Experimental Study of Impingement Effusion-Cooled Double-Wall Combustor Liners: Thermal Analysis

Abstract

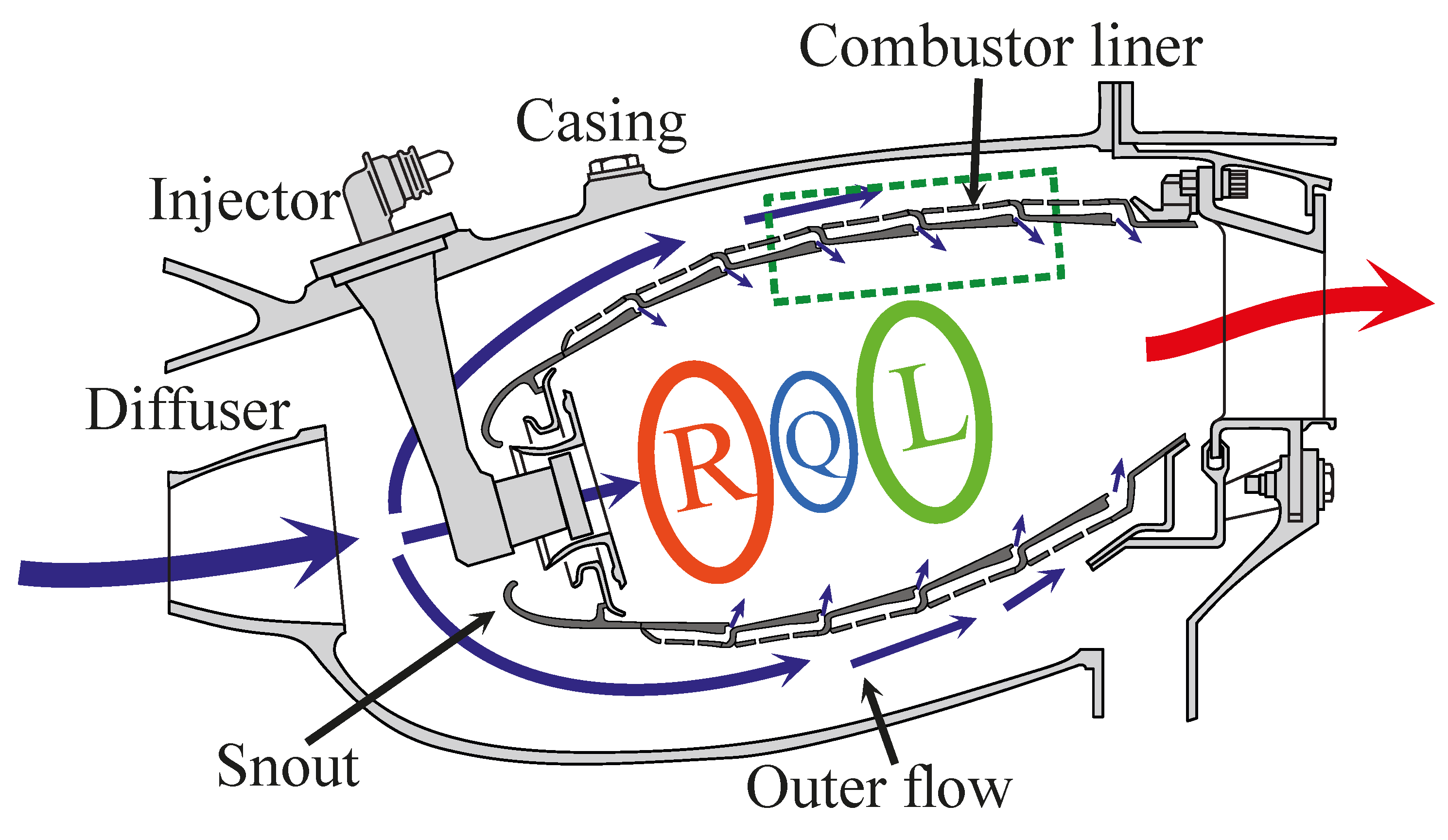

:1. Introduction

1.1. Impingement Effusion Cooling Methods for Combustor Walls

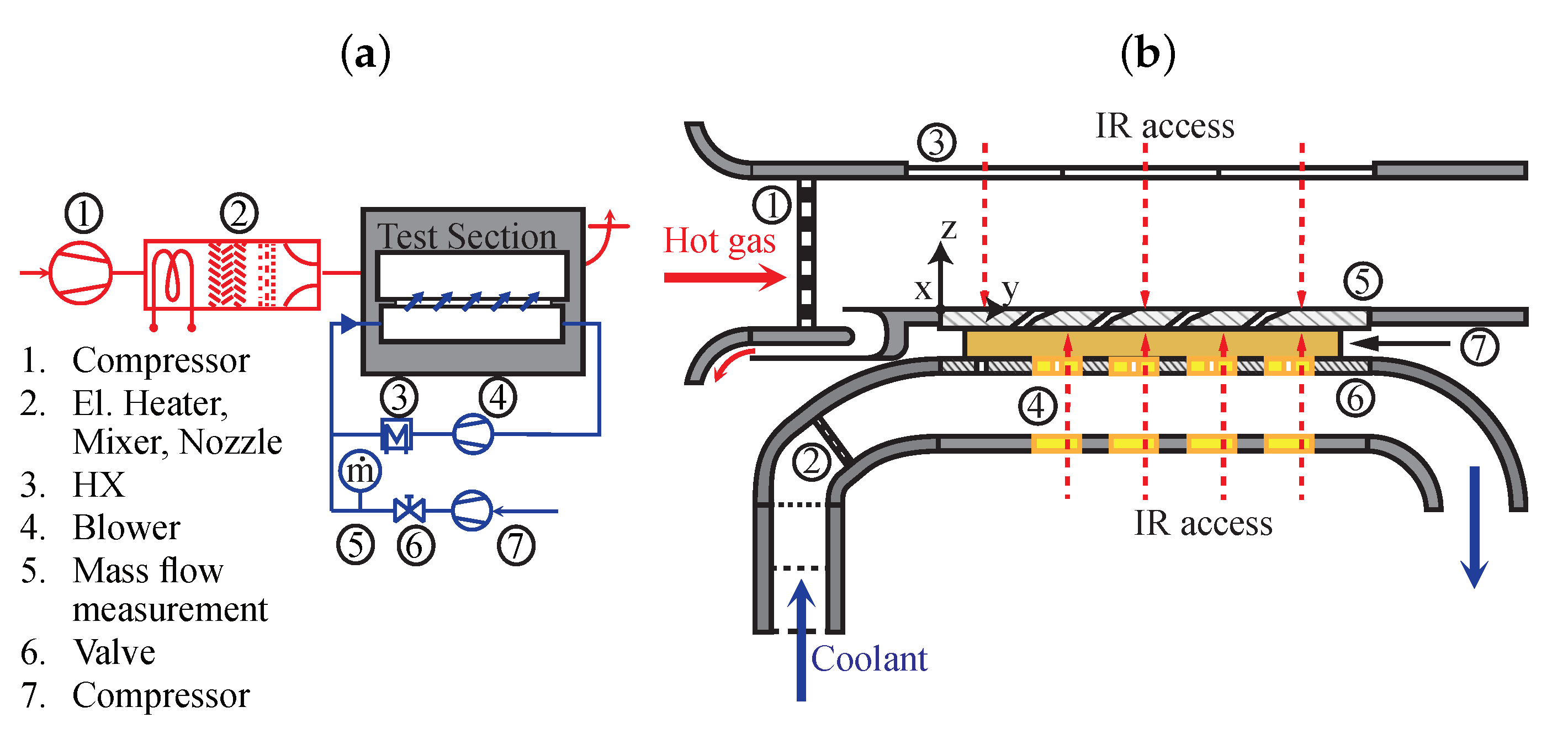

2. Experimental Methodology

2.1. Experimental Setup

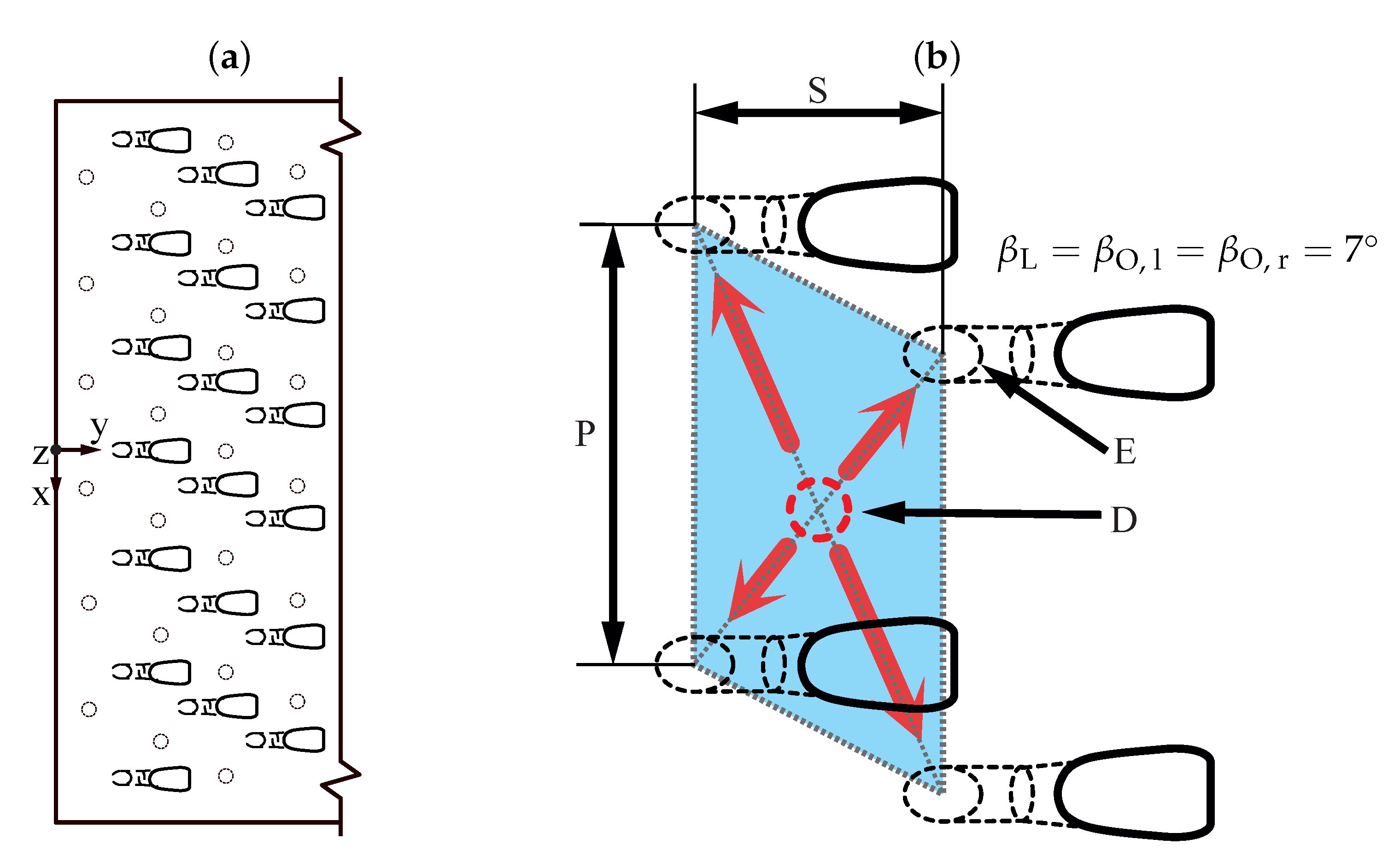

2.1.1. Test Section

2.1.2. Test Specimen

