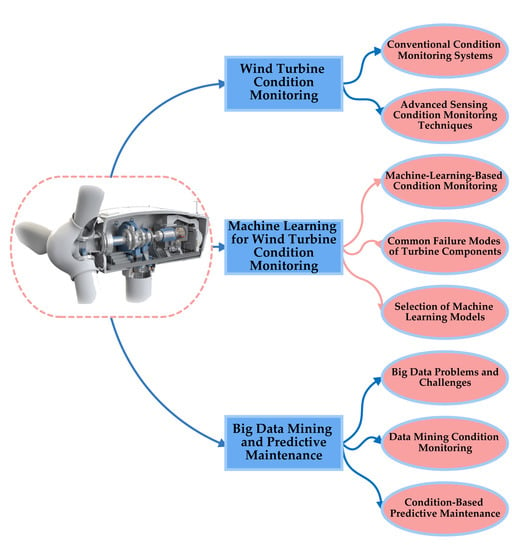

Intelligent Condition Monitoring of Wind Power Systems: State of the Art Review

Abstract

:1. Introduction

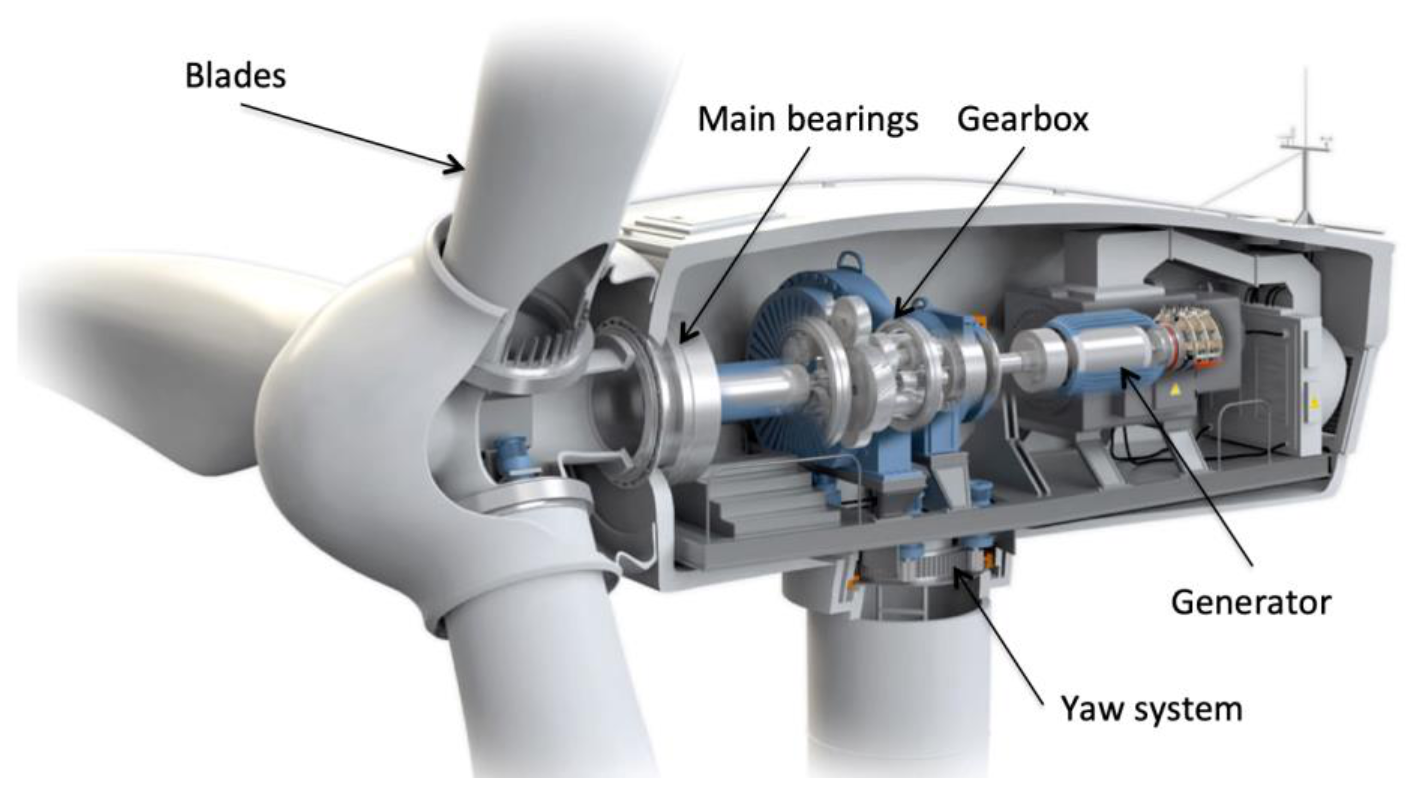

2. Wind Turbine Condition Monitoring

2.1. Conventional Condition Monitoring Systems

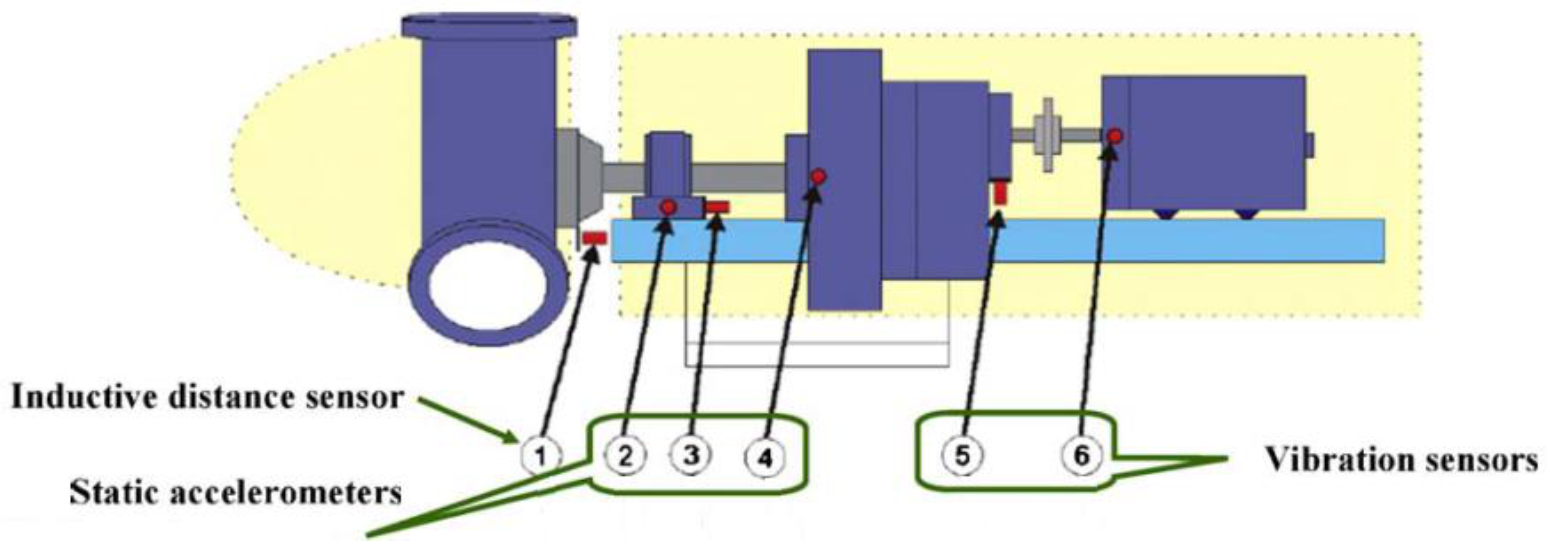

2.1.1. Vibration Monitoring

2.1.2. Oil Debris Analysis

2.1.3. Acoustic Emission (AE)

- AE sensors are required to be placed at certain proximity locations to be able to accurately detect a fault.

- Accurate AE measurements require the installation of a large number of AE sensors, which all require individual dedicated data acquisition equipment for the sensing, analysis, and data transfer process.

- AE measurements and analysis are expensive due to the data acquisition system cost and the requirement of high sampling rates for signal processing.

- WT nacelles are not particularly suitable for AE sensor application due to the high level of operational and ambient noise, which can complicate the identification of target sound components.

- The attenuation of the AE signals during propagation can also pose limitations in implementation of this technique.

