What Are the Policy Impacts on Renewable Jet Fuel in Sweden?

Abstract

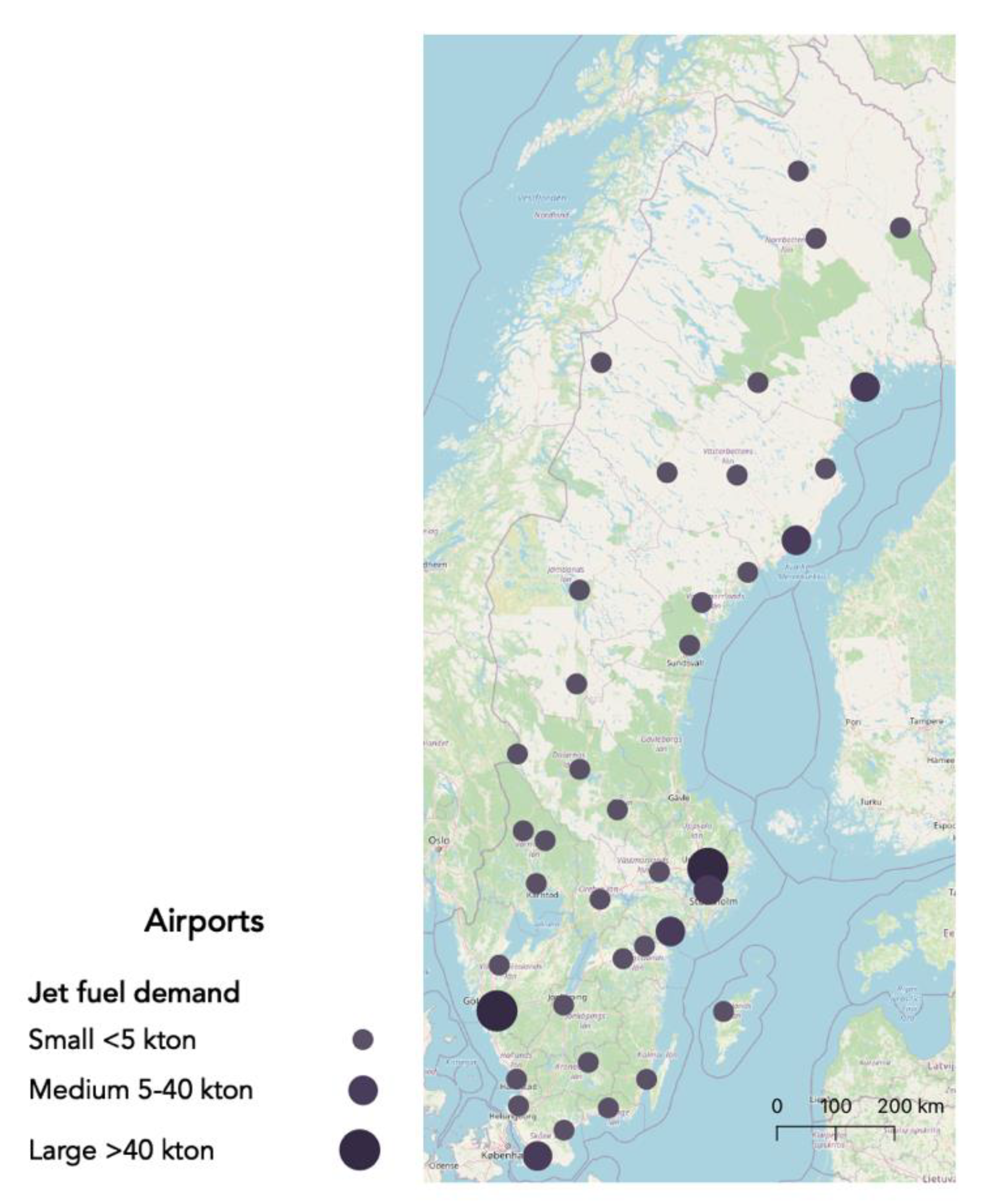

1. Introduction

1.1. Background

1.2. Climate and Energy Policies for the Aviation Industry in Sweden

- By 2045, Sweden is to achieve no net GHG-emissions into the atmosphere.

- By 2040, 100% of the electricity generation should be from renewable sources.

- By 2030, the emissions from domestic transport should be reduced by 70% compared with 2010 (excluding domestic aviation since it is included in EU ETS) [6].

