High-Temperature Fluidized Bed Processing of Waste Electrical and Electronic Equipment (WEEE) as a Way to Recover Raw Materials

Abstract

1. Introduction

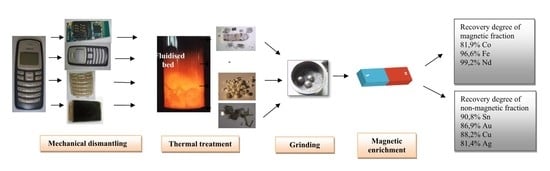

2. Materials and Methods

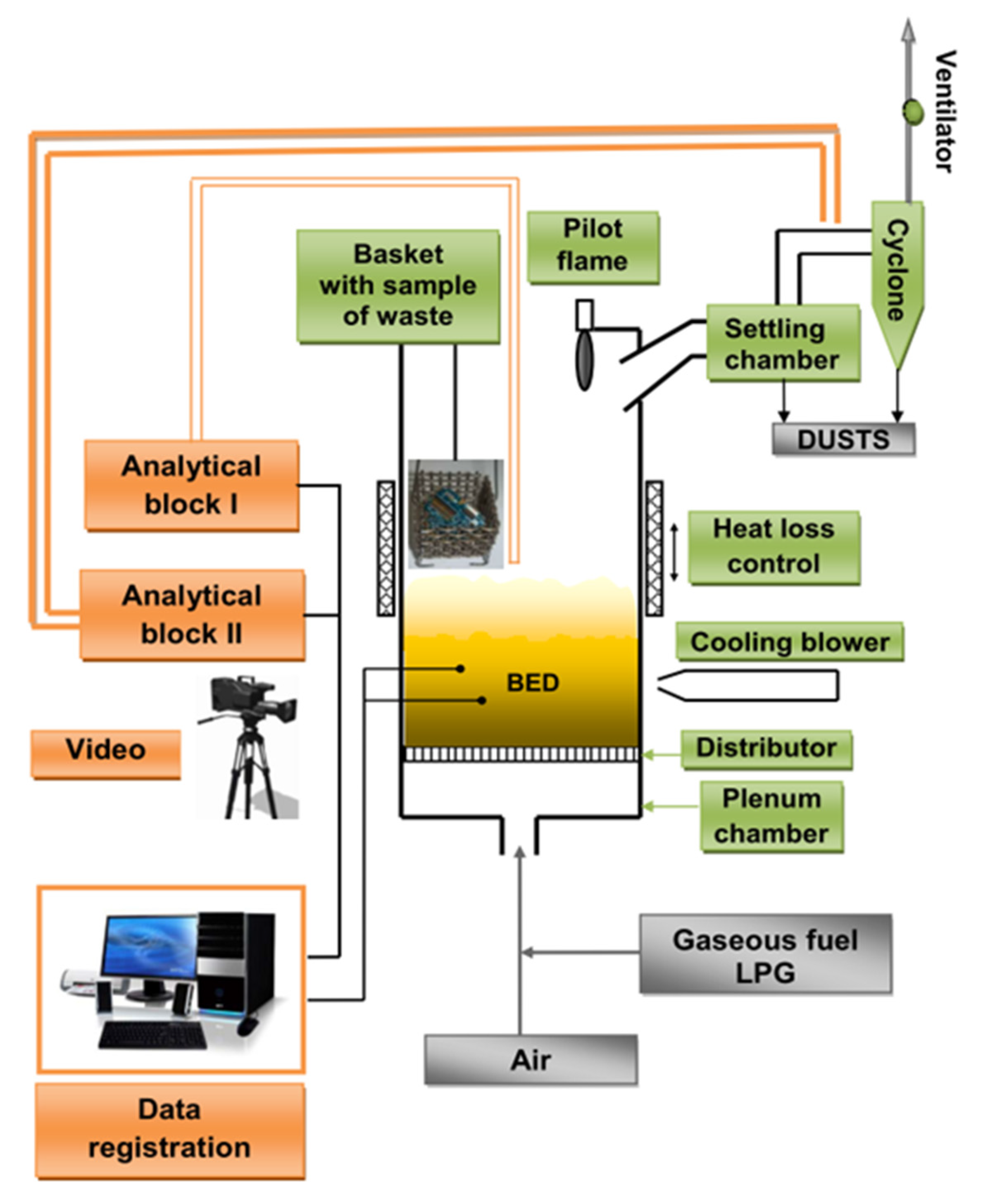

2.1. The Thermal Treatment Process

2.2. Magnetic Enrichment

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| MPhW | mobile phone waste |

| PCA | printed circuit assembly |

| PCBA | printed circuit board assembly |

| VOC | volatile organic compound |

| WEEE | waste electrical and electronic equipment |

| 0 | raw material after MPhW thermal treatment |

| I | magnetic fraction (>1 mm) after magnetic separation by neodymium magnet |

| II | non-magnetic fraction (>1 mm) after magnetic separation by neodymium magnet |

| III | magnetic fraction (<1 mm) after enrichment by three-phase plate electromagnetic separator |

| IV | magnetic fraction (<1 mm) after enrichment by belt type 1-disc electromagnetic separator |

| V | magnetic fraction (<0.5 mm) after enrichment by belt type 1-disc electromagnetic separator |

| VI | non-magnetic fraction (<0.5 mm) after enrichment by belt type 1-disc electromagnetic separator |

| Greek symbols | |

| γ | yield of the fraction; kgi/kg0, i {I,II,III,IV,V,VI} |

| ∑γ | the accumulated yield of the fractions; kg/kg0 |

| λ | the metal content in the fraction; kgMe,i/kgi |

| α | the metal content in the feed; kgMe,0/kg0 |

| β | the metal content in the combined fractions; kgMe/kg |

| K | enrichment factor |

| ε | yield of the metal; kgMe,i/kg0 |

| ∑ ε | the accumulated yield of the metal; kgMe/kg0 |

References

- Maragkos, K.G.; Hahladakis, J.N.; Gidarkos, E. Qualitative and quantitative determination of heavy metals in waste cellular phones. Waste Manag. 2013, 33, 1882–1889. [Google Scholar] [CrossRef] [PubMed]

