A Framework and Baseline for the Integration of a Sustainable Circular Economy in Offshore Wind

Abstract

:1. Introduction

2. Background: Circular Economy and Offshore Wind

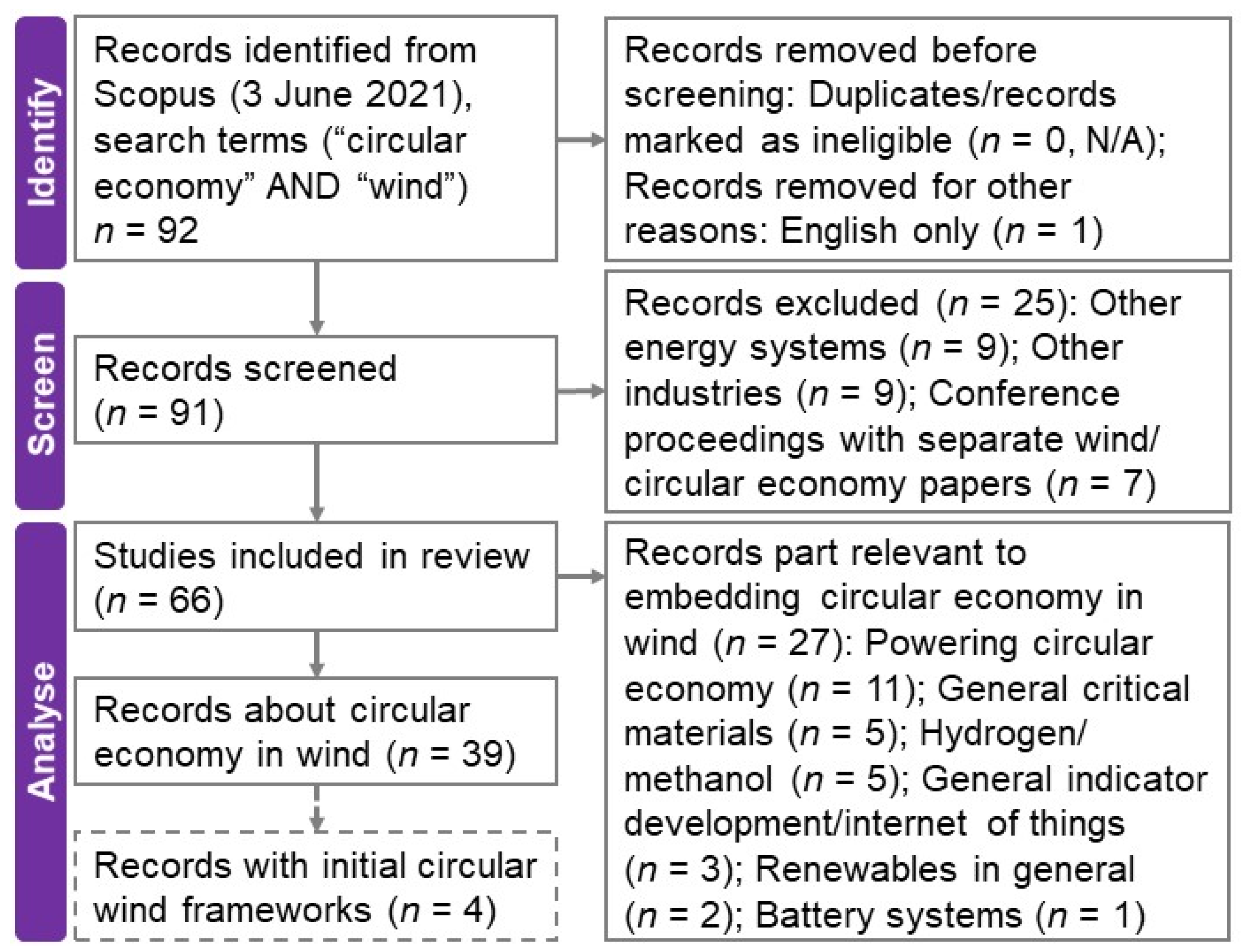

2.1. Current Circular Economy Literature on Wind Energy

2.2. Circular Economy-Related Challenges and Opportunities in Offshore Wind

3. Methods

3.1. Developing the Framework

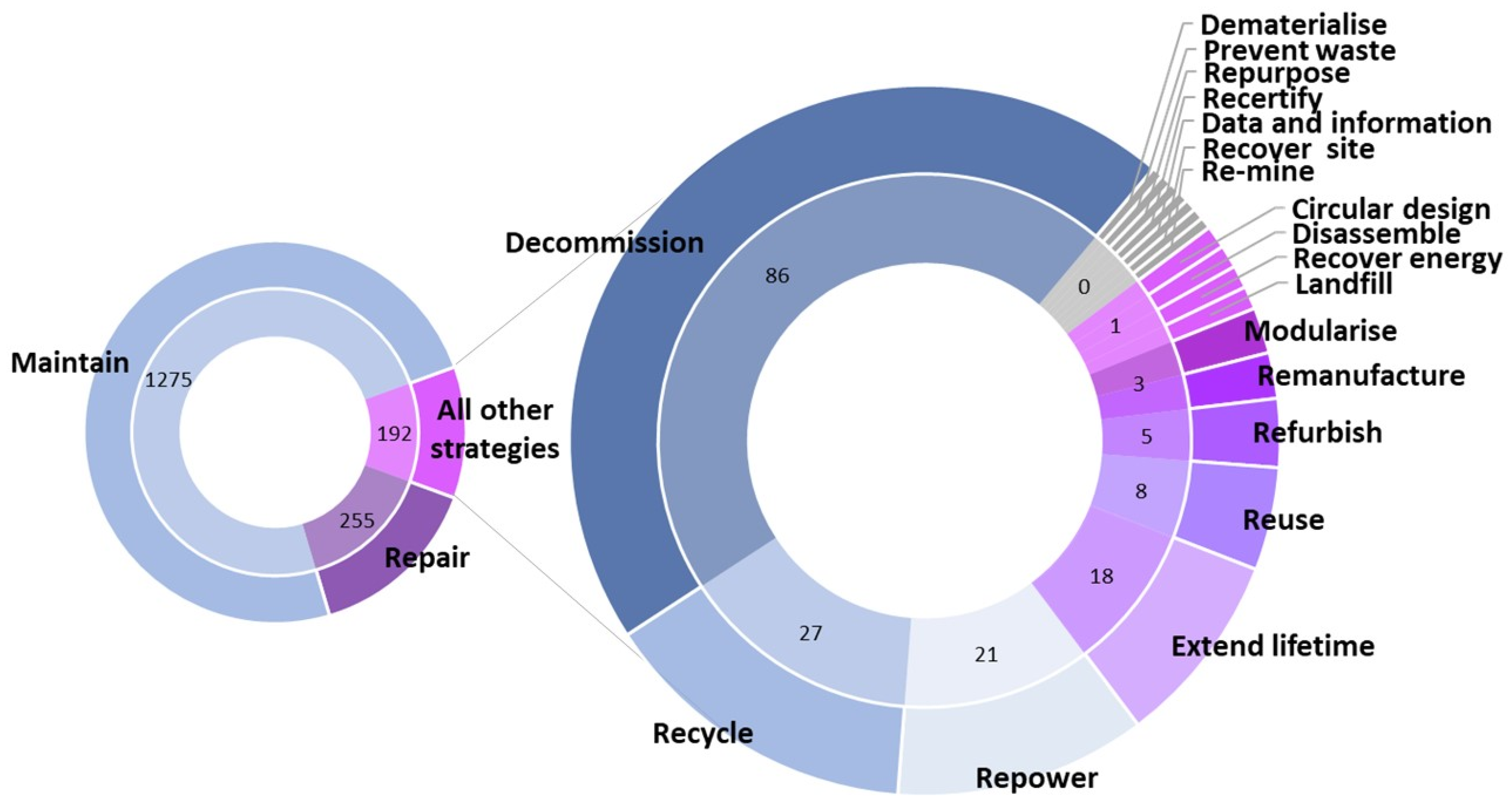

3.2. Reviews to Define and Take a Baseline of the Identified Strategies

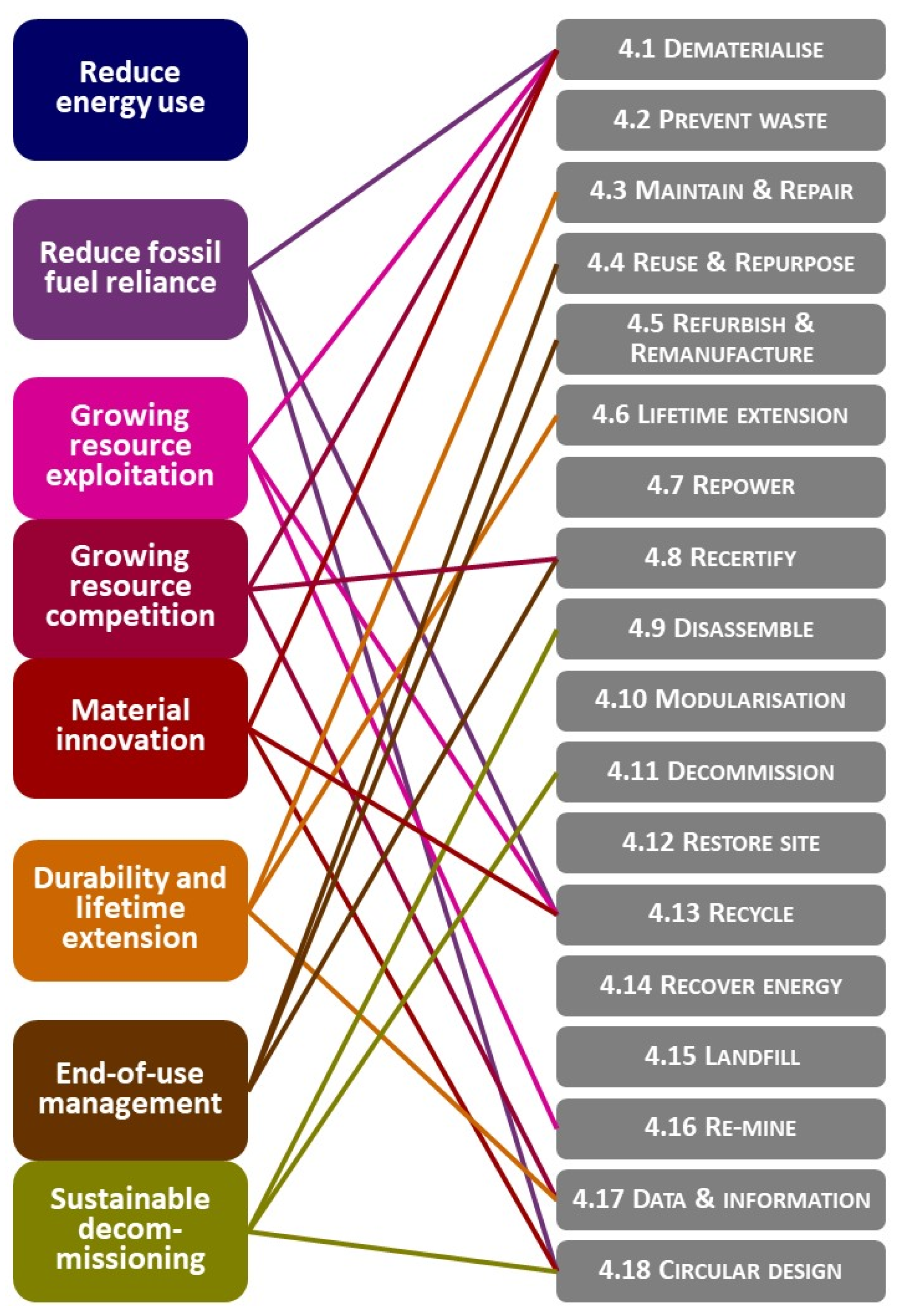

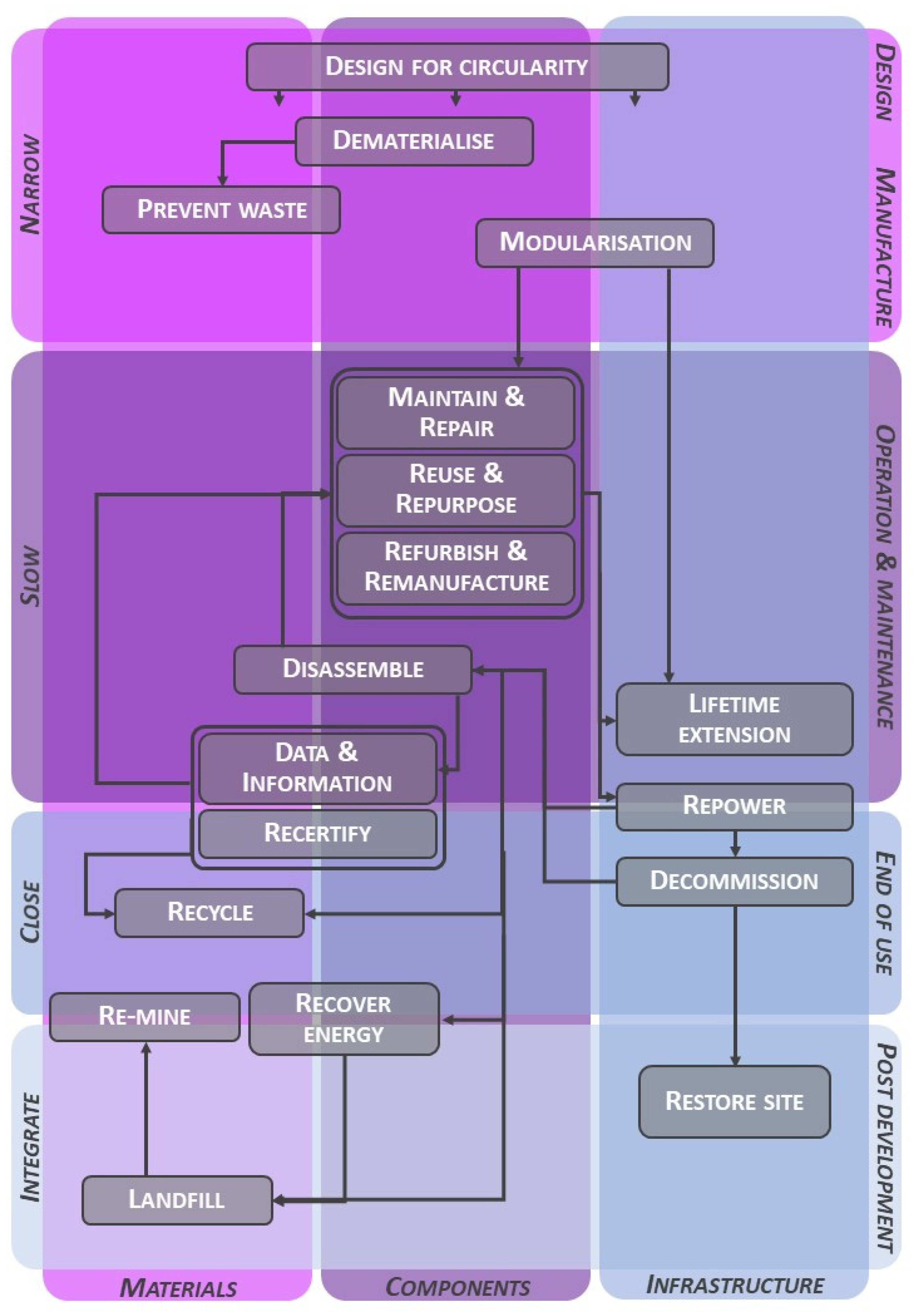

4. Results: Circular Economy Framework for Offshore Wind

4.1. Dematerialisation

4.2. Waste Prevention

4.3. Repair and Maintenance

4.4. Component Reuse and Repurposing

4.5. Lifetime Extension

4.6. Repowering

4.7. Refurbish and Remanufacture

4.8. Recertification

4.9. Disassembly

4.10. Modularisation

4.11. Decommissioning

4.12. Site Recovery

4.13. Recycle Materials

4.14. Energy Recovery

4.15. Landfill and Controlled Storage

4.16. Re-Mine

4.17. Data and Information

4.18. Design for Circularity

5. Discussion: Application and Transferability of the Framework

5.1. How to Use the Framework

5.2. Transferability to Other Sectors

5.2.1. Circular Economy Frameworks across Energy Industries

5.2.2. Application of Offshore Wind Circular Economy Framework in Other Sectors

6. Conclusions and Future Perspectives

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- UN. Paris Agreement; UN: New York, NY, USA, 2015. [Google Scholar]

- GWEC. Global Wind Report 2021; GWEC: Brussel, Belgium, 2021. [Google Scholar]

- IRENA. Global Renewables Outlook: Energy Transformation 2050; IRENA: Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- Vidal, O.; Goffé, B.; Arndt, N.T. Metals for a low-carbon society. Nat. Geosci. 2013, 6, 894–896. [Google Scholar] [CrossRef]

- Topham, E.; McMillan, D.; Bradley, S.; Hart, E. Recycling offshore wind farms at decommissioning stage. Energy Policy 2019, 129, 698–709. [Google Scholar] [CrossRef] [Green Version]

- Stamford, L.; Azapagic, A. Life cycle sustainability assessment of electricity options for the UK. Int. J. Energy Res. 2012, 36, 1263–1290. [Google Scholar] [CrossRef]

- Gallagher, J.; Basu, B.; Browne, M.; Kenna, A.; McCormack, S.; Pilla, F.; Styles, D. Adapting Stand-Alone Renewable Energy Technologies for the Circular Economy through Eco-Design and Recycling. J. Ind. Ecol. 2019, 23, 133–140. [Google Scholar] [CrossRef] [Green Version]

- Jensen, P.D.; Purnell, P.; Velenturf, A.P.M. Highlighting the need to embed circular economy in low carbon infrastructure decommissioning: The case of offshore wind. Sustain. Prod. Consum. 2020, 24, 266–280. [Google Scholar] [CrossRef]

- Invernizzi, D.C.; Locatelli, G.; Velenturf, A.P.M.; Love, P.E.; Purnell, P.; Brookes, N.J. Developing policies for the end-of-life of energy infrastructure: Coming to terms with the challenges of decommissioning. Energy Policy 2020, 144, 111677. [Google Scholar] [CrossRef]

- Velenturf, A.P.M.; Purnell, P. Principles for a sustainable circular economy. Sustain. Prod. Consum. 2021, 27, 1437–1457. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Almeida, C.M.V.B.; Agostinho, F.; Huisingh, D.; Giannetti, B.F. Cleaner Production towards a sustainable transition. J. Clean. Prod. 2017, 142, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Ashford, N.A. Reflections on the First Decade of the Journal of Cleaner Production. J. Clean. Prod. 2002, 10, 101–102. [Google Scholar] [CrossRef]

- Barnard, F. Education for management conceived as a study of industrial ecology. Vocat. Asp. Educ. 1963, 15, 22–26. [Google Scholar] [CrossRef]

- Jelinski, L.W.; Graedel, T.E.; Laudise, R.A.; McCall, D.W.; Patel, C.K. Industrial ecology: Concepts and approaches. Proc. Natl. Acad. Sci. USA 1992, 89, 793–797. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wallner, H.P.; Narodoslawsky, M. The concept of sustainable islands: Cleaner production, industrial ecology and the network paradigm as preconditions for regional sustainable development. J. Clean. Prod. 1994, 2, 167–171. [Google Scholar] [CrossRef]

- Gibbs, D.; Deutz, P. Reflections on implementing industrial ecology through eco-industrial park development. J. Clean. Prod. 2007, 15, 1683–1695. [Google Scholar] [CrossRef]

- Jensen, P.D.; Basson, L.; Leach, M. Reinterpreting Industrial Ecology. J. Ind. Ecol. 2011, 15, 680–692. [Google Scholar] [CrossRef] [Green Version]

- Johnson, D.G. Resource Efficiency and Policy. J. Farm Econ. 1950, 32, 123–128. [Google Scholar] [CrossRef]

- Duflou, J.R.; Sutherland, J.; Dornfeld, D.; Herrmann, C.; Jeswiet, J.; Kara, S.; Hauschild, M.Z.; Kellens, K. Towards energy and resource efficient manufacturing: A processes and systems approach. CIRP Ann. Manuf. Technol. 2012, 61, 587–609. [Google Scholar] [CrossRef] [Green Version]

- Allwood, J.M. Unrealistic techno-optimism is holding back progress on resource efficiency. Nat. Mater. 2018, 17, 1050–1051. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Towards a sustaining architecture for the 21st century: The promise of cradle-to-cradle design. Ind. Environ. 2003, 26, 13–16. [Google Scholar]