2. Materials and Methods

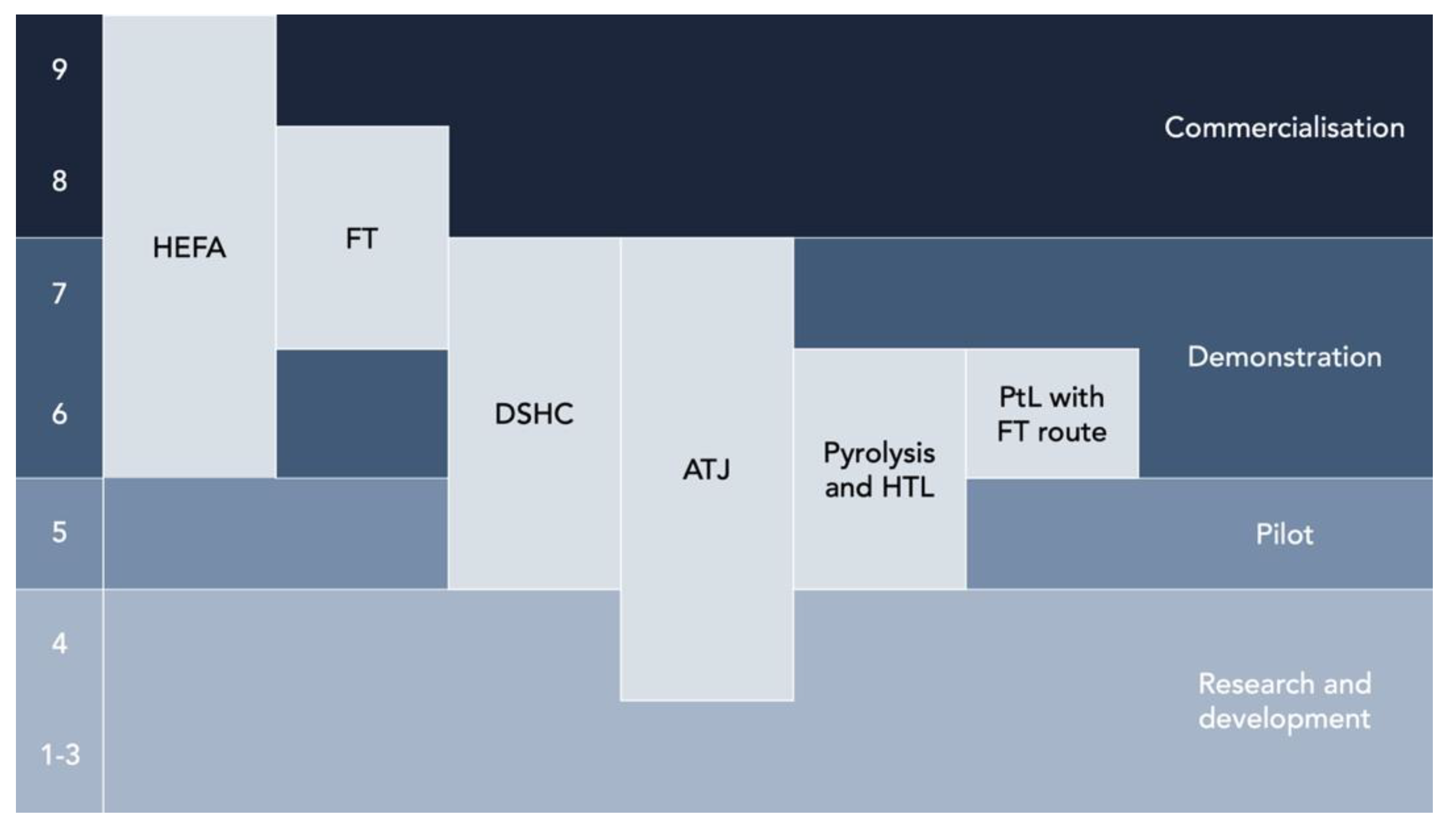

2.1. Technological Conversion Pathways

2.1.1. Hydroprocessed Esters and Fatty Acids

2.1.2. Fischer–Tropsch

2.1.3. Hydrothermal Liquefaction

2.1.4. Power-to-Liquid with Fischer–Tropsch Route

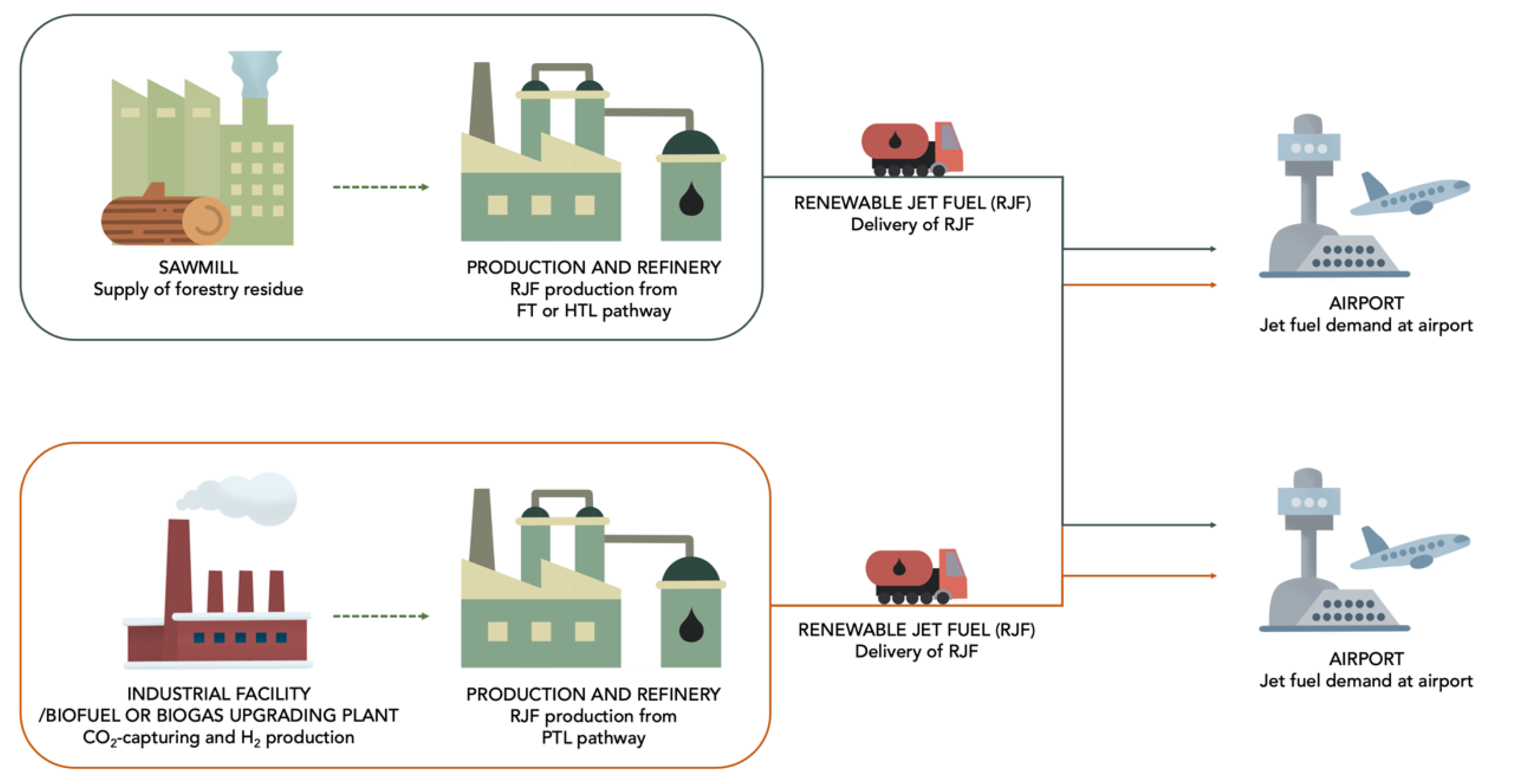

2.2. Supply Chain Model

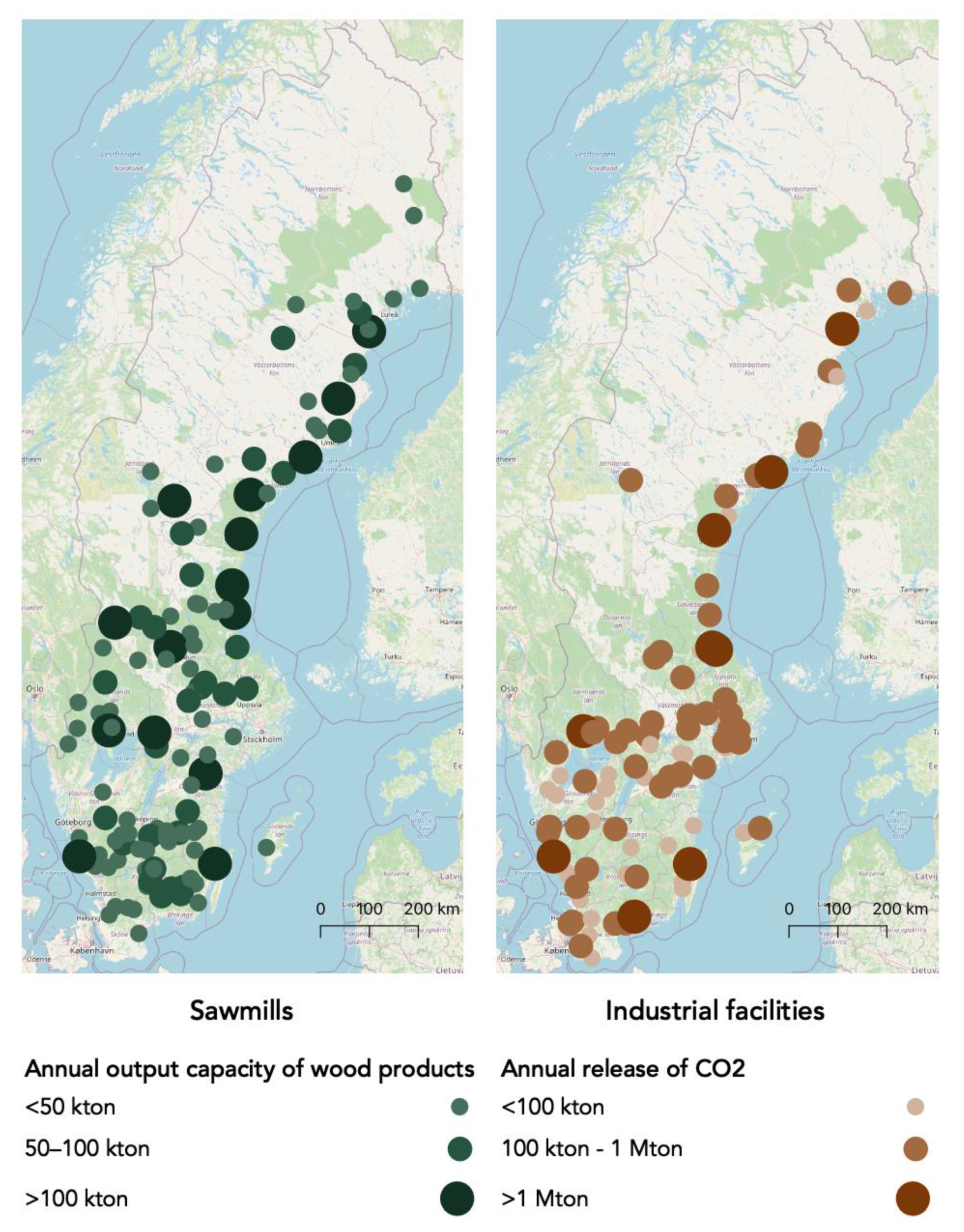

2.3. Feedstock Supply to Produce RJF

2.4. Technoeconomic Parameters

- r Discount rate

- N Number or years

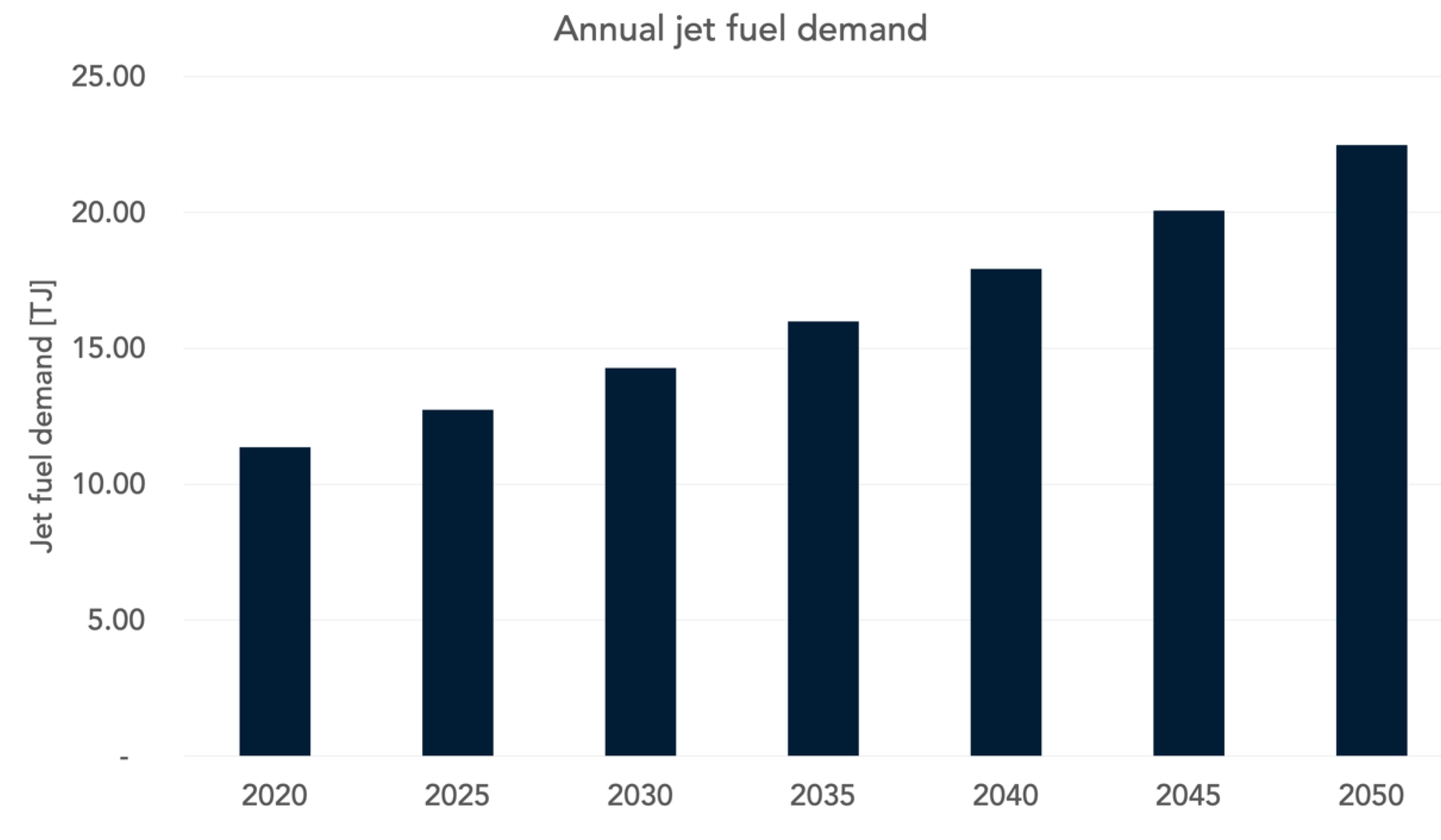

2.5. Jet Fuel Demand

2.6. Life Cycle Emissions

2.7. Optimization Model

- CS Total system cost of supply chain

- CP Total cost of production

- CN Total revenues from by-products

- CT Total cost of transport

- CR Total cost of raw materials

- CE Total cost of emissions

- CHEFA, CJF Total cost of HEFA and/or CJF

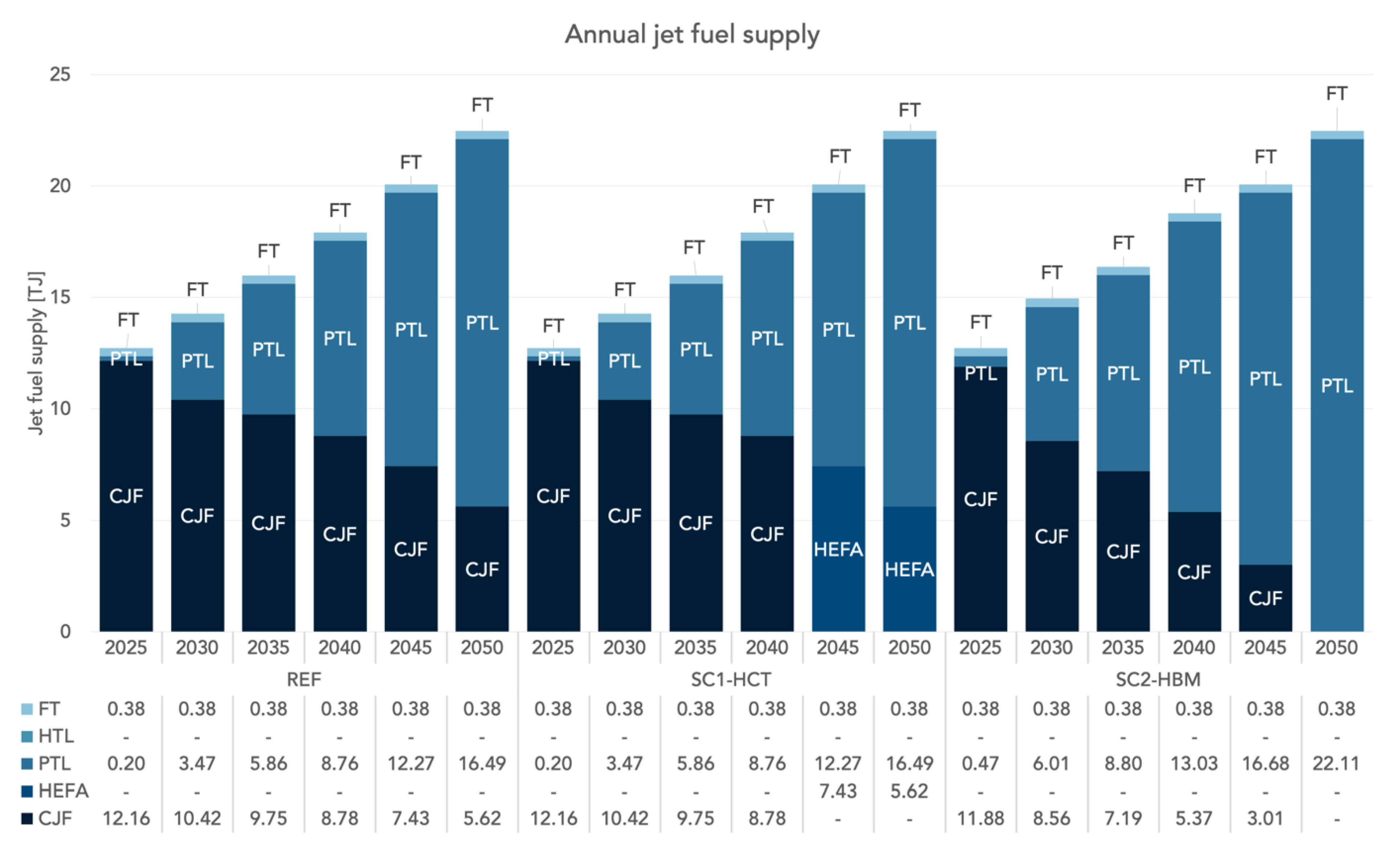

