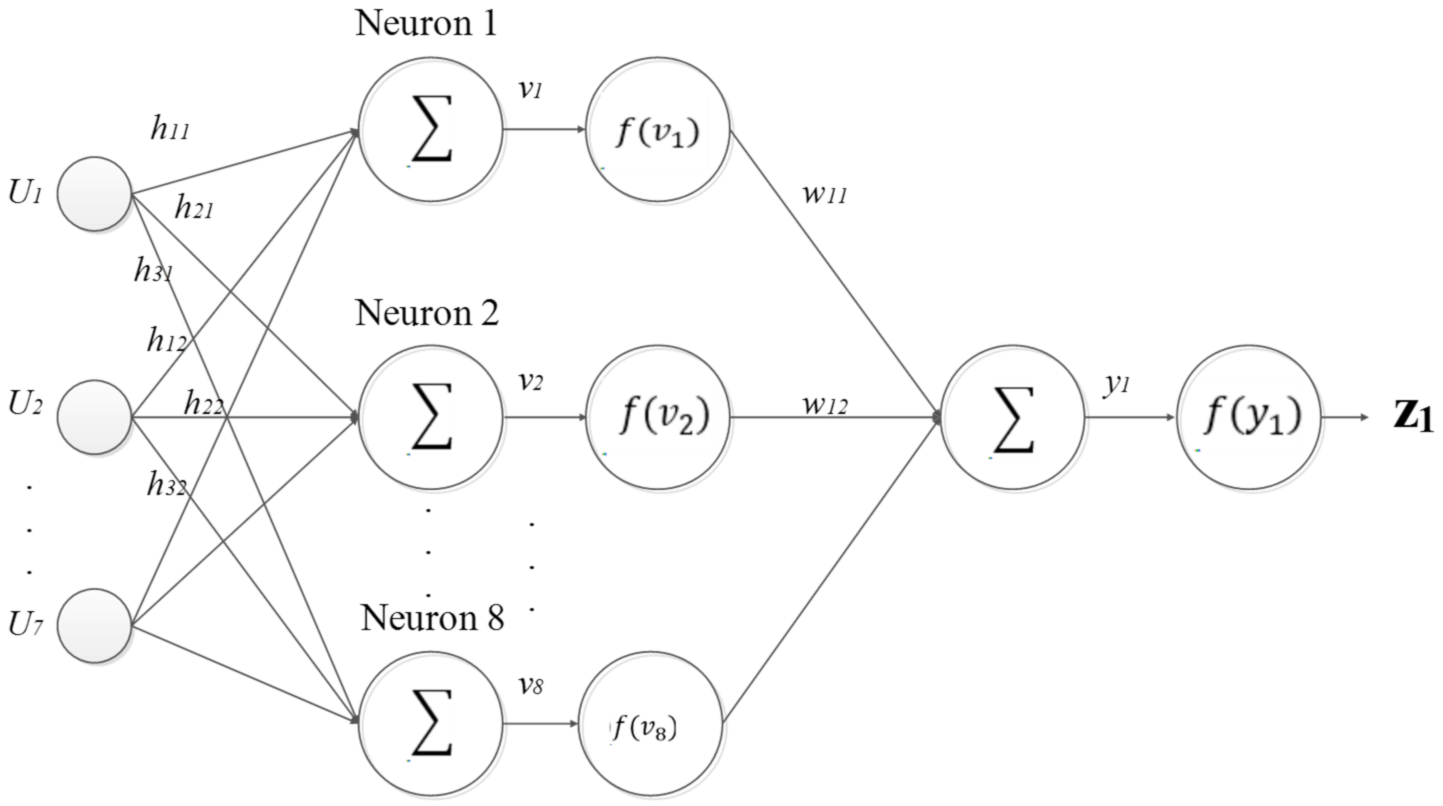

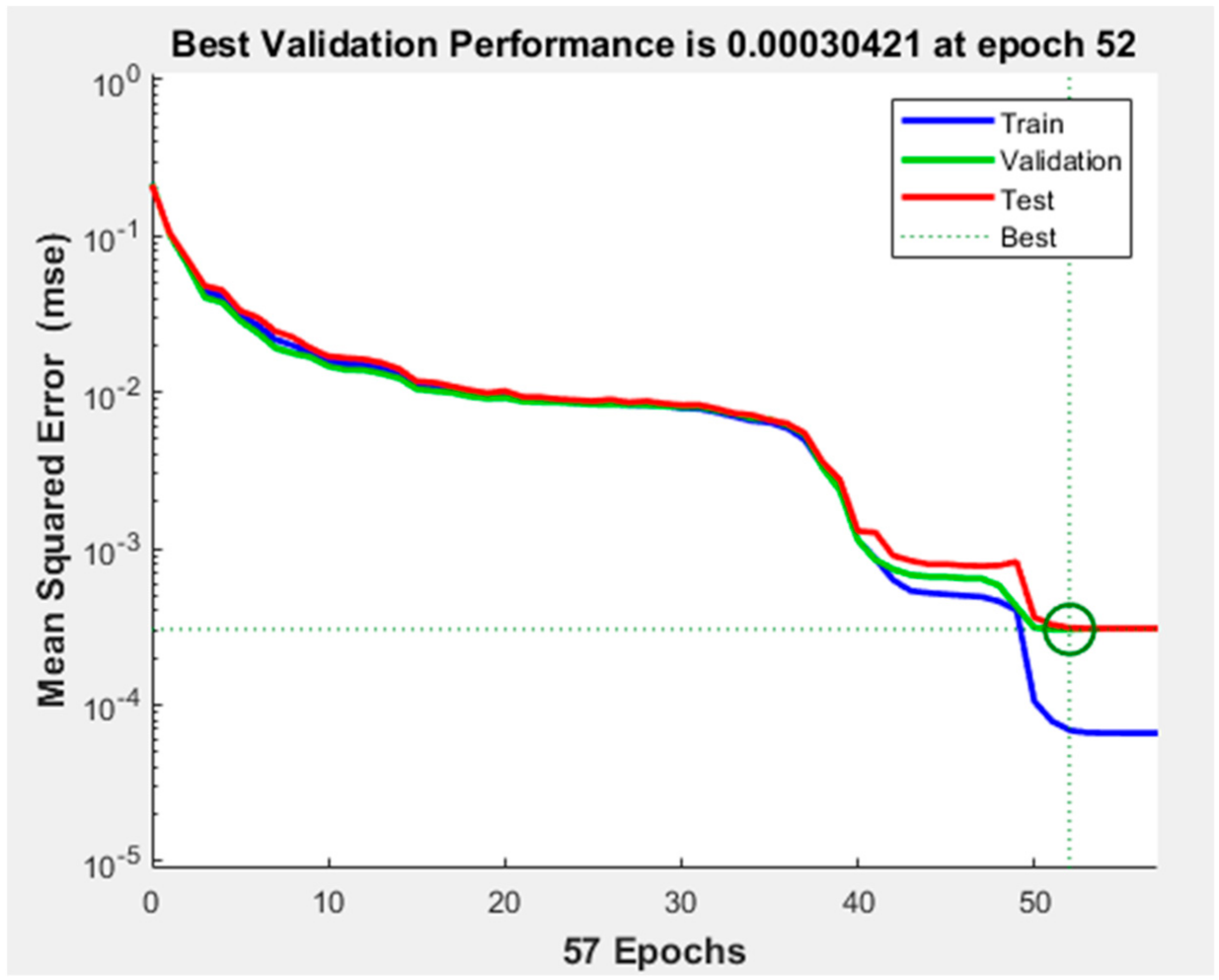

2.3. Development of a Back Propagation ANN

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Awogbemi, O.; Kallon, D.V.V. An Overview of the Classification, Production and Utilization of Biofuels for Internal Combustion Engine Applications. Energies 2021, 14, 5687. [Google Scholar] [CrossRef]

- Hernández, M.; Sierra, J. The Potential of the Biodigester as a Useful Tool in Coffee Farms. Appl. Sci. 2021, 11, 6884. [Google Scholar] [CrossRef]

- Lombardi, L.; Mendecka, B. Solar Integrated Anaerobic Digester: Energy Savings and Economics. Energies 2020, 13, 4292. [Google Scholar] [CrossRef]

