Characteristics of Waste Generated in Dimension Stone Processing

Abstract

1. Introduction

2. Stone Wastes as a by-Product of Natural Dimension Stone Processing

2.1. Definition of Stone Wastes

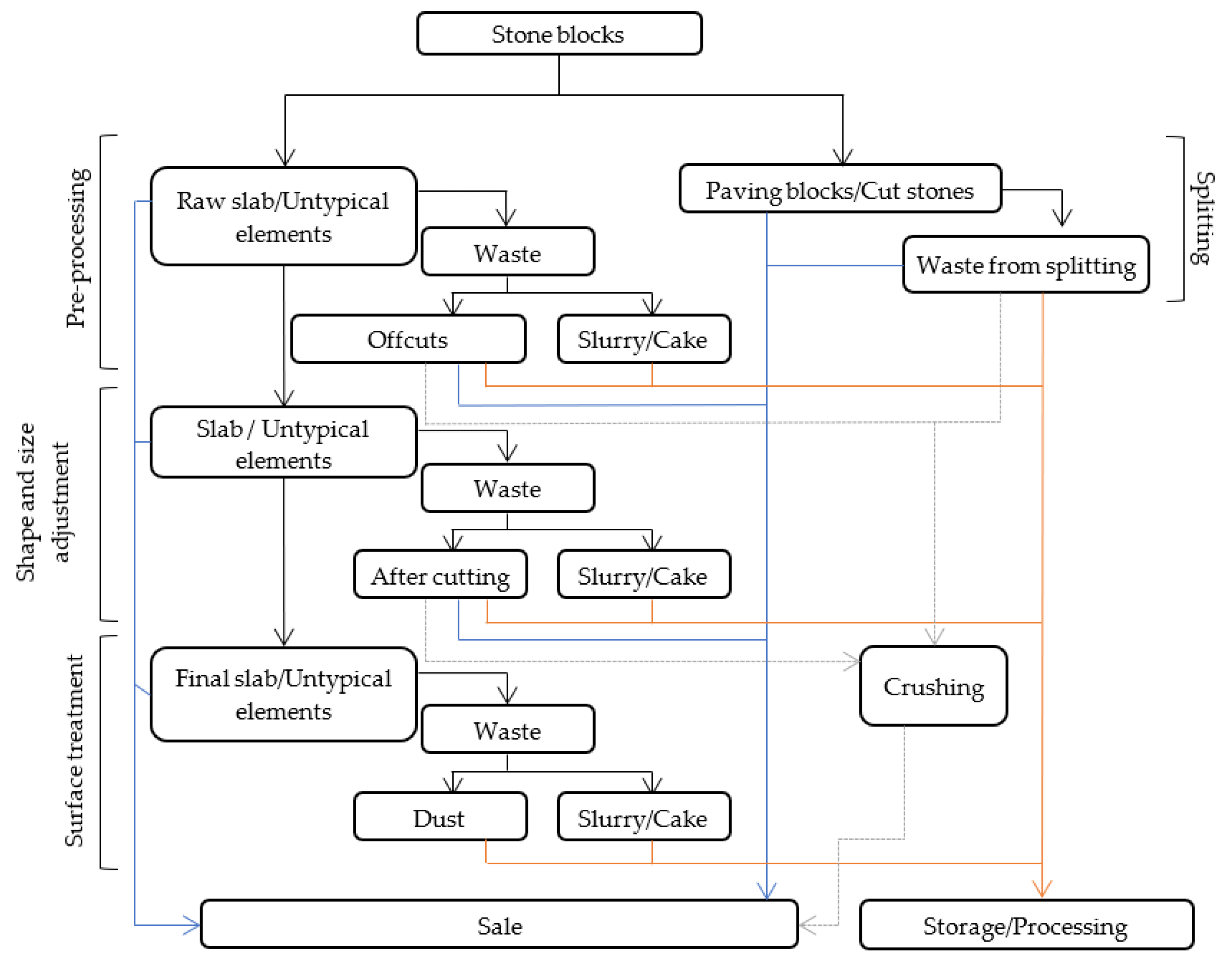

2.2. Structure of Stone Waste Production in Processing Plants

2.3. Analysis of Stone Waste Production

3. The Use of Waste from the Processing of Natural Stone

4. Conclusions

- Research efforts to find or improve a technology that reduces the volume of waste produced or the development of a waste-free technology;

- Research efforts to find possibilities of stone waste application.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Strzałkowski, P. Requirements and test methods for selected natural stone products. Gór. Odkryw. 2018, 59, 34–40. (In Polish) [Google Scholar]

- Careddu, N. Dimension stones in the circular economy world. Resour. Policy 2019, 60, 243–245. [Google Scholar] [CrossRef]

- Careddu, N.; Dino, G.A. Reuse of residual sludge from stone processing: Differences and similarities between sludge coming from carbonate and silicate stones—Italian experiences. Environ. Earth Sci. 2016, 75, 1–9. [Google Scholar] [CrossRef]

- Karaca, Z.; Pekin, A.; Deliormanlı, A.H.; Deliormanli, A.H. Classification of dimension stone wastes. Environ. Sci. Pollut. Res. 2012, 19, 2354–2362. [Google Scholar] [CrossRef]

- Kaźmierczak, U.; Blachowski, J.; Górniak-Zimroz, J.; Wirth, H. Quantitative and Qualitative Research on the Waste from the Mining of Rock Raw Materials in Lower Silesia. Minerals 2018, 8, 375. [Google Scholar] [CrossRef]

- Mosaferi, M.; Dianat, I.; Khatibi, M.S.; Mansour, S.N.; Fahiminia, M.; Hashemi, A.A. Review of environmental aspects and waste management of stone cutting and fabrication industries. J. Mater. Cycles Waste Manag. 2014, 16, 721–730. [Google Scholar] [CrossRef]

- Yurdakul, M. Natural stone waste generation from the perspective of natural stone processing plants: An industrial-scale case study in the province of Bilecik, Turkey. J. Clean. Prod. 2020, 276, 123339. [Google Scholar] [CrossRef]

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives, 2008/98/EC; EC: Brussels, Belgium, 2008.

