Q-Learning Neural Controller for Steam Generator Station in Micro Cogeneration Systems

Abstract

1. Introduction

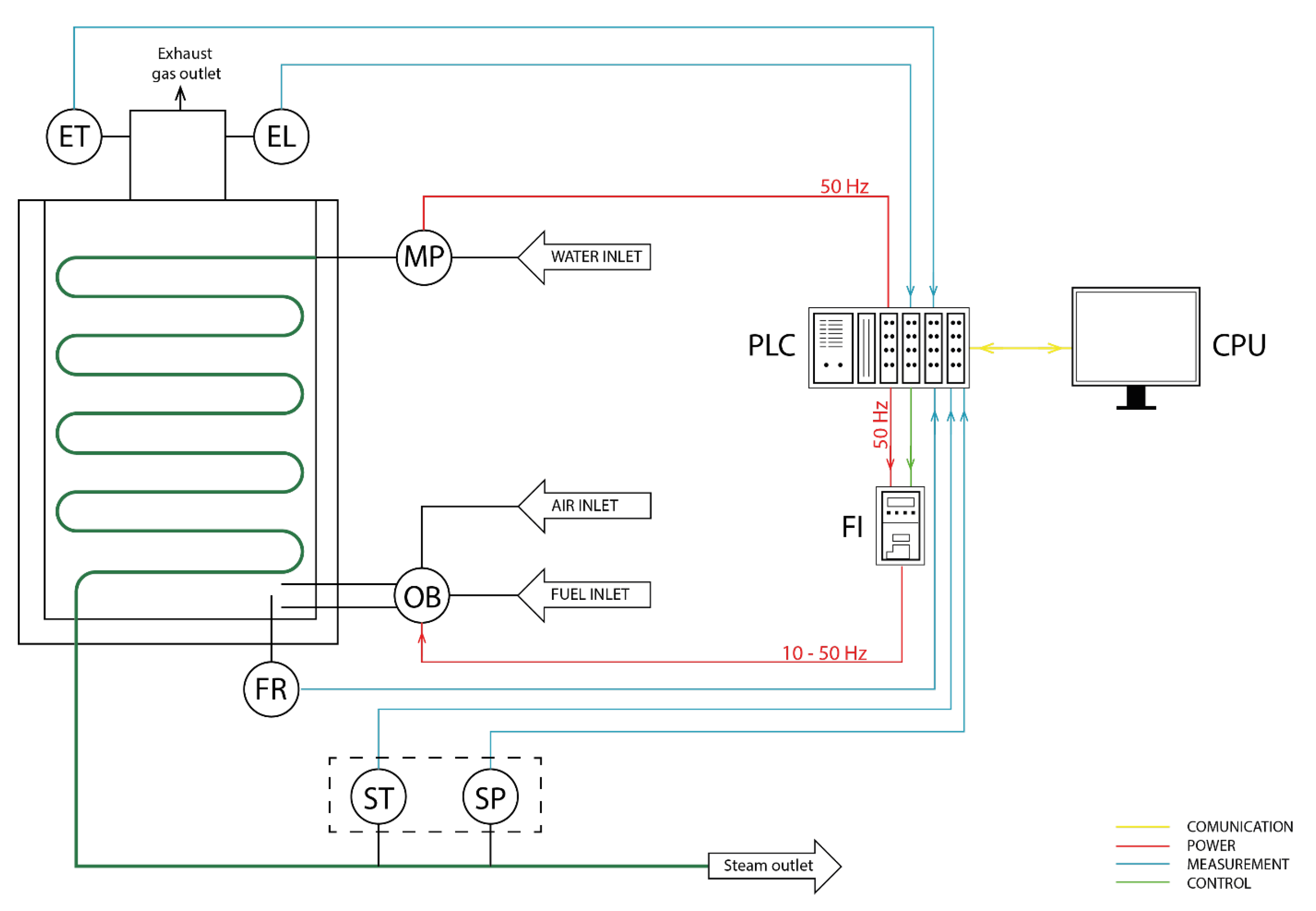

2. Measurement Stand

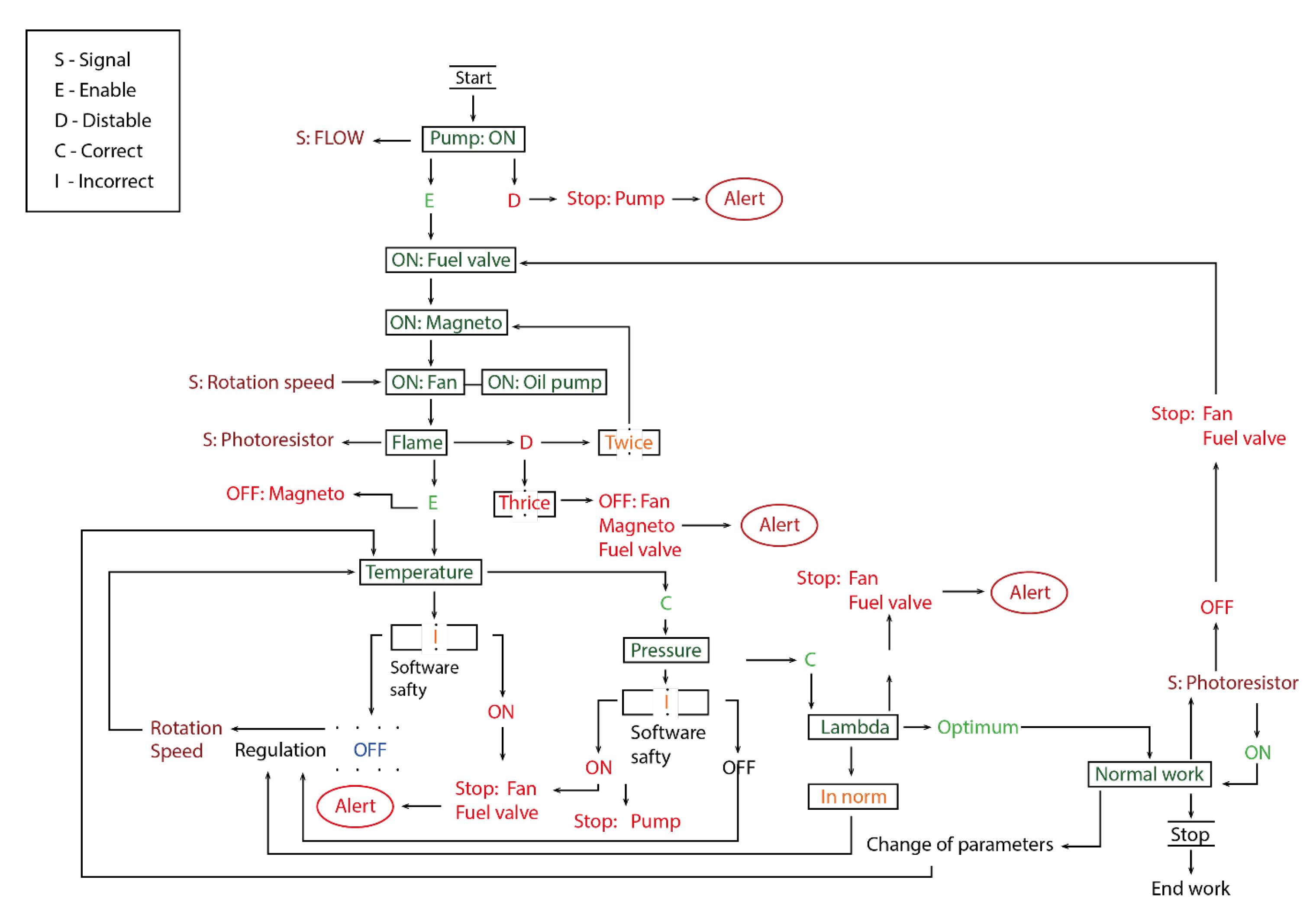

- Ignition, which includes:

- Switching on the circulator motor, fuel valve, spark igniter and fan motor and fuel pump (coupled on a common shaft),

- Checking the status of power, flow and burner operation.

- Control the operating parameters of the unit which includes a set of three cooperating PID controllers operating in parallel:

- temperature controller (based on the temperature in the steam manifold),

- Pressure controller (based on the pressure in the steam collector),

- lambda coefficient controller (based on oxygen concentration in the flue gas).

- Software protection system, which includes a system ensuring safe operation, which reacts to exceeding the operation-threatening parameters, and cuts off the operation of electric motors/closes the valves from the software level when the operation-threatening parameters have been exceeded.

- Continuous work allowing for constant work of the system after reaching stable parameters until:

- change of selected parameters,

- end of steam generator operation by the user,

- emergency situations.