- American Society for Testing and Materials (ASTM International). Norm ASTM D4439-20 Standard Terminology for Geosynthetics; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Lavoie, F.L.; Valentin, C.A. HDPE Geomembranes for Environmental Protection: Two Case Studies. Sustainability 2020, 12, 8682. [Google Scholar] [CrossRef]

- Shared Risk Trust. General Diagnosis of the Situation of Biodigestion Systems in Mexico; Federal Bureau of Agriculture, Animal Breeding and Rural Development: Mexico City, Mexico, 2010. [Google Scholar]

- Cetiner, I.; Var, A.A. Classification of Knot Defect Types Using Wavelets and KNN. Elektron. Ir Elektrotechnika 2016, 22, 67–72. [Google Scholar] [CrossRef] [Green Version]

- Lizarraga-Morales, R.A.; Correa-Tome, F.E.; Sanchez-Yanez, R.E.; Cepeda-Negrete, J. On the Use of Binary Features in a Rule-Based Approach for Defect Detection on Patterned Textiles. IEEE Access 2019, 7, 18042–18049. [Google Scholar] [CrossRef]

- Pervaiz, S.; Ul-Qayyum, Z. A Systematic Literature Review on Particle Swarm Optimization Techniques for Medical Diseases Detection. Comput. Math. Methods Med. 2021, 2021, 10. [Google Scholar] [CrossRef] [PubMed]

- Amor, N.; Noman, M.T. Classification of Textile Polymer Composites: Recent Trends and Challenges. Polymers 2021, 13, 2592. [Google Scholar] [CrossRef] [PubMed]

- De Paula, L.A.; Eckert, K.B.; Guismín, G. Clasificación de hojas de té al ingreso del proceso de secado mediante redes neuronales con datos supervisados y no supervisados. In Proceedings of the Congreso Argentino de AgroInformática, Buenos Aires, Argentina, 3–7 September 2018; Argentine Society of Informatics and Operations Research CABA: Buenos Aires, Argentine, 2018; p. 76. [Google Scholar]

- Mellit, A.; Benghanem, M. Design of a Novel Remote Monitoring System for Smart Greenhouses Using the Internet of Things and Deep Convolutional Neural Networks. Energies 2021, 14, 5045. [Google Scholar] [CrossRef]

- Essid, O.; Laga, H. Automatic detection, and classification of manufacturing defects in metal boxes using deep neural networks. PLoS ONE 2018, 13, e0203192. [Google Scholar] [CrossRef] [PubMed]

- Gómez, J.; Sánchez, J. Application of neural networks in the classification of clays. J. EIA 2012, 17, 183–191. [Google Scholar]

- Singh, V.; Tathavadkar, V. Predicting the performance of submerged arc furnace with varied raw material combinations using artificial neural network. J. Mater. Process. Technol. 2007, 183, 111–116. [Google Scholar] [CrossRef]

- Zhu, N.; Wang, K. Application of artificial neural networks to predict multiple quality of dry-cured ham based on protein degradation. Food Chem. 2021, 344, 115–124. [Google Scholar] [CrossRef] [PubMed]

- Kulisz, M.; Kujawska, J. Forecasting Water Quality Index in Groundwater Using Artificial Neural Network. Energies 2021, 14, 5875. [Google Scholar] [CrossRef]

- Kumari, S.; Rakesh, K. Leakage Rate Prediction through Composite Liner due to Geomembrane Defect using Neural Network. J. Geotech. Eng. 2019, 6, 8–17. [Google Scholar]

- Abuel-Naga, H.M.; Bouazza, A. Numerical experiment-artificial intelligence approach to develop empirical equations for predicting leakage rates through GM/GCL composite liners. Geotext. Geomembr. 2014, 42, 236–245. [Google Scholar] [CrossRef]

- Mandal, A.; Cho, H. ANN Prediction of Performance and Emissions of CI Engine Using Biogas Flow Variation. Energies 2021, 14, 2910. [Google Scholar] [CrossRef]

- Frankowski, J.; Zaborowicz, M. Biological Waste Management in the Case of a Pandemic Emergency and Other Natural Disasters. Determination of Bioenergy Production from Floricultural Waste and Modeling of Methane Production Using Deep Neural Modeling Methods. Energies 2020, 13, 3014. [Google Scholar] [CrossRef]

