FPGA Implementation of an Ant Colony Optimization Based SVM Algorithm for State of Charge Estimation in Li-Ion Batteries †

Abstract

:1. Introduction

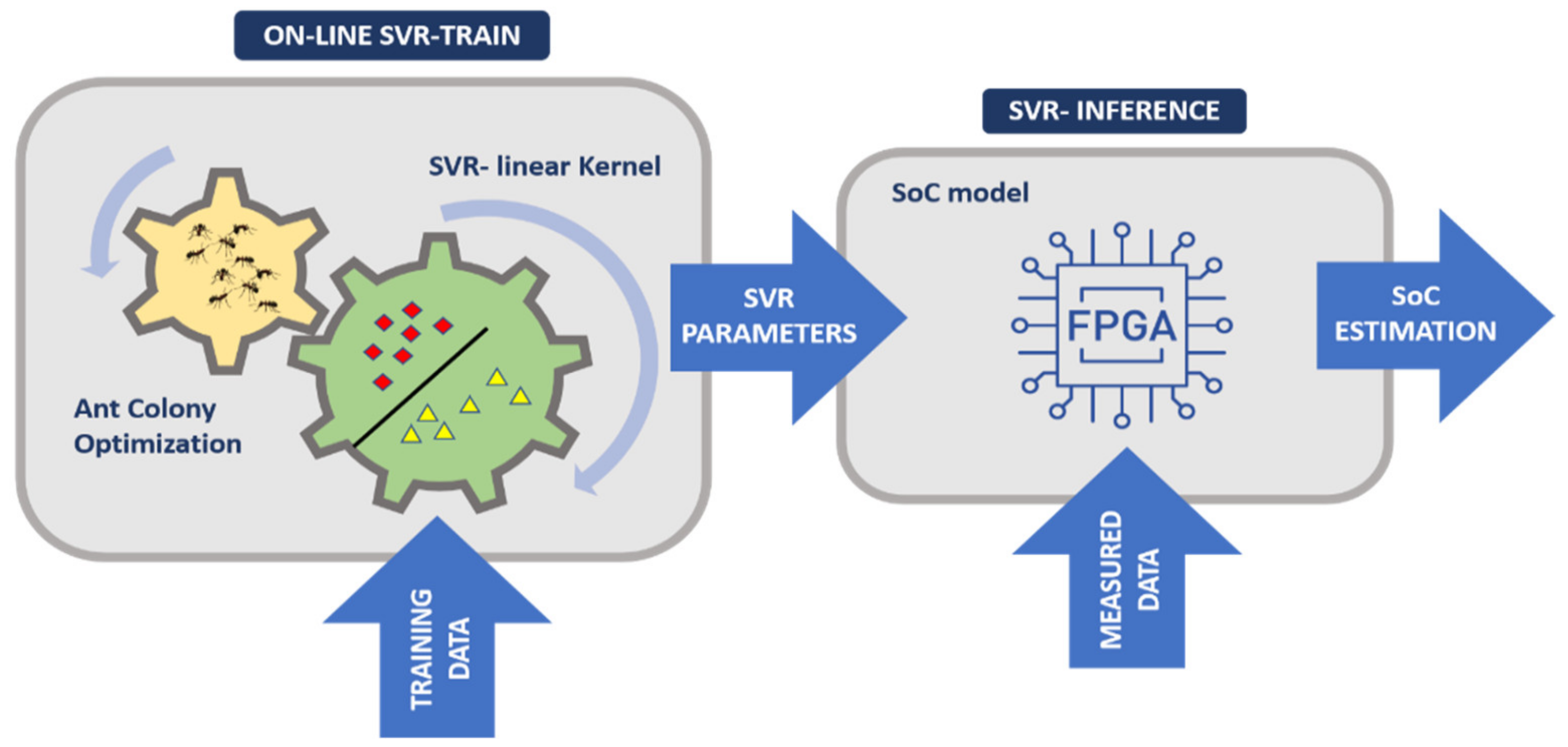

2. Materials and Methods

- Linear: K(x,xi) = x · xi;

- Polynomial: K(x,xi) = ((x · xi) + p)d;

- Gaussian Radial Basis Function (RBF): K(x,xi) = exp(−‖x − xi‖2/2σ2).