- Kaźmierczak, U.; Blachowski, J.; Górniak-Zimroz, J. Multi-Criteria Analysis of Potential Applications of Waste from Rock Minerals Mining. Appl. Sci. 2019, 9, 441. [Google Scholar] [CrossRef]

- Tayebi-Khorami, M.; Edraki, M.; Corder, G.; Golev, A. Re-Thinking Mining Waste through an Integrative Approach Led by Circular Economy Aspirations. Minerals 2019, 9, 286. [Google Scholar] [CrossRef]

- Woźniak, J.; Pactwa, K. Overview of Polish Mining Wastes with Circular Economy Model and Its Comparison with Other Wastes. Sustainbility 2018, 10, 3994. [Google Scholar] [CrossRef]

- Yilmaz, E. Advances in reducing large volumes of environmentally harmful mine waste rocks and tailings. Gospod. Surowcami Miner.–Miner. Resour. Manag. 2011, 27, 89–112. [Google Scholar]

- Lèbre, É.; Corder, G.; Golev, A. The Role of the Mining Industry in a Circular Economy: A Framework for Resource Management at the Mine Site Level. J. Ind. Ecol. 2017, 21, 662–672. [Google Scholar] [CrossRef]

- Commission Decision of 18 December 2014 Amending Decision 2000/532/EC on the List of Waste Pursuant to Directive 2008/98/EC of the European Parliament and of the Council, 2014/955/UE; EC: Brussels, Belgium, 2014.

- Singh, S.; Nagar, R.; Agrawal, V. Performance of granite cutting waste concrete under adverse exposure conditions. J. Clean. Prod. 2016, 127, 172–182. [Google Scholar] [CrossRef]

- Mitchell, C.; Harrison, D.; Robinson, H.; Ghazireh, N. Minerals from Waste: Recent BGS and Tarmac experience in finding uses for mine and quarry waste. Miner. Eng. 2004, 17, 279–284. [Google Scholar] [CrossRef][Green Version]

- Shamrai, V.I.; Korobiichuk, V.V.; Sobolevskyi, R.V. Management of waste of stone processing in the framework of Euro integration of Ukraine. J. Zhytomyr State Technol. Univ. Ser. Eng. 2017, 1, 234–239. [Google Scholar] [CrossRef][Green Version]

- Lakhani, R.; Kumar, R.; Tomar, P. Utilization of Stone Waste in the Development of Value Added Products: A State of the Art Review. J. Eng. Sci. Technol. Rev. 2014, 7, 180–187. [Google Scholar] [CrossRef]

- Simsek, C.; Karaca, Z.; Gemici, U.; Gunduz, O. The assessment of the impacts of a marble waste site on the water and sedi-ment quality in a river system. Fresenius Environ. Bull. 2005, 14, 1013–1023. [Google Scholar]

- Rizzo, G.; D’Agostino, F.; Ercoli, L. Problems of soil and groundwater pollution in the disposal of “marble” slurries in NW Sicily. Environ. Earth Sci. 2008, 55, 929–935. [Google Scholar] [CrossRef]

- Nasserdine, K.; Mimi, Z.; Bevan, B.; Elian, B. Environmental management of the stone cutting industry. J. Environ. Manag. 2009, 90, 466–470. [Google Scholar] [CrossRef] [PubMed]

- Luodes, H.; Kauppila, P.M.; Luodes, N.; Aatos, S.; Kallioinen, J.; Luukkanen, S.; Aalto, J. Characteristics and the environmental acceptability of the natural stone quarrying waste rocks. Bull. Int. Assoc. Eng. Geol. 2012, 71, 257–261. [Google Scholar] [CrossRef]

- Da Silva, J.L.; Campos, D.B.D.C.; Lordsleem, A.C.; Povoas, Y.V. Influence of the partial substitution of fine aggregate by granite powder in mortar on the process of natural carbonation. Waste Manag. Res. 2020, 38, 254–262. [Google Scholar] [CrossRef] [PubMed]

- Ghannam, S.; Najm, H.; Vasconez, R. Experimental study of concrete made with granite and iron powders as partial replacement of sand. Sustain. Mater. Technol. 2016, 9, 1–9. [Google Scholar] [CrossRef]

- Gupta, L.K.; Vyas, A.K. Impact on mechanical properties of cement sand mortar containing waste granite powder. Constr. Build. Mater. 2018, 191, 155–164. [Google Scholar] [CrossRef]

- Hussain, S.A.; Shirisha, P.; Kumar, T.; Krishna, S.V.; Satyanarayana, S.V. The Use of Granite Industry Waste as a Cement Substitute. Int. J. Eng. Res. Technol. 2013, 2, 894–898. [Google Scholar]

- Li, L.; Wang, Y.; Tan, Y.; Kwan, A. Adding granite dust as paste replacement to improve durability and dimensional stability of mortar. Powder Technol. 2018, 333, 269–276. [Google Scholar] [CrossRef]

- Lokeshwari, M.; Jagadish, K. Eco-friendly Use of Granite Fines Waste in Building Blocks. Procedia Environ. Sci. 2016, 35, 618–623. [Google Scholar] [CrossRef]

- Boadella, Í.L.; Gayarre, F.L.; González, J.S.; Gómez-Soberón, J.M.; Pérez, C.L.-C.; López, M.S.; De Brito, J. The Influence of Granite Cutting Waste on the Properties of Ultra-High Performance Concrete. Materials 2019, 12, 634. [Google Scholar] [CrossRef]

- Ramos, T.; Matos, A.M.; Schmidt, B.; Rio, J.; Sousa-Coutinho, J. Granitic quarry sludge waste in mortar: Effect on strength and durability. Constr. Build. Mater. 2013, 47, 1001–1009. [Google Scholar] [CrossRef]

- Shamsabadi, E.A.; Ghalehnovi, M.; De Brito, J.; Khodabakhshian, A. Performance of Concrete with Waste Granite Powder: The Effect of Superplasticizers. Appl. Sci. 2018, 8, 1808. [Google Scholar] [CrossRef]

