Study of the Thermal Conductivity of Soft Magnetic Materials in Electric Traction Machines

Abstract

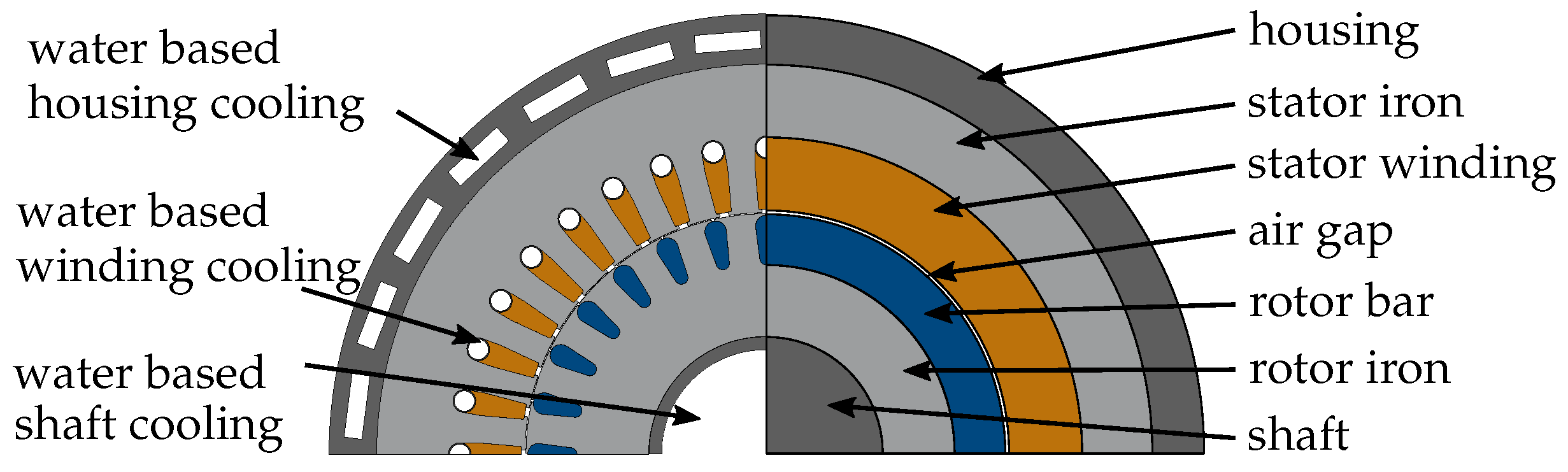

:1. Introduction

2. Analytical Formula for the Thermal Conductivity

2.1. Phonon Thermal Conductivity

