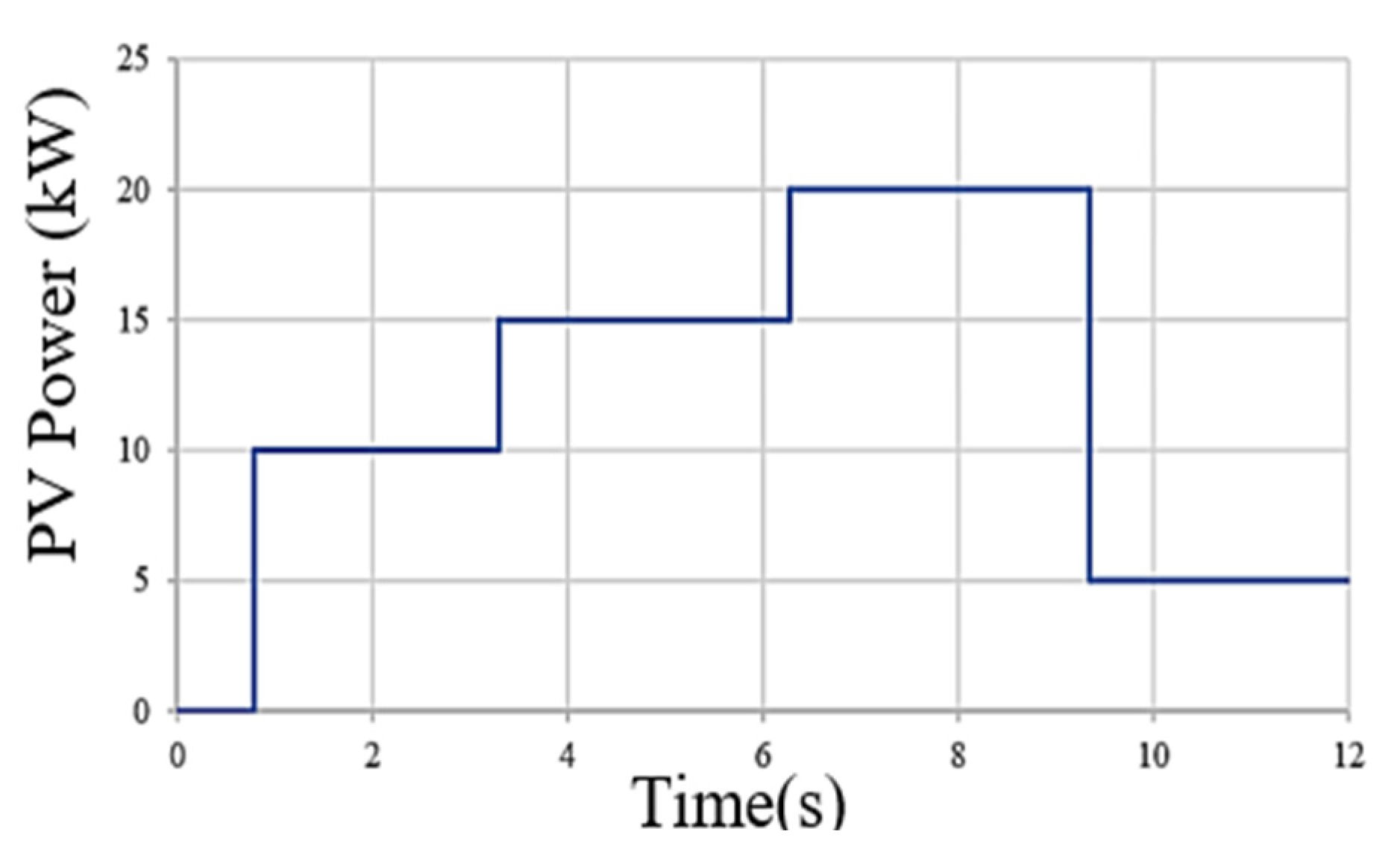

1. Introduction

Electric vehicles (EVs) are more environmentally friendly than the current internal combustion engine (ICE) vehicles, as they have the potential to dramatically reduce greenhouse gases and global warming. The electrification of transport sector promotes sustainable energy development. Even though EVs may not emit CO

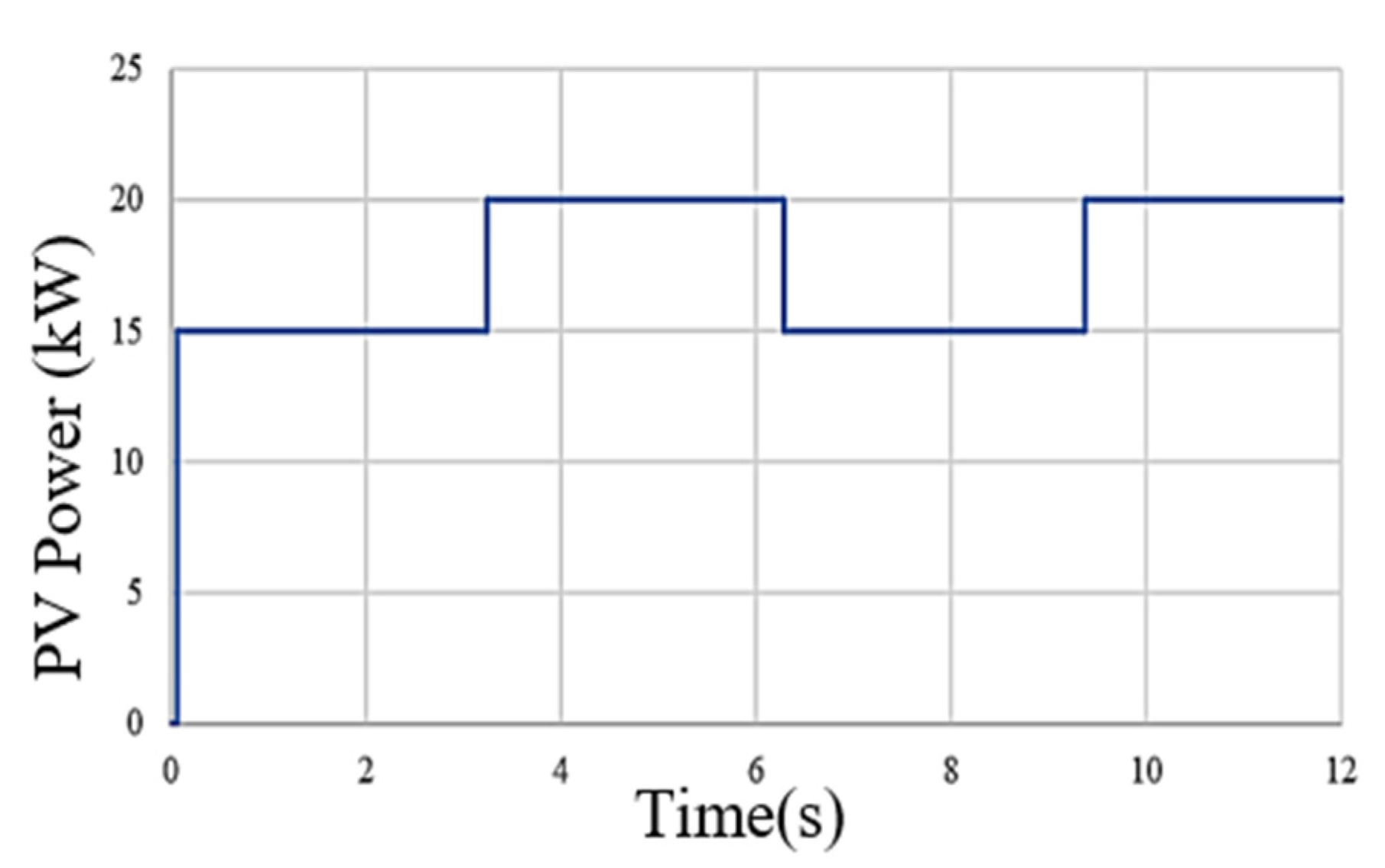

2 or other noxious gases when in use, they create a burden on the grid. Therefore, the coupling between the photovoltaics (PV) and charging stations for EVs is beneficial, as it allows greater usage of both EVs and solar energy without interrupting the grid’s capacity and provides better power quality. The solar-based charging station is primarily applicable on highways and remote locations to successfully charge EVs [

1]. Kumar et al. [

2] proposed a PV-based off-grid charging station in which the solar source is coupled with an energy storage unit (ESU) efficiently for variable irradiance conditions. The system enhances the reliability of the off-grid charging station for EVs. However, they used a non-isolated bidirectional converter with no capability of attaining zero-voltage switching (ZVS) characteristics. This is likely to result in a decrease in the overall efficiency of the charging station. Therefore, in this paper, we present a bidirectional DC–DC converter (BDC) with snubber circuits and demonstrate that a near ZVS across BDC switches is achieved for an off-grid charging station for EVs. This is expected to yield a higher efficiency PV-based charging station for EVs.

