The Architecture of a Real-Time Control System for Heating Energy Management in the Intelligent Building

Abstract

:1. Introduction

2. Preliminaries

2.1. Intelligent Building Systems

- receiving and sending information, supporting efficient management;

- ensuring satisfaction and comfort for residents;

- building management rationalization;

- adaptability to changes in the social environment and residents needs.

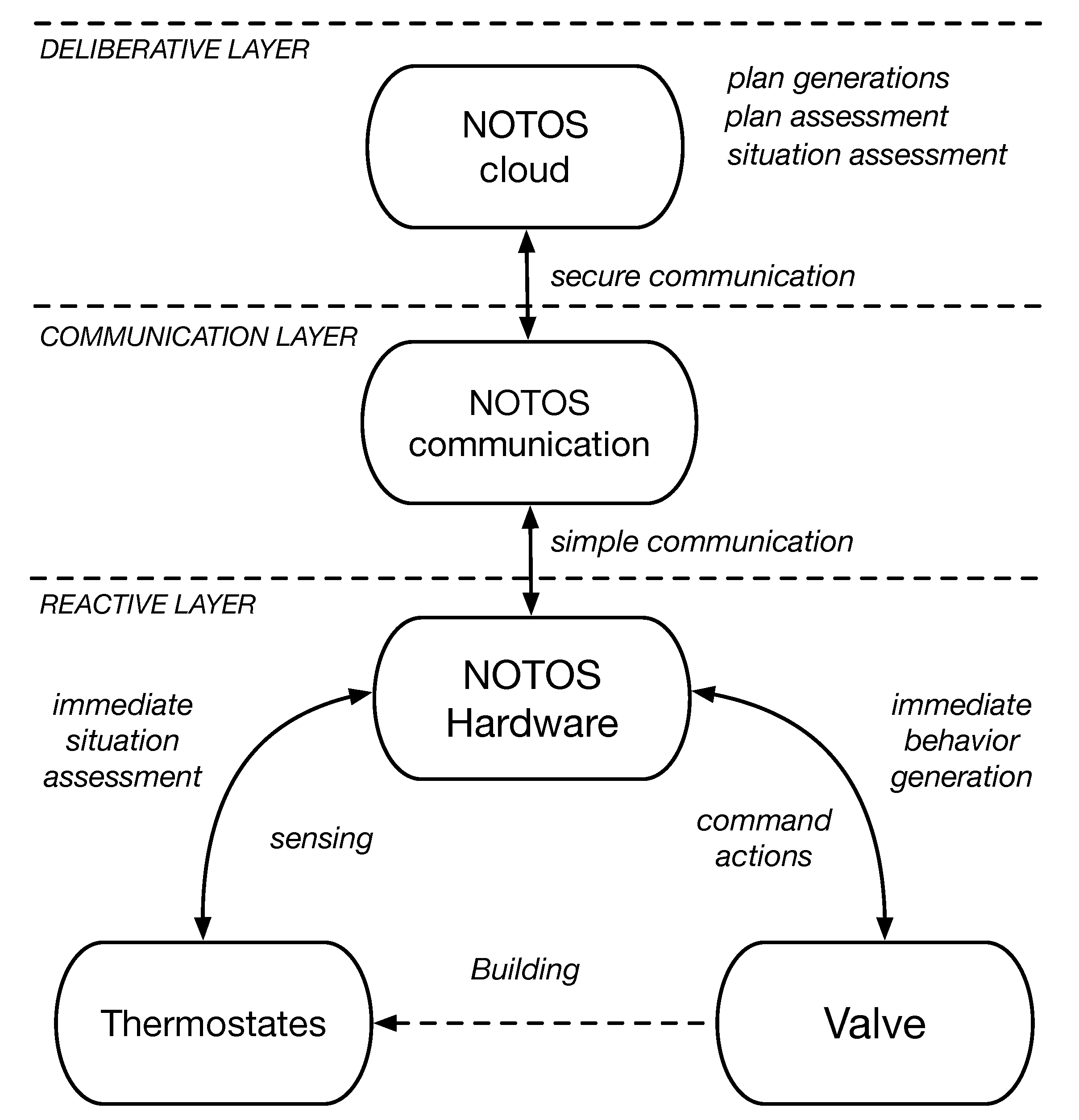

2.2. Hierarchical Real-Time Intelligent Control System

2.3. Related Works

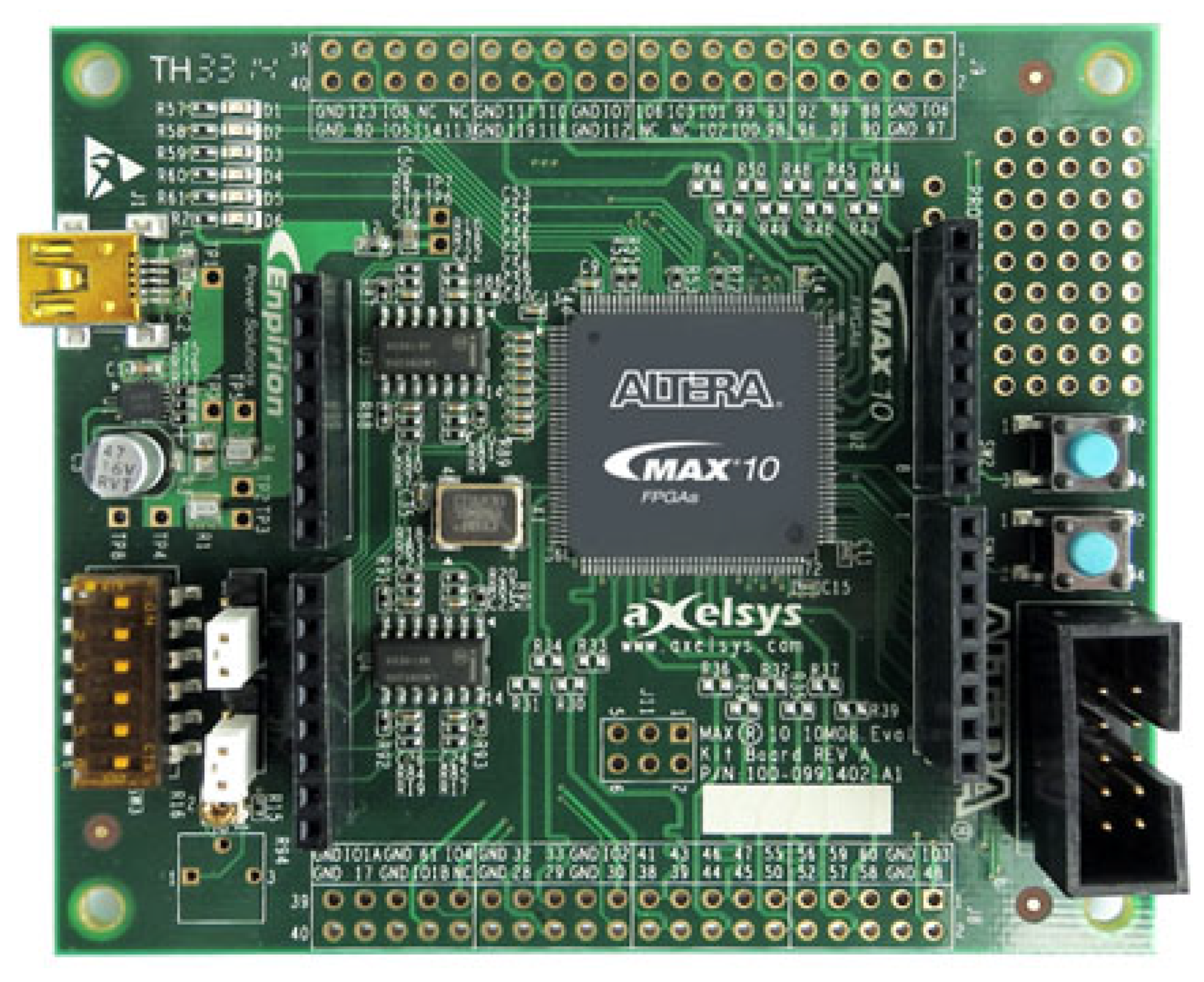

2.4. Embedded Controllers

- Ease of adding more cores;

- Structural flexibility, e.g., the system may contain dependent or independent subsystems;

- Including customized functional blocks.