2.2. Electron Thermal Conductivity

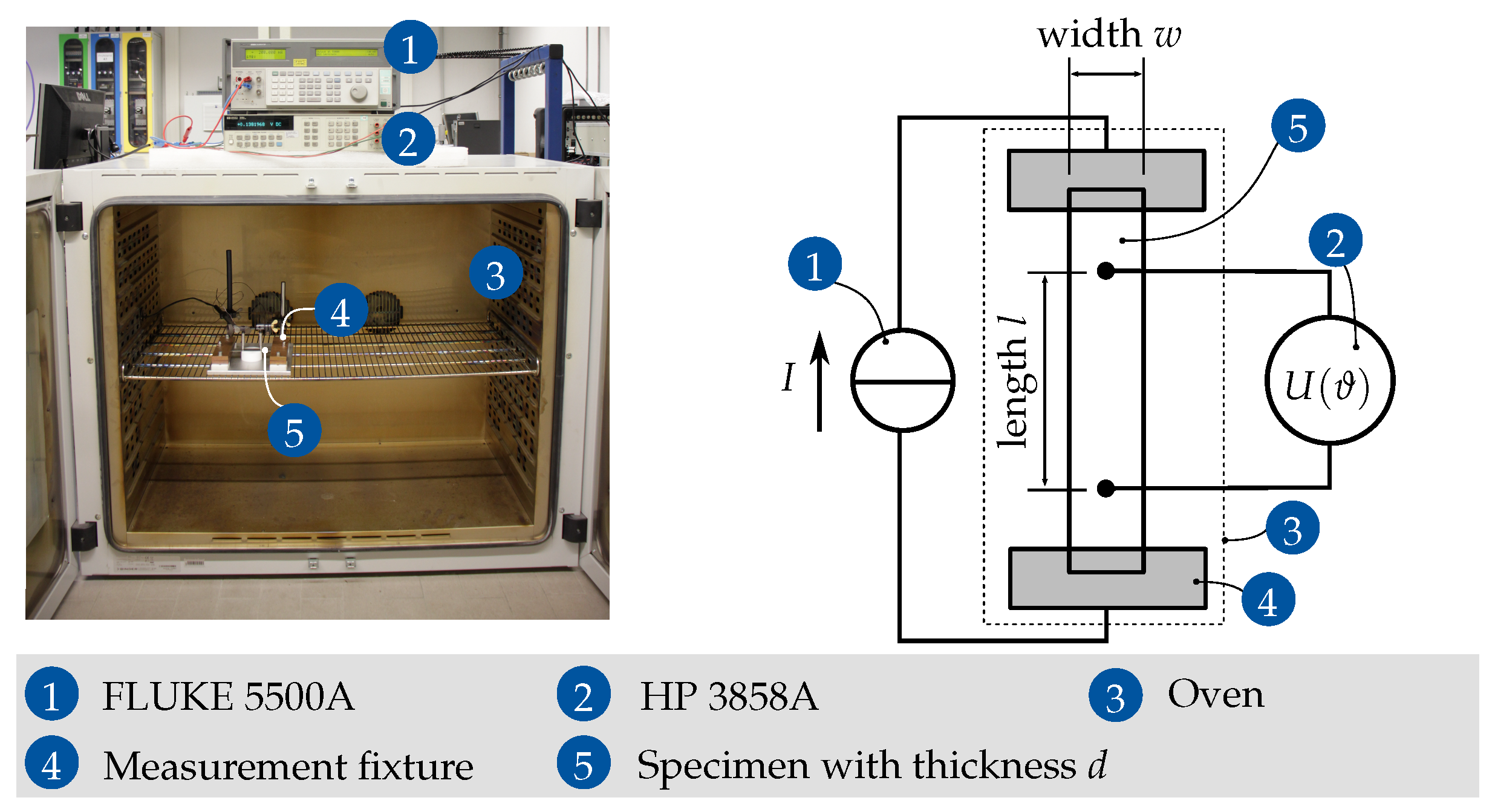

2.3. Measurements of the Temperature Dependent Electric Resistivity

3. Experimental Evaluation of the Thermal Conductivity

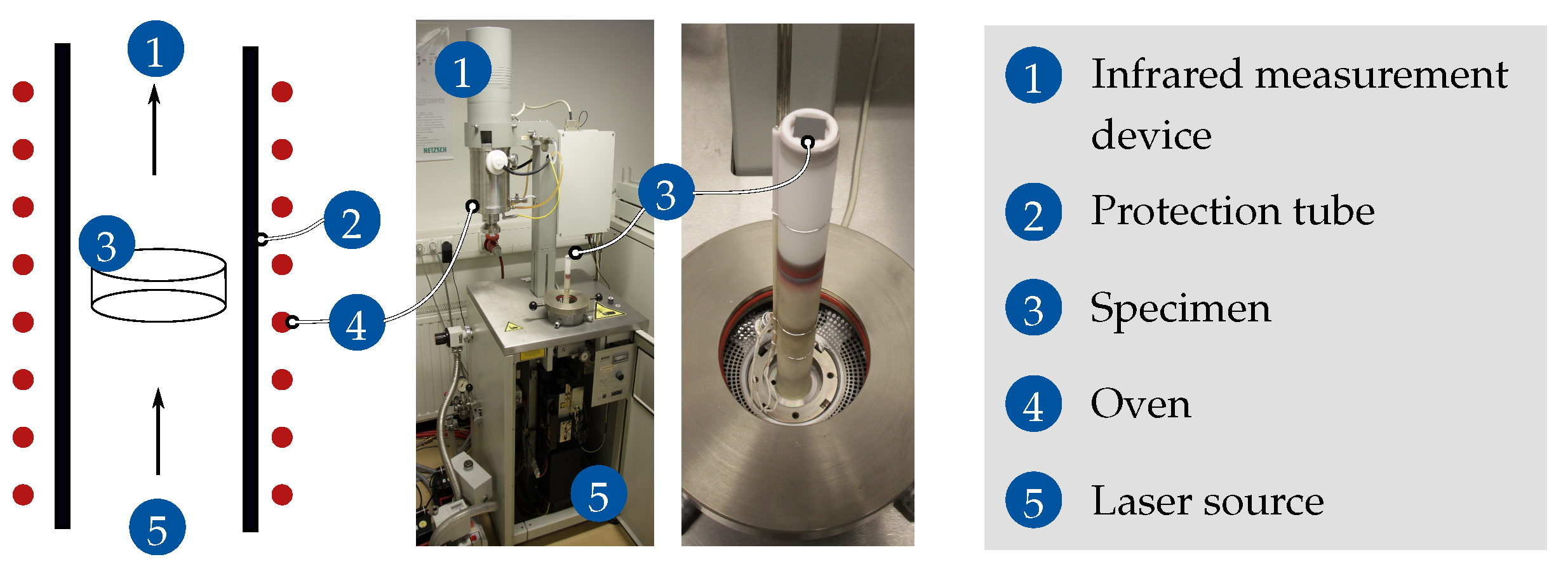