- C—control,

- —proportional gain,

- —integral gain,

- —derivative gain,

- —derivative filter constant.

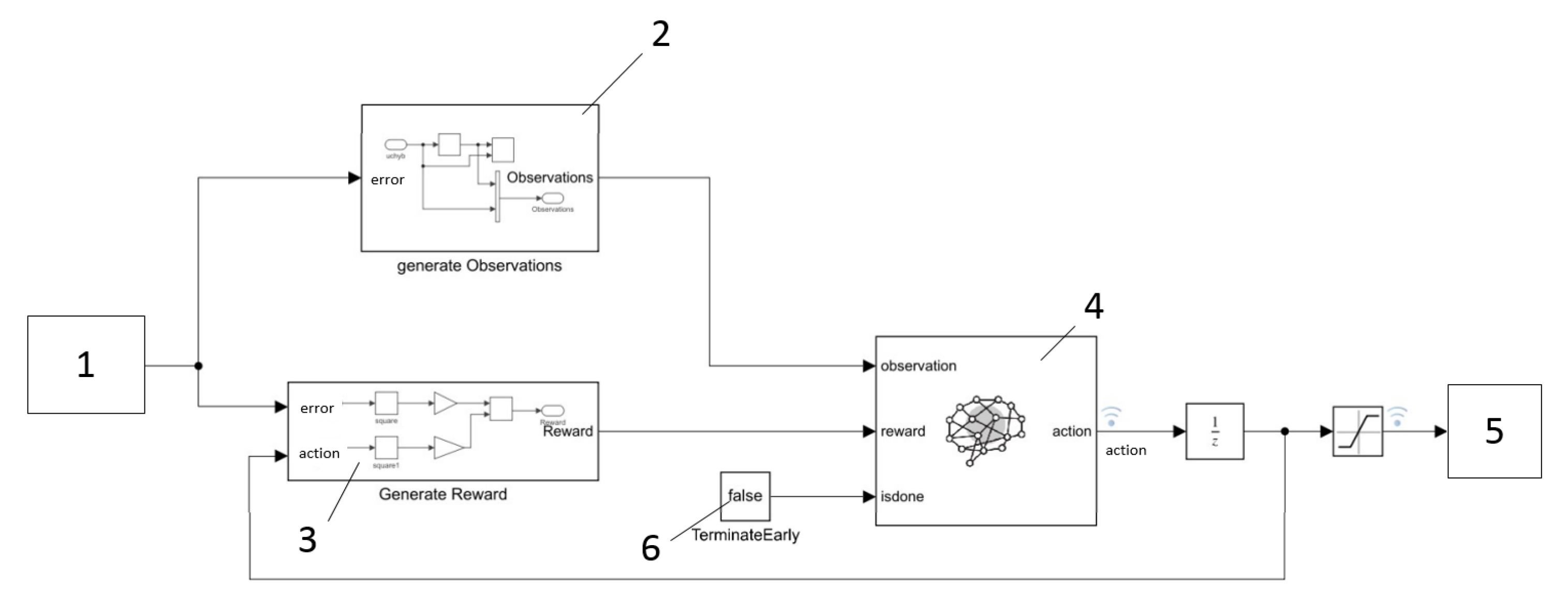

3. Methodology

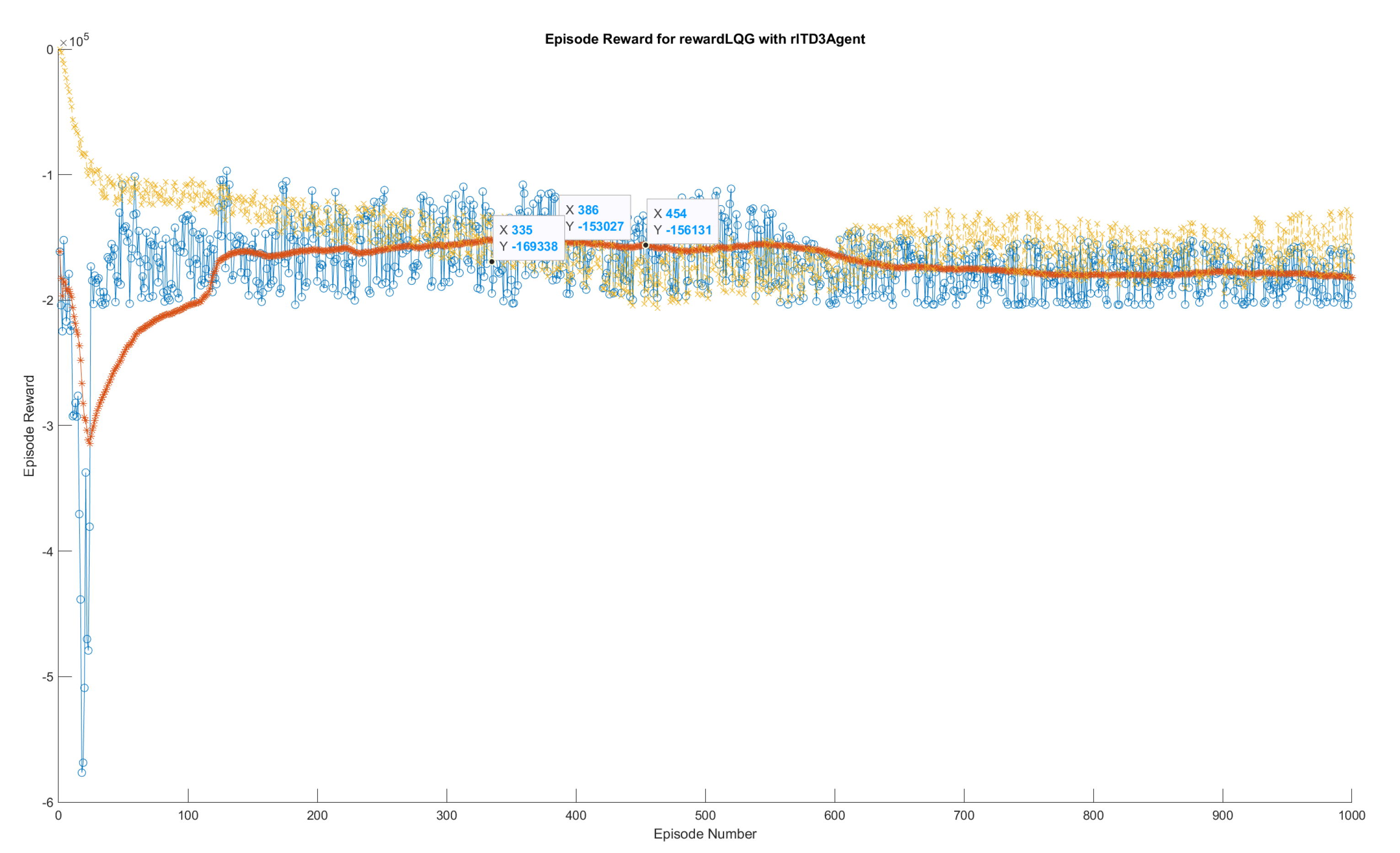

4. Results

5. Conclusions

- self-optimization of object control,

- possibility of constitution of regulator operation on the basis of intuitive selection of network rewards,

- possibility of reaching a convergent control solution without the necessity of controller synthesis.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MIMO | Multi-Input Multi-Output |

| BMS | Building Management System |

| PID | Proportional–Integral–Derivative controller |

| LQR | Linear–Quadratic Regulator |

| HVAC | Heating, Ventilation, Air Conditioning |

| TRMS | Twin Rotor MIMO System |

| DQN | Deep Q-Network |

| DDPG | Deep Deterministic Policy Gradien |

| TD3PG | Twin-Delayed Deep Deterministic Policy Gradient |

| FAME | Fatty Acid Methyl Esters |

References

- De Jesús Rubio, J.; Lughofer, E.; Pieper, J.; Cruz, P.; Martinez, D.I.; Ochoa, G.; Islas, M.A.; Garcia, E. Adapting H-infinity controller for the desired reference tracking of the sphere position in the maglev process. Inf. Sci. 2021, 569, 669–686. [Google Scholar] [CrossRef]

- Martinez, D.I.; Rubio, J.D.J.; Garcia, V.; Vargas, T.M.; Islas, M.A.; Pacheco, J.; Gutierrez, G.J.; Meda-Campaña, J.A.; Mujica-Vargas, D.; Aguilar-Ibañez, C. Transformed Structural Properties Method to Determine the Controllability and Observability of Robots. Appl. Sci. 2021, 11, 3082. [Google Scholar] [CrossRef]