- Singh, S.; Nagar, R.; Agrawal, V.; Rana, A.; Tiwari, A. Sustainable utilization of granite cutting waste in high strength concrete. J. Clean. Prod. 2016, 116, 223–235. [Google Scholar] [CrossRef]

- Vijayalakshmi, M.; Sekar, A.; Sivabharathy, M.; Prabhu, G.G. Utilization of Granite Powder Waste in Concrete Production. Defect Diffus. Forum 2012, 330, 49–61. [Google Scholar] [CrossRef]

- Alyamaç, K.E.; Ghafari, E.; Ince, R. Development of eco-efficient self-compacting concrete with waste marble powder using the response surface method. J. Clean. Prod. 2017, 144, 192–202. [Google Scholar] [CrossRef]

- Alyamaç, K.E.; Ince, R. A preliminary concrete mix design for SCC with marble powders. Constr. Build. Mater. 2009, 23, 1201–1210. [Google Scholar] [CrossRef]

- Bilgin, N.; Yeprem, H.; Arslan, S.; Bilgin, A.; Günay, E.; Marşoglu, M. Use of waste marble powder in brick industry. Constr. Build. Mater. 2012, 29, 449–457. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G.; Naik, T.R. Characterization of marble powder for its use in mortar and concrete. Constr. Build. Mater. 2010, 24, 113–117. [Google Scholar] [CrossRef]

- Eliche-Quesada, D.; Iglesias, F.J.; Pérez-Villarejo, L.; Iglesias-Godino, F. Recycling of sawdust, spent earth from oil filtration, compost and marble residues for brick manufacturing. Constr. Build. Mater. 2012, 34, 275–284. [Google Scholar] [CrossRef]

- Grilo, M.J.; Pereira, J.; Costa, C. Waste Marble Dust Blended Cement. Mater. Sci. Forum 2012, 730-732, 671–676. [Google Scholar] [CrossRef]

- Kabeer, K.S.A.; Vyas, A.K. Utilization of marble powder as fine aggregate in mortar mixes. Constr. Build. Mater. 2018, 165, 321–332. [Google Scholar] [CrossRef]

- Khyaliya, R.K.; Kabeer, K.S.A.; Vyas, A.K. Evaluation of strength and durability of lean mortar mixes containing marble waste. Constr. Build. Mater. 2017, 147, 598–607. [Google Scholar] [CrossRef]

- Kore, S.D.; Vyas, A.K.; Syed, A.K.K.I. A brief review on sustainable utilisation of marble waste in concrete. Int. J. Sustain. Eng. 2020, 13, 264–279. [Google Scholar] [CrossRef]

- Li, L.; Huang, Z.; Tan, Y.; Kwan, A.; Chen, H. Recycling of marble dust as paste replacement for improving strength, microstructure and eco-friendliness of mortar. J. Clean. Prod. 2019, 210, 55–65. [Google Scholar] [CrossRef]

- Li, L.; Huang, Z.; Tan, Y.; Kwan, A.; Liu, F. Use of marble dust as paste replacement for recycling waste and improving durability and dimensional stability of mortar. Constr. Build. Mater. 2018, 166, 423–432. [Google Scholar] [CrossRef]

- Mashaly, O.; El-Kaliouby, B.A.; Shalaby, B.; El-Gohary, A.; Rashwan, M. Effects of marble sludge incorporation on the properties of cement composites and concrete paving blocks. J. Clean. Prod. 2016, 112, 731–741. [Google Scholar] [CrossRef]

- Prošek, Z.; Nežerka, V.; Tesárek, P. Enhancing cementitious pastes with waste marble sludge. Constr. Build. Mater. 2020, 255, 119372. [Google Scholar] [CrossRef]

- Prošek, Z.; Trejbal, J.; Topič, J.; Plachý, T.; Tesárek, P. Utilization of the waste from the marble industry for application in transport infrastructure: Mechanical properties of cement pastes. IOP Conf. Ser. Mater. Sci. Eng. 2017, 236, 012092. [Google Scholar] [CrossRef]

- Rodrigues, R.; de Brito, J.; Sardinha, M. Mechanical properties of structural concrete containing very fine aggregates from marble cutting sludge. Constr. Build. Mater. 2015, 77, 349–356. [Google Scholar] [CrossRef]

- Seghir, N.T.; Mellas, M.; Sadowski, Ł.; Krolicka, A.; Żak, A.; Ostrowski, K. The Utilization of Waste Marble Dust as a Cement Replacement in Air-Cured Mortar. Sustainbility 2019, 11, 2215. [Google Scholar] [CrossRef]

- Seghir, N.T.; Mellas, M.; Sadowski, Ł.; Żak, A. Effects of marble powder on the properties of the air-cured blended cement paste. J. Clean. Prod. 2018, 183, 858–868. [Google Scholar] [CrossRef]

- Siddique, Z.; Bhargava, R.; Ansari, M.; Khan, W. Experimental study for the utilization of marble powder and in construction industry. In Proceedings of the International Conference on Sustainable Materials and Structures for Civil Infrastructures (SMSCI2019); AIP Publishing: Melville, NY, USA, 2019; Volume 2158, p. 020025. [Google Scholar]

- Tunc, E.T. Recycling of marble waste: A review based on strength of concrete containing marble waste. J. Environ. Manag. 2019, 231, 86–97. [Google Scholar] [CrossRef]

- Ulubeyli, G.C.; Bilir, T.; Artir, R. Durability Properties of Concrete Produced by Marble Waste as Aggregate or Mineral Additives. Procedia Eng. 2016, 161, 543–548. [Google Scholar] [CrossRef]

- Vardhan, K.; Goyal, S.; Siddique, R.; Singh, M. Mechanical properties and microstructural analysis of cement mortar incorporating marble powder as partial replacement of cement. Constr. Build. Mater. 2015, 96, 615–621. [Google Scholar] [CrossRef]

- Vardhan, K.; Siddique, R.; Goyal, S. Influence of marble waste as partial replacement of fine aggregates on strength and drying shrinkage of concrete. Constr. Build. Mater. 2019, 228, 116730. [Google Scholar] [CrossRef]

