Numerical and Experimental Investigation of a Semi-Active Vibration Control System by Means of Vibration Energy Conversion

Abstract

:1. Introduction

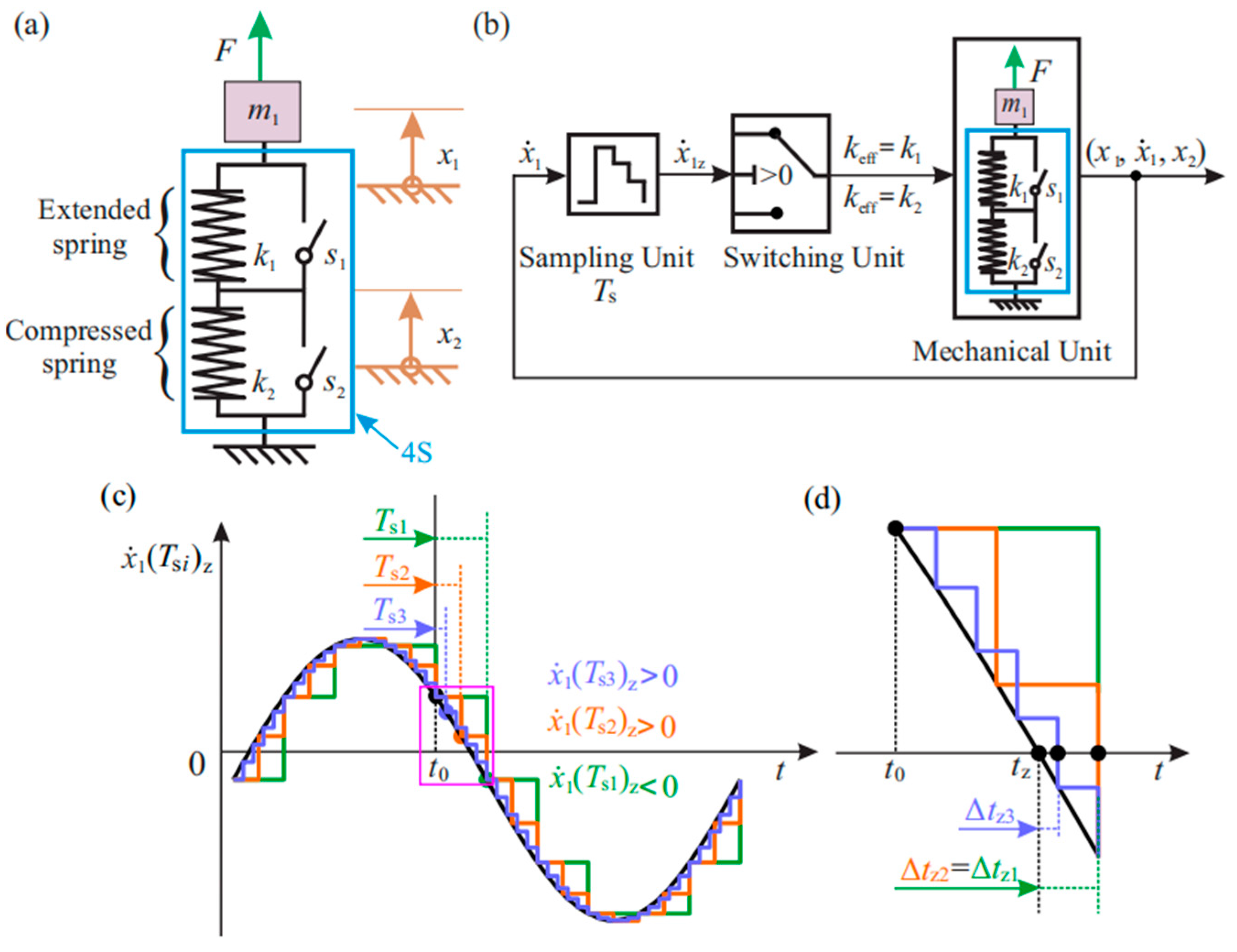

2. Vibration Control Concept with Vibration Energy Conversion and Storage

3. Experimental 4S

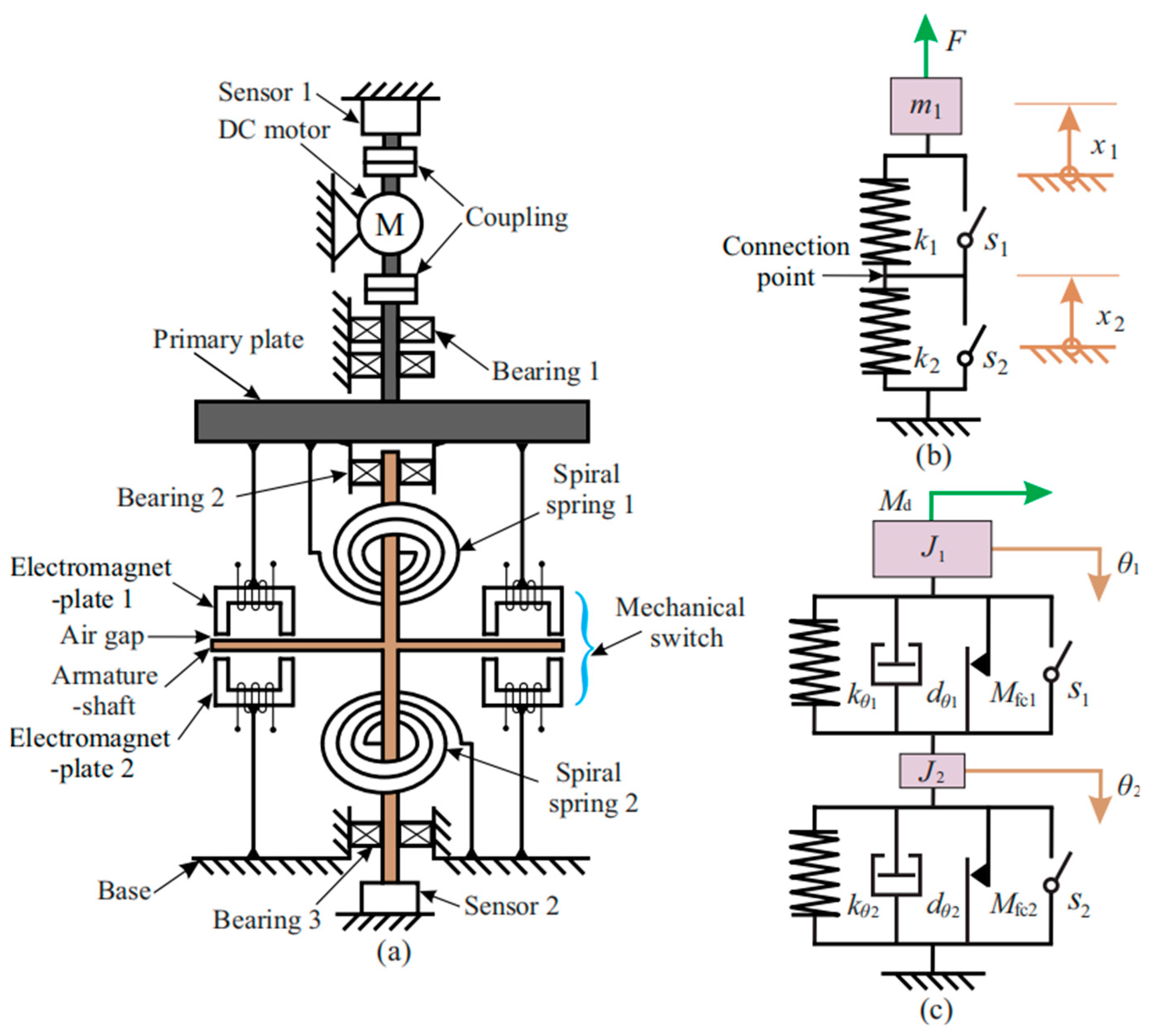