- Stahel, W.; Reday-Mulvey, G. Jobs for Tomorrow, the Potential for Substituting Manpower for Energy; Vantage Press: New York, NY, USA, 1981. [Google Scholar]

- Cole, R.J. Transitioning from green to regenerative design. Build. Res. Inf. 2012, 40, 39–53. [Google Scholar] [CrossRef]

- Roy, R. Sustainable product-service systems. Futures 2000, 32, 289–299. [Google Scholar] [CrossRef]

- Mont, O. Clarifying the concept of product–service system. J. Clean. Prod. 2002, 10, 237–245. [Google Scholar] [CrossRef]

- Tsanakas, J.A.; Van Der Heide, A.; Radavičius, T.; Denafas, J.; Lemaire, E.; Wang, K.; Poortmans, J.; Voroshazi, E. Towards a circular supply chain for PV modules: Review of today’s challenges in PV recycling, refurbishment and re-certification. Prog. Photovolt. Res. Appl. 2020, 28, 454–464. [Google Scholar] [CrossRef]

- Da Costa Fernandes, S.; Pigosso, D.C.; McAloone, T.C.; Rozenfeld, H. Towards product-service system oriented to circular economy: A systematic review of value proposition design approaches. J. Clean. Prod. 2020, 257, 120507. [Google Scholar] [CrossRef]

- Pearce, D. Economics, equity and sustainable development. Futures 1988, 20, 598–605. [Google Scholar] [CrossRef]

- Costanza, R. Valuing natural capital and ecosystem services toward the goals of efficiency, fairness, and sustainability. Ecosyst. Serv. 2020, 43, 101096. [Google Scholar] [CrossRef]

- Costanza, R.; D’Arge, R.; De Groot, R.; Farber, S.; Grasso, M.; Hannon, B.; Limburg, K.; Naeem, S.; O’Neill, R.V.; Paruelo, J.; et al. The value of the world’s ecosystem services and natural capital. Nature 1997, 387, 253–260. [Google Scholar] [CrossRef]

- Buchmann-Duck, J.; Beazley, K.F. An urgent call for circular economy advocates to acknowledge its limitations in conserving biodiversity. Sci. Total Environ. 2020, 727, 138602. [Google Scholar] [CrossRef]

- Fulton, G.P. Zero discharge of water filtration plant wastewater effluent. Public Works 1973, 104, 86–88. [Google Scholar]

- Chong, M.N.; Jin, B.; Chow, C.W.K.; Saint, C. Recent developments in photocatalytic water treatment technology: A review. Water Res. 2010, 44, 2997–3027. [Google Scholar] [CrossRef] [PubMed]

- Spooren, J.; Binnemans, K.; Björkmalm, J.; Breemersch, K.; Dams, Y.; Folens, K.; González-Moya, M.; Horckmans, L.; Komnitsas, K.; Kurylak, W.; et al. Near-zero-waste processing of low-grade, complex primary ores and secondary raw materials in Europe: Technology development trends. Resour. Conserv. Recycl. 2020, 160, 104919. [Google Scholar] [CrossRef]

- Binnemans, K.; Jones, P.T.; Blanpain, B.; Van Gerven, T.; Pontikes, Y. Towards zero-waste valorisation of rare-earth-containing industrial process residues: A critical review. J. Clean. Prod. 2015, 99, 17–38. [Google Scholar] [CrossRef] [Green Version]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Suárez-Eiroa, B.; Fernandez, E.; Martínez, G.M.; Soto-Oñate, D. Operational principles of circular economy for sustainable development: Linking theory and practice. J. Clean. Prod. 2019, 214, 952–961. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.A.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- Velenturf, A.P.M.; Archer, S.A.; Gomes, H.I.; Christgen, B.; Brotons, A.J.L.; Purnell, P. Circular economy and the matter of integrated resources. Sci. Total Environ. 2019, 689, 963–969. [Google Scholar] [CrossRef] [PubMed]

- Haas, W.; Krausmann, F.; Wiedenhofer, D.; Heinz, M. How Circular is the Global Economy?: An Assessment of Material Flows, Waste Production, and Recycling in the European Union and the World in 2005. J. Ind. Ecol. 2015, 19, 765–777. [Google Scholar] [CrossRef]

- Fishman, T.; Graedel, T.E. Impact of the establishment of US offshore wind power on neodymium flows. Nat. Sustain. 2019, 2, 332–338. [Google Scholar] [CrossRef]

- Schipper, B.W.; Lin, H.-C.; Meloni, M.A.; Wansleeben, K.; Heijungs, R.; van der Voet, E. Estimating global copper demand until 2100 with regression and stock dynamics. Resour. Conserv. Recycl. 2018, 132, 28–36. [Google Scholar] [CrossRef]

- UN. Transforming Our World: The 2030 Agenda for Sustainable Development; UN: New York, NY, USA, 2015. [Google Scholar]

- Mackie, C.; Velenturf, A.P.M. Financial security for decommissioing offshore renewable energy installations in UK waters: Trouble on the horizon. Energy Policy 2021, 157, 112479. [Google Scholar] [CrossRef]

- Jensen, J.; Skelton, K. Wind turbine blade recycling: Experiences, challenges and possibilities in a circular economy. Renew. Sustain. Energy Rev. 2018, 97, 165–176. [Google Scholar] [CrossRef]

- Jensen, J.P. Evaluating the environmental impacts of recycling wind turbines. Wind Energy 2019, 22, 316–326. [Google Scholar] [CrossRef]

- Delaney, E.L.; McKinley, J.M.; Megarry, W.; Graham, C.; Leahy, P.G.; Bank, L.C.; Gentry, R. An integrated geospatial approach for repurposing wind turbine blades. Resour. Conserv. Recycl. 2021, 170, 105601. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Green Alliance. Less in, More out: Using Resource Efficiency to Cut Carbon and Benefit the Economy; Green Alliance: London, UK, 2018. [Google Scholar]

- Circle Economy. Circularity Gap Report 2019; Circle Economy: Amsterdam, The Netherlands, 2019. [Google Scholar]

- DEFRA. Environment Bill 2020; Department for Environment, Food & Rural Affairs: Westminster, UK, 2020.