- Cavaleri, L.; Borg, R.P.; La Mantia, F.P.; Liguori, V. Quarry limestone dust as fine aggregate for concrete. IOP Conf. Ser. Mater. Sci. Eng. 2018, 442. [Google Scholar] [CrossRef]

- Chouhan, H.S.; Kalla, P.; Nagar, R.; Gautam, P.K. Gainful utilization of dimensional limestone waste as fine aggregate in cement mortar mixes. Constr. Build. Mater. 2019, 221, 363–374. [Google Scholar] [CrossRef]

- Chouhan, H.S.; Kalla, P.; Nagar, R.; Gautam, P.K.; Arora, A.N. Investigating use of dimensional limestone slurry waste as fine aggregate in mortar. Environ. Dev. Sustain. 2018, 22, 2223–2245. [Google Scholar] [CrossRef]

- Kibriya, T.; Tahir, L. Sustainable Construction—High Performance Concrete Containing Limestone Dust as Filler. World J. Eng. Technol. 2017, 5, 404–411. [Google Scholar] [CrossRef][Green Version]

- Rana, A.; Kalla, P.; Csetenyi, L. Recycling of dimension limestone industry waste in concrete. Int. J. Min. Reclam. Environ. 2017, 31, 231–250. [Google Scholar] [CrossRef]

- Turgut, P.; Algin, H.M. Limestone dust and wood sawdust as brick material. Build. Environ. 2007, 42, 3399–3403. [Google Scholar] [CrossRef]

- Andrade, F.R.D.; Pecchio, M.; Bendoraitis, D.P.; Montanheiro, T.J.; Kihara, Y. Basalt mine-tailings as raw-materials for Portland clinker. Cerâmica 2010, 56, 39–43. [Google Scholar] [CrossRef]

- Dobiszewska, M. Zastosowanie pyłu bazaltowego, jako substytutu piasku w zaprawie i betonie cementowym. Bud. Arch. 2016, 15, 075–085. [Google Scholar] [CrossRef]

- Dobiszewska, M.; Barnes, R.W. Properties of Mortar Made with Basalt Powder as Sand Replacement. Mater. J. 2020, 117, 3–9. [Google Scholar] [CrossRef]

- Dobiszewska, M.; Beycioğlu, A. Physical Properties and Microstructure of Concrete with Waste Basalt Powder Addition. Materials 2020, 13, 3503. [Google Scholar] [CrossRef] [PubMed]

- Chandar, K.R.; Gayana, B.; Sainath, V. Experimental investigation for partial replacement of fine aggregates in concrete with sandstone. Adv. Concr. Constr. 2016, 4, 243–261. [Google Scholar] [CrossRef]

- Gupta, R.C.; Basu, P.; Agrawal, S. Mechanical properties of self-compacting concrete containing sandstone slurry. IOP Conf. Ser. Mater. Sci. Eng. 2019, 689, 012002. [Google Scholar] [CrossRef]

- Kumar, S.; Gupta, R.C.; Shrivastava, S. Long term studies on the utilisation of quartz sandstone wastes in cement concrete. J. Clean. Prod. 2017, 143, 634–642. [Google Scholar] [CrossRef]

- Kumar, S.; Gupta, R.C.; Shrivastava, S.; Csetenyi, L.; Thomas, B.S. Preliminary study on the use of quartz sandstone as a partial replacement of coarse aggregate in concrete based on clay content, morphology and compressive strength of combined gradation. Constr. Build. Mater. 2016, 107, 103–108. [Google Scholar] [CrossRef]

- Kumar, S.; Thomas, B.S.; Gupta, V.; Basu, P.; Shrivastava, S. Sandstone wastes as aggregate and its usefulness in cement concrete—A comprehensive review. Renew. Sustain. Energy Rev. 2018, 81, 1147–1153. [Google Scholar] [CrossRef]

- Singhal, A.; Goel, S.; Sengupta, D. Physicochemical and elemental analyses of sandstone quarrying wastes to assess their impact on soil properties. J. Environ. Manag. 2020, 271, 111011. [Google Scholar] [CrossRef] [PubMed]

- Almada, B.S.; Melo, L.D.S.; Dutra, J.B.; Bubani, L.C.; Silva, G.J.B.; dos Santos, W.J.; Aguilar, M.T.P. Influence of the heterogeneity of waste from wet processing of ornamental stones on the performance of Portland cement composites. Constr. Build. Mater. 2020, 262, 120036. [Google Scholar] [CrossRef]

- Amin, S.K.; Allam, M.E.; Garas, G.L.; Ezz, H. A study of the chemical effect of marble and granite slurry on green mortar compressive strength. Bull. Natl. Res. Cent. 2020, 44, 1–5. [Google Scholar] [CrossRef]

- Bacarji, E.; Filho, R.T.; Koenders, E.; Figueiredo, E.; Lopes, J. Sustainability perspective of marble and granite residues as concrete fillers. Constr. Build. Mater. 2013, 45, 1–10. [Google Scholar] [CrossRef]

- Chouhan, H.S.; Kalla, P.; Nagar, R.; Gautam, P.K. Influence of dimensional stone waste on mechanical and durability properties of mortar: A review. Constr. Build. Mater. 2019, 227, 116662. [Google Scholar] [CrossRef]

- Galetakis, M.; Soultana, A. A review on the utilisation of quarry and ornamental stone industry fine by-products in the construction sector. Constr. Build. Mater. 2016, 102, 769–781. [Google Scholar] [CrossRef]

- Rana, A.; Kalla, P.; Verma, H.; Mohnot, J. Recycling of dimensional stone waste in concrete: A review. J. Clean. Prod. 2016, 135, 312–331. [Google Scholar] [CrossRef]

- Araújo, A.J.M.; O Sousa, A.R.; Macedo, D.A.; Dutra, R.P.S.; Campos, L.F.A.; De Sousa, A.R.O. Effects of granite waste addition on the technological properties of industrial silicate based-ceramics. Mater. Res. Express 2019, 6, 125205. [Google Scholar] [CrossRef]