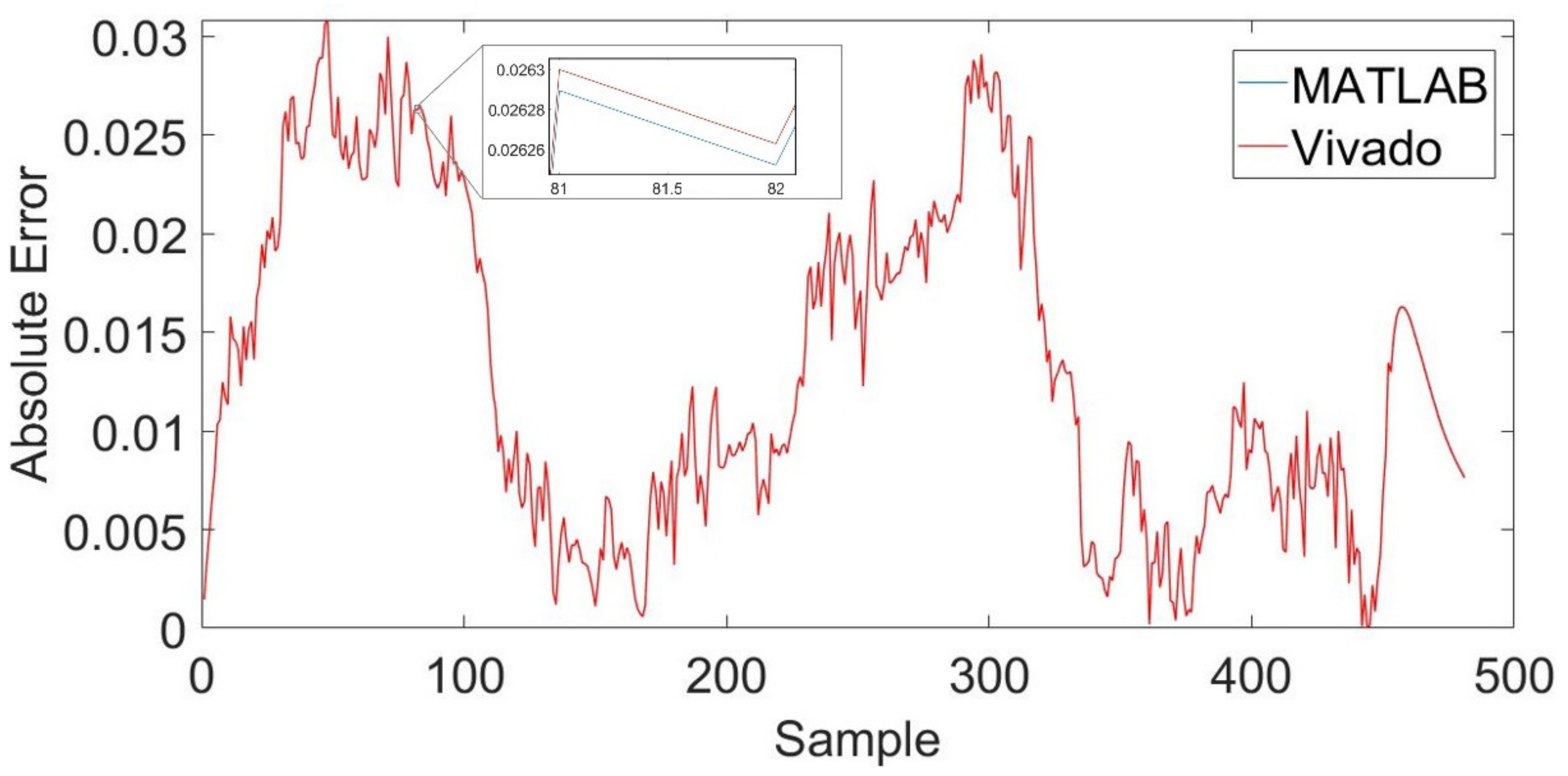

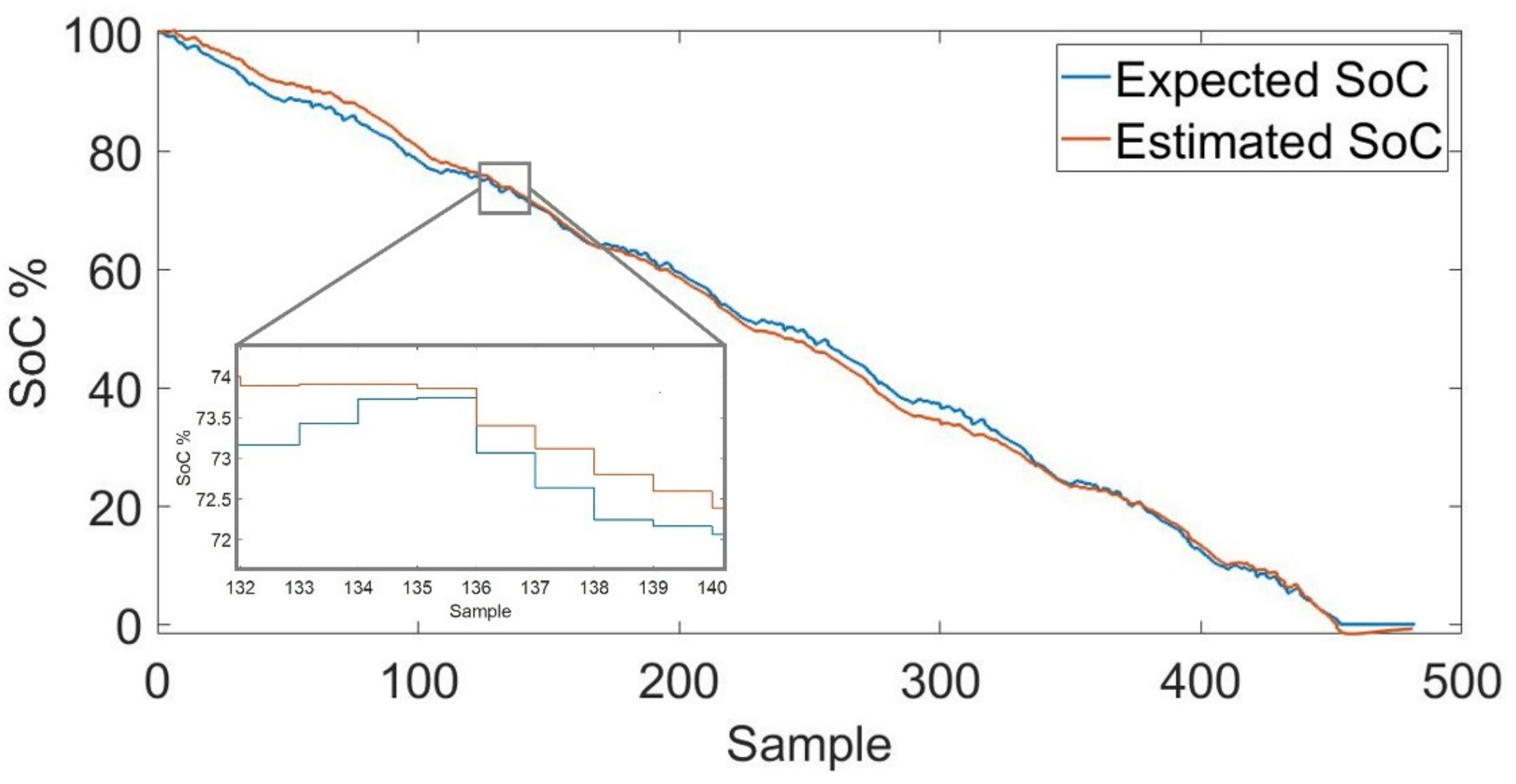

3. Results and Discussion

- Current flowing through the cell (I)

- Cell voltage (V)

- Cell temperature (T)