- Idris, M.; Abiola, O. Performance evaluation of three different-shaped bio-digesters for biogas production and optimization by artificial neural network integrated with genetic algorithm. Sustain. Energy Technol. Assess. 2018, 26, 116–124. [Google Scholar]

- Tabarquino, V.H.; González, L.O. Estimation of the volume of a balloon-type Biodigester using artificial neural networks. Tech. Informant 2016, 80, 41–48. [Google Scholar]

- Veerendra, S.; Banerjee, P.K. Artificial Neural Network Modeling of Ball Mill Grinding Process. J. Powder Metall. 2013, 2, 106–117. [Google Scholar]

- Arora, V.; Mahla, S.K. Intervention of Artificial Neural Network with an Improved Activation Function to Predict the Performance and Emission Characteristics of a Biogas Powered Dual Fuel Engine. Electronics 2021, 10, 584. [Google Scholar] [CrossRef]

- He, Y.; Gong, Z. Inland Reservoir Water Quality Inversion and Eutrophication Evaluation Using BP Neural Network and Remote Sensing Imagery: A Case Study of Dashahe Reservoir. Water 2021, 13, 2844. [Google Scholar] [CrossRef]

| Properties of the Geomembrane | Range of Specifications |

|---|---|

| Thickness (Tk) | 0.75–3.0 mm |

| Density (De) | |

| Breaking Strength (BS) | 17–84 kN/m |

| Tear Resistance (TR) | 69–342 N |

| Yield Strength (YS) | 8–44 kN/m |

| Punching Resistance (PR) | 235–835 N |

| Composition (Co) | 97.5–98.0% |

| Type (T) | GM13, Nominal |

| Size (S) | Medium, Large |

| Characteristic (Unit) | Minimum | Maximum | Different Possible Values |

|---|---|---|---|

| Tk (mm) | 0.65 | 2.5 | 30 |

| BS (kN/m) | 20 | 84 | 34 |

| TR (N) | 93 | 342 | 90 |

| PR (N) | 240 | 876 | 320 |

| Co (%) | 97 | 98 | 3 |

| T (GM13, Nominal) | 0 | 1 | 2 |

| S (Medium, Large) | 0 | 1 | 2 |

| Characteristic | Minimum | Maximum | Range of Specifications | Values |

|---|---|---|---|---|

| Tk (mm) | 1.4 | 1.5 | 0.05 | 3 |

| BS (kN/m) | 44 | 47 | 1 | 4 |

| TR (N) | 188 | 200 | 3 | 5 |

| PR (N) | 500 | 608 | 12 | 10 |

| Co (%) | 97 | 98 | 0.5 | 3 |

| T (GM13, Nominal) | 1 | 1 | 1 | 1 |

| S (Medium, Large) | 0 | 0 | 1 | 1 |

| Characteristic | Minimum | Maximum | Range of Specifications | Values |

|---|---|---|---|---|

| Tk (mm) | 1.8 | 2 | 0.05 | 5 |

| BS (kN/m) | 63 | 64 | 1 | 2 |

| TR (N) | 269 | 287 | 3 | 7 |

| PR (N) | 716 | 716 | 1 | 1 |

| Co (%) | 97.5 | 98 | 0.5 | 2 |

| T (GM13, Nominal) | 1 | 1 | 1 | 1 |

| S (Medium, Large) | 1 | 1 | 1 | 1 |

| Characteristic | Minimum | Maximum | Range of Specifications | Values |

|---|---|---|---|---|

| Tk (mm) | 2.25 | 2.5 | 0.05 | 6 |

| BS (kN/m) | 81 | 84 | 1 | 4 |

| TR (N) | 333 | 342 | 3 | 4 |

| PR (N) | 840 | 876 | 12 | 4 |

| Co (%) | 97.5 | 98 | 0.5 | 2 |

| T (GM13, Nominal) | 1 | 1 | 1 | 1 |

| S (Medium, Large) | 1 | 1 | 1 | 1 |

| Algorithms | MSE | Training Time (s) | Epoch |

|---|---|---|---|

| Gradient Descent, (Traingd) | 0.0710 | 3 | 84 |