- Huang, H.; Zhou, J.; Di, Q.; Zhou, J.; Li, J. Robust neural network–based tracking control and stabilization of a wheeled mobile robot with input saturation. Int. J. Robust Nonlinear Control 2019, 29, 375–392. [Google Scholar] [CrossRef]

- Yang, X.; He, H.; Liu, D.; Zhu, Y. Adaptive dynamic programming for robust neural control of unknown continuous-time non-linear systems. IET Control Theory Appl. 2017, 11, 2307–2316. [Google Scholar] [CrossRef]

- Escobedo-Alva, J.O.; Garcia-Estrada, E.C.; Paramo-Carranza, L.A.; Meda-Campana, J.A.; Tapia-Herrera, R. Theoretical application of a hybrid observer on altitude tracking of quadrotor losing GPS signal. IEEE Access 2018, 6, 76900–76908. [Google Scholar] [CrossRef]

- Soriano, L.A.; Zamora, E.; Vazquez-Nicolas, J.; Hernández, G.; Madrigal, J.A.B.; Balderas, D. PD Control Compensation Based on a Cascade Neural Network Applied to a Robot Manipulator. Front. Neurorobot. 2020, 14, 577749. [Google Scholar] [CrossRef]

- Yen, V.T.; Nan, W.Y.; Van Cuong, P. Recurrent fuzzy wavelet neural networks based on robust adaptive sliding mode control for industrial robot manipulators. Neural Comput. Appl. 2019, 31, 6945–6958. [Google Scholar] [CrossRef]

- Fu, J.; Liu, M.; Cao, X.; Li, A. Robust neural-network-based quasi-sliding-mode control for spacecraft-attitude maneuvering with prescribed performance. Aerosp. Sci. Technol. 2021, 112, 106667. [Google Scholar] [CrossRef]

- Anderson, M.; Buehner, M.; Young, P.; Hittle, D.; Anderson, C.; Tu, J.; Hodgson, D. MIMO robust control for HVAC systems. IEEE Trans. Control Syst. Technol. 2008, 16, 475–483. [Google Scholar] [CrossRef]

- Shen, Y.; Cai, W.J.; Li, S. Normalized decoupling control for high-dimensional MIMO processes for application in room temperature control HVAC systems. Control Eng. Pract. 2010, 18, 652–664. [Google Scholar] [CrossRef]

- Abtahi, S.; Sadati, S.; Ghaffari, A. Design of sliding mode and lQR controllers for an HVAC system. Aerosp. Mech. J. 2013, 9, 1–10. [Google Scholar]

- Haghighi, M.M.; Sangiovanni-Vincentelli, A.L. Modeling and Optimal Control Algorithm Design for HVAC Systems in Energy Efficient Buildings. Master’s Thesis, EECS Department, University of California, Berkeley, CA, USA, 2011. [Google Scholar]

- Shankar, G.; Lakshmi, S.; Nagarjuna, N. Optimal load frequency control of hybrid renewable energy system using PSO and LQR. In Proceedings of the 2015 International Conference on Power and Advanced Control Engineering (ICPACE), Bengaluru, India, 12–14 August 2015; pp. 195–199. [Google Scholar]

- Arab, N.; Vahedi, H.; Al-Haddad, K. LQR control of single-phase grid-tied PUC5 inverter with LCL filter. IEEE Trans. Ind. Electron. 2019, 67, 297–307. [Google Scholar] [CrossRef]

- Muratovich, Z.D.; Do, T.D. LQR Based SMC for Three-Phase-Inverter with LC Filter in Renewable Energy Conversion Systems. In Proceedings of the 2019 International Conference on System Science and Engineering (ICSSE), Dong Hoi, Vietnam, 20–21 July 2019; pp. 456–461. [Google Scholar]

- Homod, R.Z.; Gaeid, K.S.; Dawood, S.M.; Hatami, A.; Sahari, K.S. Evaluation of energy-saving potential for optimal time response of HVAC control system in smart buildings. Appl. Energy 2020, 271, 115255. [Google Scholar] [CrossRef]

- Escobar, L.M.; Aguilar, J.; Garcés-Jiménez, A.; De Mesa, J.A.G.; Gomez-Pulido, J.M. Advanced fuzzy-logic-based context-driven control for HVAC management systems in buildings. IEEE Access 2020, 8, 16111–16126. [Google Scholar] [CrossRef]