- Estimation of SoC at the previous time step (prevSOC) [56]

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sathiyanarayanan, J.S.; Kumar, A.S. Maximization battery lifetime and improving efficiency. In Proceedings of the 2012 International Conference on Devices, Circuits and Systems, ICDCS 2012, Tamil Nadu, India, 15–16 March 2012; pp. 603–606. [Google Scholar]

- Rong, D.; Yang, B.; Chen, C. Model Predictive Climate Control of Electric Vehicles for Improved Battery Lifetime. In Proceedings of the 2019 Chinese Automation Congress (CAC), Hangzhou, China, 22–24 November 2019; pp. 5457–5462. [Google Scholar]

- Yong, J.Y.; Ramachandaramurthy, V.K.; Tan, K.M.; Mithulananthan, N. A review on the state-of-the-art technologies of electric vehicle, its impacts and prospects. Renew. Sustain. Energy Rev. 2015, 49, 365–385. [Google Scholar] [CrossRef]

- Artakusuma, D.D.; Afrisal, H.; Cahyadi, A.I.; Wahyunggoro, O. Battery management system via bus network for multi battery electric vehicle. In Proceedings of the 2014 International Conference on Electrical Engineering and Computer Science, ICEECS 2014, Kuta, Indonesia, 24–25 November 2014; pp. 179–181. [Google Scholar]

- Lan, C.W.; Lin, S.S.; Syue, S.Y.; Hsu, H.Y.; Huang, T.C.; Tan, K.H. Development of an intelligent lithium-ion battery-charging management system for electric vehicle. In Proceedings of the 2017 IEEE International Conference on Applied System Innovation: Applied System Innovation for Modern Technology, ICASI 2017, Sapporo, Japan, 13–17 May 2017; pp. 1744–1746. [Google Scholar]

- Kim, M.J.; Chae, S.H.; Moon, Y.K. Adaptive Battery State-of-Charge Estimation Method for Electric Vehicle Battery Management System. In Proceedings of the International SoC Design Conference, ISOCC 2020, Yeosu, Korea, 21–24 October 2020; pp. 288–289. [Google Scholar]

- Alvarez, J.M.; Sachenbacher, M.; Ostermeier, D.; Stadlbauer, H.J.; Hummitzsch, U.; Alexeev, A. D6.1—Analysis of the State of the Art on BMS. Technical Report. 2017. Available online: http://everlasting-project.eu/wp-content/uploads/2016/11/EVERLASTING_D6.1_final_20170228.pdf (accessed on 23 September 2021).

- How, D.N.T.; Hannan, M.A.; Lipu, M.S.H.; Ker, P.J. State of Charge Estimation for Lithium-Ion Batteries Using Model-Based and Data-Driven Methods: A Review. IEEE Access 2019, 7, 136116–136136. [Google Scholar] [CrossRef]

- Plett, G.L. Efficient Battery Pack State Estimation using Bar-Delta Filtering. In Proceedings of the 24th International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium and Exhibition 2009, EVS 24, Stavanger, Norway, 13–16 May 2009; Volume 1, pp. 163–170. [Google Scholar]

- Zhang, R.; Xia, B.; Li, B.; Cao, L.; Lai, Y.; Zheng, W.; Wang, H.; Wang, W. State of the art of lithium-ion battery SOC estimation for electrical vehicles. Energies 2018, 11, 1820. [Google Scholar] [CrossRef] [Green Version]

- Espedal, I.B.; Jinasena, A.; Burheim, O.S.; Lamb, J.J. Current trends for state-of-charge (SoC) estimation in lithium-ion battery electric vehicles. Energies 2021, 14, 3284. [Google Scholar] [CrossRef]

- He, H.; Xiong, R.; Fan, J. Evaluation of lithium-ion battery equivalent circuit models for state of charge estimation by an experimental approach. Energies 2011, 4, 582–598. [Google Scholar] [CrossRef]

- Deng, D.; Wang, S.; Chen, L. An improved second-order electrical equivalent modeling method for the online high power Li-ion battery state of charge estimation. In Proceedings of the 12th IEEE Energy Conversion Congress & Exposition-Asia (ECCE-Asia), Singapore, 24–27 May 2021; pp. 1725–1729. [Google Scholar]