- Menezes, R.R.; Ferreira, H.S.; Neves, G.A.; Lira, H. Use of granite sawing wastes in the production of ceramic bricks and tiles. J. Eur. Ceram. Soc. 2005, 25, 1149–1158. [Google Scholar] [CrossRef]

- Panna, W.; Wyszomirski, P.; Gajek, M. Characteristics of the fine-grained fractions of the crushed Strzegom granites as possi-ble materials in manufacture of ceramic tiles. Gospod. Surowcami Miner.–Miner. Resour. Manag. 2015, 31, 59–75. [Google Scholar] [CrossRef][Green Version]

- El-Mahllawy, M.S.; Kandeel, A.M.; Latif, M.L.A.; El Nagar, A.M. The Feasibility of Using Marble Cutting Waste in a Sustainable Building Clay Industry. Recycling 2018, 3, 39. [Google Scholar]

- Montero, M.A.; Jordán, M.; Crespo, M.S.H.; Sanfeliu, T. The use of sewage sludge and marble residues in the manufacture of ceramic tile bodies. Appl. Clay Sci. 2009, 46, 404–408. [Google Scholar] [CrossRef]

- Munir, M.J.; Abbas, S.; Nehdi, M.L.; Kazmi, S.M.S.; Khitab, A. Development of Eco-Friendly Fired Clay Bricks Incorporating Recycled Marble Powder. J. Mater. Civ. Eng. 2018, 30, 04018069. [Google Scholar] [CrossRef]

- Munir, M.J.; Kazmi, S.M.S.; Wu, Y.-F.; Hanif, A.; Khan, M.U.A. Thermally efficient fired clay bricks incorporating waste marble sludge: An industrial-scale study. J. Clean. Prod. 2018, 174, 1122–1135. [Google Scholar] [CrossRef]

- Yeşilay, S.; Çakı, M.; Ergun, H. Usage of marble wastes in traditional artistic stoneware clay body. Ceram. Int. 2017, 43, 8912–8921. [Google Scholar] [CrossRef]

- El-Mehalawy, N.; El-Omla, M.; Naga, S.M. Stoneware Tiles Based on Gneiss Rocks. Interceram—Int. Ceram. Rev. 2018, 67, 26–33. [Google Scholar] [CrossRef]

- Moreira, J.; Manhães, J.; Holanda, J. Processing of red ceramic using ornamental rock powder waste. J. Mater. Process. Technol. 2008, 196, 88–93. [Google Scholar] [CrossRef]

- Souza, A.; Pinheiro, B.; Holanda, J. Recycling of gneiss rock waste in the manufacture of vitrified floor tiles. J. Environ. Manag. 2010, 91, 685–689. [Google Scholar] [CrossRef] [PubMed]

- Cavallo, A. Serpentinitic waste materials from the dimension stone industry: Characterization, possible reuses and critical issues. Resour. Policy 2018, 59, 17–23. [Google Scholar] [CrossRef]

- Díaz, L.; Torrecillas, R. Porcelain stoneware obtained from the residual muds of serpentinite raw materials. J. Eur. Ceram. Soc. 2007, 27, 2341–2345. [Google Scholar] [CrossRef]

- Amaral, L.F.; de Carvalho, J.P.R.G.; da Silva, B.M.; Delaqua, G.C.G.; Monteiro, S.N.; Vieira, C.M.F. Development of ceramic paver with ornamental rock waste. J. Mater. Res. Technol. 2019, 8, 599–608. [Google Scholar] [CrossRef]

- Luiz, N.F.; Cecchin, D.; Azevedo, A.R.G.; Alexandre, J.; Marvila, M.T.; Da Silva, F.C.; Paes, A.L.C.; Pinheiro, V.D.; Do Car-mo, D.F.; Ferraz, P.F.P.; et al. Characterization of materials used in the manufacture of ceramic tile with incorporation of or-namental rock waste. Agron. Res. 2020, 18, 904–914. [Google Scholar] [CrossRef]

- Saygili, A. Use of Waste Marble Dust for Stabilization of Clayey Soil. Mater. Sci. 2015, 21, 601–606. [Google Scholar] [CrossRef]

- Ibrahim, H.H.; Alshkane, Y.M.; Mawlood, Y.I.; Noori, K.M.G.; Hasan, A.M. Improving the geotechnical properties of high expansive clay using limestone powder. Innov. Infrastruct. Solutions 2020, 5, 1–11. [Google Scholar] [CrossRef]

- Ogila, W.A.M. The impact of natural ornamental limestone dust on swelling characteristics of high expansive soils. Environ. Earth Sci. 2016, 75, 1493. [Google Scholar] [CrossRef]

- Pastor, J.L.; Tomás, R.; Cano, M.; Riquelme, A.; Gutiérrez, E. Evaluation of the Improvement Effect of Limestone Powder Waste in the Stabilization of Swelling Clayey Soil. Sustainbility 2019, 11, 679. [Google Scholar] [CrossRef]

- Sabat, A.K.; Muni, P.K. Effects of limestone dust on geotechnical properties of an expansive soil. Int. J. Appl. Eng. Res. 2015, 10, 37724–37730. [Google Scholar]

- Igwe, O.; Adepehin, E.J. Alternative Approach to Clay Stabilization Using Granite and Dolerite Dusts. Geotech. Geol. Eng. 2017, 35, 1657–1664. [Google Scholar] [CrossRef]

- Sivrikaya, O.; Kıyıldı, K.R.; Karaca, Z. Recycling waste from natural stone processing plants to stabilise clayey soil. Environ. Earth Sci. 2014, 71, 4397–4407. [Google Scholar] [CrossRef]

- Tozsin, G.; Arol, A.I.; Oztas, T.; Kalkan, E. Using marble wastes as a soil amendment for acidic soil neutralization. J. Environ. Manag. 2014, 133, 374–377. [Google Scholar] [CrossRef]

- Artico, M.; Firpo, B.A.; Artico, L.L.; Tubino, R.M.C. Integrated use of sewage sludge and basalt mine waste as soil substitute for environmental restoration. REM-Int. Eng. J. 2020, 73, 225–232. [Google Scholar] [CrossRef]