- Balde, C.P.; Kuehr, R.; Blumenthal, K.; Gill, S.F.; Kern, M.; Micheli, P.; Magpantay, E.; Huisman, J. E-Waste Statistics: Guidelines on Classifications, Reporting and Indicators; United Nations University: Bonn, Germany, 2015; ISBN 978-92-8-084554-9. [Google Scholar]

- Khetriwal, D.S.; Kraeuchi, P.; Widmer, R. Producer responsibility for e-waste management: Key issues for consideration e learning from the Swiss experience. J. Environ. Manag. 2009, 90, 153–165. [Google Scholar] [CrossRef]

- Liu, W.; Chen, L.; Tian, J. Uncovering the Evolution of Lead In-Use Stocks in Lead-Acid Batteries and the Impact on Future Lead Metabolism in China. Environ. Sci. Technol. 2016, 50, 5412–5419. [Google Scholar] [CrossRef] [PubMed]

- Tanskanen, P. Management and recycling of electronic waste. Acta Mater. 2013, 61, 1001–1011. [Google Scholar] [CrossRef]

- Tuncuk, A.; Stazi, V.; Akcil, A.; Yazici, E.Y.; Deveci, H. Aqueous metal recovery techniques from e-scrap: Hydrometallurgy in recycling. Miner. Eng. 2012, 25, 28–37. [Google Scholar] [CrossRef]

- Bachér, J.; Mrotzek, A.; Wahlström, M. Mechanical pre-treatment of mobile phones and its effect on the Printed Circuit Assemblies (PCAs). Waste Manag. 2015, 45, 235–245. [Google Scholar] [CrossRef]

- Frost and Sullivan. European Waste Electrical and Electronics Equipment Recycling Market. 2013. Available online: http://www.endseurope.com/docs/131001c.pdf (accessed on 18 September 2020).

- Boldoczki, S.; Thorenz, A.; Tuma, A. The environmental impacts of preparation for reuse: A case study of WEEE reuse in Germany. J. Clean. Prod. 2019, 252, 119736. [Google Scholar] [CrossRef]

- Baldé, C.P.; Wang, F.; Kuehr, R.; Huisman, J. The Global e-Waste Monitor—2014; United Nations University, IAS–SCYCLE: Bonn, Germany, 2015. [Google Scholar]

- Batteiger, A.; Rotter, V.S. Material Implications of Rural Electrification—A Methodological Framework to Assess In-Use Stocks of Off-Grid Solar Products and EEE in Rural Households in Bangladesh. Recycling 2018, 3, 7. [Google Scholar] [CrossRef]

- Robinson, B.H. E-waste: An assessment of global production and environmental impacts. Sci. Total Environ. 2009, 408, 183–191. [Google Scholar] [CrossRef] [PubMed]

- UNEP. Call for Global Action on E-Waste—United Nations Environment Programme (UNEP). 2013. Available online: http://www.unep.org/Documents.Multilingual/Default.asp?ArticleID=5447&DocumentID=496&l=en (accessed on 20 August 2020).

- Glöser, S.; Soulier, M.; Espinoza, L.A.T. Dynamic Analysis of Global Copper Flows. Global Stocks, Postconsumer Material Flows, Recycling Indicators, and Uncertainty Evaluation. Environ. Sci. Technol. 2013, 47, 6564–6572. [Google Scholar] [CrossRef]

- Nikulski, J.; Ritthoff, M.; von Gries, N. The Potential and Limitations of Critical Raw Material Recycling: The Case of LED Lamps. Resources 2021, 10, 37. [Google Scholar] [CrossRef]

- Oguchi, M.; Sakanakura, H.; Terazono, A.; Takigami, H. Fate of metals contained in waste electrical and electronic equipment in a municipal waste treatment process. Waste Manag. 2012, 32, 96–103. [Google Scholar] [CrossRef]

- Kasper, A.C.; Bernardes, A.M.; Veit, H.M. Characterization and recovery of polymers from mobile phone scrap. Waste Manag. Res. 2011, 29, 714–726. [Google Scholar] [CrossRef]

- Kumar, A.; Dixit, G. A novel hybrid MCDM framework for WEEE recycling partner evaluation on the basis of green competencies. J. Clean. Prod. 2019, 241, 118017. [Google Scholar] [CrossRef]

- Directive 2002/96/EC of the European Parliament and of the Council of 27 January 2003 on Waste Electrical and Electronic Equipment. Available online: https://lexparency.org/eu/32002L0096/ (accessed on 4 July 2021).

- Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on Waste Electrical and Electronic Equipment (WEEE). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32012L0019&from=EN (accessed on 4 July 2021).

- Cui, J.; Forssberg, E. Mechanical recycling of waste electric and electronic equipment: A review. J. Hazard. Mater. 2003, 99, 243–263. [Google Scholar] [CrossRef]

- Rao, S.R. Recycling Metal. In Waste Management Series; Rao, S.R., Ed.; Vol. 7–Resources Recovery and Recycling from Metallurgical Wastes; Elsevier Science: Amsterdam, The Netherlands, 2006; Chapter 7. [Google Scholar]

- Xu, C.; Zhang, W.; He, W.; Li, G.; Huang, J. The situation of waste mobile phone management in developed countries and development status in China. Waste Manag. 2016, 58, 341–347. [Google Scholar] [CrossRef]

- Eurostat. Waste Statistics–Electrical and Electronic Equipment. 2016. Available online: http://ec.europa.eu/eurostat/statisticsexplained/index.php/Waste_statistics_electrical_and_electronic_equipment#EEE_put_on_the_market_and_WEEE_collected_and_treated_in_the_EU (accessed on 27 January 2020).