- Saboo, K.; Mangsule, R.; Deshpande, A.S. State of Charge (SoC) Estimation of Li-Ion Battery. In Proceedings of the International Conference on Emerging Smart Computing and Informatics, ESCI 2021, Pune, India, 5–7 March 2021; pp. 340–345. [Google Scholar]

- Wang, L.; Wang, L.; Liao, C. Research on improved EKF algorithm applied on estimate EV battery SOC. In Proceedings of the Asia-Pacific Power and Energy Engineering Conference, APPEEC, Chengdu, China, 28–31 March 2010; pp. 1–4. [Google Scholar]

- Zhang, F.; Ur Rehman, M.M.; Wang, H.; Levron, Y.; Plett, G.; Zane, R.; Maksimović, D. State-of-charge estimation based on microcontroller-implemented sigma-point Kalman filter in a modular cell balancing system for Lithium-Ion battery packs. In Proceedings of the 2015 IEEE 16th Workshop on Control and Modeling for Power Electronics (COMPEL), Vancouver, BC, Canada, 12–15 July 2015; pp. 1–7. [Google Scholar]

- Johnsema, B.; Janakiraman, K. Reliable SOC estimation for battery powered embedded system. In Proceedings of the International Conference on Information Communication and Embedded Systems (ICICES2014), Chennai, India, 27–28 February 2014; pp. 1–5. [Google Scholar]

- Monmasson, E.; Idkhajine, L.; Naouar, M.W. FPGA-based controllers. IEEE Ind. Electron. Mag. 2011, 5, 14–26. [Google Scholar] [CrossRef]

- Otero, N.; Rahimi-Eichi, H.; Rodriguez-Andina, J.J.; Chow, M.Y. FPGA implementation of an observer for state of charge estimation in lithium-polymer batteries. In Proceedings of the International Conference on Mechatronics and Control (ICMC), Jinzhou, China, 3–5 July; 2014; pp. 1646–1651. [Google Scholar]

- Morello, R.; Di Rienzo, R.; Roncella, R.; Saletti, R.; Baronti, F. Hardware-in-the-loop platform for assessing battery state estimators in electric vehicles. IEEE Access 2018, 6, 68210–68220. [Google Scholar] [CrossRef]

- Stighezza, M.; Bianchi, V.; De Munari, I. HDL Code Generation from SIMULINK Environment for Li-Ion Cells State of Charge and Parameter Estimation. Lect. Notes Electr. Eng. 2021, 738, 136–143. [Google Scholar]

- Zhang, R.; Xia, B.; Li, B.; Cao, L.; Lai, Y.; Zheng, W.; Wang, H.; Wang, W.; Wang, M. A study on the open circuit voltage and state of charge characterization of high capacity lithium-ion battery under different temperature. Energies 2018, 11, 2408. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.Y.; Ma, J.; Zhang, K. State of Charge Estimation for Battery Based on Improved Cubature Kalman Filter. In Proceedings of the 20th COTA International Conference of Transportation Professionals: Advanced Transportation Technologies and Development-Enhancing Connections, CICTP 2020, Xi’an, China, 14–16 August 2021; pp. 2303–2316. [Google Scholar]

- Danko, M.; Adamec, J.; Taraba, M.; Drgona, P. Overview of batteries State of Charge estimation methods. In Proceedings of the13th International Scientific Conference On Suistanable, modern and safe transport (TRANSCOM 2019), Novy Smokovec, Slovak Republic, 29–31 May 2019; pp. 186–192. [Google Scholar]

- Kollmeyer, P. Panasonic 18650PF Li-ion Battery Data. Available online: https://data.mendeley.com/datasets/wykht8y7tg/1 (accessed on 23 September 2021).

- Bole, B.; Kulkarni, C.; Daigle, M. Randomized Battery Usage Data Set. Available online: https://ti.arc.nasa.gov/tech/dash/groups/pcoe/prognostic-data-repository/ (accessed on 1 September 2021).