2.2. Measurement Methods and Derived Quantities

3. Results and Discussion

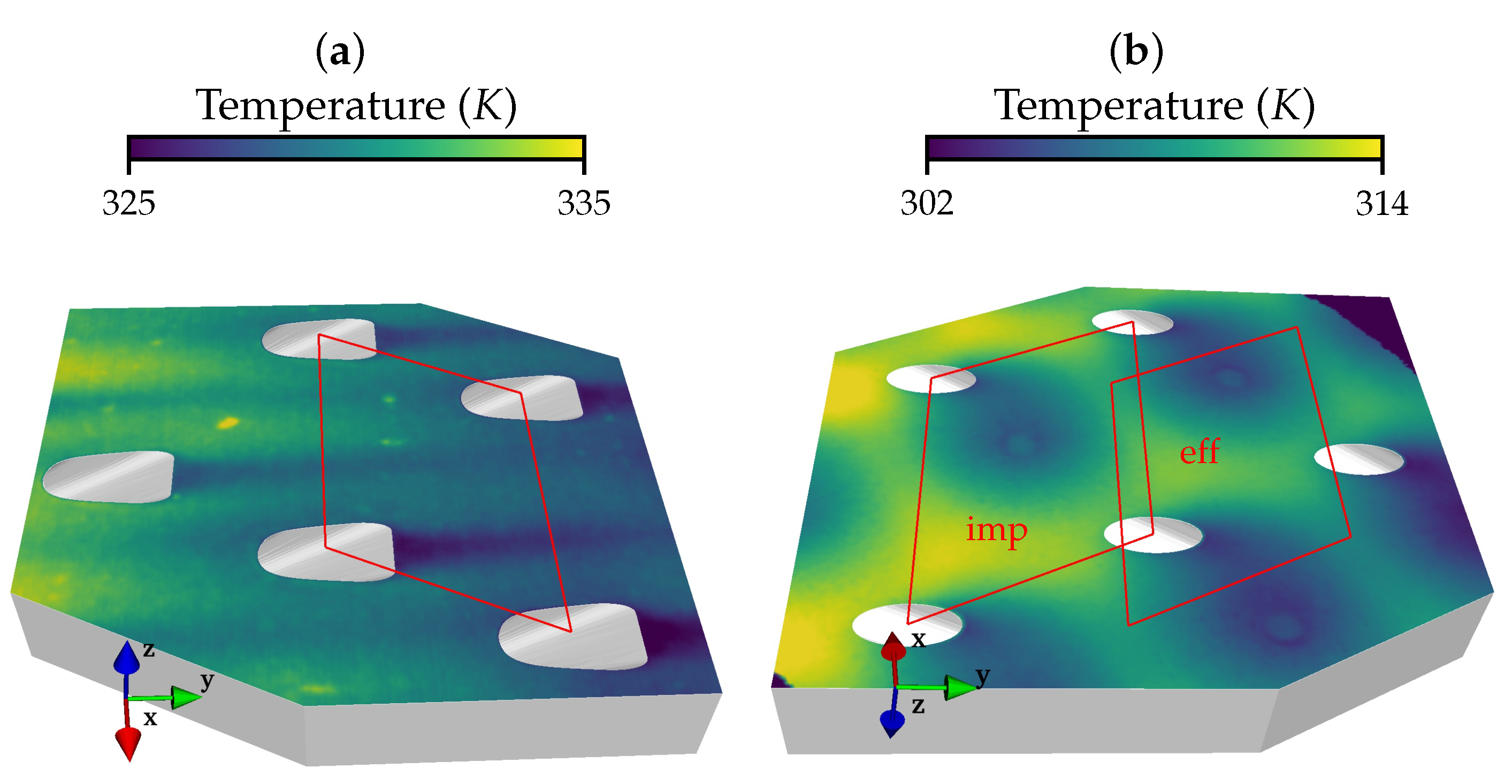

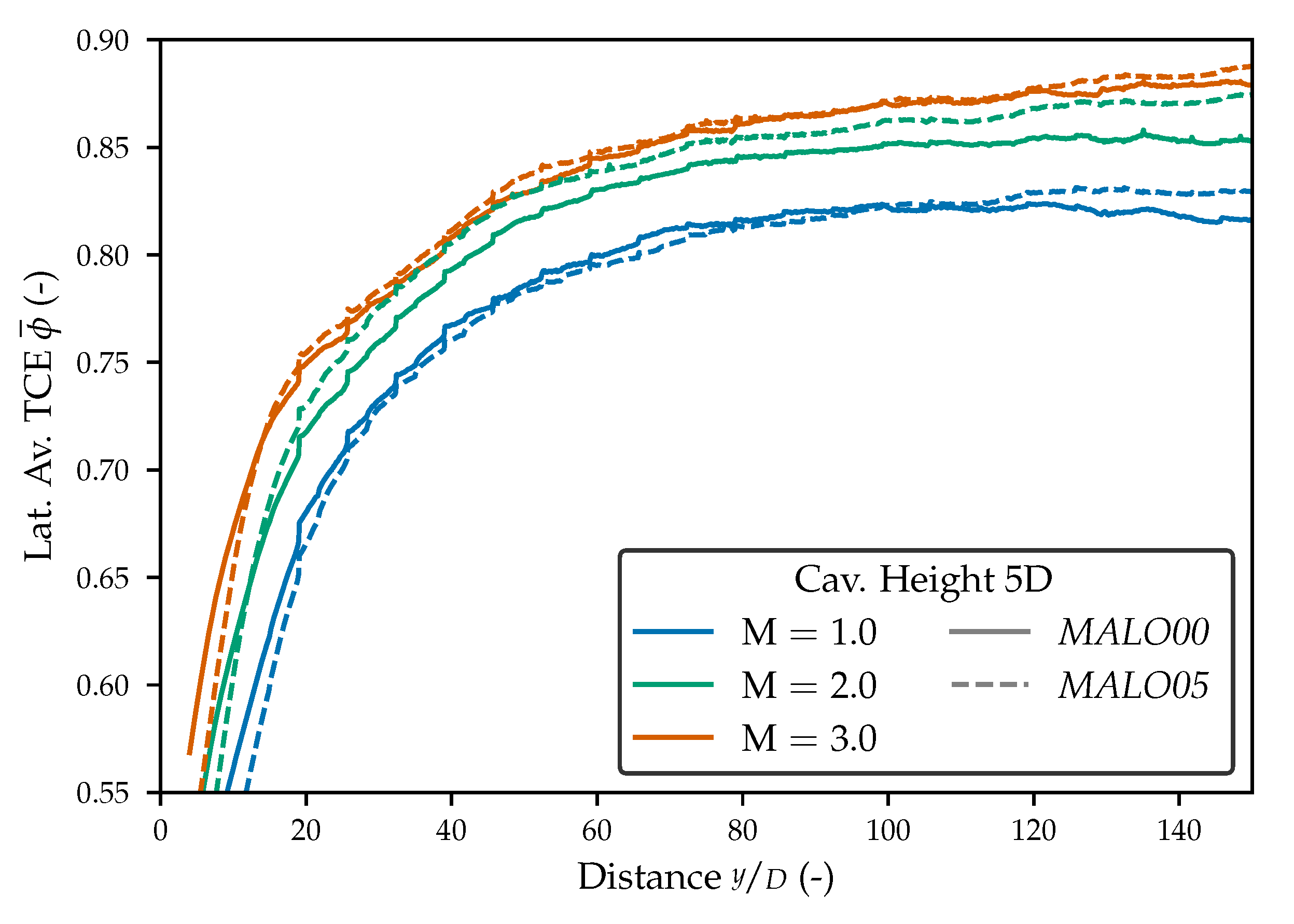

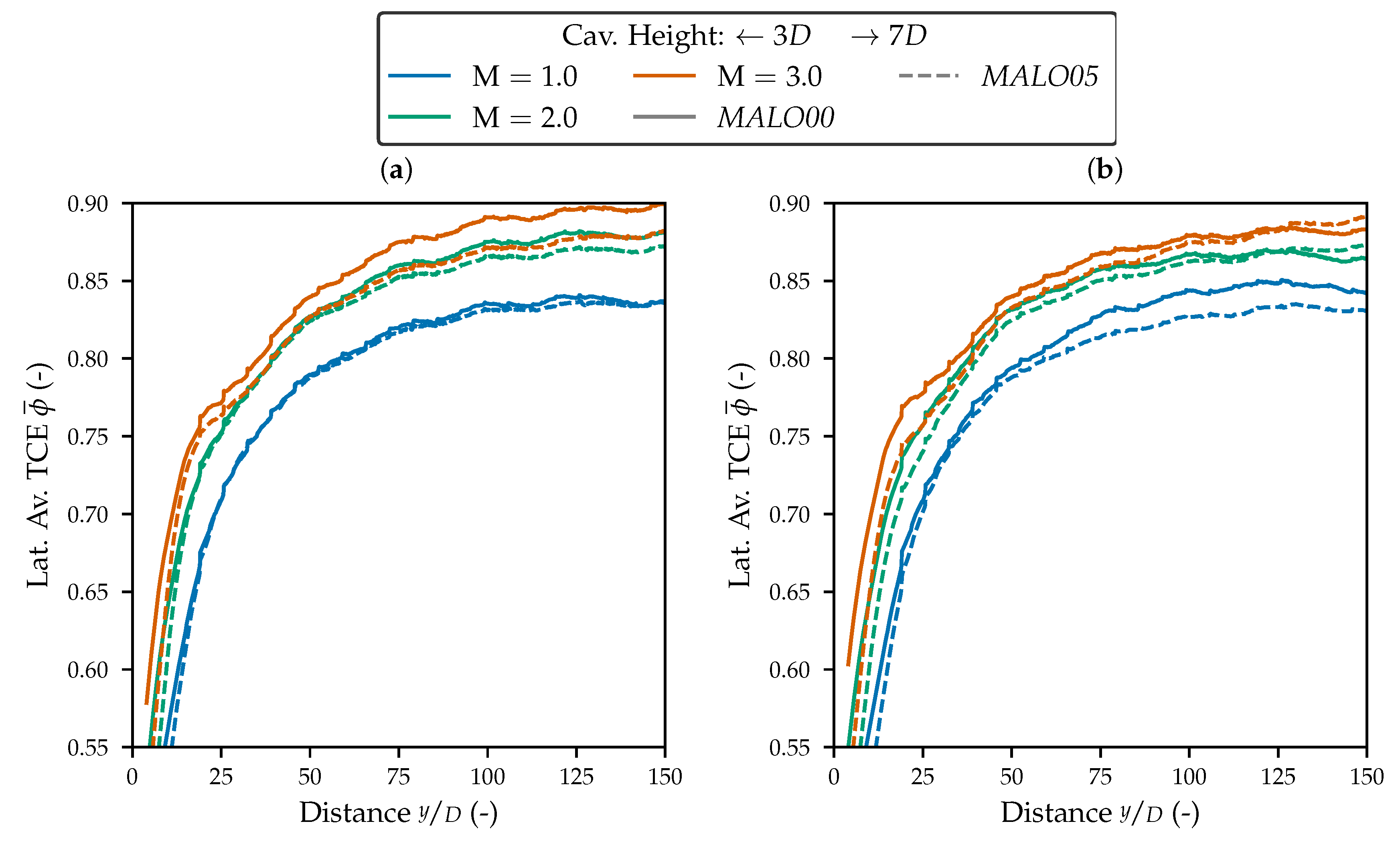

3.1. Cooling on the Hot Gas Side

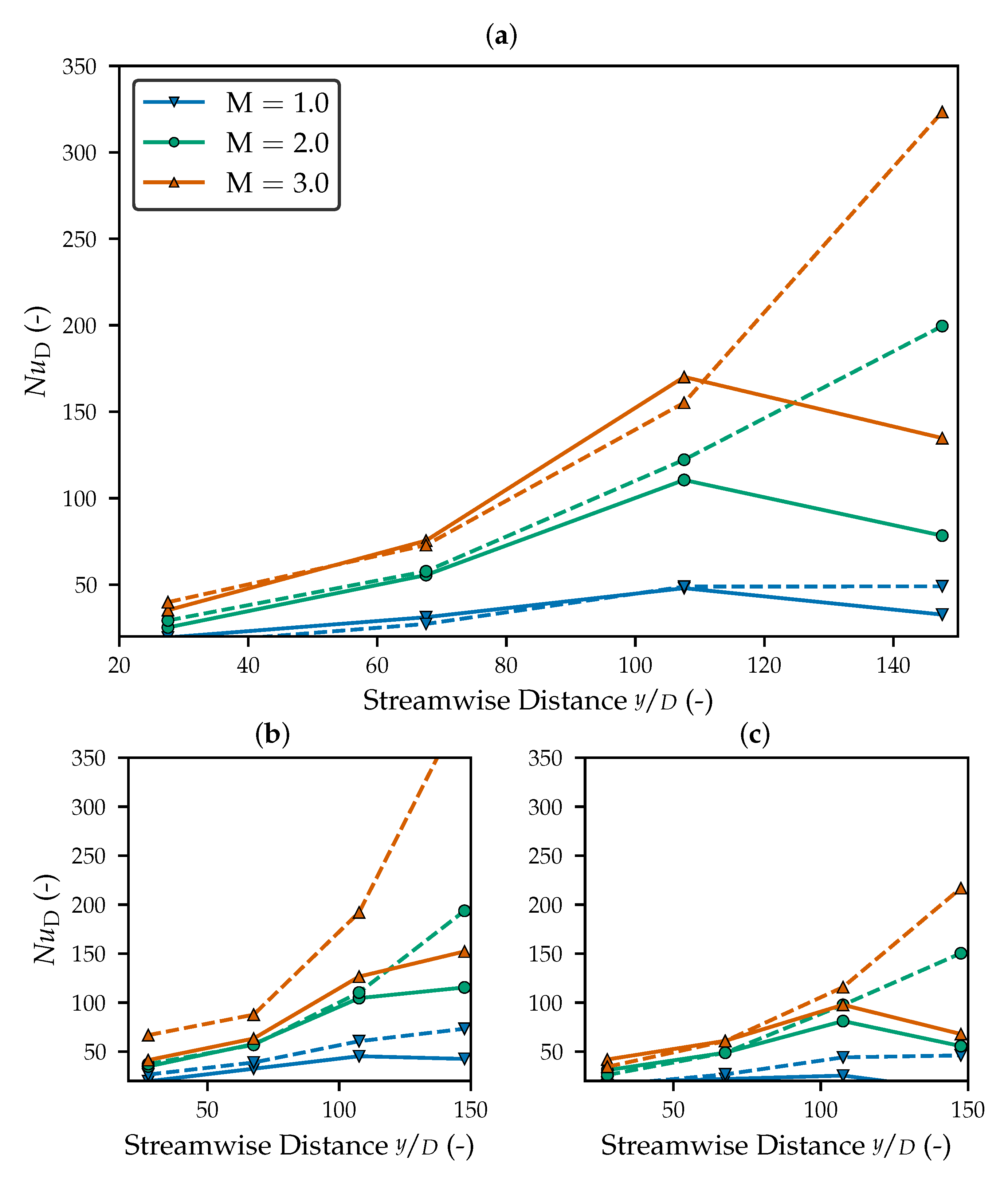

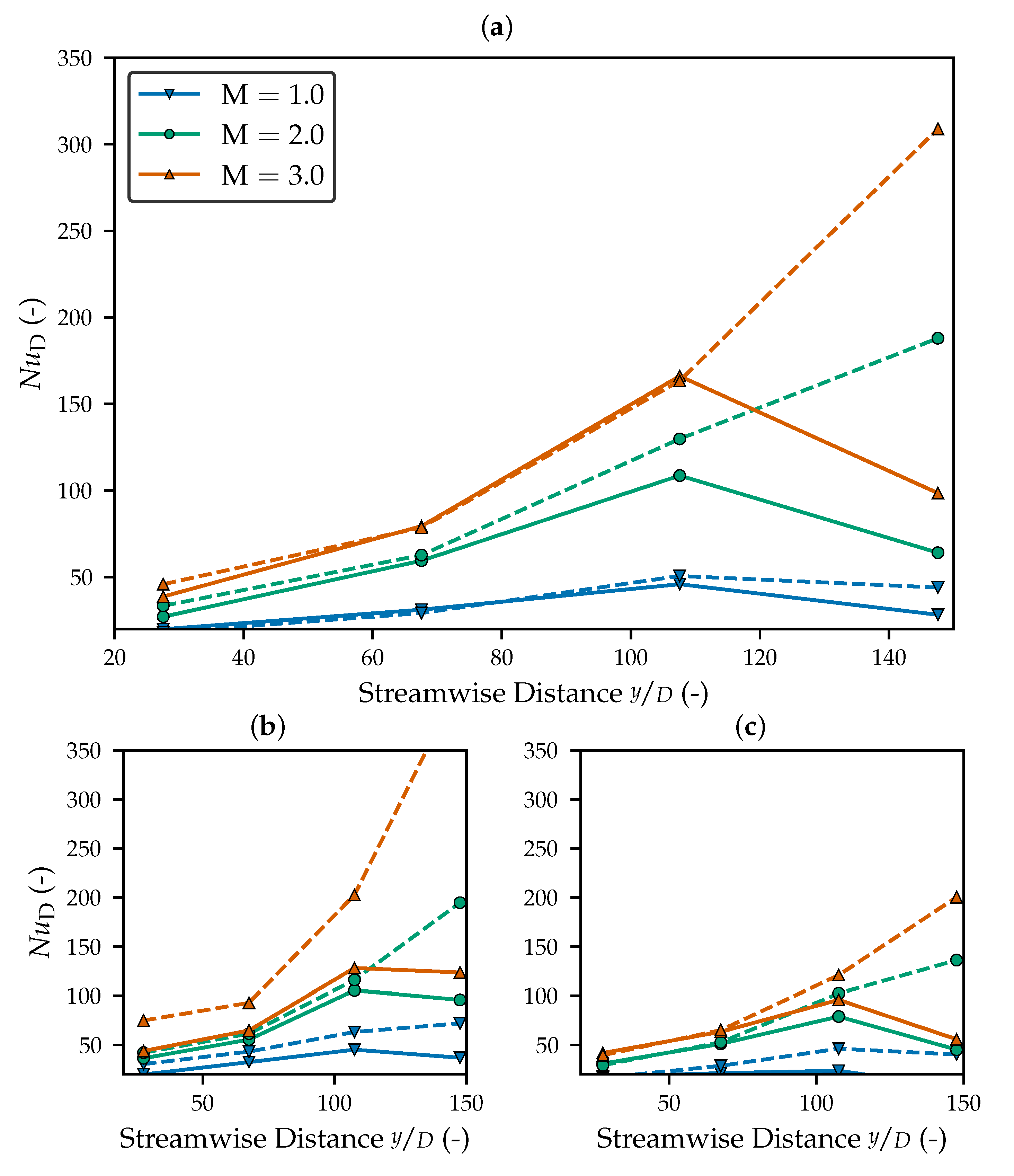

3.2. Heat Transfer on Cavity Side

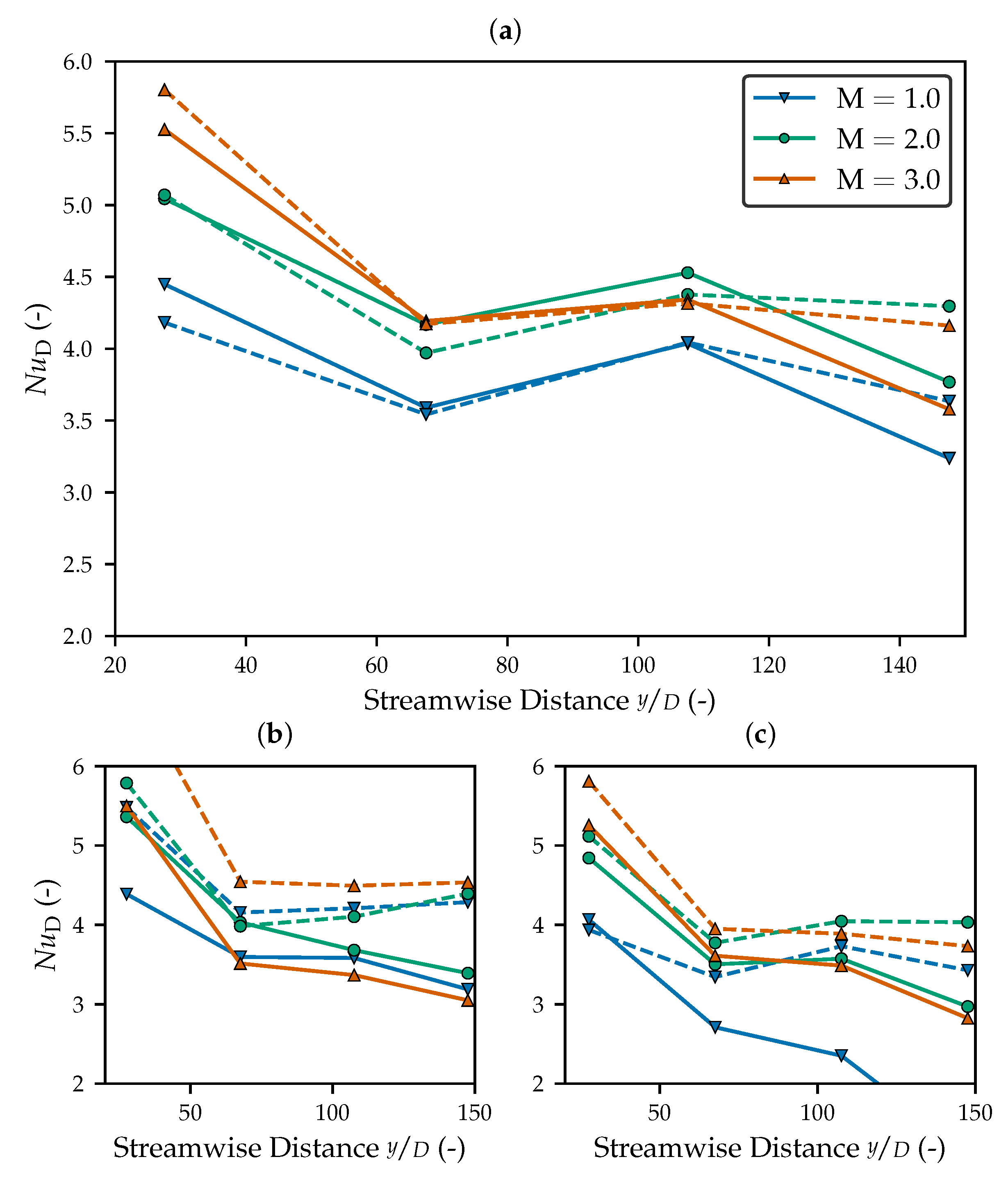

3.3. Thermal Gradients on the Cavity Side

4. Conclusions

- Using a double-wall configuration with impingement effusion cooling can achieve very high total cooling effectivenesses on the inner hot gas side, especially considering full conjugate heat transfer. The main cooling contribution, in particular downstream where the effusion coolant film is built up, comes from the very same. After short running lengths downstream of the initial effusion row, total cooling effectivenesses up to are achieved (lateral average).

- The influence of impingement cooling was found to be marginal in the single digit percentage considering the hot gas side total cooling effectiveness. This influence is more pronounced upstream with the effusion cooling, which is, however, derived from other studies and only marginally visible in the total cooling effectiveness with superposition data missing.

- The effect of geometry variation is especially pronounced in the cavity flow and thus cavity side heat transfer. The analyzed misaligned configurations show a strong influence of cavity height (small and nominal height), while the aligned configurations are less influenced. The largest cavity height of shows a decreased heat transfer performance at any alignment, especially at low blowing ratios.