2.1.4. Temperature Monitoring

2.1.5. Electrical Signal Analysis

2.1.6. Torque Measurement

2.1.7. SCADA Signals

2.2. Advanced Sensing Condition Monitoring Techniques

2.2.1. Thermography Analysis (Infrared Thermography)

2.2.2. Shock Pulse Method

2.2.3. X-ray Micro-Tomography

2.2.4. Fiber Bragg Grating Sensors Measurement

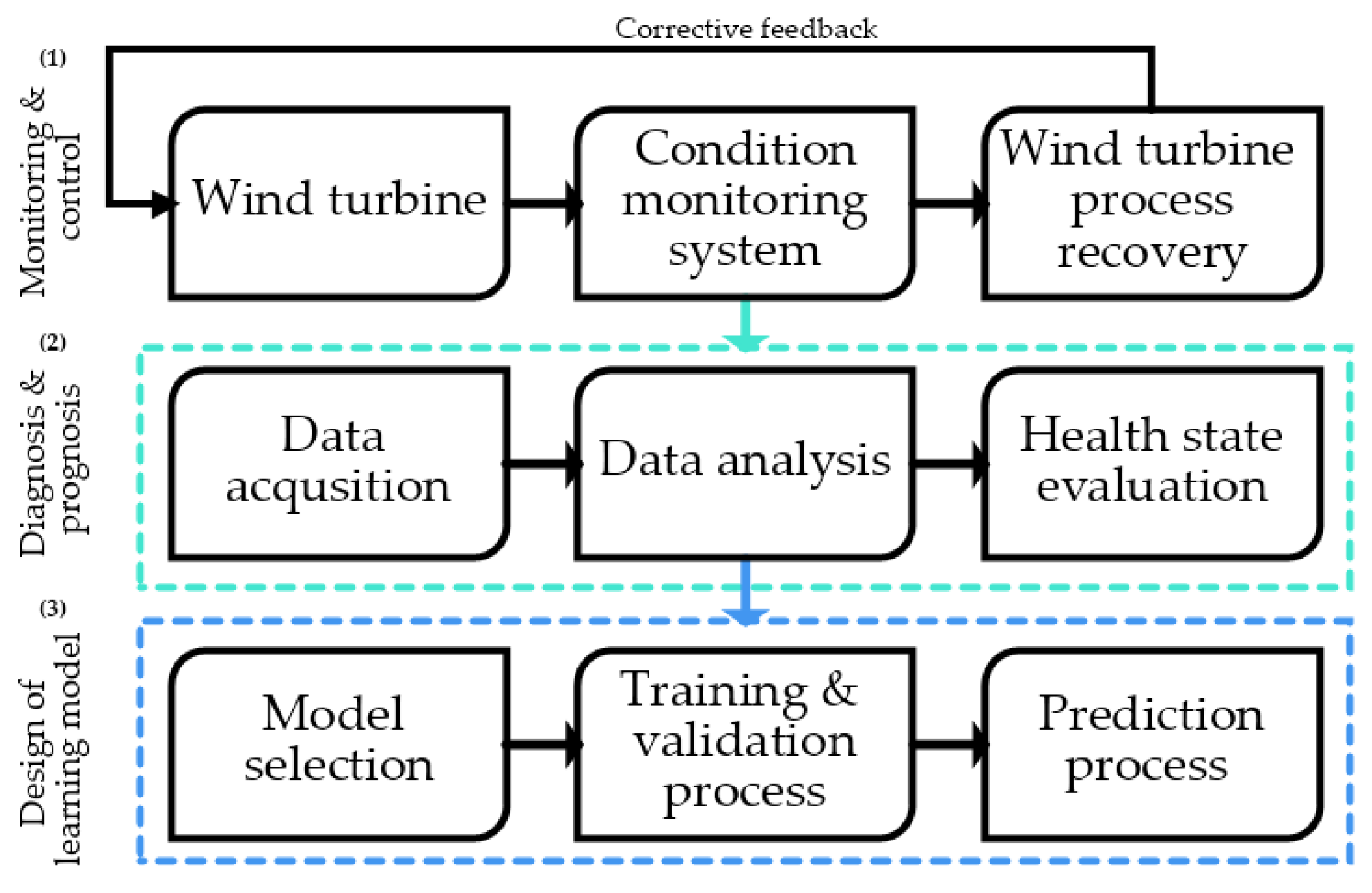

3. Machine Learning for Wind Turbine Condition Monitoring

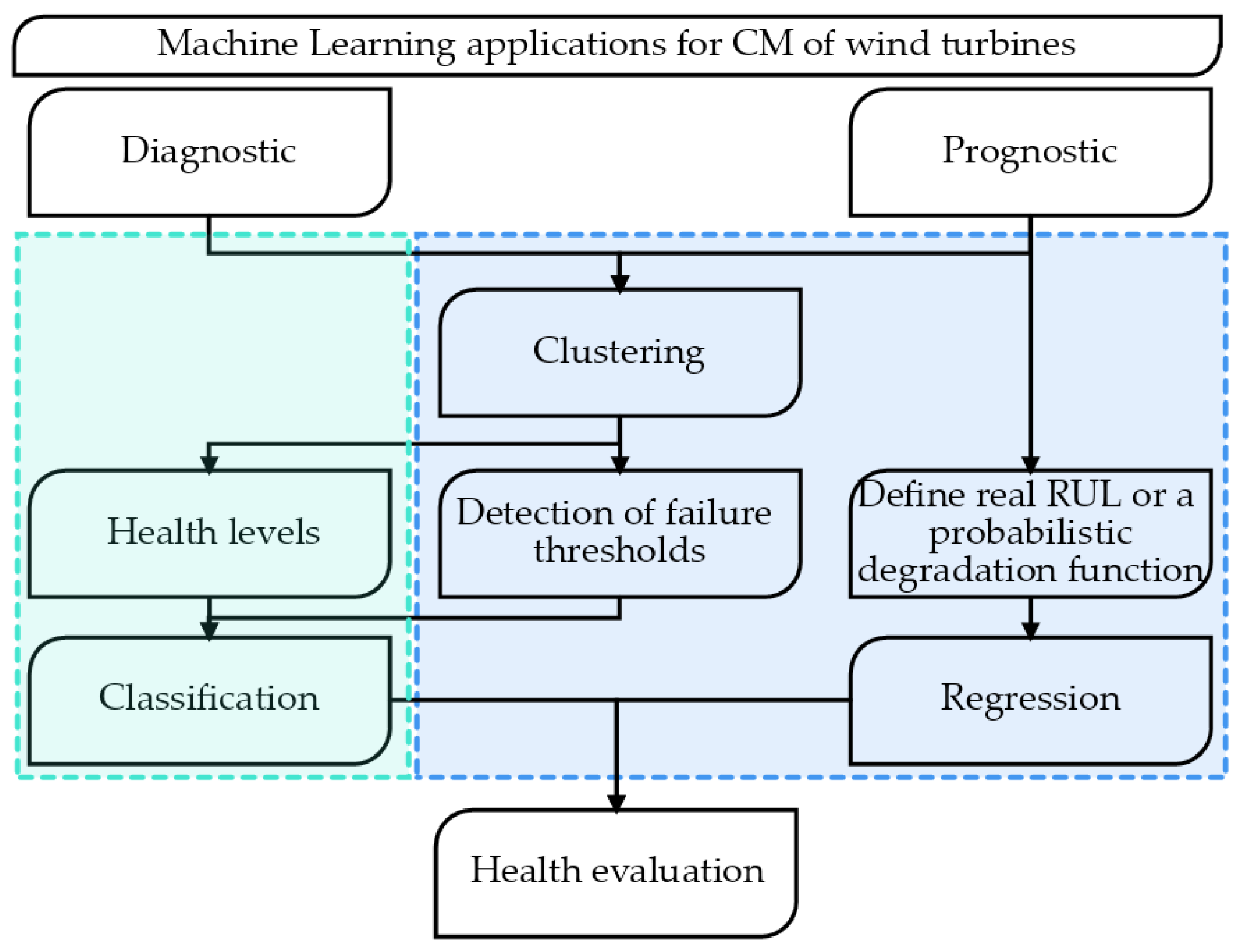

3.1. Machine-Learning-Based Condition Monitoring

3.1.1. Data Acquisition

3.1.2. Data Analysis

3.2. Common Failure Modes of Turbine Components

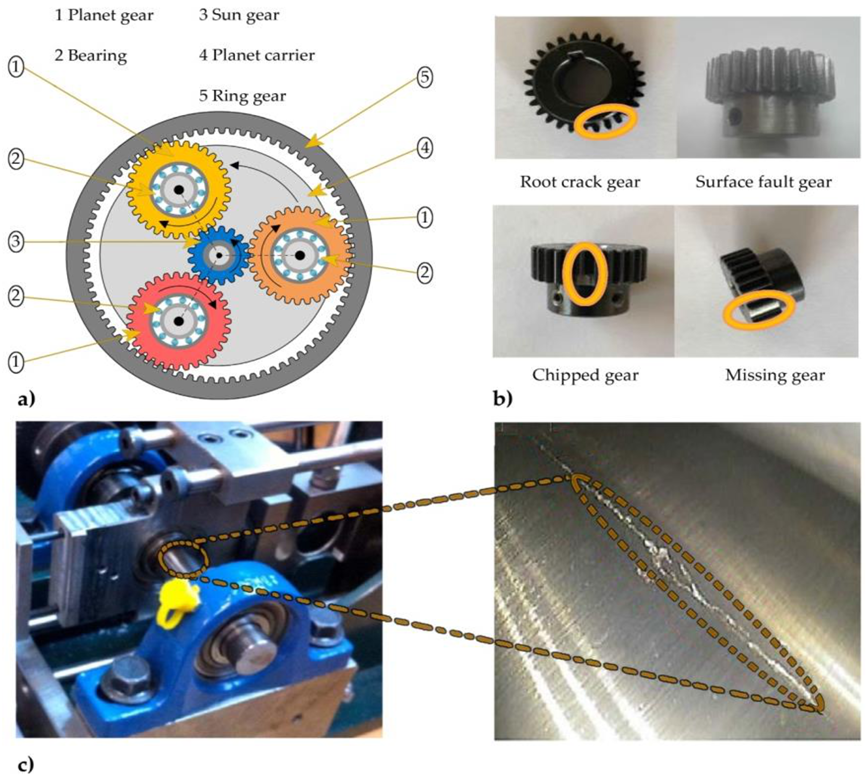

3.2.1. Gearbox

| Method | Tools | Extraction Techniques | Data Type | Learning Algorithm | Application | |||

|---|---|---|---|---|---|---|---|---|

| DL | TL | GAN | TML | |||||

| Y. Kong et al. [103] | Bi-LSTM | Time domain features | Vibration | √ | Faults classification | |||