- Amin, N.M.; Ab Ghani, M.; Jidin, A.; Othman, S.; Jano, Z. Development of e-help manual using graphical user interface (gui) for battery management system (bms) in electric vehicle. J. Adv. Manuf. Technol. (JAMT) 2019, 13, 39–50. [Google Scholar]

- Kotowicz, J. Analysis of operation of the gas turbine in a poligeneration combined cycle. Arch. Thermodyn. 2013, 34, 137–159. [Google Scholar] [CrossRef][Green Version]

- Labella, A.; Mestriner, D.; Procopio, R.; Delfino, F. A simplified first harmonic model for the Savona Campus Smart Polygeneration Microgrid. In Proceedings of the 2017 IEEE International Conference on Environment and Electrical Engineering and 2017 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I CPS Europe), Milan, Italy, 6–9 June 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Collazos, A.; Maréchal, F.; Gähler, C. Predictive optimal management method for the control of polygeneration systems. Comput. Chem. Eng. 2009, 33, 1584–1592. [Google Scholar] [CrossRef]

- Menon, R.P.; Paolone, M.; Maréchal, F. Study of optimal design of polygeneration systems in optimal control strategies. Energy 2013, 55, 134–141. [Google Scholar] [CrossRef]

- Karavas, C.S.; Kyriakarakos, G.; Arvanitis, K.G.; Papadakis, G. A multi-agent decentralized energy management system based on distributed intelligence for the design and control of autonomous polygeneration microgrids. Energy Convers. Manag. 2015, 103, 166–179. [Google Scholar] [CrossRef]

- Sornek, K.; Filipowicz, M.; Żołądek, M.; Kot, R.; Mikrut, M. Comparative analysis of selected thermoelectric generators operating with wood-fired stove. Energy 2019, 166, 1303–1313. [Google Scholar] [CrossRef]

- Sornek, K.; Filipowicz, M.; Rzepka, K. The development of a thermoelectric power generator dedicated to stove-fireplaces with heat accumulation systems. Energy Convers. Manag. 2016, 125, 185–193. [Google Scholar] [CrossRef]

- Bianco, V.; Szubel, M.; Matras, B.; Filipowicz, M.; Papis, K.; Podlasek, S. CFD analysis and design optimization of an air manifold for a biomass boiler. Renew. Energy 2021, 163, 2018–2028. [Google Scholar] [CrossRef]

- El Rifai, K. Nonlinearly parameterized adaptive PID control for parallel and series realizations. In Proceedings of the 2009 American Control Conference, St. Louis, MO, USA, 10–12 June 2009; pp. 5150–5155. [Google Scholar]

- Lee, Y.; Skliar, M.; Lee, M. Analytical method of PID controller design for parallel cascade control. J. Process. Control 2006, 16, 809–818. [Google Scholar] [CrossRef]

- Rehrl, J.; Horn, M. Temperature control for HVAC systems based on exact linearization and model predictive control. In Proceedings of the 2011 IEEE International Conference on Control Applications (CCA), Denver, CO, USA, 28–30 September 2011; pp. 1119–1124. [Google Scholar]

- Rehrl, J.; Horn, M.; Reichhartinger, M. Elimination of limit cycles in hvac systems using the describing function method. In Proceedings of the 48h IEEE Conference on Decision and Control (CDC) Held Jointly with 2009 28th Chinese Control Conference, Shanghai, China, 15–18 December 2009; pp. 133–139. [Google Scholar]

- Mahmoodabadi, M.J.; Maafi, R.A.; Taherkhorsandi, M. An optimal adaptive robust PID controller subject to fuzzy rules and sliding modes for MIMO uncertain chaotic systems. Appl. Soft Comput. 2017, 52, 1191–1199. [Google Scholar] [CrossRef]

- Pandey, S.K.; Dey, J.; Banerjee, S. Design and real-time implementation of robust PID controller for Twin Rotor MIMO System (TRMS) based on Kharitonov’s theorem. In Proceedings of the 2016 IEEE 1st International Conference on Power Electronics, Intelligent Control and Energy Systems (ICPEICES), Delhi, India, 4–6 July 2016; pp. 1–6. [Google Scholar]

- Dominik, I. Interval Type-2 Fuzzy Logic Control of NM70 Shape Memory Actuator. In Proceedings of the Smart Materials, Adaptive Structures and Intelligent Systems, Newport, RI, USA, 8–10 September 2014; Volume 46148. [Google Scholar]