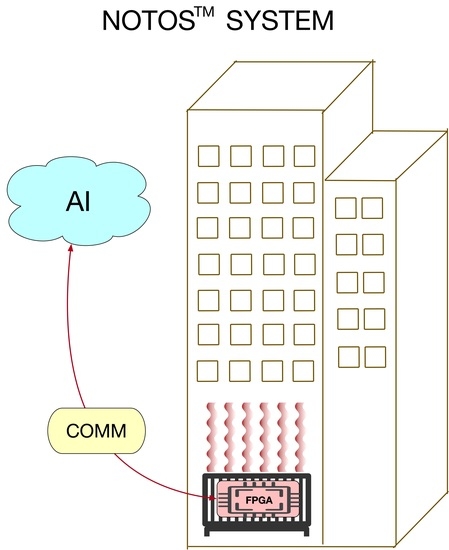

3. NOTOS System

3.1. System Assumptions

- fault tolerance and intrusion prevention;

- access control and preventing against unauthorized access;

- a mechanism for updating and tuning the system during its operation;

- monitoring the correctness of the performed operations;

- access to historical data;

- system design open for further development;

- real-time control capability;

- autonomous work within defined boundaries.

3.2. System Components

- NOTOS embedded—a hardware part of the system responsible for the actual control of heating substation;

- NOTOS communication—a communication module responsible for the safe data transfer between the hardware layer and the cloud;

- NOTOS cloud—a cloud application responsible for long-term planning, tuning, data collection, and analysis.

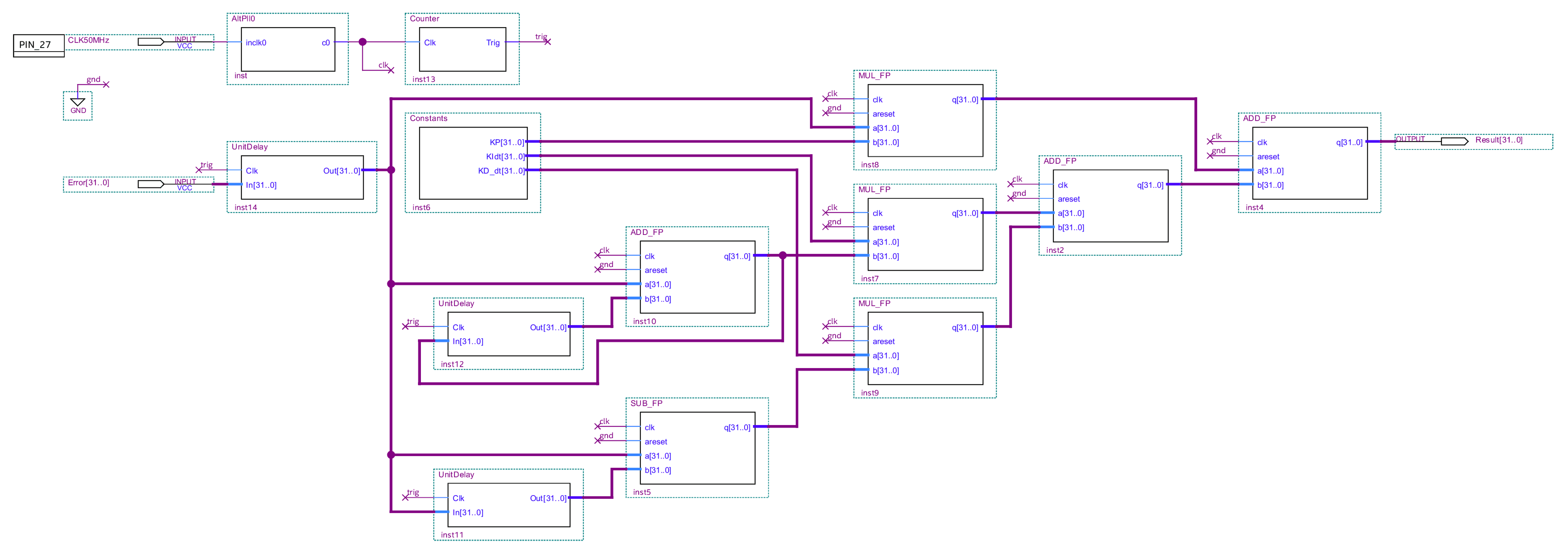

3.2.1. Hardware Controller

- AltPll0 block (library) converts input frequency 50 MHz to 10 MHz;

- Counter block (implemented) generates frequency for 100 Hz PID;

- UnitDelay block (implemented) latches the input data using trigger frequency (i.e., 100 Hz);

- ADD_FP and SUB_FP (library) are floating-point blocks responsible for adding and subtracting. They work in single-precision arithmetic with one cycle latency, 10 MHz frequency (42 MHz is the highest available frequency), 938 LUT;

- MK_FP (library) is a single-precision multiplication floating point block with the two cycles latency, maximal frequency 46 MHz, and LUT 288.