- Purnell, P.; Velenturf, A.P.M.; Marshall, R. Chapter 16: New Governance for Circular Economy: Policy, Regulation and Market Contexts for Resource Recovery from Waste. RSC Green Chem. 2020, 2020, 395–422. [Google Scholar] [CrossRef]

- Lacy, P.; Rutqvist, J. Waste to Wealth: The Circular Economy Advantage; Pallgrave Macmillan: Basingstoke, UK, 2015; pp. 1–264. [Google Scholar]

- Stahel, W.R. The circular economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Li, Y.; Chen, C.; Zhang, Y.; Chen, D.; Hu, S. Research on high-power pump systems of nongrid connected wind power. In Proceedings of the 2010 World Non-Grid-Connected Wind Power and Energy Conference, WNWEC 2010, Nanjing, China, 5–7 November 2010; pp. 192–197. [Google Scholar]

- Pego, A.C. The Portuguese Offshore Energy SWOT Analysis. J. Phys. Conf. Ser. 2019, 1222, 012036. [Google Scholar] [CrossRef]

- Lichtenegger, G.; Rentizelas, A.A.; Trivyza, N.; Siegl, S. Offshore and onshore wind turbine blade waste material forecast at a regional level in Europe until 2050. Waste Manag. 2020, 106, 120–131. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Cai, G.; Zheng, L.; Zhang, Y.; Qi, X.; Ke, S.; Gao, L.; Bai, R.; Liu, G. Modeling waste generation and end-of-life management of wind power development in Guangdong, China until 2050. Resour. Conserv. Recycl. 2021, 169, 105533. [Google Scholar] [CrossRef]

- Chen, S.-H.; Ou, Y.-P. Digital transformation and structural change in Taiwan’s national innovation system. In Industrial Development of Taiwan: Past Achievement and Future Challenges Beyond 2020; Routledge: London, UK, 2021; pp. 34–54. [Google Scholar]

- Cullen, J.M. Circular Economy: Theoretical Benchmark or Perpetual Motion Machine? J. Ind. Ecol. 2017, 21, 483–486. [Google Scholar] [CrossRef]

- Giampietro, M.; Funtowicz, S.O. From elite folk science to the policy legend of the circular economy. Environ. Sci. Policy 2020, 109, 64–72. [Google Scholar] [CrossRef]

- OREC; University of Leeds; NCC; OGTC. Sustainable Decommissioning: Wind Turbine Blade Recycling; Offshore Renewable Energy Catapult: Glasgow, UK, 2021. [Google Scholar]

- WindEurope; Cefic; EuCIA. Accelerating Wind Turbine Blade Circularity; WindEurope: Brussels, Belgium, 2020. [Google Scholar]

- Purnell, P.; Velenturf, A.P.M.; Jensen, P.D.; Cliffe, N.; Jopson, J.S. Developing Technology, Approaches and Business Models for Decommissioning of Low-Carbon Infrastructure; Resource Recovery from Waste: Leeds, UK, 2018. [Google Scholar]

- Van Wijk, A.; Verhoef, L. Our Car as Power Plant; IOS Press: Amsterdam, The Netherlands, 2014; pp. 1–107. [Google Scholar] [CrossRef]

- Ji, P.; Zhou, X.X.; Wu, S. Review on sustainable development of island microgrid. In Proceedings of the 2011 International Conference on Advanced Power System Automation and Protection, Beijing, China, 16–20 October 2011; Volume 3, pp. 1806–1813. [Google Scholar]

- Proskuryakova, L.N.; Ermolenko, G.V. The future of Russia’s renewable energy sector: Trends, scenarios and policies. Renew. Energy 2019, 143, 1670–1686. [Google Scholar] [CrossRef]

- Zambon, I.; Monarca, D.; Cecchini, M.; Bedini, R.; Longo, L.; Romagnoli, M.; Marucci, A. Alternative energy and the development of local rural contexts: An approach to improve the degree of smart cities in the Central-Southern Italy. Contemp. Eng. Sci. 2016, 9, 1371–1386. [Google Scholar] [CrossRef]

- Cascone, S.; Ingrao, C.; Valenti, F.; Porto, S.M. Energy and environmental assessment of plastic granule production from recycled greenhouse covering films in a circular economy perspective. J. Environ. Manag. 2020, 254, 109796. [Google Scholar] [CrossRef]

- Díaz-Ramírez, M.; Ferreira, V.J.; García-Armingol, T.; López-Sabirón, A.M.; Ferreira, G. Environmental Assessment of Electrochemical Energy Storage Device Manufacturing to Identify Drivers for Attaining Goals of Sustainable Materials 4.0. Sustainability 2020, 12, 342. [Google Scholar] [CrossRef] [Green Version]

- Desing, H.; Widmer, R.; Beloin-Saint-Pierre, D.; Hischier, R.; Wäger, P. Powering a Sustainable and Circular Economy—An Engineering Approach to Estimating Renewable Energy Potentials within Earth System Boundaries. Energies 2019, 12, 4723. [Google Scholar] [CrossRef] [Green Version]

- Dong, Q. Study on the development strategy of tourism circular economy based on renewable energy technology. J. Adv. Oxid. Technol. 2018, 21. [Google Scholar] [CrossRef]

- Kiviranta, K.; Thomasson, T.; Hirvonen, J.; Tähtinen, M. Connecting circular economy and energy industry: A techno-economic study for the Åland Islands. Appl. Energy 2020, 279, 115883. [Google Scholar] [CrossRef]

- Jin, T.; Liao, H.; Taboada, H.; Jimenez, J.; Sun, F. Integration of reliability, service and renewables for sustainable manufacturing initiatives. In Proceedings of the IIE Annual Conference and Expo 2014, Montreal, QC, Canada, 31 May–3 June 2014; pp. 577–586. [Google Scholar]

- Kılkış, Ş.; Kilkis, B. Integrated circular economy and education model to address aspects of an energy-water-food nexus in a dairy facility and local contexts. J. Clean. Prod. 2017, 167, 1084–1098. [Google Scholar] [CrossRef]

- Carbone, C.; Gracceva, F.; Pierro, N.; Motola, V.; Zong, Y.; You, S.; Pérez-Fortes, M.; Wang, L.; Agostini, A. Potential Deployment of Reversible Solid-Oxide Cell Systems to Valorise Organic Waste, Balance the Power Grid and Produce Renewable Methane: A Case Study in the Southern Italian Peninsula. Front. Energy Res. 2021, 9, 15. [Google Scholar] [CrossRef]

- Nadaleti, W.C.; dos Santos, G.B.; Lourenço, V.A. Integration of renewable energies using the surplus capacity of wind farms to generate H2 and electricity in Brazil and in the Rio Grande do Sul state: Energy planning and avoided emissions within a circular economy. Int. J. Hydrogen Energy 2020, 45, 24190–24202. [Google Scholar] [CrossRef]

- Rusmanis, D.; O’Shea, R.; Wall, D.M.; Murphy, J.D. Biological hydrogen methanation systems—An overview of design and efficiency. Bioengineered 2019, 10, 604–634. [Google Scholar] [CrossRef] [Green Version]

- Eggemann, L.; Escobar, N.; Peters, R.; Burauel, P.; Stolten, D. Life cycle assessment of a small-scale methanol production system: A Power-to-Fuel strategy for biogas plants. J. Clean. Prod. 2020, 271, 122476. [Google Scholar] [CrossRef]

- Bazaluk, O.; Havrysh, V.; Nitsenko, V.; Baležentis, T.; Streimikiene, D.; Tarkhanova, E.A. Assessment of Green Methanol Production Potential and Related Economic and Environmental Benefits: The Case of China. Energies 2020, 13, 3113. [Google Scholar] [CrossRef]

- Schoden, F.; Siebert, A.; Keskin, A.; Herzig, K.; Straus, M.; Schwenzfeier-Hellkamp, E. Building a Wind Power Plant from Scrap and Raising Public Awareness for Renewable Energy Technology in a Circular Economy. Sustainability 2020, 12, 90. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.L.; Bella, V.D.; Magnano, I.; Harryson, S.; Sciuto, G. Industrial symbiosis-based renewable energy: A sustainable way to draw advantages from Sicily’s sun and wind. Procedia Environ. Sci. Eng. Manag. 2019, 6, 149–157. [Google Scholar]

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef] [Green Version]

- Eriksson, O. Energy and Waste Management. Energies 2017, 10, 1072. [Google Scholar] [CrossRef] [Green Version]

- Novais, R.M.; Carvalheiras, J.; Seabra, M.; Pullar, R.; Labrincha, J. Effective mechanical reinforcement of inorganic polymers using glass fibre waste. J. Clean. Prod. 2017, 166, 343–349. [Google Scholar] [CrossRef]

- Hao, S.; Kuah, A.T.; Rudd, C.D.; Wong, K.H.; Lai, N.Y.G.; Mao, J.; Liu, X. A circular economy approach to green energy: Wind turbine, waste, and material recovery. Sci. Total Environ. 2020, 702, 135054. [Google Scholar] [CrossRef] [PubMed]

- Sommer, V.; Stockschläder, J.; Walther, G. Estimation of glass and carbon fiber reinforced plastic waste from end-of-life rotor blades of wind power plants within the European Union. Waste Manag. 2020, 115, 83–94. [Google Scholar] [CrossRef] [PubMed]

- Psomopoulos, C.S.; Kalkanis, K.; Kaminaris, S.; Ioannidis, G.C.; Pachos, P. A Review of the Potential for the Recovery of Wind Turbine Blade Waste Materials. Recycling 2019, 4, 7. [Google Scholar] [CrossRef] [Green Version]

- Dubey, P.K.; Mahanth, S.K.; Dixit, A.; Changmongkol, S. Recyclable epoxy systems for rotor blades. IOP Conf. Ser. Mater. Sci. Eng. 2021, 942, 012014. [Google Scholar] [CrossRef]

- Romani, A.; Mantelli, A.; Suriano, R.; Levi, M.; Turri, S. Additive Re-Manufacturing of Mechanically Recycled End-of-Life Glass Fiber-Reinforced Polymers for Value-Added Circular Design. Materials 2020, 13, 3545. [Google Scholar] [CrossRef]

- Joustra, J.; Flipsen, B.; Balkenende, R. Structural reuse of high end composite products: A design case study on wind turbine blades. Resour. Conserv. Recycl. 2021, 167, 105393. [Google Scholar] [CrossRef]

- Cooperman, A.; Eberle, A.; Lantz, E. Wind turbine blade material in the United States: Quantities, costs, and end-of-life options. Resour. Conserv. Recycl. 2021, 168, 105439. [Google Scholar] [CrossRef]

- Rentizelas, A.; Trivyza, N.; Oswald, S.; Siegl, S. Reverse supply network design for circular economy pathways of wind turbine blades in Europe. Int. J. Prod. Res. 2021. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite Material Recycling Technology—State-of-the-Art and Sustainable Development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

- Lapko, Y.; Trianni, A.; Nuur, C.; Masi, D. In Pursuit of Closed-Loop Supply Chains for Critical Materials: An Exploratory Study in the Green Energy Sector. J. Ind. Ecol. 2019, 23, 182–196. [Google Scholar] [CrossRef] [Green Version]

- Nelson, J.J.M.; Schelter, E.J. Sustainable Inorganic Chemistry: Metal Separations for Recycling. Inorg. Chem. 2019, 58, 979–990. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Anawati, J.; Yao, Y.; Azimi, G. Aeriometallurgical Extraction of Rare Earth Elements from a NdFeB Magnet Utilizing Supercritical Fluids. ACS Sustain. Chem. Eng. 2018, 6, 16713–16725. [Google Scholar] [CrossRef]