| F. Cheng et al. [104] | Stacked autoencoder Support vector machine | Rotation fundamental frequency Hilbert transform Angular resampling | Rotation frequency | √ | √ | Faults classification | ||

| B. Corley et al. [105] | Thermal Modeling Machine Learning | SCADA black box models preprocessing | Temperature | √ | Faults classification | |||

| J. Fu et al. [106] | CNN LSTM | Adaptive elastic network | Temperature | √ | √ | Faults classification | ||

| W.Hu et al. [100] | Kernel extreme learning machine PSO | Wavelet packet transform Time-domain sequence approximate entropy | Vibration | √ | Health-level classification | |||

| V. Inturi et al. [88] | Decision tree ANFIS | Wavelet coefficients | Multiple sensors | √ | Clustering and classification | |||

| G. Jiang et al. [107] | Multiscale CNN | NAN (no data pre-processing: raw data are directly fed into the learning model) | Vibration | √ | Faults classification | |||

| Y. Kong [84] | Sparse representation classification | Discriminative dictionary learning K-singular value decomposition | Multiple sensors | √ | Faults classification | |||

| L. Lu et al. [93] | Deep belief neural network Chaotic quantum PSO Least-squares (SVM) | Compressed sensing | Vibration signals through self-powered wireless sensor | √ | √ | Faults classification | ||

| L. Lu et al. [94] | Least-squares SVM Quantum PSO Stacked denoising autoencoder | Stacked denoising autoencoder | Vibration signals through self-powered wireless sensor | √ | √ | Faults classification | ||

| L. Lu et al. [95] | Deep belief network Quantum PSO Least squares SVM | NAN | Vibration signals through self-powered wireless sensor | √ | √ | Faults classification | ||

| Y.Pan et al. [108] | Extreme learning machine Fruit fly of algorithm | Empirical mode decomposition with adaptive noise Kernel principal component analysis (KPCA) | Vibration | √ | Regression (remaining use life) | |||

| H. Ren et al. [109] | Weighted distribution adaptation Nearest neighbor | Composite variational mode entropy | Vibration | √ | √ | Faults classification | ||

| S. Saufi et al. [98] | Deep neural network | Stacked sparse autoencoder Spectral kurtosis Fourier transform Wavelet transform | Images extracted from multiple sensors | √ | Faults classification | |||

| L. Xiang et al. [6] | CNN LSTM with attention mechanism | SCADA black box models preprocessing | Multiple sensors | √ | Faults classification | |||

| L. Yang et al. [99] | Deep joint variational autoencoder | SCADA black box models preprocessing | SCADA data | √ | Faults classification | |||

| J. Zhang et al. [110] | Multi-branch CNN | Fast spectral kurtosis images | Vibration | √ | Faults classification | |||

| X. Zhang et al. [86] | CNN PSO SVM | CNN | Vibration | √ | √ | Faults classification | ||

| J.H. Zhong et al. [101] | Sparse Bayesian ELM | Hilbert−Huang transform | Vibration | √ | Faults classification | |||

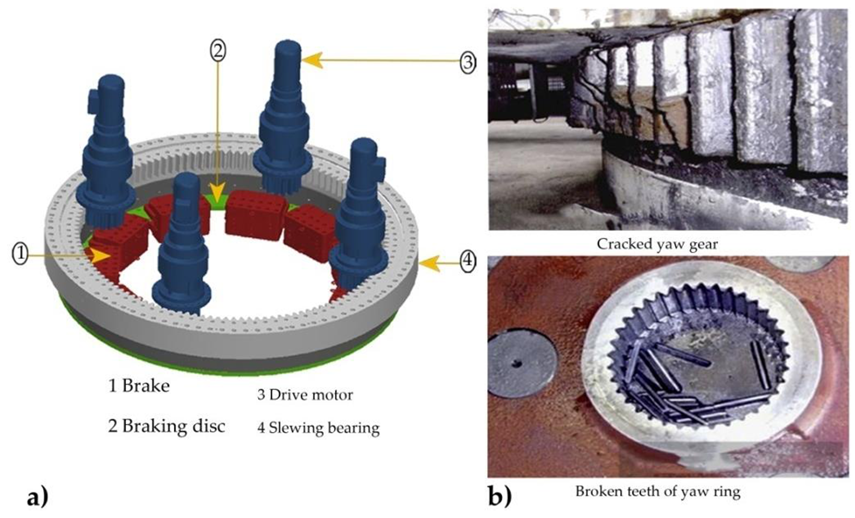

3.2.2. Yaw System

| Method | Tools | Extraction Techniques | Data Type | Learning Algorithm | Application | |||

|---|---|---|---|---|---|---|---|---|

| DL | TL | GAN | TML | Faults classification | ||||

| M. Reder et al. [112] | k-means | NAN | Meteorological data | √ | Clustering and classification of faults | |||

| H. Chen et al. [113] | Adaptive threshold. LSTM SVM | Time window | Multiple sensors | √ | √ | Faults classification | ||

| B. Chen et al. [87] | Bayesian network | Self-organizing map Information gain rate | Acoustic signals | √ | Faults classification | |||

3.2.3. Blades

| Method | Tools | Extraction Techniques | Data Type | Learning Algorithm | Application | |||

|---|---|---|---|---|---|---|---|---|

| DL | TL | GAN | TML | |||||

| L. Chen et al. [117] | Triplet loss CNN | SCADA black box models preprocessing | Multiple sensors | √ | √ | Faults classification | ||

| X. Yang et al. [92] | CNN (Alesxnet) Ensemble random forest | Otsu threshold segmentation | Unmanned aerial vehicle (UAV) images | √ | √ | √ | Faults classification | |

| W. Chen et al. [118] | Inception V3 TrAdaBoost | SCADA black box models preprocessing | Multiple sensors | √ | √ | Faults classification | ||

| M. Kreutz et al. [119] | Traditional artificial neural networks | Time window | Temperature | √ | Faults classification | |||

| A. Joshuva et al. [120] | J48 decision tree Locally weighted learning | Histogram features | Vibration signals | √ | Faults classification | |||

| K. Chandrasekhar et al. [121] | Gaussian Processes | Frequency analysis | Rotation signals | √ | Faults classification | |||

| A.A. Jiménez et al. [122] | 20 Machine Learning classifiers | Autoregressive and principal component analysis Nonlinear-AR exogenous and hierarchical non-linear principal component analysis | Ultrasonic signal | √ | Faults classification | |||

3.2.4. Generator

| Method | Tools | Extraction Techniques | Data Type | Learning Algorithm | Application | |||

|---|---|---|---|---|---|---|---|---|

| DL | TL | GAN | TML | |||||

| P. Chen [85] | Generative adversarial networks CNN | Time window Fast Fourier transforms | Vibration | √ | √ | Faults classification | ||

| Y. Chang [89] | Parallel CNN Multi-scale kernels | NAN | Vibration | √ | √ | Faults classification | ||

| T. Zhang [123] | Generative adversarial networks Convolutional autoencoder Self-taught learning networks Dropout regularization | NAN | Vibration | √ | √ | √ | √ | Faults classification |

