1. Introduction

The utilization of sustainable energy is a key element of the contemporary world and the EU, with the European Green Deal, has made a decisive step towards its 3 × 20 targets. The growth in renewable energy usage and improvements of energy efficiency are of vital importance in this regard [

1]. Biomass is one of the keys to supporting the Green Deal target to achieve climate neutrality in 2050. One crucial biomass technology is pellet incineration in domestic pellet boilers. This is the most effective and cleanest biomass utilization for heating in households.

Pellet boilers in the Polish heating market are increasingly popular, especially since low-stack emissions were revealed to be one of the main sources of air pollution in Poland [

2]. In 2018, Poland launched its “Clean Air” program, the main goals of which are improving the energy efficiency of buildings and reducing the emission of dust and other pollutants into the atmosphere, mainly from the heating systems of single-family houses where old and low quality solid fuel boilers burning low-quality fuel are used [

3,

4]. Even so, coal combustion remains one of the main sources of household heating, representing the most common energy carrier in the Polish countryside [

5]. Solid fuels were used in 48.7% of households in Poland (from a total 14,276,000 households). In the countryside, 76.4% of single-detached dwellings use coal for heating and 23.5% use it in the cities [

6]. Poland has 47% of the European market share of solid fuel boilers (mainly coal-fired boilers) [

7]. The use of such old manual feed solid fuel boilers frequently leads to high levels of dust particles in the air during the heating season. In Poland, the daily limit values for airborne particles (PM10) is often exceeded during the heating season. Particulate matter pollution in Poland is mainly caused by low-stack emissions (emissions from stacks with a height lower than 40 m) from household heating [

8,

9]. An increase in the Polish market of pellet boilers has also been observed. In 2014, 26,000 units of biomass boilers were sold and 14% of the total amount were pellet boilers [

10]. In 2019, a drop in sales of solid fuel boilers was observed; the amount of sold coal fired boilers decreased. On the other hand, the share of biomass boilers of the total solid fuel boilers in 2019 was 60–65% [

11]. The share of investment in biomass boilers in households between 2014 and 2019 in Poland was 20% [

12]. Most biomass boilers are automatic pellet boilers fed by wood pellets.

For a number of years, the Centre of Sustainable Development and Energy Saving AGH WGGiOŚ “Miekinia” has conducted lectures for students and workshops for local societies (mainly in the Malopolska region) in the field of ecological utilization of solid fuels, mainly biomass fuels and low emission causes [

13,

14,

15]. In the Centre, research and tests to prepare data for proper education in that field are also prepared [

16,

17].

Availability and Prevalence of Biomass Fuel

The share of biomass in heating and cooling production in the residential sector in 2018 was around 20% on average for EU-28 countries [

18]. The phase-out of coal-fired and oil-fired boilers and, in a later phase of decarbonisation, also gas-fired boilers creates the market potential for pellet heating appliances (in particular pellet boilers). The greatest such potential exists in Poland, Ireland, Belgium, Italy, Germany, and the Netherlands [

18].

In order to reduce the impact of fossil fuel use on the climate, it is very important to replace fossil fuel boilers in the domestic sector with technologies based on renewable energy sources such as biomass. Pellets are the most convenient of the available solid biomass fuels. They have a higher fuel density than wood chips and hence the transportation and storage surface demands are lower. Compared to wood log boilers, pellet boilers have automatic feeders, automatic cleaning systems, and automatic ignition systems. In comparison to uncompacted biomass, pellets possess a lower moisture content, higher heating value, uniform shape, clear incineration, and ash reduction [

19,

20,

21].

Pellet boilers are devices which cause the lowest emissions of air pollutants compared to other solid fuel boilers. However, the problem of hazardous substances in flue gas cannot be eliminated [

22,

23]. Most pellet boilers on the market are of the fifth best class according to the PN-EN 303-5:2012 standard [

15]. The minimal efficiency for a 20 kW pellet boiler in the fifth class is 88%. According to PN-EN 303-5:2012 [

24], the maximum CO emission for automatic biomass boilers is 500 mg/m

3, OGC emission is 20 mg/m

3 and particulate matter emissions are 40 mg/m

3 (each value is recalculated for 10% oxygen concentration in flue gas). These boilers also meet the Ecodesign directive requirements [

25] and are in the A+ efficiency class according to the Commission Delegated Regulation (EU) No 811/2013 [

26]. The efficiency in terms of the nominal heating capacity of pellet boilers is over 90% [

26]. The annual efficiency for a standard house from 2004, understood as the heat quotient produced by the boiler and energy feed to the boiler in the fuel, was 83%, when the efficiency during the standard testing conditions in nominal capacity was 93,2%. For the part load (in modulating capacity mode), it was 90.9% [

27].