2.8. Scenario Description

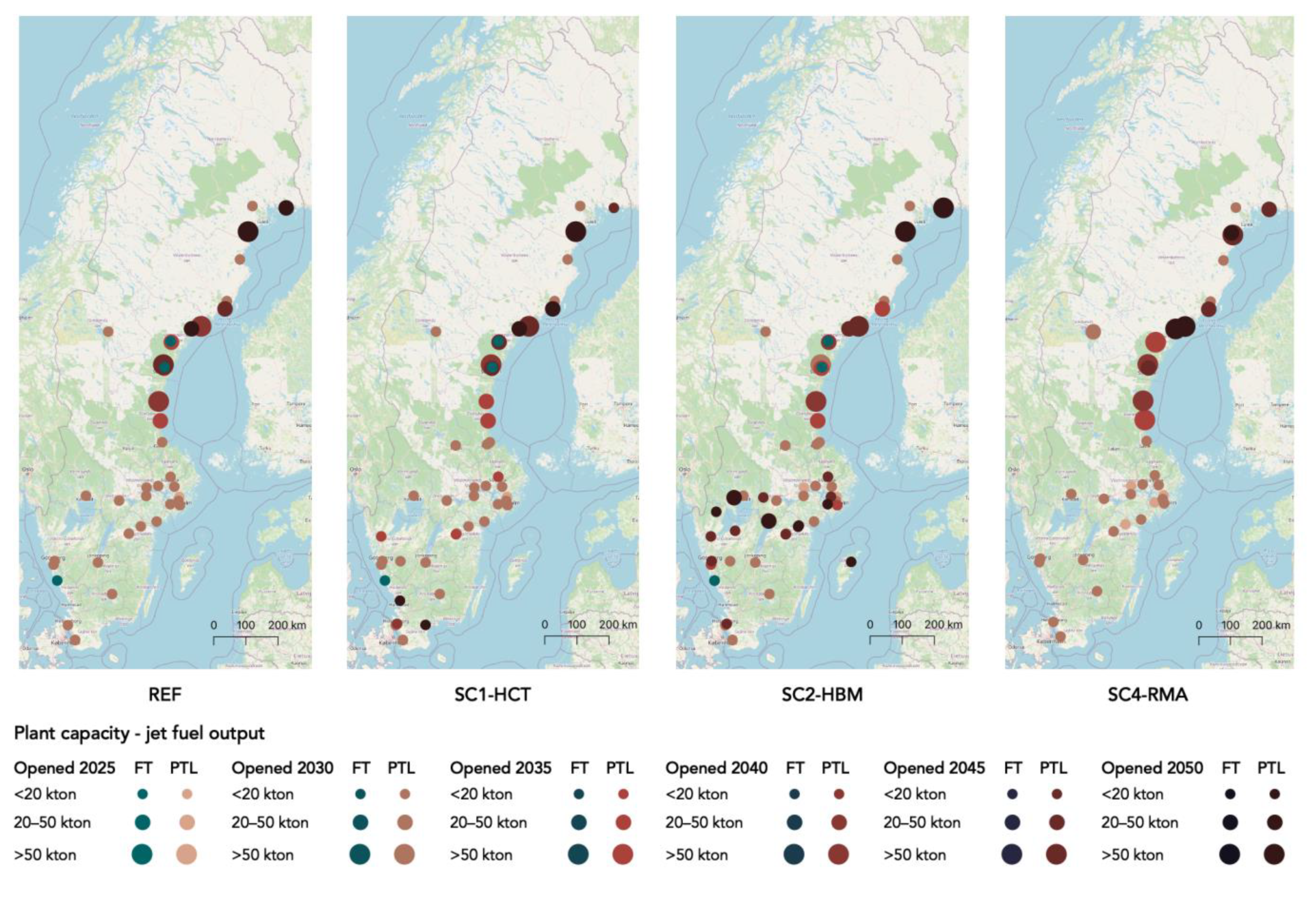

- Reference scenario (REF)

- Scenario 1–Higher carbon tax (SC1-HCT)

- Scenario 2–Higher blending mandate (SC2-HBM)

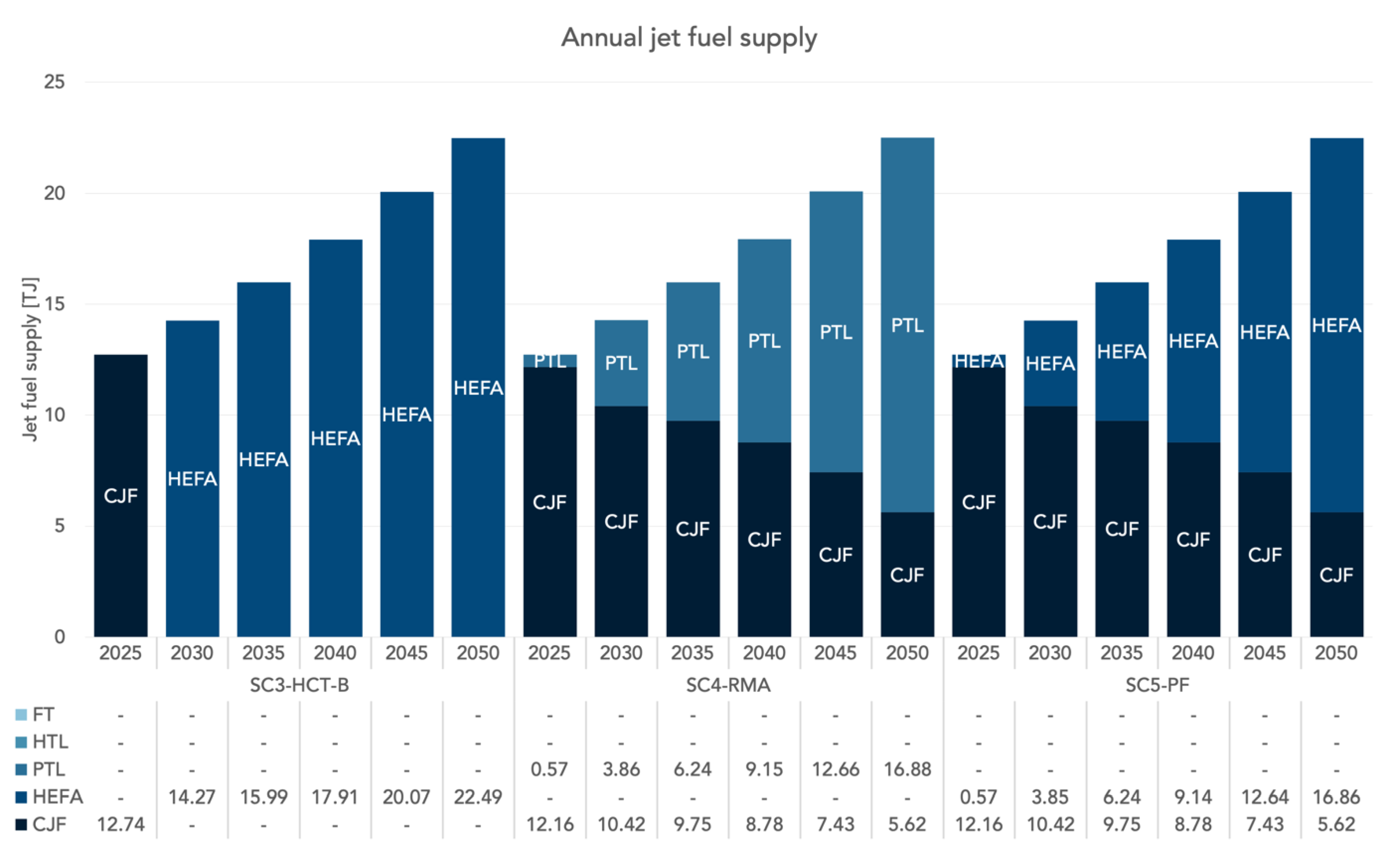

- Scenario 3–Higher carbon tax without blending mandate (SC3-HCT-B)

- Scenario 4–Higher or lower raw material availability (SC4-RMA)

- Scenario 5–Inclusion of penalty fee (SC5-PF)

3. Results and Discussion

3.1. Optimal Conversion Pathway and Production Site

3.2. Production Cost of Renewable Jet Fuel

3.3. Environmental Performance

4. Conclusions and Policy Implications

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Energy Agency (IEA). Data and Statistics—CO2 Emissions by Sector, World 1990–2018. 2020. Available online: https://www.iea.org/data-and-statistics/data-browser/?country=WORLD&fuel=CO2%20emissions&indicator=CO2BySector (accessed on 10 September 2021).