3.1. Principle of the Experimental 4S

3.2. Modeling of the Experimental 4S

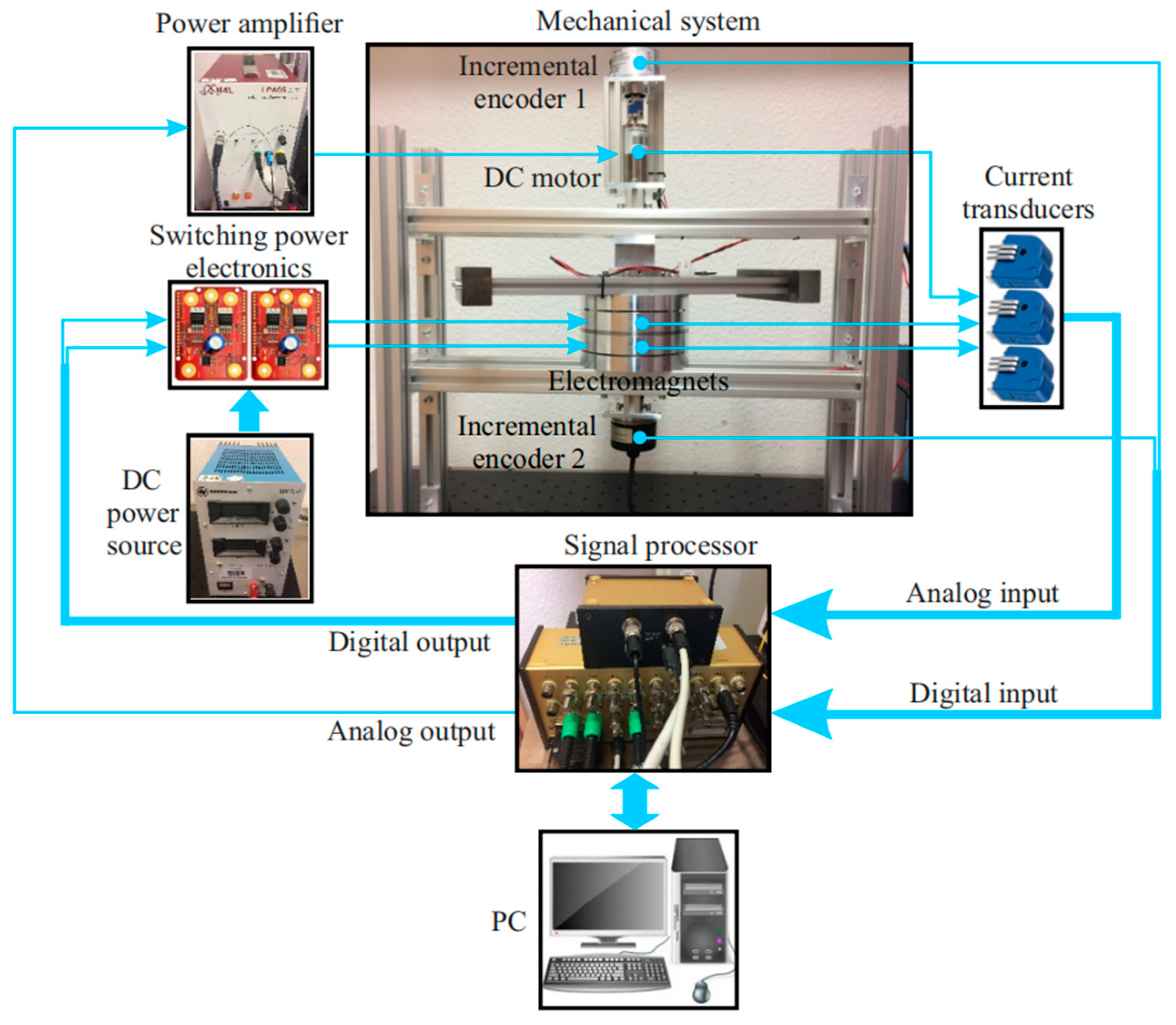

3.3. Setup of the Experimental 4S

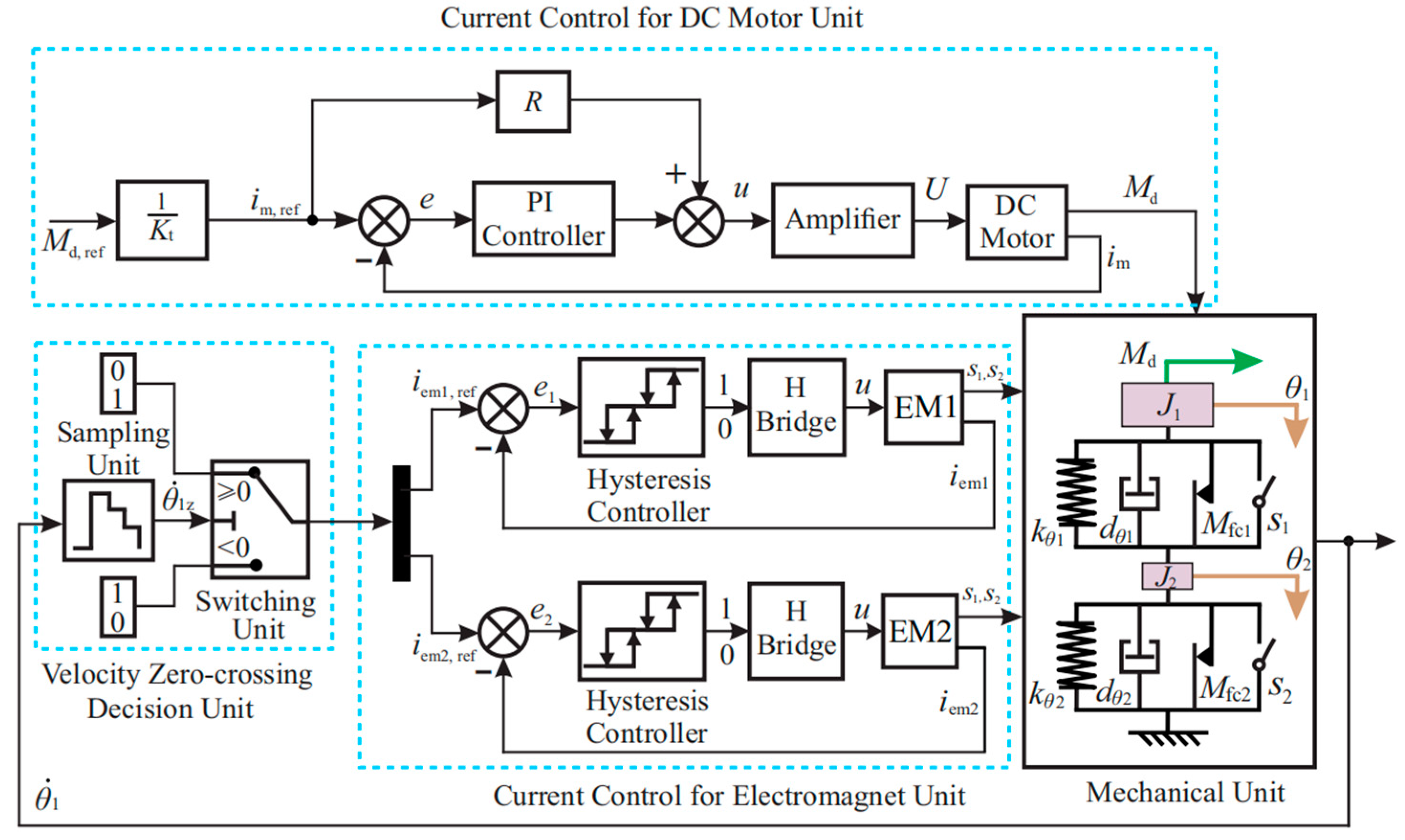

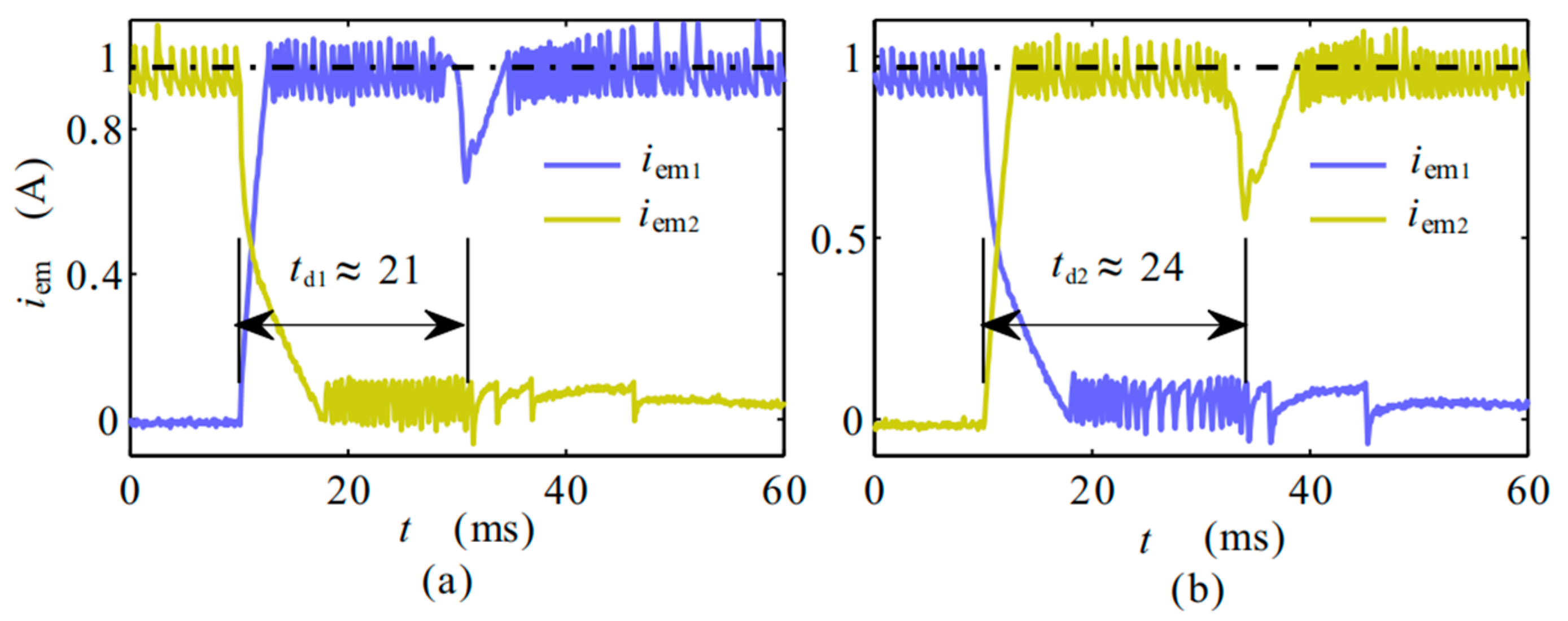

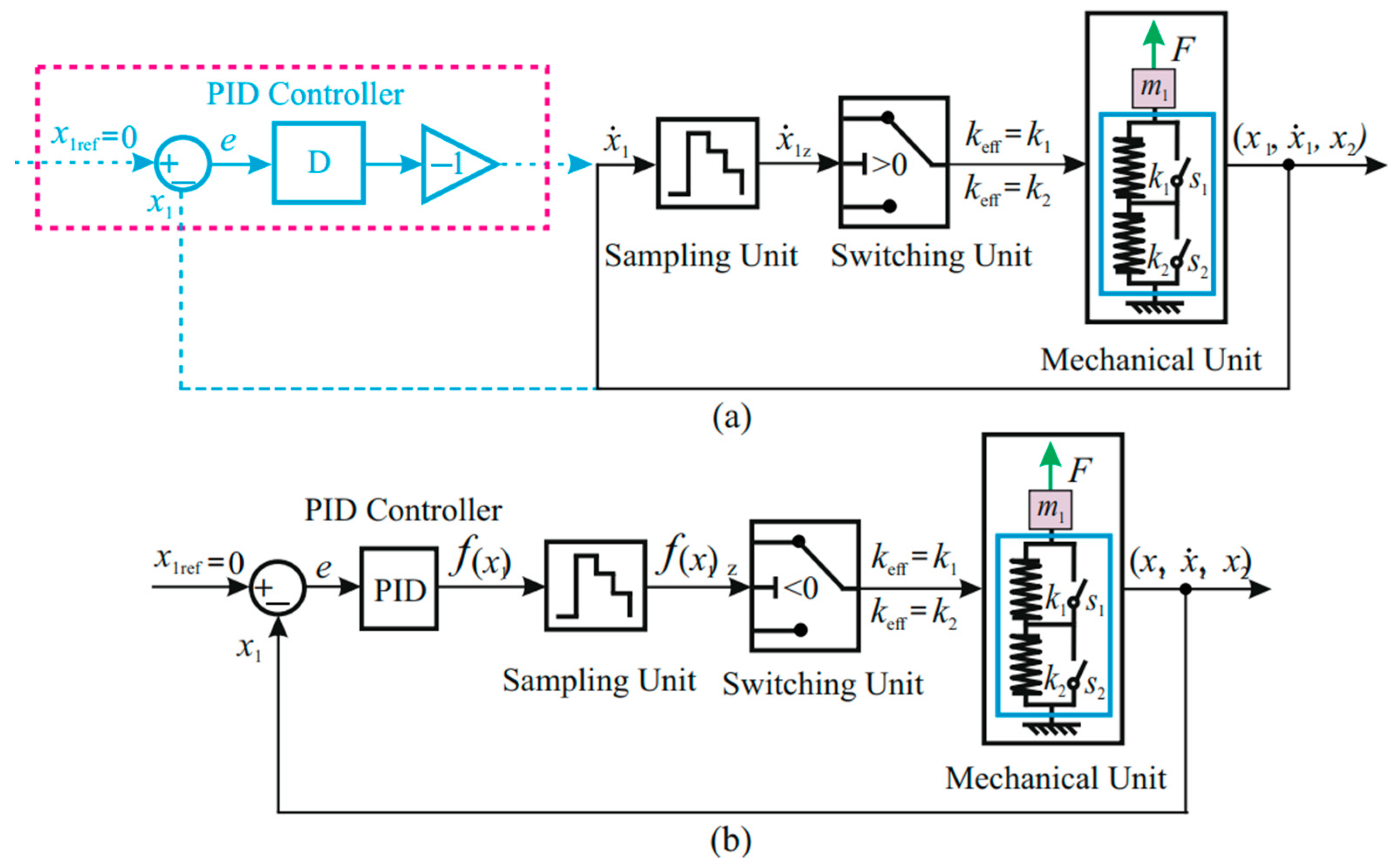

3.4. Power Electronics and Control of the Experimental 4S