The main aim of this study was to verify the possibility of burning non-wood biomass, something that has not been tested to date on low-power boilers with moving grates that meet the Ecodesign and EN-303-5:2012 standards. Locally, such fuels are burned by users of domestic boilers, and have not been tested by the manufacturers of these boilers. The conducted tests were aimed at checking the possibility of using agro-pellets as a substitute fuel for low-power boilers with a moving grate burner, and verifying that these boilers still meet or are close to meeting the requirements of the above standards. For testing, we selected miscanthus pellets, sunflower husk pellets, corn stover pellets, and wood pellets for a comparison.

2. Materials and Methods

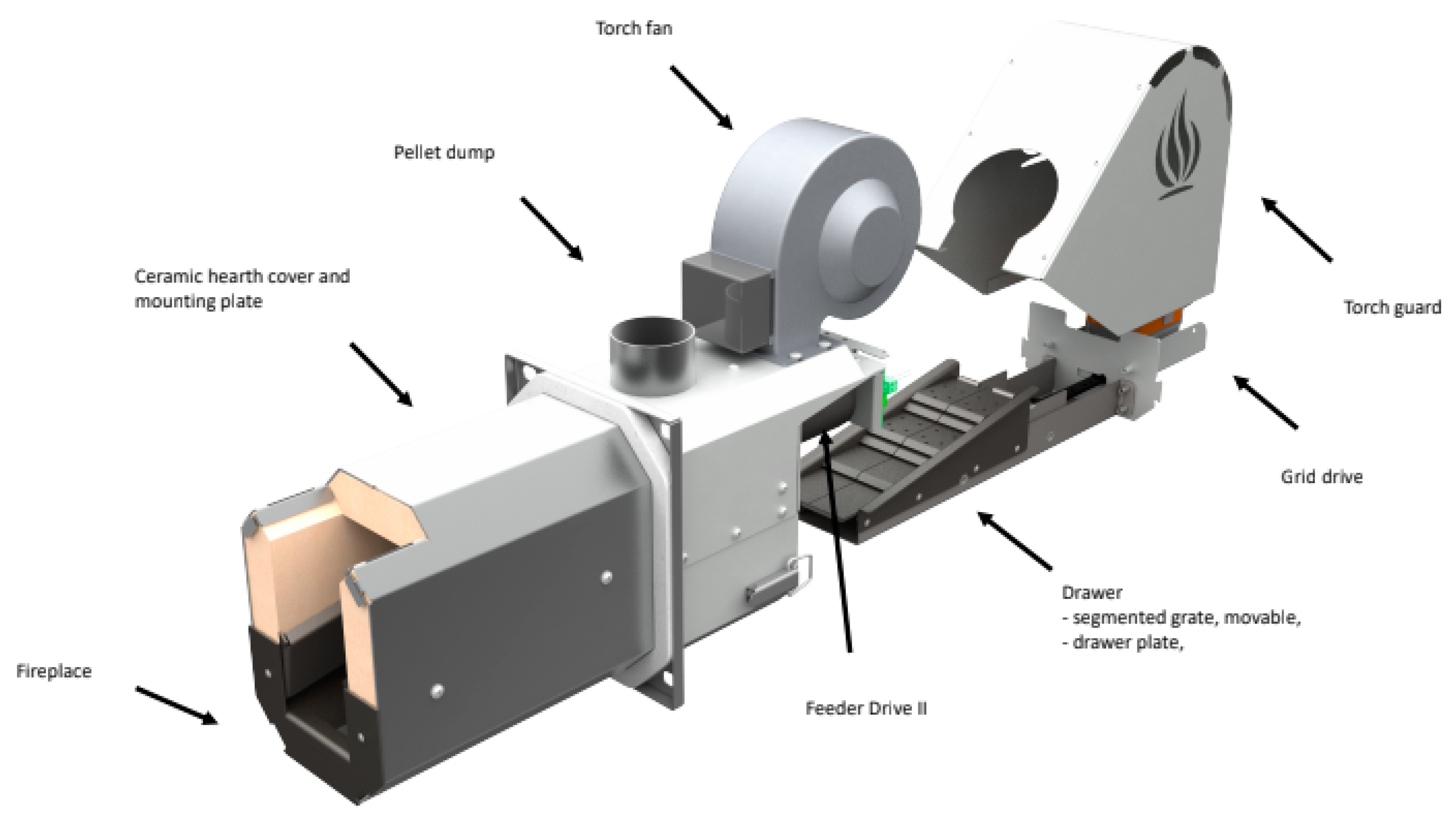

The subject of this research was a 20 kW heating capacity solid fuel boiler equipped with a suitable pellet burner. The boiler has vertical flow of fumes via two pass heat exchangers with turbulization elements in each tube (

Figure 1). Such a structure allows the boiler to achieve a high level of efficiency. The authors of the article decided to analyze the combustion process of pellets from non-wood biomass and to compare it to wood pellets. As a result, a moving grate pellet burner capable of burning various pellets was installed in the tested boiler. The burner has a modular structure, consisting of the following components, as shown in

Figure 2:

A furnace: furnace plate, mounting plate, ceramic furnace mantle that seals the grate, and igniter tube with an igniter. The furnace is rectangular in shape and, once installed, is completely inside the boiler;

drawers: with a movable segmented grate and auto-cleaning drive;

a blower fan;

stoker plates: with stoker drive, stoker worm, FD-1 photodetector, plate;

a burner connection;

ceramic hearth cover.

On the front of the door, the burner was installed (

