An Analytical Modelling of Demand for Driving Torque of a Wheelchair with Electromechanical Drive

Abstract

:1. Introduction

2. Materials and Methods

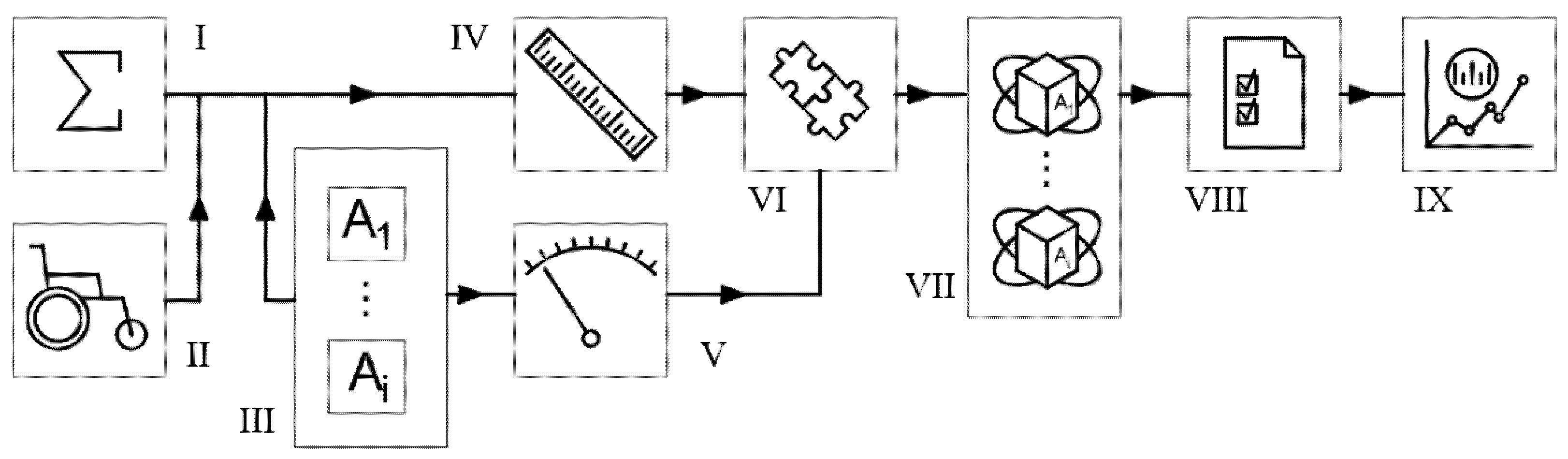

2.1. Research Work Conception

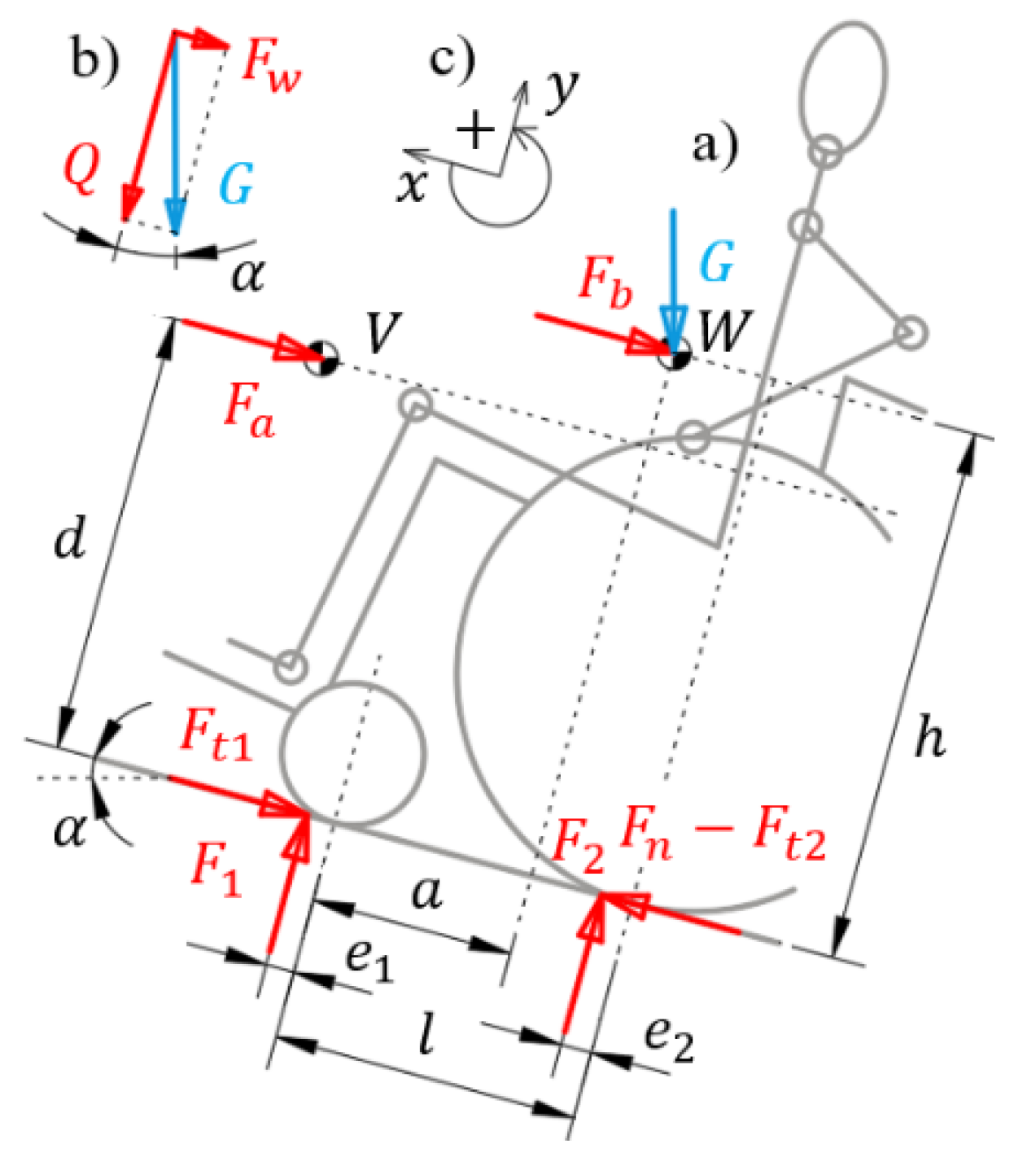

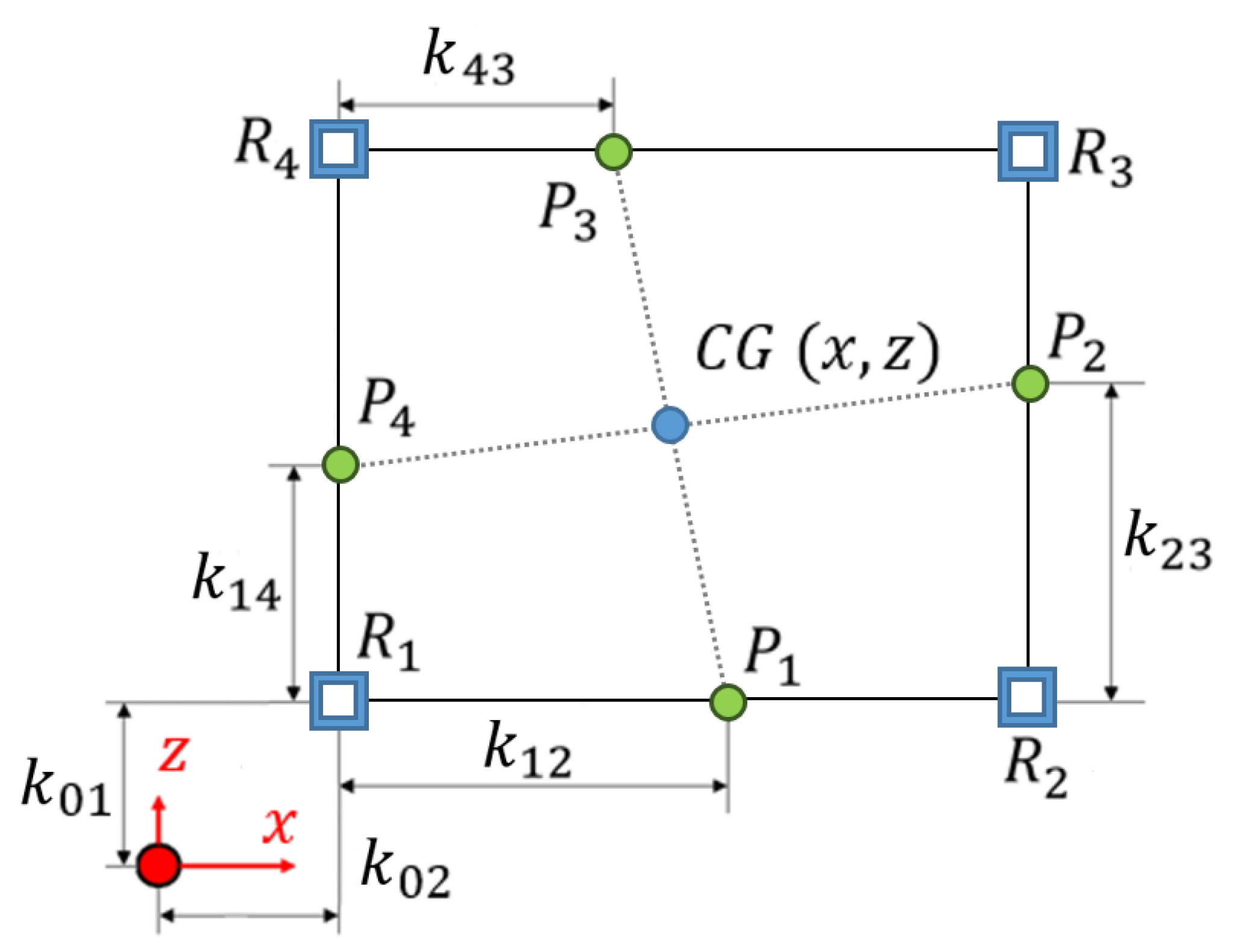

2.2. Analytical Basics of Modelling

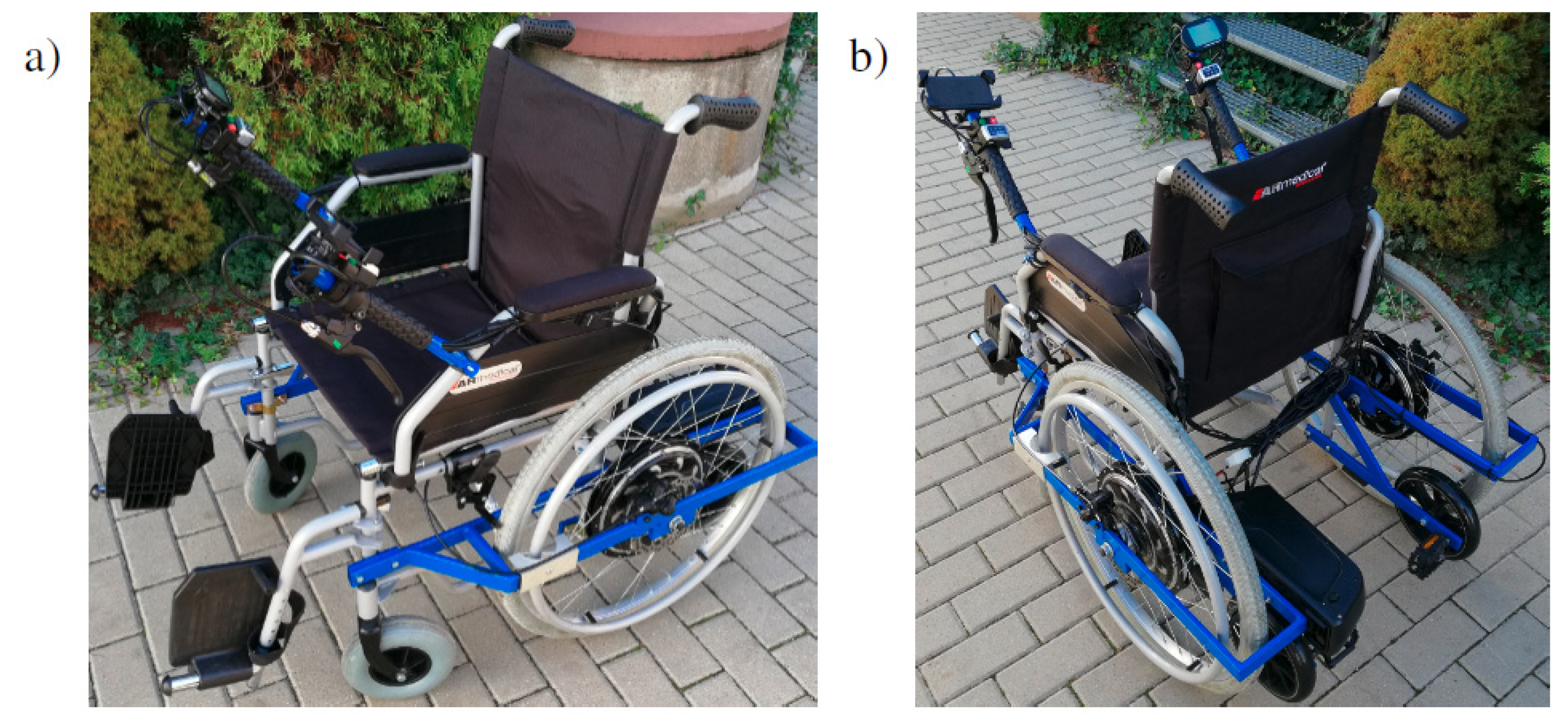