- Biot numbers and thus thermal gradients show comparable behavior. The misaligned cases with small and nominal cavity height especially show high Biot numbers and Biot number gradients at the effusion inflow locations, which can lead to material deterioration during service.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbols | |

| Difference | |

| Hole inclination | |

| Laidback and fanshape angle | |

| Emissivity | |

| Wavelength | |

| Total cooling effectiveness | |

| Transmissivity | |

| A | Area |

| D | Reference diameter, diameter |

| DR | Density ratio |

| E | Effusion hole diameter |

| H | Height |

| h | Heat transfer coefficient |

| I | Momentum ratio |

| k | Heat conductivity |

| L | Length |

| M | Blowing ratio M |

| P | Pitch |

| p | Pressure |

| q | Heat flux |

| S | Shift |

| SF | Scaling factor |

| T | Temperature |

| Tu | Turbulence level |

| t | Thickness |

| VR | Velocity ratio |

| W | Width |

| Abbreviations | |

| Bi | Biot number |

| FE | Finite elements |

| ITS | Institute of Thermal Turbomachinery |

| LW | Long-wave (infrared) |

| MALO | Longitudinal misalignment |

| MW | Mid-wave (infrared) |

| Nu | Nusselt number |

| PEEK | Polyetheretherketone |

| PTFE | Teflon ™ |

| Re | Reynolds number |

| RQL | Rich-quench-lean |

| Scripts | |

| ∞ | Free stream |

| , f | Film cooling |

| aw | Adiabatic wall |

| c | Cold |

| cal | Calibrated |

| comb | Combined |

| e | Effective |

| eff | Effusion |

| h | Hot |

| imp | Impingement |

| int | Internal |

| L | Laidback (angle) |

| tc | Thermocouple |

| NVC | Nextel velvet coating |

| O | Opening (angle) |

| p | Paint |

| tot | Total |

| w | Wall, window |

Appendix A. Additional Data

| Wind. # | Wind. # | Wind. # | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MALO00 | 1 | 2 | 3 | 4 | Avg. | 1 | 2 | 3 | 4 | Avg. | 1 | 2 | 3 | 4 | Avg. |

| 1.07 | 0.54 | 0.48 | 0.42 | 0.63 | 1.20 | 0.66 | 0.60 | 0.47 | 0.73 | 1.26 | 0.58 | 0.47 | 0.40 | 0.68 | |

| 1.25 | 0.53 | 0.52 | 0.38 | 0.67 | 1.30 | 0.58 | 0.59 | 0.56 | 0.76 | 1.34 | 0.62 | 0.56 | 0.44 | 0.74 | |

| 1.20 | 0.50 | 0.44 | 0.30 | 0.61 | 1.23 | 0.51 | 0.51 | 0.39 | 0.66 | 1.29 | 0.58 | 0.50 | 0.41 | 0.70 | |

| MALO05 | |||||||||||||||

| 1.01 | 0.49 | 0.50 | 0.51 | 0.63 | 1.09 | 0.52 | 0.57 | 0.56 | 0.73 | 1.20 | 0.65 | 0.57 | 0.56 | 0.68 | |

| 1.23 | 0.50 | 0.52 | 0.47 | 0.67 | 1.33 | 0.67 | 0.59 | 0.53 | 0.76 | 1.28 | 0.62 | 0.60 | 0.53 | 0.74 | |

| 1.13 | 0.52 | 0.46 | 0.40 | 0.61 | 1.20 | 0.56 | 0.52 | 0.51 | 0.66 | 1.25 | 0.61 | 0.52 | 0.50 | 0.70 | |

| Wind. # | Wind. # | Wind. # | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MALO00 | 1 | 2 | 3 | 4 | Avg. | 1 | 2 | 3 | 4 | Avg. | 1 | 2 | 3 | 4 | Avg. |

| 9.61 | 12.48 | 14.29 | 13.53 | 12.48 | 16.78 | 28.07 | 32.57 | 42.24 | 29.92 | 21.63 | 27.43 | 47.70 | 72.55 | 42.33 | |

| 8.03 | 10.14 | 11.90 | 9.70 | 9.94 | 11.55 | 18.09 | 26.15 | 20.22 | 19.00 | 16.02 | 27.30 | 51.01 | 46.37 | 35.18 | |

| 6.65 | 7.40 | 7.68 | 5.67 | 6.85 | 10.92 | 13.72 | 16.79 | 13.91 | 13.84 | 14.88 | 18.76 | 22.51 | 19.16 | 18.83 | |

| MALO05 | |||||||||||||||

| 11.59 | 13.84 | 16.96 | 16.93 | 12.48 | 17.54 | 20.24 | 29.51 | 52.39 | 29.92 | 31.27 | 32.52 | 66.10 | 179.63 | 42.33 | |

| 7.97 | 8.96 | 12.51 | 10.14 | 9.94 | 13.55 | 17.49 | 28.30 | 45.91 | 19.00 | 18.14 | 24.65 | 39.96 | 100.87 | 35.18 | |

| 5.91 | 7.41 | 9.48 | 7.62 | 6.85 | 9.55 | 12.20 | 18.01 | 24.85 | 13.84 | 12.65 | 16.19 | 23.40 | 44.37 | 18.83 | |

| Wind. # | Wind. # | Wind. # | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MALO00 | 1 | 2 | 3 | 4 | Avg. | 1 | 2 | 3 | 4 | Avg. | 1 | 2 | 3 | 4 | Avg. |

| 10.00 | 12.29 | 12.87 | 11.01 | 11.54 | 17.67 | 19.43 | 29.45 | 29.84 | 24.10 | 22.62 | 27.58 | 45.32 | 50.26 | 36.44 | |

| 8.22 | 9.55 | 10.55 | 7.52 | 8.96 | 11.91 | 17.99 | 23.43 | 15.24 | 17.14 | 16.97 | 28.59 | 46.51 | 31.25 | 30.83 | |

| 6.77 | 7.21 | 7.43 | 5.06 | 6.62 | 11.15 | 13.50 | 15.47 | 10.68 | 12.70 | 15.02 | 18.31 | 21.50 | 14.54 | 17.35 | |

| MALO05 | |||||||||||||||

| 12.35 | 14.74 | 17.73 | 19.29 | 11.54 | 18.63 | 22.11 | 33.79 | 60.82 | 24.10 | 34.02 | 36.55 | 74.93 | 205.41 | 36.44 | |

| 7.73 | 9.40 | 12.63 | 11.23 | 8.96 | 13.76 | 19.29 | 32.55 | 52.36 | 17.14 | 18.72 | 27.38 | 45.06 | 114.48 | 30.83 | |

| 5.87 | 7.64 | 9.65 | 9.00 | 6.62 | 9.64 | 12.81 | 19.29 | 28.33 | 12.70 | 13.06 | 17.14 | 25.11 | 48.72 | 17.35 | |

References

- Lefebvre, A.H.; Ballal, D.R. Gas Turbine Combustion: Alternative Fuels and Emissions, 3rd ed.; Taylor & Francis: Boca Raton, FL, USA, 2010. [Google Scholar]

- Lazik, W.; Doerr, T.; Bake, S.; vd Bank, R.; Rackwitz, L. Development of Lean-Burn Low-NOx Combustion Technology at Rolls-Royce Deutschland. In Proceedings of the ASME Turbo Expo, Berlin, Germany, 9–13 June 2008; p. GT2008-5115. [Google Scholar] [CrossRef]

- Sweeney, P.C.; Rhodes, J.F. An Infrared Technique for Evaluating Turbine Airfoil Cooling Designs. J. Turbomach. 1999, 122, 170–177. [Google Scholar] [CrossRef]