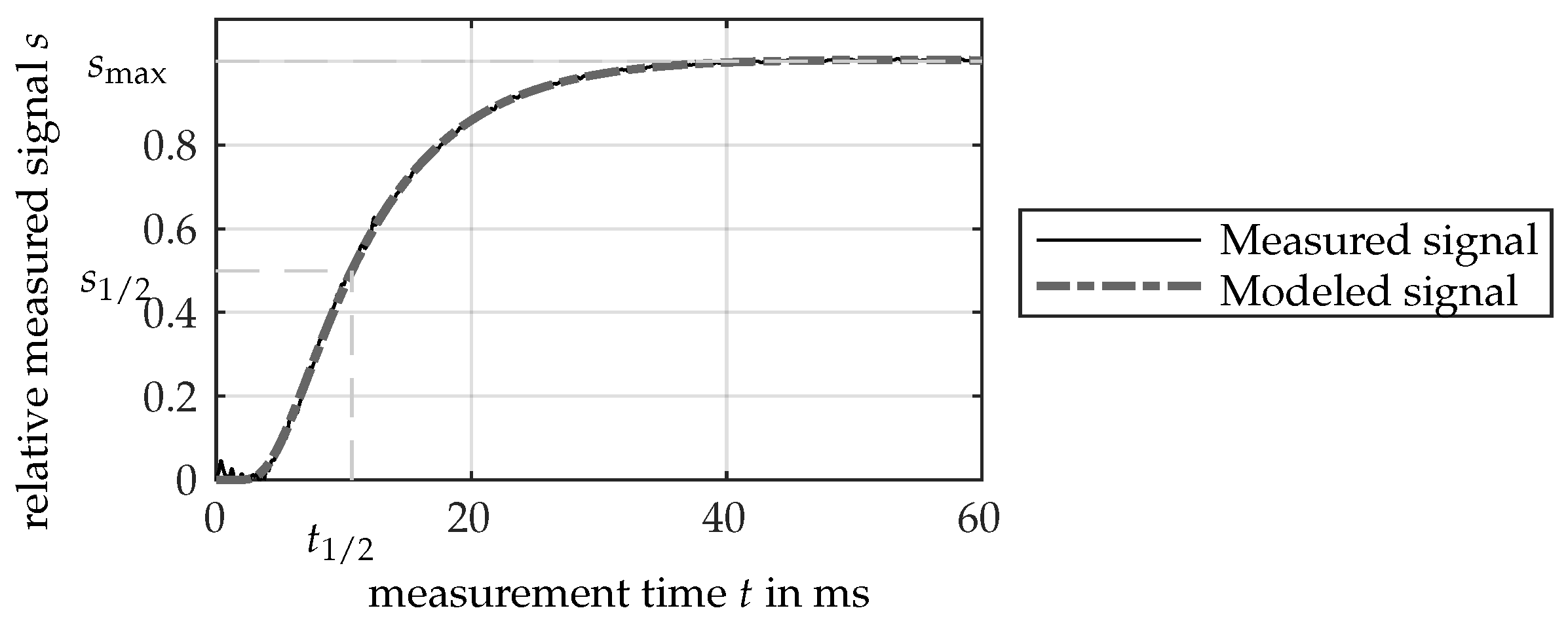

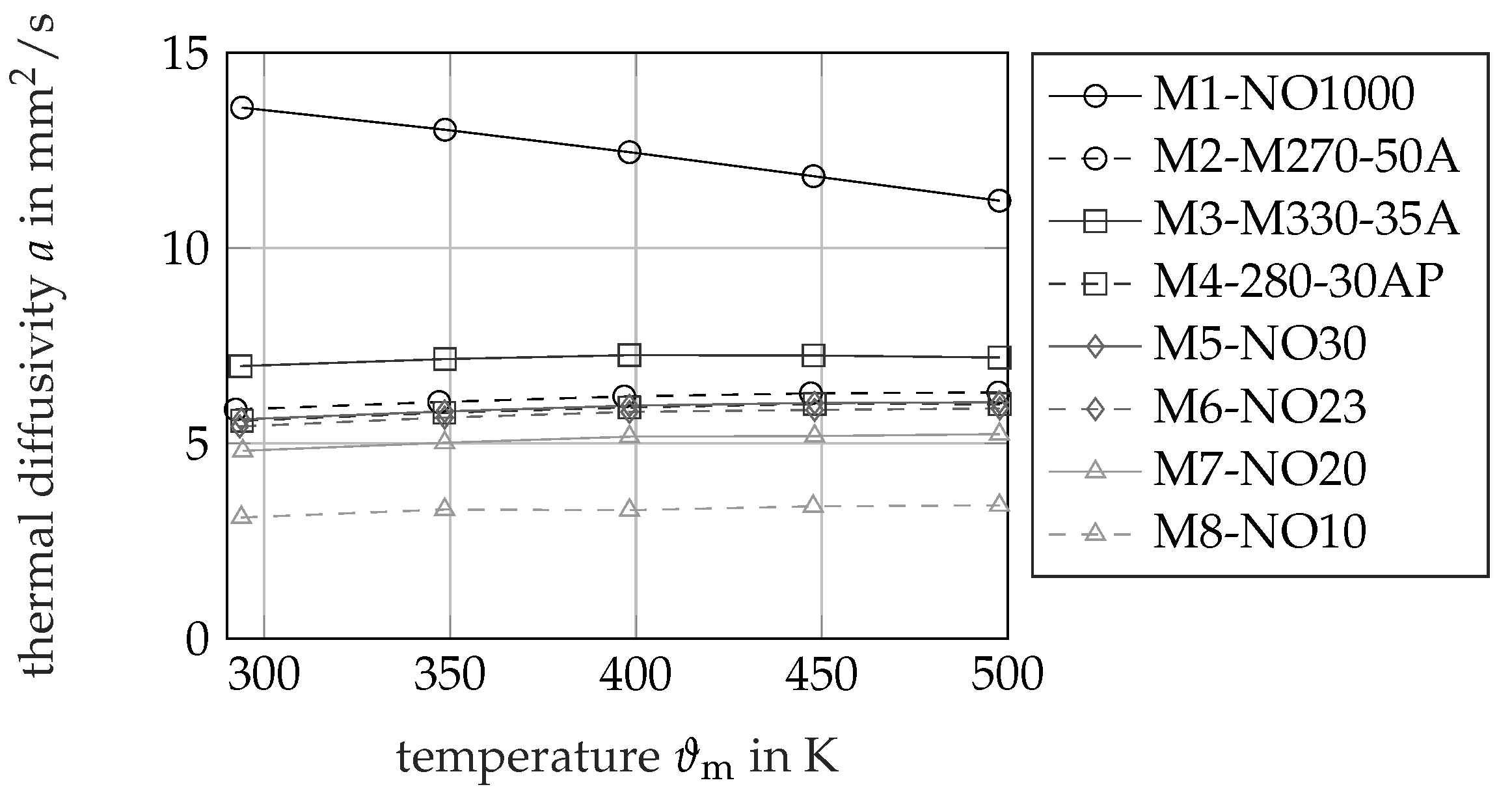

3.1. Measurements of the Thermal Diffusivity

3.2. Measurements of the Density

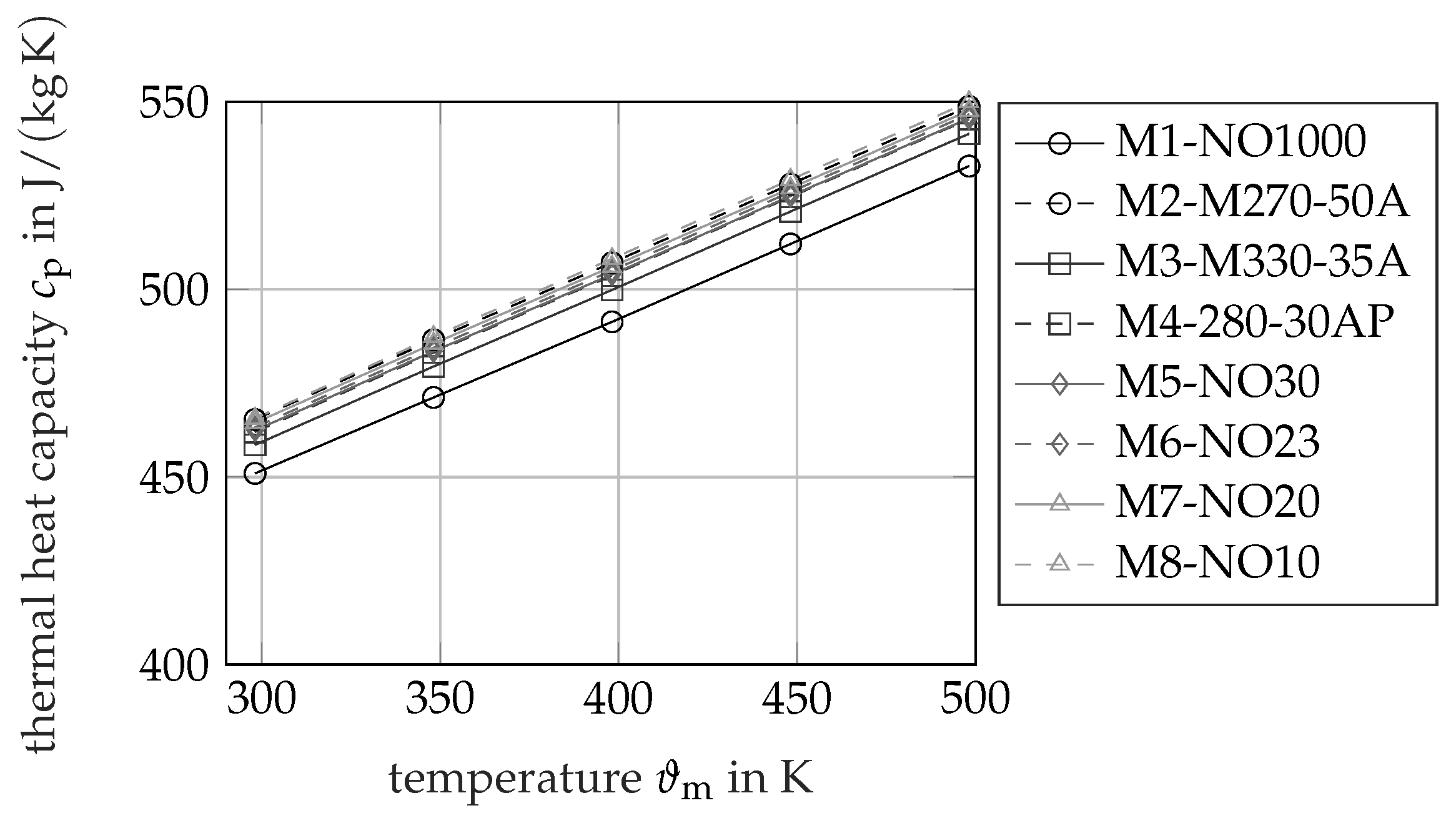

3.3. Evaluation of the Thermal Heat Capacity