2.3. Hybrid Electric-Manual Wheelchair

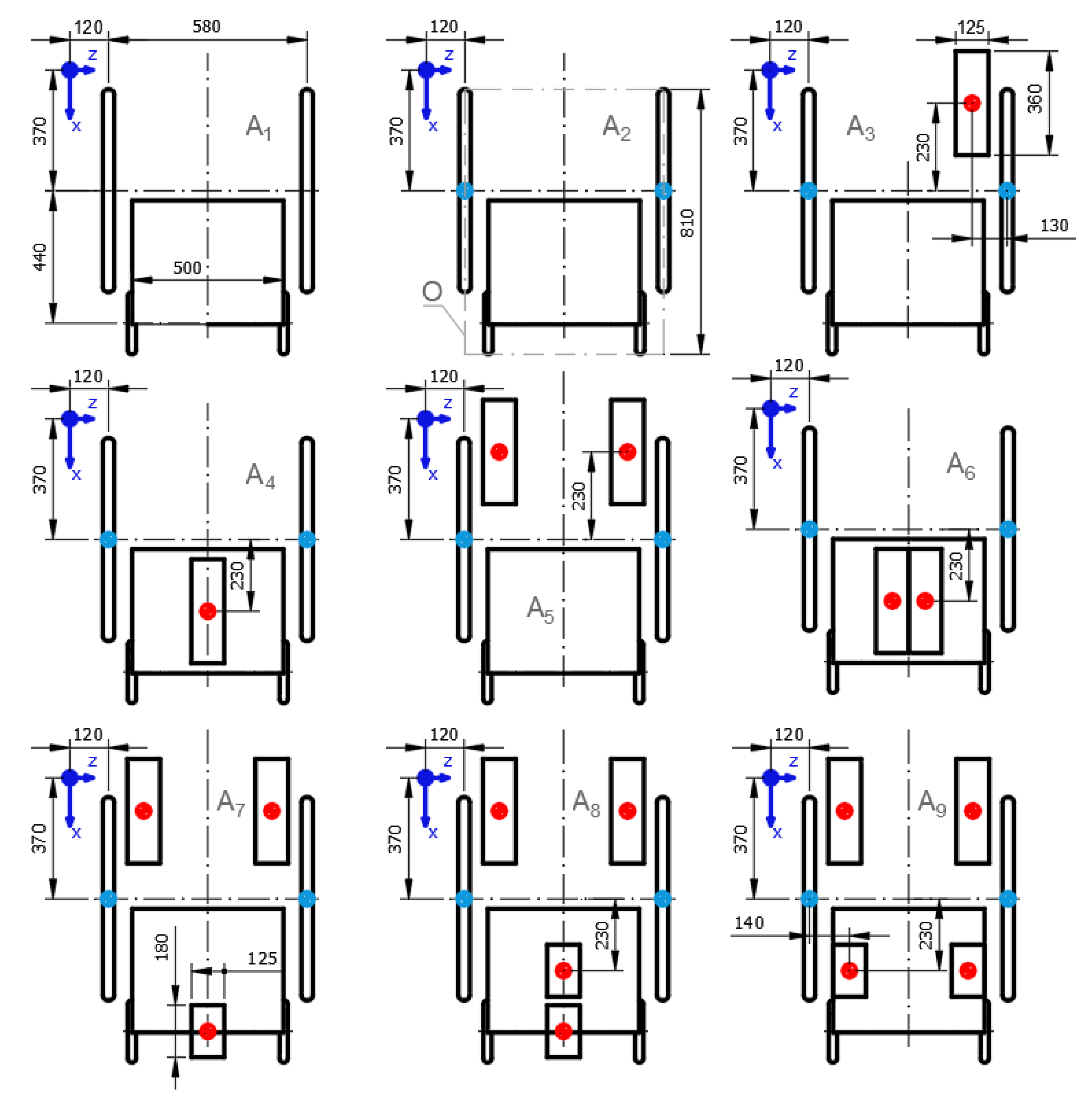

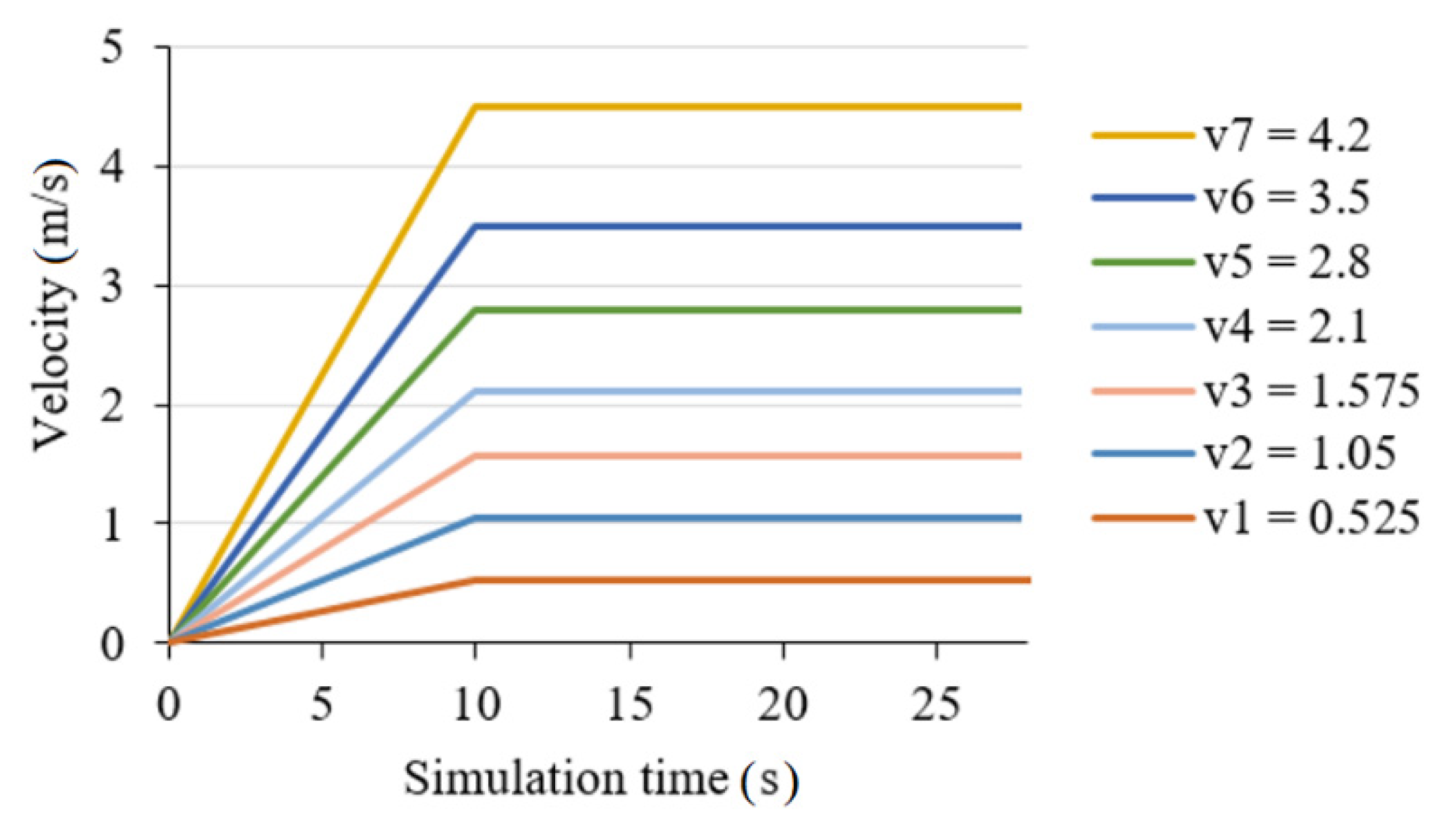

2.4. Test and Simulation Variants

2.5. Constant Parameters of the Simulation

2.6. Variable Parameters of the Simulation

2.7. Numerical Simulation

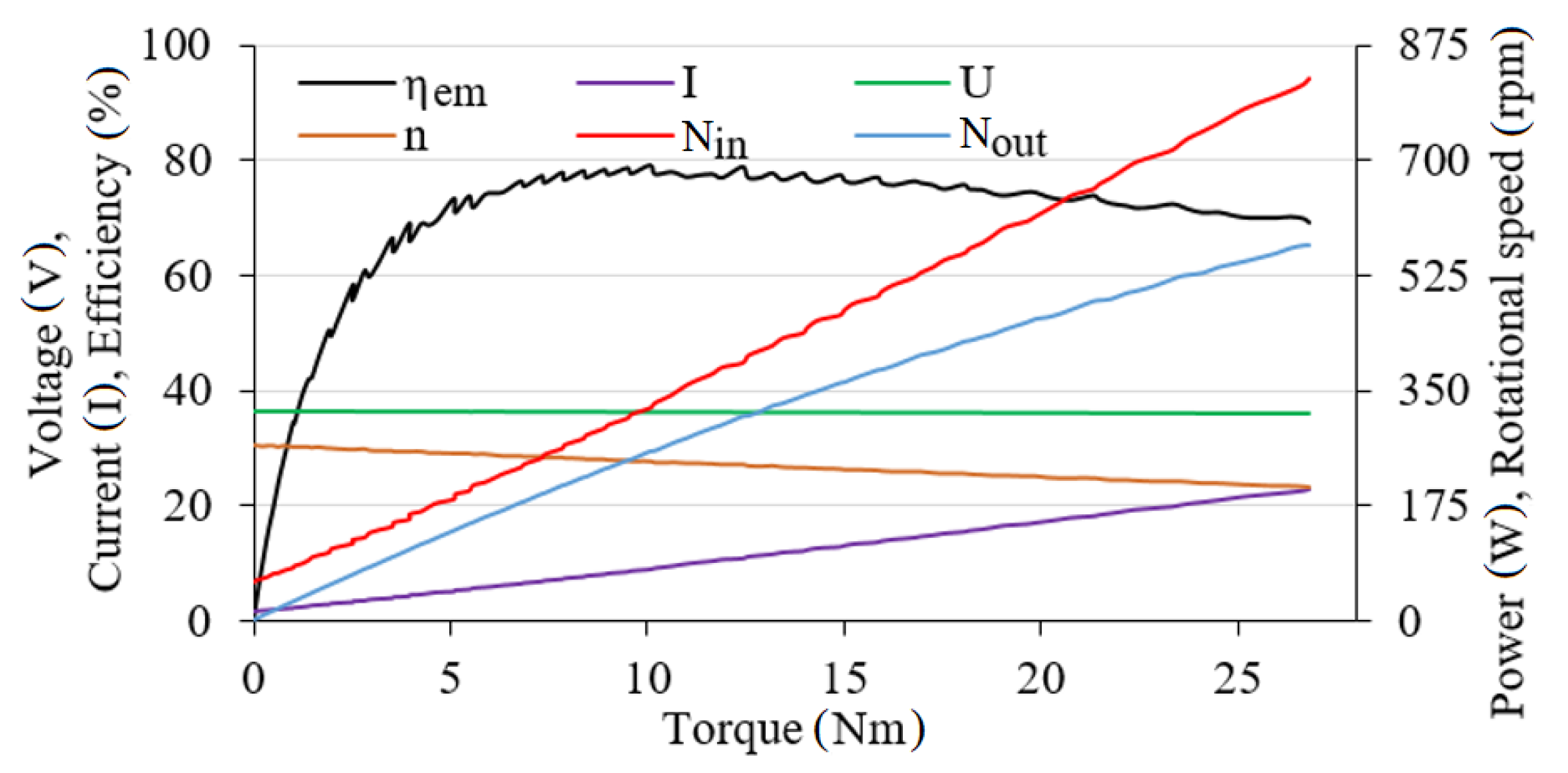

2.8. Characteristics of the Electric Drive

3. Results and Discussion