Since EVs are operated at low voltage levels, there is a need for an interface between the BDC and the charging station. Isolated BDC offers many advantages over non-isolated BDC: for example, bidirectional energy flow, electrical isolation, high reliability, etc. This BDC will be used for both stepping up and stepping down the voltage. Thus, charging and discharging can be combined in one circuit topology. Moreover, a full-bridge BDC is popular, due to its high power-handling capacity. However, the leakage inductance of the isolation transformer will result in high voltage and current spikes during switching transitions.

Additionally, the freewheeling current increases the conduction losses and reduce the effective duty cycle, due to the effect of leakage inductance. An alternative method is to charge the leakage inductance to the current level of the current-fed inductor, thereby reducing the current difference as well as reducing the voltage and current spikes. However, it is difficult to tune the switching diagram to match these two currents, as the current level varies with the load conditions [

3].

The aforementioned problems can be overcome by using different types of snubber circuits. The snubber circuits provide an alternate path for the circulating current across BDC switches. The snubber is used to control the effect of the reactance of the circuit. It improves the switching circuit’s performance overall. The snubber absorbs the energy from the reactive elements in the circuit. As a result, the stress across the switch is reduced. This automatically increases the converter’s reliability [

4,

5]. Snubbers may be either passive or active networks. Passive snubbers are made of resistors, inductors, capacitors, or diodes, whereas active snubbers use transistors or other types of active switching elements. A conventional passive approach is to employ a resistive capacitive diode (RCD) snubber to clamp the voltage and the resistor limits the capacitor discharge current. The active clamped snubber used for BDC recycles the energy stored in the leakage inductance, thereby improving the converter efficiency. Another type of snubber is a flyback snubber in which the voltage spike across the switches gets clamped by a capacitor-diode circuit and is recovered. This snubber also provides an effective solution to reduce the circulating current across the BDC switches [

6].

The implementation and benefits of snubber based BDCs in EVs were reported in the recent past [

6,

7]. However, there are negligible data on the use of snubber based BDCs for use in off-grid charging stations for EVs. Kumar et al. [

2] described a standalone charging station, but this station does not use any snubber circuit. In the previous study [

3], the beneficial effects of using a flyback snubber were reported. However, a systematic comparison of the performance of the off-grid EVs charging station with various available snubber circuit configurations was not performed. Hence, in this paper, RCD, active clamp, and flyback snubbers for the BDC in terms of the overall performance off-grid charging station for EVs are compared. Such a study was carried out on the BDCs in EVs which operate at low-voltage levels only [

6,

7]. However, there have been no reported results on either off-grid or grid-connected charging stations for EVs. In this paper, the proposed configuration of BDC with snubber circuits effectively reduces the impact of circulating current on the main switches, thereby effectively clamping the voltage spikes across the switches. This leads to an improved performance of the off-grid charging station for EVs. Furthermore, it is cheaper and cost-effective to have just one snubber circuit in the charging station instead of having one in each electric vehicle. Hence, a study of the performance of charging stations for EVs with various snubber circuit configurations is both meaningful and important.

2. Analyses of the Snubbers

The BDC used in [

2] consists of a voltage source as a DC link capacitor and MOSFET switches for step-up and step-down modes. The load source is inductive, as the converter is a voltage source. When the switch’s state changes from turn-off or turn-on, the time lapse for transition can cause an overvoltage condition. Additionally, due to the reverse recovery of the free-wheeling diode, the switches show a current spike at turn-on, leading to high switching losses, especially at turn-off. These problems can be minimized/eliminated with the introduction of snubber circuits.

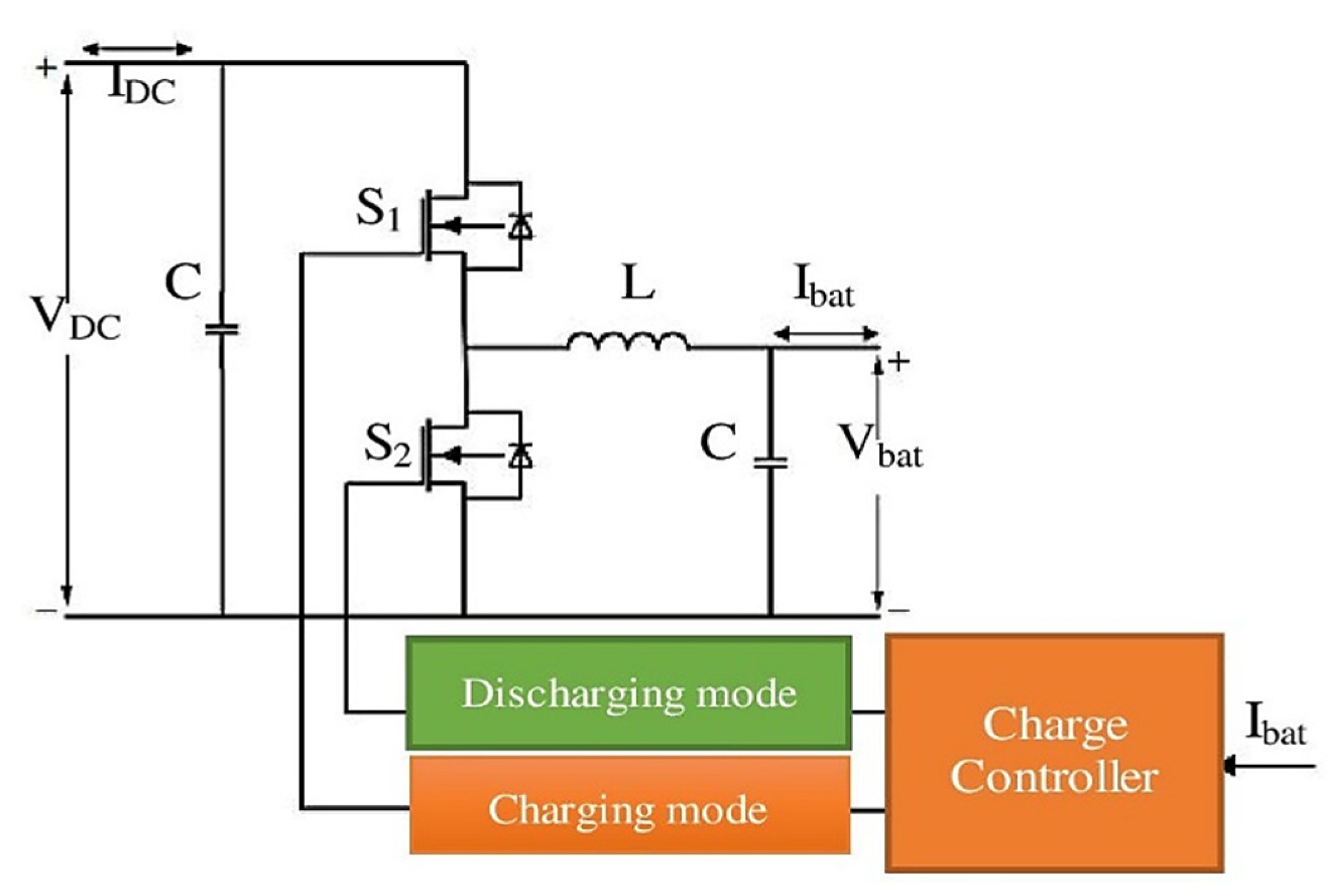

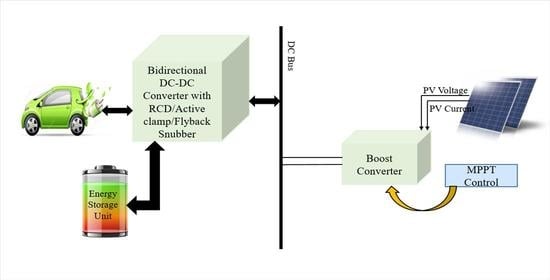

The proposed system [

2] consists of a BDC model, which operates both in charging (buck) and discharging (boost) modes as shown in

Figure 1. In the charging mode, DC-link acts as an input of BDC and the battery acts as a load on the output side. The battery’s voltage level is achieved at the output side when BDC operates in buck mode with component as an inductor (

Lbuck). This value is calculated as follows:

where

ΔiL and

fs are the ripple current switching frequency of the buck mode, respectively.