- Diehl, O.; Schönfeldt, M.; Brouwer, E.; Dirks, A.; Rachut, K.; Gassmann, J.; Güth, K.; Buckow, A.; Gauß, R.; Stauber, R.; et al. Towards an Alloy Recycling of Nd–Fe–B Permanent Magnets in a Circular Economy. J. Sustain. Met. 2018, 4, 163–175. [Google Scholar] [CrossRef]

- Rhodes, C.J. Endangered elements, critical raw materials and conflict minerals. Sci. Prog. 2019, 102, 304–350. [Google Scholar] [CrossRef]

- Ranta-Korhonen, T.; Soininen, H. Ash fractions from incineration of municipal waste and solid biofuels as secondary resources for circular economy and recovery of rees. In Proceedings of the 27th European Biomass Conference and Exhibition Proceedings, Lisbon, Portugal, 27–30 May 2019; pp. 163–165. [Google Scholar]

- Bonfante, M.C.; Raspini, J.P.; Fernandes, I.B.; Fernandes, S.; Campos, L.M.; Alarcon, O.E. Achieving Sustainable Development Goals in rare earth magnets production: A review on state of the art and SWOT analysis. Renew. Sustain. Energy Rev. 2021, 137, 110616. [Google Scholar] [CrossRef]

- Lima, A.T.; Ottosen, L. Recovering rare earth elements from contaminated soils: Critical overview of current remediation technologies. Chemosphere 2021, 265, 129163. [Google Scholar] [CrossRef]

- Maani, T.; Mathur, N.; Singh, S.; Rong, C.; Sutherland, J.W. Potential for Nd and Dy Recovery from End-of-Life Products to Meet Future Electric Vehicle Demand in the U.S. Procedia CIRP 2021, 98, 109–114. [Google Scholar] [CrossRef]

- Tansel, B. Increasing gaps between materials demand and materials recycling rates: A historical perspective for evolution of consumer products and waste quantities. J. Environ. Manag. 2020, 276, 111196. [Google Scholar] [CrossRef]

- Tabelin, C.B.; Dallas, J.; Casanova, S.; Pelech, T.; Bournival, G.; Saydam, S.; Canbulat, I. Towards a low-carbon society: A review of lithium resource availability, challenges and innovations in mining, extraction and recycling, and future perspectives. Miner. Eng. 2021, 163, 106743. [Google Scholar] [CrossRef]

- Mulvaney, D.; Richards, R.M.; Bazilian, M.D.; Hensley, E.; Clough, G.; Sridhar, S. Progress towards a circular economy in materials to decarbonize electricity and mobility. Renew. Sustain. Energy Rev. 2021, 137, 110604. [Google Scholar] [CrossRef]

- Norgren, A.; Carpenter, A.; Heath, G. Design for Recycling Principles Applicable to Selected Clean Energy Technologies: Crystalline-Silicon Photovoltaic Modules, Electric Vehicle Batteries, and Wind Turbine Blades. J. Sustain. Metall. 2020, 6, 761–774. [Google Scholar] [CrossRef]

- Pasquali, F.; Suk, H.; Behdad, S.; Hall, J. Method for design life of energy system components based on Levelized Cost of Energy. J. Clean. Prod. 2020, 268, 121971. [Google Scholar] [CrossRef]

- Pasquali, F.M.; Meza, J.; Hall, J.F. Decision-Based Design Method for Computing Marginal Cost of Durability. In Proceedings of the 25th Design for Manufacturing and the Life Cycle Conference (DFMLC), Virtual, Online, 17–19 August 2020. [Google Scholar]

- Medici, P.; van den Dobbelsteen, A.; Peck, D. Safety and Health Concerns for the Users of a Playground, Built with Reused Rotor Blades from a Dismantled Wind Turbine. Sustainability 2020, 12, 3626. [Google Scholar] [CrossRef]

- Bank, L.; Arias, F.R.; Gentry, T.R.; Al-Haddad, T.; Tasistro-Hart, B.; Chen, J.-F. Structural analysis of FRP parts from waste wind turbine blades for building reuse applications. In Proceedings of the 7th International Conference on Structural Engineering, Mechanics and Computation; Cape Town, South Africa, 2–4 September 2019, pp. 1520–1524.

- Jensen, J.P.; Prendeville, S.M.; Bocken, N.M.; Peck, D. Creating sustainable value through remanufacturing: Three industry cases. J. Clean. Prod. 2019, 218, 304–314. [Google Scholar] [CrossRef] [Green Version]

- Velenturf, A.P.; Jopson, J.S. Making the business case for resource recovery. Sci. Total Environ. 2019, 648, 1031–1041. [Google Scholar] [CrossRef]

- Hatzivasilis, G.; Fysarakis, K.; Soultatos, O.; Askoxylakis, I.; Papaefstathiou, I.; Demetriou, G. The Industrial Internet of Things as an enabler for a Circular Economy Hy-LP: A novel IIoT protocol, evaluated on a wind park’s SDN/NFV-enabled 5G industrial network. Comput. Commun. 2018, 119, 127–137. [Google Scholar] [CrossRef]

- Adibi, N.; Lafhaj, Z.; Yehya, M.; Payet, J. Global Resource Indicator for life cycle impact assessment: Applied in wind turbine case study. J. Clean. Prod. 2017, 165, 1517–1528. [Google Scholar] [CrossRef]

- Mathews, J.A.; Huang, C.X. The global green shift in electric power: China in comparative perspective. Asia-Pac. J. Japan Focus 2021, 19, 5589. [Google Scholar]

- Lesniewska, F. Renewable energy, waste management and the circular economy in the EU: Solar PV and wind power. In Research Handbook on EU Energy Law and Policy; Edward Elgar Publishing Limited: Cheltenham, UK, 2017; pp. 460–468. [Google Scholar] [CrossRef]

- Kopnina, H. Energy Policy in the European Union: Renewable Energy and the Risks of Subversion. In Governance and Security Issues of the European Union; Asser press: The Hague, The Netherlands; Springer Verlag: Berlin/Heidelberg, Germany, 2016; pp. 167–184. [Google Scholar]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. PLoS Med. 2021, 18, e1003583. [Google Scholar] [CrossRef]

- Marsh, A.T.M.; Velenturf, A.P.M.; Bernal, S.A. Circular Economy strategies for concrete: Implementation and integration. Under review.

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Velenturf, A.P.M. Challenges and Opportunities for Sustainable Offshore Wind Development: Preliminary Findings from a Literature Review and Expert Survey; SRI Working paper series; University of Leeds: Leeds, UK, 2020. [Google Scholar]

- Köller, J.; Köppel, J.; Peters, W. Conclusion and perspective. In Offshore Wind Energy: Research on Environmental Impacts; Springer-Verlag: Berlin/Heidelberg, Germany, 2006; pp. 345–352. [Google Scholar]

- Amran, Y.A.; Alyousef, R.; Alabduljabbar, H. Renewable and sustainable energy production in Saudi Arabia according to Saudi Vision 2030; Current status and future prospects. J. Clean. Prod. 2020, 247, 119602. [Google Scholar] [CrossRef]

- Karakosta, C.; Pappas, C.; Marinakis, V.; Psarras, J. Renewable energy and nuclear power towards sustainable development: Characteristics and prospects. Renew. Sustain. Energy Rev. 2013, 22, 187–197. [Google Scholar] [CrossRef]

- Apergis, N.; Payne, J.E.; Menyah, K.; Wolde-Rufael, Y. On the causal dynamics between emissions, nuclear energy, renewable energy, and economic growth. Ecol. Econ. 2010, 69, 2255–2260. [Google Scholar] [CrossRef]

- Widger, P.; Haddad, A. Evaluation of SF6 Leakage from Gas Insulated Equipment on Electricity Networks in Great Britain. Energies 2018, 11, 2037. [Google Scholar] [CrossRef] [Green Version]

- IEA. World Energy Outlook 2020; IEA: Paris, France, 2020. [Google Scholar]

- Morrissey, J.; Heidkamp, C.P. A transitions perspective on coastal sustainability. In Towards Coastal Resilience and Sustainability; Taylor & Francis Group: London, UK, 2018; pp. 15–32. [Google Scholar]

- Busch, J.; Dawson, D.; Roelich, K.; Steinberger, J.; Purnell, P. Enhancing stocks and flows modelling to support sustainable resource management in low carbon infrastructure transitions. In Proceedings of the iEMSs 2012—Managing Resources of a Limited Planet: Proceedings of the 6th Biennial Meeting of the International Environmental Modelling and Software Society, Leipzig, Germany, 1–5 July 2012; pp. 1793–1800. [Google Scholar]

- Roelich, K.; Dawson, D.; Purnell, P.; Knoeri, C.; Revell, R.; Busch, J.; Steinberger, J. Assessing the dynamic material criticality of infrastructure transitions: A case of low carbon electricity. Appl. Energy 2014, 123, 378–386. [Google Scholar] [CrossRef] [Green Version]

- Soukissian, T.H.; Denaxa, D.; Karathanasi, F.; Prospathopoulos, A.; Sarantakos, K.; Iona, A.; Georgantas, K.; Mavrakos, S. Marine Renewable Energy in the Mediterranean Sea: Status and Perspectives. Energies 2017, 10, 1512. [Google Scholar] [CrossRef] [Green Version]

- BBC. US, EU and Japan Challenge China on Rare Earths at WTO; BBC: London, UK, 2012. [Google Scholar]

- Borthwick, A.G. Marine Renewable Energy Seascape. Engineering 2016, 2, 69–78. [Google Scholar] [CrossRef] [Green Version]

- Herring, R.; Dyer, K.; Martin, F.; Ward, C. The increasing importance of leading edge erosion and a review of existing protection solutions. Renew. Sustain. Energy Rev. 2019, 115, 109382. [Google Scholar] [CrossRef]

- Simani, S. Overview of Modelling and Advanced Control Strategies for Wind Turbine Systems. Energies 2015, 8, 13395–13418. [Google Scholar] [CrossRef] [Green Version]

- Velenturf, A.P.M. The National Materials Datahub Can Improve Governance for Better Material Use by Industry: An Evidence Briefing from the Resource Recovery from Waste Programme; Resource Recovery from Waste: Leeds, UK, 2019. [Google Scholar]

- Ahsan, D.; Pedersen, S. The influence of stakeholder groups in operation and maintenance services of offshore wind farms: Lesson from Denmark. Renew. Energy 2018, 125, 819–828. [Google Scholar] [CrossRef] [Green Version]

- Topham, E.; McMillan, D. Sustainable decommissioning of an offshore wind farm. Renew. Energy 2017, 102, 470–480. [Google Scholar] [CrossRef] [Green Version]

- Shaker, M.S.; Patton, R.J. A Fault Tolerant Control Approach to Sustainable Offshore Wind Turbines. Adv. Ind. Control 2014, 157–190. [Google Scholar] [CrossRef]

- Velenturf, A.P.M.; Purnell, P.; Jensen, P.D. Groundhog Day for Decommissioning? The Case of the Offshore Wind Industry. Invited Presentation at Chartered Institution of Wastes Management London and Southern Counties, Waste Ahoy! Management of Offshore Wastes: London, UK, 2017. [Google Scholar]

- Velenturf, A.P.M. Circular Economy Strategies for More Sustainable Wind Energy; Offshore Renewable Energy Catapult: Glasgow, UK, 2020. [Google Scholar]

- Velenturf, A.P.M. Towards A Circular Economy Framework for Offshore Wind; Chartered Institution of Wastes Management: Northampton, UK, 2020. [Google Scholar]

- Velenturf, A.P.M. Strategies for a Sustainable Circular Economy in Offshore Wind. In Proceedings of the Eolis 2020, Brussels, Belgium, 18–20 November 2021; 2020. [Google Scholar]

- Velenturf, A.P.M. Strategies for a Sustainable Circular Economy in Offshore Wind. In Proceedings of the Innovation Offshore: The Role of Offshore Wind in Driving a Green Recovery, Berlin, Germany, 19 November 2020; 2020. [Google Scholar]

- Velenturf, A.P.M. Integrating circular economy with energy infrastructure lifecycle management: Knowledge exchange between North Sea oil & gas and offshore wind. In Proceedings of the Offshore Decommissioning Conference 2020, Aberdeen, UK, 24–25 November 2020. [Google Scholar]

- OREC; Renewable Parts; University of Leeds. Circular Economy for the Offshore wind Industry; Re-energise; Offshore Renewable Energy Catapult: Glasgow, UK, 2020. [Google Scholar]

- WindEurope. Offshore Wind Infrastructure in a Sustainable Circular Economy. In Business News Live; Wind Energy Hamburg: Hamburg, Germany, 2020. [Google Scholar]

- Velenturf, A.P.M. Circular Economy Business Opportunities in Offshore Wind: Workshop Proceedings; University of Leeds: Leeds, UK, 2021. [Google Scholar]

- Parrique, T.; Barth, J.; Briens, F.; Kerschner, C.; Kraus-Polk, A.; Kuokkanen, A.; Spangenberg, J.H. Decoupling Debunked: Evidence and Arguments against Green Growth As a Sole Strategy for Sustainability; European Environmental Bureau: Brussel, Belgium, 2019. [Google Scholar]

- Wiedmann, T.; Schandl, H.; Lenzen, M.; Moran, D.; Suh, S.; West, J.; Kanemoto, K. The material footprint of nations. Proc. Natl. Acad. Sci. USA 2015, 112, 6271–6276. [Google Scholar] [CrossRef] [Green Version]

- Wiedmann, T.; Lenzen, M.; Keyßer, L.T.; Steinberger, J.K. Scientists’ warning on affluence. Nat. Commun. 2020, 11, 3107. [Google Scholar] [CrossRef] [PubMed]

- Bakker, C.; Wang, F.; Huisman, J.; Hollander, M.D. Products that go round: Exploring product life extension through design. J. Clean. Prod. 2014, 69, 10–16. [Google Scholar] [CrossRef]

- Andrews, D. The circular economy, design thinking and education for sustainability. Local Econ. 2015, 30, 305–315. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, L.; Chang, Y.; Hao, Y.; Liu, G.; Yan, Q.; Zhao, Y. Understanding the material efficiency of the wind power sector in China: A spatial-temporal assessment. Resour. Conserv. Recycl. 2020, 155, 104668. [Google Scholar] [CrossRef]

- DEFRA. Guidance on Applying the Waste Hierarchy 2011; Department for Environment, Food & Rural Affairs: Westminster, UK, 2011.