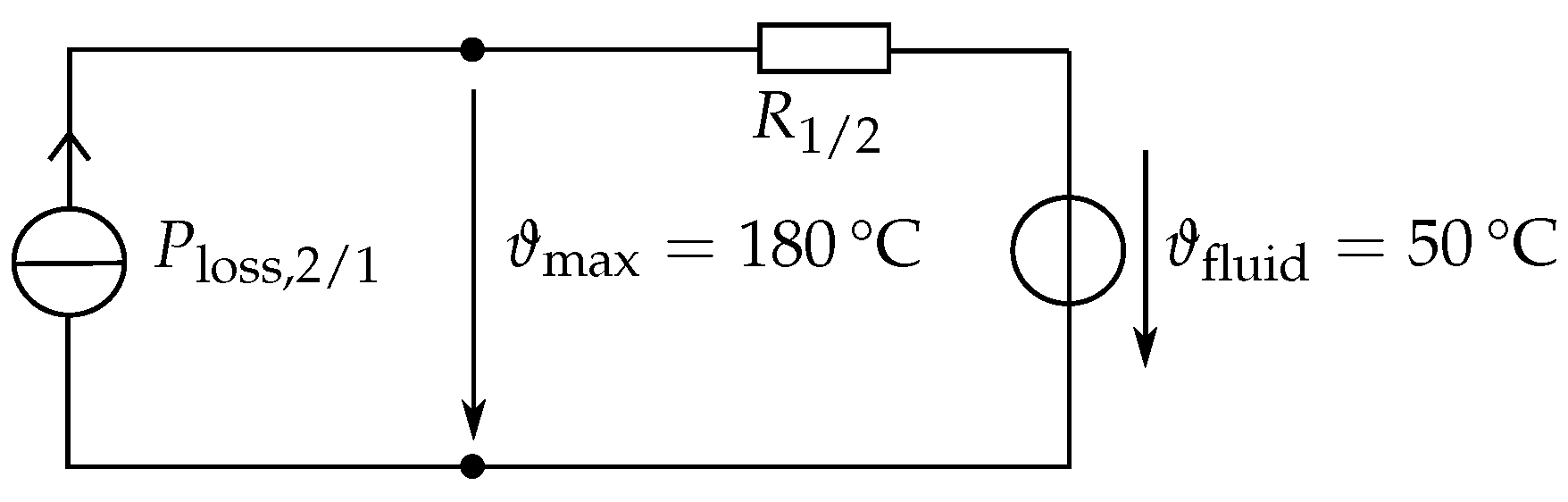

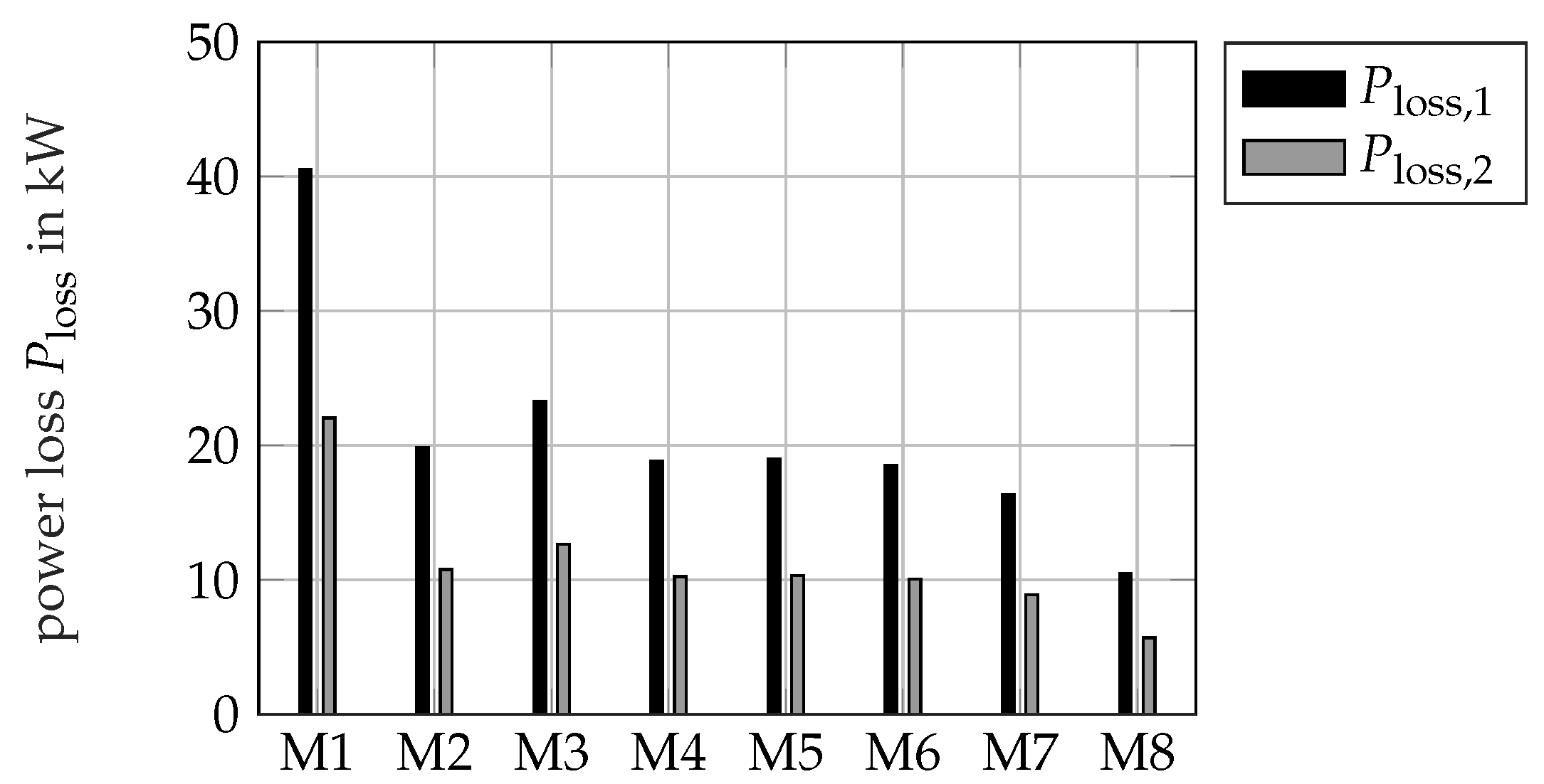

4. Simplified Case Study

How much loss power can be extracted from the electric machine in dependency of the used soft magnetic material?