3.3. Selection of Machine Learning Models

4. Big Data Mining and Predictive Maintenance

4.1. Big Data Problems and Challenges

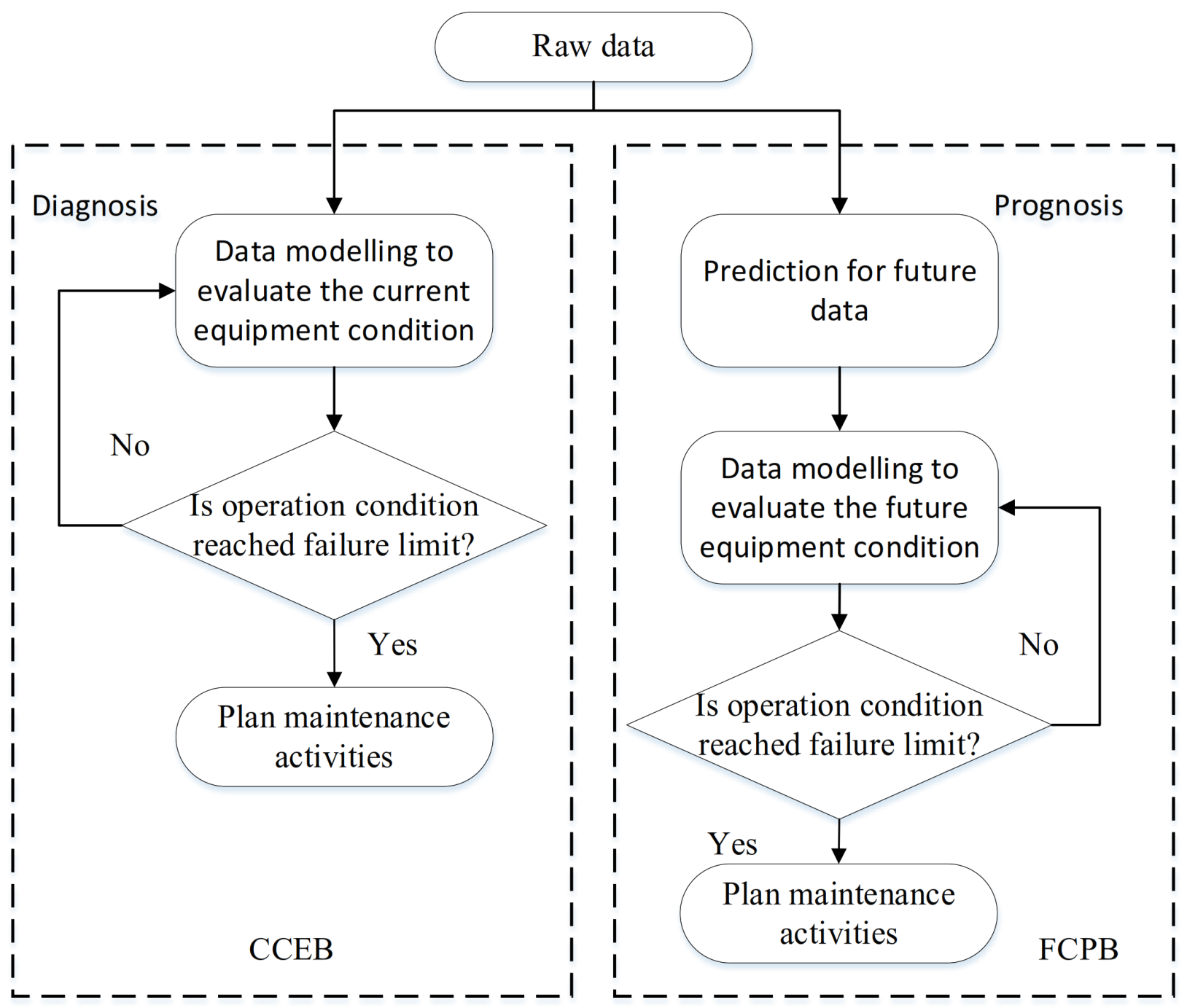

4.2. Data Mining Condition Monitoring

4.3. Condition-Based Predictive Maintenance

4.3.1. Decision-Making Framework

4.3.2. Remaining Useful Life Estimation

5. Discussion and Future Work

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stetco, A.; Dinmohammadi, F.; Zhao, X.; Robu, V.; Flynn, D.; Barnes, M.; Keane, J.; Nenadic, G. Machine learning methods for wind turbine condition monitoring: A review. Renew. Energy 2019, 133, 620–635. [Google Scholar] [CrossRef]

- US Energy Information Administration. Annual Energy Ooutlook. 2021. Available online: https://www.eia.gov/outlooks/aeo/pdf/04AEO2021Electricity.pdf (accessed on 5 July 2021).

- Gao, Z.; Liu, X. An Overview on Fault Diagnosis, Prognosis and Resilient Control for Wind Turbine Systems. Processes 2021, 9, 300. [Google Scholar] [CrossRef]

- Rezamand, M.; Kordestani, M.; Carriveau, R.; Ting, D.S.K.; Orchard, M.E.; Saif, M. Critical Wind Turbine Components Prognostics: A Comprehensive Review. IEEE Trans. Instrum. Meas. 2020, 69, 9306–9328. [Google Scholar] [CrossRef]

- Qian, P.; Ma, X.; Zhang, D.; Wang, J. Data-driven condition monitoring approaches to improving power output of wind turbines. IEEE Trans. Ind. Electron. 2019, 66, 6012–6020. [Google Scholar] [CrossRef] [Green Version]

- Xiang, L.; Wang, P.; Yang, X.; Hu, A.; Su, H. Fault detection of wind turbine based on SCADA data analysis using CNN and LSTM with attention mechanism. Meas. J. Int. Meas. Confed. 2021, 175, 109094. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, W.; Zhang, G.; Shu, L. Wind turbine fault diagnosis based on transfer learning and convolutional autoencoder with small-scale data. Renew. Energy 2021, 171, 103–115. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Meas. J. Int. Meas. Confed. 2020, 149, 107002. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, X.; Joyce, M. Reducing sensor complexity for monitoring wind turbine performance using principal component analysis. Renew. Energy 2016, 97, 444–456. [Google Scholar] [CrossRef] [Green Version]

- Habibi, H.; Howard, I.; Simani, S. Reliability improvement of wind turbine power generation using model-based fault detection and fault tolerant control: A review. Renew. Energy 2019, 135, 877–896. [Google Scholar] [CrossRef]

- Yang, W.; Tavner, P.J.; Crabtree, C.J.; Feng, Y.; Qiu, Y. Wind turbine condition monitoring: Technical and commercial challenges. Wind Energy 2012, 17, 673–693. [Google Scholar] [CrossRef] [Green Version]

- Qiao, W.; Lu, D. Survey on wind turbine condition monitoring and fault diagnosis-Part i: Components and subsystems. IEEE Trans. Ind. Elec. 2015, 62, 6536–6545. [Google Scholar] [CrossRef]

- Brüel & Kjær Vibro. Available online: www.bkvibro.com/industries/wind-power/condition-monitoring-for-wind-turbines/ (accessed on 5 July 2021).

- Pruftechnick. Available online: https://www.pruftechnik.com/en-GB/Products-and-Services/Condition-Monitoring-Systems/Online-Condition-Monitoring/#Online+Condition+Monitoring+Systems (accessed on 5 July 2021).

- Karlsen, A.; Pivano, L.; Ruth, E. DNV GL DP Capability—A New Standard for Assessment of the Station-Keeping Capability of DP Vessels. In Proceedings of the Marine Technology Society (MTS) DP Conference, Houston, TX, USA, 11–12 October 2016; pp. 1–15. [Google Scholar]

- Siplus CMS. Available online: https://new.siemens.com/global/en/products/automation/products-for-specific-requirements/siplus-cms.html (accessed on 5 July 2021).

- Tavner, P. Offshore Wind Power, Reliability, Availability and Maintenance; IET: London, UK, 2021; ISBN 9781849192293. [Google Scholar]

- Jin, X.; Xu, Z.; Qiao, W. Condition monitoring of wind turbine generators using SCADA data analysis. IEEE Trans. Sust. Energy 2020, 12, 202–210. [Google Scholar] [CrossRef]

- Amirat, Y.; Benbouzid, M.E.; Bensaker, B.; Wamkeue, R. Condition Monitoring and Fault Diagnosis in Wind Energy Conversion Systems: A review. In Proceedings of the IEEE International Electric Machines & Drives Conference (IEMDC’07), Antalya, Turkey, 3–5 May 2007; ISBN 1-4244-0742-7. [Google Scholar]

- Tavner, P.; Ran, L.; Penman, J.; Sedding, H. Condition Monitoring of Rotating Electrical Machines; IET: London, UK, 2008. [Google Scholar]

- The Standard ISO 10816-1. Mechanical Vibration. Evaluation of Mechanical Vibration by Measurements on Non-Rotating Parts—Part 1: General Guidelines. Available online: https://www.iso.org/standard/18866.html (accessed on 5 July 2021).

- Liton, H.M.; Abu-Siada, A.; Muyeen, S.M. Methods for advanced wind turbine condition monitoring and early diagnosis: A literature review. Energies 2018, 11, 1309. [Google Scholar] [CrossRef] [Green Version]

- Qiao, W.; Lu, D. A survey on wind turbine condition monitoring and fault diagnosis—Part ii: Signals and signal processing methods. IEEE Trans. Ind. Elec. 2015, 62, 6546–6557. [Google Scholar] [CrossRef]

- Amirat, Y.; Benbouzid, M.E.H.; Al-Ahmar, E.; Bensaker, B.; Turri, S. A brief status on condition monitoring and fault diagnosis in wind energy conversion systems. Renew. Sustain. Energy Rev. 2009, 13, 2629–2636. [Google Scholar] [CrossRef] [Green Version]

- Hatch, C. Improved wind turbine condition monitoring using acceleration enveloping. Orbit 2014, 61, 58–61. [Google Scholar]

- Huang, Q.; Jiang, D.; Hong, L.; Ding, Y. Application of Wavelet Neural Networks on Vibration Fault Diagnosis for Wind Turbine Gearbox. In International Symposium on Neural Networks; Springer: Berlin/Heidelberg, 2008; ISBN 978-3-540-87733-2. [Google Scholar]

- Sarma, N.; Li, Q.; Djurovic, S.; Smith, A.C.; Rowland, S.M. Analysis of a Wound Rotor Induction Machine Low Frequency Vibroacoustic Emissions under Stator Winding Fault Conditions. In Proceedings of the 8th IET International Conference on Power Electronics, Machines and Drives (PEMD), Glasgow, UK, 19–21 April 2016; ISBN 978-1-78561-188-9. [Google Scholar]

- Tchakoua, P.; Wamk, R.; Ouhrouche, M.; Slaoui-Hasnaoui, F.; Tameghe, T.A.; Ekemb, G. Wind turbine condition monitoring: State-of-the-art review, new trends, and future challenges. Energies 2014, 7, 2595–2630. [Google Scholar] [CrossRef] [Green Version]

- Escaler, X.; Mebarki, T. Full-ScaleWind Turbine Vibration Signature Analysis. Machines 2018, 6, 63. [Google Scholar] [CrossRef] [Green Version]

- Djurović, S.; Vilchis-Rodriguez, D.; Smith, A.C. Vibration Monitoring for Wound rotor Induction Machine Winding Fault Detection. In Proceedings of the 20th International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; ISBN 978-1-4673-0143-5. [Google Scholar]

- Spinato, F.; Tavner, P.; Van Bussel, G.J.W.; Koutoulakos, E. Reliability of wind turbine subassemblies. IET Renew. Power Gener. 2009, 3, 387–401. [Google Scholar] [CrossRef] [Green Version]

- Daneshi-Far, Z.; Capolino, G.A.; Henao, H. Review of Failures and Condition Monitoring in Wind Turbine Generators. In Proceedings of the 19th International Conference on Electrical Machines (ICEM), Rome, Italy, 6–8 September 2010; ISBN 978-1-4244-4174-7. [Google Scholar]

- Crabtree, C.J.; Zappalá, D.; Tavner, P.J. Survey of Commercially Available Condition Monitoring Systems for Wind Turbines. Technical Report, Durham University School of Engineering and Computing Sciences and the Supergen Wind Energy Technologies Consortium. 2014. Available online: https://dro.dur.ac.uk/12497/ (accessed on 5 July 2021).