- Francis, C.G. The chemical industry from an industrial ecology perspective. In Perspectives on Industrial Ecology; Bourg, D., Erkman, S., Eds.; Greenleaf Publishing Limited: Sheffield, UK, 2003; pp. 120–135. [Google Scholar]

- Laybourn, P.; Morrissey, M. National Industrial Symbiosis Programme: The Pathway to a Low Carbon Sustainable Economy; International Synergies Ltd.: Kings Norton, UK, 2009. [Google Scholar]

- Jensen, P.D.; Basson, L.; Hellawell, E.; Bailey, M.R.; Leach, M. Quantifying ‘geographic proximity’: Experiences from the United Kingdom’s National Industrial Symbiosis Programme. Resour. Conserv. Recycl. 2011, 55, 703–712. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, H.T.; Pearce, J.M. Renewable Powered Desalination in the Coastal Mekong Delta. In Proceedings of the ASME 2010 4th International Conference on Energy Sustainability, Phoenix, AZ, USA, 17–22 May 2010; pp. 935–946. [Google Scholar]

- Kikuchi, Y.; Kanematsu, Y.; Okubo, T. A computer-aided scenario analysis of national and regional energy systems based on feasible technology options. Computer Aided Chem. Eng. 2016, 38, 1959–1964. [Google Scholar] [CrossRef]

- Sedlar, D.K.; Vulin, D.; Krajačić, G.; Jukić, L. Offshore gas production infrastructure reutilisation for blue energy production. Renew. Sustain. Energy Rev. 2019, 108, 159–174. [Google Scholar] [CrossRef]

- Den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product Design in a Circular Economy: Development of a Typology of Key Concepts and Terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- EU. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance); EU: Brussels, Belgium, 2008. [Google Scholar]

- Gentry, T.R.; Al-Haddad, T.; Bank, L.C.; Arias, F.R.; Nagle, A.; Leahy, P. Structural Analysis of a Roof Extracted from a Wind Turbine Blade. J. Arch. Eng. 2020, 26, 04020040. [Google Scholar] [CrossRef]

- Bank, L.; Arias, F.R.; Yazdanbakhsh, A.; Gentry, T.R.; Al-Haddad, T.; Chen, J.-F.; Morrow, R. Concepts for Reusing Composite Materials from Decommissioned Wind Turbine Blades in Affordable Housing. Recycling 2018, 3, 3. [Google Scholar] [CrossRef] [Green Version]

- Zaaijer, M.B. Integrated offshore wind farm planning and design. In Wind Energy Systems: Optimising Design and Construction for Safe and Reliable Operation; Woodhead Publishing Limited: Cambridge, UK, 2010; pp. 519–545. [Google Scholar]

- Iliopoulos, A.N.; Weijtjens, W.; Van Hemelrijck, D.; Devriendt, C. Remaining useful life assessment of offshore wind turbines: Validation of virtual sensing on long term measurements. In Proceedings of the 8th European Workshop on Structural Health Monitoring, EWSHM 2016, Bilbao, Spain, 5–8 July 2016; pp. 2312–2319. [Google Scholar]

- Sun, H.; Yang, H.; Gao, X. Study on offshore wind farm layout optimization based on decommissioning strategy. Energy Procedia 2017, 143, 566–571. [Google Scholar] [CrossRef]

- Oudman, B.L. Green decommissioning: Re-use of north sea offshore assets in a sustainable energy future. In Proceedings of the Offshore Mediterranean Conference and Exhibition 2017, OMC 2017, Ravenna, Italy, 29–31 March 2017. [Google Scholar]

- Barros, J.C.; Fernandes, G.C.; Silva, M.M.; Da Silva, R.P.; Santos, B. Fixed platforms at ageing oil fields—Feasibility study for reuse to wind farms. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 1–4 May 2017; pp. 4564–4581. [Google Scholar]

- Klabučar, B.; Sedlar, D.K.; Smajla, I. Analysis of blue energy production using natural gas infrastructure: Case study for the Northern Adriatic. Renew. Energy 2020, 156, 677–688. [Google Scholar] [CrossRef]

- Schaffel, S.B.; Westin, F.F.; Hernandez, O.M.; La Rovere, E.L. Replacing Fossil Fuels by Wind Power in Energy Supply to Offshore Oil&Gas Exploration and Production Activities—Possibilities for Brazil. In Proceedings of the Offshore Technology Conference Brasil 2019, OTCB 2019, Rio de Janeiro, Brazil, 29–31 October 2019. [Google Scholar]

- Boman, K. Reduce, reuse, recycle. Offshore Eng. 2017, 42, 34–35. [Google Scholar]

- Topham, E.; Gonzalez, E.; McMillan, D.; João, E. Challenges of decommissioning offshore wind farms: Overview of the European experience. J. Phys. Conf. Ser. 2019, 1222, 012035. [Google Scholar] [CrossRef]

- Luengo, M.M.; Kolios, A. Failure Mode Identification and End of Life Scenarios of Offshore Wind Turbines: A Review. Energies 2015, 8, 8339–8354. [Google Scholar] [CrossRef] [Green Version]

- Bezbradica, M.; Kerkvliet, H.; Borbolla, I.M.; Lehtimaki, P. Introducing multi-criteria decision analysis for wind farm repowering: A case study on Gotland. In Proceedings of the 1st International Conference on Multidisciplinary Engineering Design Optimization, MEDO 2016, Belgrade, Serbia, 14–16 September 2016. [Google Scholar]

- Noppe, N.; Hübler, C.; Devriendt, C.; Weijtjens, W. Validated extrapolation of measured damage within an offshore wind farm using instrumented fleet leaders. J. Phys. Conf. Ser. 2020, 1618, 022005. [Google Scholar] [CrossRef]

- Henkel, M.; Häfele, J.; Weijtjens, W.; Devriendt, C.; Gebhardt, C.G.; Rolfes, R. Strain estimation for offshore wind turbines with jacket substructures using dual-band modal expansion. Mar. Struct. 2020, 71, 102731. [Google Scholar] [CrossRef]

- Bouty, C.; Schafhirt, S.; Ziegler, L.; Muskulus, M. Lifetime extension for large offshore wind farms: Is it enough to reassess fatigue for selected design positions? Energy Procedia 2017, 137, 523–530. [Google Scholar] [CrossRef]

- Stutzmann, J.; Ziegler, L.; Muskulus, M. Fatigue Crack Detection for Lifetime Extension of Monopile-based Offshore Wind Turbines. Energy Procedia 2017, 137, 143–151. [Google Scholar] [CrossRef]

- Ziegler, L.; Cosack, N.; Kolios, A.; Muskulus, M. Structural monitoring for lifetime extension of offshore wind monopiles: Verification of strain-based load extrapolation algorithm. Mar. Struct. 2019, 66, 154–163. [Google Scholar] [CrossRef]

- Ziegler, L.; Muskulus, M. Comparing a Fracture Mechanics Model to the SN-Curve Approach for Jacket-Supported Offshore Wind Turbines: Challenges and Opportunities for Lifetime Prediction. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Busan, Korea, 19–24 June 2016. [Google Scholar]

- Ziegler, L.; Muskulus, M. Fatigue reassessment for lifetime extension of offshore wind monopile substructures. J. Phys. Conf. Ser. 2016, 753, 92010. [Google Scholar] [CrossRef]

- Ziegler, L.; Smolka, U.; Cosack, N.; Muskulus, M. Brief communication: Structural monitoring for lifetime extension of offshore wind monopiles: Can strain measurements at one level tell us everything? Wind Energy Sci. 2017, 2, 469–476. [Google Scholar] [CrossRef] [Green Version]

- Hübler, C.; Weijtjens, W.; Rolfes, R.; Devriendt, C. Reliability analysis of fatigue damage extrapolations of wind turbines using offshore strain measurements. J. Phys. Conf. Ser. 2018, 1037, 032035. [Google Scholar] [CrossRef]

- Rahim, A.; Sparrevik, P.; Mirdamadi, A. Structural Health Monitoring for Offshore Wind Turbine Towers and Foundations. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018; pp. 3181–3198. [Google Scholar]

- Fallais, D.; Voormeeren, S.; Lourens, E.-M. Vibration-based Identification of Hydrodynamic Loads and System Parameters for Offshore Wind Turbine Support Structures. Energy Procedia 2016, 94, 191–198. [Google Scholar] [CrossRef] [Green Version]

- Beganovic, N.; Soeffker, D. Structural health management utilization for lifetime prognosis and advanced control strategy deployment of wind turbines: An overview and outlook concerning actual methods, tools, and obtained results. Renew. Sustain. Energy Rev. 2016, 64, 68–83. [Google Scholar] [CrossRef]

- Energy Procedia. In Proceedings of the 14th Deep Sea Offshore Wind R and D Conference, EERA DeepWind 2017, Trondheim, Norway, 18–20 January 2017; Volume 137, p. 133177.

- Petrovska, E.; Le Dreff, J.-B.; Oterkus, S.; Thies, P.; McCarthy, E. Application of Structural Monitoring Data for Fatigue Life Predictions of Monopile-Supported Offshore Wind Turbines. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Virtual, Online, 3–7 August 2020. [Google Scholar]

- Augustyn, D.; Tygesen, U.T.; Ulriksen, M.D.; Sørensen, J.D. Data-driven design and operation of offshore wind structures. In Proceedings of the International Offshore and Polar Engineering Conference, Honolulu, HI, USA, 16–21 June 2019; pp. 491–498. [Google Scholar]

- He, W.; Grant, R.J.; Baden, V.; Suntharalingam, J. Innovative alternatives for repowering offshore wind farms. J. Phys. Conf. Ser. 2020, 1618, 042037. [Google Scholar] [CrossRef]

- Natarajan, A.; Pedersen, T.F. Remaining Life Assessment of Offshore Wind Turbines Subject to Curtailment. In Proceedings of the International Offshore and Polar Engineering Conference, Sapporo, Japan, 10–15 June 2018; pp. 527–532. [Google Scholar]

- Mehmanparast, A.; Vidament, A. An accelerated corrosion-fatigue testing methodology for offshore wind applications. Eng. Struct. 2021, 240, 112414. [Google Scholar] [CrossRef]

- Anandavijayan, S.; Mehmanparast, A.; Braithwaite, J.; Brennan, F.; Chahardehi, A. Material pre-straining effects on fatigue behaviour of S355 structural steel. J. Constr. Steel Res. 2021, 183, 106707. [Google Scholar] [CrossRef]

- Hou, P.; Enevoldsen, P.; Hu, W.; Chen, C.; Chen, Z. Offshore wind farm repowering optimization. Appl. Energy 2017, 208, 834–844. [Google Scholar] [CrossRef]

- Sun, H.; Gao, X.; Yang, H. Investigation into offshore wind farm repowering optimization in Hong Kong. Int. J. Low-Carbon Technol. 2019, 14, 302–311. [Google Scholar] [CrossRef] [Green Version]

- Safaei, F.; Tazi, N.; Chatelet, E.; Bouzidi, Y. Optimal Topology and Repowering Time for Offshore Wind Turbines. In Proceedings of the 2019 6th International Conference on Control, Decision and Information Technologies (CoDIT), Paris, France, 23–26 April 2019; pp. 1344–1349. [Google Scholar]