- Ismail, H.; Hanafiah, M.M. An overview of LCA application in WEEE management: Current practices, progress and challenges. J. Clean. Prod. 2019, 232, 79–93. [Google Scholar] [CrossRef]

- Khaliq, A.; Rhamdhani, M.A.; Brooks, G.; Masood, S. Metal Extraction Processes for Electronic Waste and Existing Industrial Routes: A Review and Australian Perspective. Resources 2014, 3, 152–179. [Google Scholar] [CrossRef]

- Kiddee, P.; Naidu, R.; Wong, M.H. Electronic waste management approaches: An overview. Waste Manag. 2013, 33, 1237–1250. [Google Scholar] [CrossRef]

- Kolias, K.; Hahladakis, J.N.; Gidarakos, E. Assessment of toxic metals in waste personal computers. Waste Manag. 2014, 34, 1480–1487. [Google Scholar] [CrossRef] [PubMed]

- Salhofer, S.; Steuer, B.; Ramusch, R.; Beigl, P. WEEE management in Europe and China–A comparison. Waste Manag. 2016, 57, 27–35. [Google Scholar] [CrossRef]

- Singh, N.; Duan, H.; Yin, F.; Song, Q.; Li, J. Characterizing the Materials Composition and Recovery Potential from Waste Mobile Phones: A Comparative Evaluation of Cellular and Smart Phones. ACS Sustain. Chem. Eng. 2018, 6, 13016–13024. [Google Scholar] [CrossRef]

- Widmer, R.; Oswald-Krapf, H.; Sinha-Khetriwal, D.; Schnellmann, M.; Böni, H. Global perspectives on e-waste. Environ. Impact Assess. Rev. 2005, 25, 436–458. [Google Scholar] [CrossRef]

- Kasper, A.C.; Berselli, G.B.T.; Freitas, B.D.; Tenório, J.A.S.; Bernardes, A.M. Printed wiring boards from mobile phones: Characterization and recycling of copper. Waste Manag. 2011, 31, 2536–2545. [Google Scholar] [CrossRef]

- Monneron-Enaud, B.; Wiche, O.; Schlömann, M. Biodismantling, a Novel Application of Bioleaching in Recycling of Electronic Wastes. Recycling 2020, 5, 22. [Google Scholar] [CrossRef]

- Murugan, R.V.; Bharat, S.; Deshpande, A.P.; Varughese, S.; Haridoss, P. Milling and separation of the multi-component printed circuit board materials and the analysis of elutriation based on a single particle model. Powder Technol. 2008, 183, 169–176. [Google Scholar] [CrossRef]

- Palmieri, R.; Bonifazi, G.; Serranti, S. Recycling-oriented characterization of plastic frames and printed circuit boards from mobile phones by electronic and chemical imaging. Waste Manag. 2014, 34, 2120–2130. [Google Scholar] [CrossRef] [PubMed]

- Yamane, L.H.; de Moraes, V.T.; Espinosa, D.C.R.; Ten’orio, J. Recycling of WEEE: Characterization of spent printed circuit boards from mobile phones and computers. Waste Manag. 2011, 31, 2553–2558. [Google Scholar] [CrossRef]

- Kaya, M. Electronic Waste and Printed Circuit Board Recycling Technologies; Springer: Berlin, Germany, 2019. [Google Scholar] [CrossRef]

- Rene, E.R.; Sethurajan, M.; Ponnusamy, V.K.; Kumar, G.; Dung, T.N.B.; Brindhadevi, K.; Pugazhendhi, A. Electronic waste generation, recycling and resource recovery: Technological perspectives and trends. J. Hazard. Mater. 2021, 416, 125664. [Google Scholar] [CrossRef]

- Rieger, T.; Oey, J.; Palchyk, V.; Hofmann, A.; Franke, M.; Hornung, A. Chemical Recycling of WEEE Plastics—Production of High Purity Monocyclic Aromatic Chemicals. Processes 2021, 9, 530. [Google Scholar] [CrossRef]

- Woynarowska, A.; Żelazny, S.; Żukowski, W. Thermal treatment of electronic waste in a fluidised bed and chemical digestion of solid products. Waste Manag. Res. 2016, 34, 605–618. [Google Scholar] [CrossRef] [PubMed]

- Schmidt-Szałkowski, K.; Szafran, M.; Bobryk, E.; Sentek, J. Chemical Technology-Inorganic Industry; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2013. [Google Scholar]

- Cesaro, A.; Belgiorno, V.; Gorrasi, G.; Viscusi, G.; Vaccari, M.; Vinti, G.; Jandric, A.; Dias, M.I.; Hursthouse, A.; Salhofer, S. A relative risk assessment of the open burning of WEEE. Environ. Sci. Pollut. Res. 2019, 26, 11042–11052. [Google Scholar] [CrossRef]

- Berkowicz, G.; Majka, T.; Żukowski, W. The pyrolysis and combustion of polyoxymethylene in a fluidised bed with the possibility of incorporating CO2. Energy Convers. Manag. 2020, 214, 112888. [Google Scholar] [CrossRef]

- Żukowski, W.; Berkowicz, G. The combustion of polyolefins in inert and catalytic fluidised beds. J. Clean. Prod. 2019, 236, 117663. [Google Scholar] [CrossRef]

- Żukowski, W.; Berkowicz, G. The combustion of liquids and low-density solids in a cenospheric fluidised bed. Combust. Flame 2019, 206, 476–489. [Google Scholar] [CrossRef]

- Żukowski, W.; Berkowicz, G. Hydrogen production through the partial oxidation of methanol using N2O in a fluidised bed of an iron-chromium catalyst. Int. J. Hydrogen Energy 2017, 42, 28247–28253. [Google Scholar] [CrossRef]

- Olek, M.; Baron, J.; Żukowski, W. Thermal decomposition of selected chlorinated hydrocarbons during gas combustion in fluidized bed. Chem. Cent. J. 2013, 7, 2. [Google Scholar] [CrossRef][Green Version]