4. Measurement of Physical Properties of the Experimental 4S

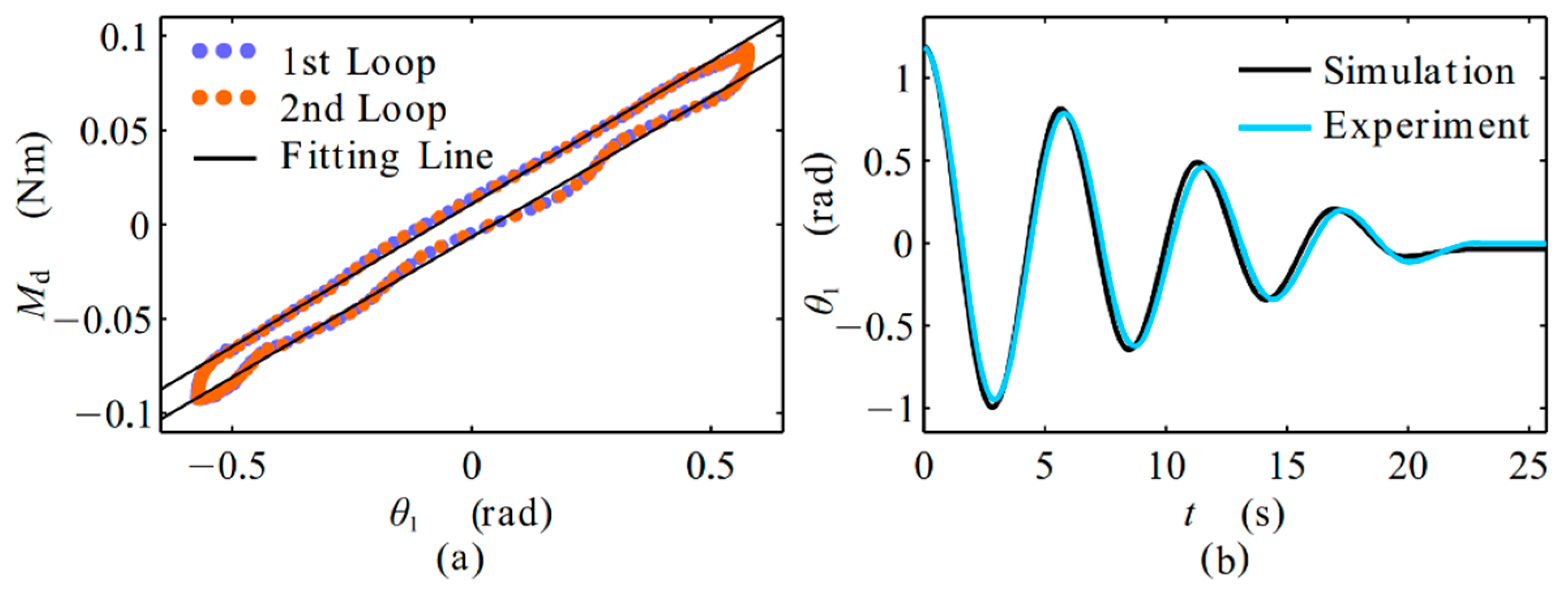

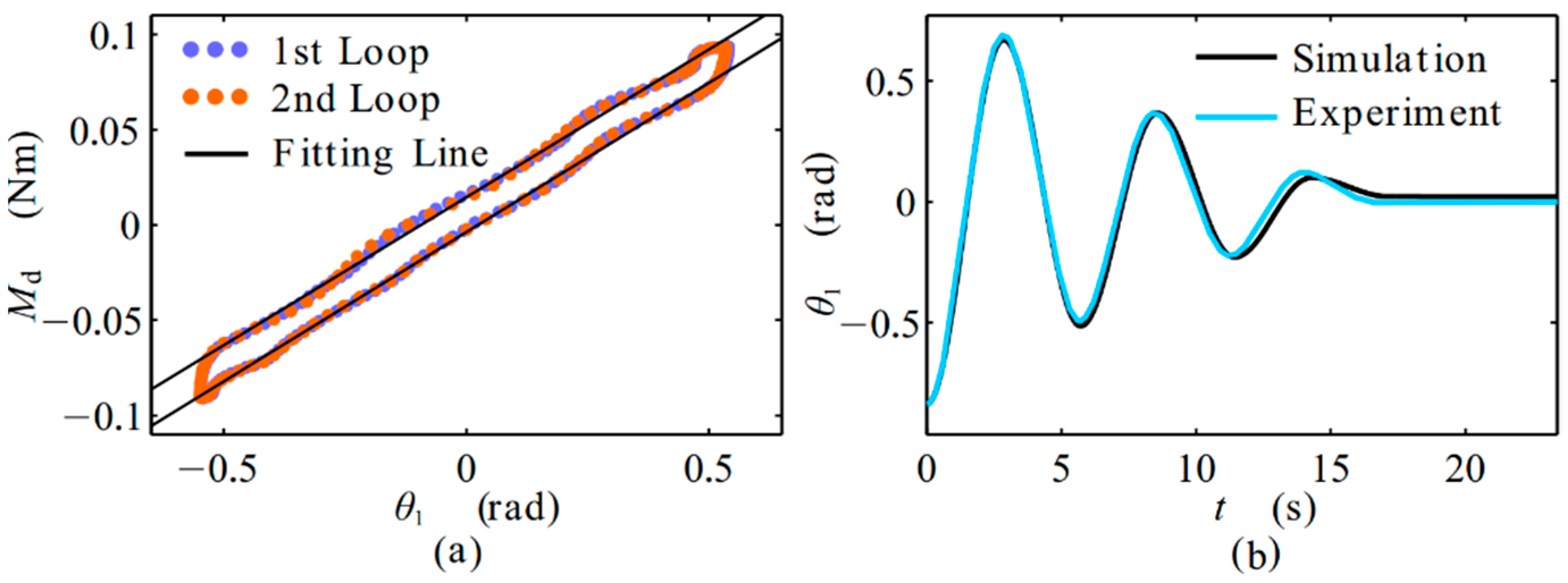

System Parameter Identification

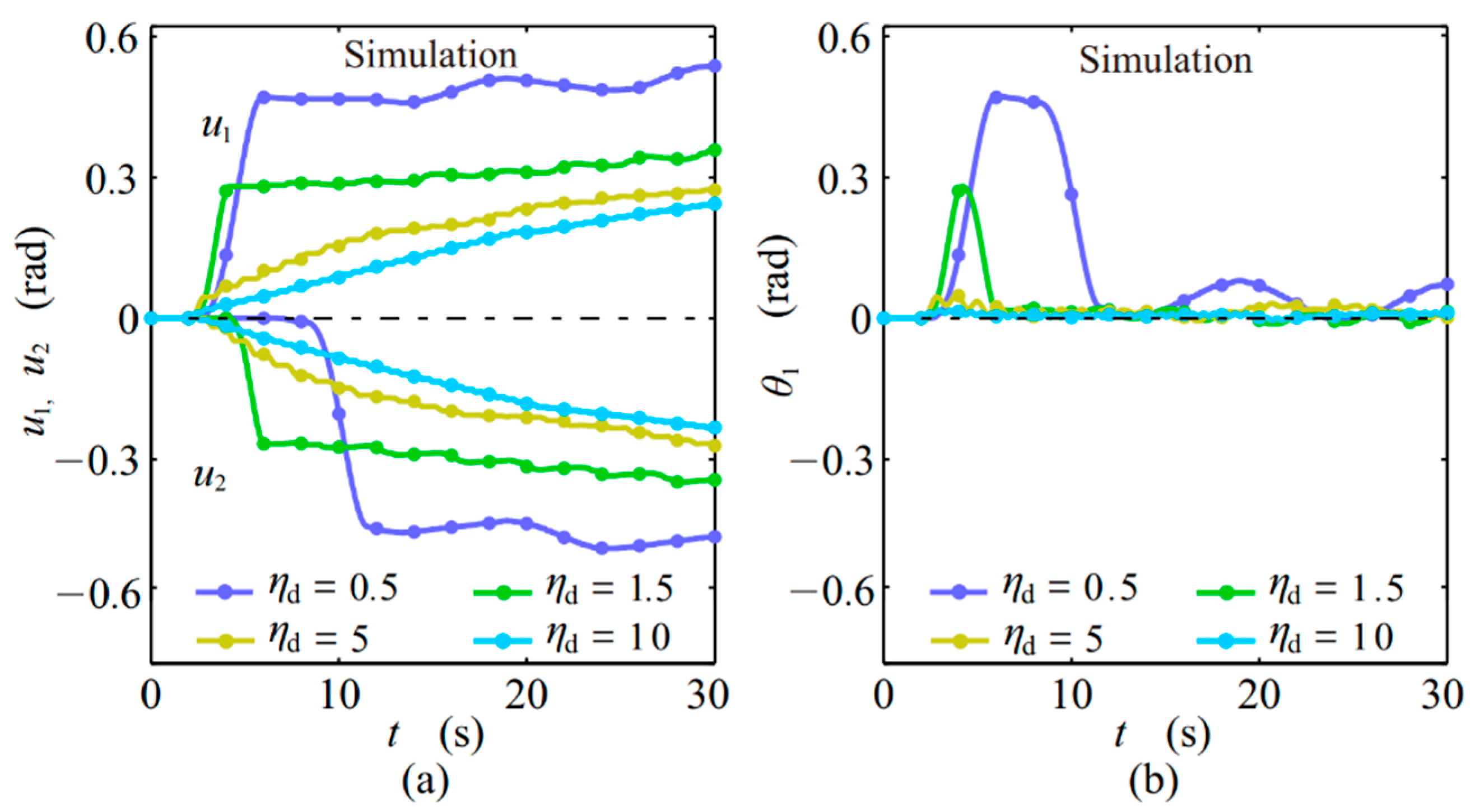

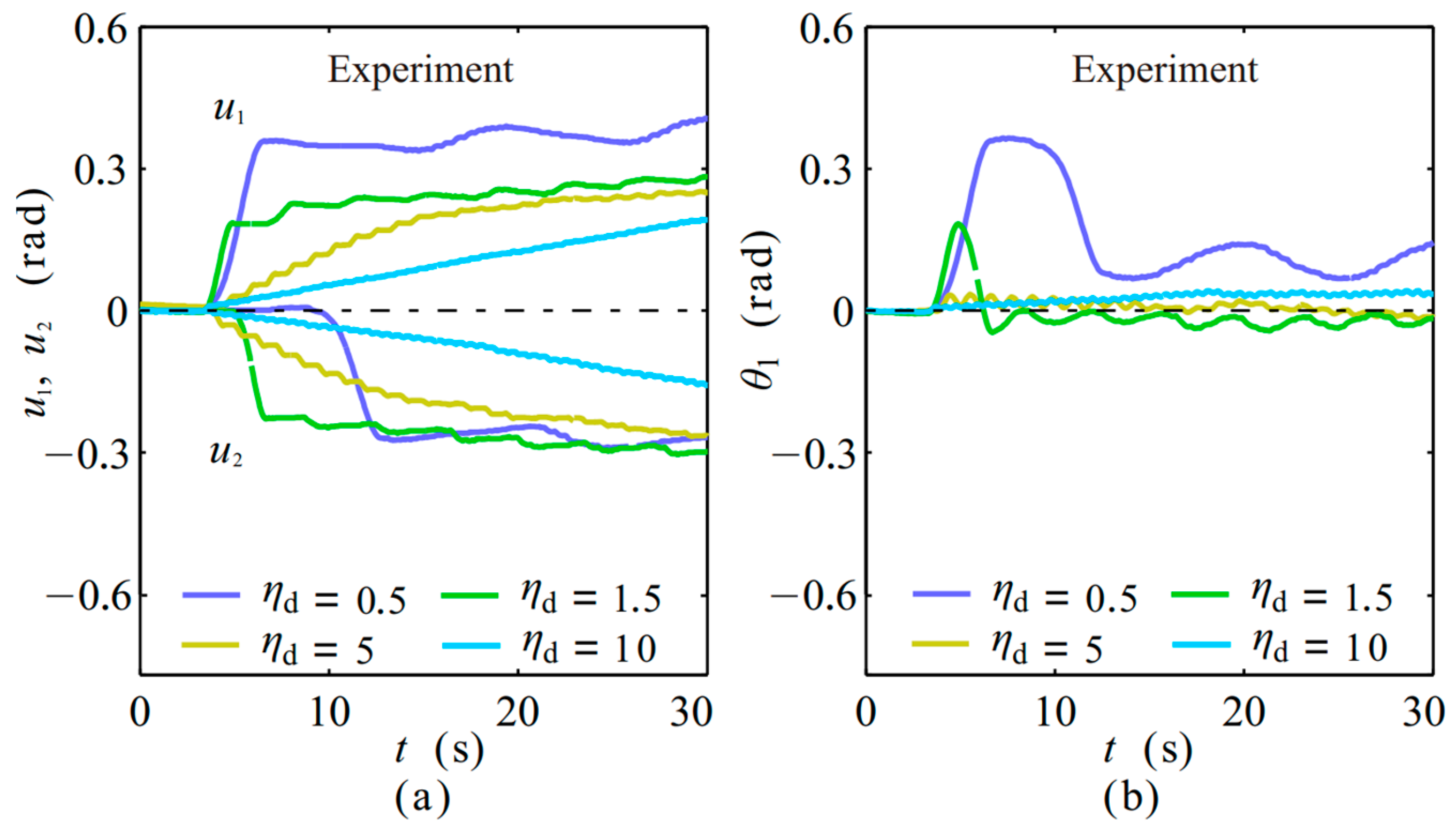

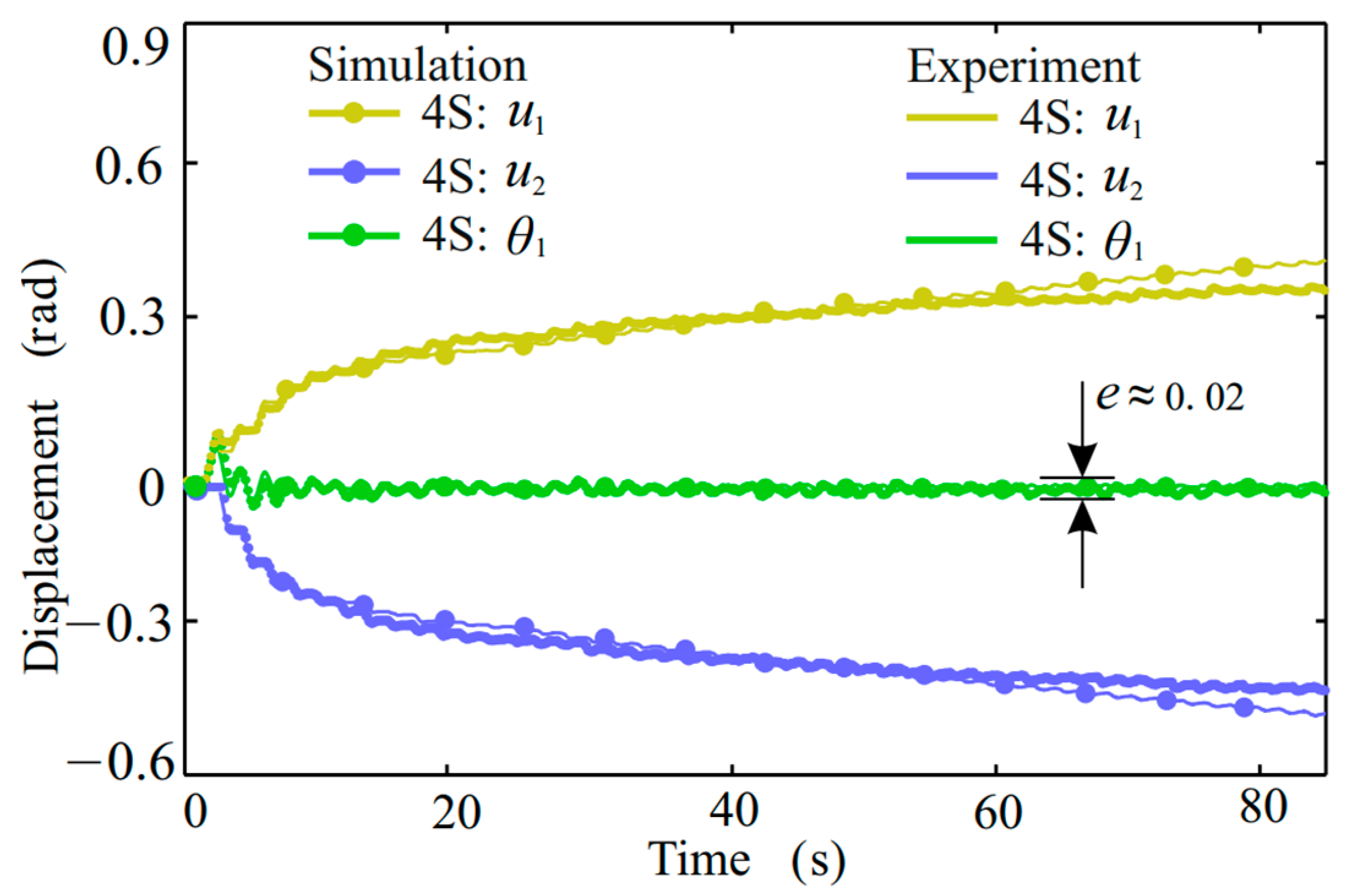

5. Experimental Validation of Vibration Control