- Barrett, M.P.; Stover, J. Understanding Oil Analysis and How It Can Improve the Reliability of Wind Turbine Gearboxes; Gear Technology: Elk Grove Village, IL, USA, 2013. [Google Scholar]

- Sheng, S. Monitoring of wind turbine gearbox condition through oil and wear debris analysis: A full-scale testing perspective. Tribology Transactions 2016, 59, 149–162. [Google Scholar] [CrossRef]

- Sheng, S.; Veers, P. Wind Turbine Drivetrain Condition Monitoring-an Overview. NREL. 2011. Available online: https://www.osti.gov/biblio/1087787 (accessed on 5 July 2021).

- Graf, M. Wind Turbine Gearbox Lubrication: Performance, Selection and Cleanliness. In Wind Turbine Condition Monitoring; Workshop: Broomfield, CO, USA, 2009. [Google Scholar]

- Hamilton, A.; Quail, F. Detailed state of the art review for the different online/inline oil analysis techniques in context of wind turbine gearboxes. J. Tribol. 2011, 133, 044001. [Google Scholar] [CrossRef] [Green Version]

- Walsh, D.P. Oil Analysis 101. Orbit 2005, 25, 50–55. [Google Scholar]

- Zhu, X.; Zhong, C.; Zhe, J. Lubricating oil conditioning sensors for online machine health monitoring–A review. Tribol. Int. 2017, 109, 473–484. [Google Scholar] [CrossRef] [Green Version]

- Lin, L.; Lu, W.; Chu, F. Application of AE Techniques for the Detection of Wind Turbine Using Hilbert-Huang Transform. In Proceedings of the Prognostics and Health Management Conference, Macao, China, 12–14 January 2010; ISBN 978-1-4244-4756-5. [Google Scholar]

- Ferrando Chacon, J.; Artigao Andicoberry, E.; Kappatos, V. Shaft angular misalignment detection using acoustic emission. Appl. Acoust. 2014, 85, 12–22. [Google Scholar] [CrossRef]

- Soua, S.; Lieshout, P.V.; Perera, A.; Gan, T.H.; Bridge, B. Determination of the combined vibrational and acoustic emission signature of a wind turbine gearbox and generator shaft in service as a pre-requisite for effective condition monitoring. Renew. Energy 2013, 51, 175–181. [Google Scholar] [CrossRef] [Green Version]

- Chacon, J.L.F.; Andicoberry, E.A.; Kappatos, V.; Papaelias, M.; Selcuk, C.; Gan, T.H. An experimental study on the applicability of acoustic emission for wind turbine gearbox health diagnosis. J. Low Freq. Noise Vib. Act. Control 2016, 35, 64–76. [Google Scholar] [CrossRef]

- IEEE Std 1310–2012, IEEE Recommended Practice for Thermal Cycle Testing of Form-Wound Stator Bars and Coils for Large Rotating Machines. Available online: https://standards.ieee.org/standard/1310-2012.html (accessed on 5 July 2021).

- IEEE Guide for Temperature Monitoring of Cable Systems, IEEE 1718–2012. Available online: https://standards.ieee.org/standard/1718-2012.html (accessed on 5 July 2021).

- Hitchcock, L. ISO Standards for Condition Monitoring; Engineering Asset Management; Springer: London, UK, 2006; ISBN 978-1-84628-814-2. [Google Scholar]

- Zhang, P.; Chen, Z. Non-Invasive Condition Monitoring and Diagnostics Techniques for Wind Turbines. In Proceedings of the IEEE 8th International Power Electronics and Motion Control Conference (IPEMC-ECCE Asia), Hefei, China, 22–26 May 2016; ISBN 978-1-5090-1211-4. [Google Scholar]

- Zappalá, D.; Sarma, N.; Djurović, S.; Crabtree, C.J.; Mohammad, A.; Tavner, P.J. Electrical & mechanical diagnostic indicators of wind turbine induction generator rotor faults. Renew. Energy 2019, 131, 14–24. [Google Scholar] [CrossRef]

- Sarma, N.; Tuohy, P.M.; Djurović, S. Stator electrical fault detection in dfigs using wide-band analysis of the embedded signals from the controllers. IEEE Trans. Energy Conv. 2021, 36, 800–811. [Google Scholar] [CrossRef]

- Sarma, N.; Tuohy, P.M.; Mohammed, A.; Djurović, S. Rotor electrical fault detection in dfigs using wide-band controller signals. IEEE Trans. Sust. Energy 2021, 12, 623–633. [Google Scholar] [CrossRef]

- Lu, D.; Qiao, W.; Gong, X. Current-based gear fault detection for wind turbine gearboxes. IEEE Trans. Sust. Energy 2017, 8, 1453–1462. [Google Scholar] [CrossRef]

- Gong, X.; Qiao, W. Bearing fault diagnosis for direct-drive wind turbines via current-demodulated signals. IEEE Trans. Ind. Elec. 2013, 60, 3419–3428. [Google Scholar] [CrossRef] [Green Version]

- Artigao, E.; Koukoura, S.; Honrubia-Escribano, A.; Carroll, J.; McDonald, A.; Gómez-Lázaro, E. Current signature and vibration analyses to diagnose an in-service wind turbine drive train. Energies 2018, 11, 960. [Google Scholar] [CrossRef] [Green Version]

- Crabtree, C.J.; Djurović, S.; Tavner, P.J.; Smith, A.C. Fault Frequency Tracking during Transient Operation of Wind Turbine Generators. In Proceedings of the XIX International Conference on Electrical Machines (ICEM), Rome, Italy, 6–8 September 2010; ISBN 978-1-4244-4174-7. [Google Scholar]

- Lu, B.; Li, Y.; Wu, X.; Yang, Z. A review of recent advances in wind turbine condition monitoring and fault diagnosis. In Proceedings of the IEEE Power Electronics and Machines in Wind Applications, Lincoln, NE, USA, 24–26 June 2009. [Google Scholar]

- Djurović, S.; Vilchis-Rodriguez, D.; Smith, A.C. Investigation of wound rotor induction machine vibration signal under stator electrical fault conditions. J. Eng. 2014, 5, 248–258. [Google Scholar] [CrossRef]

- Maldonado-Correa, J.; Martín-Martínez, S.; Artigao, E.; Gómez-Lázaro, E. Using SCADA data for wind turbine condition monitoring: A systematic literature review. Energies 2020, 13, 3132. [Google Scholar] [CrossRef]

- Tautz-Weinert, J.; Watson, S.J. Using SCADA data for wind turbine condition monitoring—A review. IET Renew. Power Gener. 2017, 11, 382–394. [Google Scholar] [CrossRef] [Green Version]

- Qiu, Y.; Feng, Y.; Tavner, P.; Richardson, P.; Erdos, G.; Chen, B. Wind turbine SCADA alarm analysis for improving reliability. Wind Energy 2012, 15, 951–966. [Google Scholar] [CrossRef]

- Ren, Z.; Verma, A.S.; Li, Y. Offshore wind turbine operations and maintenance: A state-of-the-art review. Renew. Sustain. Energy Rev. 2021, 144, 110886. [Google Scholar] [CrossRef]

- Hellier, C. Handbook of Nondestructive Evaluation; McGraw-Hill Professional Publishing: New York, NY, USA, 2003; ISBN 9780071777148. [Google Scholar]

- Márquez, F.P.G.; Tobias, A.M.; Pérez, J.M.P.; Papaelias, M. Condition monitoring of wind turbines: Techniques and methods. Renew. Energy 2012, 46, 169–178. [Google Scholar] [CrossRef]

- Yang, W. Condition Monitoring of Offshore Wind Turbines; Woodhead Publishing: Sawston, UK, 2016; pp. 543–572. ISBN 9780081007792. [Google Scholar]

- Yang, R.; Kang, J.; Zhao, J.; Li, J.; Li, H. A Case Study of Bearing Condition Monitoring Using SPM. In Proceedings of the Prognostics and System Health Management Conference (PHM-2014 Hunan), Zhangjiajie, China, 24–27 August 2014; ISBN 978-1-4799-7957-8. [Google Scholar]

- Yang, R.; Kang, J. Bearing fault detection of wind turbine using vibration and SPM. Vibroeng. Procedia 2016, 10, 173–178. [Google Scholar]

- Tandon, Z.; Yadava, G.S.; Ramakrishna, K.M. A comparison of some condition monitoring techniques for the detection of defect in induction motor ball bearings. Mech. Syst. Signal Process. 2007, 21, 244–256. [Google Scholar] [CrossRef]

- Bogue, R. Sensors for condition monitoring: A review of technologies and applications. Sensor Review 2013, 33, 295–299. [Google Scholar] [CrossRef]

- Evans, M.; Richardson, A.; Wang, L.; Wood, R.J.K. Serial sectioning investigation of butterfly and white etching crack (WEC) formation in wind turbine gearbox bearings. Wear 2013, 302, 1573–1582. [Google Scholar] [CrossRef]