- Olek, M.; Kandefer, S.; Kaniowski, W.; Żukowski, W.; Baron, J. Carbon shale combustion in the fluidized bed reactor. Pol. J. Chem. Technol. 2014, 16. [Google Scholar] [CrossRef]

- Żukowski, W.; Jankowski, D.; Baron, J.; Wrona, J. Combustion dynamics of polymer wastes in a bubbling fluidized bed. J. Clean. Prod. 2021, 320, 128807. [Google Scholar] [CrossRef]

| Mobile Phone before Mechanical Dismantling | Mobile Phone after Mechanical Dismantling |

|---|---|

|  |

| kit no. I | |

|  |

| kit no. II | |

|  |

| kit no. III | |

| No. | Sample before Thermal Treatment | m0 (g) | Sample after Thermal Treatment | m1 (g) | Weight Loss (%) |

|---|---|---|---|---|---|

| 1 |  | 2.68 |  | 1.86 | 30.60 |

| 2 |  | 4.24 |  | 2.82 | 33.50 |

| 3 |  | 0.96 |  | 0.30 | 68.75 |

| 4 |  | 4.95 |  | 3.24 | 34.54 |

| 5 |  | 3.15 |  | 2.39 | 24.13 |

| 6 |  | 3.06 | - | 0.00 | 100 |

| 7 |  | 2.18 |  | 1.95 | 10.55 |

| 8 |  | 3.46 |  | 2.13 | 38.44 |

| 9 |  | 2.30 | - | 0.00 | 100 |

| 10 |  | 3.54 |  | 2.72 | 23.16 |

| 11 |  | 2.35 |  | 0.64 | 72.77 |

| No. | Sample before Thermal Treatment | m0 (g) | Sample after Thermal Treatment | m1 (g) | Weight Loss (%) |

|---|---|---|---|---|---|

| 12 |  | 4.13 |  | 2.78 | 32.69 |

| 13 |  | 2.20 |  | 0.58 | 73.63 |

| 14 |  | 3.29 |  | 2.38 | 27.66 |

| 15 |  | 1.90 |  | 1.71 | 10.00 |

| 16 |  | 4.69 |  | 3.54 | 24.52 |

| 17 |  | 4.81 |  | 3.40 | 29.31 |

| 18 |  | 2.14 | - | 0.00 | 100 |

| 19 |  | 4.73 |  | 4.41 | 6.76 |

| 20 |  | 6.00 |  | 4.84 | 19.33 |

| No. | Mass (g) | Emission (mg) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sample | CO | C6H6 | C6H6O | C10H8 | CH4 | C2H6 | C2H2 | C2H4 | VOCs | |

| 1 | 2.68 | 235 | 4.54 | 0.69 | 1.54 | 1.61 | 0.62 | 0.87 | 1.59 | 11.46 |

| 2 | 4.24 | 317 | 5.71 | 1.25 | 2.49 | 2.31 | 0.99 | 1.02 | 1.99 | 15.76 |

| 3 | 0.96 | 307 | 4.95 | 0.57 | 2.19 | 2.30 | 0.88 | 1.08 | 2.92 | 14.89 |

| 4 | 4.95 | 397 | 7.30 | 2.04 | 3.25 | 3.09 | 1.32 | 1.13 | 2.60 | 20.73 |

| 5 | 3.16 | 290 | 5.26 | 0.27 | 4.07 | 2.52 | 1.00 | 1.01 | 2.81 | 16.94 |

| 6 | 3.06 | 724 | 23.5 | 13.4 | 10.4 | 5.05 | 4.40 | 2.22 | 3.00 | 61.97 |

| 7 | 2.18 | 14.0 | 0.32 | 0.10 | 0.17 | 0.05 | 0.00 | 0.00 | 0.04 | 0.68 |

| 8 | 3.46 | 309 | 5.35 | 2.42 | 2.00 | 3.11 | 1.06 | 0.47 | 1.50 | 15.91 |

| 9 | 2.30 | 711 | 20.3 | 10.6 | 9.67 | 4.75 | 3.44 | 2.21 | 3.65 | 54.62 |

| 10 | 3.54 | 327 | 6.70 | 4.48 | 2.32 | 3.84 | 1.57 | 0.45 | 1.66 | 21.02 |

| 11 | 2.35 | 255 | 1.41 | 0.03 | 0.25 | 3.52 | 0.32 | 0.36 | 1.15 | 7.04 |

| 12 | 4.13 | 463 | 8.13 | 4.65 | 3.20 | 4.34 | 1.85 | 0.70 | 2.29 | 25.16 |

| 13 | 2.21 | 240 | 3.59 | 0.53 | 1.13 | 2.16 | 0.54 | 1.11 | 1.89 | 10.95 |

| 14 | 3.29 | 374 | 5.30 | 2.11 | 2.46 | 3.63 | 1.09 | 0.53 | 1.94 | 17.06 |

| 15 | 1.90 | 242 | 5.98 | 1.54 | 1.83 | 2.62 | 0.85 | 0.51 | 1.65 | 14.98 |

| 16 | 4.69 | 232 | 3.82 | 0.32 | 1.02 | 2.11 | 0.67 | 0.94 | 2.46 | 11.34 |

| 17 | 4.81 | 534 | 5.91 | 1.62 | 2.53 | 3.81 | 1.09 | 0.88 | 2.50 | 18.34 |

| 18 | 2.14 | 750 | 20.6 | 2.60 | 10.4 | 3.79 | 2.32 | 3.26 | 4.55 | 47.52 |

| 19 | 4.73 | 682 | 7.31 | 2.61 | 3.23 | 5.29 | 1.71 | 1.04 | 3.76 | 24.95 |

| 20 | 6.00 | 692 | 9.55 | 3.34 | 4.41 | 5.85 | 2.21 | 0.94 | 3.95 | 30.25 |

| ∑ | 66.76 | 8093 | 156 | 55.2 | 69.0 | 66.0 | 27.9 | 20.7 | 47.9 | 442.7 |

| No. | Mass (g) | Emission Coefficient (mg g−1) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sample | CO | C6H6 | C6H6O | C10H8 | CH4 | C2H6 | C2H2 | C2H4 | VOCs | |