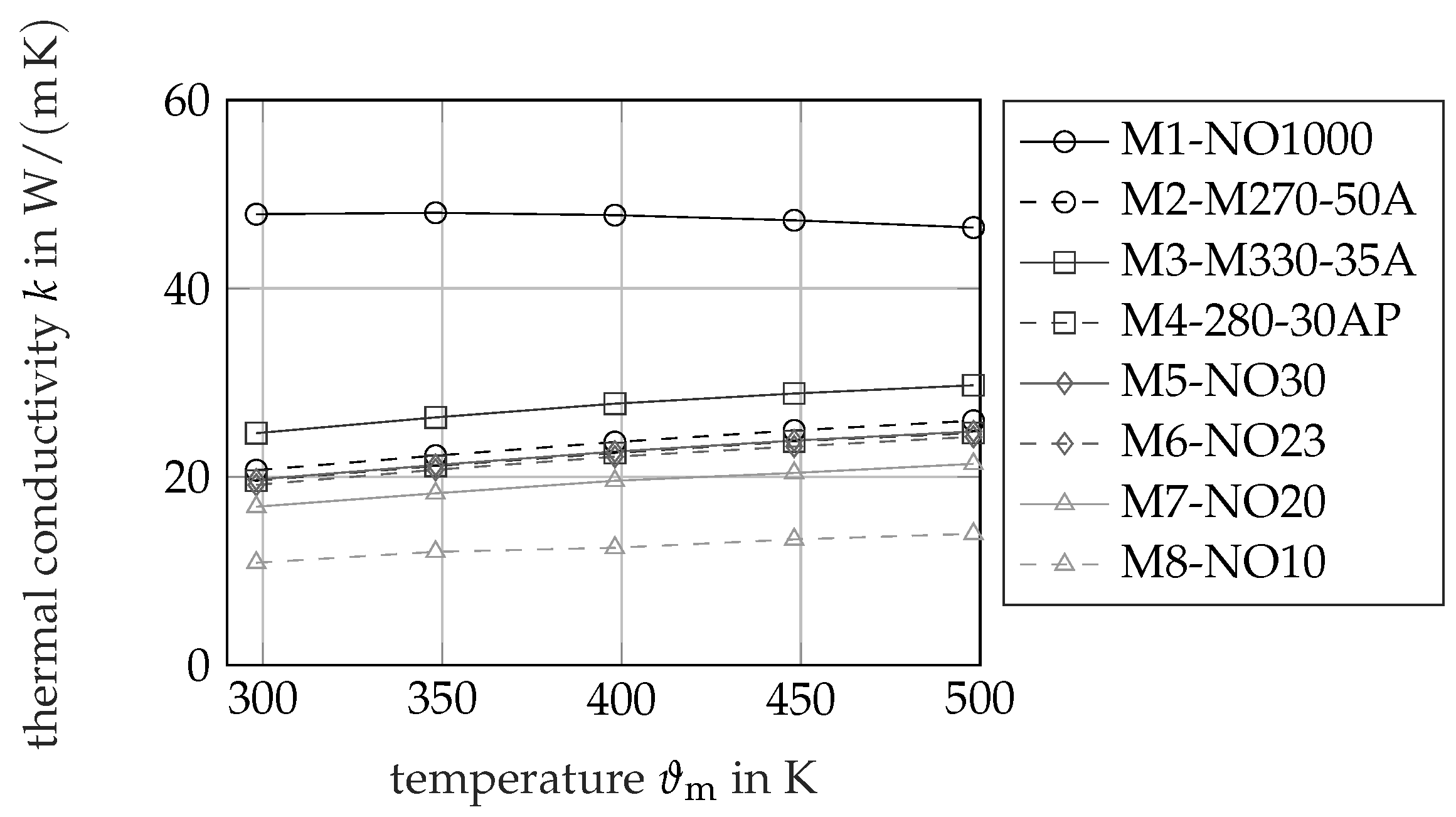

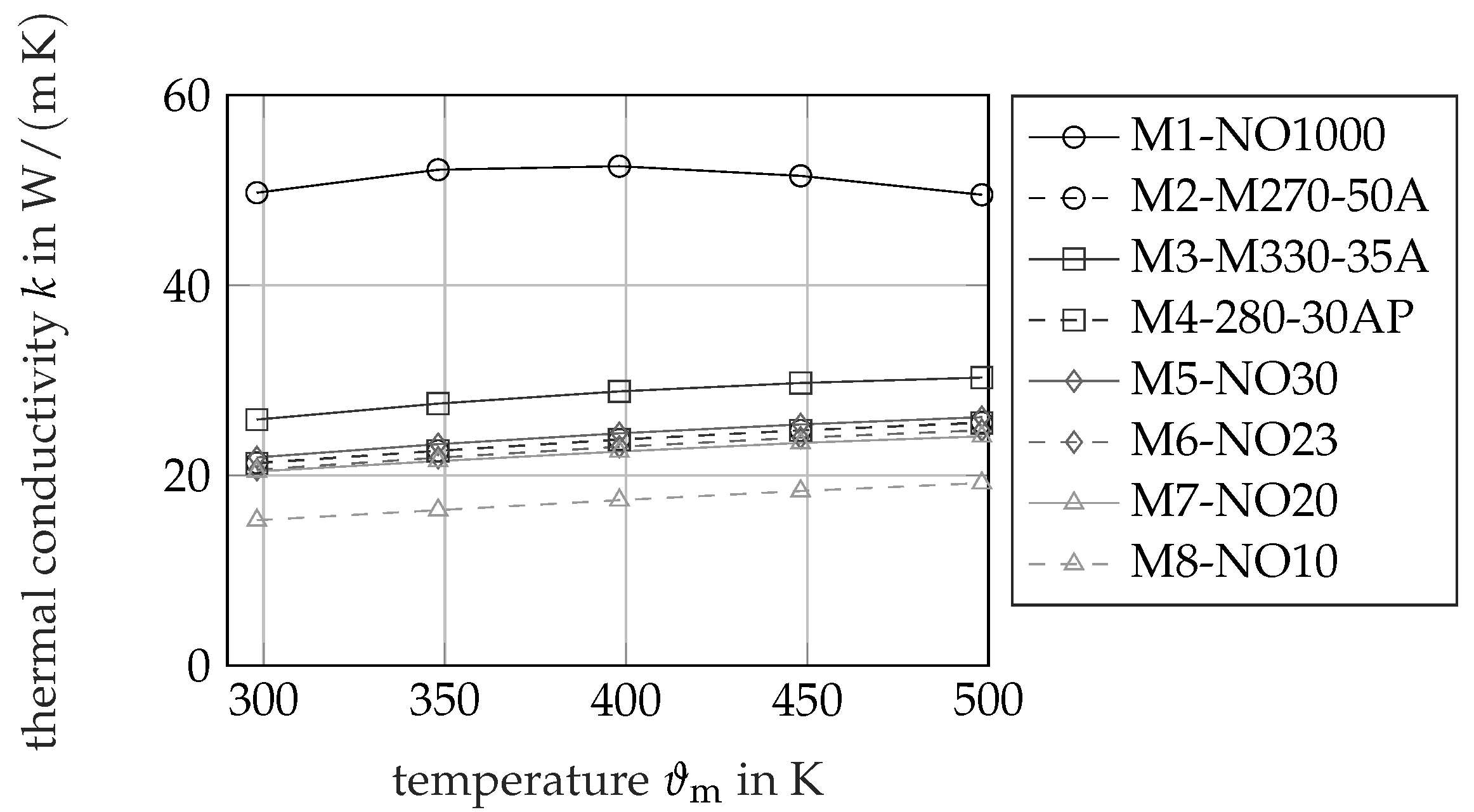

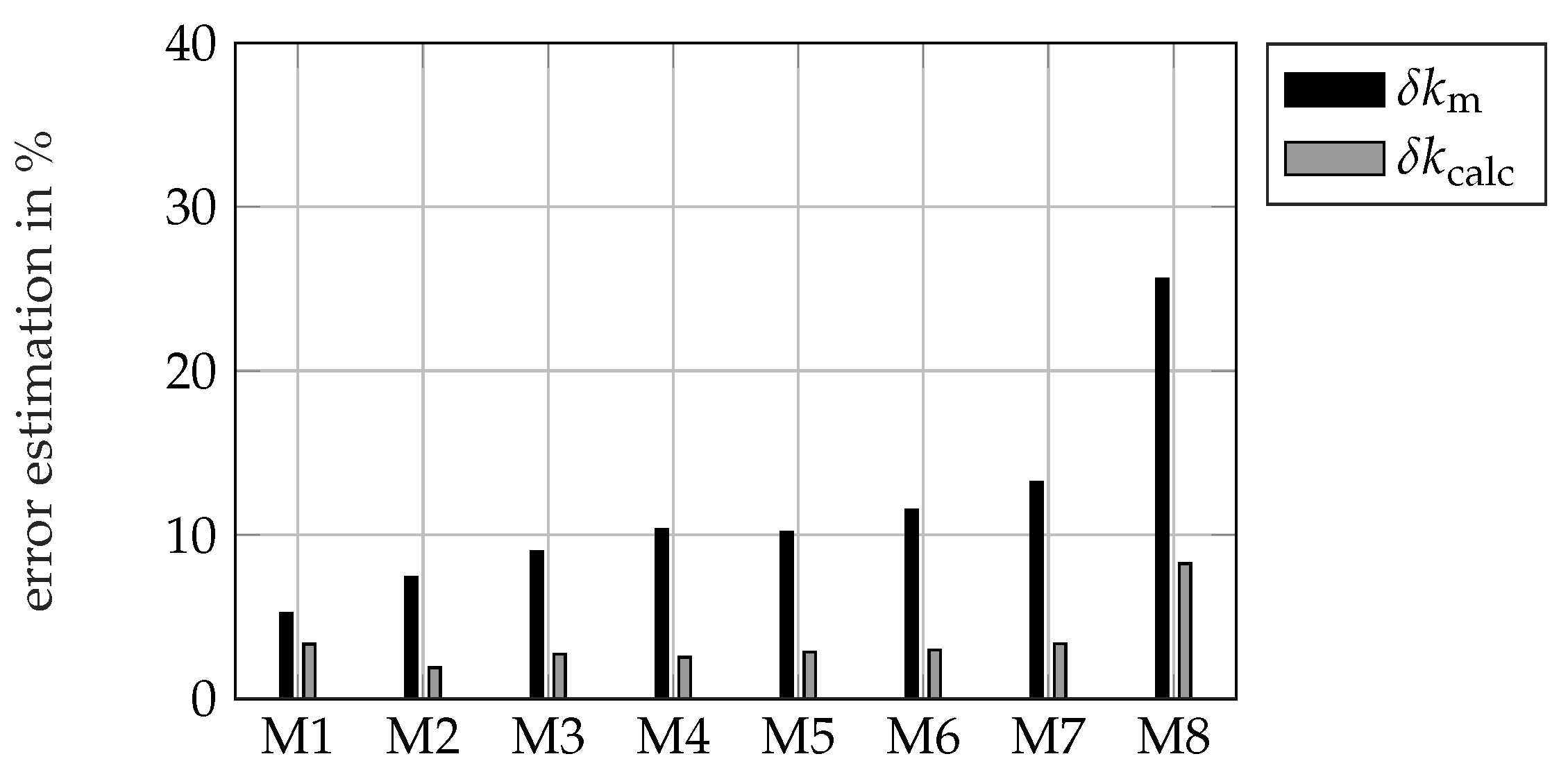

5. Results

6. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Acr. | Acronym |

| Al | Aluminum |

| IM | Induction Motor |

| InSb | Indium Antimonide |

| LFA | Laser Flash Analysis |

| LPTN | Lumped Parameter Thermal Network |

| SI | Silicon |

References

- Ruf, A.; Steentjes, S.; von Pfingsten, G.; Grosse, T.; Hameyer, K. Requirements on Soft Magnetic Materials for Electric Traction Motors. In Proceedings of the 7th international Conference on Magnetism and Metallurgy (WMM), Rome, Italy, 13–15 June 2016; pp. 111–128. [Google Scholar]

- Leuning, N.; Pauli, F.; Hameyer, K. Most appropriate soft magnetic material choice with consideration of structural material parameters for electrical machines. In Proceedings of the 8th International Conference on Magnetism and Metallurgy (WMM), Dresden, Germany, 12–14 June 2018; Universitätsverlag: Freiberg, Germany, 2018. [Google Scholar]

- Staton, D.; Boglietti, A.; Cavagnino, A. Solving the More Difficult Aspects of Electric Motor Thermal Analysis in Small and Medium Size Industrial Induction Motors. IEEE Trans. Energy Convers. 2005, 20, 620–628. [Google Scholar] [CrossRef] [Green Version]

- Groschup, B.; Nell, M.; Pauli, F.; Hameyer, K. Characteristic Thermal Parameters in Electric Motors: Comparison between Induction- and Permanent Magnet Excited Machine. IEEE Trans. Energy Convers. 2021, 36, 2239–2248. [Google Scholar] [CrossRef]

- Köller, S.; Uerlich, R.; Westphal, C.; Franck, M. Design of an Electric Drive Axle for a Heavy Truck. ATZ Heavyduty Worldw. 2021, 14, 20–25. [Google Scholar]