- Gould, B.; Greco, A.; Stadler, K.; Xiao, X. An analysis of premature cracking associated with microstructural alterations in an AISI 52100 failed wind turbine bearing using X-ray tomography. Mater. Des. 2017, 117, 417–429. [Google Scholar] [CrossRef] [Green Version]

- Glavind, L.; Olesen, I.S.; Skipper, B.F.; Kristensen, M.V. Fiber-optical grating sensors for wind turbine blades. Opt. Eng. 2013, 52, 030901. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Mohammed, A.; Sarma, N.; Djurović, S. Double fed induction generator shaft misalignment monitoring by FBG frame strain sensing. IEEE Sens. J. 2020, 20, 8541–8551. [Google Scholar] [CrossRef]

- Bang, H.J.; Kim, H.I.; Lee, K.S. Measurement of strain and bending deflection of a wind turbine tower using arrayed FBG sensors. Int. J. Precis. Eng. Manuf. 2012, 13, 2121–2126. [Google Scholar] [CrossRef]

- Mohammed, A.; Djurovic, S. In-Situ Thermal and Mechanical Fibre Optic Sensing for In-Service Electric Machinery Bearing Condition Monitoring. In Proceedings of the IEEE International Electric Machines & Drives Conference (IEMDC), San Diego, CA, USA, 12–15 May 2019; ISBN 978-1-5386-9351-3. [Google Scholar]

- Mohammed, A.; Hu, B.; Hu, Z.; Djurović, S.; Ran, L.; Barnes, M.; Mawby, P.A. Distributed thermal monitoring of wind turbine power electronic modules using FBG sensing technology. IEEE Sens. J. 2020, 20, 9886–9894. [Google Scholar] [CrossRef]

- Mohammed, A.; Melecio, J.I.; Djurović, S. Open-circuit fault detection in stranded PMSM windings using embedded FBG thermal sensors. IEEE Sens. J. 2019, 19, 3358–3367. [Google Scholar] [CrossRef]

- Mohammed, A.; Melecio, J.I.; Djurović, S. Electrical machine permanent magnets health monitoring and diagnosis using an air-gap magnetic sensor. IEEE Sens. J. 2020, 20, 5251–5259. [Google Scholar] [CrossRef]

- Marignetti, F.; Santis, E.D.; Avino, S.; Tomassi, G.; Giorgini, A.; Malara, P.; De Natale, P.; Gagliardi, G. Fiber Bragg grating sensor for electric field measure-ment in the end windings of high-voltage electric machines. IEEE Trans. Ind. Elec. 2016, 63, 2796–2802. [Google Scholar] [CrossRef]

- Fabian, M.; Ams, M.; Gerada, C.; Sun, T.; Grattan, K.T.V. Vibration Measurement of Electrical Machines Using Integrated Fibre Bragg Gratings. In Proceedings of the 24th International Conference on Optical Fibre Sensors, Curitiba, Brazil, 28 September 2015. [Google Scholar]

- Leiteet, R.C.; Dmitriev, V.; Hudon, C.; Gingras, S.; Guddemi, C.; Piccard, J.; Mydlarsky, L. Analysis of thermo-mechanical stress in fiber Bragg grating used for generator rotor temperature monitoring. J. Microw. Optoelectron. Electromagn. Appl. 2017, 16, 445–459. [Google Scholar] [CrossRef] [Green Version]

- Sousa, K.D.M.; Hafiner, A.A.; da Silva, J.C.C. Determination oftemperature dynamics and mechanical and stator losses relationships ina three-phase induction motor using fiber Bragg grating sensors. IEEE Sens. J. 2012, 12, 3054–3061. [Google Scholar] [CrossRef]

- Vilchis-Rodriguez, D.S.; Djurović, S.; Kung, P.; Comanici, M.I.; Smith, A.C. Investigation of Induction Generator Wide Band Vibration Monitoring Using Fibre Bragg Grating Accelerometers. In Proceedings of the International Conference on Electrical Machines (ICEM), Berlin, Germany, 2–5 September 2014; ISBN 978-1-4799-4389-0. [Google Scholar]

- Méndez, A. Fiber Bragg Grating Sensors: A Market Overview. In Proceedings of the Third European Workshop on Optical Fibre Sensors, Napoli, Italy, 2 July 2007. [Google Scholar]

- Kong, Y.; Wang, T.; Feng, Z.; Chu, F. Discriminative dictionary learning based sparse representation classification for intel-ligent fault identification of planet bearings in wind turbine. Renew. Energy 2020, 152, 754–769. [Google Scholar] [CrossRef]

- Chen, P.; Li, Y.; Wang, K.; Zuo, M.J.; Heyns, P.S.; Baggeröhr, S. A threshold self-setting condition monitoring scheme for wind turbine generator bearings based on deep convolutional generative adversarial networks. Meas. J. Int. Meas. Confed. 2020, 167, 108234. [Google Scholar] [CrossRef]

- Zhang, X.; Han, P.; Xu, L.; Zhang, F.; Wang, Y.; Gao, L. Research on Bearing Fault Diagnosis of Wind Turbine Gearbox Based on 1DCNN-PSO-SVM. IEEE Access 2020, 8, 192248–192258. [Google Scholar] [CrossRef]

- Chen, B.; Xie, L.; Li, Y.; Gao, B. Acoustical damage detection of wind turbine yaw system using Bayesian network. Renew. Energy 2020, 160, 1364–1372. [Google Scholar] [CrossRef]

- Inturi, V.; Shreyas, N.; Chetti, K.; Sabareesh, G.R. Comprehensive fault diagnostics of wind turbine gearbox through adaptive condition monitoring scheme. Appl. Acoust. 2021, 174, 107738. [Google Scholar] [CrossRef]

- Chang, Y.; Chen, J.; Qu, C.; Pan, T. Intelligent fault diagnosis of Wind Turbines via a Deep Learning Network Using Parallel Convolution Layers with Multi-Scale Kernels. Renew. Energy 2020, 153, 205–213. [Google Scholar] [CrossRef]

- Pang, Y.; He, Q.; Jiang, G.; Xie, P. Spatio-temporal fusion neural network for multi-class fault diagnosis of wind turbines based on SCADA data. Renew. Energy 2020, 161, 510–524. [Google Scholar] [CrossRef]

- Kreutz, M.; Alla, A.A.; Eisenstadt, A.; Freitag, M.; Thoben, K.D. Ice detection on rotor blades of wind turbines using RGB images and convolutional neural networks. Procedia CIRP 2020, 93, 1292–1297. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y.; Lv, W.; Wang, D. Image recognition of wind turbine blade damage based on a deep learning model with transfer learning and an ensemble learning classifier. Renew. Energy 2021, 163, 386–397. [Google Scholar] [CrossRef]

- Lu, L.; He, Y.; Ruan, Y.; Yuan, W. Wind Turbine Planetary Gearbox Condition Monitoring Method Based on Wireless Sensor and Deep Learning Approach. IEEE Trans. Instrum. Meas. 2021, 70. [Google Scholar] [CrossRef]

- Lu, L.; He, Y.; Wang, T.; Shi, T.; Li, B. Self-Powered Wireless Sensor for Fault Diagnosis of Wind Turbine Planetary Gearbox. IEEE Access 2019, 7, 87382–87395. [Google Scholar] [CrossRef]

- Lu, L.; He, Y.; Wang, T.; Shi, T.; Ruan, Y. Wind Turbine Planetary Gearbox Fault Diagnosis Based on Self-Powered Wireless Sensor and Deep Learning Approach. IEEE Access 2019, 7, 119430–119442. [Google Scholar] [CrossRef]

- García Márquez, F.P.; Peco Chacón, A.M. A review of non-destructive testing on wind turbines blades. Renew. Energy 2020, 161, 998–1010. [Google Scholar] [CrossRef]

- Yi, H.; Jiang, Q.; Yan, X.; Wang, B. Imbalanced Classification Based on Minority Clustering SMOTE with Wind Turbine Fault Detection Application. IEEE Trans. Ind. Inform. 2020, 3203, 5867–5875. [Google Scholar] [CrossRef]

- Saufi, S.R.; Ahmad, Z.A.B.; Leong, M.S.; Lim, M.H. Gearbox Fault Diagnosis Using a Deep Learning Model with Limited Data Sample. IEEE Trans. Ind. Inform. 2020, 16, 6263–6271. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, Z. Wind Turbine Gearbox Failure Detection Based on SCADA Data: A Deep Learning-Based Approach. IEEE Trans. Instrum. Meas. 2021, 70. [Google Scholar] [CrossRef]

- Hu, W.; Chang, H.; Gu, X. A novel fault diagnosis technique for wind turbine gearbox. Appl. Soft Comput. J. 2019, 82, 105556. [Google Scholar] [CrossRef]

- Zhong, J.H.; Zhang, J.; Liang, J.; Wang, H. Multi-Fault Rapid Diagnosis for Wind Turbine Gearbox Using Sparse Bayesian Extreme Learning Machine. IEEE Access 2019, 7, 773–781. [Google Scholar] [CrossRef]

- Berghout, T.; Benbouzid, M.; Mouss, L.-H. Leveraging Label Information in a Knowledge-Driven Approach for Roll-ing-Element Bearings Remaining Useful Life Prediction. Energies 2021, 14, 2163. [Google Scholar] [CrossRef]

- Cao, L.; Qian, Z.; Zareipour, H.; Huang, Z.; Zhang, F. Fault diagnosis of wind turbine gearbox based on deep bi-directional long short-term memory under time-varying non-stationary operating conditions. IEEE Access 2019, 7, 155219–155228. [Google Scholar] [CrossRef]