- Zhang, R. The role of the transport sector in energy transition and climate change mitigation: Insights from an integrated assessment model. In Transport and Energy Research; Zhang, J., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 15–30. [Google Scholar] [CrossRef]

- Hoen, A.; van Grinsven, A.; Kampman, B.; Faber, J.; van Essen, H.; Skinner, I. Research for TRAN Committee—Decarbonisation of EU Transport, European Parliament, Policy Department for Structural and Cohesion Policies. 2017. Available online: https://www.europarl.europa.eu/RegData/etudes/STUD/2017/601989/IPOL_STU(2017)601989_EN.pdf (accessed on 6 November 2020).

- Klkş, B.; Holistic, A. View of Sustainable Aviation. In Sustainable Aviation; Karakoc, T.H., Colpan, C.O., Altuntas, O., Sohret, Y., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 97–117. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). World Energy Statistics. 2016. Available online: https://www.oecd-ilibrary.org/content/data/data-00510-en (accessed on 15 September 2020).

- Swedish Energy Agency. Energiläget 2020 [Energy in Sweden 2020]. 2020. Available online: https://energimyndigheten.a-w2m.se/Home.mvc?ResourceId=173928 (accessed on 15 September 2020).

- International Energy Agency (IEA). Energy Policies of IEA Countries: Sweden 2019. 2019. Available online: https://www.oecd-ilibrary.org/content/publication/d4ff3340-en (accessed on 30 September 2020).

- Gegg, P.; Budd, L.; Ison, S. The market development of aviation biofuel: Drivers and constraints. J. Air Transp. Manag. 2014, 39, 34–40. [Google Scholar] [CrossRef]

- Winchester, N.; McConnachie, D.; Wollersheim, C.; Waitz, I.A. Economic and emissions impacts of renewable fuel goals for aviation in the US. Transp. Res. Part A Policy Pr. 2013, 58, 116–128. [Google Scholar] [CrossRef]

- ATAG. Powering the Future of Flight: The Six Easy Steps to Growing a Viable Aviation Biofuels Industry. 2011. Available online: https://seors.unfccc.int/applications/seors/attachments/get_attachment?code=GRPR31ZA287D3KAP5XOXQO2WP1JE9SQQ (accessed on 27 August 2021).

- Dahal, K.; Brynolf, S.; Xisto, C.; Hansson, J.; Grahn, M.; Grönstedt, T.; Lehtveer, M. Techno-economic review of alternative fuels and propulsion systems for the aviation sector. Renew. Sustain. Energy Rev. 2021, 151, 111564. [Google Scholar] [CrossRef]

- Larkin, A.; Anderson, K. Carbon Budgets for Aviation or Gamble with Our Future? Transp. Sustain. 2013, 4, 65–84. [Google Scholar] [CrossRef]

- Anger, A. Including aviation in the European emissions trading scheme: Impacts on the industry, CO2 emissions and macroeconomic activity in the EU. J. Air Transp. Manag. 2010, 16, 100–105. [Google Scholar] [CrossRef]

- Scheelhaase, J.; Grimme, W.; Schaefer, M. The inclusion of aviation into the EU emission trading scheme—Impacts on competition between European and non-European network airlines. Transp. Res. Part D Transp. Environ. 2010, 15, 14–25. [Google Scholar] [CrossRef]

- Schaefer, M.; Scheelhaase, J.; Grimme, W.; Maertens, S. The economic impact of the upcoming EU emissions trading system on airlines and EU Member States—an empirical estimation. Eur. Transp. Res. Rev. 2010, 2, 189–200. [Google Scholar] [CrossRef][Green Version]

- Morrell, P. An evaluation of possible EU air transport emissions trading scheme allocation methods. Energy Policy 2007, 35, 5562–5570. [Google Scholar] [CrossRef]

- Vespermann, J.; Wald, A. Intermodal integration in air transportation: Status quo, motives and future developments. J. Transp. Geogr. 2011, 19, 1187–1197. [Google Scholar] [CrossRef]

- Mayor, K.; Tol, R. The impact of the UK aviation tax on carbon dioxide emissions and visitor numbers. Transp. Policy 2007, 14, 507–513. [Google Scholar] [CrossRef]

- De Jong, S.; Van Stralen, J.; Londo, M.; Hoefnagels, R.; Faaij, A.; Junginger, M. Renewable jet fuel supply scenarios in the European Union in 2021-2030 in the context of proposed biofuel policy and competing biomass demand. GCB Bioenergy 2018, 10, 661–682. [Google Scholar] [CrossRef]

- Sgouridis, S.; Bonnefoy, P.A.; Hansman, R.J. Air transportation in a carbon constrained world: Long-term dynamics of policies and strategies for mitigating the carbon footprint of commercial aviation. Transp. Res. Part A Policy Pract. 2011, 45, 1077–1091. [Google Scholar] [CrossRef]

- Dray, L.; Doyme, K. Carbon leakage in aviation policy. Clim. Policy 2019, 19, 1284–1296. [Google Scholar] [CrossRef]

- Moncada, J.A.; Verstegen, J.A.; Posada, J.; Junginger, M.; Lukszo, Z.; Faaij, A.; Weijnen, M. Exploring the emergence of a biojet fuel supply chain in Brazil: An agent-based modeling approach. GCB Bioenergy 2018, 11, 773–790. [Google Scholar] [CrossRef]

- Nakata, T.; Silva, D.; Rodionov, M. Application of energy system models for designing a low-carbon society. Prog. Energy Combust. Sci. 2011, 37, 462–502. [Google Scholar] [CrossRef]

- Yue, D.; You, F.; Snyder, S.W. Biomass-to-bioenergy and biofuel supply chain optimization: Overview, key issues and challenges. Comput. Chem. Eng. 2014, 66, 36–56. [Google Scholar] [CrossRef]

- Doliente, S.; Narayan, A.; Tapia, J.F.D.; Samsatli, N.J.; Zhao, Y.; Samsatli, S. Bio-aviation Fuel: A Comprehensive Review and Analysis of the Supply Chain Components. Front. Energy Res. 2020, 8, 110. [Google Scholar] [CrossRef]

- De Jong, S.; Hoefnagels, R.; Wetterlund, E.; Pettersson, K.; Faaij, A.; Junginger, M. Cost optimization of biofuel production—The impact of scale, integration, transport and supply chain configurations. Appl. Energy 2017, 195, 1055–1070. [Google Scholar] [CrossRef]

- Leong, H.; Foo, D.C.; Ng, L.Y.; Andiappan, V. Hybrid approach for carbon-constrained planning of bioenergy supply chain network. Sustain. Prod. Consum. 2019, 18, 250–267. [Google Scholar] [CrossRef]

- Börjesson, P.; Hansson, J.; Berndes, G. Future demand for forest-based biomass for energy purposes in Sweden. For. Ecol. Manag. 2017, 383, 17–26. [Google Scholar] [CrossRef]

- de Jong, J.; Akselsson, C.; Egnell, G.; Löfgren, S.; Olsson, B.A. Realizing the energy potential of forest biomass in Sweden—How much is environmentally sustainable? For. Ecol. Manag. 2017, 383, 3–16. [Google Scholar] [CrossRef]

- Hansson, J.; Hackl, R.; Taljegard, M.; Brynolf, S.; Grahn, M. The Potential for Electrofuels Production in Sweden Utilizing Fossil and Biogenic CO2 Point Sources. Front. Energy Res. 2017, 5, 4. [Google Scholar] [CrossRef]

- Swedavia Airports. The Change is Already Underway. Available online: https://www.swedavia.com/the-change-is-already-underway/ (accessed on 6 September 2021).

- SOU 2019:11, Biojet för Flyget. Available online: https://www.regeringen.se/493238/contentassets/6d591e58fd9b4cad8171af2cd7e59f6f/biojet-for-flyget-sou-201911 (accessed on 30 September 2020).

- SFS 2017:1200, Lag om Skatt på Flygresort. Available online: https://www.riksdagen.se/sv/dokument-lagar/dokument/svensk-forfattningssamling/lag-20171200-om-skatt-pa-flygresor_sfs-2017-1200 (accessed on 1 October 2020).

- Swedish Energy Agency. Greenhouse Gas Reduction Mandate. 2020. Available online: http://www.energimyndigheten.se/en/sustainability/sustainable-fuels/greenhouse-gas-reduction-mandate/ (accessed on 4 October 2020).

- Proposition 2020/21:135, Reduktionsplikt för Flygfotogen. Available online: https://data.riksdagen.se/fil/5BBB452E-16A1-478B-8D66-D6B6CF103106 (accessed on 30 September 2020).

- Ministry of Finance, Sweden’s Carbon Tax. 2021. Available online: https://www.government.se/government-policy/taxes-and-tariffs/swedens-carbon-tax/ (accessed on 10 April 2021).

- ICAO. ICAO’S Policies on Taxation in the Field of International Air Transport. 1994. Available online: https://www.icao.int/publications/Documents/8632_2ed_en.pdf (accessed on 10 May 2021).

- International Air Transport Association (IATA). Fact Sheet 2—Sustainable Aviation Fuel: Technical Certification. Available online: https://www.iata.org/contentassets/d13875e9ed784f75bac90f000760e998/saf-technical-certifications.pdf (accessed on 29 October 2020).

- Swedish Energy Agency. Luftfartens Omställning Till Fossilfrihet [The Aviation Industry’s Transition towards Being Fossil Free]. 2017. Available online: https://energimyndigheten.a-w2m.se/FolderContents.mvc/Download?ResourceId=104637 (accessed on 29 October 2020).

- European Commission. Horizon 2020—Work Programme 2014–2015 general Annexes—G. Technology Readiness Levels (TRL). 2021. Available online: https://ec.europa.eu/research/participants/data/ref/h2020/wp/2014_2015/annexes/h2020-wp1415-annex-g-trl_en.pdf (accessed on 10 May 2021).

- NASA. Technology Readiness Level. 2021. Available online: https://www.nasa.gov/directorates/heo/scan/engineering/technology/technology_readiness_level (accessed on 10 May 2021).

- de Jong, S.A. Green Horizons: On the Production Costs, Climate Impact and Future Supply of Renewable Jet Fuels. Ph.D. Thesis, Utrecht University, Utrecht, The Netherlands, 2018. Available online: https://www.researchgate.net/publication/325719256_Green_Horizons_-_On_the_production_costs_climate_impact_and_future_supply_of_renewable_jet_fuels_PhD_thesis_Sierk_De_Jong_2018 (accessed on 10 May 2021).

- O’Connell, A.; Konti, A.; Padella, M.; Prussi, M.; Lonza, L. Advanced Alternative Fuels Technology Market Report 2018. 2019. EUR 29937 EN. European Commission. Luxembourg. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC118306 (accessed on 10 May 2021).

- Wijeyekoon, S.; Torr, K.; Corkran, H.; Bennett, P. Commercial status of direct thermochemical liquefaction technologies. IEA Bioenergy Task 34. 2020. p. 2. Available online: https://www.ieabioenergy.com/wp-content/uploads/2020/09/Direct-Thermochemical-Liquefaction_Commercialization_Overview.pdf (accessed on 21 August 2021).