- Kollmeyer, P.; Vidal, C.; Naguib, M.; Skells, M. LG 18650HG2 Li-ion Battery Data and Example Deep Neural Network xEV SOC Estimator Script. Available online: https://data.mendeley.com/datasets/cp3473x7xv/3 (accessed on 1 October 2021).

- Vidal, C.; Malysz, P.; Kollmeyer, P.; Emadi, A. Machine Learning Applied to Electrified Vehicle Battery State of Charge and State of Health Estimation: State-of-the-Art. IEEE Access 2020, 8, 52796–52814. [Google Scholar] [CrossRef]

- Song, X.; Yang, F.; Wang, D.; Tsui, K.L. Combined CNN-LSTM Network for State-of-Charge Estimation of Lithium-Ion Batteries. IEEE Access 2019, 7, 88894–88902. [Google Scholar] [CrossRef]

- Kang, L.W.; Zhao, X.; Ma, J. A new neural network model for the state-of-charge estimation in the battery degradation process. Appl. Energy 2014, 121, 20–27. [Google Scholar] [CrossRef]

- Tong, S.; Lacap, J.H.; Park, J.W. Battery state of charge estimation using a load-classifying neural network. J. Energy Storage 2016, 7, 236–243. [Google Scholar] [CrossRef]

- Trinandana, G.A.; Pratama, A.W.; Prasetyono, E.; Anggriawan, D.O. Real Time State of Charge Estimation for Lead Acid Battery Using Artificial Neural Network. In Proceedings of the 2020 International Seminar on Intelligent Technology and Its Applications (ISITIA), Surabaya, Indonesia, 22–23 July 2020; pp. 363–368. [Google Scholar]

- Chemali, E.; Kollmeyer, P.J.; Preindl, M.; Emadi, A. State-of-charge estimation of Li-ion batteries using deep neural networks: A machine learning approach. J. Power Sources 2018, 400, 242–255. [Google Scholar] [CrossRef]

- Yang, F.; Song, X.; Xu, F.; Tsui, K.L. State-of-Charge Estimation of Lithium-Ion Batteries via Long Short-Term Memory Network. IEEE Access 2019, 7, 53792–53799. [Google Scholar] [CrossRef]

- Hansen, T.; Wang, C.J. Support vector based battery state of charge estimator. J. Power Sources 2005, 141, 351–358. [Google Scholar] [CrossRef]

- Li, R.; Xu, S.; Li, S.; Zhou, Y.; Zhou, K.; Liu, X.; Yao, J. State of charge prediction algorithm of lithium-ion battery based on PSO-SVR cross validation. IEEE Access 2020, 8, 10234–10242. [Google Scholar] [CrossRef]

- Antón, J.C.Á.; Nieto, P.J.G.; de Cos Juez, F.J.; Lasheras, F.S.; Vega, M.G.; Gutiérrez, M.N.R. Battery state-of-charge estimator using the SVM technique. Appl. Math. Model. 2013, 37, 6244–6253. [Google Scholar] [CrossRef]

- Osornio-Rios, R.A.; Romero-Troncoso, R.D.J.; Morales-Velazquez, L.; De Santiago-Perez, J.J.; Rivera-Guillen, R.D.J.; Rangel-Magdaleno, J.D.J. A real-time FPGA based platform for applications in mechatronics. In Proceedings of the 2008 International Conference on Reconfigurable Computing and FPGAs, Cancun, Mexico, 3–5 December 2008; pp. 289–294. [Google Scholar]

- Al-Mahmood, A.; Opoku, M. A Study of FPGA-based System-on-Chip Designs for Real-Time Industrial Application. Int. J. Comput. Appl. 2017, 163, 9–19. [Google Scholar] [CrossRef]

- Kilic, A.; Koroglu, S.; Demircali, A.; Kesler, S.; Oner, Y.; Karakas, E.; Sergeant, P. Design of Master and Slave Modules on Battery Management System for Electric Vehicles. In Proceedings of the 6th International Conference on Advanced Technology & Sciences (ICAT’Riga), Riga, Latvia, 12–15 September 2017; pp. 161–166. [Google Scholar]