- Wang, R.; An, A.; Wen, Y.; Song, H. Study on the Influence of Parallel Fuzzy PID Control on the Regulating System of a Bulb Tubular Turbine Generator Unit. J. Electr. Eng. Technol. 2021, 16, 1403–1414. [Google Scholar] [CrossRef]

- Dominik, I. Type-2 fuzzy logic controller for position control of shape memory alloy wire actuator. J. Intell. Mater. Syst. Struct. 2016, 27, 1917–1926. [Google Scholar] [CrossRef]

- Dominik, I. Fuzzy logic control of rotational inverted pendulum. In Solid State Phenomena; Trans Tech Publ.: Baech, Switzerland, 2011; Volume 177, pp. 84–92. [Google Scholar]

- Ketata, R.; De Geest, D.; Titli, A. Fuzzy controller: Design, evaluation, parallel and hierarchial combination with a pid controller. Fuzzy Sets Syst. 1995, 71, 113–129. [Google Scholar] [CrossRef]

- Homod, R.Z.; Togun, H.; Abd, H.J.; Sahari, K.S. A novel hybrid modelling structure fabricated by using Takagi-Sugeno fuzzy to forecast HVAC systems energy demand in real-time for Basra city. Sustain. Cities Soc. 2020, 56, 102091. [Google Scholar] [CrossRef]

- Kozek, M. Transfer Learning algorithm in image analysis with Augmented Reality headset for Industry 4.0 technology. In Proceedings of the 2020 International Conference Mechatronic Systems and Materials (MSM), Bialystok, Poland, 1–3 July 2020; pp. 1–5. [Google Scholar]

- Bartoszewicz, A.; Kabziński, J.; Kacprzyk, J. Advanced, Contemporary Control: Proceedings of KKA 2020. In Proceedings of the 20th Polish Control Conference, Łódź, Poland, 21–28 October 2020; Volume 1196. [Google Scholar]

- Chen, Y.; Tong, Z.; Zheng, Y.; Samuelson, H.; Norford, L. Transfer learning with deep neural networks for model predictive control of HVAC and natural ventilation in smart buildings. J. Clean. Prod. 2020, 254, 119866. [Google Scholar] [CrossRef]

- Demirezen, G.; Fung, A.S.; Deprez, M. Development and optimization of artificial neural network algorithms for the prediction of building specific local temperature for HVAC control. Int. J. Energy Res. 2020, 44, 8513–8531. [Google Scholar] [CrossRef]

- Ahn, K.; Park, C. Application of deep Q-networks for model-free optimal control balancing between different HVAC systems. Sci. Technol. Built Environ. 2020, 26, 61–74. [Google Scholar] [CrossRef]

| Measuring and Safety Elements | Executive and Control Elements |

|---|---|

| ST—temperature measurement of the circulating medium | MP—feeding pump |

| SP—circulating medium pressure measurement | OB—liquid fuel burner |

| ET—flue gas temperature measurement | PLC—programmable logic controller |

| EL—measurement of concentration of oxygen in flue gas | FI—frequency inverter |