- Zagożdżon, P.P. Basalt Powder in Agricultural Use. Min. Sci. 2008, 10, 133–142. (In Polish) [Google Scholar]

- De Souza, M.E.P.; Cardoso, I.M.; De Carvalho, A.M.X.; Lopes, A.P.; Jucksch, I. Gneiss and steatite vermicomposted with organic residues: Release of nutrients and heavy metals. Int. J. Recycl. Org. Waste Agric. 2019, 8, 233–240. [Google Scholar] [CrossRef]

- De Souza, M.E.P.; Cardoso, I.M.; De Carvalho, A.M.X.; Lopes, A.P.; Jucksch, I.; Janssen, A. Rock Powder Can Improve Vermicompost Chemical Properties and Plant Nutrition: An On-farm Experiment. Commun. Soil Sci. Plant Anal. 2018, 49, 1–12. [Google Scholar] [CrossRef]

- Dino, G.A.; Passarella, I.; Ajmone-Marsan, F. Quarry rehabilitation employing treated residual sludge from dimension stone working plant. Environ. Earth Sci. 2014, 73, 7157–7164. [Google Scholar] [CrossRef]

- Kufka, D.; Cichoń, T.; Pomorski, A. Use of Gneiss Waste for Cultivation of Maize under Natural Sunflow Conditions. Gór. Odkryw. 2019, 60, 25–29. (In Polish) [Google Scholar]

- Karimi, D.; Crawford, B.; Milani, A.S. Manufacturing process and mechanical properties of a novel acrylonitrile butadiene styrene-based composite, with recycled natural granite micro-particles. Manuf. Lett. 2020, 23, 79–84. [Google Scholar] [CrossRef]

- Bakshi, P.; Pappu, A.; Patidar, R.; Gupta, M.K.; Thakur, V.K. Transforming Marble Waste into High-Performance, Water-Resistant, and Thermally Insulative Hybrid Polymer Composites for Environmental Sustainability. Polymers 2020, 12, 1781. [Google Scholar] [CrossRef] [PubMed]

- Çınar, M.E.; Kar, F. Characterization of composite produced from waste PET and marble dust. Constr. Build. Mater. 2018, 163, 734–741. [Google Scholar] [CrossRef]

- Doan, T.T.L.; Brodowsky, H.M.; Gohs, U.; Mäder, E. Re-Use of Marble Stone Powders in Producing Unsaturated Polyester Composites. Adv. Eng. Mater. 2018, 20, 1701061. [Google Scholar] [CrossRef]

- Thakur, A.K.; Pappu, A.; Thakur, V.K. Synthesis and characterization of new class of geopolymer hybrid composite materials from industrial wastes. J. Clean. Prod. 2019, 230, 11–20. [Google Scholar] [CrossRef]

- Conde-Vázquez, C.; Martín, O.D.M.-S.; García-Herbosa, G. Artificial arenite from wastes of natural sandstone industry. Mater. Constr. 2019, 69, 178. [Google Scholar] [CrossRef]

- Kurańska, M.; Barczewski, M.; Uram, K.; Lewandowski, K.; Prociak, A.; Michałowski, S. Basalt waste management in the production of highly effective porous polyurethane composites for thermal insulating applications. Polym. Test. 2019, 76, 90–100. [Google Scholar] [CrossRef]

- Petropavlovskaya, V.B.; Novichenkova, T.B.; Zavadko, M.Y.; Petropavlovskii, K.S. On the potential use of basalt waste as mineral fillers. IOP Conf. Ser. Mater. Sci. Eng. 2020, 791, 012070. [Google Scholar] [CrossRef]

- Alves, J.O.; Espinosa, D.C.R.; Tenório, J.A.S. Recovery of Steelmaking Slag and Granite Waste in the Production of Rock Wool. Mater. Res. 2015, 18, 204–211. [Google Scholar] [CrossRef][Green Version]

- Agrawal, S.; Mandot, S.; Bandyopadhyay, S.; Mukhopadhyay, R.; Dasgupta, M.; De, P.; Deuri, A. Use of Marble Waste in Rubber Industry: Part I (in NR Compound). Prog. Rubber Plast. Recycl. Technol. 2004, 20, 229–246. [Google Scholar] [CrossRef]

- Marras, G.; Careddu, N. Sustainable reuse of marble sludge in tyre mixtures. Resour. Policy 2018, 59, 77–84. [Google Scholar] [CrossRef]

- Nawar, A.; Ghaedi, H.; Ali, M.; Zhao, M.; Iqbal, N.; Khan, R. Recycling waste-derived marble powder for CO2 capture. Process. Saf. Environ. Prot. 2019, 132, 214–225. [Google Scholar] [CrossRef]

- Özkaya, K.; Ayrilmis, N.; Özdemir, S. Potential use of waste marble powder as adhesive filler in the manufacture of laminated veneer lumber. BioRes 2015, 10, 1686–1695. [Google Scholar] [CrossRef]

- Shirazi, E.K. Reusing of stone waste in various industrial activities. In Proceedings of the 2nd International Conference on Environmental Science and Development, Singapore, 26–28 February 2011; Volume 4, pp. 217–219. [Google Scholar]

- Kawalec, W.; Suchorab, N.; Konieczna-Fuławka, M.; Król, R. Specific Energy Consumption of a Belt Conveyor System in a Continuous Surface Mine. Energies 2020, 13, 5214. [Google Scholar] [CrossRef]