- Andrews, G.E.; Asere, A.A.; Hussain, C.I.; Mkpadi, M.C.; Nazari, A. Impingement/Effusion Cooling: Overall Wall Heat Transfer. In Proceedings of the ASME 1988 International Gas Turbine and Aeroengine Congress, Amsterdam, The Netherlands, 6 June 1988; p. V004T09A036. [Google Scholar] [CrossRef] [Green Version]

- Al Dabagh, A.M.; Andrews, G.E.; Abdul Husain, R.A.A..; Husain, C.I.; Nazari, A.; Wu, J. Impingement/Effusion Cooling: The Influence of the Number of Impingement Holes and Pressure Loss on the Heat Transfer Coefficient. J. Turbomach. 1990, 112, 467. [Google Scholar] [CrossRef]

- El-Jummah, A.; Nazari, A.; Andrews, G.E.; Staggs, J.E. Impingement/Effusion Cooling Wall Heat Transfer: Reduced Number of Impingement Jet Holes Relative to the Effusion Holes. In Proceedings of the ASME Turbo Expo, Charlotte, NC, USA, 26–30 June 2017; p. GT2017-63494. [Google Scholar] [CrossRef]

- Oguntade, H.I.; Andrews, G.E.; Burns, A.D.; Ingham, D.B.; Pourkashanian, M. Impingement/Effusion Cooling with Low Coolant Mass Flow. In Proceedings of the ASME Turbo Expo, Charlotte, NC, USA, 26–30 June 2017; p. GT2017-63484. [Google Scholar] [CrossRef]

- Martiny, M.; Schulz, A.; Wittig, S. Effusion Cooled Combustor Liners of Gas Turbines—An Assessment of the Contributions of Convective, Impingement, and Film Cooling. In Proceedings of the Symposium on Energy Engineering in the 21st Century (SEE2000), Hong Kong, China, 9–13 January 2000; pp. 221–228. [Google Scholar]

- Andreini, A.; Caciolli, G.; Facchini, B.; Tarchi, L.; Coutandin, D.; Taddei, S.; Peschiulli, A. Combustor Liner Cooled By a Combined Slot/Effusion System. In Proceedings of the ASME Turbo Expo, Copenhagen, Denmark, 11–15 June 2012; p. GT2012-68263. [Google Scholar] [CrossRef] [Green Version]

- Cocchi, L.; Picchi, A.; Mazzei, L.; Andreini, A.; Belloci, L. Effect of Holes Arrangement on Heat Transfer in Impingement/Effusion Cooling Double Wall Schemes. In Proceedings of the 1st GPPS, Zurich, Switzerland, 16–18 January 2017; p. GPPF-2017-77. [Google Scholar]

- Chen, G.; Liu, Y.; Rao, Y.; He, J.; Qu, Y. Numerical Investigation on Conjugate Heat Transfer of Impingement/Effusion Double-Wall Cooling with Different Crossflow Schemes. Appl. Therm. Eng. 2019, 155, 515–524. [Google Scholar] [CrossRef]

- Rogers, N.; Ren, Z.; Buzzard, W.; Sweeney, B.; Tinker, N.; Ligrani, P.M. Effects of Double Wall Cooling Configuration and Conditions on Performance of Full Coverage Effusion Cooling. In Proceedings of the ASME Turbo Expo, Seoul, Korea, 13–17 June 2016; p. GT2016-56515. [Google Scholar] [CrossRef]

- Ligrani, P.; Ren, Z.; Liberatore, F.; Patel, R.; Srinivasan, R.; Ho, Y.H. Double Wall Cooling of a Full-Coverage Effusion Plate, Including Internal Impingement Array Cooling. J. Eng. Gas Turbines Power 2017, 140, 051901. [Google Scholar] [CrossRef]

- Click, A.; Ritchie, D.; Ligrani, P.M.; Liberatore, F.; Patel, R.; Ho, Y.H. Double Wall Cooling of an Effusion Plate with Cross Flow and Impingement Jet Combination Internal Cooling: Comparisons of Main Flow Contraction Ratio Effects. In Proceedings of the AIAA Propulsion and Energy 2019 Forum, Indianapolis, IN, USA, 19–22 August 2019; American Institute of Aeronautics and Astronautics. [Google Scholar] [CrossRef]

- Click, A.; Ligrani, P.; Ritchie, D.; Liberatore, F.; Patel, R.; Ho, Y.H. Effects of Coolant Supply Arrangement on Double Wall Cooling: Hot-side Effusion Performance and Cold-Side Nusselt Numbers at Different Initial Blowing Ratios. Int. J. Heat Mass Transf. 2020, 156, 119808. [Google Scholar] [CrossRef]

- Vanga, S.R.; Ritchie, D.; Click, A.; Ren, Z.; Ligrani, P.; Liberatore, F.; Patel, R.; Srinivasan, R.; Ho, Y.H. Double Wall Cooling of a Full-Coverage Effusion Plate With Main Flow Pressure Gradient, Including Internal Impingement Array Cooling. J. Turbomach. 2019, 141, 041002. [Google Scholar] [CrossRef]

- Vanga, S.R.; Ligrani, P.M.; Knox, J.; Liberatore, F.; Patel, R.; Ho, Y.H. Louver and effusion cooling heat transfer for a double wall effusion plate with impingement jet array coolant supply. Int. J. Heat Mass Transf. 2021, 168, 120861. [Google Scholar] [CrossRef]

- Ngetich, G.C.; Murray, A.V.; Ireland, P.T.; Romero, E. A Three-Dimensional Conjugate Approach for Analysing a Double-Walled Effusion-Cooled Turbine Blade. J. Turbomach. 2019, 141, 011002. [Google Scholar] [CrossRef]

- Ngetich, G.C.; Ireland, P.T.; Romero, E. Study of Film Cooling Effectiveness on a Double-Walled Effusion-Cooled Turbine Blade in a High-Speed Flow Using Pressure Sensitive Paint. In Proceedings of the ASME Turbo Expo, Phoenix, AZ, USA, 17–21 June 2019; p. GT2019-90545. [Google Scholar] [CrossRef]

- Murray, A.V.; Ireland, P.T.; Rawlinson, A.J. An Integrated Conjugate Computational Approach for Evaluating the Aerothermal and Thermomechanical Performance of Double-Wall Effusion Cooled Systems. In Proceedings of the ASME Turbo Expo, Charlotte, NC, USA, 26–30 June 2017; p. GT2017-64711. [Google Scholar] [CrossRef]

- Murray, A.V.; Ireland, P.T.; Romero, E. Development of a Steady-State Experimental Facility for the Analysis of Double-Wall Effusion Cooling Geometries. J. Turbomach. 2019, 141, 041008. [Google Scholar] [CrossRef]

- Murray, A.V.; Ireland, P.T.; Romero, E. Experimental and Computational Methods for the Evaluation of Double-Wall, Effusion Cooling Systems. J. Turbomach. 2020, 142, 111003. [Google Scholar] [CrossRef]

- Shrager, A.C.; Thole, K.A.; Mongillo, D. Effects of Effusion Cooling Pattern Near the Dilution Hole for a Double-Walled Combustor Liner-Part 1: Overall Effectiveness Measurements. J. Eng. Gas Turbines Power 2019, 141, 10. [Google Scholar] [CrossRef] [Green Version]

- Shrager, A.C.; Thole, K.A.; Mongillo, D. Effects of Effusion Cooling Pattern Near the Dilution Hole for a Double-Walled Combustor Liner-Part II: Flowfield Measurements. J. Eng. Gas Turbines Power 2019, 141, 10. [Google Scholar] [CrossRef] [Green Version]