- JCGM. International Vocabulary of Metrology—Basic and General Concepts and Assocciated Terms (VIM), 3rd ed.; JCGM: Sevres, France, 2012. [Google Scholar]

- Klemens, P.G.; Williams, R.K. Thermal conductivity of metals and alloys. J. Appl. Phys. 1986, 31, 197–215. [Google Scholar]

- Wang, G.; Li, Y. Effects of alloying elements and temperature on thermal conductivity of ferrite. J. Appl. Phys. 2019, 126, 125118.1–125118.9. [Google Scholar] [CrossRef]

- Herbstein, F.H.; Smuts, J. Determination of Debye temperature of alpha-iron by X-ray diffraction. Philos. Mag. 1963, 8, 367–385. [Google Scholar] [CrossRef]

- Williams, R.K.; Yarbrough, D.W.; Masey, J.W.; Holder, T.K.; Graves, R.S. Experimental determination of the phonon and electron components of the thermal conductivity of bcc iron. J. Phys. Chem. Ref. Data 1981, 52, 5167–5175. [Google Scholar] [CrossRef]

- Williams, R.K.; Graves, R.S.; McElroy, D.L. Thermal and electrical conductivities of an improved 9 Cr-1 Mo steel from 360 to 1000 K. Int. J. Thermophys. 1984, 5, 301–313. [Google Scholar] [CrossRef]

- Julian, C.L. Theory of Heat Conduction in Rare-Gas Crystals. Phys. Rev. 1965, 137, A128–A137. [Google Scholar] [CrossRef]

- Bäcklund, N.G. An experimental investigation of the electrical and thermal conductivity of iron and some dilute iron alloys at temperatures above 100 °K. J. Phys. Chem. Solids 1961, 20, 1–16. [Google Scholar] [CrossRef]

- DIN German Institute for Standardization. Magnetic Materials—Part 3: Methods of Measurement of the Magnetic Properties of Electrical Steel Strip and Sheet by Means of a Single Sheet Tester (IEC 60404-3:1992 + A1:2002 + A2:2009); Beuth Verlag GmbH: Berlin, Germany, 2010. [Google Scholar]

- Corporation Fluke. Datasheet: Service Manual 5500A Multi-Product Calibrator; Fluke Corporation: Everett, WA, USA, 1995. [Google Scholar]

- Hewlett-Packard Company (HP). Datasheet: 3458A Multimeter Operating, Programming and Configuration; Manual, Hewlett-Packard Company (HP): Palo Alto, CA, USA, 1988. [Google Scholar]

- Wijn, H.P.J. Magnetic Alloys for Technical Applications. Soft Magnetic Alloys, Invar and Elinvar Alloys; Springer: Berlin/Heidelberg, Germany, 1994; Volume 19i1. [Google Scholar] [CrossRef]

- Parker, W.J.; Jenkins, R.J.; Butler, C.P.; Abbott, G.L. Flash Method of Determining Thermal Diffusivity, Heat Capacity, and Thermal Conductivity. J. Appl. Phys. 1961, 32, 1679–1684. [Google Scholar] [CrossRef]

- Cowan, R.D. Pulse Method of Measuring Thermal Diffusivity at High Temperatures. J. Appl. Phys. 1963, 34, 926–927. [Google Scholar] [CrossRef]

- Cape, J.A.; Lehman, G.W. Temperature and Finite Pulse—Time Effects in the Flash Method for Measuring Thermal Diffusivity. J. Appl. Phys. 1963, 34, 1909–1913. [Google Scholar] [CrossRef]

- NETZSCH. Laser Flash Apparatus LFA 427: Brochure; Netzsch-Gerätebau GmbH: Seib, Germany, 2021. [Google Scholar]

- Desai, P.D. Thermodynamic Properties of Iron and Silicon. J. Phys. Chem. Ref. Data 1986, 15, 967–983. [Google Scholar] [CrossRef]

- Chao, J.; Phillips, E.W.; Sinke, G.C.; Hu, A.T.; Prophet, H.; Syverud, A.N.; Karris, G.C.; Wollert, S.K. JANAF Thermochemical Tables Addendum; U.S. Department of Commerce: Washington, DC, USA, 1966.

- Chase, M.W.; Curnutt, J.L.; Downey, J.R.; McDonald, R.A.; Syverud, A.N.; Valenzuela, E.A. JANAF Thermochemical Tables, 1982 Supplement. J. Phys. Chem. Ref. Data 1982, 11, 695–940. [Google Scholar] [CrossRef] [Green Version]

- Novikov, V.V. Debye–Einstein model and anomalies of heat capacity temperature dependences of solid solutions at low temperatures. J. Therm. Anal. Calorim. 2019, 138, 265–272. [Google Scholar] [CrossRef]

- Hafenstein, S.; Werner, E.; Wilzer, J.; Theisen, W.; Weber, S.; Sunderkötter, C.; Bachmann, M. Influence of Temperature and Tempering Conditions on Thermal Conductivity of Hot Work Tool Steels for Hot Stamping Applications. Steel Res. Int. 2015, 86, 1628–1635. [Google Scholar] [CrossRef]