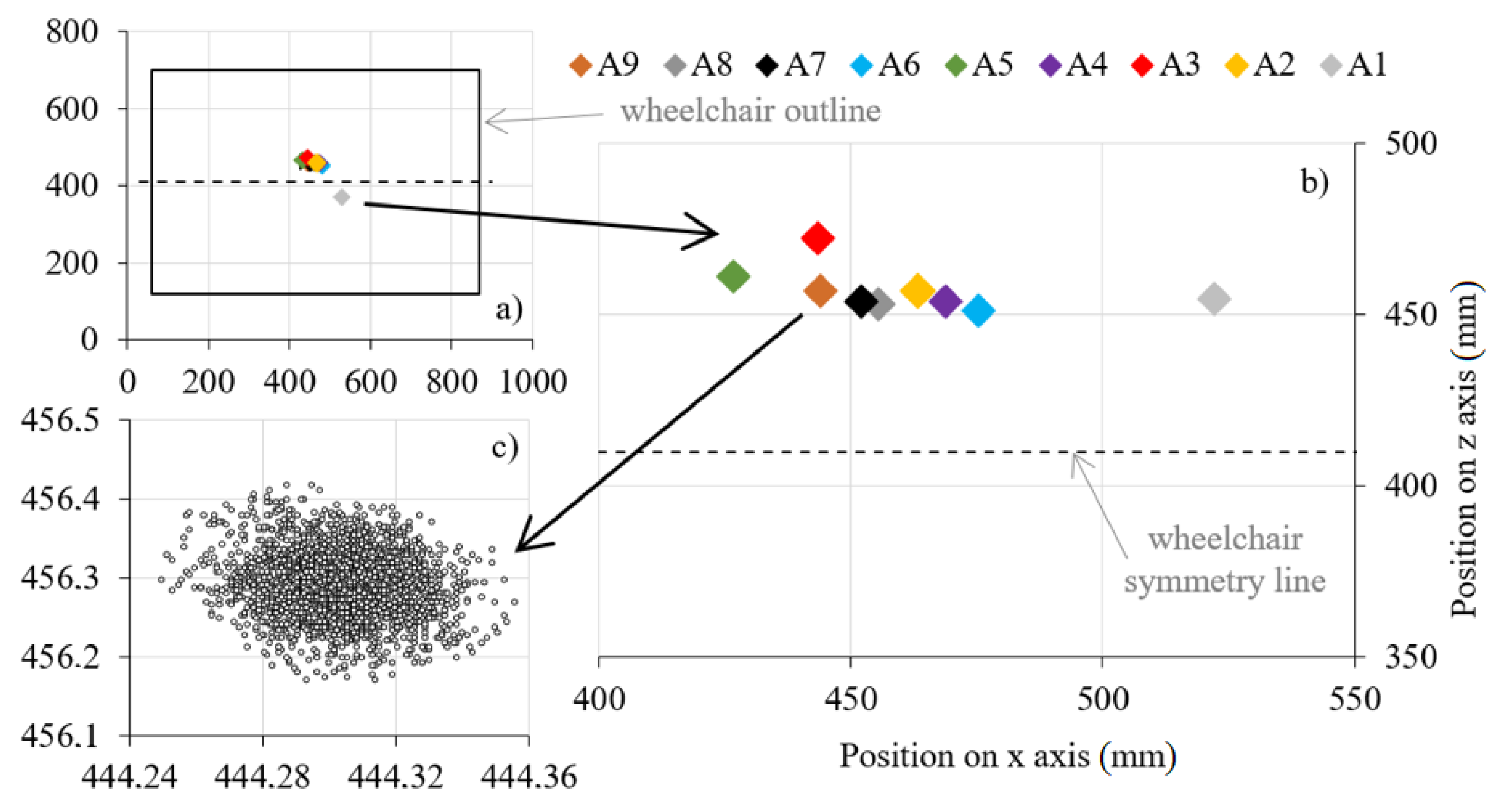

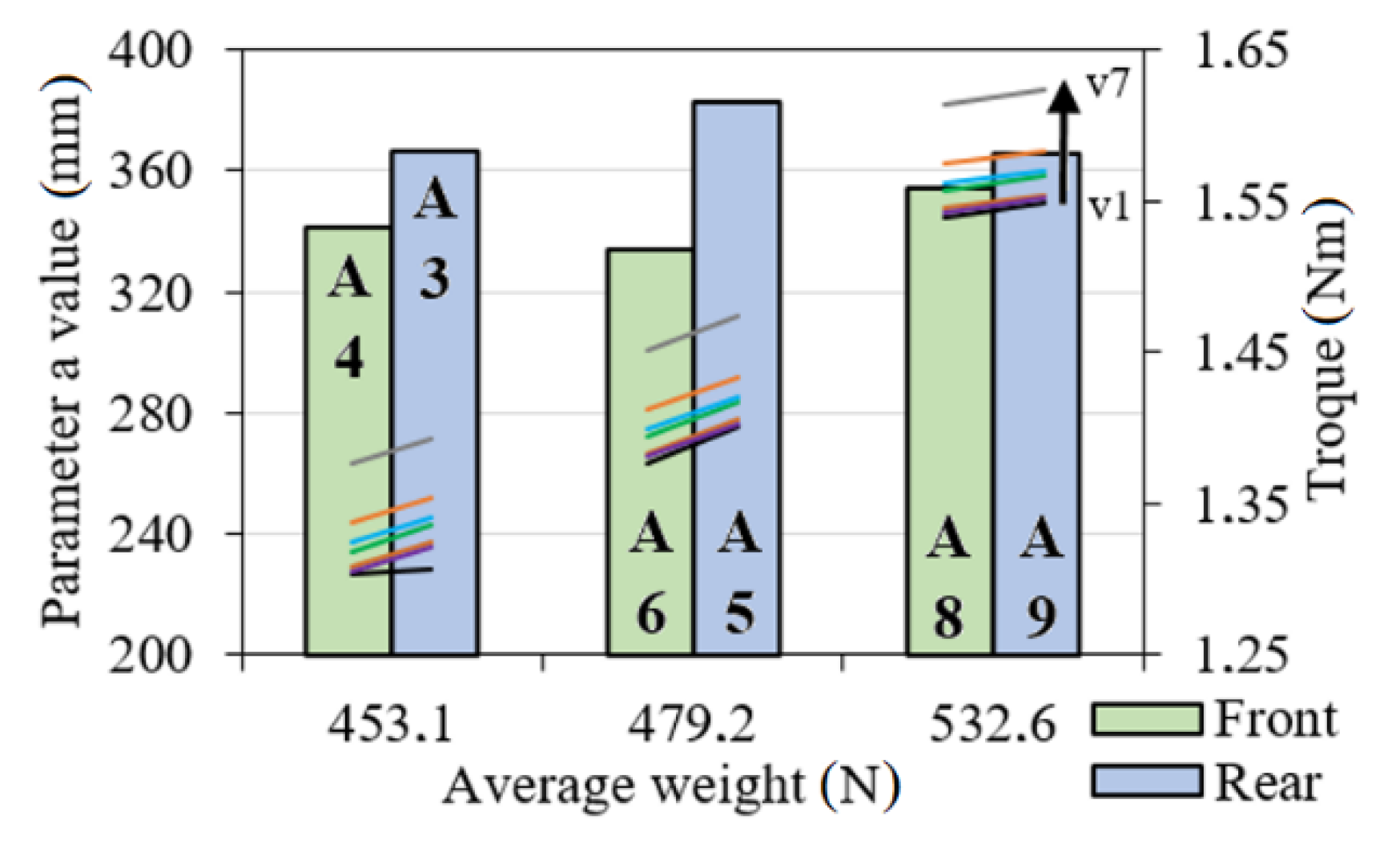

3.1. Centre of Gravity and Mass Measurements Results

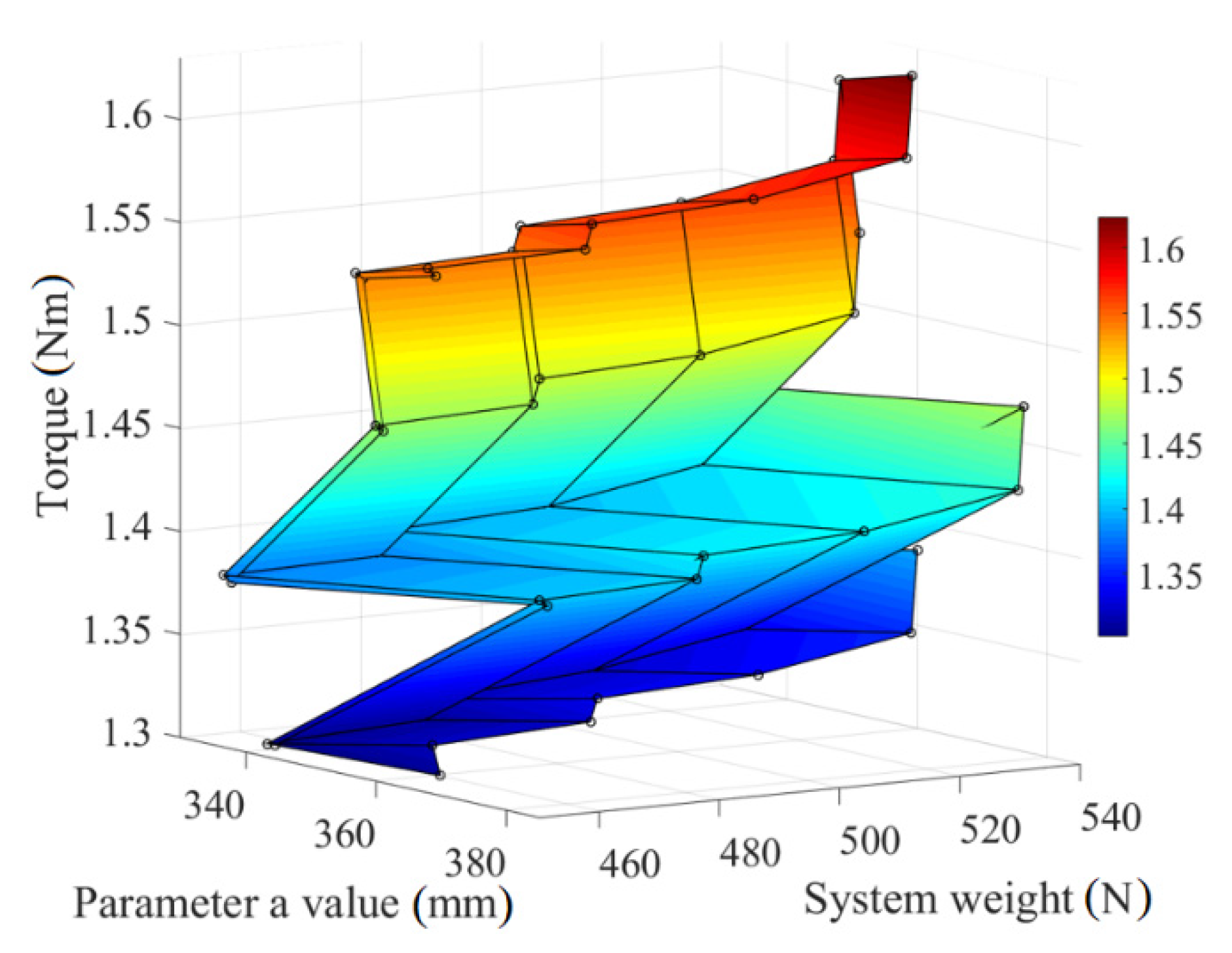

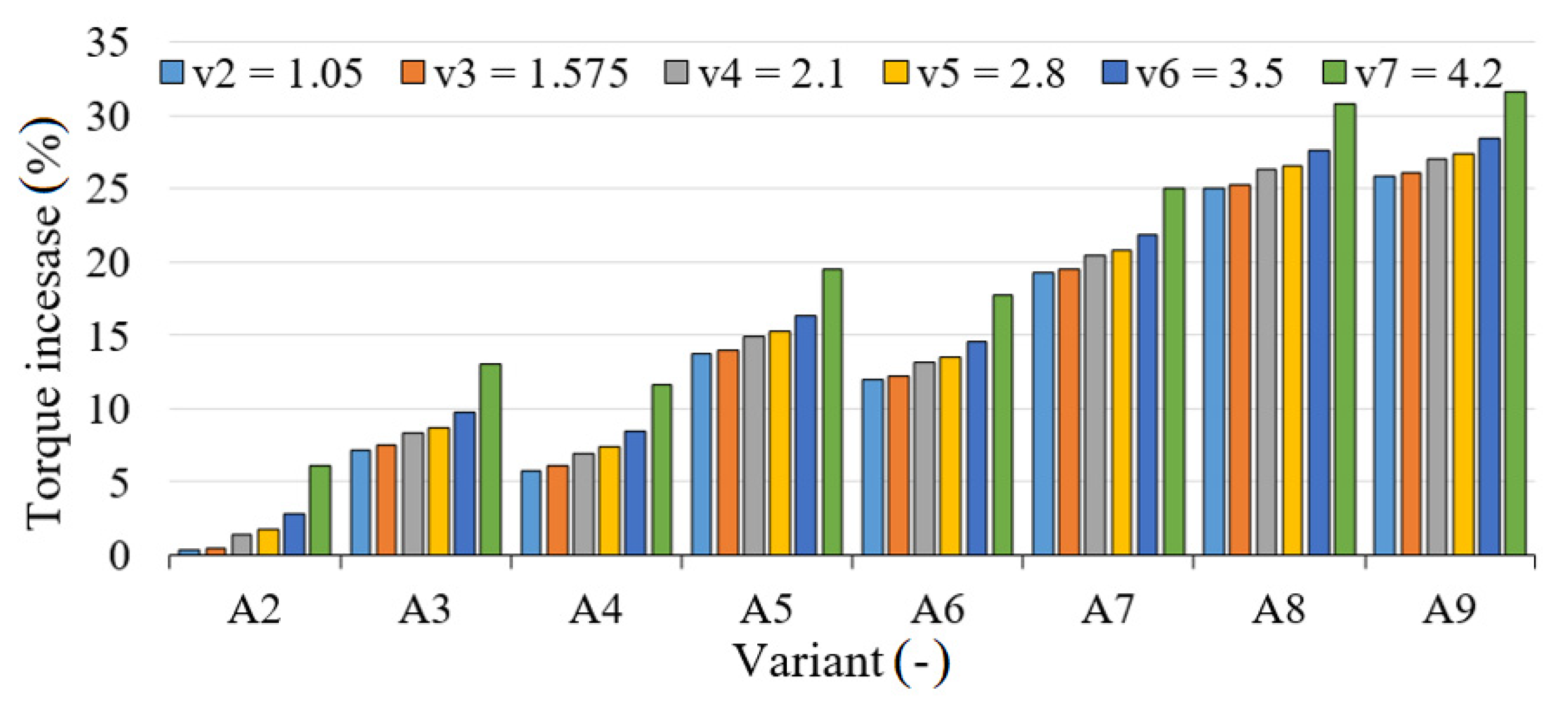

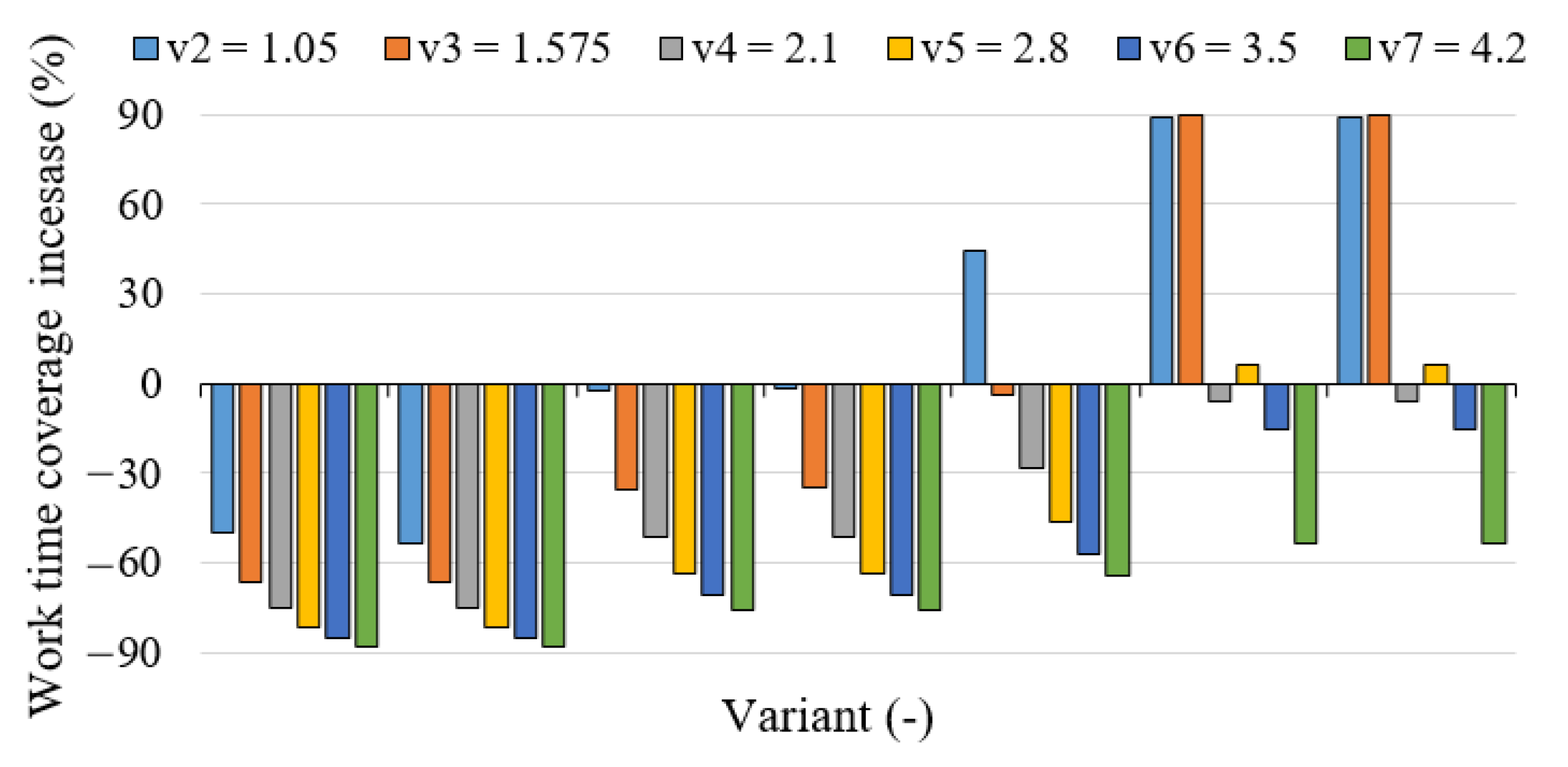

3.2. Work Time Coverage and Torque Demand

4. Conclusions

- As the weight of the system increases, the demand for drive torque increases and work time coverage is increasing, with an approximately linear trend;

- As the weight of the system increases, so does the work time coverage despite the increase in driving torque demand;

- The increase in the simulated velocity causes changes in the demand for driving torque and work time coverage, the change being approximately a square function;

- The set of recorded data does not allow for an unambiguous and direct determination of impact nature of the parameter value (distance from the axle of the smaller wheel to the center of gravity) on the torque demand and work time coverage. This issue remains open and requires further research;

- The most advantageous case is one where the greatest possible mass of the battery is placed as close as possible to the front wheels of the wheelchair.