- Arvesen, A.; Hertwich, E. Environmental implications of large-scale adoption of wind power: A scenario-based life cycle assessment. Environ. Res. Lett. 2011, 6. [Google Scholar] [CrossRef]

- Himpler, S.; Madlener, R. Optimal timing of wind farm repowering: A two-factor real options analysis. J. Energy Mark. 2014, 7, 3–34. [Google Scholar] [CrossRef]

- Jadali, A.M.; Ioannou, A.; Salonitis, K.; Kolios, A. Decommissioning vs. repowering of offshore wind farms—a techno-economic assessment. Int. J. Adv. Manuf. Technol. 2021, 112, 2519–2532. [Google Scholar] [CrossRef]

- Zuo, T.; Zhang, Y.; Meng, K.; Tong, Z.; Dong, Z.Y.; Fu, Y. Collector System Topology Design for Offshore Wind Farm’s Repowering and Expansion. IEEE Trans. Sustain. Energy 2021, 12, 847–859. [Google Scholar] [CrossRef]

- Pakenham, B.; Ermakova, A.; Mehmanparast, A. A Review of Life Extension Strategies for Offshore Wind Farms Using Techno-Economic Assessments. Energies 2021, 14, 1936. [Google Scholar] [CrossRef]

- Grau, L.; Jung, C.; Schindler, D. Sounding out the repowering potential of wind energy—A scenario-based assessment from Germany. J. Clean. Prod. 2021, 293, 126094. [Google Scholar] [CrossRef]

- De Bona, J.C.; Ferreira, J.C.E.; Duran, J.F.O. Analysis of scenarios for repowering wind farms in Brazil. Renew. Sustain. Energy Rev. 2021, 135, 110197. [Google Scholar] [CrossRef]

- Boopathi, K.; Ramaswamy, S.; Kirubakaran, V.; Uma, K.; Saravanan, G.; Thyagaraj, S.; Balaraman, K. Economic investigation of repowering of the existing wind farms with hybrid wind and solar power plants: A case study. Int. J. Energy Environ. Eng. 2021. [Google Scholar] [CrossRef]

- Kitzing, L.; Jensen, M.K.; Telsnig, T.; Lantz, E. Multifaceted drivers for onshore wind energy repowering and their implications for energy transition. Nat. Energy 2020, 5, 1012–1021. [Google Scholar] [CrossRef]

- Fuchs, C.; Kasten, J.; Vent, M. Current State and Future Prospective of Repowering Wind Turbines: An Economic Analysis. Energies 2020, 13, 3048. [Google Scholar] [CrossRef]

- Piel, J.; Stetter, C.; Heumann, M.; Westbomke, M.; Breitner, M.H. Lifetime Extension, Repowering or Decommissioning? Decision Support for Operators of Ageing Wind Turbines. J. Phys. Conf. Ser. 2019, 1222, 012033. [Google Scholar] [CrossRef]

- Windemer, R. Considering time in land use planning: An assessment of end-of-life decision making for commercially managed onshore wind schemes. Land Use Policy 2019, 87, 104024. [Google Scholar] [CrossRef]

- Vicente-Ramirez, J.; Garcia-Vasquez, E.; Iracheta-Cortez, R.; Dorrego-Portela, J.R. Economic feasibility study for the repowering of La V enta I and La V enta II wind farms in Mexico. In Proceedings of the 2019 IEEE 39th Central America and Panama Convention, CONCAPAN 2019, Guatemala City, Guatemala, 20–22 November 2019. [Google Scholar]

- Madlener, R.; Glensk, B.; Gläsel, L. Optimal Timing of Onshore Wind Repowering in Germany under Policy Regime Changes: A Real Options Analysis. Energies 2019, 12, 4703. [Google Scholar] [CrossRef] [Green Version]

- Windemer, R.; Cowell, R. Are the impacts of wind energy reversible? Critically reviewing the research literature, the governance challenges and presenting an agenda for social science. Energy Res. Soc. Sci. 2021, 79, 102162. [Google Scholar] [CrossRef]

- Priyono, A.; Ijomah, W.; Bititci, U. Disassembly for remanufacturing: A systematic literature review, new model development and future research needs. J. Ind. Eng. Manag. 2016, 9, 899–932. [Google Scholar] [CrossRef] [Green Version]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- EU (European Union); IRP (International Resource Panel); G7 ARE (G7 Alliance on Resource Efficiency). Workshop Report: Promoting Remanufacturing, Refurbishment, Repair, and Direct Reuse; European Union: Brussels, Belgium, 2017. [Google Scholar]

- Matsumoto, M.; Ijomah, W. Remanufacturing. In Handbook of Sustainable Engineering; Kauffman, J., Lee, K.-M., Eds.; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar]

- Ness, D. Sustainable urban infrastructure in China: Towards a Factor 10 improvement in resource productivity through integrated infrastructure systems. Int. J. Sustain. Dev. World Ecol. 2008, 15, 288–301. [Google Scholar] [CrossRef]

- Priyono, A. Understanding the benefits of product-service system for involved parties in remanufacturing. J. Ind. Eng. Manag. 2017, 10, 323–351. [Google Scholar] [CrossRef] [Green Version]

- Gertmar, L.; Reza, M.; Parres, A.; Tenca, P.; Svechkarenko, D.; Peretti, L.; Islam, J. Wind power-from shafts to transmission systems on land-looking forward and back. In Proceedings of the European Wind Energy Conference and Exhibition 2012, EWEC 2012, Copenhagen, Denmark, 16–19 April 2012; pp. 1947–1951. [Google Scholar]

- Dorn, J.; Huang, H.; Retzmann, D. Novel voltage-Sourced Converters for HVDC and FACTS applications. In Proceedings of the CIGRE Symposium Osaka 2007: System Development and Asset Management under Restructuring, Osaka, Japan, 1–4 November 2007. [Google Scholar]

- Junior, V.L.J.; Zhou, J.; Roshanmanesh, S.; Hayati, F.; Hajiabady, S.; Li, X.Y.; Dong, H.; Papaelias, M. Evaluation of damage mechanics of industrial wind turbine gearboxes. Insight Non-Destr. Test. Cond. Monit. 2017, 59, 410–414. [Google Scholar] [CrossRef] [Green Version]

- Junior, V.L.J.; Zhou, J.; Roshanmanesh, S.; Hayati, F.; Hajiabady, S.; Li, X.Y.; Dong, H.; Papaelias, M. Evaluation of damage mechanics of industrial wind turbine gearboxes. In Proceedings of the WCCM 2017—1st World Congress on Condition Monitoring 2017, London, UK, 13–16 June 2017. [Google Scholar]

- Dahane, M.; Sahnoun, M.; Bettayeb, B.; Baudry, D.; Boudhar, H. Impact of spare parts remanufacturing on the operation and maintenance performance of offshore wind turbines: A multi-agent approach. J. Intell. Manuf. 2017, 28, 1531–1549. [Google Scholar] [CrossRef]

- Parlier, G.; Liberatore, F.; Demange, M. (Eds.) Operations Research and Enterprise Systems. In Proceedings of the 6th International Conference on Operations Research and Enterprise Systems (ICORES 2017), Porto, Portugal, 23–25 February 2018; Volume 884. [Google Scholar]

- Hamzah, S.K.; Lacey, G.; Pillai, G. Optimization Modeling for Offshore Wind Farms. In Proceedings of the 2020 55th International Universities Power Engineering Conference (UPEC), Turin, Italy, 1–4 September 2020. [Google Scholar]

- Conlon, T.; Waite, M.; Modi, V. Assessing new transmission and energy storage in achieving increasing renewable generation targets in a regional grid. Appl. Energy 2019, 250, 1085–1098. [Google Scholar] [CrossRef]

- Pierri, E.; Binder, O.; Hemdan, N.; Kurrat, M. Challenges and opportunities for a European HVDC grid. Renew. Sustain. Energy Rev. 2017, 70, 427–456. [Google Scholar] [CrossRef]

- Hagelüken, C.; Lee-Shin, J.U.; Carpentier, A.; Heron, C. The EU Circular Economy and Its Relevance to Metal Recycling. Recycling 2016, 1, 242–253. [Google Scholar] [CrossRef]

- Nordby, A.S. Barriers and opportunities to reuse of building materials in the Norwegian construction sector. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012061. [Google Scholar] [CrossRef]

- Kopnina, H. Towards Ecological Management: Identifying Barriers and Opportunities in Transition from Linear to Circular Economy. Philos. Manag. 2021, 20, 5–19. [Google Scholar] [CrossRef]

- Barbaritano, M.; Bravi, L.; Savelli, E. Sustainability and Quality Management in the Italian Luxury Furniture Sector: A Circular Economy Perspective. Sustainability 2019, 11, 3089. [Google Scholar] [CrossRef] [Green Version]

- Milios, L.; Matsumoto, M. Consumer Perception of Remanufactured Automotive Parts and Policy Implications for Transitioning to a Circular Economy in Sweden. Sustainability 2019, 11, 6264. [Google Scholar] [CrossRef] [Green Version]

- Thies, P.R.; Johanning, L.; Bashir, I.; Tuk, T.; Tuk, M.; Marta, M.; Müller-Schütze, S. Accelerated reliability testing of articulated cable bend restrictor for offshore wind applications. Int. J. Mar. Energy 2016, 16, 65–82. [Google Scholar] [CrossRef]

- Jordaens, P.J.; Milis, S.; Van Riet, N.; Devriendt, C. The use of a large climate chamber for extreme temperature testing & turbine component validation. In Proceedings of the European Wind Energy Conference and Exhibition, EWEC 2013, Vienna, Austra, 4–7 February 2013; pp. 181–186. [Google Scholar]

- Rajesh, J. The cape wind project. Oil Gas J. 2011, 109, 26–27. [Google Scholar]

- Woebbeking, M.; Argyriadis, K. New guidelines for the certification of offshore wind turbines. In Proceedings of the International Offshore and Polar Engineering Conference, Anchorage, AK, USA, 30 June–5 July 2013; pp. 114–118. [Google Scholar]

- Van Der Valk, P.L.C.; Voormeeren, S.N.; De Valk, P.C.; Rixen, D.J. Dynamic Models for Load Calculation Procedures of Offshore Wind Turbine Support Structures: Overview, Assessment, and Outlook. J. Comput. Nonlinear Dyn. 2015, 10, 041013. [Google Scholar] [CrossRef]

- Kerin, M.; Pham, D.T. A review of emerging industry 4.0 technologies in remanufacturing. J. Clean. Prod. 2019, 237, 237. [Google Scholar] [CrossRef]

- Priyono, A.; Ijomah, W.; Bititci, U.S. Strategic operations framework for disassembly in remanufacturing. J. Remanuf. 2015, 5, 11. [Google Scholar] [CrossRef] [Green Version]

- Sitcharangsie, S.; Ijomah, W.; Wong, T. Decision makings in key remanufacturing activities to optimise remanufacturing outcomes: A review. J. Clean. Prod. 2019, 232, 1465–1481. [Google Scholar] [CrossRef]

- Sommerville, R.; Shaw-Stewart, J.; Goodship, V.; Rowson, N.; Kendrick, E. A review of physical processes used in the safe recycling of lithium ion batteries. Sustain. Mater. Technol. 2020, 25, e00197. [Google Scholar] [CrossRef]

- Jia, J.; Dou, S.; Yang, S.; Wu, Y.; Cao, F.; Li, B.; Cui, H. Study on the application framework of BIM in the life cycle management of offshore wind farms. In Proceedings of the International Offshore and Polar Engineering Conference, Honolulu, HI, USA, 16–21 June 2019; pp. 513–520. [Google Scholar]

- Mignacca, B.; Locatelli, G.; Velenturf, A. Modularisation as enabler of circular economy in energy infrastructure. Energy Policy 2020, 139, 111371. [Google Scholar] [CrossRef]

- Hata, T.; Kat, S.; Kimura, F. Design of product modularity for life cycle management. In Proceedings of the Second International Symposium on Environmentally Conscious Design and Inverse Manufacturing, Tokyo, Japan, 11–15 December 2001; pp. 93–96. [Google Scholar]

- Kimura, F.; Kato, S.; Hata, T.; Masuda, T. Product Modularization for Parts Reuse in Inverse Manufacturing. CIRP Ann. 2001, 50, 89–92. [Google Scholar] [CrossRef]

- Allwood, J.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material efficiency: A white paper. Resour. Conserv. Recycl. 2011, 55, 362–381. [Google Scholar] [CrossRef]

- Ding, L.; Li, Y.W. Multilevel CSC System Based on Series–Parallel Connected Three-Phase Modules With Optimized Carrier-Shift SPWM. IEEE Trans. Power Electron. 2021, 36, 3957–3966. [Google Scholar] [CrossRef]