- Bortnowski, P.; Gładysiewicz, L.; Król, R.; Ozdoba, M. Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems. Energies 2021, 14, 1786. [Google Scholar] [CrossRef]

| Type of Waste | Definition of Waste | Description of Waste Source |

|---|---|---|

| SOLID STONE SCRAPS | ||

| Damaged stone blocks | Stone blocks that have significant defects or have been damaged and are characterised by different sizes and irregular shapes. | Stone blocks that have insufficient material quality or have been damaged during transport or unsuccessfully divided into smaller parts. |

| Damaged final stone products | Final stone products with inherent and secondary defects. | During the processing operation, fractures or defects in the final stone products may occur (secondary defects) or primary defects are revealed. |

| Offcuts | The first and last slab of a stone block cut in a head saw, having one surface smooth and one surface raw/split. | Offcuts occur when a stone block with uneven surfaces is cut. The basic operation behind cutting a stone block is to approximate its shape to a cube. Offcuts are due to the technology employed in natural stone processing. |

| Valvestones | Lower part of the cut stone block | Waste is generated after cutting a stone block due to safety reasons and in order not to damage the cut raw slabs. This waste is generated as a result of using certain stone block cutting technologies (e.g., disc saw) and is less and less frequent. |

| Waste from splitting | Parts of the split material outside the size standard of the product (e.g., paving stone). | When splitting natural stone into smaller-size elements (e.g., in the production of paving stone), oversize rock parts of the desired element are split off. |

| Waste from cutting | Parts of rock material which are smaller in volume than offcuts and have a minimum of 3 smooth surfaces. | Waste is produced as part of the size and shape adjustment. Rock material is produced as a result of cutting off the oversize parts of natural stone. The quantity of this waste depends on the volume of the cutoff stone parts and on the planned cutting locations. |

| Dust | Fine fraction rock and abrasive material. | As stone is processed, fine fractions of rock material and spalls are split/chipped off the rock. In addition, depending on the surface treatment technology used, this type of waste may include abrasive material (e.g., sand being the product of sandblasting). |

| STONE SLUDGE | ||

| Slurry/Cake | A mixture of water, ground fine rock, and particles of the cutting tool. | This type of waste is generated at each stage of stone processing. Stone is abraded by the processing elements and subsequently mixed with water. This type of waste additionally comprises small amounts of particles from the working tools. |

| Processing Plant 1 | Processing Plant 2 | Processing Plant 3 | Processing Plant 4 | Processing Plant 5 | Processing Plant 6 | Processing Plant 7 | Processing Plant 8 | Processing Plant 9 | Processing Plant 10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Type of natural stone | granite, limestone, marble | granite, marble | granite, sandstone | granite, gneiss, marble, sandstone, limestone, onyx | sandstone | granite | sandstone, limestone, marble | granite, sandstone, limestone, marble | sandstone | granite, sandstone |

| Production | cladding slabs, stairs, window sills, paving blocks | raw slabs stairs, window sills, paving blocks, curbs | cladding slabs, stairs, window sills, curbs | raw slabs | raw slabs, cladding slabs, formed elements, untypical elements | raw slabs, paving blocks, curbs | raw slabs, cladding slabs, stairs, window sills, formed elements | raw slabs, cladding slabs, stairs, window sills, formed elements, curbs | raw slabs, cladding slabs, formed elements | raw slabs |

| Pre-processing | gang saw, disc saw, multi-wire diamond saw | gang saw, disc saw | gang saw | multi-wire diamond saw | gang saw | gang saw, multi-wire diamond saw, stone splitting machine | gang saw, multi-wire diamond saw | gang saw, multi-wire diamond saw | multi-wire diamond saw | gang saw |

| Shape and size adjustment | table saw | table saw | table saw | - | table saw | - | table saw | table saw | table saw | - |

| Surface treatment | abrasive-polishing line, side grinder, thermal burner, graining machine, sandblaster | abrasive-polishing line, side grinder, thermal burner | abrasive-polishing line, side grinder, graining machine, sandblaster | abrasive-polishing line, thermal burner | abrasive-polishing line | - | abrasive-polishing line | abrasive-polishing line, graining machine | abrasive-polishing line | abrasive-polishing line, sandblaster |

| Processing Plant 1 | Processing Plant 2 | Processing Plant 3 | Processing Plant 4 | Processing Plant 5 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Quantity of rock material to be processed, m3 | 268.00 | 244.88 | 175.25 | 291.67 | 179.79 | |||||||||||

| Quantity of stone waste | Loss of stone material | Quantity of stone waste | Loss of stone material | Quantity of stone waste | Loss of stone material | Quantity of stone waste | Loss of stone material | Quantity of stone waste | Loss of stone material | |||||||

| m3 | Mg | % | m3 | Mg | % | m3 | Mg | % | m3 | Mg | % | m3 | Mg | % | ||

| Pre-processing | Stone sludge * | 22.35 | 211.50 | 8.34 | 19.15 | 181.72 | 7.82 | 38.51 | 182.00 | 21.98 | 42.00 | 112.14 | 14.40 | 8.55 | 23.00 | 4.76 |

| Solid stone scraps | 8.45 | 82.30 | 3.15 | 8.76 | 71.18 | 3.58 | 14.39 | 68.00 | 8.21 | 16.80 | 44.86 | 5.76 | 9.18 | 24.70 | 5.11 | |

| Shape and size adjustment | Stone sludge * | 1.91 | 6.00 | 0.71 | 0.08 | 0.30 | 0.03 | 1.54 | 5.00 | 0.88 | - | - | 0.00 | 1.49 | 4.00 | 0.83 |

| Solid stone scraps | 5.09 | 16.00 | 1.90 | 0.42 | 1.50 | 0.17 | 2.46 | 8.00 | 1.40 | - | - | 0.00 | 3.79 | 10.20 | 2.11 | |

| Surface treatment | Stone sludge * | 5.10 | 15.60 | 1.90 | 0.60 | 10.70 | 0.25 | 4.10 | 17.20 | 2.34 | 18.90 | 50.46 | 6.48 | 2.96 | 8.50 | 1.65 |

| Solid stone scraps | 2.80 | 11.40 | 1.04 | 0.70 | 11.00 | 0.29 | 1.10 | 10.60 | 0.63 | 2.10 | 5.61 | 0.72 | - | - | 0.00 | |

| Total | Stone sludge * | 29.36 | 233.10 | 10.96 | 19.83 | 192.72 | 8.10 | 44.15 | 204.20 | 25.19 | 60.90 | 162.60 | 20.88 | 13.00 | 35.50 | 7.23 |