3.2.2. Communication Module

3.2.3. Cloud Subsystem

3.3. NOTOS as an Intelligent Control Hierarchy

3.4. Self-Adaptation

4. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wilkins, C.K.; Doeffinger, R.C.; Rutkowski, H.T. Peak Cooling and Heating Load Calculations in Buildings Except Low-Rise Residential Buildings; Technical Report; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2020. [Google Scholar]

- Dounis, A.I.; Caraiscos, C. Advanced control systems engineering for energy and comfort management in a building environment—A review. Renew. Sustain. Energy Rev. 2009, 13, 1246–1261. [Google Scholar] [CrossRef]

- Castilla, M.; Domingo Álvarez, J.; Rodríguez, F.; Berenguel, M. Comfort Control in Buildings; Springer: London, UK, 2014. [Google Scholar]

- Marks-Bielska, R.; Bielski, S.; Pik, K.; Kurowska, K. The importance of renewable energy sources in Poland’s energy mix. Energies 2020, 13, 4624. [Google Scholar] [CrossRef]

- Omar, O. Intelligent building, definitions, factors and evaluation criteria of selection. Alex. Eng. J. 2018, 57, 2903–2910. [Google Scholar] [CrossRef]

- Wang, S. Intelligent Buildings and Building Automation; Spon Press: New York, NY, USA, 2010; p. 260. [Google Scholar]

- Russell, S.; Norvig, P. Artificial Intelligence: A Modern Approach, 3rd ed.; Prentice Hall: Hoboken, NJ, USA, 2009. [Google Scholar]

- Gupta, A.; Chandra, A.K.; Luksch, P. Distributed Real-Time Systems; CRC Press: Boca Raton, FL, USA, 2020; pp. 46–63. [Google Scholar]

- Kurzweil, R. The Age of Intelligent Machines; MIT Press: Cambridge, MA, USA, 1990. [Google Scholar]

- Albus, J.S. Outline for a Theory of Intelligence. IEEE Trans. Syst. Man Cybern. 1991, 21, 473–509. [Google Scholar] [CrossRef] [Green Version]

- Quintero, R.; Barbera, A. A Real-Time Control System Methodology for Developing Intelligent Control Systems; NIST: Gaitheresburg, MD, USA, 1992. [Google Scholar]

- Kułakowski, K.; Wąs, J. World model for autonomous mobile robot—Formal approach. In Proceedings of the Intelligent Information Systems, Siedlce, Poland, 8–10 June 2010; pp. 37–45. [Google Scholar]

- Morari, M.; Lee, J.H. Model predictive control: Past, present and future. Comput. Chem. Eng. 1999, 23, 667–682. [Google Scholar] [CrossRef]

- Brooks, R. Planning Is Just a Way of Avoiding Figuring out What to Do Next; Technical Report; MIT Artificial Intelligence Laboratory: Cambridge, MA, USA, 1987. [Google Scholar]

- Albus, J.; Huang, H.M.; Lacaze, A.; Schneier, M.; Juberts, M.; Scott, H.; Balakirsky, S.; Shackleford, P.W.; Hong, T.; Murphy, K.; et al. 4D/RCS: A Reference Model Architecture for Unmanned Vehicle Systems Version 2.0; Technical Report; NIST: Gaitheresburg, MD, USA, 2002. [Google Scholar] [CrossRef]

- Lefort, A.; Bourdais, R.; Ansanay-Alex, G.; Guéguen, H. Hierarchical control method applied to energy management of a residential house. Energy Build. 2013, 64, 53–61. [Google Scholar] [CrossRef]

- Dounis, A.I.; Tiropanis, P.; Argiriou, A.; Diamantis, A. Intelligent control system for reconciliation of the energy savings with comfort in buildings using soft computing techniques. Energy Build. 2011, 43, 66–74. [Google Scholar] [CrossRef]

- Papantoniou, S.; Mangili, S.; Mangialenti, I. Using Intelligent Building Energy Management System for the Integration of Several Systems to one Overall Monitoring and Management System. Energy Procedia 2017, 111, 639–647. [Google Scholar] [CrossRef]

- Hazyuk, I.; Ghiaus, C.; Penhouet, D. Optimal temperature control of intermittently heated buildings using Model Predictive Control: Part II - Control algorithm. Build. Environ. 2012, 51, 388–394. [Google Scholar] [CrossRef]