VDC and

Vbat are input and output voltages of the bidirectional converter, respectively, and D is the converter’s duty ratio.

In the discharging mode, the battery is connected as an input and DC-link connected as the output and the DC-link voltage is more than the battery terminal voltage. The component inductor (

Lboost) in boost mode is calculated as follows:

Since the BDC is operating in both boost and buck modes, the value of

L is chosen as follows:

For comparison, the converters with an RCD passive snubber, an active clamping circuit, and a flyback snubber were simulated.

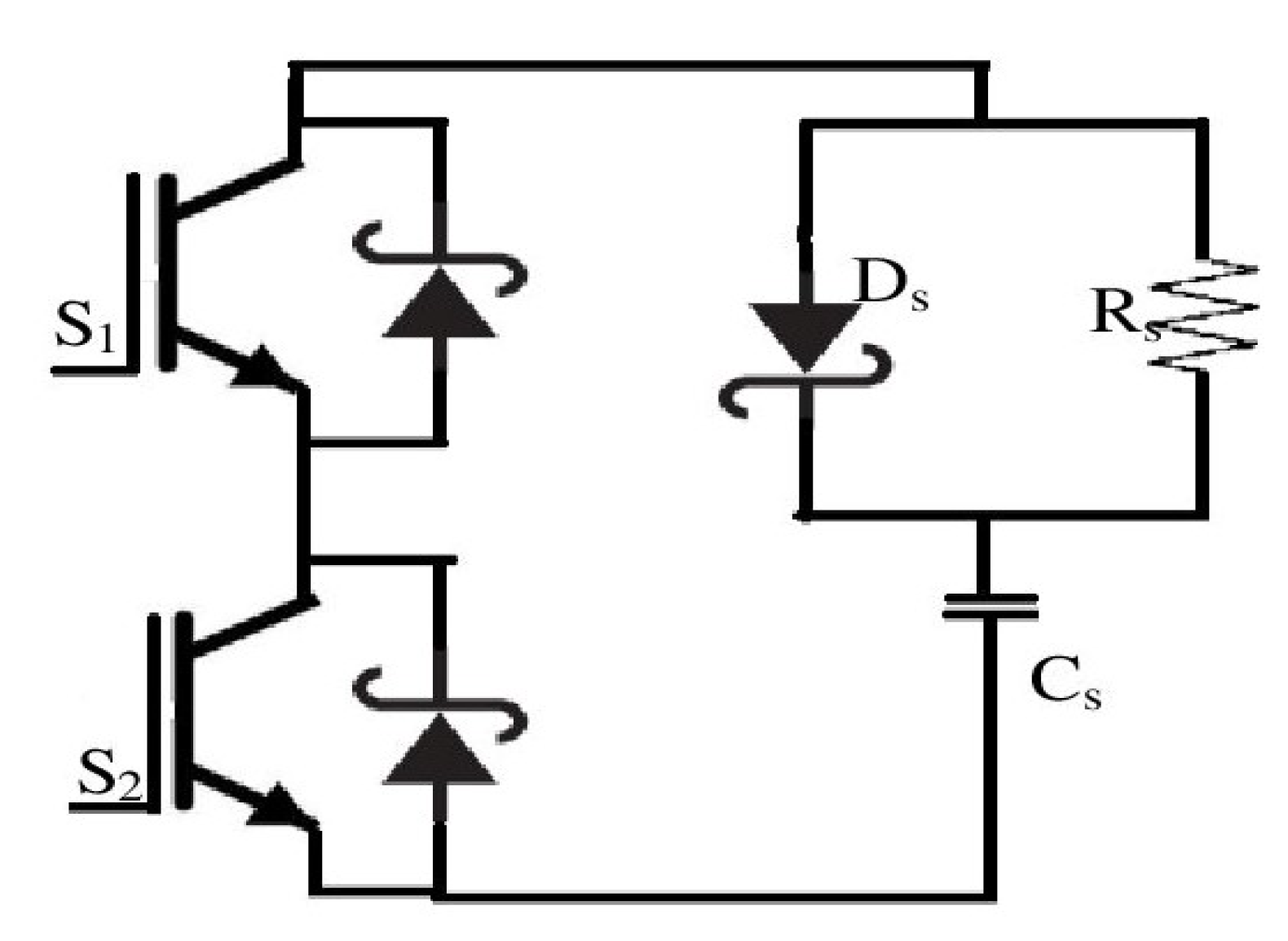

2.1. RCD Snubber

RCD snubber or RCD clamp limits any sharp voltage fluctuations across the switches. The three main components of RCD snubber are resistor

Rs, the capacitance

Cs, and diode

Ds for as shown in

Figure 2. The stored leakage energy is dissipated through the resistor while the capacitor acts as a filter to and guarantees a low ripple DC source. The diode here is nothing but a unidirectional switch. The clamping of the spikes using an RCD snubber requires calculating the resonant circuit’s characteristic impedance, given by the following equation:

If the snubber resistor value is equal to the characteristic impedance, the ringing effect is reduced. Therefore, to select the resistor, the following equation is used:

The snubber capacitor,

Cs, allows the resistor to be most effective at the ringing frequency by reducing the dissipation to a minimum at the switching frequency. The capacitor is designed so that the impedance of the capacitor at the clamping frequency is considered equal to the resistor, as shown in the following equation:

where

fs is the switching frequency of the converter.

The RCD snubber works by absorbing the inductor’s current when the switch’s drain voltage exceeds the clamp capacitor voltage. The relatively large capacitor used in the circuit manages to keep the voltage constant over a switching cycle. By using a larger capacitor value, the peak power will increase while the switching loss will decrease [

8].