| FR—photoresistor | CPU—computer |

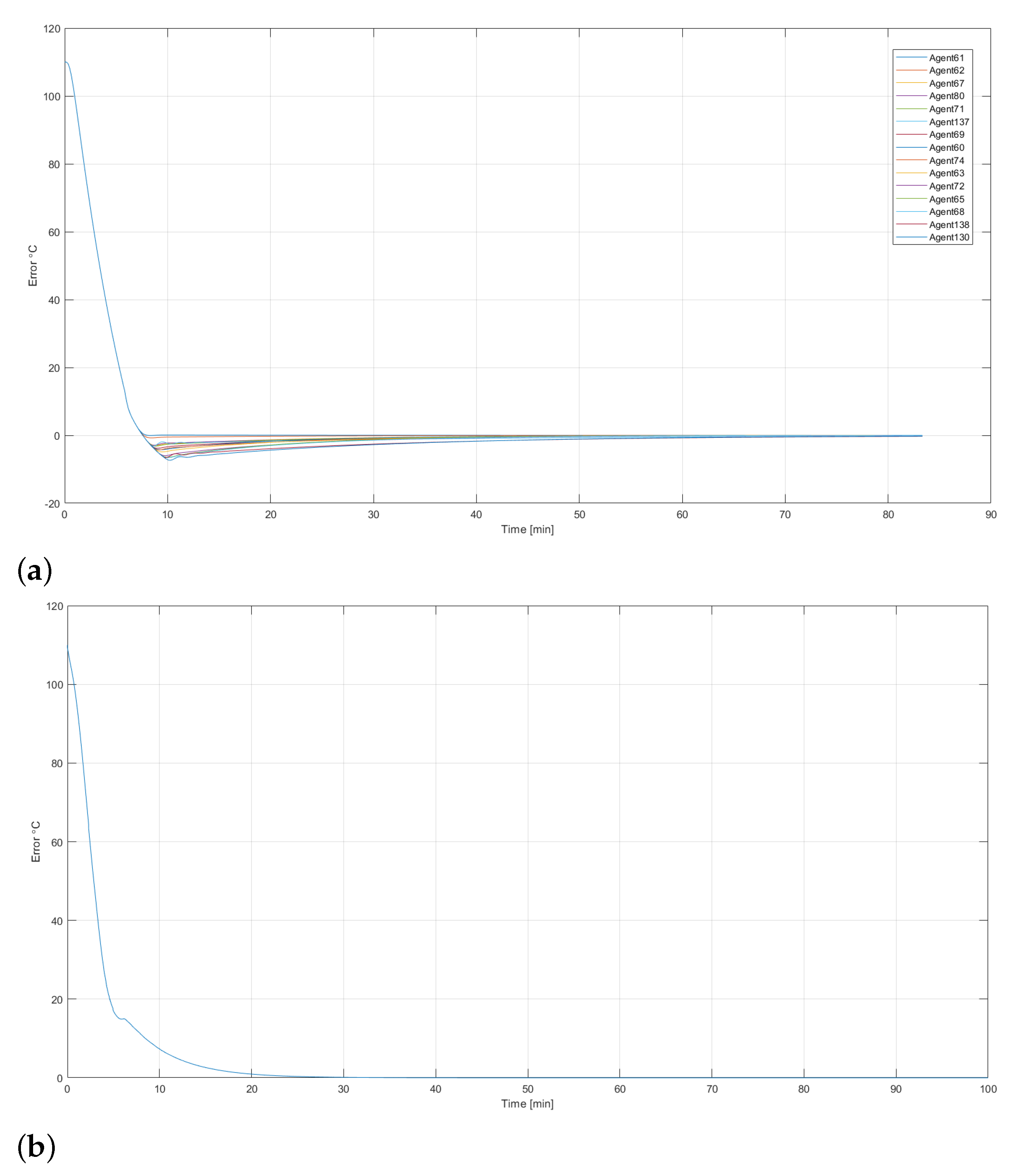

| Rising Time | Settling Time | Steady State Error | Overshoot | Undershoot | |

|---|---|---|---|---|---|

| PID | 440 | 691.67 | 0 | 0 | N/A |

| Agent67 | 280 | 389.99 | 0 | −2.95 | N/A |

| Agent60 | 280 | 389.99 | 0 | −4.24 | N/A |

| Agent72 | 280 | 634.44 | −0.00012 | −5.98 | N/A |

| Agent138 | 280 | 722.55 | −0.009 | −6.56 | N/A |

| Agent130 | 280 | 894.93 | −0.005 | −7.35 | N/A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lalik, K.; Kozek, M.; Podlasek, S.; Figaj, R.; Gut, P. Q-Learning Neural Controller for Steam Generator Station in Micro Cogeneration Systems. Energies 2021, 14, 5334. https://doi.org/10.3390/en14175334

Lalik K, Kozek M, Podlasek S, Figaj R, Gut P. Q-Learning Neural Controller for Steam Generator Station in Micro Cogeneration Systems. Energies. 2021; 14(17):5334. https://doi.org/10.3390/en14175334

Chicago/Turabian StyleLalik, Krzysztof, Mateusz Kozek, Szymon Podlasek, Rafał Figaj, and Paweł Gut. 2021. "Q-Learning Neural Controller for Steam Generator Station in Micro Cogeneration Systems" Energies 14, no. 17: 5334. https://doi.org/10.3390/en14175334

APA StyleLalik, K., Kozek, M., Podlasek, S., Figaj, R., & Gut, P. (2021). Q-Learning Neural Controller for Steam Generator Station in Micro Cogeneration Systems. Energies, 14(17), 5334. https://doi.org/10.3390/en14175334