- Ma, Y.; Borrelli, F.; Hencey, B.; Packard, A.; Bortoff, S. Model Predictive Control of Thermal Energy Storage in Building Cooling Systems. In Proceedings of the 48th IEEE Conference on Decision and Control, Shanghai, China, 15–18 December 2009; pp. 392–397. [Google Scholar]

- Yuan, S.; Perez, R. Multiple-zone ventilation and temperature control of a single-duct VAV system using model predictive strategy. Energy Build. 2006, 38, 1248–1261. [Google Scholar] [CrossRef]

- Chen, Y. Building Control Knowledge Information Modeling and Control Self-Configuration. Ph.D. Thesis, The Pennsylvania State University, State College, PA, USA, 2015. [Google Scholar]

- Babar, M.; Grela, J.; Ożadowicz, A.; Nguyen, P.H.; Hanzelka, Z.; Kamphuis, I.G. Energy Flexometer: Transactive Energy-Based Internet of Things Technology. Energies 2018, 11, 568. [Google Scholar] [CrossRef] [Green Version]

- Ożadowicz, A.; Grela, J. An event-driven building energy management system enabling active demand side management. In Proceedings of the 2016 Second International Conference on Event-based Control, Communication, and Signal Processing (EBCCSP), Kraków, Poland, 13–15 June 2016; pp. 1–8. [Google Scholar] [CrossRef]

- Lilis, G.; Conus, G.; Asadi, N.; Kayal, M. Towards the next generation of intelligent building: An assessment study of current automation and future IoT based systems with a proposal for transitional design. Sustain. Cities Soc. 2017, 28, 473–481. [Google Scholar] [CrossRef]

- Treado, S.; Chen, Y. Saving building energy through advanced control strategies. Energies 2013, 6, 4769–4785. [Google Scholar] [CrossRef]

- Dounis, A.; Caraiscos, C. Fuzzy comfort and its use in the design of an intelligent coordinator of fuzzy controller-agents for environmental conditions control in buildings. J. Uncertain Syst. 2008, 2, 101–112. [Google Scholar]

- Peeters, L.; Veken, J.V.D.; Hens, H.; Helsen, L.; D’haeseleer, W. Control of heating systems in residential buildings: Current practice. Energy Build. 2008, 40, 1446–1455. [Google Scholar] [CrossRef]

- Meier, A.; Aragon, C.; Hurwitz, B.; Peffer, P.; Pritoni, M. How People Actually Use Thermostats. In Proceedings of the 2010 ACEEE Summer Study on Energy Efficiency in Buildings, Pacific Grove, CA, USA, 15–20 August 2010; pp. 193–206. [Google Scholar]

- Intell. Nios® II Processor Reference Guide; Intel: Santa Clara, CA, USA, 2020. [Google Scholar]

| Level | Name | Event Detection Interval | Command Update Interval | Short Term Memory | Planning Horizon |

|---|---|---|---|---|---|

| 1 | servo | 3 ms | 3 ms | 30 ms | 30 ms |

| 2 | primitive | 30 ms | 30 ms | 300 ms | 300 ms |

| 3 | move | 300 ms | 300 ms | 3 s | 3 s |

| 4 | individual | 3 s | 3 s | 30 s | 30 s |

| 5 | group 1 | 30 s | 30 s | 5 min | 5 min |

| 6 | group 2 | 5 min | 5 min | 1 h | 1 h |

| 7 | world | 1 h | 1 h | events of the day | plan for the day |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prusak, D.; Karpiel, G.; Kułakowski, K. The Architecture of a Real-Time Control System for Heating Energy Management in the Intelligent Building. Energies 2021, 14, 5402. https://doi.org/10.3390/en14175402

Prusak D, Karpiel G, Kułakowski K. The Architecture of a Real-Time Control System for Heating Energy Management in the Intelligent Building. Energies. 2021; 14(17):5402. https://doi.org/10.3390/en14175402

Chicago/Turabian StylePrusak, Daniel, Grzegorz Karpiel, and Konrad Kułakowski. 2021. "The Architecture of a Real-Time Control System for Heating Energy Management in the Intelligent Building" Energies 14, no. 17: 5402. https://doi.org/10.3390/en14175402

APA StylePrusak, D., Karpiel, G., & Kułakowski, K. (2021). The Architecture of a Real-Time Control System for Heating Energy Management in the Intelligent Building. Energies, 14(17), 5402. https://doi.org/10.3390/en14175402