| 1 | 2.68 | 87.9 | 1.70 | 0.26 | 0.58 | 0.60 | 0.23 | 0.32 | 0.60 | 4.29 |

| 2 | 4.24 | 74.8 | 1.35 | 0.29 | 0.59 | 0.55 | 0.23 | 0.24 | 0.47 | 3.72 |

| 3 | 0.96 | 319 | 5.15 | 0.60 | 2.28 | 2.39 | 0.91 | 1.13 | 3.03 | 15.5 |

| 4 | 4.95 | 80.2 | 1.48 | 0.41 | 0.66 | 0.63 | 0.27 | 0.23 | 0.53 | 4.21 |

| 5 | 3.16 | 91.9 | 1.67 | 0.09 | 1.29 | 0.80 | 0.32 | 0.32 | 0.89 | 5.38 |

| 6 | 3.06 | 236 | 7.68 | 4.39 | 3.40 | 1.65 | 1.44 | 0.72 | 0.98 | 20.3 |

| 7 | 2.18 | 6.41 | 0.15 | 0.05 | 0.08 | 0.02 | 0.00 | 0.00 | 0.02 | 0.32 |

| 8 | 3.46 | 89.2 | 1.54 | 0.70 | 0.58 | 0.9 | 0.31 | 0.14 | 0.43 | 4.60 |

| 9 | 2.30 | 309 | 8.82 | 4.60 | 4.20 | 2.07 | 1.49 | 0.96 | 1.59 | 23.7 |

| 10 | 3.54 | 92.3 | 1.89 | 1.26 | 0.65 | 1.09 | 0.44 | 0.13 | 0.47 | 5.93 |

| 11 | 2.35 | 109 | 0.60 | 0.00 | 0.11 | 1.5 | 0.14 | 0.15 | 0.49 | 2.99 |

| 12 | 4.13 | 112 | 1.97 | 1.12 | 0.77 | 1.05 | 0.45 | 0.17 | 0.55 | 6.08 |

| 13 | 2.21 | 109 | 1.63 | 0.24 | 0.51 | 0.98 | 0.24 | 0.50 | 0.86 | 4.96 |

| 14 | 3.29 | 114 | 1.61 | 0.64 | 0.75 | 1.11 | 0.33 | 0.16 | 0.59 | 5.19 |

| 15 | 1.90 | 127 | 3.14 | 0.81 | 0.96 | 1.38 | 0.45 | 0.27 | 0.87 | 7.88 |

| 16 | 4.69 | 49.4 | 0.81 | 0.07 | 0.22 | 0.45 | 0.14 | 0.20 | 0.53 | 2.42 |

| 17 | 4.81 | 111 | 1.23 | 0.34 | 0.53 | 0.79 | 0.23 | 0.18 | 0.52 | 3.82 |

| 18 | 2.14 | 351 | 9.64 | 1.22 | 4.85 | 1.77 | 1.08 | 1.52 | 2.13 | 22.2 |

| 19 | 4.73 | 144 | 1.55 | 0.55 | 0.68 | 1.12 | 0.36 | 0.22 | 0.79 | 5.27 |

| 20 | 6.00 | 115 | 1.59 | 0.56 | 0.73 | 0.97 | 0.37 | 0.16 | 0.66 | 5.04 |

| Average coefficient | 136 | 2.76 | 0.91 | 1.22 | 1.09 | 0.47 | 0.39 | 0.85 | 7.69 | |