Figure 1). Over the burner in the burning chamber there is a ceramic plate as catalysator and deflector. The fuel is supplied from storage by means of a screw conveyor from the bottom of the hopper to the top and then gravitational descent through the backflow preventer to the stoker chamber. Then, the stoker transports pellets to the grate.

Four working stages were implemented with the tested pellet boiler, the first of which is the ignition stage. In this stage, first the fan starts to remove ash from the grate. After that, a starting dose of pellets is supplied to the grate, and the electric igniter and blower fan are activated. During this step, the pellet warms up on the grate to reach the ignition temperature. The igniter is in operation until a flame occurs. This is signaled by the light sensor. When the fuel is combusted, the fan operates continuously with fuel fed periodically to the grate. It is transported from the pellet hopper to the grate by two auger conveyors.

When the flame occurs, the boiler goes into heating mode. During this stage, the screw auger conveyor, fan, stoker, and moving grate are all in operation. The burner has three power levels. While working at nominal capacity, parameters such as time of pellet feeding, the pause for pellet feeding, and fan capacity are set by the manufacturer. In the case of part load working, ex. 2/3 or 1/3, the time of pellet feeding and fan capacity are properly reduced. The burner works with nominal heating capacity as long as the boiler water temperature remains at 8 °C below the set temperature. If the water outflow temperature is less than 8 °C lower than the set temperature, the controller modulates the burner capacity.

When the set temperature is reached, the controller switches the boiler to extinguishing mode. During this stage, fuel is not fed into the system and the fan is still working to finish burning the last fuel and to blow ash from the grate while the moving grate cleans up the ash.

After extinguishing, the controller goes into standby mode and measures the temperature of the water supply. When the supply water temperature is lower than the set temperature minus the hysteresis temperature, the boiler starts the process of ignition again.