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Symbol | Description | |

|---|---|---|

| – | Inclination angle | |

| – | Time step of a simulation | |

| – | Angular velocity | |

| – | Angular acceleration | |

| – | Total efficiency | |

| – | Electric motor efficiency | |

| – | Bearing efficiency | |

| – | Efficiency of the rest of the system | |

| – | Distance from the axle of the smaller wheel to the centre of gravity | |

| – | Equation parameters | |

| – | Variants of wheelchair configuration | |

| – | Surface area of the front face of the system | |

| – | Dimensionless factor of aerodynamic drag | |

| – | Vertical position of system’s centre of height | |

| – | Moment arm of rolling resistance for smaller wheel | |

| – | Moment arm of rolling resistance for larger wheel | |

| – | Rolling resistance coefficient of the smaller wheel | |

| – | Rolling resistance coefficient of the larger wheel | |

| – | Load on the smaller wheel axle | |

| – | Load on the larger wheel axle | |

| – | Aerodynamic drag force | |

| – | Inertia force of the system | |

| – | Propulsion force | |

| – | Total friction force | |

| – | Frictional force of the smaller wheel | |

| – | Frictional force of the larger wheel | |

| – | Longitudinal force | |

| – | Acceleration due to gravity | |

| – | Weight of the system | |

| – | Vertical position system’s centre of gravity | |

| – | Electric current | |

| – | Moment of inertia of the smaller wheel with respect to the axis of rotation | |

| – | Moment of inertia of the larger wheel with respect to the axis of rotation | |

| – | Characteristic dimensions of the system for determining the position of the center of gravity | |

| – | The distance between the axles of the wheelchair’s wheels | |

| – | Mass of the wheelchair | |

| – | Mass of the drives with accessories and mounting elements | |

| – | Mass of the battery | |

| – | Average mass of the weight plate | |

| – | Rotational speed | |

| – | Wheelchair outline | |

| – | Characteristic points of the system for determining the position of the centre of gravity | |

| – | Electrical power | |

| – | Mechanical power | |

| – | Radius of the smaller wheel | |

| – | Radius of the larger wheel | |

| – | Dynamic radius of the smaller wheel | |

| – | Rolling radius of the smaller wheel | |

| – | Dynamic radius of the larger wheel | |

| – | Rolling radius of the larger wheel. | |

| – | Point of support | |

| – | Propulsion torque | |

| – | Work time of the electric system | |

| – | Work time coverage (work time of the mechanical part) | |

| – | Voltage | |

| – | Velocity variants | |

| – | Linear acceleration |

References

- Zhou, H.; Hou, K.-M.; Zuo, D.; Li, J. Intelligent Urban Public Transportation for Accessibility Dedicated to People with Disabilities. Sensors 2012, 12, 10678–10692. [Google Scholar] [CrossRef] [PubMed]

- Morales, Y.; Watanabe, A.; Ferreri, F.; Even, J.; Shinozawa, K.; Hagita, N. Passenger discomfort map for autonomous navigation in a robotic wheelchair. Robot. Auton. Syst. 2018, 103, 13–26. [Google Scholar] [CrossRef]

- Wong, M.C.S.; Yap, R.C.Y. Social Impact Investing for Marginalized Communities in Hong Kong: Cases and Issues. Sustainability 2019, 11, 2831. [Google Scholar] [CrossRef] [Green Version]

- Rousseau-Harrison, K.; Rochette, A.; Routhier, F.; Dessureault, D.; Thibault, F.; Côté, O. Impact of wheelchair acquisition on social participation. Disabil. Rehabil. Assist. Technol. 2009, 4, 344–352. [Google Scholar] [CrossRef]

- Szrek, J.; Muraszkowski, A. Synthesis of an Automatic Obstacle overcoming Control Module, dedicated for Manual Wheelchairs. Acta Polytech. Hung. 2018, 15, 45–57. [Google Scholar]

- Hinderer, M.; Friedrich, P.; Wolf, B. An autonomous stair-climbing wheelchair. Robot. Auton. Syst. 2017, 94, 219–225. [Google Scholar] [CrossRef]

- Sasaki, K.; Eguchi, Y.; Suzuki, K. Stair-climbing wheelchair with lever propulsion control of rotary legs. Adv. Robot. 2020, 34, 802–813. [Google Scholar] [CrossRef]

- Madanhire, I.; Gwizo, T.; Mbowa, C. Design Improvement of Off-road Rough Uneven Rural Terrain Wheelchair. In Proceedings of the 2nd European Conference on Industrial Engineering and Operations Management (IEOM), Paris, France, 26–27 July 2018; pp. 2613–2626. [Google Scholar]

- Wu, B.F.; Chen, Y.S.; Huang, C.W.; Chang, P.J. An uphill safety controller with deep learning-based ramp detection for intelligent wheelchairs. IEEE Access 2018, 6, 28356–28371. [Google Scholar] [CrossRef]

- Favey, C.; Farcy, R.; Donnez, J.; Villanueva, J.; Zogaghi, A. Development of a New Negative Obstacle Sensor for Augmented Electric Wheelchair. Sensors 2021, 21, 6341. [Google Scholar] [CrossRef]

- Nonaka, M.; Kashiwazaki, H.; Ura, S.; Nagamori, M.; Uchiyama, H.; Shionoya, A. Evaluation of Driving Performance of Two Types of Competitive Wheelchairs for Badminton Made of Two Different Metallic Materials. Proceedings 2020, 49, 161. [Google Scholar] [CrossRef]

- Zipfel, E.; Cooper, R.A.; Pearlman, J.; Cooper, R.; Mccartney, M. New design and development of a manual wheelchair for India. Disabil. Rehabil. 2007, 29, 949–962. [Google Scholar] [CrossRef]

- Shionoya, A.; Kenmotsu, Y. Development of new wheelchair for sports competition. Proceedings 2018, 2, 257. [Google Scholar] [CrossRef] [Green Version]

- Quaglia, G.; Bonisoli, E.; Cavallone, P. The Design of a New Manual Wheelchair for Sport. Machines 2019, 7, 31. [Google Scholar] [CrossRef] [Green Version]

- Rozendaal, L.A.; Veeger, H.E.J.; Van Der Woude, L.H.V. The push force pattern in manual wheelchair propulsion as a balance between cost and effect. J. Biomech. 2003, 36, 239–247. [Google Scholar] [CrossRef]

- Lee, J.; Jeong, W.; Han, J.; Kim, T.; Oh, S. Barrier-Free Wheelchair with a Mechanical Transmission. Appl. Sci. 2021, 11, 5280. [Google Scholar] [CrossRef]

- Gowran, R.J.; Clifford, A.; Gallagher, A.; McKee, J.; O’Regan, B.; McKay, E.A. Wheelchair and seating assistive technology provision: A gateway to freedom. Disabil. Rehabil. 2020, 8, 1–12. [Google Scholar] [CrossRef]

- Oh, S.; Hori, Y. Disturbance attenuation control for power-assist wheelchair operation on slopes. IEEE Trans. Control. Syst. Technol. 2013, 22, 828–837. [Google Scholar]

- Oh, S.; Kong, K.; Hori, Y. Operation state observation and condition recognition for the control of power-assisted wheelchair. Mechatronics 2014, 24, 1101–1111. [Google Scholar] [CrossRef]

- Wieczorek, B.; Warguła, Ł.; Rybarczyk, D. Impact of a Hybrid Assisted Wheelchair Propulsion System on Motion Kinematics during Climbing up a Slope. Appl. Sci. 2020, 10, 1025. [Google Scholar] [CrossRef] [Green Version]

- Conners, R.T.; Bates, L.C.; Lassalle, P.P.; Zieff, G.; Whitehead, P.N.; Stevens, S.; Killen, L.; Cochrum, R.; Rodebaugh, K.L.; Faghy, M.; et al. Current and Future Implications of COVID-19 among Youth Wheelchair Users: 24-Hour Activity Behavior. Children 2021, 8, 690. [Google Scholar] [CrossRef]

- Wargua, Ł.; Kukla, M.; Wieczorek, B. The impact of wheelchairs driving support systems on the rolling resistance coefficient. IOP Conf. Ser. Mater. Sci. Eng. 2020, 776, 012076. [Google Scholar] [CrossRef]

- Van der Woude, L.H.; De Groot, S.; Janssen, T.W. Manual wheelchairs: Research and innovation in rehabilitation, sports, daily life and health. Med. Eng. Phys. 2006, 28, 905–915. [Google Scholar] [CrossRef]

- Yang, Y.-S.; Koontz, A.M.; Hsiao, Y.-H.; Pan, C.-T.; Chang, J.-J. Assessment of Wheelchair Propulsion Performance in an Immersive Virtual Reality Simulator. Int. J. Environ. Res. Public Health 2021, 18, 8016. [Google Scholar] [CrossRef]

- Kloosterman, M.G.; Snoek, G.J.; Van der Woude, L.H.; Buurke, J.H.; Rietman, J.S. A systematic review on the pros and cons of using a pushrim-activated power-assisted wheelchair. Clin. Rehabil. 2013, 27, 299–313. [Google Scholar] [CrossRef]