| No. | Mass (g) | Emission (mg) | |||||

|---|---|---|---|---|---|---|---|

| Sample | SO2 | NOx | HCN | NH3 | HBr | HCl | |

| 1 | 2.68 | 2.06 | 3.39 | 1.15 | 0.00 | 0.00 | 0.00 |

| 2 | 4.24 | 1.82 | 3.20 | 0.84 | 0.00 | 0.00 | 0.00 |

| 3 | 0.96 | 2.41 | 1.64 | 1.16 | 0.00 | 0.00 | 0.00 |

| 4 | 4.95 | 1.44 | 3.91 | 1.36 | 0.00 | 0.00 | 0.00 |

| 5 | 3.16 | 3.31 | 0.74 | 0.70 | 0.00 | 0.00 | 0.00 |

| 6 | 3.06 | 3.03 | 1.25 | 1.83 | 0.00 | 2.39 | 0.00 |

| 7 | 2.18 | 0.07 | 4.67 | 0.00 | 0.00 | 0.00 | 0.00 |

| 8 | 3.46 | 2.92 | 3.45 | 1.02 | 0.12 | 0.00 | 2.58 |

| 9 | 2.30 | 4.95 | 0.42 | 1.16 | 0.00 | 0.00 | 0.00 |

| 10 | 3.54 | 3.10 | 3.73 | 0.98 | 0.24 | 0.00 | 3.45 |

| 11 | 2.35 | 0.02 | 0.02 | 0.34 | 0.00 | 0.00 | 0.00 |

| 12 | 4.13 | 4.59 | 4.90 | 1.42 | 0.25 | 0.00 | 3.33 |

| 13 | 2.21 | 2.46 | 0.46 | 0.65 | 0.00 | 0.00 | 0.00 |

| 14 | 3.29 | 3.12 | 4.09 | 1.15 | 0.13 | 0.00 | 2.03 |

| 15 | 1.90 | 1.47 | 1.96 | 0.86 | 0.00 | 0.00 | 1.27 |

| 16 | 4.69 | 1.61 | 0.62 | 0.54 | 0.00 | 0.00 | 0.00 |

| 17 | 4.81 | 3.81 | 4.91 | 1.19 | 0.08 | 0.00 | 1.86 |

| 18 | 2.14 | 6.00 | 6.13 | 3.41 | 0.00 | 0.00 | 0.00 |

| 19 | 4.73 | 5.6 | 7.73 | 1.72 | 0.18 | 2.62 | 2.8 |

| 20 | 6.00 | 5.51 | 5.13 | 1.21 | 0.14 | 4.43 | 2.46 |

| ∑ | 66.76 | 59.3 | 62.4 | 22.7 | 1.15 | 9.44 | 19.8 |

| No. | Mass (g) | Emission Coefficient (mg g−1) | |||||

|---|---|---|---|---|---|---|---|

| Sample | SO2 | NOx | HCN | NH3 | HBr | HCl | |

| 1 | 2.68 | 0.77 | 1.27 | 0.43 | 0.00 | 0.00 | 0.00 |

| 2 | 4.24 | 0.43 | 0.76 | 0.20 | 0.00 | 0.00 | 0.00 |

| 3 | 0.96 | 2.51 | 1.71 | 1.21 | 0.00 | 0.00 | 0.00 |

| 4 | 4.95 | 0.29 | 0.79 | 0.28 | 0.00 | 0.00 | 0.00 |

| 5 | 3.16 | 1.05 | 0.23 | 0.22 | 0.00 | 0.00 | 0.00 |

| 6 | 3.06 | 0.99 | 0.41 | 0.60 | 0.00 | 0.78 | 0.00 |

| 7 | 2.18 | 0.03 | 2.14 | 0.00 | 0.00 | 0.00 | 0.00 |

| 8 | 3.46 | 0.84 | 1.00 | 0.29 | 0.04 | 0.00 | 0.74 |

| 9 | 2.30 | 2.15 | 0.18 | 0.50 | 0.00 | 0.00 | 0.00 |

| 10 | 3.54 | 0.88 | 1.05 | 0.28 | 0.07 | 0.00 | 0.97 |

| 11 | 2.35 | 0.01 | 0.01 | 0.14 | 0.00 | 0.00 | 0.00 |

| 12 | 4.13 | 1.11 | 1.19 | 0.34 | 0.06 | 0.00 | 0.81 |

| 13 | 2.21 | 1.12 | 0.21 | 0.29 | 0.00 | 0.00 | 0.00 |

| 14 | 3.29 | 0.95 | 1.24 | 0.35 | 0.04 | 0.00 | 0.62 |

| 15 | 1.90 | 0.77 | 1.03 | 0.45 | 0.00 | 0.00 | 0.67 |

| 16 | 4.69 | 0.34 | 0.13 | 0.12 | 0.00 | 0.00 | 0.00 |

| 17 | 4.81 | 0.79 | 1.02 | 0.25 | 0.02 | 0.00 | 0.39 |

| 18 | 2.14 | 2.81 | 2.87 | 1.59 | 0.00 | 0.00 | 0.00 |

| 19 | 4.73 | 1.18 | 1.63 | 0.36 | 0.04 | 0.55 | 0.59 |

| 20 | 6.00 | 0.92 | 0.85 | 0.20 | 0.02 | 0.74 | 0.41 |

| Average coefficient | 1.00 | 0.99 | 0.41 | 0.01 | 0.10 | 0.26 | |

| Separation | Fraction | Grain Size (mm) | Mass (g) | Picture |

|---|---|---|---|---|

| The sample after crumbling and separating with sieves | >1 | 70.4 |  | |

| Neodymium magnet | Magnetic (I) | >1 | 27.2 |  |

| Non-magnetic (II) | >1 | 43.2 |  | |

| The sample after crumbling and separating with sieves | < 1 | 263.2 |  | |

| Plate separator | Magnetic (III) | < 1 | 2.5 |  |

| Disc separator | Magnetic (IV) | < 1 | 19.8 |  |

| Disc separator | Magnetic (V) | <0.5 | 22.6 |  |

| Non-magnetic (VI) | <0.5 | 207.7 |  | |

| Chemical Element | Chemical Element Content in Fraction (g) | ||||||

|---|---|---|---|---|---|---|---|

| 0 | I | II | III | IV | V | VI | |

| Cu | 79.462 | 2.258 | 32.358 | 7.76 × 10−2 | 3.01 | 4.048 | 37.71 |

| Fe | 27.247 | 23.344 | 0.764 | 1.425 | 1.416 | 0.135 | 0.164 |

| Al | 1.805 | 1.83 × 10−2 | 6.81 × 10−2 | 1 × 10−6 | 0.23 | 0.256 | 1.233 |

| Sn | 1.62 | 0.113 | 0.631 | 3.23 × 10−3 | 3.22 × 10−2 | 1.18 × 10−3 | 0.839 |

| Zn | 3.123 | 0.169 | 2.268 | 7.4×10−2 | 0.134 | 8.42 × 10−2 | 0.394 |

| Nd | 0.508 | 1.58 × 10−3 | 7.9 × 10−5 | 0.338 | 0.159 | 5.22 × 10−3 | 3.99 × 10−3 |

| Au | 0.197 | 2.32 × 10−3 | 6.47 × 10−3 | 8.76 × 10−4 | 1.53 × 10−2 | 7.19 × 10−3 | 0.164 |

| Co | 0.205 | 0.145 | 3.32 × 10−2 | 1.69 × 10−2 | 4.71 × 10−3 | 1.29 × 10−3 | 3.8 × 10−3 |

| Ag | 1.2 × 10−2 | 2.6 × 10−5 | 5.6 × 10−5 | 1.8 × 10−4 | 1.51 × 10−3 | 4.7 × 10−4 | 9.47 × 10−3 |

| Mo | 1.9 × 10−2 | 3.89 × 10−3 | 1.16 × 10−2 | 4.6 × 10−4 | 3.1 × 10−4 | 1.4 × 10−4 | 2.15 × 10−3 |