5.1. Harmonic Disturbance

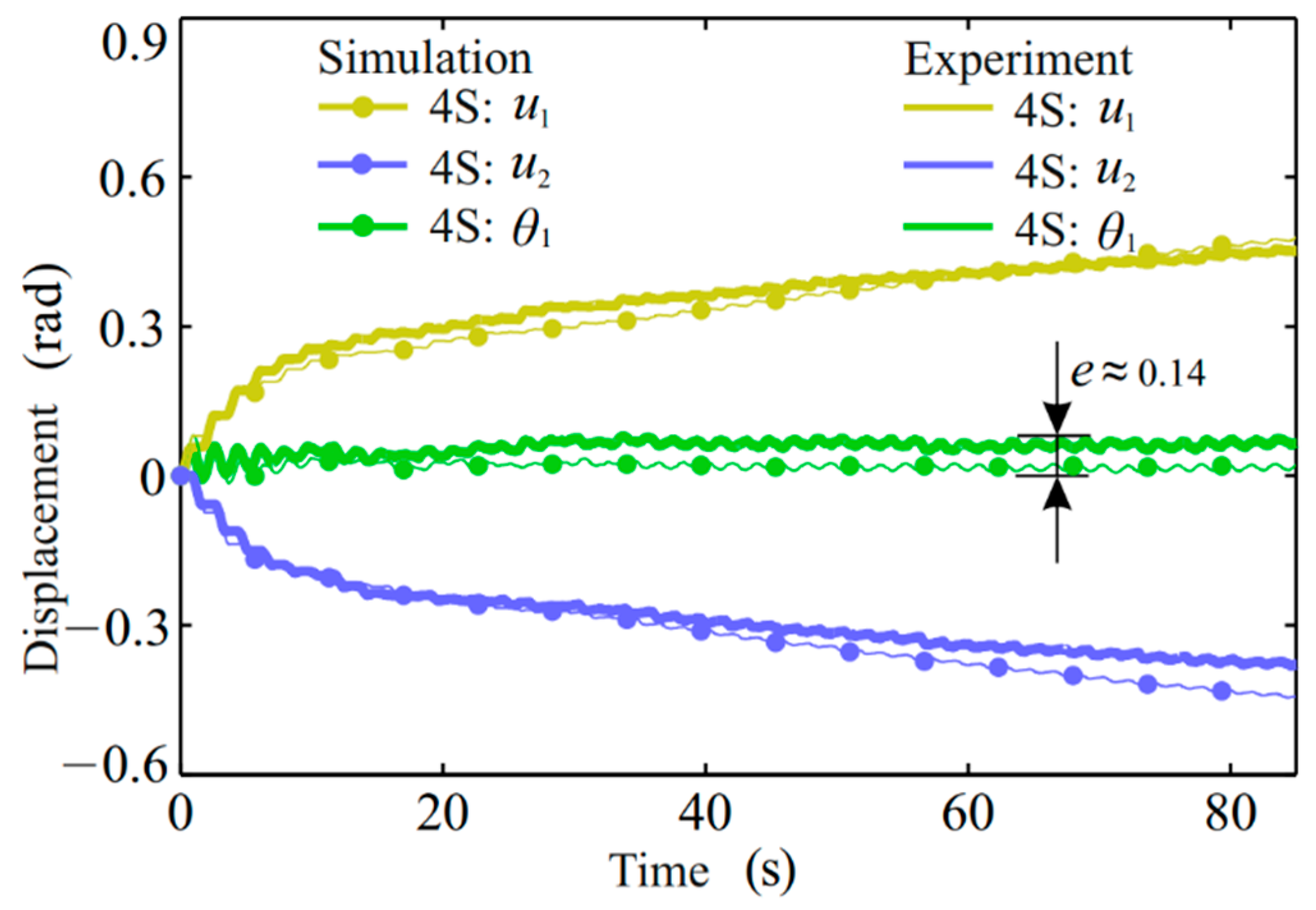

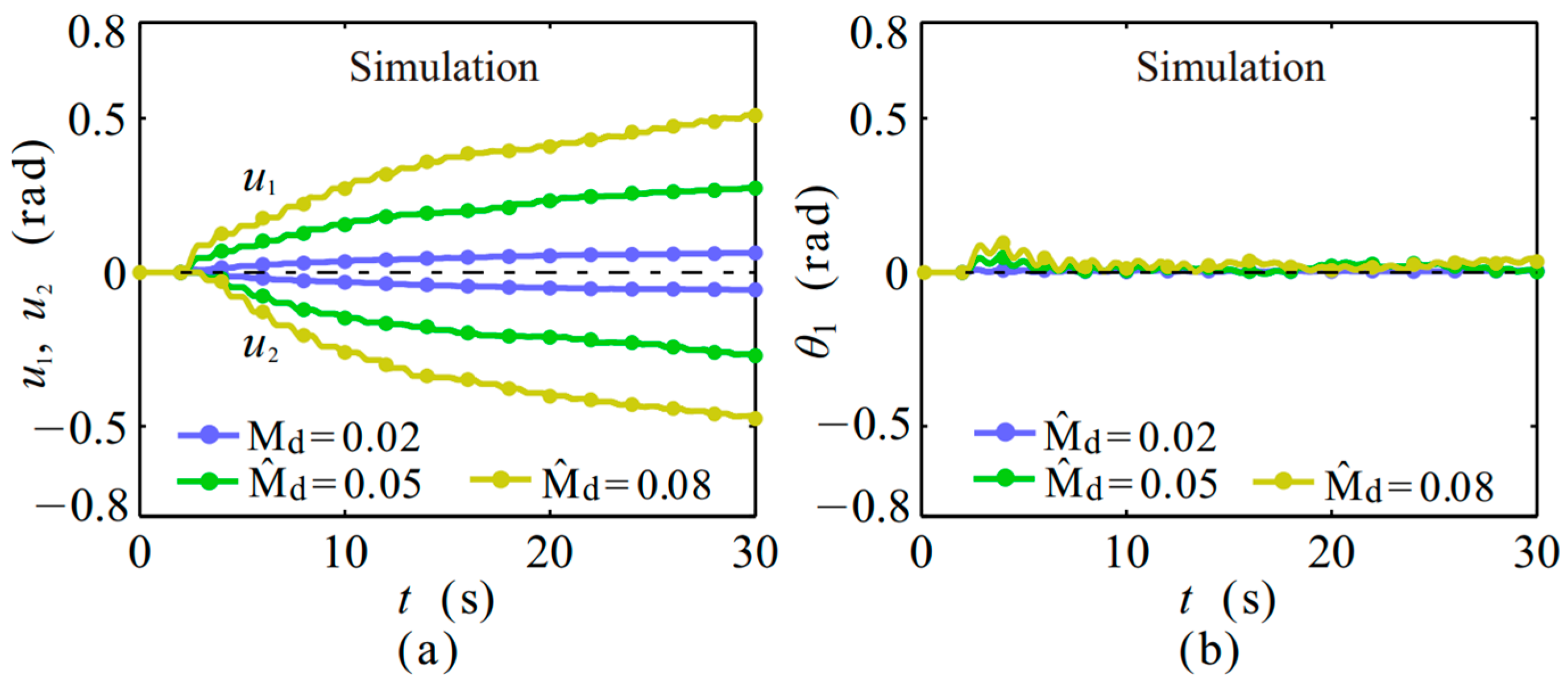

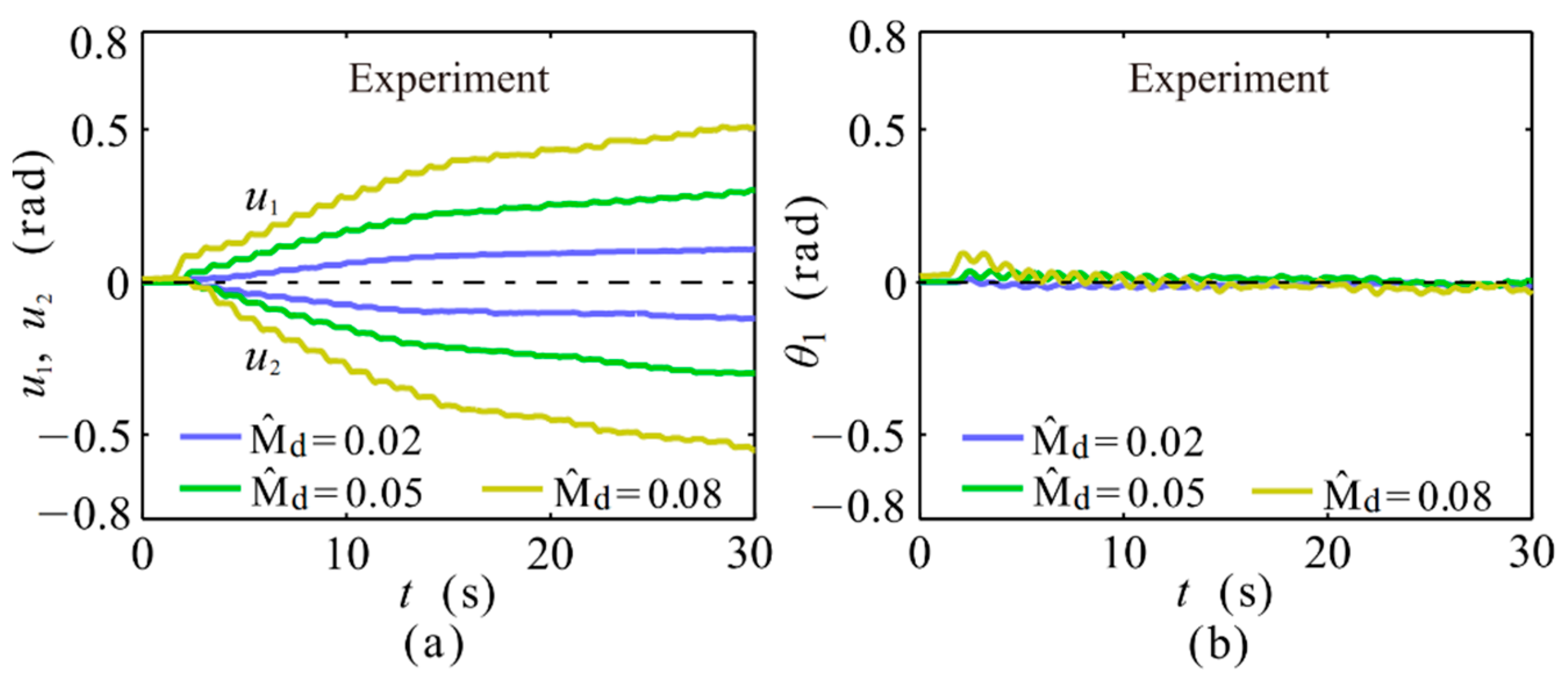

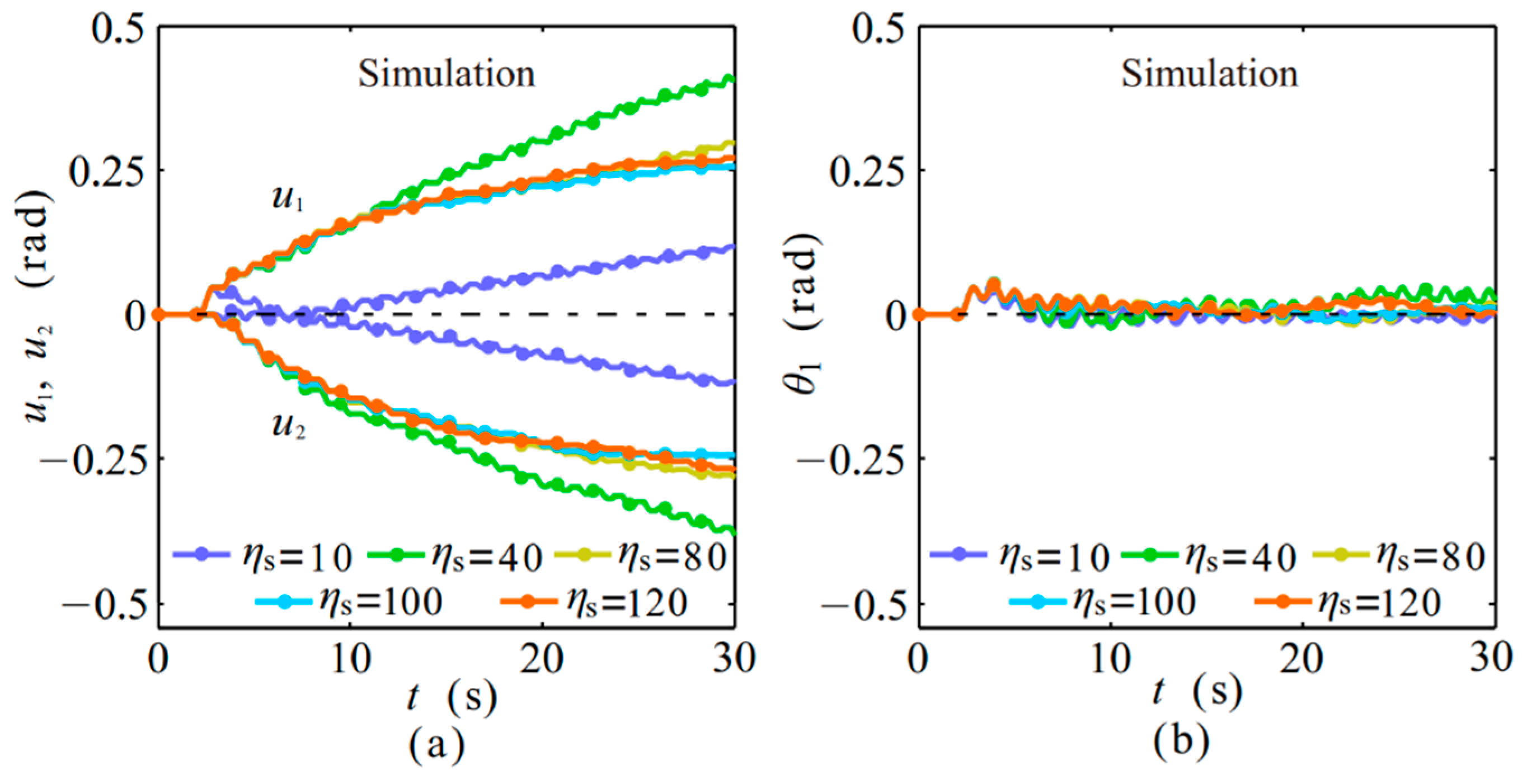

5.2. Parameter Variation

6. Improved Semi-Active Vibration Control Strategy

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liu, C.; Jing, X.; Daley, S.; Li, F. Recent advances in micro-vibration isolation. Mech. Syst. Signal Process 2015, 56, 55–80. [Google Scholar] [CrossRef]

- Lee, C.Y.; Pai, C.A. Design and implementation of tunable multi-degree-of-freedom vibration absorber made of hybrid shape memory helical springs. J. Intel. Mat. Syst. Str. 2016, 27, 1047–1060. [Google Scholar] [CrossRef]

- Du, H.; Li, W.; Zhang, N. Semi-active variable stiffness vibration control of vehicle seat suspension using an mr elastomer isolator. Smart Mater. Struct. 2011, 20, 105003. [Google Scholar] [CrossRef]

- Scheidler, J.; Asnani, V.; Dapino, M. Dynamically tuned magneto-strictive spring with electrically controlled stiffness. Smart Mater. Struct. 2016, 25, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Bajkowski, J.; Dyniewicz, B.; Bajer, C. Semi-active damping strategy for beams system with pneumatically controlled granular structure. Mech. Syst. Signal Process 2016, 56, 55–80. [Google Scholar] [CrossRef]