- Cheng, F.; Wang, J.; Qu, L.; Qiao, W. Rotor current-based fault diagnosis for DFIG wind turbine drivetrain gearboxes using frequency analysis and a deep classifier. IEEE Trans. Ind. Appl. 2017, 54, 1062–1071. [Google Scholar] [CrossRef]

- Corley, B.; Koukoura, S.; Carroll, J.; McDonald, A. Combination of Thermal Modelling and Machine Learning Approaches for Fault Detection in Wind Turbine Gearboxes. Energies 2021, 14, 1375. [Google Scholar] [CrossRef]

- Fu, J.; Chu, J.; Guo, P.; Chen, Z. Condition Monitoring of Wind Turbine Gearbox Bearing Based on Deep Learning Model. IEEE Access 2019, 7, 57078–57087. [Google Scholar] [CrossRef]

- Jiang, G.; He, H.; Yan, J.; Xie, P. Multiscale Convolutional Neural Networks for Fault Diagnosis of Wind Turbine Gearbox. IEEE Trans. Ind. Electron. 2019, 66, 3196–3207. [Google Scholar] [CrossRef]

- Pan, Y.; Hong, R.; Chen, J.; Singh, J.; Jia, X. Performance degradation assessment of a wind turbine gearbox based on mul-ti-sensor data fusion. Mech. Mach. Theory 2019, 137, 509–526. [Google Scholar] [CrossRef]

- Ren, H.; Liu, W.; Shan, M.; Wang, X.; Wang, Z. A novel wind turbine health condition monitoring method based on com-posite variational mode entropy and weighted distribution adaptation. Renew. Energy 2021, 168, 972–980. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, B.; Wang, Z.; Zhang, J. An FSK-MBCNN based method for compound fault diagnosis in wind turbine gear-boxes. Meas. J. Int. Meas. Confed. 2021, 172, 108933. [Google Scholar] [CrossRef]

- Li, Z.; Chen, S.; Ma, H.; Feng, T. Design defect of wind turbine operating in typhoon activity zone. Eng. Fail. Anal. 2013, 27, 165–172. [Google Scholar] [CrossRef]

- Reder, M.; Yürüşen, N.Y.; Melero, J.J. Data-driven learning framework for associating weather conditions and wind turbine failures. Reliab. Eng. Syst. Saf. 2018, 169, 554–569. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Liu, H.; Chu, X.; Liu, Q.; Xue, D. Anomaly detection and critical SCADA parameters identification for wind turbines based on LSTM-AE neural network. Renew. Energy 2021, 172, 829–840. [Google Scholar] [CrossRef]

- Dong, X.; Gao, D.; Li, J.; Jincao, Z.; Zheng, K. Blades icing identification model of wind turbines based on SCADA data. Renew. Energy 2020, 162, 575–586. [Google Scholar] [CrossRef]

- Márqueza, F.P.G.; Pinar-Pérezb, J.M. Non-Destructive Testing for the Evaluation of Icing Blades in Wind Turbines; Elsevier Ltd.: Amsterdam, The Netherlands, 2019; ISBN 9780081010945. [Google Scholar]

- Kreutz, M.; Alla, A.A.; Varasteh, K.; Lütjen, M.; Freitag, M.; Thoben, K.-D. Investigation of icing causes on wind turbine rotor blades using machine learning models, minimalistic input data and a full-factorial design. Procedia Manuf. 2020, 52, 168–173. [Google Scholar] [CrossRef]

- Chen, L.; Xu, G.; Zhang, Q.; Zhang, X. Learning deep representation of imbalanced SCADA data for fault detection of wind turbines. Meas. J. Int. Meas. Confed. 2019, 139, 370–379. [Google Scholar] [CrossRef]

- Chen, W.; Qiu, Y.; Feng, Y.; Li, Y.; Kusiak, A. Diagnosis of wind turbine faults with transfer learning algorithms. Renew. Energy 2021, 163, 2053–2067. [Google Scholar] [CrossRef]

- Kreutz, M.; Ait-Alla, A.; Varasteh, K.; Oelker, S.; Greulich, A.; Freitag, M.; Thoben, K.D. Machine learning-based icing prediction on wind turbines. Procedia CIRP 2019, 81, 423–428. [Google Scholar] [CrossRef]

- Joshuva, A.; Sugumaran, V. A lazy learning approach for condition monitoring of wind turbine blade using vibration signals and histogram features. Meas. J. Int. Meas. Confed. 2020, 152, 107295. [Google Scholar] [CrossRef]

- Chandrasekhar, K.; Stevanovic, N.; Cross, E.J.; Dervilis, N.; Worden, K. Damage detection in operational wind turbine blades using a new approach based on machine learning. Renew. Energy 2021, 168, 1249–1264. [Google Scholar] [CrossRef]

- Jiménez, A.A.; García Márquez, F.P.; Moraleda, V.B.; Gómez Muñoz, C.Q. Linear and nonlinear features and machine learning for wind turbine blade ice detection and diagnosis. Renew. Energy 2019, 132, 1034–1048. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; Chen, J.; Xie, J.; Pan, T. SASLN: Signals Augmented Self-Taught Learning Networks for Mechanical Fault Diagnosis under Small Sample Condition. IEEE Trans. Instrum. Meas. 2021, 70. [Google Scholar] [CrossRef]

- Khine, P.; Shun, W. Big Data for Organizations: A Review. J. Comput. Commun 2017, 5, 40–48. [Google Scholar] [CrossRef] [Green Version]

- Gupta, S.; Modgil, S.; Gunasekaran, A. Big data in lean six sigma: A review and further research directions. Int. J. Prod. Res 2019, 58, 947–969. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, X.; Qian, P. Wind Turbine Fault Detection and Identification Through PCA-Based Optimal Variable Selection. IEEE Trans. Sustain. Energy 2018, 9, 1627–1635. [Google Scholar] [CrossRef] [Green Version]

- Dao, P.; Staszewski, W.; Barszcz, T.; Uhl, T. Condition monitoring and fault detection in wind turbines based on cointegration analysis of SCADA data. Renew. Energy 2018, 116, 107–122. [Google Scholar] [CrossRef]

- Manyika, J.; Chui, M.; Brown, B.; Bughin, J.; Dobbs, R.; Roxburgh, C.; Hung Byers, A. Big Data: The Next Frontier for Innovation, Competition, and Productivity; McKinsey Global Institute: Chicago, IL, USA, 2011; ISBN 139780983179696. [Google Scholar]

- Zheng, Y. Methodologies for Cross-Domain Data Fusion: An Overview. IEEE Trans. Big Data 2015, 1, 16–34. [Google Scholar] [CrossRef]

- Fan, J.; Han, F.; Liu, H. Challenges of Big Data analysis. Natl. Sci. 2014, 1, 293–314. [Google Scholar] [CrossRef] [Green Version]

- Swan, M. The Quantified Self: Fundamental Disruption in Big Data Science and Biological Discovery. Big Data 2013, 1, 85–99. [Google Scholar] [CrossRef]

- Parker, C. Unexpected Challenges in Large Scale Machine Learning. In Proceedings of the 1st International Workshop on Big Data, Streams and Heterogeneous Source Mining: Algorithms, Systems, Programming Models and Applications, Beijing, China, 12 August 2012; pp. 1–6. [Google Scholar] [CrossRef]

- Gandomi, A.; Haider, M. Beyond the hype: Big data concepts, methods, and analytics. Int. J. Inf. Manag. 2015, 35, 137–144. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Crawl, D.; Purawat, S.; Nguyen, M.; Altintas, I. Big Data Provenance: Challenges, State of the Art and Opportunities. In Proceedings of the 2015 IEEE International Conference on Big Data (Big Data), Santa Clara, CA, USA, 1 October 2015; pp. 2509–2516. [Google Scholar] [CrossRef]

- Pecht, M. Product Reliability, Maintainability, and Supportability Handbook; CRC Press: Boca Raton, FL, USA, 1995; ISBN 9780849398797. [Google Scholar]

- Scarf, P. A Framework for Condition Monitoring and Condition Based Maintenance. Qual. Technol. Quant. Manag. 2007, 4, 301–312. [Google Scholar] [CrossRef]

- Perišić, N.; Kirkegaard, P.; Pedersen, B. Cost-effective shaft torque observer for condition monitoring of wind turbines. Wind Energy 2013, 1, 263–271. [Google Scholar] [CrossRef]

- Xu, X.; Lei, Y.; Li, Z. An Incorrect Data Detection Method for Big Data Cleaning of Machinery Condition Monitoring. IEEE Trans. Ind. Electron. 2020, 67, 2326–2336. [Google Scholar] [CrossRef]

- Liang, G.; Su, Y.; Chen, F.; Long, H.; Song, Z.; Gan, Y. Wind Power Curve Data Cleaning by Image Thresholding Based on Class Uncertainty and Shape Dissimilarity. IEEE Trans. Sustain. Energy 2021, 12, 1383–1393. [Google Scholar] [CrossRef]

- Zhang, W.; Ma, X. Simultaneous Fault Detection and Sensor Selection for Condition Monitoring of Wind Turbines. Energies 2016, 9, 280. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.; Yan, C.; Wen, J. Intelligent Bearing Fault Diagnosis Method Combining Compressed Data Acquisition and Deep Learning. IEEE Trans. Instrum. Meas. 2018, 67, 185–195. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, H.; Zhang, H.; Duan, W.; Liang, T.; Wu, S. Rolling bearing fault feature learning using improved convolutional deep belief network with compressed sensing. Mech. Syst. Signal Process. 2018, 100, 743–765. [Google Scholar] [CrossRef]