| Other element (Si, O, etc.) | 219.40 | 1145 | 7059 | 0.563 | 14.79 | 18.06 | 167.17 |

| fraction mass | 333.6 | 27.2 | 43.2 | 2.50 | 19.8 | 22.6 | 207.7 |

| Cu, α = 24.6% | |||||||

| Fraction | γ, % | ∑γ,% | λ, % | β = ∑(γ × λ)/∑γ, % | K = β/α | ε = γ × λ/α, % | ∑ ε = K × ∑γ, % |

| I | 8.42 | 8.42 | 8.30 | 8.30 | 0.337 | 2.84 | 2.84 |

| II | 13.4 | 21.8 | 74.9 | 49.17 | 2.00 | 40.7 | 43.6 |

| III | 0.77 | 22.6 | 3.10 | 47.59 | 1.93 | 0.098 | 43.7 |

| IV | 6.13 | 28.7 | 15.2 | 40.67 | 1.65 | 3.79 | 47.4 |

| V | 7.00 | 35.7 | 17.9 | 36.21 | 1.47 | 5.09 | 52.5 |

| VI | 64.3 | 100 | 18.2 | 24.60 | 1.00 | 47.5 | 100 |

| Fe, α = 8.44% | |||||||

| Fraction | γ,% | ∑γ,% | λ, % | β = ∑(γ × λ)/∑γ, % | K = β/α | ε = γ × λ/α,% | ∑ ε = K × ∑γ, % |

| I | 8.42 | 8.42 | 85.8 | 85.8 | 10.2 | 85.7 | 85.7 |

| II | 13.4 | 21.8 | 1.77 | 34.2 | 4.06 | 2.80 | 88.5 |

| III | 0.77 | 22.6 | 57.0 | 35.0 | 4.15 | 5.23 | 93.7 |

| IV | 6.13 | 28.7 | 7.15 | 29.1 | 3.45 | 5.20 | 98.9 |

| V | 7.00 | 35.7 | 0.597 | 23.5 | 2.78 | 0.495 | 99.4 |

| VI | 64.3 | 100 | 0.079 | 8.44 | 1.00 | 0.602 | 100 |

| Nd, α = 0.16% | |||||||

| Fraction | γ,% | ∑γ,% | λ, % | β = ∑(γ × λ)/∑γ,% | K = β/α | ε = γ × λ/α,% | ∑ ε = K × ∑γ, % |

| I | 8.42 | 8.42 | 0.006 | 0.006 | 0.037 | 0.311 | 0.311 |

| II | 13.4 | 21.8 | 0.0002 | 0.002 | 0.015 | 0.016 | 0.327 |

| III | 0.77 | 22.6 | 13.5 | 0.466 | 2.96 | 66.6 | 66.9 |

| IV | 6.13 | 28.7 | 0.803 | 0.538 | 3.42 | 31.3 | 98.2 |

| V | 7.00 | 35.7 | 0.023 | 0.437 | 2.78 | 1.03 | 99.2 |

| VI | 64.3 | 100 | 0.002 | 0.157 | 1.00 | 0.786 | 100 |

| Co, α = 0.06% | |||||||

| Fraction | γ,% | ∑γ,% | λ, % | β = ∑(γ × λ)/∑γ, % | K = β/α | ε = γ × λ/α,% | ∑ ε = K × ∑γ, % |

| I | 8.42 | 8.42 | 0.533 | 0.533 | 8.40 | 70.8 | 70.8 |

| II | 13.4 | 21.8 | 0.077 | 0.253 | 3.99 | 16.2 | 87.0 |

| III | 0.77 | 22.6 | 0.676 | 0.268 | 4.22 | 8.25 | 95.2 |

| IV | 6.13 | 28.7 | 0.024 | 0.216 | 3.40 | 2.30 | 97.5 |

| V | 7.00 | 35.7 | 0.006 | 0.174 | 2.75 | 0.630 | 98.1 |

| VI | 64.3 | 100 | 0.002 | 0.063 | 1.00 | 1.85 | 100 |

| Mo, α = 0.006% | |||||||

| Fraction | γ,% | ∑γ,% | λ, % | β = ∑(γ × λ)/∑γ, % | K = β/α | ε = γ × λ/α,% | ∑ ε = K × ∑γ, % |

| I | 8.42 | 8.42 | 0.014 | 0.014 | 2.49 | 21.0 | 21.0 |

| II | 13.4 | 21.8 | 0.027 | 0.022 | 3.83 | 62.5 | 83.5 |

| III | 0.77 | 22.6 | 0.018 | 0.022 | 3.81 | 2.48 | 86.0 |

| IV | 6.13 | 28.7 | 0.002 | 0.018 | 3.05 | 1.67 | 87.7 |

| V | 7.00 | 35.7 | 0.001 | 0.014 | 2.48 | 0.755 | 88.4 |

| VI | 64.3 | 100 | 0.001 | 0.006 | 1.00 | 11.6 | 100 |

| Al, α = 0.56% | |||||||

| Fraction | γ, % | ∑γ, % | λ, % | β = ∑(γ × λ)/∑γ, % | K = β/α | ε = γ × λ/α, % | ∑ ε = K × ∑γ, % |

| I | 8.42 | 8.42 | 0.067 | 0.067 | 0.120 | 1.0 | 1.0 |

| II | 13.4 | 21.8 | 0.158 | 0.123 | 0.220 | 3.8 | 4.8 |

| III | 0.77 | 22.6 | 0.000 | 0.119 | 0.212 | 0.000 | 4.8 |

| IV | 6.13 | 28.7 | 1.16 | 0.341 | 0.611 | 12.7 | 17.5 |

| V | 7.00 | 35.7 | 1.13 | 0.496 | 0.888 | 14.2 | 31.7 |

| VI | 64.3 | 100 | 0.594 | 0.559 | 1.00 | 68.3 | 100 |

| Zn, α = 0.97% | |||||||

| Fraction | γ, % | ∑γ, % | λ, % | β = ∑ γ × λ/∑ γ, % | K = β/α | ε = γ × λ/α, % | ∑ ε = K × ∑γ, % |