- Ruiz-Llata, M.; Yébenes-Calvino, M. FPGA implementation of support vector machines for 3D object identification. Lect. Notes Comput. Sci. 2009, 5768, 467–474. [Google Scholar]

- Ruiz-Llata, M.; Guarnizo, G.; Yébenes-Calvino, M. FPGA implementation of a support vector machine for classification and regression. In Proceedings of the 2010 International Joint Conference on Neural Networks (IJCNN), Barcelona, Spain, 18–23 July 2010; pp. 1–5. [Google Scholar]

- Kumar, B.; Khare, N.; Chaturvedi, P.K. FPGA-based design of advanced BMS implementing SoC/SoH estimators. Microelectron. Reliab. 2018, 84, 66–74. [Google Scholar] [CrossRef]

- Dorigo, M.; Blum, C. Ant colony optimization theory: A survey. Theor. Comput. Sci. 2005, 344, 243–278. [Google Scholar] [CrossRef]

- Zheng, L.; Yu, M.; Yu, S. Support vector regression and ant colony optimization for combustion performance of boilers. In Proceedings of the 2008 Fourth International Conference on Natural Computation, Jinan, China, 18–20 October 2008; pp. 178–182. [Google Scholar]

- Hong, W.C.; Dong, Y.; Zheng, F.; Lai, C.Y. Forecasting urban traffic flow by SVR with continuous ACO. Appl. Math. Model. 2011, 35, 1282–1291. [Google Scholar] [CrossRef]

- Wang, H.; Yang, S. Electricity Consumption Prediction Based on SVR with Ant Colony Optimization. Telkomnika Indones. J. Electr. Eng. 2013, 11, 6928–6934. [Google Scholar] [CrossRef]

- Xilinx Inc. 7 Series FPGAs Data Sheet: Overview (DS180). Available online: https://www.xilinx.com/support/documentation/data_sheets/ds180_7Series_Overview.pdf (accessed on 23 September 2021).

- Cortes, C.; Vapnik, V. Support-Vector Networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Flake, G.W.; Lawrence, S. Efficient SVM regression training with SMO. Mach. Learn. 2002, 46, 271–290. [Google Scholar] [CrossRef]

- Fletcher, T. Support Vector Machines Explained. Available online: https://www.csd.uwo.ca/~xling/cs860/papers/SVM_Explained.pdf (accessed on 23 September 2021).

- Wang, H.; Hu, D. Comparison of SVM and LS-SVM for Regression. In Proceedings of the 2005 International Conference on Neural Networks and Brain, Beijing, China, 13–15 October 2005; pp. 279–283. [Google Scholar]

- Mathworks Fitrsvm MATLAB Function. Available online: https://it.mathworks.com/help/stats/fitrsvm.html (accessed on 23 September 2021).

- US06 Drive Cycle. Available online: https://dieselnet.com/standards/cycles/ftp_us06.php (accessed on 23 September 2021).

- Bhatti, A.H.U.; Kazmi, S.A.A.; Tariq, A.; Ali, G. Development and analysis of electric vehicle driving cycle for hilly urban areas. Transp. Res. Part D Transport. Environ. 2021, 99, 103025. [Google Scholar] [CrossRef]

- Li, J.; Ye, M.; Meng, W.; Xu, X.; Jiao, S. A Novel State of Charge Approach of Lithium Ion Battery Using Least Squares Support Vector Machine. IEEE Access 2020, 8, 195398–195410. [Google Scholar] [CrossRef]

- Mahmoodi, D.; Soleimani, A.; Khosravi, H.; Taghizadeh, M. FPGA Simulation of Linear and Nonlinear Support Vector Machine. J. Softw. Eng. Appl. 2011, 4, 320–328. [Google Scholar] [CrossRef] [Green Version]

- Batista, G.C.; Oliveira, D.L.; Saotome, O.; Silva, W.L.S. A low-power asynchronous hardware implementation of a novel SVM classifier, with an application in a speech recognition system. Microelectron. J. 2020, 105, 1–17. [Google Scholar] [CrossRef]