- Xing, J.; Wang, T.; Wang, D. Design and Research of Modular Multiphase Permanent Magnet Direct Drive Generator. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019. [Google Scholar]

- Petersen, K.R.; Madsen, E.S.; Bilberg, A. First Lean, then modularization: Improving the maintenance of offshore wind turbines. Int. J. Energy Sect. Manag. 2016, 10, 221–244. [Google Scholar] [CrossRef]

- Soloot, A.H.; Høidalen, H.K.; Gustavsen, B. Influence of the winding design of wind turbine transformers for resonant overvoltage vulnerability. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1250–1257. [Google Scholar] [CrossRef]

- Yeter, B.; Garbatov, Y.; Soares, C. Modular jacket offshore wind turbine support structure for the Northern Portuguese coastal zone. In Proceedings of the Progress in Renewable Energies Offshore—Proceedings of 2nd International Conference on Renewable Energies Offshore, RENEW 2016, Lisbon, Portugal, 24–26 October 2016; pp. 655–666. [Google Scholar] [CrossRef]

- Sun, J.; Sanz, S.; Ramalingam, R.; Neumann, H. Prototype modular cryostat utilized for 10 MW offshore superconducting wind turbine. Refrigeration Science and Technology. In Proceedings of the 14th IIR International Conference, Dresden, Germany, 15–19 May 2017; pp. 120–125. [Google Scholar]

- Adam, F.; Walia, D.; Hartmann, H.; Schünemann, P.; Großmann, J. A Novel Modular TLP-Design for Offshore Wind Turbines Using Ultra High Performance Concrete. Lect. Notes Civ. Eng. 2019, 37, 257–268. [Google Scholar] [CrossRef]

- Arlabán, T.; Comech, M.P.; Villén, M.T.; Cova, M.A.; García-Gracia, M. Effects of the modularity in PMSM synchronous machine behaviour. In Proceedings of the CIGRE Session 45—45th International Conference on Large High Voltage Electric Systems 2014, Paris, France, 24–29 August 2014. [Google Scholar]

- Welstead, J.; Hirst, R.; Keogh, D.; Robb, G.; Bainsfair, R. Research and Guidance on Restoration and Decommissioning of Onshore Wind Farms; Scottish Natural Heritage Commissioned Report No. 591; Scottish Natural Heritage: Inverness, Scotland, 2013.

- Smith, G.; Lamont, G. Decommissioning of Offshore Wind Installations—What we can learn. In Proceedings of the Offshore Wind Energy 2017, London, UK, 6–8 June 2017. [Google Scholar]

- Xu, W.; Liu, Y.; Wu, W.; Dong, Y.; Lu, W.; Liu, Y.; Zhao, B.; Li, H.; Yang, R. Proliferation of offshore wind farms in the North Sea and surrounding waters revealed by satellite image time series. Renew. Sustain. Energy Rev. 2020, 133, 110167. [Google Scholar] [CrossRef]

- Kruse, M. Energy Transition: Where is the Long-Term Thinking on Offshore Wind Energy? Wirtschaftsdienst 2020, 100, 695–700. [Google Scholar] [CrossRef]

- Gudmestad, O.T.; Grønli, J.; Straume, H. Marine operations for installation and intervention of offshore wind turbines. In Proceedings of the RINA, Royal Institution of Naval Architects—Marine Renewable and Offshore Wind Energy—Papers, London, UK, 21–23 April 2010; pp. 175–183. [Google Scholar]

- Kaiser, M.J.; Snyder, B.F. Offshore Wind Energy Cost Modeling. Green Energy Technol. 2012, 85. [Google Scholar] [CrossRef]

- Kaiser, M.J.; Snyder, B. Modeling the decommissioning cost of offshore wind development on the U.S. Outer Continental Shelf. Mar. Policy 2012, 36, 153–164. [Google Scholar] [CrossRef]

- Kaiser, M.J.; Snyder, B.F. Modeling offshore wind installation costs on the U.S. Outer Continental Shelf. Renew. Energy 2013, 50, 676–691. [Google Scholar] [CrossRef]

- Shafiee, M.; Brennan, F.; Espinosa, I.A. Towards whole life-cycle costing of large-scale offshore wind farms. In Proceedings of the European Wind Energy Association Annual Conference and Exhibition 2015, EWEA 2015—Scientific Proceedings, Paris, France, 17–20 November 2015; pp. 140–144. [Google Scholar]

- Shafiee, M.; Brennan, F.; Espinosa, I. Development of a whole life cost model for offshore wind farms. In Proceedings of the Safety and Reliability of Complex Engineered Systems—Proceedings of the 25th European Safety and Reliability Conference, ESREL 2015, Zurich, Swaziland, 7–10 September 2015; pp. 1019–1027. [Google Scholar]

- McAuliffe, F.D.; Desmond, C.; Chester, R.; Flannery, B.; Judge, F.; Lynch, K.; Murphy, J. A tool to simulate decommissioning offshore wind farms. J. Phys. Conf. Ser. 2019, 1356, 012021. [Google Scholar] [CrossRef] [Green Version]

- Castro-Santos, L. Decision variables for floating offshore wind farms based on life-cycle cost: The case study of Galicia (North-West of Spain). Ocean Eng. 2016, 127, 114–123. [Google Scholar] [CrossRef]

- Irawan, C.A.; Wall, G.; Jones, D.F. An optimisation model for scheduling the decommissioning of an offshore wind farm. OR Spectr. 2019, 41, 513–548. [Google Scholar] [CrossRef]

- Hou, P.; Hu, W.; Soltani, M.; Zhang, B.; Chen, Z. Optimization of decommission strategy for offshore wind farms. In Proceedings of the 2016 IEEE Power and Energy Society General Meeting (PESGM), Boston, MA, USA, 17–21 July 2016. [Google Scholar]

- Adedipe, T.; Shafiee, M. An economic assessment framework for decommissioning of offshore wind farms using a cost breakdown structure. Int. J. Life Cycle Assess. 2021, 26, 344–370. [Google Scholar] [CrossRef]

- Gjødvad, J.F.; Ibsen, M.D. ODIN-WIND: An Overview of the Decommissioning Process for Offshore Wind Turbines. In MARE-WINT: New Materials and Reliability in Offshore Wind Turbine Technology; Springer International Publishing: Cham, Switzerland, 2016; pp. 403–419. [Google Scholar]

- Hinzmann, N.; Stein, P.; Gattermann, J. Decommissioning of Offshore Monopiles, Occuring Problems and Alternative Solutions. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Madrid, Spain, 17–22 June 2018. [Google Scholar]

- Scott, T. Dynamic ports for a dynamic market: Visiting the Dutch offshore ports. Marit. Holl. 2016, 65, 64–68. [Google Scholar]

- Kerkvliet, H.; Polatidis, H. Offshore wind farms’ decommissioning: A semi quantitative Multi-Criteria Decision Aid framework. Sustain. Energy Technol. Assess. 2016, 18, 69–79. [Google Scholar] [CrossRef]

- Maheri, A.; Jalili, S. A Decision Support System for Decommissioning of Offshore Windfarms: The Data Platform. In Proceedings of the 2021 6th International Symposium on Environment-Friendly Energies and Applications (EFEA), Sofia, Bulgaria, 24–26 March 2021. [Google Scholar]

- McGugan, M.; McKirdy, S. Structural health monitoring tools for late & end of life management of offshore wind turbines. In Proceedings of the 8th European Workshop on Structural Health Monitoring, EWSHM 2016, Bilbao, Spain, 8 July 2016; pp. 2420–2429. [Google Scholar]

- Galinos, C.; Dimitrov, N.K.; Larsen, T.; Natarajan, A.; Hansen, K.S. Mapping Wind Farm Loads and Power Production—A Case Study on Horns Rev 1. J. Phys. Conf. Ser. 2016, 753, 032010. [Google Scholar] [CrossRef]

- Jensen, B.B. Specifying corrosion protection for the offshore wind turbine industry. NACE Int. Corros. Conf. Ser. 2017, 3, 1936–1946. [Google Scholar]

- Cabboi, A.; Segeren, M.; Hendrikse, H.; Metrikine, A. Vibration-assisted installation and decommissioning of a slip-joint. Eng. Struct. 2020, 209, 109949. [Google Scholar] [CrossRef]

- Sanders, N.; Haynes, T.; Goriup, P.D. Marine Protected Areas and Offshore Wind Farms. In Management of Marine Protected Areas: A Network Perspective; Wiley-Blackwell: Chichester, UK, 2017; pp. 263–280. [Google Scholar]

- Carlos, R.G. Very shallow water noise impact of offshore windfarms. In Parameters to be considered. In Proceedings of the 15th International Congress on Sound and Vibration 2008, ICSV 2008, Daejeon, Korea, 6–10 July 2008; pp. 1074–1081. [Google Scholar]

- Hall, R.; João, E.; Knapp, C.W. Environmental impacts of decommissioning: Onshore versus offshore wind farms. Environ. Impact Assess. Rev. 2020, 83, 106404. [Google Scholar] [CrossRef]

- C, O.M.H.; Shadman, M.; Amiri, M.M.; Silva, C.; Estefen, S.F.; La Rovere, E. Environmental impacts of offshore wind installation, operation and maintenance, and decommissioning activities: A case study of Brazil. Renew. Sustain. Energy Rev. 2021, 144, 110994. [Google Scholar] [CrossRef]

- Januário, C.; Semino, S.; Bell, M. Offshore Windfarm Decommissioning: A proposal for guidelines to be included in the European Maritime Policy. In Proceedings of the European Wind Energy Conference and Exhibition 2007, EWEC 2007, Milan, Italy, 7–10 May 2007; pp. 362–371. [Google Scholar]

- Feld, T. New risks and rewards in offshore wind energy. In Proceedings of the NGCWP 2007—Proceedings of 2007 Non-Grid-Connected Wind Power Systems—Wind Power Shanghai 2007—Symposium on Non-Grid-Connected Wind Power 2007, San Diego, CA, USA, 10–15 June 2007; pp. 441–448. [Google Scholar]

- González, M.O.A.; Santiso, A.M.; de Melo, D.C.; de Vasconcelos, R.M. Regulation for offshore wind power development in Brazil. Energy Policy 2020, 145, 111756. [Google Scholar] [CrossRef]

- Jørgensen, D. OSPAR’s exclusion of rigs-to-reefs in the North Sea. Ocean Coast. Manag. 2012, 58, 57–61. [Google Scholar] [CrossRef]

- Bull, A.S.; Love, M.S. Worldwide oil and gas platform decommissioning: A review of practices and reefing options. Ocean Coast. Manag. 2019, 168, 274–306. [Google Scholar] [CrossRef]

- Macreadie, P.I.; Fowler, A.; Booth, D. Rigs-to-reefs: Will the deep sea benefit from artificial habitat? Front. Ecol. Environ. 2011, 9, 455–461. [Google Scholar] [CrossRef] [Green Version]

- Smyth, K.; Christie, N.; Burdon, D.; Atkins, J.P.; Barnes, R.; Elliott, M. Renewables-to-reefs?—Decommissioning options for the offshore wind power industry. Mar. Pollut. Bull. 2015, 90, 247–258. [Google Scholar] [CrossRef]

- Fowler, A.M.; Jørgensen, A.-M.; Coolen, J.W.P.; Jones, D.O.B.; Svendsen, J.C.; Brabant, R.; Rumes, B.; Degraer, S. The ecology of infrastructure decommissioning in the North Sea: What we need to know and how to achieve it. ICES J. Mar. Sci. 2020, 77, 1109–1126. [Google Scholar] [CrossRef]

- Kamermans, P.; Walles, B.; Kraan, M.; Van Duren, L.A.; Kleissen, F.; Van Der Have, T.M.; Smaal, A.C.; Poelman, M. Offshore Wind Farms as Potential Locations for Flat Oyster (Ostrea edulis) Restoration in the Dutch North Sea. Sustainability 2018, 10, 3942. [Google Scholar] [CrossRef] [Green Version]

- Dundas, S.J.; Levine, A.S.; Lewison, R.L.; Doerr, A.N.; White, C.; Galloway, A.W.E.; Garza, C.; Hazen, E.L.; Padilla-Gamiño, J.; Samhouri, J.F.; et al. Integrating oceans into climate policy: Any green new deal needs a splash of blue. Conserv. Lett. 2020, 13. [Google Scholar] [CrossRef]

- EU. Waste Framework Directive; EU: Brussels, Belgium, 2008. [Google Scholar]

- Schleisner, L. Life cycle assessment of a wind farm and related externalities. Renew. Energy 2000, 20, 279–288. [Google Scholar] [CrossRef]

- Weinzettel, J.; Reenaas, M.; Solli, C.; Hertwich, E.G. Life cycle assessment of a floating offshore wind turbine. Renew. Energy 2009, 34, 742–747. [Google Scholar] [CrossRef]