| Solid stone scraps | 16.34 | 109.70 | 6.10 | 9.88 | 83.68 | 4.03 | 17.95 | 86.60 | 10.24 | 18.90 | 50.46 | 6.48 | 12.97 | 34.90 | 7.22 | |

| Total volume | 45.70 | 342.80 | 17.06 | 29.71 | 276.40 | 12.13 | 62.10 | 290.80 | 35.43 | 79.80 | 213.06 | 27.36 | 25.97 | 70.40 | 14.45 | |

| Processing plant 6 | Processing plant 7 | Processing plant 8 | Processing plant 9 | Processing plant 10 | ||||||||||||

| Quantity of rock material to be processed, m3 | 330.00 | 259.75 | 360.00 | 86.48 | 250.60 | |||||||||||

| Quantity of stone waste | Loss of stone material | Quantity of stone waste | Loss of stone material | Quantity of stone waste | Loss of stone material | Quantity of stone waste | Loss of stone material | Quantity of stone waste | Loss of stone material | |||||||

| m3 | Mg | % | m3 | Mg | % | m3 | Mg | % | m3 | Mg | % | m3 | Mg | % | ||

| Pre-processing | Stone sludge * | 18.74 | 51.54 | 5.68 | 28.71 | 73.21 | 11.05 | 41.49 | 112.02 | 11.53 | 5.79 | 15.63 | 6.70 | 15.82 | 43.82 | 6.31 |

| Solid stone scraps | 18.70 | 51.43 | 5.67 | 16.34 | 41.67 | 6.29 | 21.44 | 57.89 | 5.96 | 3.10 | 8.37 | 3.58 | 8.50 | 23.55 | 3.39 | |

| Shape and size adjustment | Stone sludge * | - | - | 0.00 | 2.12 | 5.41 | 0.82 | 5.67 | 15.31 | 1.58 | 2.70 | 7.29 | 3.12 | - | - | 0.00 |

| Solid stone scraps | - | - | 0.00 | 5.40 | 13.77 | 2.08 | 7.60 | 20.52 | 2.11 | 3.44 | 9.29 | 3.98 | - | - | 0.00 | |

| Surface treatment | Stone sludge * | - | - | 0.00 | 4.59 | 11.70 | 1.77 | 8.01 | 21.62 | 2.22 | 2.90 | 7.84 | 3.36 | 9.33 | 25.86 | 3.72 |

| Solid stone scraps | - | - | 0.00 | - | - | 0.00 | 1.33 | 3.60 | 0.37 | - | - | 0.00 | 0.57 | 1.57 | 0.23 | |

| Total | Stone sludge * | 18.74 | 51.54 | 5.68 | 35.42 | 90.32 | 13.64 | 55.17 | 148.95 | 15.32 | 11.39 | 30.77 | 13.18 | 25.15 | 69.68 | 10.04 |

| Solid stone scraps | 18.70 | 51.43 | 5.67 | 21.74 | 55.44 | 8.37 | 30.37 | 82.01 | 8.44 | 6.54 | 17.66 | 7.56 | 9.07 | 25.11 | 3.62 | |

| Total volume | 37.44 | 102.97 | 11.35 | 57.16 | 145.76 | 22.01 | 85.54 | 230.97 | 23.76 | 17.93 | 48.42 | 20.74 | 34.22 | 94.79 | 13.66 | |

| Application of Stone Scrap | Type of Stone Scrap | Material | References |

|---|---|---|---|

| Building materials (mortar/concrete/brick) | powder/fine aggregate | granite | [23,24,25,26,27,28,29,30,31,32,33] |

| marble | [34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55] | ||

| limestone | [56,57,58,59,60,61] | ||

| powder/fine aggregate | basalt | [62,63,64,65] | |

| coarse/fine aggregate | sandstone | [66,67,68,69,70,71] | |

| powder | mix/unidentified | [72,73,74,75,76,77] | |

| Ceramic materials | fine grained waste/powder | granite | [78,79,80] |

| marble | [81,82,83,84,85] | ||

| powder | gneiss | [86,87,88] | |

| serpentinite | [89,90] | ||

| mix/unidentified | [91,92] | ||

| Stabilised clay soil | powder | marble | [93] |

| limestone | [94,95,96,97] | ||

| mix/unidentified | [98,99] | ||

| Fertilisation | unidentified | marble | [100] |

| basalt | [101,102] | ||

| powder | gneiss | [103,104,105,106] | |

| Various composite materials | powder | granite | [107] |

| marble | [108,109,110,111] | ||

| sandstone | [112] | ||

| basalt | [113,114] | ||

| Other applications | powder | granite | [115] |

| marble | [116,117,118,119] |

| Type of Stone Scrap | Different Applications of Scrap from Dimension Natural Stone Processing |

|---|---|

| Small stone waste (including sludge) | Asphalt and concrete production Brick manufacturing Construction fill Production of synthetic aggregate Media for biofiltration systems or soil remediation Mineral content for soil Tire mixtures production |

| Waste in the form of aggregates | Construction fill Construction mixture ingredient For road filling For reclamation in landscaping and decorative use Media for biofiltration systems |

| Larger stone pieces and paving | Fill for gabion retaining walls and foundations For reclamation in landscaping and decorative use |

| Damaged blocks or slabs | Use as a foundation filler Production of aggregates For cutting tiles of small size Production of paving stones or tiles |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Strzałkowski, P. Characteristics of Waste Generated in Dimension Stone Processing. Energies 2021, 14, 7232. https://doi.org/10.3390/en14217232

Strzałkowski P. Characteristics of Waste Generated in Dimension Stone Processing. Energies. 2021; 14(21):7232. https://doi.org/10.3390/en14217232

Chicago/Turabian StyleStrzałkowski, Paweł. 2021. "Characteristics of Waste Generated in Dimension Stone Processing" Energies 14, no. 21: 7232. https://doi.org/10.3390/en14217232

APA StyleStrzałkowski, P. (2021). Characteristics of Waste Generated in Dimension Stone Processing. Energies, 14(21), 7232. https://doi.org/10.3390/en14217232