- Alobaedy, M.M.; Khalaf, A.A.; Muraina, I.D. Analysis of the number of ants in ant colony system algorithm. In Proceedings of the 2017 5th International Conference on Information and Communication Technology (ICoIC7), Melaka, Malaysia, 17–19 May 2017; pp. 1–5. [Google Scholar]

- Panasonic Lithium Ion NCR18650PF Datasheet. Available online: https://na.industrial.panasonic.com/products/batteries/rechargeable-batteries/lineup/lithium-ion/series/90729/model/90730 (accessed on 23 September 2021).

- EEMB Lithium-Ion Battery LIR18650 2600mAh Datasheet. Available online: https://www.eemb.com/model/lir18650(2600).html (accessed on 23 September 2021).

| Phase | Train Set | Test Set |

|---|---|---|

| Evaluation of different Kernel functions | NN drive cycle | US06 drive cycle |

| Comparison between different MATLAB optimization strategies with ACO | NN drive cycle | US06 drive cycle |

| ACO-optimized Linear SVM cross-fold validation evaluation | NN drive cycle | NN drive cycle |

| FPGA-implemented ACO-optimized Linear SVM evaluation | Not performed | US06 drive cycle |

| Kernel | RMSE (%) |

|---|---|

| Linear | 8.7 |

| Quadratic | 16.7 |

| Cubic | 35.9 |

| Sigmoid | 30.2 |

| RBF | 35.5 |

| Algorithm | RMSE (%) | MAE (%) | ||||

|---|---|---|---|---|---|---|

| Min | Mean | Max | Min | Mean | Max | |

| Bayesian | 1.9 | 9.6 | 25.3 | 1.6 | 8.4 | 21.8 |

| Grid Search | 1.6 | 7.2 | 18.8 | 1.3 | 6.1 | 15.0 |

| Random Search | 1.4 | 6.8 | 53.6 | 1.2 | 5.9 | 46.5 |

| ACO | 1.4 | 3.9 | 7.2 | 1.2 | 3.2 | 5.8 |

| FPGA | Slice LUTs Utilization (%) | Slice Registers (%) | DSP Slices (%) | |

|---|---|---|---|---|

| Proposed | Artix 7 | 880/63,400 (1.39%) | 300/126,800 (0.24%) | 0/240 (0%) |

| [20] | Artix 7 | 14,427/63,400 (22.76%) | 196/126,800 (0.15%) | 8/240 (3.33%) |

| [41] | Virtex 7 | 1123/303,600 (1%) | 751/607,200 (1%) | 1125/2800 (40%) |

| Approach | RMSE (%) | Max Error (%) | MAE (%) |

|---|---|---|---|

| ACO-SVR | 1.4 | 3.1 | 1.2 |

| [21] const. par. | 1.5 | 4.3 | 1.1 |

| [21] var. par. | 2.5 | 5.4 | 2.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stighezza, M.; Bianchi, V.; De Munari, I. FPGA Implementation of an Ant Colony Optimization Based SVM Algorithm for State of Charge Estimation in Li-Ion Batteries. Energies 2021, 14, 7064. https://doi.org/10.3390/en14217064

Stighezza M, Bianchi V, De Munari I. FPGA Implementation of an Ant Colony Optimization Based SVM Algorithm for State of Charge Estimation in Li-Ion Batteries. Energies. 2021; 14(21):7064. https://doi.org/10.3390/en14217064

Chicago/Turabian StyleStighezza, Mattia, Valentina Bianchi, and Ilaria De Munari. 2021. "FPGA Implementation of an Ant Colony Optimization Based SVM Algorithm for State of Charge Estimation in Li-Ion Batteries" Energies 14, no. 21: 7064. https://doi.org/10.3390/en14217064

APA StyleStighezza, M., Bianchi, V., & De Munari, I. (2021). FPGA Implementation of an Ant Colony Optimization Based SVM Algorithm for State of Charge Estimation in Li-Ion Batteries. Energies, 14(21), 7064. https://doi.org/10.3390/en14217064