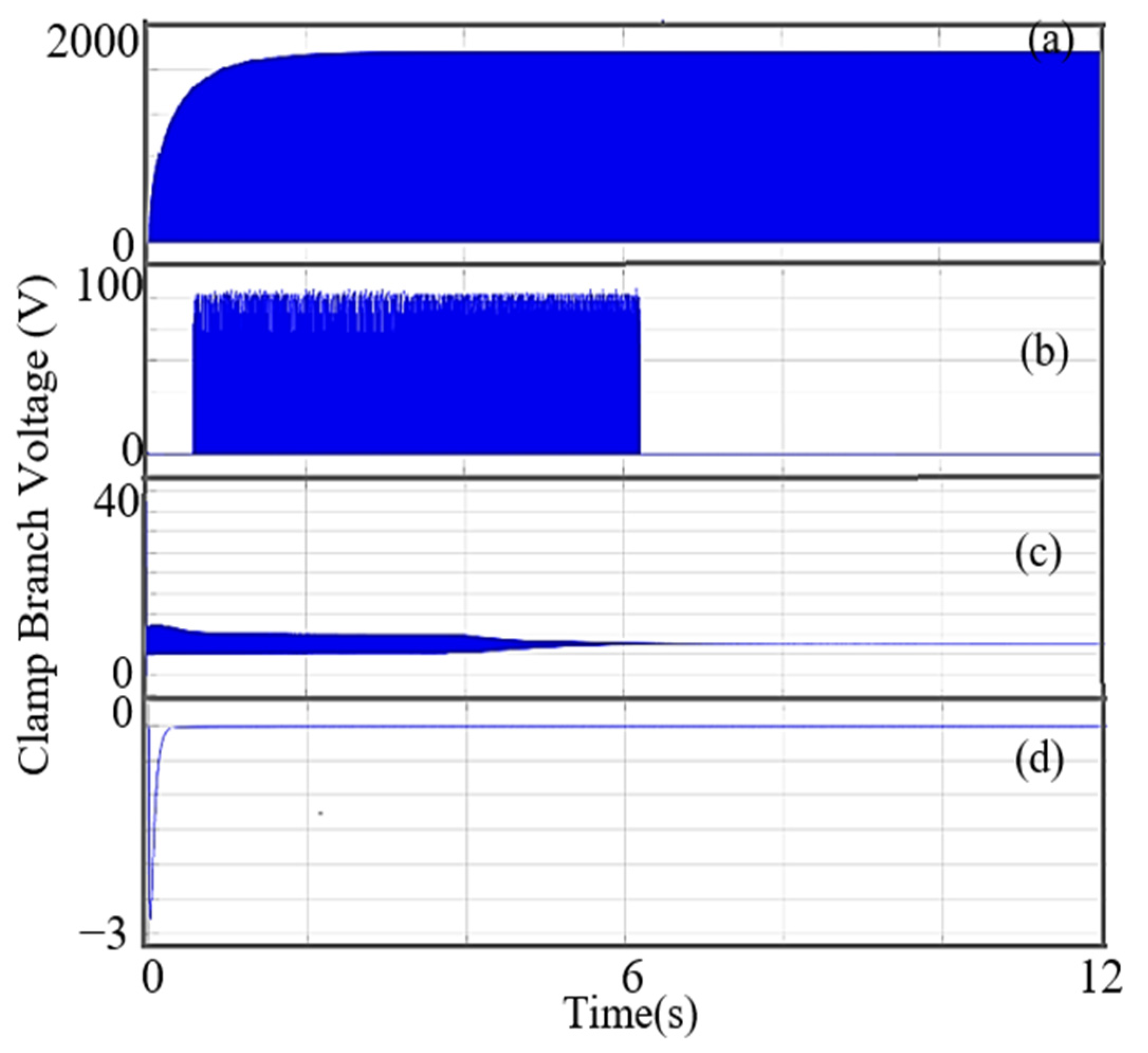

2.2. Active Clamp Snubber

An active clamp for the BDC’s higher power applications is a good choice. It limits the overshoot of the bridge switch’s turn-off voltage, thus enabling the energy stored for ZVS. The output diode’s reverse-recovery problem can partly be overcome by utilizing an appropriate design for the leakage inductance. However, the switches in these converters work under hard switching conditions. The active clamp circuit replaces the role of the passive lossless clamp circuit. The primary and the clamp switches turn ON under the ZVS condition, and the use of parallel capacitors help significantly reduce the turn OFF losses.