- Guillon, B.; Van-Hecke, G.; Iddir, J.; Pellegrini, N.; Beghoul, N.; Vaugier, I.; Figère, M.; Pradon, D.; Lofaso, F. Evaluation of 3 pushrim-activated power-assisted wheelchairs in patients with spinal cord injury. Arch. Phys. Med. Rehabil. 2015, 96, 894–904. [Google Scholar] [CrossRef]

- Kloosterman, M.G.; Eising, H.; Schaake, L.; Buurke, J.H.; Rietman, J.S. Comparison of shoulder load during power-assisted and purely hand-rim wheelchair propulsion. Clin. Biomech. 2012, 27, 428–435. [Google Scholar] [CrossRef]

- Antonelli, M.G.; Alleva, S.; Beomonte Zobel, P.; Durante, F.; Raparelli, T. Powered off-road wheelchair for the transportation of tetraplegics along mountain trails. Disabil. Rehabil. Assist. Technol. 2019, 14, 172–181. [Google Scholar] [CrossRef]

- Alqahtani, S.; Joseph, J.; Dicianno, B.; Layton, N.A.; Toro, M.L.; Ferretti, E.; Tuakli-Wosornu, Y.A.; Chhabra, H.; Neyedli, H.; Lopes, C.R.; et al. Stakeholder perspectives on research and development priorities for mobility assistive-technology: A literature review. Disabil. Rehabil. Assist. Technol. 2021, 16, 362–376. [Google Scholar] [CrossRef]

- Hussain, S.; Ali, M.U.; Nengroo, S.H.; Khan, I.; Ishfaq, M.; Kim, H.-J. Semiactive Hybrid Energy Management System: A Solution for Electric Wheelchairs. Electronics 2019, 8, 345. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.A.; Zeb, K.; Sathishkumar, P.; Ali, M.U.; Uddin, W.; Hussain, S.; Ishfaq, M.; Khan, I.; Cho, H.-G.; Kim, H.-J. A Novel Supercapacitor/Lithium-Ion Hybrid Energy System with a Fuzzy Logic-Controlled Fast Charging and Intelligent Energy Management System. Electronics 2018, 7, 63. [Google Scholar] [CrossRef] [Green Version]

- Burhanpurkar, M.; Labbé, M.; Guan, C.; Michaud, F.; Kelly, J. Cheap or robust? The practical realization of self-driving wheelchair technology. In Proceedings of the 2017 International Conference on Rehabilitation Robotics (ICORR), London, UK, 17–20 July 2017; pp. 1079–1086. [Google Scholar]

- Maksud, A.; Chowdhury, R.I.; Chowdhury, T.T.; Fattah, S.A.; Shahanaz, C.; Chowdhury, S.S. Low-cost eeg based electric wheelchair with advanced control features. In Proceedings of the TENCON 2017-2017 IEEE Region 10 Conference, Penang, Malaysia, 5–8 November 2017; pp. 2648–2653. [Google Scholar]

- Shahnaz, C.; Maksud, A.; Fattah, S.A.; Chowdhury, S.S. Low-cost smart electric wheelchair with destination mapping and intelligent control features. In Proceedings of the 2017 IEEE International Symposium on Technology and Society (ISTAS), Sydney, Australia, 10–11 August 2017; pp. 1–6. [Google Scholar]

- Na, R.; Hu, C.; Sun, Y.; Wang, S.; Zhang, S.; Han, M.; Yin, W.; Zhang, J.; Chen, X.; Zheng, D. An embedded lightweight SSVEP-BCI electric wheelchair with hybrid stimulator. Digit. Signal Process. 2021, 116, 103101. [Google Scholar] [CrossRef]

- Suzuki, T.; Boampong, D.; Utsuno, H.; Papadosifos, N.; Holloway, C.; Tyler, N. Powered attendant-propelled wheelchair with assist-as-needed control based on individual physical capabilities. J. Biomech. Sci. Eng. 2021, 16, 20-00474. [Google Scholar] [CrossRef]

- Hwang, B.; Jeon, D. A Method to Accurately Estimate the Muscular Torques of Human Wearing Exoskeletons by Torque Sensors. Sensors 2015, 15, 8337–8357. [Google Scholar] [CrossRef] [PubMed]

- Wieczorek, B.; Kukla, M. Biomechanical Relationships Between Manual Wheelchair Steering and the Position of the Human Body’s Center of Gravity. J. Biomech. Eng. 2020, 142, 081006. [Google Scholar] [CrossRef] [PubMed]

- Ramirez, D.Z.M.; Rasha, L.; Barbareschi, G.; Suzuki, T.; Caplan, I.; McKinnon, I.; Brett, D.J.L.; Holloway, C. Adjusted method to calculate an electric wheelchair power cycle: Fuel cell implementation example. J. Energy Storage 2019, 23, 371–380. [Google Scholar] [CrossRef]

- Sprigle, S.; Huang, M.; Misch, J. Measurement of rolling resistance and scrub torque of manual wheelchair drive wheels and casters. Assist. Technol. 2019, 1–13. [Google Scholar] [CrossRef]

- Kaňuch, J.; Girovský, P. Motor for direct drive of electric wheelchair. Int. J. Eng. Res. Afr. 2017, 31, 94–103. [Google Scholar] [CrossRef]

- Galkin, I.; Blinov, A.; Verbytskyi, I.; Zinchenko, D. Modular Self-Balancing Battery Charger Concept for Cost-Effective Power-Assist Wheelchairs. Energies 2019, 12, 1526. [Google Scholar] [CrossRef] [Green Version]

- Wieczorek, B.; Kukla, M.; Warguła, Ł. The Symmetric Nature of the Position Distribution of the Human Body Center of Gravity during Propelling Manual Wheelchairs with Innovative Propulsion Systems. Symmetry 2021, 13, 1–17. [Google Scholar] [CrossRef]

- Kukla, M.; Wieczorek, B.; Warguła, Ł.; Berdychwoski, M. An analytical model of the demand for propulsion torque during manual wheelchair propelling. Disabil. Rehabil. Assist. Technol. 2021, 16, 9–16. [Google Scholar] [CrossRef]

- Warguła, Ł. Design of a modular electric-manual hybrid propulsion system for a wheelchair. In Research on the Biomechanics of Manual Wheelchair Drive for Innovative Manual and Hybrid Drives, 1st ed.; Wieczorek, B., Ed.; Publishing House of the University of Technology and Humanities Kazimierz Pułaski: Radom, Poland, 2019; pp. 131–133. [Google Scholar]

- Sydor, M. Selection and Operation of a Wheelchair (Original Title in Polish: Wybór i Eksploatacja Wózka Inwalidzkiego). Ph.D. Thesis, Poznań University of Technology, Poznań, Poland, 2003. [Google Scholar]

- Wieczorek, B. Studies on Development of Transport Facilities Assisted Technique (on Example of Innovative Wheelchair and Their Families) (Original Title in Polish: Studia Nad Rozwojem Środków Lokomocji Techniki Asystującej na Przykładzie Innowacyjnych Wózków Inwalidzkich i Ich Rodzin). Ph.D. Thesis, Poznań University of Technology, Poznań, Poland, 2015. [Google Scholar]

- Untaru, M.; Potincu, G. Dinamica Autovehiculelor pe Roti; Editura Didactica si Pedagogica: Bucuresti, Romania, 1981. [Google Scholar]

- Anghelache, G.; Moisescu, R. The measurement of dynamic radii for passenger car tyre. OP Conf. Ser. Mater. Sci. Eng. 2017, 252, 012014. [Google Scholar] [CrossRef]

- Shigley, J.E.; Mischke, C.R. Standard Handbook of Machine Design, 2nd ed.; McGraw-Hill Publisher: New York, NY, USA, 1986. [Google Scholar]

- Kwarciak, A.M.; Yarossi, M.; Ramanujam, A.; Dyson-Hudson, T.A.; Sisto, S.A. Evaluation of wheelchair tyre rolling resistance using dynamometer-based coast-down tests. J. Rehabil. Res. Dev. 2009, 46, 931–938. [Google Scholar] [CrossRef]

- Golenko, A. Fundamentals of Machine Design: A Coursebook for Polish and Foreign Students; Publishing House of the Wrocław University of Technology: Wrocław, Poland, 2010; Available online: https://www.dbc.wroc.pl/Content/7154/Golenko_Fundamentals%20of%20Machine%20Design.pdf (accessed on 21 April 2021).

- Goldern Motor. Available online: https://www.goldenmotor.com/magicpie/magicpie.html (accessed on 21 September 2021).

- LiFePO4 Power Battery. Available online: https://www.miromax.lt/pl/m-6/c-28/c-29-akumulatory_do_el_rowera/product-454-li-ion_akumulator_36v_13ah_z_adowarka_i_akcesoria#product (accessed on 21 September 2021).