- Huelsmann, N.C.; Thole, K.A. Effects of Jet Impingement on Convective Heat Transfer in Effusion Holes. J. Turbomach. 2021, 143, 10. [Google Scholar] [CrossRef]

- Jackowski, T.; Elfner, M.; Bauer, H.J. Numerical Investigation of Conjugate Heat Transfer in an Effusion and Impingement Cooled Combustor Wall. In Proceedings of the ASME Turbo Expo, Online. 21–25 September 2020; p. GT2020-15505. [Google Scholar]

- Goldstein, R.J. Film Cooling. In Advances in Heat Transfer; Elsevier: Amsterdam, The Netherlands, 1971; pp. 321–379. [Google Scholar] [CrossRef]

- Choe, H.; Kays, W.M.; Moffat, R.J. The Superposition Approach to Film-Cooling. In Proceedings of the American Society of Mechanical Engineers, New York, NY, USA, 17–22 November 1974; Volume 74-WA. [Google Scholar]

- Albert, J.E.; Bogard, D.G.; Cunha, F. Adiabatic and Overall Effectiveness for a Film Cooled Blade. In Proceedings of the ASME Turbo Expo 2004, Vienna, Austria, 14–17 June 2004. [Google Scholar] [CrossRef]

- Nathan, M.L.; Dyson, T.E.; Bogard, D.G.; Bradshaw, S.D. Adiabatic and Overall Effectiveness for the Showerhead Film Cooling of a Turbine Vane. J. Turbomach. 2013, 136, 031005. [Google Scholar] [CrossRef]

- Roach, P. The Generation of Nearly Isotropic Turbulence by Means of Grids. Int. J. Heat Fluid Flow 1987, 8, 82–92. [Google Scholar] [CrossRef]

- Schroeder, R.P.; Thole, K.A. Adiabatic Effectiveness Measurements for a Baseline Shaped Film Cooling Hole. In Volume 5B: Heat Transfer; American Society of Mechanical Engineers: New York, NY, USA, 2014. [Google Scholar] [CrossRef] [Green Version]

- Ochs, M.; Horbach, T.; Schulz, A.; Koch, R.; Bauer, H.J. A Novel Calibration Method for an Infrared Thermography System Applied to Heat Transfer Experiments. Meas. Sci. Technol. 2009, 20, 9. [Google Scholar] [CrossRef]

- Ochs, M.; Schulz, A.; Bauer, H.J. High Dynamic Range Infrared Thermography by Pixelwise Radiometric Self Calibration. Infrared Phys. Technol. 2010, 53, 112–119. [Google Scholar] [CrossRef]

- Elfner, M.; Schulz, A.; Bauer, H.J. Surface Temperature Measurement on Complex Topology by Infrared Thermography. In The Art of Measuring in the Thermal Sciences, 1st ed.; Meyer, J.P., De Paepe, M., Eds.; Taylor and Francis Group: Boca Raton, FL, USA, 2020; Chapter 10; p. 482. [Google Scholar]

- Lohrengel, J.; Todtenhaupt, R. Wärmeleitfähigkeit, Gesamtemissionsgrade und spektrale Emissionsgrade der Beschichtung Nextel Velvet Coating 811-21. PTB-Mitteilungen 1996, 106, 259–265. [Google Scholar]

- Elfner, M.; Schulz, A.; Bauer, H.J.; Lehmann, K. Comparative Experimental Investigation of Leading Edge Cooling Concepts of Turbine Rotor Blades. In Proceedings of the ASME Turbo Expo, Oslo, Norway, 11–15 June 2018; p. GT2018-75360. [Google Scholar] [CrossRef]

- Hennig, J.; Elfner, M.; Feder, J. MPh; OpenSource Software; Zendo: Geneva, Switzerland, 2021. [Google Scholar] [CrossRef]

- O’Donovan, T.S.; Murray, D.B. Jet Impingement Heat Transfer-Part I: Mean and Root-Mean-Square Heat Transfer and Velocity Distributions. Int. J. Heat Mass Transf. 2007, 50, 3291–3301. [Google Scholar] [CrossRef]

- Sagot, B.; Antonini, G.; Christgen, A.; Buron, F. Jet Impingement Heat Transfer on a Flat Plate at a Constant Wall Temperature. Int. J. Therm. Sci. 2008, 47, 1610–1619. [Google Scholar] [CrossRef]

| Normal Al. (MALO00) | Shifted Al. (MALO05) | |

|---|---|---|

| Cavity Height H | 3D, 5D, 7D | 3D, 5D, 7D |

| Longitudinal Shift | 0.0 | |

| Blowing ratios M | 0.5, 1, 1.5, 2, 2.5, 3 | 0.5, 1, 1.5, 2, 2.5, 3 |

| Flow Conditions | |||

|---|---|---|---|

| Hot Gas Inlet | 523 ± 0.2% | 523 ± 0.1% | 523 ± 0.1% |

| Hot Gas Re | 1.916 ± 0.3% | 1.916 ± 0.2% | 1.915 ± 0.3% |

| Hot Gas Tu | 9.8% | ← | ← |

| Coolant Inlet | 295 ± 0.4% | 295 ± 0.3% | 295 ± 0.3% |

| Coolant Tu | 5% | ← | ← |

| Coolant Crossflow Re | 4.231 ± 0.5% | 4.231 ± 0.03% | 4.237 ± 0.3% |

| Coolant Imp. Re | 5.894 ± 0.9% | 11.800 ± 0.5% | 17.716 ± 0.5% |

| Operating Conditions | |||

| Overall Pressure Drop | 0.74 ± 2.0% | 2.20 ± 1.6% | 4.23 ± 2.3% |

| Pressure Drop Ratio | 22.2 ± 1.3% | 26.1 ± 1.0% | 27.5 ± 1.3% |

| Density Ratio DR | ± 0.5% | ± 0.4% | ± 0.4% |

| Blowing Ratio M | ± 0.6% | ± 0.3% | ± 0.3% |

| Velocity Ratio VR | ± 0.6% | ± 0.4% | ± 0.3% |

| Momentum Flux Ratio I | ± 1.1% | ± 0.7% | ± 0.4% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jackowski, T.; Elfner, M.; Bauer, H.-J. Experimental Study of Impingement Effusion-Cooled Double-Wall Combustor Liners: Thermal Analysis. Energies 2021, 14, 4843. https://doi.org/10.3390/en14164843

Jackowski T, Elfner M, Bauer H-J. Experimental Study of Impingement Effusion-Cooled Double-Wall Combustor Liners: Thermal Analysis. Energies. 2021; 14(16):4843. https://doi.org/10.3390/en14164843

Chicago/Turabian StyleJackowski, Thomas, Maximilian Elfner, and Hans-Jörg Bauer. 2021. "Experimental Study of Impingement Effusion-Cooled Double-Wall Combustor Liners: Thermal Analysis" Energies 14, no. 16: 4843. https://doi.org/10.3390/en14164843

APA StyleJackowski, T., Elfner, M., & Bauer, H.-J. (2021). Experimental Study of Impingement Effusion-Cooled Double-Wall Combustor Liners: Thermal Analysis. Energies, 14(16), 4843. https://doi.org/10.3390/en14164843