| I | 8.42 | 8.42 | 0.621 | 0.621 | 0.643 | 5.41 | 5.41 |

| II | 13.4 | 21.8 | 5.25 | 3,46 | 3.58 | 72.6 | 78,0 |

| III | 0.77 | 22.6 | 2.96 | 3.44 | 3.56 | 2.37 | 80.4 |

| IV | 6.13 | 28.7 | 0.677 | 2.85 | 2.95 | 4.29 | 84.7 |

| V | 7.00 | 35.7 | 0.373 | 2.37 | 2.45 | 2.70 | 87.4 |

| VI | 64.3 | 100 | 0.190 | 0.967 | 1.00 | 12.6 | 100 |

| Sn, α = 0.50% | |||||||

| Fraction | γ, % | ∑γ, % | λ, % | β = ∑ γ × λ/∑ γ, % | K = β/α | ε = γ × λ/α, % | ∑ ε = K × ∑γ, % |

| I | 8.42 | 8.42 | 0.415 | 0.415 | 0.829 | 6.98 | 6.98 |

| II | 13.4 | 21.8 | 1.46 | 1.06 | 2.11 | 39.0 | 45.9 |

| III | 0.77 | 22.6 | 0.129 | 1.03 | 2.04 | 0.199 | 46.1 |

| IV | 6.13 | 28.7 | 0.163 | 0.841 | 1.68 | 1.99 | 48.1 |

| V | 7.00 | 35.7 | 0.005 | 0.677 | 1.35 | 0.073 | 48.2 |

| VI | 64.3 | 100 | 0.404 | 0.501 | 1.00 | 51.8 | 100 |

| Au, α = 0.06% | |||||||

| Fraction | γ, % | ∑γ, % | λ, % | β = ∑ γ × λ/∑ γ, % | K = β/α | ε = γ × λ/α, % | ∑ ε = K × ∑γ, % |

| I | 8.42 | 8.42 | 0.009 | 0.009 | 0.140 | 1.18 | 1.18 |

| II | 13.4 | 21.8 | 0.015 | 0.012 | 0.206 | 3.30 | 4.48 |

| III | 0.77 | 22.6 | 0.035 | 0.013 | 0.218 | 0.447 | 4.93 |

| IV | 6.13 | 28.7 | 0.077 | 0.027 | 0.443 | 7.80 | 12.7 |

| V | 7.00 | 35.7 | 0.032 | 0.028 | 0.459 | 3.67 | 16.4 |

| VI | 64.3 | 100 | 0.079 | 0.061 | 1.00 | 83.6 | 100 |

| Ag, α = 0.004% | |||||||

| Fraction | γ, % | ∑γ, % | λ, % | β = ∑ γ × λ/∑ γ, % | K = β/α | ε = γ × λ/α, % | ∑ ε = K × ∑γ, % |

| I | 8.42 | 8.42 | 0.0001 | 0.0001 | 0.026 | 0.222 | 0.222 |

| II | 13.4 | 21.8 | 0.0001 | 0.0001 | 0.032 | 0.478 | 0.700 |

| III | 0.77 | 22.6 | 0.007 | 0.0004 | 0.099 | 1.54 | 2.24 |

| IV | 6.13 | 28.7 | 0.008 | 0.0019 | 0.527 | 12.9 | 15.1 |

| V | 7.00 | 35.7 | 0.002 | 0.0019 | 0.536 | 4.01 | 19.1 |

| VI | 64.3 | 100 | 0.005 | 0.0036 | 1.00 | 80.9 | 100 |

| Fraction | Crystalline Phase Identified | ||||

|---|---|---|---|---|---|

| Si | Cu | Fe | Sn | Others | |

| I | - | Cu—42.2% | Fe—57.3% | - | W—0.5% |

| II | Si—1.1% | Cu—46.5% Cu (Zn)—23.9% Cu (Pb, Sn, Zn)—11.3% | - | - | Al—13.6% C—3.6% |

| III | - | - | Fe14Nd2B—31.4% Fe3O4—25.7% | SnO2—5.7% | Ni—37.2% |

| IV | SiO2—62.3% | Cu2O—8.9% CuO—4.8% Cu—5.6% | CuFe—3.0% | SnO3Sr—2.7% SnO2—2.2% | BaTiO3—10.6% |

| V | SiO2—61.0% | Cu2O—25.3% Tl0.01Cu3.99 —6.7% CuO—3.6% CuGaTe2—1.4% | - | SnO2—2.2% | - |

| VI | SiO2—59.8% | Cu2O—29.4% Tl0.01Cu3.99 —5.1% CuO—2.1% | - | SnO2—3.5% | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Żukowski, W.; Kowalska, A.; Wrona, J. High-Temperature Fluidized Bed Processing of Waste Electrical and Electronic Equipment (WEEE) as a Way to Recover Raw Materials. Energies 2021, 14, 5639. https://doi.org/10.3390/en14185639

Żukowski W, Kowalska A, Wrona J. High-Temperature Fluidized Bed Processing of Waste Electrical and Electronic Equipment (WEEE) as a Way to Recover Raw Materials. Energies. 2021; 14(18):5639. https://doi.org/10.3390/en14185639

Chicago/Turabian StyleŻukowski, Witold, Amelia Kowalska, and Jan Wrona. 2021. "High-Temperature Fluidized Bed Processing of Waste Electrical and Electronic Equipment (WEEE) as a Way to Recover Raw Materials" Energies 14, no. 18: 5639. https://doi.org/10.3390/en14185639

APA StyleŻukowski, W., Kowalska, A., & Wrona, J. (2021). High-Temperature Fluidized Bed Processing of Waste Electrical and Electronic Equipment (WEEE) as a Way to Recover Raw Materials. Energies, 14(18), 5639. https://doi.org/10.3390/en14185639