- International Civil Aviation Organization (ICAO). Assembly—40th Session: Agenda Item 16: Environmental Protection—International Aviation and Climate Change—Policy and Standardization: Power-to-Liquids (PTL): Sustainable Fuels for Aviation. 2019. Available online: https://www.icao.int/Meetings/a40/Documents/WP/wp_526_en.pdf (accessed on 28 September 2021).

- Balli, O.; Sohret, Y.; Karakoc, H.T. The effects of hydrogen fuel usage on the exergetic performance of a turbojet engine. Int. J. Hydrogen Energy 2018, 43, 10848–10858. [Google Scholar] [CrossRef]

- Bicer, Y.; Dincer, I. Life cycle evaluation of hydrogen and other potential fuels for aircrafts. Int. J. Hydrogen Energy 2017, 42, 10722–10738. [Google Scholar] [CrossRef]

- Brelje, B.J.; Martins, J.R. Electric, hybrid, and turboelectric fixed-wing aircraft: A review of concepts, models, and design approaches. Prog. Aerosp. Sci. 2019, 104, 1–19. [Google Scholar] [CrossRef]

- World Economic Forum (WEF). Joint Policy Proposal to Accelerate the Deployment of Sustainable Aviation Fuels in Europe—A Clean Skies for Tomorrow Publication. 2020. Available online: http://www3.weforum.org/docs/WEF_CST_Policy_European_Commission_SAF_2020.pdf (accessed on 4 November 2020).

- de Souza, L.M.; Mendes, P.A.; Aranda, D.A. Oleaginous feedstocks for hydro-processed esters and fatty acids (HEFA) biojet production in southeastern Brazil: A multi-criteria decision analysis. Renew. Energy 2020, 149, 1339–1351. [Google Scholar] [CrossRef]

- Lorenzi, G.; Mignini, L.; Venezia, B.; Silva, C.A.S.; Santarelli, M.; Migninic, L.; Veneziad, B. Integration of high-temperature electrolysis in an HVO production process using waste vegetable oil. Energy Procedia 2019, 158, 2005–2011. [Google Scholar] [CrossRef]

- Soam, S.; Hillman, K. Factors influencing the environmental sustainability and growth of hydrotreated vegetable oil (HVO) in Sweden. Bioresour. Technol. Rep. 2019, 7, 100244. [Google Scholar] [CrossRef]

- Richter, S.; Braun-Unkhoff, M.; Naumann, C.; Riedel, U. Paths to alternative fuels for aviation. CEAS Aeronaut. J. 2018, 9, 389–403. [Google Scholar] [CrossRef]

- Evans, G.; Smith, C. Biomass to Liquids Technology. In Comprehensive Renewable Energy; Sayigh, A., Ed.; Elsevier: Oxford, UK, 2012; pp. 155–204. [Google Scholar]

- de Klerk, A. Chapter 10—Aviation Turbine Fuels Through the Fischer–Tropsch Process. In Biofuels for Aviation; Elsevier Inc.: Edmonton, AB, Canada, 2016; pp. 241–259. [Google Scholar]

- Shahabuddin, M.; Alam, T.; Krishna, B.B.; Bhaskar, T.; Perkins, G. A review on the production of renewable aviation fuels from the gasification of biomass and residual wastes. Bioresour. Technol. 2020, 312, 123596. [Google Scholar] [CrossRef]

- F3 Centre. Bioflygbränsle, Biojet [Aviation biofuel, Biojet]. 2020. Available online: https://f3centre.se/en/fact-sheets/aviation-biofuel-biojet/ (accessed on 10 January 2021).

- Sahu, S.; Sahoo, N.; Naik, S.; Mahapatra, D. Advancements in Hydrothermal Liquefaction Reactors: Overview and Prospects; Elsevier: Amsterdam, The Netherlands, 2020; pp. 195–213. [Google Scholar]

- Baldino, C.; Berg, R.; Pavlenko, N.; Searle, S.; Advanced alternative fuel pathways: Technology overview and status. In The International Council on Clean Transportation; 2019. Available online: https://theicct.org/sites/default/files/publications/ICCT_advanced_alt_fuel_pathways_20190723.pdf (accessed on 2 March 2021).

- Tews, I.J.; Zhu, Y.; Drennan, C.; Elliott, D.C.; Snowden-Swan, L.J.; Onarheim, K.; Solantausta, Y.; Beckman, D. Biomass Direct Liquefaction Options. TechnoEconomic and Life Cycle Assessment. In Biomass Direct Liquefaction Options. TechnoEconomic and Life Cycle Assessment; Pacific Northwest National Lab (PNNL): Richland, WA, USA, 2014. [Google Scholar]

- Biller, P.; Roth, A. Hydrothermal Liquefaction: A Promising Pathway towards Renewable Jet Fuel. In Biokerosene: Status and Prospects; Springer: Berlin/Heidelberg, Germany, 2018; pp. 607–635. [Google Scholar]

- Elliott, D.; Biller, P.; Ross, A.B.; Schmidt, A.J.; Jones, S.B. Hydrothermal liquefaction of biomass: Developments from batch to continuous process. Bioresour. Technol. 2015, 178, 147–156. [Google Scholar] [CrossRef]

- Drünert, S.; Neuling, U.; Zitscher, T.; Kaltschmitt, M. Power-to-Liquid fuels for aviation—Processes, resources and supply potential under German conditions. Appl. Energy 2020, 277, 115578. [Google Scholar] [CrossRef]

- Schmidt, P.; Batteiger, V.; Roth, A.; Weindorf, W.; Raksha, T. Power-to-Liquids as Renewable Fuel Option for Aviation: A Review. Chem. Ing. Tech. 2018, 90, 127–140. [Google Scholar] [CrossRef]

- Fagerström, A.; Grahn, D.; Lundberg, S.; Sreetama Ghosh, D.C.; Olsson, L.; Abdelaziz, O.; Wallberg, O.; Hultberg, C.; Poulikidou, S.; Rydberg, T.; et al. Large Scale bio Electro jet Fuel Production Integration at CHP-Plant in Östersund, Sweden. 2021. Available online: https://www.ivl.se/download/18.2f05652c1775c6085c01a6/1612270805586/B2407.pdf (accessed on 2 March 2021).

- Keith, D.W.; Holmes, G.; Angelo, D.S.; Heidel, K. A Process for Capturing CO2 from the Atmosphere. Joule 2018, 2, 1573–1594. [Google Scholar] [CrossRef]

- Sreedhar, I.; Nahar, T.; Venugopal, A.; Srinivas, B. Carbon capture by absorption—Path covered and ahead. Renew. Sustain. Energy Rev. 2017, 76, 1080–1107. [Google Scholar] [CrossRef]

- Herzog, H.J. Carbon Capture; 2018; MIT Press essential knowledge series: Cambridge, MA, USA; ISBN 0-262-34886-1. Available online: https://mitpress.mit.edu/books/carbon-capture (accessed on 2 March 2021).

- Gielen, D.; Taibi, E.; Miranda, R. Hydrogen: A Renewable Energy Perspective. 2019. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2019/Sep/IRENA_Hydrogen_2019.pdf (accessed on 4 March 2021).

- Voitic, G.; Pichler, B.; Basile, A.; Iulianelli, A.; Malli, K.; Bock, S.; Hacker, V. Hydrogen Production. In Fuel Cells and Hydrogen; Elsevier: Amsterdam, The Netherlands, 2018; pp. 215–241. [Google Scholar]

- Sawmills Database, Sawmills. Available online: https://www.sawmilldatabase.com/sawmills.php?countryid=1&companyid=-1&productionfrom=30000&productionto= (accessed on 22 January 2021).

- Svebio, Biodrivmedel i Norden 2019 [Biofuels in the Nordic 2019]. 2019. Available online: https://www.mynewsdesk.com/se/svebio/documents/biodrivmedel-i-norden-2019-92374 (accessed on 27 January 2021).

- European Environment Agency. Industrial Reporting under the Industrial Emissions Directive 2010/75/EU and European Pollutant Release and Transfer Register Regulation (EC) No 166/2006. 2020. Available online: https://www.eea.europa.eu/data-and-maps/data/industrial-reporting-under-the-industrial-2 (accessed on 28 January 2021).

- Transport Analysis (TRAFA). Luftfart 2019—Tabell 1.2 Svenska Trafikflygplatser 2019-12-31 [Civil Aviation 2019—Airports with Scheduled and/or Non-Scheduled Traffic 31 December 2019]. 2019. Available online: https://www.trafa.se/luftfart/ (accessed on 10 November 2020).

- Swedish Transport Agency. Flygplatsstatistik [Airport Statistics]. 2020. Available online: https://www.transportstyrelsen.se/sv/luftfart/Statistik/Flygplatsstatistik-/ (accessed on 10 November 2020).

- Icons Made by Freepik from Flaticon, Truck. Available online: https://www.freepik.com(https://www.flaticon.com/premium-icon/oil-truck_4038674?term=oil%20truck&page=1&position=72&page=1&position=72&related_id=4038674&origin=search) (accessed on 6 September 2021).

- Icons Made by Smashicons from Flaticon, Refinery. Available online: https://www.flaticon.com/authors/smashicons(https://www.flaticon.com/free-icon/refinery_2296960?term=refinery&page=2&position=18&page=2&position=18&related_id=2296960&origin=search) (accessed on 6 September 2021).

- Icons Made by Freepik from Flaticon, Airport. Available online: https://www.freepik.com/(https://www.flaticon.com/premium-icon/airport_1830349?term=airport&page=1&position=2&page=1&position=2&related_id=1830349&origin=search) (accessed on 6 September 2021).

- Icons made by Freepik from Flaticon, Factory. Available online: https://www.flaticon.com/authors/freepik(https://www.flaticon.com/free-icon/factory_699505?term=industrial%20factory&page=1&position=31&page=1&position=31&related_id=699505&origin=search) (accessed on 6 September 2021).

- Icons Made by Ultimatearm from Flaticon. Biomass Factory. Available online: https://www.flaticon.com/authors/ultimatearm(https://www.flaticon.com/free-icon/biomass_2646951?related_id=2646951) (accessed on 6 September 2021).

- Harris, Z.M.; Milner, S.; Taylor, G. Taylor, Biogenic Carbon—Capture and Sequestration. In Greenhouse Gas Balances of Bioenergy Systems; Academic Press: Cambridge, MA, USA, 2018; pp. 55–76. [Google Scholar]

- SGC. Basic Data for Biogas. 2012. p. 7. Available online: http://www.sgc.se/ckfinder/userfiles/files/BasicDataonBiogas2012.pdf (accessed on 28 January 2021).

- F3 Centre. Metanol. 2017. Available online: https://f3centre.se/sv/faktablad/metanol/ (accessed on 1 February 2021).

- Swedish Energy Agency. Värmevärden Från Energimyndighetens Datalager (DW) [Thermal Values from the Swedish Energy Agency’s Database (DW)]. 2017. Available online: https://www.energimyndigheten.se/statistik/den-officiella-statistiken/statistikprodukter/varmevarden-och-densiteter/ (accessed on 1 February 2021).