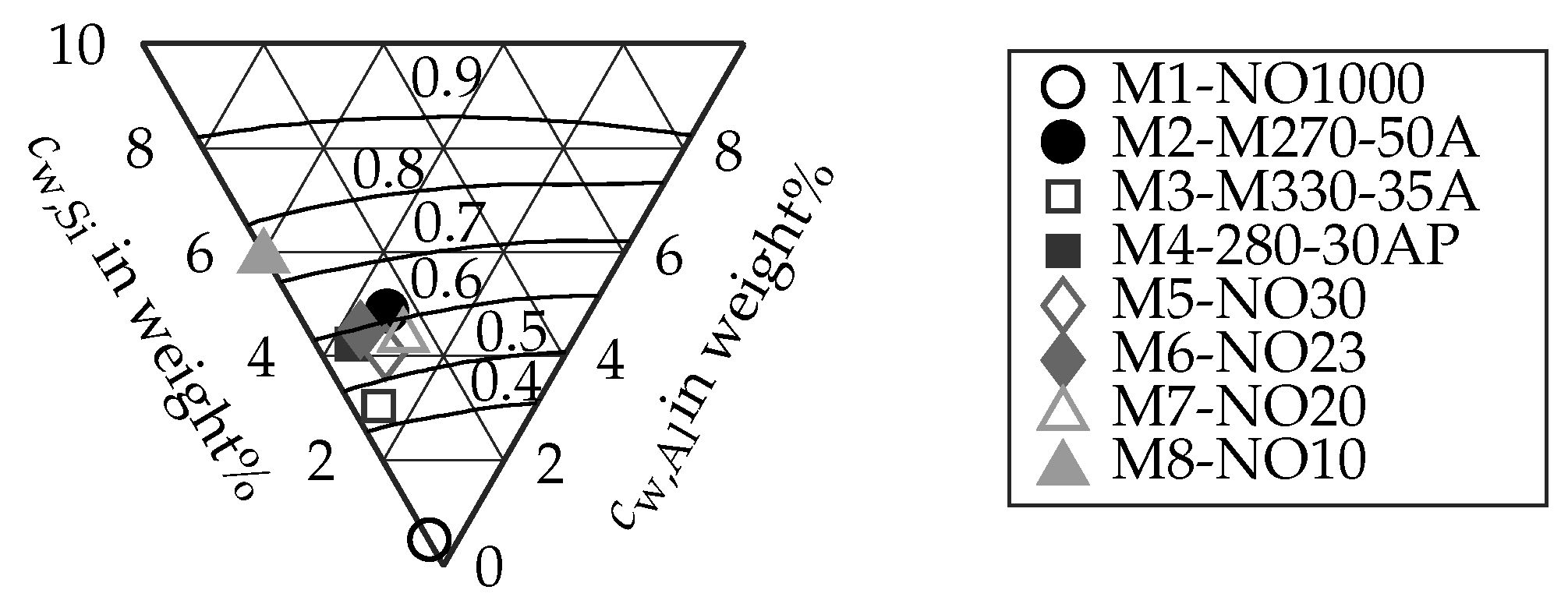

| Name | Acr. | Si in % | Al in % | d in mm |

|---|---|---|---|---|

| NO1000 | M1 | 0.47 | 0.03 | 1 |

| M270-50A | M2 | 3.38 | 1.49 | 0.5 |

| M330-35A | M3 | 2.6 | 0.44 | 0.35 |

| 280-30AP | M4 | 3.64 | 0.59 | 0.30 |

| NO30 | M5 | 3 | 1.067 | 0.30 |

| NO23 | M6 | 3.64 | 0.87 | 0.23 |

| NO20 | M7 | 2.91 | 1.57 | 0.20 |

| NO10 | M8 | 6 | 0 | 0.10 |

| Material | |||

|---|---|---|---|

| M1-NO1000 | 0.29 | 0.04 | 0.08 |

| M2-M270-50A | 0.09 | 0.04 | 1.00 |

| M3-M330-35A | 0.41 | 0.02 | 0.91 |

| M4-280-30AP | 0.09 | 0.03 | 0.63 |

| M5-NO30 | 0.19 | 0.03 | 0.85 |

| M6-NO23 | 0.06 | 0.08 | 0.54 |

| M7-NO20 | 0.30 | 0.04 | 0.72 |

| M8-NO10 | 0.30 | 0.06 | 1.28 |

| Material | Material | Material | |||

|---|---|---|---|---|---|

| M1-NO1000 | 4.3 | M2-M270-50A | 2.9 | M3-M330-35A | 3.9 |

| M4-280-30AP | 3.8 | M5-NO30 | 4.3 | M6-NO23 | 4.5 |

| M7-NO20 | 5.3 | M8-NO10 | 11.7 |

| Material | = 293 K | = 348 K | = 398 K | = 448 K | = 498 K |

|---|---|---|---|---|---|

| M1-NO1000 | 1.13 | 0.80 | 0.62 | 1.22 | 0.52 |

| M2-M270-50A | 0.90 | 0.33 | 0.21 | 0.19 | 0.21 |

| M3-M330-35A | 0.66 | 0.45 | 0.40 | 0.51 | 0.40 |

| M4-280-30AP | 0.41 | 0.61 | 0.44 | 0.52 | 0.72 |

| M5-NO30 | 0.61 | 0.46 | 0.60 | 0.50 | 0.36 |

| M6-NO23 | 0.63 | 0.72 | 0.59 | 0.70 | 0.70 |

| M7-NO20 | 0.98 | 0.74 | 0.56 | 0.81 | 0.94 |

| M8-NO10 | 1.61 | 1.24 | 2.65 | 1.53 | 0.76 |

| Material | Material | Material | |||

|---|---|---|---|---|---|

| M1-NO1000 | 3.0 | M2-M270-50A | 5.2 | M3-M330-35A | 6.8 |

| M4-280-30AP | 8.1 | M5-NO30 | 8.0 | M6-NO23 | 9.3 |

| M7-NO20 | 11.0 | M8-NO10 | 23.4 |

| Geometrical Principle | Archimedes Principle | |||||||

|---|---|---|---|---|---|---|---|---|

| Material | in % | in % | in % | in kg/m3 | in % | in % | in kg/m3 | in % |

| M1-NO1000 | 0.15 | 0.05 | 0.25 | 7581 | 2.2 | 0.13 | 7834 | 0.21 |

| M2-M270-50A | 0.02 | 0.06 | 1.05 | 7288 | 3.4 | 0.02 | 7553 | 0.21 |

| M3-M330-35A | 0.06 | 0.07 | 0.57 | 7398 | 4.4 | 0.13 | 7678 | 0.20 |

| M4-280-30AP | 0.03 | 1.10 | 0.38 | 7222 | 5.2 | 0.06 | 7579 | 0.21 |

| M5-NO30 | 0.08 | 0.07 | 0.45 | 7302 | 5.1 | 0.04 | 7565 | 0.21 |

| M6-NO23 | 0.16 | 0.02 | 1.86 | 7271 | 5.9 | 0.01 | 7576 | 0.20 |

| M7-NO20 | 0.10 | 0.02 | 0.56 | 7162 | 6.9 | 0.02 | 7503 | 0.24 |

| M8-NO10 | 0.07 | 0.20 | 2.50 | 6964 | 14.7 | 0.12 | 7479 | 0.22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Groschup, B.; Rosca, A.; Leuning, N.; Hameyer, K. Study of the Thermal Conductivity of Soft Magnetic Materials in Electric Traction Machines. Energies 2021, 14, 5310. https://doi.org/10.3390/en14175310

Groschup B, Rosca A, Leuning N, Hameyer K. Study of the Thermal Conductivity of Soft Magnetic Materials in Electric Traction Machines. Energies. 2021; 14(17):5310. https://doi.org/10.3390/en14175310

Chicago/Turabian StyleGroschup, Benedikt, Alexandru Rosca, Nora Leuning, and Kay Hameyer. 2021. "Study of the Thermal Conductivity of Soft Magnetic Materials in Electric Traction Machines" Energies 14, no. 17: 5310. https://doi.org/10.3390/en14175310

APA StyleGroschup, B., Rosca, A., Leuning, N., & Hameyer, K. (2021). Study of the Thermal Conductivity of Soft Magnetic Materials in Electric Traction Machines. Energies, 14(17), 5310. https://doi.org/10.3390/en14175310