- Arvesen, A.; Hertwich, E.G. Assessing the life cycle environmental impacts of wind power: A review of present knowledge and research needs. Renew. Sustain. Energy Rev. 2012, 16, 5994–6006. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Sun, T. Life cycle assessment of CO2 emissions from wind power plants: Methodology and case studies. Renew. Energy 2012, 43, 30–36. [Google Scholar] [CrossRef]

- Huang, Y.-F.; Gan, X.-J.; Chiueh, P.-T. Life cycle assessment and net energy analysis of offshore wind power systems. Renew. Energy 2017, 102, 98–106. [Google Scholar] [CrossRef]

- Properzi, S.; Herk-Hansen, H. Life cycle assessment of a 150 MW offshore wind turbine farm at Nysted/Roedsand, Denmark. Int. J. Environ. Sustain. Dev. 2002, 1, 113–121. [Google Scholar] [CrossRef]

- Tsai, L.; Kelly, J.C.; Simon, B.S.; Chalat, R.M.; Keoleian, G.A. Life Cycle Assessment of Offshore Wind Farm Siting: Effects of Locational Factors, Lake Depth, and Distance from Shore. J. Ind. Ecol. 2016, 20, 1370–1383. [Google Scholar] [CrossRef]

- Berndt, M.L. Influence of concrete mix design on CO2 emissions for large wind turbine foundations. Renew. Energy 2015, 83, 608–614. [Google Scholar] [CrossRef]

- Deng, X.; Ge, J. Global wind power development leads to high demand for neodymium praseodymium (NdPr): A scenario analysis based on market and technology development from 2019 to 2040. J. Clean. Prod. 2020, 277, 123299. [Google Scholar] [CrossRef]

- Andersen, P.D.; Borup, M.; Krogh, T. Managing long-term environmental aspects of wind turbines: A prospective case study. Int. J. Technol. Policy Manag. 2007, 7, 339–354. [Google Scholar] [CrossRef]

- Cousins, D.S.; Suzuki, Y.; Murray, R.; Samaniuk, J.R.; Stebner, A.P. Recycling glass fiber thermoplastic composites from wind turbine blades. J. Clean. Prod. 2019, 209, 1252–1263. [Google Scholar] [CrossRef]

- Mamanpush, S.H.; Li, H.; Englund, K.; Tabatabae, A.T. Recycled wind turbine blades as a feedstock for second generation composites. Waste Manag. 2018, 76, 708–714. [Google Scholar] [CrossRef]

- Leahy, P. End-of-life Options for Composite Material Wind Turbine Blades: Recover, Repurpose or Reuse? In Proceedings of the 14th SWEDES Conference, Dubrovnik, Croatia, 1–6 October 2019.

- Worrell, E.; Reuter, M.A. Handbook of Recycling: State-Of-The-Art for Practitioners, Analysts, and Scientists; Elsevier: Oxford, UK, 2014. [Google Scholar]

- Lombardi, L.; Carnevale, E.; Corti, A. A review of technologies and performances of thermal treatment systems for energy recovery from waste. Waste Manag. 2015, 37, 26–44. [Google Scholar] [CrossRef]

- Nagle, A.J.; Delaney, E.L.; Bank, L.C.; Leahy, P.G. A Comparative Life Cycle Assessment between landfilling and Co-Processing of waste from decommissioned Irish wind turbine blades. J. Clean. Prod. 2020, 277, 277. [Google Scholar] [CrossRef]

- Fonte, R.; Xydis, G. Wind turbine blade recycling: An evaluation of the European market potential for recycled composite materials. J. Environ. Manag. 2021, 287, 112269. [Google Scholar] [CrossRef] [PubMed]

- Townsend, T.G.; Powell, J.; Jain, P.; Xu, Q.; Tolaymat, T.; Reinhart, D. Sustainable Practices for Landfill Design and Operation; Springer: New York, NY, USA, 2015. [Google Scholar]

- Macaskie, L.E.; Sapsford, D.J.; Mayes, W.M. Resource Recovery from Wastes: Towards a Circular Economy; The Royal Society of Chemistry: London, UK, 2020. [Google Scholar]

- Sapsford, D.; Cleall, P.; Harbottle, M. In Situ Resource Recovery from Waste Repositories: Exploring the Potential for Mobilization and Capture of Metals from Anthropogenic Ores. J. Sustain. Met. 2017, 3, 375–392. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Wang, S.; Liu, J. Life-cycle green-house gas emissions of onshore and offshore wind turbines. J. Clean. Prod. 2019, 210, 804–810. [Google Scholar] [CrossRef]

- Deeney, P.; Nagle, A.J.; Gough, F.; Lemmertz, H.; Delaney, E.L.; McKinley, J.M.; Graham, C.; Leahy, P.G.; Dunphy, N.P.; Mullally, G. End-of-Life alternatives for wind turbine blades: Sustainability Indices based on the UN sustainable development goals. Resour. Conserv. Recycl. 2021, 171, 105642. [Google Scholar] [CrossRef]

- Morini, A.A.; Ribeiro, M.J.; Hotza, D. Carbon footprint and embodied energy of a wind turbine blade—A case study. Int. J. Life Cycle Assess. 2021, 26, 1177–1187. [Google Scholar] [CrossRef]

- Marshall., R.; Velenturf, A.; Jopson, J. Making the Most of Industrial Wastes: Strengthening Resource Security of Valuable Metals for Clean Growth in the UK; Policy and Practice Note; Resource Recovery from Waste: Leeds, UK, 2018. [Google Scholar]

- Gomes, H.I.; Mayes, W.; Whitby, P.; Rogerson, M. Constructed wetlands for steel slag leachate management: Partitioning of arsenic, chromium, and vanadium in waters, sediments, and plants. J. Environ. Manag. 2019, 243, 30–38. [Google Scholar] [CrossRef]

- Fromer, N.A.; Diallo, M.S. Nanotechnology and clean energy: Sustainable utilization and supply of critical materials. J. Nanoparticle Res. 2013, 15, 2011. [Google Scholar] [CrossRef]

- Yang, Y.; Walton, A.; Sheridan, R.; Güth, K.; Gauß, R.; Gutfleisch, O.; Buchert, M.; Steenari, B.-M.; Van Gerven, T.; Jones, P.T.; et al. REE Recovery from End-of-Life NdFeB Permanent Magnet Scrap: A Critical Review. J. Sustain. Met. 2017, 3, 122–149. [Google Scholar] [CrossRef]

- Tunsu, C. Hydrometallurgy in the recycling of spent NdFeB permanent magnets. In Waste Electrical and Electronic Equipment Recycling; Woodhead Publishing: Sawston, UK, 2018; pp. 175–211. [Google Scholar]

- Chen, P.-C.; Liu, K.-H.; Ma, H.-W. Resource and waste-stream modeling and visualization as decision support tools for sustainable materials management. J. Clean. Prod. 2017, 150, 16–25. [Google Scholar] [CrossRef]

- Dawson, D.A.; Purnell, P.; Roelich, K.; Busch, J.; Steinberger, J.K. Low Carbon Technology Performance vs Infrastructure Vulnerability: Analysis through the Local and Global Properties Space. Environ. Sci. Technol. 2014, 48, 12970–12977. [Google Scholar] [CrossRef]

- Zhao, W.; Siegel, D.; Lee, J.; Su, L. An Integrated Framework of Drivetrain Degradation Assessment and Fault Localization for Offshore Wind Turbines. Int. J. Progn. Health Manag. 2013, 4, 4. [Google Scholar] [CrossRef]

- Cheng, Y.; Cheng, M.; Ge, H.; Guo, Y.; Hao, Y.; Sun, X.; Qin, X.; Lu, W.; Chen, Y.; Du, X. MiDBench: Multimodel Industrial Big Data Benchmark. In Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Berlin/Heidelberg, Germany, 2019; Volume 11459 LNCS, pp. 172–185. [Google Scholar]

- Burdon, D.; Boyes, S.J.; Elliott, M.; Smyth, K.; Atkins, J.P.; Barnes, R.A.; Wurzel, R.K. Integrating natural and social sciences to manage sustainably vectors of change in the marine environment: Dogger Bank transnational case study. Estuar. Coast. Shelf Sci. 2018, 201, 234–247. [Google Scholar] [CrossRef]

- Gumus, S.; Kucukvar, M.; Tatari, O. Intuitionistic fuzzy multi-criteria decision making framework based on life cycle environmental, economic and social impacts: The case of U.S. wind energy. Sustain. Prod. Consum. 2016, 8, 78–92. [Google Scholar] [CrossRef]

- Taylor, C.M.; Smith, B.; Stein, D. The role of MarineCadastre. In gov in offshore energy planning. In Proceedings of the OCEANS 2012 MTS/IEEE: Harnessing the Power of the Ocean, Hampton Roads, VA, USA, 14–19 October 2012. [Google Scholar]

- Copping, A.; Smith, C.; Hanna, L.; Battey, H.; Whiting, J.; Reed, M.; Brown-Saracino, J.; Gilman, P.; Massaua, M. Tethys: Developing a commons for understanding environmental effects of ocean renewable energy. Int. J. Mar. Energy 2013, 3–4, 41–51. [Google Scholar] [CrossRef]

- Mont, O. Innovative approaches to optimising design and use of durable consumer goods. Int. J. Prod. Dev. 2008, 6, 227–250. [Google Scholar] [CrossRef]

- Stahel, W.R. The Performance Economy; Palgrave Macmillan: Hampshire, UK, 2010. [Google Scholar]

- EC. Directive 2009/125/EC Establishing a Framework for the Setting of Ecodesign Requirements for Energy-Related Products (Recast); EC: Brussels, Belgium, 2009; Volume 2011. [Google Scholar]

- Faber, N.; Jorna, R.; van Engelen, J.O. The sustainability of “sustainability”—A study into the conceptual foundations of the notion of “sustainability”. J. Environ. Assess. Policy Manag. 2005, 7, 1–33. [Google Scholar] [CrossRef]

- Schaumann, P.; Gottschalk, M.; Mickley, M.; Kutterer, H.J.; Neuner, H. Influence of manufacturing aspects on fatigue assessment. In Proceedings of the European Wind Energy Conference and Exhibition 2010, EWEC 2010, Warsaw, Poland, 20–23 April 2010; pp. 3666–3671. [Google Scholar]

- Häfele, J.; Rolfes, R. Approaching the ideal design of jacket substructures for offshore wind turbines with a Particle Swarm Optimization algorithm. In Proceedings of the International Offshore and Polar Engineering Conference, Rhodes, Greece, 26 June–2 July 2016; pp. 156–163. [Google Scholar]

- Wang, S.; Nejad, A.R.; Moan, T. On design, modelling, and analysis of a 10-MW medium-speed drivetrain for offshore wind turbines. Wind. Energy 2020, 23, 1099–1117. [Google Scholar] [CrossRef] [Green Version]

- Schaumann, P.; Bechtel, A.; Eichstädt, R.; Stranghöner, N.; Berg, J.; Gorbachov, A.; Wagner, H.-J.; Röder, J. Sustainability of steel constructions of renewables. Stahlbau 2014, 83, 487–494. [Google Scholar] [CrossRef]

- Schaumann, P.; Bechtel, A. Sustainability assessment of steel constructions of offshore wind energy turbines. Stahlbau 2013, 82, 665–670. [Google Scholar] [CrossRef]

- Schaumann, P.; Bechtel, A.; Wagner, H.J.; Stranghöner, N. Indicators for sustainability assessment of renewables. In Life-Cycle and Sustainability of Civil Infrastructure Systems, Proceedings of the 3rd International Symposium on Life-Cycle Civil Engineering, IALCCE 2012, Vienna, Austria, 3–6 October 2012; Taylor & Francis Group: London, UK, 2012; pp. 1745–1752. [Google Scholar]

- Boero, F.; Foglini, F.; Fraschetti, S.; Goriup, P.; Macpherson, E.; Planes, S.; Soukissian, T.; Adiloglu, B.; Cristens, G.; Delahaye, C.; et al. CoCoNet: Towards coast to coast networks of marine protected areas (From the shore to the high and deep sea), coupled with sea-based wind energy potential. SCIRES-IT 2016, 6, 1–95. [Google Scholar] [CrossRef]

- Glisic, A.; Nguyen, N.D.; Schaumann, P. Comparison of integrated and sequential design approaches for fatigue analysis of a jacket offshore wind turbine structure. In Proceedings of the International Offshore and Polar Engineering Conference, Sapporo, Japan, 10–15 June 2018; pp. 440–447. [Google Scholar]

- Kennedy, C.; Zhong, M.; Corfee-Morlot, J. Infrastructure for China’s Ecologically Balanced Civilization. Engineering 2016, 2, 414–425. [Google Scholar] [CrossRef]