- Energimyndigheten, Faktisk Elcertifikatberättigad Elproduktion 2017 2018 [Actual Electricity Production Eligible for Electricity Certificate 2017 2018]. Available online: https://www.energimyndigheten.se/fornybart/elcertifikatsystemet/marknadsstatistik/ (accessed on 17 September 2021).

- Bodens Energi, Elens Ursprung [The Origin of Electricity]. Available online: https://bodensenergi.se/elavtal/elens-ursprung/ (accessed on 17 September 2021).

- Anders Haaker, Vattenfall Planerar att Investera 3,5 Miljarder i Uppsala under sex år [Vattenfall Plans to Invest SEK 3.5 Billion in Uppsala over Six Years]. 2017. Available online: https://bioenergitidningen.se/biovarme/vattenfall-planerar-att-investera-35-miljarder-uppsala-sex-ar (accessed on 17 September 2021).

- Stockholm Exergi, Bristaverket—Stockholm Exergi, Miljörapport 2020 [Bristaverket—Stockholm Exergi, Environmental Report 2020]. 2021. Available online: https://www.stockholmexergi.se/content/uploads/2021/05/VARME-678587-v1-Bristaverket-MR-2020-v1.pdf (accessed on 17 September 2021).

- Öresundskraft, Filbornaverket. Available online: https://www.oresundskraft.se/om-oss/filbornaverket/ (accessed on 17 September 2021).

- Tekniska Verken, Gärstadverket—Tekniska Verken. Available online: https://www.tekniskaverken.se/om-oss/anlaggningar/kraftvarmeverk/garstadverket/ (accessed on 17 September 2021).

- Skellefteå Kraft, Fjärrvärme—Skellefteå Kraft. Available online: https://www.skekraft.se/om-oss/verksamhet/fjarrvarme/#box-no-4 (accessed on 17 September 2021).

- Tengbom, Hedenverket—Effektiv Miljösatsning I Karlstad. Available online: https://tengbom.se/projekt/hedenverket/ (accessed on 17 September 2021).

- ENA Energi AB, Våra anläggningar|ENA Energi AB. Available online: https://www.enae.se/fjarrvarme/produktion/vara-anlaggningar/ (accessed on 17 September 2021).

- E.ON Värme, Med Värme Från Händelö Kraftvärmeverk [with Heat from Händelö Heat and Power Plant]. Available online: http://mb.cision.com/Public/MigratedWpy/93678/9122214/ac456242581ba855.pdf (accessed on 17 September 2021).

- Stockholm Exergi, Hässelbyverket—Stockholm Exergi, Miljörapport 2020 [Hässelbyverket—Stockholm Exergi, Environmental Report 2020]. 2021. Available online: https://www.stockholmexergi.se/content/uploads/2021/05/VARME-679666-v1-Milj%C3%B6rapport-H%C3%A4sselbyverket-2020.pdf (accessed on 17 September 2021).

- Stockholm Exergi, Högdalenverket—Stockholm Exergi. Available online: https://www.stockholmexergi.se/om-stockholm-exergi/vara-anlaggningar/hogdalenverket/ (accessed on 17 September 2021).

- Svebio, Biokraft 2020. 2020. Available online: https://bioenergitidningen.se/app/uploads/sites/2/2020/11/Biokraftkartan2020.pdf (accessed on 17 September 2021).

- Söderenergi, Teknik i Framkant|Söderenergi—Tillsammans för en Hållbar Uppvärmning. Available online: https://www.soderenergi.se/teknik-i-framkant/ (accessed on 17 September 2021).

- Tekniska Verken, Kraftvärmeverket i Linköping—Tekniska Verken. Available online: https://www.tekniskaverken.se/om-oss/anlaggningar/kraftvarmeverk/kraftvarmeverket-i-linkoping/ (accessed on 17 September 2021).

- Göteborg Energi, Miljörapport 2020—Sävenäsverket. 2020. Available online: https://www.goteborgenergi.se/Files/Webb20/Kategoriserad%20information/Informationsmaterial/Milj%C3%B6rapporter/2020/MR%20S%C3%A4ven%C3%A4sverket%202020.pdf?TS=637570015939206198 (accessed on 17 September 2021).

- Stockholm Exergi, Värtaverket Stockholm Exergi, Miljörapport 2020 [Värtaverket Stockholm Exergi, Environmental Report 2020]. 2021. Available online: https://www.stockholmexergi.se/content/uploads/2021/05/VARME-678899-v1-Milj%C3%B6rapport-V%C3%A4rtaverket-2020.pdf (accessed on 17 September 2021).

- Mälarenergi, Kraftvärmeverket—Västerås Hjärta. Available online: https://www.malarenergi.se/om-malarenergi/framtidens-samhalle/vara-anlaggningar/kraftvarmeverket/kraftvarmeverket-vasteras/ (accessed on 17 September 2021).

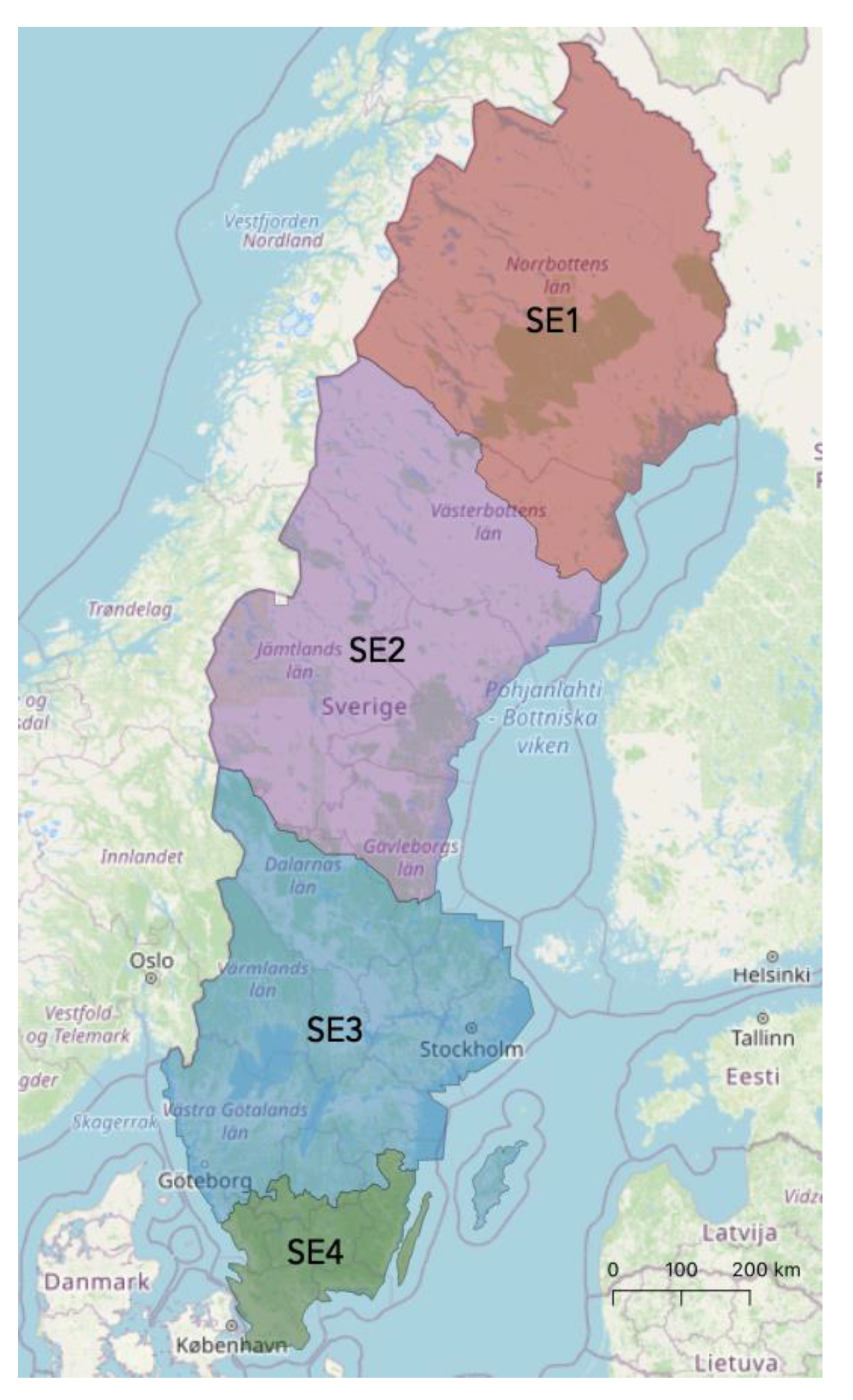

- Svenska Kraftnät, Varför Delades Sverige upp i Fyra Elområden? [Why was Sweden Divided into Four Electricity Pricing Areas?]. 2020. Available online: https://www.svk.se/utveckling-av-kraftsystemet/systemansvar–elmarknad/elomradesoversyn/fragor-och-svar-om-elomradesoversyn/varfor-delades-sverige-in-i-fyra-elomraden-2011/ (accessed on 15 May 2021).

- Swedish Energy Agency. Scenarier över Sveriges Energisystem 2020 [Scenarios of Sweden’s Energy System 2020]. 2021. Available online: https://www.energimyndigheten.se/nyhetsarkiv/2021/sveriges-energisystem-2050--sa-kan-det-se-ut/ (accessed on 1 April 2021).

- Nord Pool, Day-Ahead Prices. 2020. Available online: https://www.nordpoolgroup.com/Market-data1/Dayahead/Area-Prices/SE/Yearly/?view=table (accessed on 26 April 2021).

- OpenStreetMap contributors. Copyright and License. Available online: https://www.openstreetmap.org/copyright/en (accessed on 26 November 2020).

- Swedens’ County Administrative Board & S., E. Agency, Vindbrukskollen. Available online: https://vbk.lansstyrelsen.se/ (accessed on 26 April 2021).

- de Jong, S.; Hoefnagels, R.; Faaij, A.; Slade, R.; Mawhood, R.; Junginger, M. The feasibility of short-term production strategies for renewable jet fuels—a comprehensive techno-economic comparison. Biofuels Bioprod. Biorefining 2015, 9, 778–800. [Google Scholar] [CrossRef]

- Diederichs, G.W.; Mandegari, M.A.; Farzad, S.; Gorgens, J. Techno-economic comparison of biojet fuel production from lignocellulose, vegetable oil and sugar cane juice. Bioresour. Technol. 2016, 216, 331–339. [Google Scholar] [CrossRef] [PubMed]

- Statistics Sweden, CPI, Historical Numbers, 1830–2021. Available online: https://www.scb.se/en/finding-statistics/statistics-by-subject-area/prices-and-consumption/consumer-price-index/consumer-price-index-cpi/pong/tables-and-graphs/consumer-price-index-cpi/cpi-historical-numbers-1830/ (accessed on 26 April 2021).