- L’Heureux, A.; Grolinger, K.; Elyamany, H.; Capretz, M. Machine Learning with Big Data: Challenges and Approaches. IEEE Access 2017, 5, 7776–7797. [Google Scholar] [CrossRef]

- Gu, B.; Sheng, V.S.; Wang, Z.; Ho, D.; Osman, S.; Li, S. Incremental learning for ν-support vector regression. Neural Netw. 2015, 67, 140–150. [Google Scholar] [CrossRef]

- Qian, P.; Zhang, D.; Tian, X.; Si, Y.; Li, L. A novel wind turbine condition monitoring method based on cloud computing. Renew. Energy 2019, 135, 390–398. [Google Scholar] [CrossRef]

- Ben-Daya, M.; Duffuaa, S.O.; Raouf, A.; Knezevic, J.; Ait-Kadi, D. (Eds.) Handbook of Maintenance Management and Engineering; Springer: London, UK, 2009; ISBN 9781848824720. [Google Scholar]

- Lee, J.; Ni, J.; Djurdjanovic, D.; Qiu, H.; Liao, H. Intelligent prognostics tools and e-maintenance. Comput. Ind. 2006, 57, 476–489. [Google Scholar] [CrossRef]

- Kang, J.; Soares, C.G. An opportunistic maintenance policy for offshore wind farms. Ocean Eng. 2020, 216, 108075. [Google Scholar] [CrossRef]

- Shafiee, M.; Finkelstein, M.; Bérenguer, C. An opportunistic condition-based maintenance policy for offshore wind turbine blades subjected to degradation and environmental shocks. Reliab. Eng. Syst. Saf. 2015, 142, 463–471. [Google Scholar] [CrossRef]

- Kang, J.; Sobral, J.; Soares, C.G. Review of condition-based maintenance strategies for offshore wind energy. J. Mar. Sci. Appl. 2019, 18, 1–16. [Google Scholar] [CrossRef]

- Campbell, J.D.; Jardine, A.K. Maintenance Excellence: Optimizing Equipment Life-Cycle Decisions; CRC Press: Boca Raton, FL, USA, 2001; ISBN 9780849303005. [Google Scholar]

- Pedregal, D.; García, F.; Roberts, C. An algorithmic approach for maintenance management based on advanced state space systems and harmonic regressions. Ann. Oper. Res. 2008, 166, 109–124. [Google Scholar] [CrossRef]

- Sahal, R.; Breslin, J.; Ali, M. Big data and stream processing platforms for Industry 4.0 requirements mapping for a predictive maintenance use case. J. Manuf. Syst. 2020, 54, 138–151. [Google Scholar] [CrossRef]

- Yang, W.; Court, R.; Jiang, J. Wind turbine condition monitoring by the approach of SCADA data analysis. Renew. Energy 2013, 53, 365–376. [Google Scholar] [CrossRef]

- Dahane, M.; Sahnoun, M.; Bettayeb, B.; Baudry, D.; Boudhar, H. Impact of spare parts remanufacturing on the operation and maintenance performance of offshore wind turbines: A multi-agent approach. J. Intell. Manuf. 2015, 28, 1531–1549. [Google Scholar] [CrossRef]

- Heinermann, J.; Kramer, O. Machine learning ensembles for wind power prediction. Renew. Energy 2016, 89, 671–679. [Google Scholar] [CrossRef]

- Van Bussel, G.J.; Henderson, A.R.; Morgan, C.A.; Smith, B.; Barthelmie, R.; Argyriadis, K.; Arena, A.; Niklasson, G.; Peltola, E. State of the Art and Technology Trends for Offshore wind Energy: Operation and Maintenance Issues. In Proceedings of the Offshore Wind Energy EWEA Special Topic Conference, Brussels, Belgium, 10 December 2001. [Google Scholar]

- Ahmad, R.; Kamaruddin, S. An overview of time-based and condition-based maintenance in industrial application. Comput. Ind. Eng. 2012, 63, 135–149. [Google Scholar] [CrossRef]

- Kang, J.; Wang, Z.; Soares, C.G. Condition-based maintenance for offshore wind turbines based on support vector machine. Energies 2020, 13, 3518. [Google Scholar] [CrossRef]

- Ghamlouch, H.; Fouladirad, M.; Grall, A. The use of real option in condition-based maintenance scheduling for wind turbines with production and deterioration uncertainties. Reliab. Eng. Syst. Saf. 2019, 188, 614–623. [Google Scholar] [CrossRef]

- Cheng, F.; Qu, L.; Qiao, W. Fault Prognosis and Remaining Useful Life Prediction of Wind Turbine Gearboxes Using Current Signal Analysis. IEEE Trans. Sustain. Energy 2018, 9, 157–167. [Google Scholar] [CrossRef]

- Lei, X.; Sandborn, P. Maintenance scheduling based on remaining useful life predictions for wind farms managed using power purchase agreements. Renew. Energy 2018, 116, 188–198. [Google Scholar] [CrossRef]

- Zhang, C.; Tee, K. Application of gamma process and maintenance cost for fatigue damage of wind turbine blade. Energy Procedia 2019, 158, 3729–3734. [Google Scholar] [CrossRef]

- Zhu, X.; Chen, Z.; Borgonovo, E. Remaining-useful-lifetime and system-remaining-profit based importance measures for decisions on preventive maintenance. Reliab. Eng. Syst. Saf. 2021, 216, 107951. [Google Scholar] [CrossRef]

- Ismail, A.; Saidi, L.; Sayadi, M.; Benbouzid, M. Gaussian Process Regression Remaining Useful Lifetime Prediction of Thermally Aged Power IGBT, IECON 2019. In Proceedings of the 45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14 October 2019; pp. 6004–6009. [Google Scholar]

- Garcia, M.C.; Sanz-Bobi, M.A.; Del Pico, J. SIMAP: Intelligent System for Predictive Maintenance: Application to the health condition monitoring of a windturbine gearbox. Comput. Ind. 2006, 6, 552–568. [Google Scholar] [CrossRef]

- Zhong, S.; Pantelous, A.A.; Goh, M.; Zhou, J. A reliability-and-cost-based fuzzy approach to optimize preventive maintenance scheduling for offshore wind farms. Mech. Syst. Signal Process. 2019, 124, 643–663. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Miao, J.; Yan, B.; Zhang, Z. Bio-objective long-term maintenance scheduling for wind turbines in multiple wind farms. Renew. Energy 2020, 160, 1136–1147. [Google Scholar] [CrossRef]

- Yürüşen, N.Y.; Rowley, P.N.; Watson, S.J.; Melero, J.J. Automated wind turbine maintenance scheduling. Reliab. Eng. Syst. Saf. 2020, 200, 106965. [Google Scholar] [CrossRef]

- Fan, D.; Ren, Y.; Feng, Q.; Zhu, B.; Liu, Y.; Wang, Z. A hybrid heuristic optimization of maintenance routing and scheduling for offshore wind farms. J. Loss. Prev. Process. Ind. 2019, 62, 103949. [Google Scholar] [CrossRef]

- Hameed, Z.; Vatn, J.; Heggset, J. Challenges in the reliability and maintainability data collection for offshore wind tur-bines. Renew. Energy 2011, 36, 2154–2165. [Google Scholar] [CrossRef]

- Horenbeek, A.V.; Ostaeyen, J.V.; Duflou, J.R.; Pintelon, L. Quantifying the added value of an imperfectly performing condition monitoring system-application to a wind turbine gearbox. Reliab. Eng. Syst. Saf. 2013, 111, 45–57. [Google Scholar] [CrossRef]

| CM Techniques | Monitored Drivetrain Components | Intrusion | Online/Offline | Cost |

|---|---|---|---|---|

| Vibration Monitoring | Main shaft Bearings Generator Gearbox | Invasive | Online | High |

| Oil Debris Analysis | Bearings Gearbox Generator | Invasive | Online/Offline | Medium to High |

| Acoustic Emission | Main shaft Bearings Gearbox Generator | Non-invasive | Online | High |

| Temperature Monitoring | Bearings Gearbox Generator | Invasive | Online | Medium |

| Torque Measurement | Main shaft Bearings Gearbox Generator | Invasive | Online | High |

| Electric Signals | Main shaft Bearings Gearbox Generator | Non-invasive | Online | Low |

| SCADA Signals | Main shaft Gearbox Generator | Non-invasive | Online | Low |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benbouzid, M.; Berghout, T.; Sarma, N.; Djurović, S.; Wu, Y.; Ma, X. Intelligent Condition Monitoring of Wind Power Systems: State of the Art Review. Energies 2021, 14, 5967. https://doi.org/10.3390/en14185967

Benbouzid M, Berghout T, Sarma N, Djurović S, Wu Y, Ma X. Intelligent Condition Monitoring of Wind Power Systems: State of the Art Review. Energies. 2021; 14(18):5967. https://doi.org/10.3390/en14185967

Chicago/Turabian StyleBenbouzid, Mohamed, Tarek Berghout, Nur Sarma, Siniša Djurović, Yueqi Wu, and Xiandong Ma. 2021. "Intelligent Condition Monitoring of Wind Power Systems: State of the Art Review" Energies 14, no. 18: 5967. https://doi.org/10.3390/en14185967

APA StyleBenbouzid, M., Berghout, T., Sarma, N., Djurović, S., Wu, Y., & Ma, X. (2021). Intelligent Condition Monitoring of Wind Power Systems: State of the Art Review. Energies, 14(18), 5967. https://doi.org/10.3390/en14185967