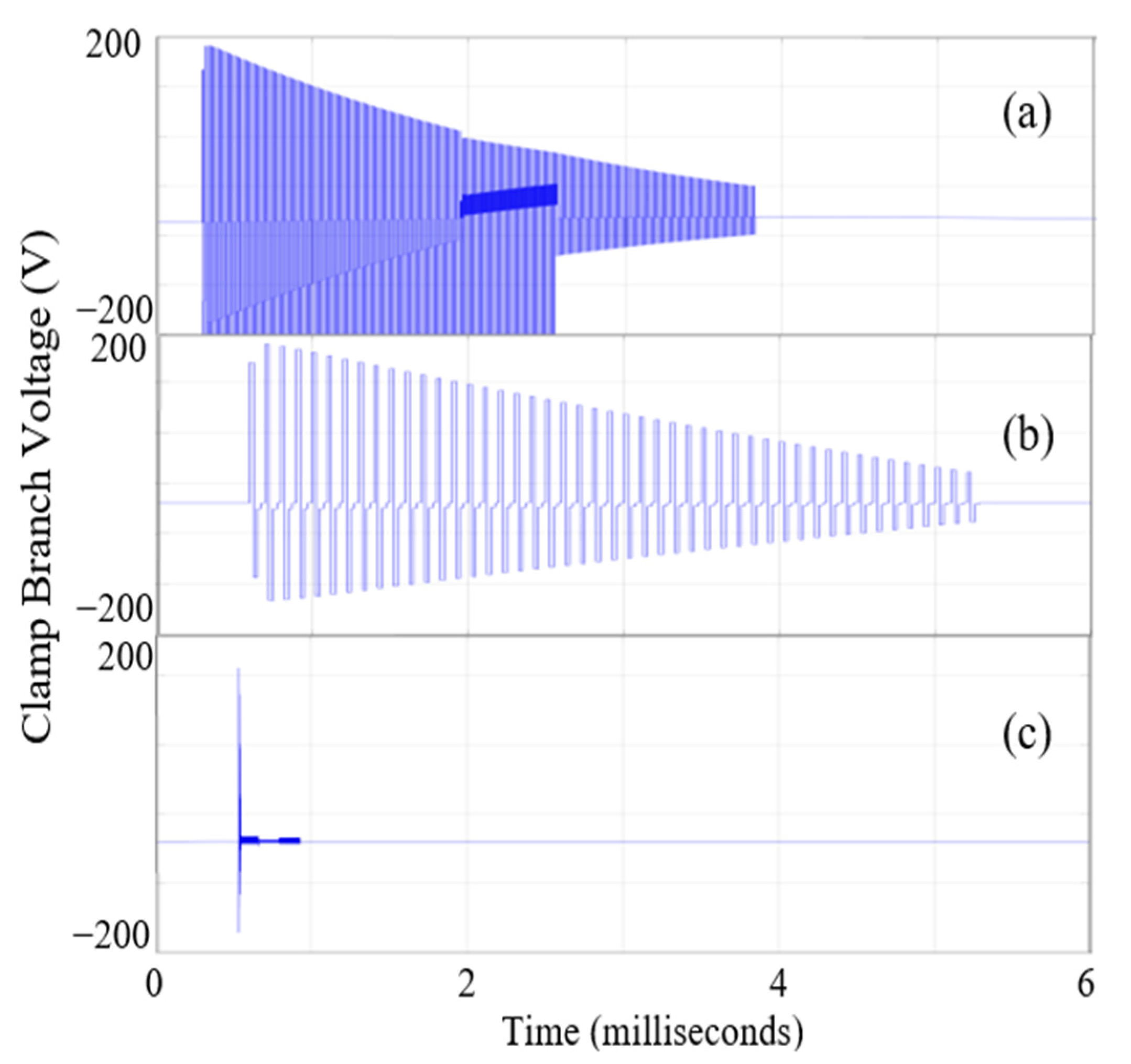

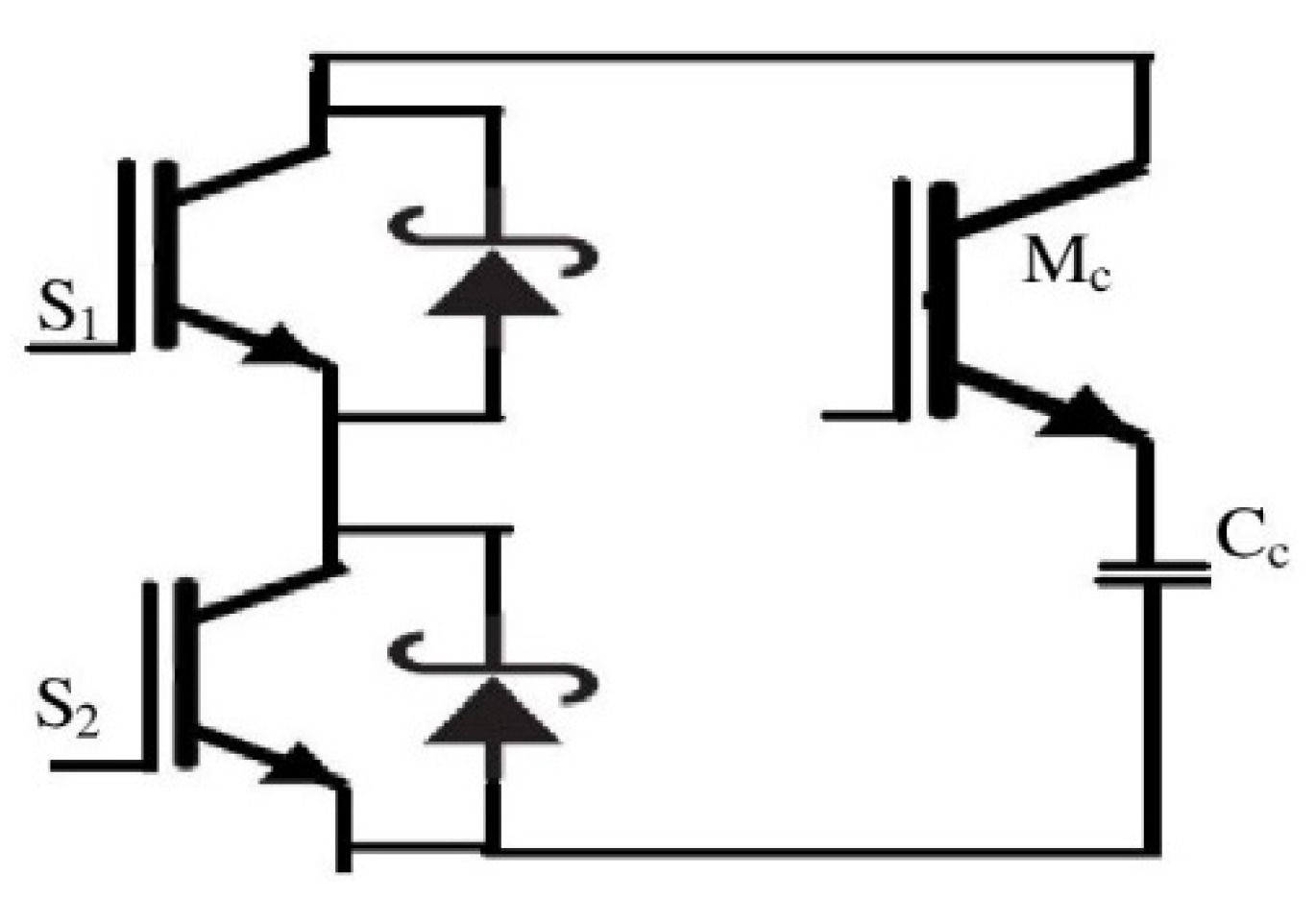

As shown in

Figure 3, the coupled inductor included in the topology is used to recycle the leakage inductance energy and achieve the ZVS condition for the main and clamp switches. The switches and diodes’ voltage stresses are lower than the output voltage. Thus, by using an active clamp circuit with an active switch

Mc, and a capacitor,

Cc,, conduction losses and cost can be significantly reduced.

The design is based on the resonant tank circuit formed by the clamping capacitor

Cc and the leakage inductance

Lk. Resonance occurs during the off-stage of the boost mode operation. The criterion to select

Cc is such that the following holds:

where

Ts is the period of the driving signal for each bridge switch of the converter [

9,

10].

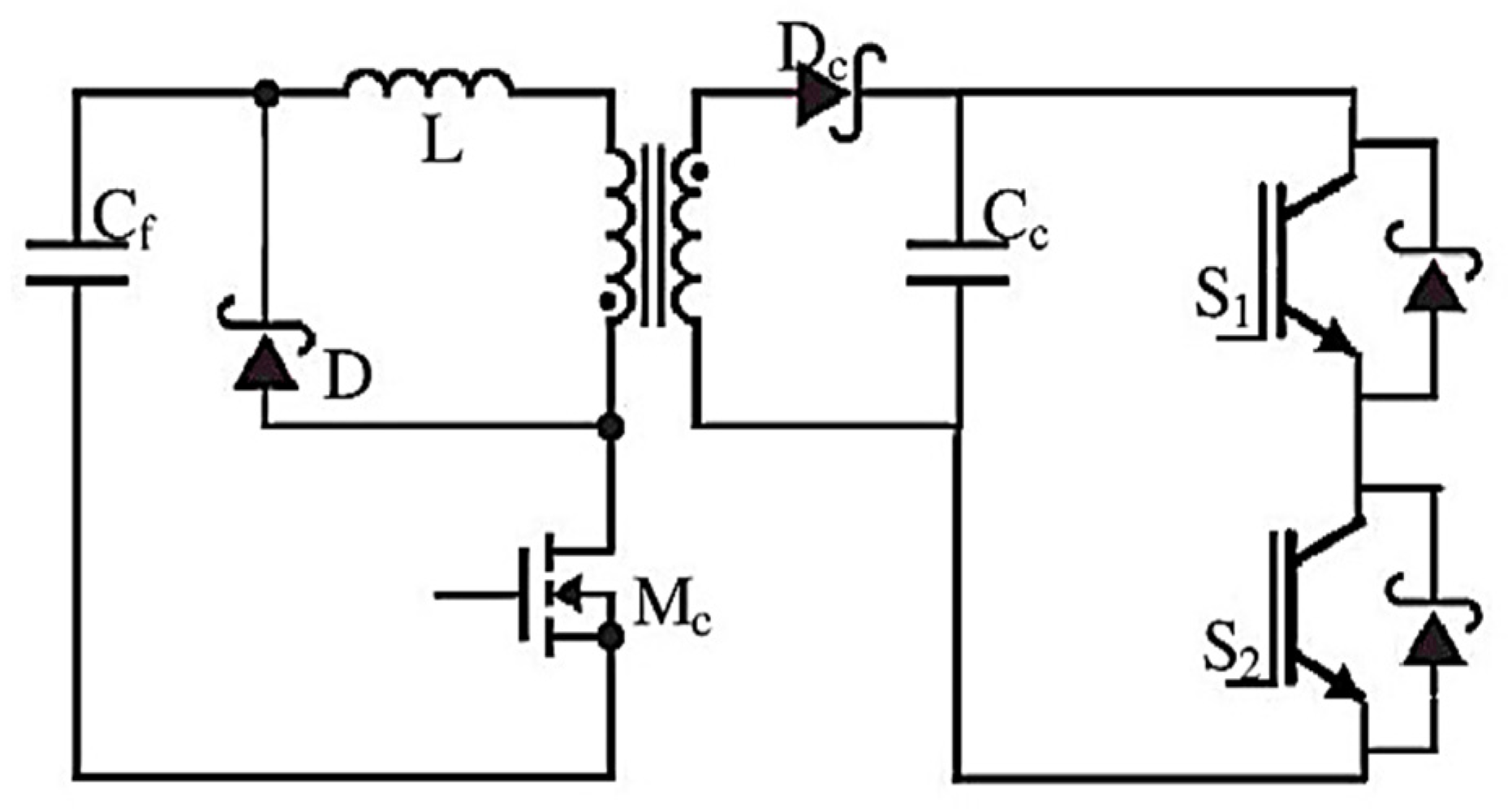

2.3. Flyback Snubber

A flyback snubber is suitable for high power applications and is shown in

Figure 4. This snubber circuit enables the main switch to achieve a ZVS turn-on or a ZCS turn-off process as a result of short time interval of ZVS or ZCS characteristics. The use of the series inductor results in slowing down the diode’s reverse recovery current. However, these inductors increase the switching loss, due to additional voltage stress on the main switch at turn-off transition. The snubber capacitor enables to clamp the switch voltage by absorbing the stored energy of the snubber inductor. However, the converter reliability and life span deteriorate as a result of the snubber capacitor’s energy reprocessing through the main switch, resulting in high current stress. The use of flyback snubber helps overcome this problem through its ability to attain soft-switching features and thus, significantly reduces both the voltage and current stresses. The flyback snubber can also achieve near ZVS and ZCS. It also significantly reduces any current and voltage stresses on the main switch. The output voltage ripple in flyback converter is given by the following:

where

Cf is the capacitor of the flyback converter, and the output voltage ripple (Δ

V0/V0) is considered to be 3%. Thus, the snubber capacitor for the flyback snubber can be calculated using Equation (8) [

11,

12].