- Sveriges Riksbank, Årsgenomsnitt Valutakurser (Ackumulerat)|Sveriges Riksbank. Available online: https://www.riksbank.se/sv/statistik/sok-rantor--valutakurser/arsgenomsnitt-valutakurser/?y=2021&m=8&s=Comma&f=y (accessed on 23 September 2021).

- Sveriges Riksbank [Sweden’s Central Bank], Årsgenomsnitt Valutakurser 2020 [Annual Average Exchange Rates 2020]. 2020. Available online: https://www.riksbank.se/sv/statistik/sok-rantor--valutakurser/valutakurser-till-deklarationen/ (accessed on 25 March 2021).

- Sorrels, J.L.; Walton, T.G. Chapter 2—Cost Estimation: Concepts and Methodology. In EPA Air Pollution Control Cost Manual; U.S. Environmental Protection Agency: Washington, DC, USA, 2017; p. 35. Available online: https://www.epa.gov/sites/production/files/2017-12/documents/epaccmcostestimationmethodchapter_7thedition_2017.pdf (accessed on 26 November 2020).

- Stockholm Vatten Och Avfall, Avgift för Vatten Och Avlopp [Fee for Water and Sewage]. 2021. Available online: https://www.stockholmvattenochavfall.se/kundservice/avgifter-och-taxor/avgift-for-vatten-och-avlopp/#!/flerbostadshus-industrier-och-andra-fastigheter (accessed on 25 March 2021).

- Göteborgs Stad, Vatten Och Avloppstaxa [Fee for Water and Sewage]. 2021. Available online: https://goteborg.se/wps/portal/start/vatten-och-avlopp/avgifter/vatten--och-avloppstaxa?uri=gbglnk%3Agbg.page.caf8bb3f-28f6-41fe-8158-314aa4cd49e1 (accessed on 25 March 2021).

- VASYD, Taxebilaga 2 Brukningsavgifter (inkl. moms) [Tax Appendix 2 Usage Fees (incl. VAT)]. 2020. Available online: https://www.vasyd.se/-/media/Documents/Informationsmaterial/Avgifter-vatten-och-avlopp/Malmo/Taxebilaga2_brukningsavgifter_Malmo2021.pdf (accessed on 25 March 2021).

- Uppsala Vatten, Taxa för den Allmänna Vatten- Och Avloppsanläggningen i Uppsala Kommun [Fee for the Public Water and Sewage System in Uppsala Municipality]. 2020. Available online: https://www.uppsalavatten.se/hushall/betalning-och-avgifter/taxor-och-avgifter/ny-va-taxa-2020/va-taxa/ (accessed on 25 March 2021).

- Tekniska Verken, TAXA/PRISLISTA 2021—för Linköpings Kommuns Allmänna Vatten- Och Avloppsanläggning [TAX/PRICE LIST 2021—for Linköping Municipality’s General Water and Sewage System]. 2021. Available online: https://www.tekniskaverken.se/siteassets/tekniska-verken/vatten-och-avlopp/prislistor/ao_vatten_avlopp_prislista_2021.pdf (accessed on 25 March 2021).

- Swedish Energy Agency. Trädbränsle Och Torvpriser, per år Exklusive Skatt, Från Och Med 1993, Kronor/MWh Fritt Förbrukare, Löpande Priser [Wood Fuel and Peat Prices, per Year Excluding Tax, from 1993, SEK/MWh Free Consumer, Current Prices]. 2020. Available online: http://pxexternal.energimyndigheten.se/sq/c92731ba-13e3-445d-9fe6-eea55da29701 (accessed on 24 March 2021).

- IEA. Oil Product Spot Prices. 2016; Available online: https://www.oecd-ilibrary.org/content/data/data-00450-en (accessed on 1 April 2021). [CrossRef]

- IEA. Fossil Jet Kerosene Market Price Compared with HEFA aviation Biofuel Production Cost, 2019–2020. 2020. Available online: https://www.iea.org/data-and-statistics/charts/fossil-jet-kerosene-market-price-compared-with-hefa-aviation-biofuel-production-cost-2019-2020 (accessed on 1 April 2021).

- Transportstyrelsen, Analys av en Ökad Risk för Ekonomitankning Till Följd av Införande av en Nationell Skatt på Fossilt Flygfotogen vid Kommersiella Resor [Analysis of an Increased Risk of Refueling as a Result of Introduction of a National Tax on Fossil Fuels Aviation Kerosene on Commercial Trips]. 2020. Available online: https://www.transportstyrelsen.se/4a8215/globalassets/global/publikationer/luftfart/slutrapport-transportstyrelsen_fi2020_01022_s2_-200928.pdf (accessed on 1 April 2021).

- WSP. Sweden and 21st Century Water Challenges. 2020. Available online: https://www.wsp.com/en-SE/insights/sweden-and-21st-century-water-challenges (accessed on 25 March 2021).

- Duić, N.; Štefanić, N.; Lulić, Z.; Krajačić, G.; Pukšec, T.; Novosel, T. EU28 Fuel Prices for 2015, 2030 and 2050—Appendix 2. 2017. Available online: https://heatroadmap.eu/wp-content/uploads/2020/01/HRE4_D6.1-Future-fuel-price-review.pdf (accessed on 24 March 2021).

- Berglund, M. (Torsby Flygplats AB, Torsby, Sweden). Personal communication through e-mail correspondence, January 2021.

- Eriksson, J. (Härjedalen Sveg Airport, Sveg, Sweden). Personal communication through e-mail correspondence, January 2021.

- Schwartz, P.; Henriksson, L. (Sundsvall Timrå Airport, Sundsvall, Sweden). Personal communication through e-mail correspondence, January 2021.

- Jansson, P. (Norrköping Airport, Norrköping, Sweden). Personal communication through e-mail correspondence, January 2021.

- Scherman, T. (Pajala Airport, Pajala, Sweden). Personal communication through e-mail correspondence, January 2021.

- Mjöberg, A. (AB Dalaflyget, Borlänge, Sweden). Personal communication through e-mail correspondence, January 2021.

- Vänersborgs TR M 2251-18 Deldom 2019-11-27. Available online: https://www.naturvardsverket.se/upload/stod-i-miljoarbetet/rattsfall/domar/V%c3%a4nersborgs%20TR%20M%202251-18%20Deldom%202019-11-27.pdf (accessed on 11 October 2020).

- ICAO. ICAO Carbon Emissions Calculator Methodology—Version 9. 2016. Available online: https://www.icao.int/environmental-protection/CarbonOffset/Documents/Methodology_ICAO_Carbon_Calculator_v9_2016.pdf (accessed on 1 December 2020).

- Eurostat Database. Air Transport (2015–2019). 2019. Available online: https://ec.europa.eu/eurostat/web/transport/data/database (accessed on 25 January 2021).

- Swedish Transport Administration. Resandeprognos för Flygtrafiken 2040 [Travel Forecast for Air Traffic 2040]. 2020. Available online: http://trafikverket.diva-portal.org/smash/get/diva2:1443411/FULLTEXT01.pdf (accessed on 1 December 2020).

- QGIS. QGIS—A Free and Open Source Geographic Information System. 2020. Available online: https://qgis.org/en/site/ (accessed on 26 November 2020).

- Swedish Transport Administration, Kapitel 7 Värdering av Kortare Restid och Transporttid [Chapter 7 Valuation of Shorter Travel Time and Transport Time]. Analysmetod och Samhällsekonomiska Kalkylvärden för Transportsektorn: ASEK 7.0 [Analysis Method and Socio-Economic Calculation Values for the Transport Sector: ASEK 7.0]. 2020, p. 15. Available online: https://www.trafikverket.se/contentassets/4b1c1005597d47bda386d81dd3444b24/asek-7.0--2020/07_restid_o_transporttid_a70.pdf (accessed on 25 January 2021).

- Swedish Transport Administration, Kapitel 14 Operativa Trafikeringskostnader för Godstransporter [Chapter 14 Operative traffic Costs for Freight Transports]. Analysmetod och Samhällsekonomiska Kalkylvärden för Transportsektorn: ASEK 7.0 [Analysis Method and Socio-Economic Calculation Values for the Transport Sector: ASEK ASEK 7.0]. 2020, pp. 6–12. Available online: https://www.trafikverket.se/contentassets/4b1c1005597d47bda386d81dd3444b24/14_trafikeringskostnad_gods_a70.pdf (accessed on 25 January 2021).

- Swedish Transport Administration, Kapitel 12 Samhällsekonomisk Kostnad för Klimateffekter [Chapter 12 Socio-Economic Cost for Climate Effects]. Analysmetod och Samhällsekonomiska Kalkylvärden för Transportsektorn: ASEK 7.0 [Analysis method and Socio-Economic Calculation Values for the Transport Sector: ASEK 7.0]. 2020, p. 3. Available online: https://www.trafikverket.se/contentassets/4b1c1005597d47bda386d81dd3444b24/asek-7.0--2020/12_klimateffekter_a70_200624.pdf (accessed on 25 January 2021).

- De Jong, S.; Antonissen, K.; Hoefnagels, R.; Lonza, L.; Wang, M.; Faaij, A.; Junginger, M. Life-cycle analysis of greenhouse gas emissions from renewable jet fuel production. Biotechnol. Biofuels 2017, 10, 64. [Google Scholar] [CrossRef]

- Bokinge, P.; Heyne, S.; Nyström, I.; Hentschel, J.; Magnus, E.; Skaret-Thoresen, L.; Zafosching, L.A.; Behm, K.; Fabritius, T.; Koponen, K.; et al. Nordic P2X for Sustainable Road Transport. 2020. Available online: https://www.nordicenergy.org/wp-content/uploads/2020/09/Nordic-Power-2X-for-Sustainable-Road-Transport.pdf (accessed on 6 May 2021).

- CORSIA. Corsia Supporting Document—Corsia Eligible Fuels—Life Cycle Assessment Methodology. 2019. Available online: https://www.icao.int/environmental-protection/CORSIA/Documents/CORSIA%20Supporting%20Document_CORSIA%20Eligible%20Fuels_LCA%20Methodology.pdf (accessed on 26 April 2021).

- PuLP. A Transportation Problem. 2009. Available online: https://coin-or.github.io/pulp/CaseStudies/a_transportation_problem.html (accessed on 26 November 2020).

- Pedroso, J.P.; Rais, A.; Kubo, M.; Muramatsu, M. Facility Location Problems. 2012. Available online: https://scipbook.readthedocs.io/en/latest/flp.html (accessed on 26 November 2020).

- Ismiguzel, I. How to Develop Optimization Models in Python. 2020. Available online: https://towardsdatascience.com/how-to-develop-optimization-models-in-python-1a03ef72f5b4 (accessed on 26 November 2020).