- Wu, T.; Lan, C. A wide-range variable stiffness mechanism for semi-active vibration systems. J. Sound Vib. 2016, 363, 18–32. [Google Scholar] [CrossRef]

- Pu, H.; Peng, S.Y.; Meng, K.; Zhao, J.; Xie, R.; Huang, Y.; Sun, Y.; Yang, Y.; Xie, S.; Luo, J.; et al. Multi-layer electromagnetic spring with tunable negative stiffness for semi-active vibration isolation. Mech. Syst. Signal Process 2019, 121, 942–960. [Google Scholar] [CrossRef]

- Winthrop, M.F.; Baker, W.P.; Cobb, R.G. A variable stiffness device selection and design tool for lightly damped structures. J. Sound Vib. 2005, 287, 667–682. [Google Scholar] [CrossRef]

- Ledezma-Ramirez, D.F.; Ferguson, N.S.; Brennan, M.J. An expeimental switchable stiffness device for shock isolation. J. Sound Vib. 2012, 331, 4987–5001. [Google Scholar] [CrossRef]

- Dyniewicz, B.; Bajkowski, J.M.; Bajer, C. Semi-active control of a sandwich beam partially filled with magnetorheological elastomer. JSME Intel J. C 2015, 60, 695–705. [Google Scholar] [CrossRef]

- Onoda, J.; Endo, T.; Tamaoki, H.; Watanbe, N. Vibration suppression by variable-stiffness members. AIAA J. 1991, 29, 977–983. [Google Scholar] [CrossRef]

- Wang, X.; Gordaninejad, F. Performance of a new magnetorheological elastomer isolation system. Smart Mater. Struct. 2014, 23, 045014. [Google Scholar]

- Irie, T.; Shingu, K. Vibraion control of variable rigidity frame structure by magnetic clutch. J. Comput. Sci. Technol. 2008, 2, 393–400. [Google Scholar] [CrossRef] [Green Version]

- Leavitt, J.; Bobrow, J.E.; Jabbari, F. Design of a 20,000 pound variable stiffness actuator for structural vibration attenuation. Shock. Vib. 2008, 15, 687–696. [Google Scholar] [CrossRef]

- Opie, S.; Yim, W. Design and control of a real-time variable stiffness vibration isolator. In Proceedings of the 2009 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Singapore, 14–17 July 2009; pp. 380–385. [Google Scholar]

- Tran, T.; Liu, K. Time-delay control of a switchable stiffness system. J. Sound Vib. 2015, 20, 1–16. [Google Scholar] [CrossRef]

- Nguyen, X.; Komatsuzaki, T.; Iwata, Y.; Asanuma, H. Modeling and semi-active fuzzy control of magnetorheological elastomer-based isolator for seismic response reduction. Mech. Syst. Signal Process 2018, 101, 449–466. [Google Scholar] [CrossRef] [Green Version]

- Gu, X.; Yu, Y.; Li, Y.; Li, J.; Askari, M.; Samali, B. Experimental study of semi-active magnetorheological elastomer base isolation system using optimal neuro fuzzy logic control. Mech. Syst. Signal Process 2019, 119, 380–398. [Google Scholar] [CrossRef]

- Min, C.; Dahlman, M.; Sattel, T. A concept for semi-active vibration control with a serial-stiffness-switch system. J. Sound Vib. 2017, 405, 234–250. [Google Scholar] [CrossRef]

- Min, C.; Dahlman, M.; Sattel, T. A semi-active shock isolation concept with serial-stiffness-switch system. J. Sound Vib. 2019, 445, 117–131. [Google Scholar] [CrossRef]

- Gao, W.; Wang, Y.; Homaifa, A. Discrete-time variable structure control systems. IEEE T. Ind. Electron. 2002, 42, 117–122. [Google Scholar]

- Yamaguchi, H.; Yashima, M. Vibration reduction and isolation performance for on-off control of a friction force at a spring support. J. Sound Vib. 1997, 208, 729–743. [Google Scholar] [CrossRef]

- Yong, C.; Zimcik, D.G.; Wickramsinghe, V.K.; Nitzsche, F. Development of the smart spring for active vibration control of helicopter blades. J. Intel. Mat. Syst. Str. 2004, 15, 37–47. [Google Scholar] [CrossRef]

- Sun, S.; Tang, X.; Li, W.; Du, H. Advanced vehicle suspension with variable stiffness and damping mr damper. In Proceedings of the 2017 IEEE International Conference on Mechatronics (ICM), Churchill, VIC, Australia, 13–15 February 2017; pp. 444–448. [Google Scholar]

- Greiner-Petter, C.; Tan, A.S.; Sattel, T. A semi-active magnetorheological fluid mechanism with variable stiffness and damping. Smart Mater. Struct. 2014, 23, 1–10. [Google Scholar] [CrossRef]

- Deng, H.; Wang, M.; Han, G.; Zhang, J.; Ma, M.; Zhong, X.; Yu, L. Variable stiffness mechanisms of dual parameters changing magnetorheological fluid devices. Smart Mater. Struct. 2017, 26, 125014. [Google Scholar] [CrossRef]

- Dong, X.; Liu, W.; An, G.; Zhou, Y.; Yu, J.; Lin, Q. A novel rotary magnetorheological flexible joint with variable stiffness and damping. Smart Mater. Struct. 2018, 27, 105045. [Google Scholar] [CrossRef]

- Deng, H.; Deng, J.; Yue, R.; Han, G.; Zhang, J.; Ma, M.; Zhong, X. Design and verification of a seat suspension with variable stiffness and damping. Smart Mater. Struct. 2019, 28, 065015. [Google Scholar] [CrossRef]

- Ramaratnam, A.; Nader, J. A switched stiffness approach for structural vibration control: Theory and real-time implementation. J. Sound Vib. 2006, 291, 258–274. [Google Scholar] [CrossRef]

- Alotaibi, S.A.; Al-Ajmi, M.A. A variable stiffness approach to vibration control. Int. J. Comput. Inf. Eng. 2014, 8, 565–567. [Google Scholar]

- Tran, T. Vibration Control Using Switchable Stiffness. Master’s Thesis, Lakehead University, Thunder Bay, ON, Canada, 2014. [Google Scholar]

- Du, G.; Huang, X.; Li, Y.; Ouyang, Q.; Wang, J. Performance of a semi-active/passive integrated isolator based on a magnetorheological elastomer and spring. Smart Mater. Struct. 2017, 26, 095024. [Google Scholar] [CrossRef]

- Gripp, J.; Rade, D. Vibration and noise control using shunted piezoelectric transducers: A review. Mech. Syst. Signal Process 2018, 112, 359–383. [Google Scholar] [CrossRef]

| Item | D | |||||

|---|---|---|---|---|---|---|

| Case 1 | 0.121 | 0.15 | 0.023 | 0.0087 | 5.7 | 5.624 |

| Case 2 | 0.129 | 0.156 | 0.02 | 0.0092 | 5.57 | 5.699 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Min, C.; Dahlmann, M.; Sattel, T. Numerical and Experimental Investigation of a Semi-Active Vibration Control System by Means of Vibration Energy Conversion. Energies 2021, 14, 5177. https://doi.org/10.3390/en14165177

Min C, Dahlmann M, Sattel T. Numerical and Experimental Investigation of a Semi-Active Vibration Control System by Means of Vibration Energy Conversion. Energies. 2021; 14(16):5177. https://doi.org/10.3390/en14165177

Chicago/Turabian StyleMin, Chaoqing, Martin Dahlmann, and Thomas Sattel. 2021. "Numerical and Experimental Investigation of a Semi-Active Vibration Control System by Means of Vibration Energy Conversion" Energies 14, no. 16: 5177. https://doi.org/10.3390/en14165177

APA StyleMin, C., Dahlmann, M., & Sattel, T. (2021). Numerical and Experimental Investigation of a Semi-Active Vibration Control System by Means of Vibration Energy Conversion. Energies, 14(16), 5177. https://doi.org/10.3390/en14165177