- Cowan, R.E.; Nash, M.S.; Collinger, J.L.; Koontz, A.M.; Boninger, M.L. Impact of surface type, wheelchair weight, and axle position on wheelchair propulsion by novice older adults. Arch. Phys. Med. Rehabil. 2009, 90, 1076–1083. [Google Scholar] [CrossRef] [Green Version]

- Van Drongelen, S.; Van der Woude, L.H.; Janssen, T.W.; Angenot, E.L.; Chadwick, E.K.; Veeger, D.H. Mechanical load on the upper extremity during wheelchair activities. Arch. Phys. Med. Rehabil. 2005, 86, 1214–1220. [Google Scholar] [CrossRef] [Green Version]

- Minav, T.A.; Virtanen, A.; Laurila, L.; Pyrhönen, J. Storage of energy recovered from an industrial forklift. Autom. Constr. 2012, 22, 506–515. [Google Scholar] [CrossRef]

- Yang, Y.P.; Guan, R.M.; Huang, Y.M. Hybrid fuel cell powertrain for a powered wheelchair driven by rim motors. Autom. Constr. 2012, 212, 192–204. [Google Scholar] [CrossRef]

- Krawiec, P.; Czarnecka-Komorowska, D.; Warguła, Ł.; Wojciechowski, S. Geometric Specification of Non-Circular Pulleys Made with Various Additive Manufacturing Techniques. Materials 2021, 14, 1682. [Google Scholar] [CrossRef]

- Sprigle, S.; Huang, M. Impact of mass and weight distribution on manual wheelchair propulsion torque. Assist. Technol. 2015, 27, 226–235. [Google Scholar] [CrossRef]

- Brubaker, C.E. Wheelchair prescription: An analysis of factors that affect mobility and performance. J. Rehabil. Res. Dev. 1986, 23, 19–26. [Google Scholar]

- Bertocci, G.E.; Hobson, D.A.; Digges, K.H. Development of transportable wheelchair design criteria using computer crash simulation. IEEE Trans. Rehabil. Eng. 1996, 4, 171–181. [Google Scholar] [CrossRef]

- Al-Rawashdeh, Y.M.; Elshafei, M.; Al-Malki, M.F. In-flight estimation of center of gravity position using all-accelerometers. Sensors 2014, 14, 17567–17585. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, Z.; Wang, J. Simultaneous estimation of vehicle’s center of gravity and inertial parameters based on Ackermann’s steering geometry. J. Dyn. Syst. Meas. Control 2017, 139, 031006. [Google Scholar] [CrossRef]

- Mango, N. Measurement & Calculation of Vehicle Center of Gravity Using Portable Wheel Scales, SAE Technical Paper; SAE: Warrendale, PA, USA, 2004; 2004-01-1076. [Google Scholar] [CrossRef]

- Skrúcaný, T.; Synák, F.; Semanová, S.; Ondruš, J.; Rievaj, V. Detection of road vehicle’s centre of gravity. In Proceedings of the 2018 XI International Science-Technical Conference Automotive Safety, Casta, Slovakia, 18–20 April 2018; pp. 1–7. [Google Scholar] [CrossRef]

- Hejtmánek, P.; Blaťák, O.; Vančura, J. New approach to measure the vehicle centre of gravity height. Perners Contacts 2015, 10, 18–27. Available online: https://pernerscontacts.upce.cz/index.php/perner/article/view/701 (accessed on 20 September 2021).

- Pierri, E.; Cirillo, V.; Vietor, T.; Sorrentino, M. Adopting a Conversion Design Approach to Maximize the Energy Density of Battery Packs in Electric Vehicles. Energies 2021, 14, 1939. [Google Scholar] [CrossRef]

| Value | Description | Value | Description | ||

|---|---|---|---|---|---|

| 0 rad | Constant value | 0.09 kg·m2 | Estimated based on [46] | ||

| 0.5 m2 | Value estimated based on [47] | 0.400 m | Measured value | ||

| 0.62 | Value estimated based on [16] | 0.05 m | Measured value | ||

| 0.4575 m | Measured value | 0.315 m | Measured value | ||

| 4.046·10−4 m | 0.0476 m | Estimated based on [48,49] | |||

| 2.937·10−3 m | 0.2937 m | Estimated based on [48,49] | |||

| 8.5·10−3 | Assumed value as in [44] | 0.0488 m | = 0.02 | ||

| 0.01 | Measured value | 0.3075 m | = 0.02 | ||

| 9.81 m/s2 | Physical constant | 0.765 | Assumed value | ||

| 0.390 m | Measured value | 0.99 | Estimated based on [50,51] | ||

| 0.034 kg·m2 | Estimated based on [52] |

| Variant | (mm) | (mm) | (kg) | (N) | (mm) | |

|---|---|---|---|---|---|---|

| 522.7 | 365.5 | 17.5 | 172.1 | 287.3 | ||

| 0.055 | 0.100 | 0.003 | ||||

| 463.4 | 456.4 | 43.6 | 427.7 | 346.6 | ||

| 0.022 | 0.040 | 0.005 | ||||

| 443.6 | 472.0 | 46.3 | 453.8 | 366.4 | ||

| 0.027 | 0.047 | 0.003 | ||||

| 469.0 | 453.4 | 46.1 | 452.5 | 341.0 | ||

| 0.024 | 0.041 | 0.010 | ||||

| 427.2 | 461.0 | 48.8 | 478.7 | 382.8 | ||

| 469.0 | 453.4 | 46.1 | ||||

| 475.7 | 451.2 | 48.9 | 479.8 | 334.3 | ||

| 0.039 | 0.148 | 0.012 | ||||

| 452.4 | 453.2 | 51.6 | 506.6 | 357.6 | ||

| 0.022 | 0.043 | 0.012 | ||||

| 455.4 | 452.6 | 54.2 | 533.1 | 354.6 | ||

| 0.019 | 0.041 | 0.012 | ||||

| 444.3 | 456.3 | 54.3 | 532.1 | 365.7 | ||

| 475.7 | 451.2 | 48.9 |

| Velocity | Variant | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| = 0.525 (m/s) | (Nm) | 1.233 | 1.306 | 1.303 | 1.4 | 1.377 | 1.467 | 1.539 | 1.548 |

| (h) | – | 32.19 | 32.19 | 62.64 | 63.03 | 92.89 | 121.9 | 121.5 | |

| = 1.05 (m/s) | (Nm) | 1.237 | 1.321 | 1.304 | 1.403 | 1.381 | 1.470 | 1.542 | 1.552 |

| (h) | – | 16.01 | 14.96 | 31.28 | 31.49 | 46.39 | 60.74 | 60.72 | |

| = 1.575 (m/s) | (Nm) | 1.239 | 1.325 | 1.308 | 1.406 | 1.383 | 1.473 | 1.545 | 1.554 |

| (h) | – | 10.66 | 10.71 | 20.84 | 20.97 | 30.91 | 61.07 | 60.91 | |

| = 2.1 (m/s) | (Nm) | 1.251 | 1.336 | 1.318 | 1.417 | 1.395 | 1.485 | 1.557 | 1.566 |

| (h) | – | 7.97 | 8.01 | 15.58 | 15.68 | 23.11 | 30.32 | 30.24 | |

| = 2.8 (m/s) | (Nm) | 1.255 | 1.340 | 1.324 | 1.421 | 1.399 | 1.489 | 1.561 | 1.57 |

| (h) | – | 5.97 | 6.00 | 11.67 | 11.75 | 17.31 | 34.2 | 34.11 | |

| = 3.5 (m/s) | (Nm) | 1.267 | 1.35 | 1.34 | 1.434 | 1.412 | 1.502 | 1.574 | 1.583 |

| (h) | – | 4.76 | 4.78 | 9.30 | 9.36 | 13.8 | 27.27 | 27.2 | |

| = 4.2 (m/s) | (Nm) | 1.308 | 1.393 | 1.376 | 1.474 | 1.451 | 1.541 | 1.613 | 1.623 |

| (h) | – | 3.92 | 3.94 | 7.67 | 7.71 | 11.37 | 14.93 | 14.89 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kukla, M.; Wieczorek, B.; Warguła, Ł.; Górecki, J.; Giedrowicz, M. An Analytical Modelling of Demand for Driving Torque of a Wheelchair with Electromechanical Drive. Energies 2021, 14, 7315. https://doi.org/10.3390/en14217315

Kukla M, Wieczorek B, Warguła Ł, Górecki J, Giedrowicz M. An Analytical Modelling of Demand for Driving Torque of a Wheelchair with Electromechanical Drive. Energies. 2021; 14(21):7315. https://doi.org/10.3390/en14217315

Chicago/Turabian StyleKukla, Mateusz, Bartosz Wieczorek, Łukasz Warguła, Jan Górecki, and Marcin Giedrowicz. 2021. "An Analytical Modelling of Demand for Driving Torque of a Wheelchair with Electromechanical Drive" Energies 14, no. 21: 7315. https://doi.org/10.3390/en14217315

APA StyleKukla, M., Wieczorek, B., Warguła, Ł., Górecki, J., & Giedrowicz, M. (2021). An Analytical Modelling of Demand for Driving Torque of a Wheelchair with Electromechanical Drive. Energies, 14(21), 7315. https://doi.org/10.3390/en14217315