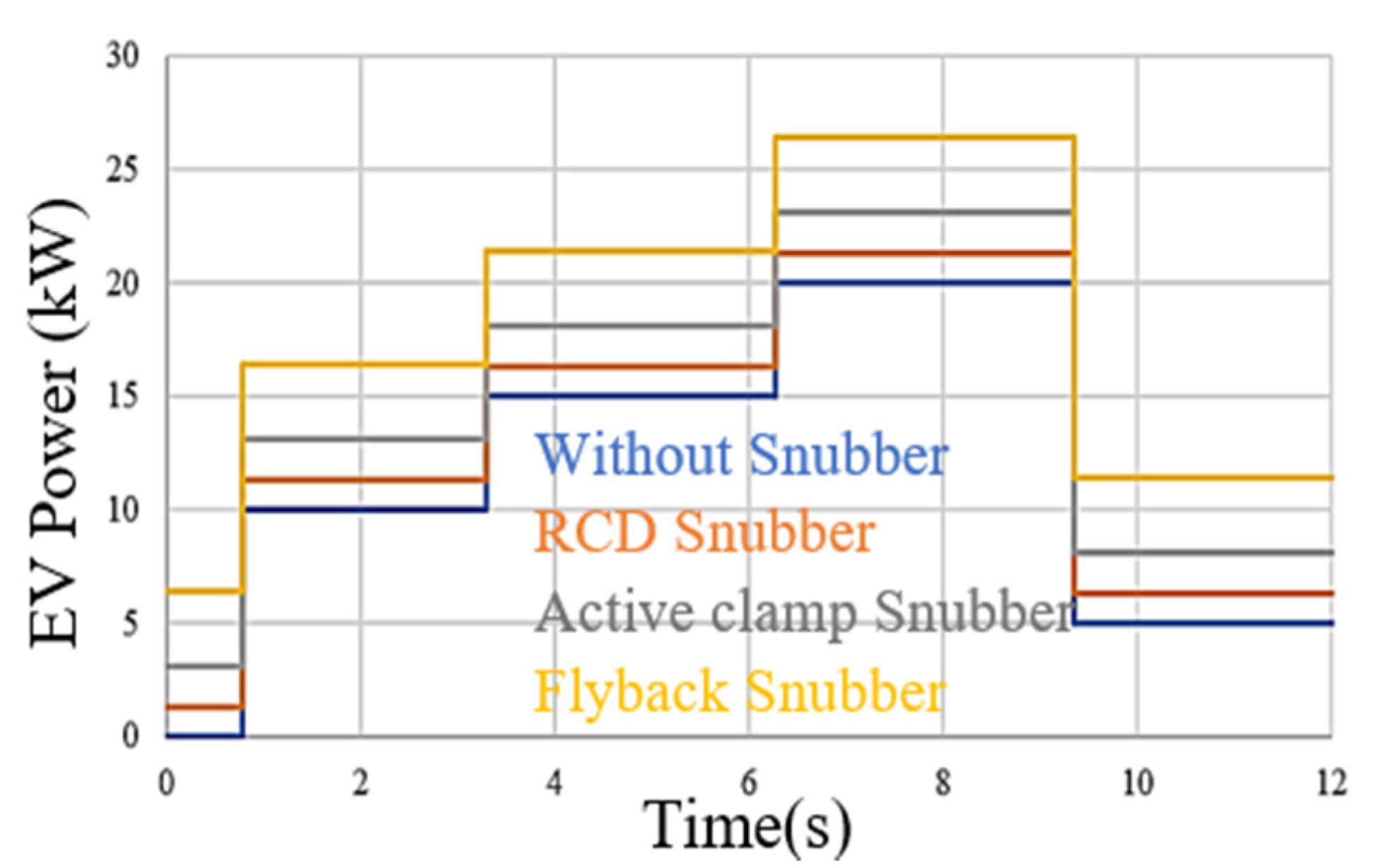

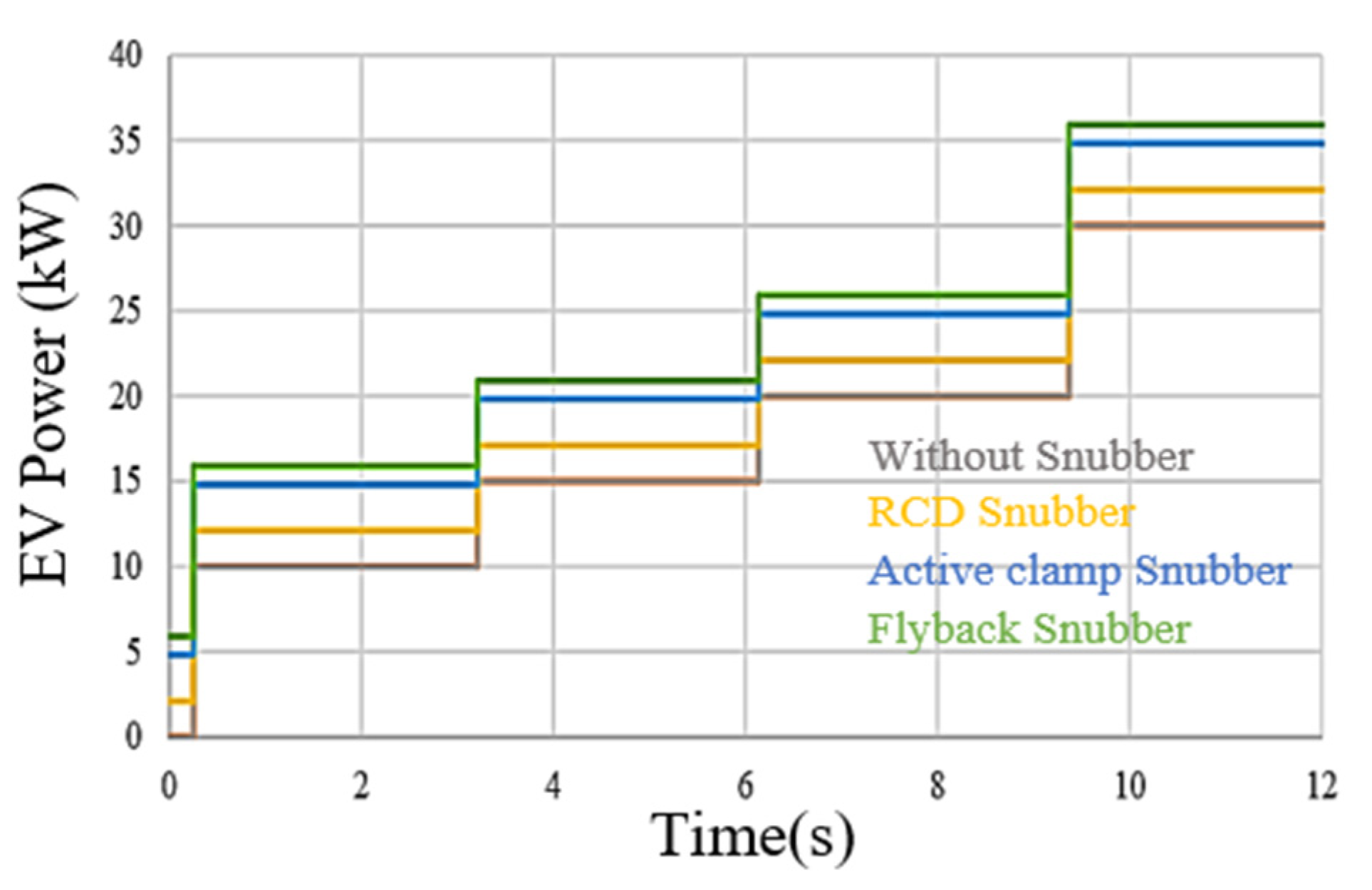

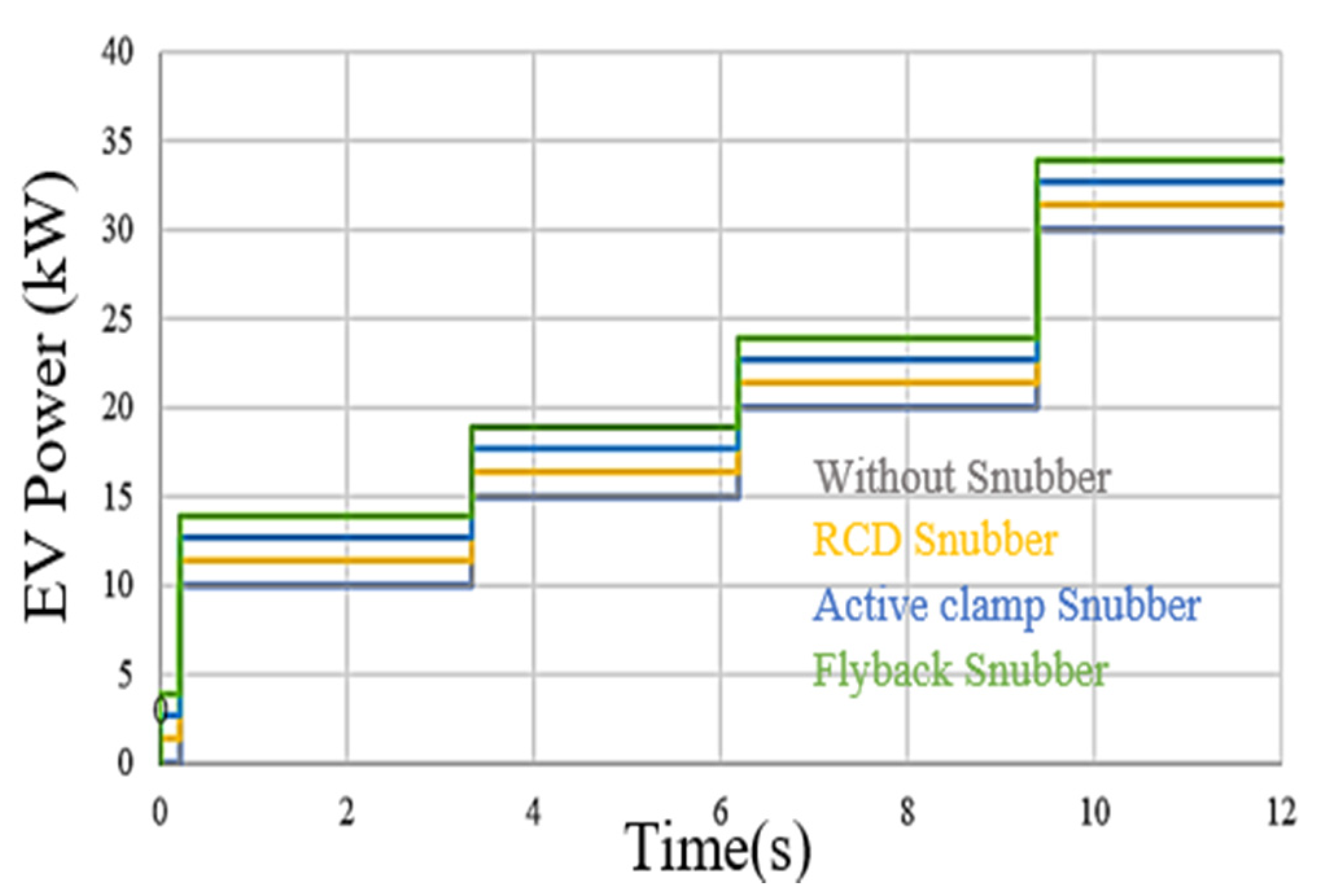

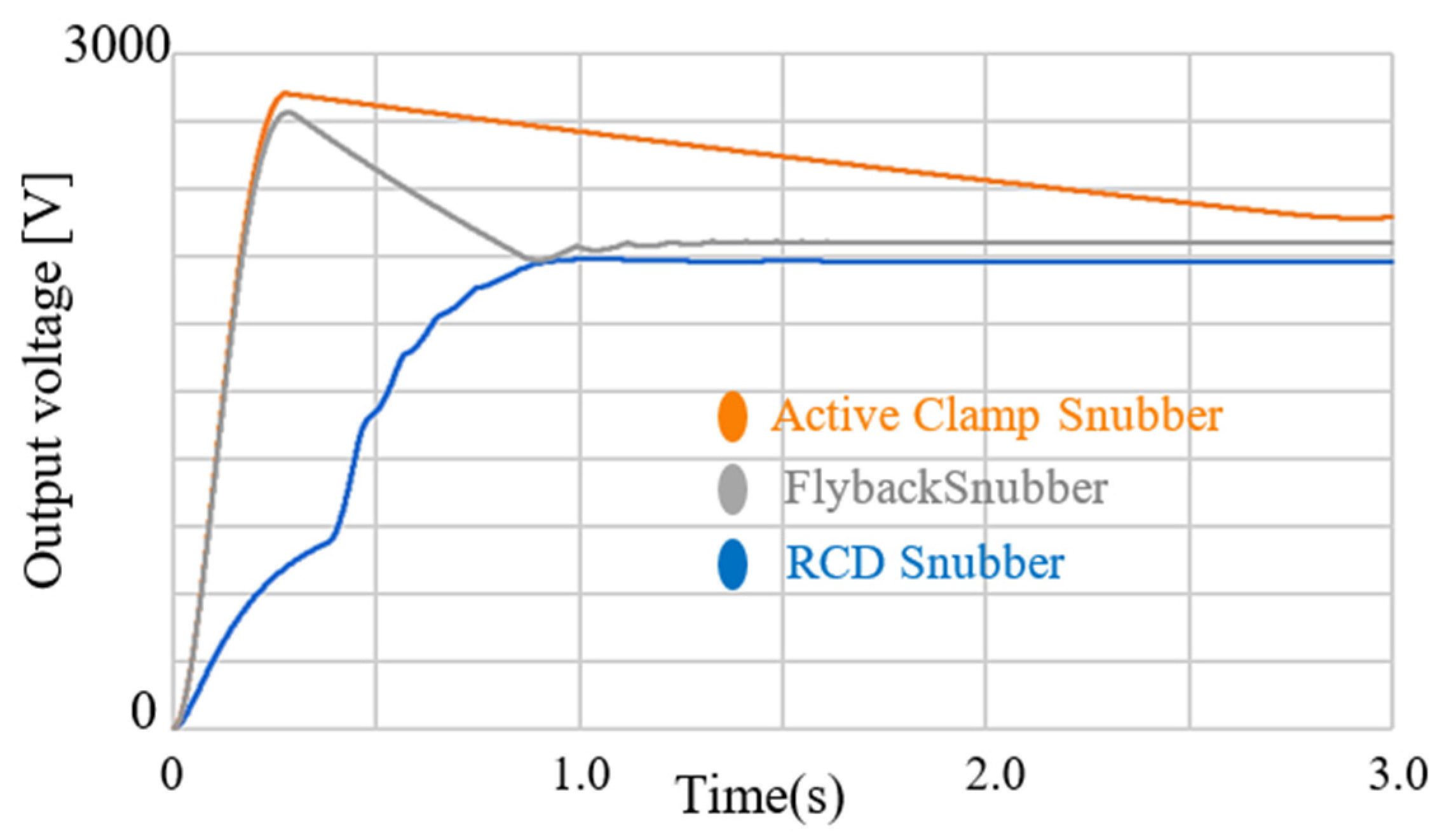

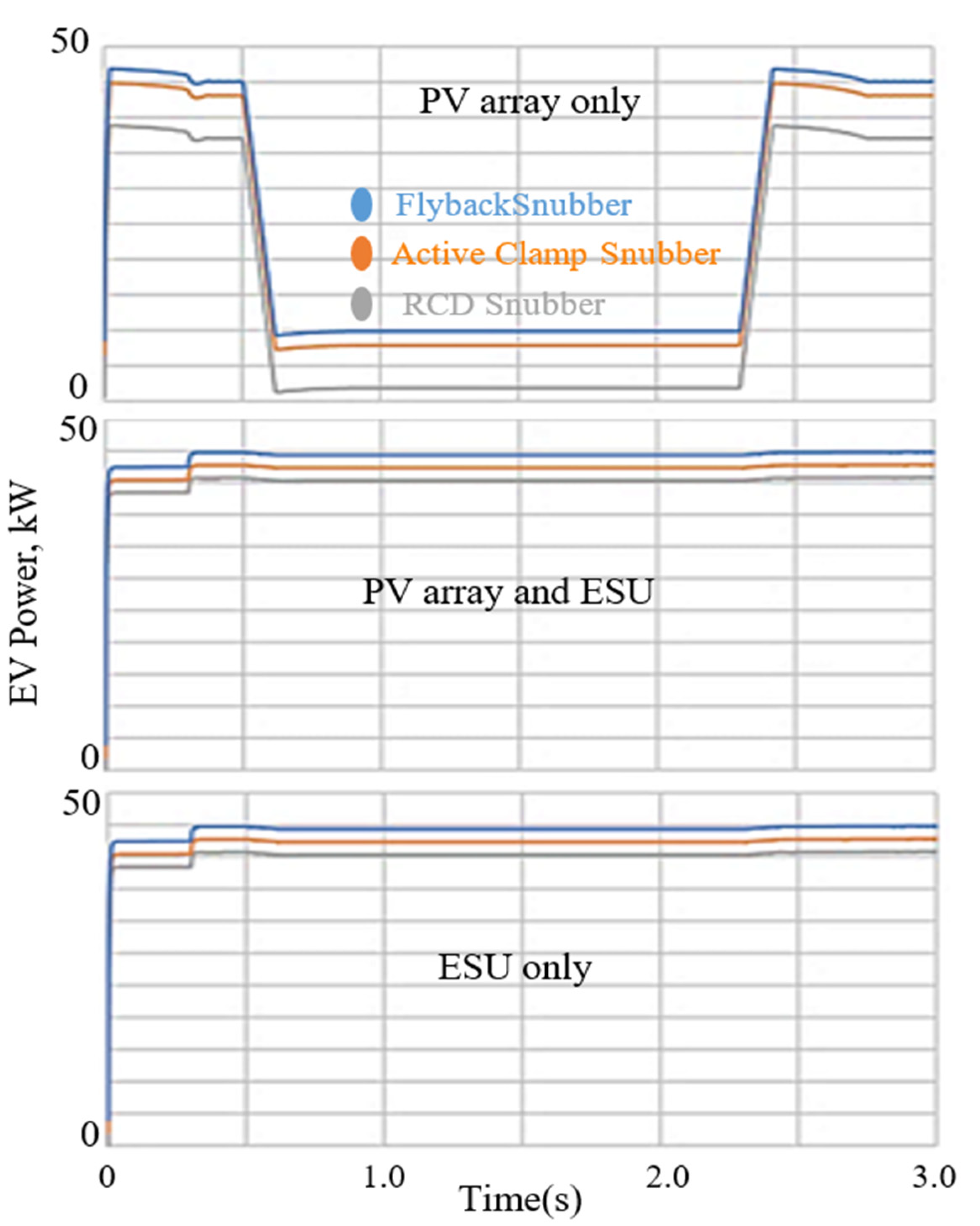

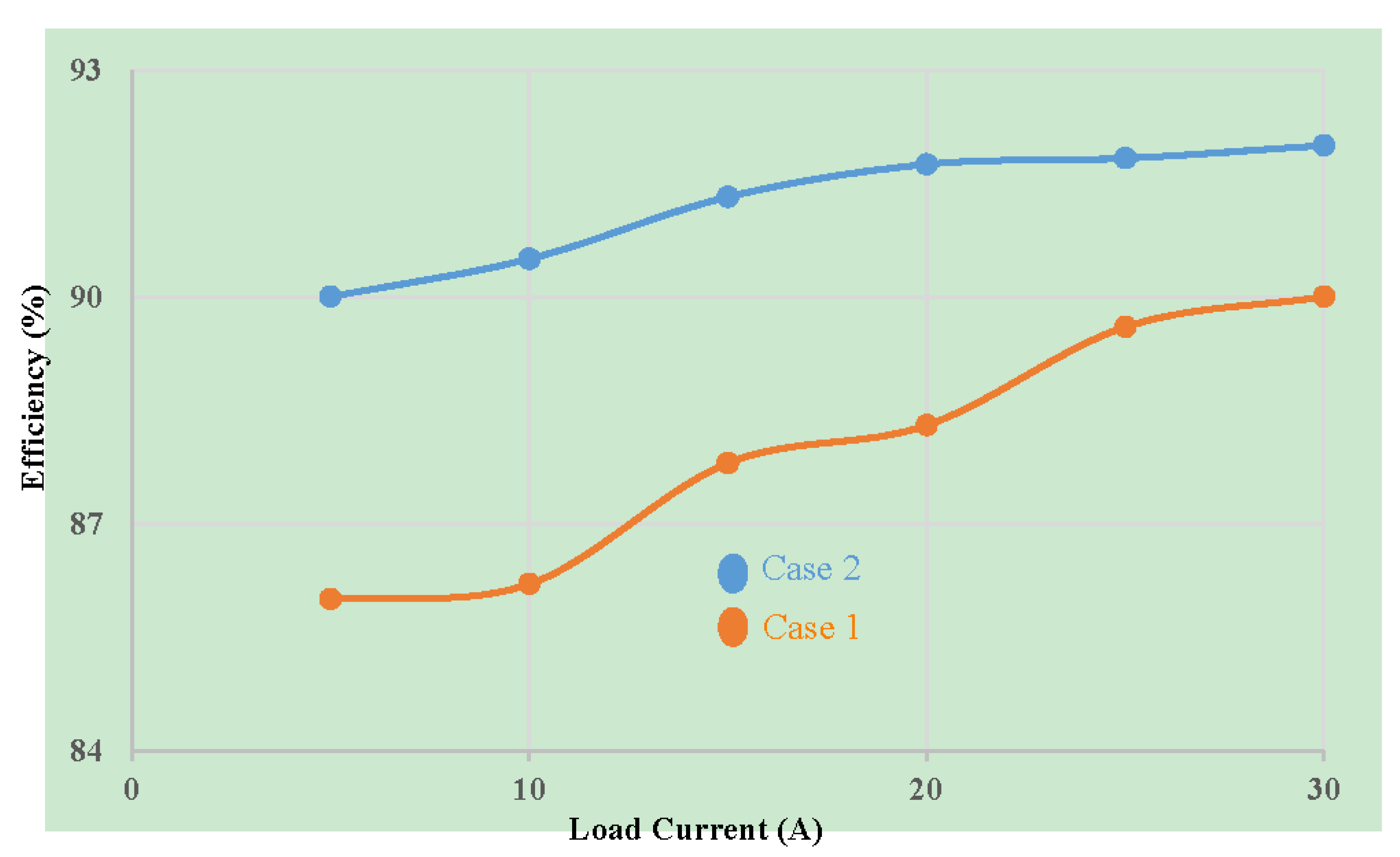

4. Conclusions

In this paper, various snubber circuits for the BDC of two different models of an off-grid solar-based charging station for EVs were implemented and studied. A performance comparison of the charging station was carried out. The use of PV to charge EVs in an off-grid charging station will help to achieve clean energy generation and reduce the grid burden. Thus, the use of EVs in remote locations can be significantly increased. An ESU is coupled with the system to work under any circumstances. The proposed BDC incorporates either RCD snubber or active clamp snubber or flyback snubber to reduce the voltage spike caused by the current fed inductor. The proposed station’s design using various snubber circuits was explained and validated in MATLAB/Simulink. It was successfully tested on two independent models, thus making the method both credible and robust. The efficiency of the proposed converter with the snubber circuits in both the cases is higher, compared to the converter without snubbers. The converter can achieve ZVS conditions more rapidly than a converter without the snubber. Thus, the use of an appropriate snubber enhances the system reliability efficiency. In both the models reported here, the flyback snubber consistently offered the best possible results.