- Prussi, M.; O’Connell, A.; Lonza, L. Analysis of current aviation biofuel technical production potential in EU28. Biomass- Bioenergy 2019, 130, 105371. [Google Scholar] [CrossRef]

- Swedish Energy Agency. Ökning av Förnybar Elproduktion under 2020 [Increase in Renewable Electricity Production in 2020]. 2021. Available online: https://www.energimyndigheten.se/nyhetsarkiv/2021/okning-av-fornybar-elproduktion-under-2020/ (accessed on 20 May 2021).

- World Economic Forum (WEF). Clean Skies for Tomorrow: Sustainable Aviation Fuels as a Pathway to Net-Zero Aviation. 2020. Available online: https://www.weforum.org/reports/clean-skies-for-tomorrow-sustainable-aviation-fuels-as-a-pathway-to-net-zero-aviation (accessed on 1 December 2020).

| Technology | Feedstocks | Maximum Blend | Year |

|---|---|---|---|

| Fisher–Tropsch (FT-SPK) | Wastes (MSW, etc.) coal, gas, sawdust | 50% | 2009 |

| Hydroprocessed Esters and Fatty Acids (HEFA) | Vegetable oils: palm, camelina, jatropha, used cooking oil | 50% | 2011 |

| Synthesized Isoparaffin (SIP) | Sugarcane and sugar beet | 10% | 2014 |

| Fisher–Tropsch containing aromatics (FT-SPK/A) | Wastes (MSW, etc.) coal, gas, sawdust | 50% | 2015 |

| Alcohol-to-Jet (AtJ) (Isobutanol and Ethanol) | Sugar, sugar beet, saw dust, lignocellulosic residues (straw) | 50% | 2016/2018 |

| Hydroprocessed Hydrocarbons (HH-SPK or HC-HEFA) | Oils produced from algae | 10% | 2020 |

| Hydrothermal liquefaction (HTL) | Waste oils or energy oils | 50% | 2020 |

| Parameter | Value | Unit |

|---|---|---|

| Plant lifetime | 30 | Year |

| Discount rate | 10 | % |

| Start of time frame | 2020 | |

| End of time frame | 2050 |

| Conversion Pathway | Feedstock | Product Output | Input Capacity of the Ref. Study [tin/Year] 1 | Output Capacity of the Ref. Study [tout/Year] | TCI [MEUR] | TCI [MSEK] 2 | Ref. |

|---|---|---|---|---|---|---|---|

| Gasification-based Fischer–Tropsch (FT) | Forestry residue | Jet fuel, Diesel, Naphtha | 614,010 | 79,820 | 482 3 | 4842 | [109] |

| Hydrothermal liquefaction (HTL) | Forestry residue | Jet fuel, Diesel, Gasoline | 164,670 4 | 57,320 5 | 132.3 6 | 1240 | [26] |

| Power-to-Liquid (PTL) through the FT route | CO2 7 | Jet fuel, Diesel, Gasoline | 58,162 | 14,080 | 65 | 682 | [65] |

| Conversion Pathway | Total Product Yield | Jet Fuel | Naphtha | Gasoline | Diesel | Unit | Ref. |

|---|---|---|---|---|---|---|---|

| Gasification-based Fischer–Tropsch (FT) 1 | 0.13 | 0.10 | - | - | 0.01 | tout/tin | [109] |

| Hydrothermal liquefaction (HTL) | 0.35 | 0.06 | - | 0.09 | 0.25 | tout/tin | [26] |

| Power-to-Liquid (PTL) through the FT route 2 | 0.24 | 0.10 | - | 0.09 | 0.03 | tout/tCO2, in | [65] |

| Parameter | FT [108] | HTL [26] | PTL [65] | Unit | |

|---|---|---|---|---|---|

| RJF Production | CO2 Capture | ||||

| Annualized capital cost (CAPEX) | 7924 | 13,420 | 12,900 | - | SEK/tRJF,out |

| Fixed cost | 317 | 537 | 516 | - | SEK/tRJF,out |

| Utilities for variable cost | |||||

| Electricity demand | 0.06 | 0.09 | 10.30 | 0.54 2 | MWh/tin |

| Water demand | - | 0.86 | 14.50 | 19.70 | m3/tin |

| Catalysts and chemicals | 808.6 | 71.76 | - | - | SEK/tin |

| Hydrogen | - | 411 | See footnote. 1 | - | SEK/tin |

| Parameter | 2020 | 2030 | 2040 | 2050 | Unit | Ref. |

| Water 1 | 12.4 | 18.35 | 27.17 | 40.22 | SEK/m3 | [114,115,116,117,118] |

| Forestry residue 2 | 952.78 | 996.4 | 1 043.74 | 1093.33 | SEK/t | [119] |

| Naphtha 3 | 4239.96 | 5596.74 | 6439.89 | 7554.39 | SEK/t | [120] |

| Gasoline 3 | 5595.96 | 7386.67 | 8499.47 | 9970.41 | SEK/t | [120] |

| Diesel | 875 | 1155 | 1329 | 1559 | SEK/t | [104] |

| HEFA | 13,450.68 (10.81) | 13,450.68 (10.81) | 13,450.68 (10.81) | 13,450.68 (10.81) | SEK/t (SEK/liter) | [121] |

| CJF 3 | 2918 (2.35) | 3851 (3.10) | 4431.38 (3.56) | 5198.28 (4.18) | SEK/t (SEK/liter) | [122] |

| Parameter | Variable | Value | Unit | Ref. |

|---|---|---|---|---|

| Average domestic trip length | 486.9 | km | [134] | |

| Average European trip length | 3000 | km | See footnote. 1 | |

| Average fuel burn/passenger | 0.03 | liter/km | [32] | |

| Departing passengers domestic | - | - | [74,75] | |

| Departing passengers to Europe | - | - | [74,75] |

| Emission Factor | Value | Unit | Ref. |

|---|---|---|---|

| Forestry residue feedstock cultivation and collection | 2.4 | gCO2, eq/MJ jet fuel | [141] |

| Feedstock to fuel conversion for FT production | 0.03 | gCO2, eq/MJ jet fuel | [141] |

| Chemicals and catalysts used in PTL production | 0.1 | gCO2, eq/MJ jet fuel | [140] |

| HEFA | 16 | gCO2, eq/MJ jet fuel | [32] |

| CJF | 94 | gCO2, eq/MJ jet fuel | [32] |

| Scenario | Blending Ratio | Carbon Tax | Raw Material Availability | Penalty Fee | Description | ||

|---|---|---|---|---|---|---|---|

| SEK/kg CO2 | Forestry Residue | CO2 from PP, CHP, CI and WT/WI Plants 1 | CO2 from BG and BF Plants 1 | SEK/kgCO2 | |||

| Reference (REF) | 0–75% | 1.2 | 30% | 70% | 100% | 0 | The REF scenario is a base case to which the other scenarios are compared. The variables have been set to reflect the current situation in Sweden. |

| Scenario 1–Higher carbon tax (SC1-HCT) | 0–75% | 1.2–4.4 | 30% | 70% | 100% | 0 | In SC1-HCT, the carbon tax is increased to investigate how the life cycle GHG emissions affect the outcome of the model. |

| Scenario 2–Higher blending mandate (SC2-HBM) | 0–100% | 1.2 | 30% | 70% | 100% | 0 | In SC2-HBM, the blending mandate is increased to investigate how the policy will affect the outcome of the model. |

| Scenario 3–Higher carbon tax without a blending mandate (SC3-HCT-B) | 0% | 1.2–8.7 | 30% | 70% | 100% | 0 | In SC3-HCT-B, the carbon tax is further increased while the blending mandate has been removed. |

| Scenario 4–Raw material availability (SC4-RMA) | 0–75% | 1.2 | 10–30% | 70–100% | 100% | 0 | In SC4-RMA, the raw material availability is changed. Due to rising demand in other sectors the availability of forestry residue is reduced, and the availability of CO2 is increased due to technological improvements. |

| Scenario 5–Penalty fee (SC5-PF) | 0–75% | 1.2 | 30% | 70 | 100% | 6 | In SC5-PF, the penalty fee from the blending mandate has been added. In the optimization model, a constraint has also been changed which is described in the Supplementary Materials in Section S3, Equations (S23)–(S27). |

| FT | PTL | |||

|---|---|---|---|---|

| SEK/liter | SEK/GJ | SEK/liter | SEK/GJ | |

| Total production cost excl. transport costs | 15.3–16.3 | 432.9–460.3 | 16.8–23.1 | 474.9–652.8 |

| Total production cost incl. transport costs | 21.5–22.4 | 606.9–634.0 | 22.9–29.2 | 646.6–826.1 |

| Revenues from by-products | 0.1–0.2 | 3.0–4.6 | 5.0–7.7 | 142.1–218.3 |

| Total production cost excl. transport costs minus revenues of by-products | 15.2–16.1 | 429.9–455.7 | 11.8–15.4 | 332.8–434.6 |

| Scenario | Emissions Reduction Relative REF | Emissions Reduction Relative CJF | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2025 | 2030 | 2035 | 2040 | 2045 | 2050 | 2025 | 2030 | 2035 | 2040 | 2045 | 2050 | |

| REF | - | - | - | - | - | - | 4.43% | 19.60% | 26.18% | 31.51% | 36.54% | 42.17% |

| SC1-HCT | 0.00% | 0.22% | 0.35% | 0.40% | 95.19% | 57.08% | 4.43% | 19.78% | 26.43% | 31.78% | 67.49% | 63.18% |

| SC2-HBM | 0.99% | 8.56% | 13.24% | 17.09% | 22.24% | 29.11% | 5.34% | 25.94% | 34.81% | 44.22% | 48.08% | 55.21% |

| SC3-HCT-B | −4.41% | 372.35% | 333.71% | 302.37% | 272.85% | 239.75% | 0.00% | 82.98% | 82.98% | 82.98% | 82.98% | 82.98% |

| SC4-RMA | 0.00% | −1.59% | −1.38% | −1.36% | −1.35% | −1.33% | 4.41% | 18.37% | 25.15% | 30.62% | 35.71% | 41.43% |

| SC5-PF | 2025 | 2030 | 2035 | 2040 | 2045 | 2050 | 3.73% | 22.40% | 32.36% | 42.32% | 52.28% | 62.23% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trinh, J.; Harahap, F.; Fagerström, A.; Hansson, J. What Are the Policy Impacts on Renewable Jet Fuel in Sweden? Energies 2021, 14, 7194. https://doi.org/10.3390/en14217194

Trinh J, Harahap F, Fagerström A, Hansson J. What Are the Policy Impacts on Renewable Jet Fuel in Sweden? Energies. 2021; 14(21):7194. https://doi.org/10.3390/en14217194

Chicago/Turabian StyleTrinh, Jenny, Fumi Harahap, Anton Fagerström, and Julia Hansson. 2021. "What Are the Policy Impacts on Renewable Jet Fuel in Sweden?" Energies 14, no. 21: 7194. https://doi.org/10.3390/en14217194

APA StyleTrinh, J., Harahap, F., Fagerström, A., & Hansson, J. (2021). What Are the Policy Impacts on Renewable Jet Fuel in Sweden? Energies, 14(21), 7194. https://doi.org/10.3390/en14217194