| Gradient Descent with Momentum, (Traingdm) | 0.0410 | 4 | 97 |

| Resilient Backpropagation, (Trainrp) | 0.0110 | 5 | 112 |

| Variable Learning Rate Gradient Descent, (Traingdx) | 0.0830 | 5 | 145 |

| Fletcher-Powell Conjugate Gradient, (Traincgf) | 0.0370 | 4 | 116 |

| Polak-Ribiére Conjugate Gradient, (Traincgp) | 0.0072 | 3 | 84 |

| Scaled Conjugate Gradient, (Trainscg) | 0.0240 | 4 | 146 |

| BFGS Quasi-Newton, (Trainbfg) | 0.0130 | 5 | 134 |

| One Step Secant, (Trainoss) | 0.0084 | 4 | 144 |

| Levenberg-Marquardt, (Trainlm) | 0.0045 | 3 | 76 |

| Transfer Functions | MSE | Training Time (s) | Epoch |

|---|---|---|---|

| Purely | 0.0051 | 3 | 53 |

| Tansig | 0.0008 | 4 | 77 |

| Logsig | 0.0004 | 2 | 82 |

| Neurons | MSE | Training Time (s) | Epoch |

|---|---|---|---|

| 6 | 0.0051 | 3 | 85 |

| 7 | 0.0061 | 4 | 98 |

| 8 | 0.0003 | 2 | 65 |

| 9 | 0.0058 | 2 | 74 |

| 10 | 0.0066 | 1 | 87 |

| 11 | 0.0067 | 2 | 122 |

| 12 | 0.0144 | 1 | 101 |

| 13 | 0.0054 | 1 | 136 |

| 14 | 0.0133 | 3 | 85 |

| 15 | 0.0064 | 4 | 86 |

| 16 | 0.0562 | 1 | 98 |

| 17 | 0.0142 | 1 | 150 |

| 18 | 0.0101 | 1 | 150 |

| Class | Correct Classifications | Wrong Classifications | % of Success |

|---|---|---|---|

| Unsuitable geomembrane | 13,278 | 1 | 99.9 |

| Appropriate geomembrane | 1849 | 0 | 100 |

| Overall | 15,127 | 1 | 99.9 |

| Class | Correct Classifications | Wrong Classifications | % of Success |

|---|---|---|---|

| Unsuitable geomembrane | 2800 | 1 | 99.9 |

| Appropriate geomembrane | 441 | 0 | 100 |

| Overall | 3241 | 1 | 99.9 |

| Class | Correct Classifications | Wrong Classifications | % of Success |

|---|---|---|---|

| Unsuitable geomembrane | 2824 | 0 | 100 |

| Appropriate geomembrane | 418 | 0 | 100 |

| Overall | 3242 | 0 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Camarena-Martinez, R.; Lizarraga-Morales, R.A.; Baeza-Serrato, R. Classification of Geomembranes as Raw Material for Defects Reduction in the Manufacture of Biodigesters Using an Artificial Neuronal Network. Energies 2021, 14, 7345. https://doi.org/10.3390/en14217345

Camarena-Martinez R, Lizarraga-Morales RA, Baeza-Serrato R. Classification of Geomembranes as Raw Material for Defects Reduction in the Manufacture of Biodigesters Using an Artificial Neuronal Network. Energies. 2021; 14(21):7345. https://doi.org/10.3390/en14217345

Chicago/Turabian StyleCamarena-Martinez, Rocio, Rocio A. Lizarraga-Morales, and Roberto Baeza-Serrato. 2021. "Classification of Geomembranes as Raw Material for Defects Reduction in the Manufacture of Biodigesters Using an Artificial Neuronal Network" Energies 14, no. 21: 7345. https://doi.org/10.3390/en14217345

APA StyleCamarena-Martinez, R., Lizarraga-Morales, R. A., & Baeza-Serrato, R. (2021). Classification of Geomembranes as Raw Material for Defects Reduction in the Manufacture of Biodigesters Using an Artificial Neuronal Network. Energies, 14(21), 7345. https://doi.org/10.3390/en14217345