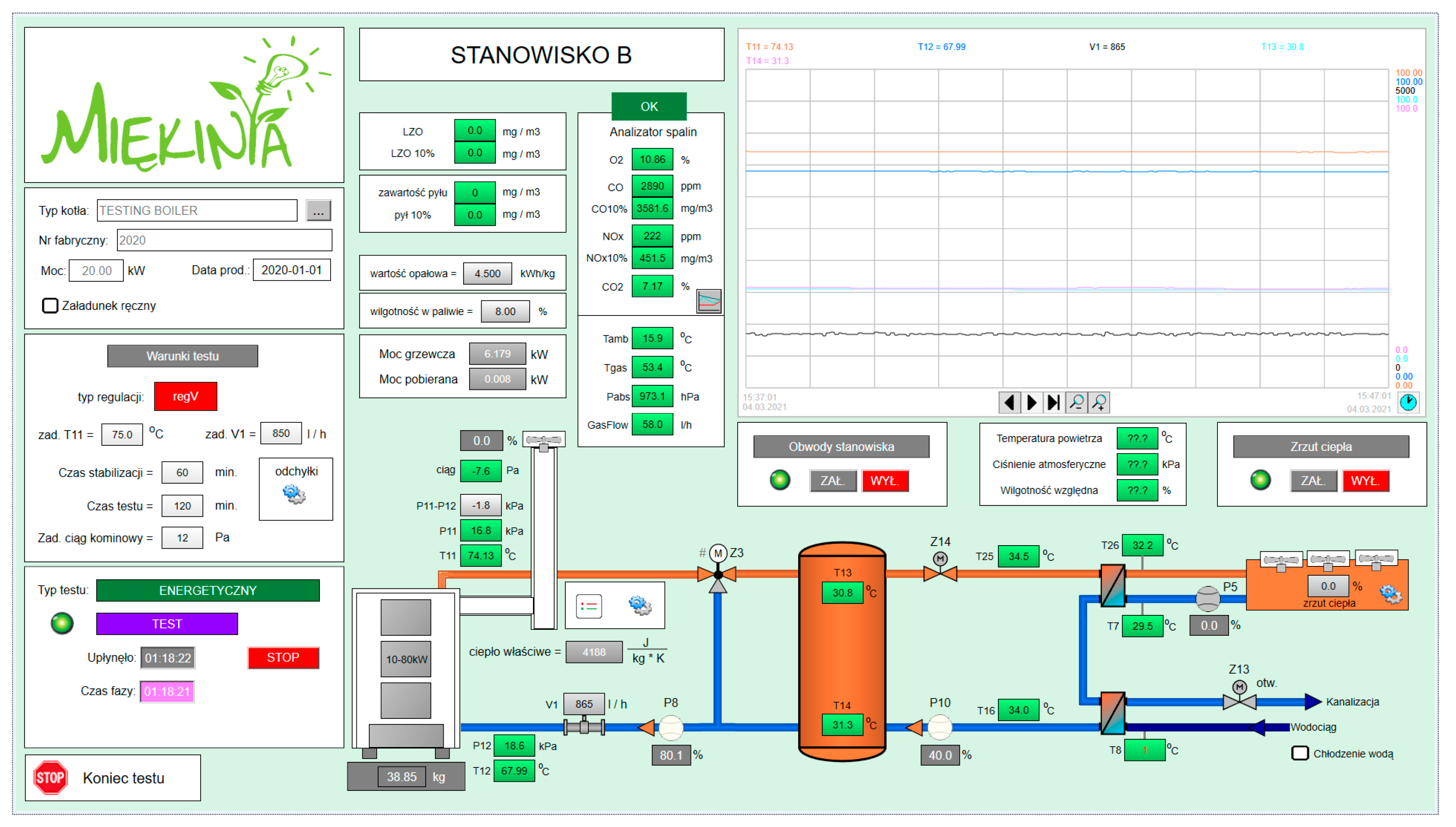

The research was carried out on equipment for solid fuel boiler testing (

Figure 3) at the Centre of Sustainable Development and Energy Saving AGH WGGiOŚ “Miękinia”. The testing equipment consisted of a heating loop with heat meter, pressure sensors, and a system for stabilizing water flow and temperatures (inlet and outlet). The flowmeter in the heat meter is an electromagnetic flow meter made by Aplisens, model PEM-1000 DN25, inlet and outlet transducers are PT100. The flue gas chimney is equipped with a draft fan and draft sensor with a system for draft stabilizing. On the testing stand there is also an electric power meter. The flue gas analyzing system consisted of a Sensonic IR-1 with Sensonic MANOX-CLD and Sensonic D-2 gas conditioner which continuously monitored O

2, CO, CO

2 and NOx. For O

2 measurement, a paramagnetic sensor was used, for CO and CO

2 was user NDIR sensors and for NOx was used CLD method. Dust measurement was done with the particulate matter measurement system MRU 7 FSM as a total mass concentration. The material of the filter was made from borosilicate. Before and after sampling, the filter was dried and weighed. The uncertainty of dust measurement (sampling system and drying and weighting system) is no higher than 10 mg/m

3. To control the parameters of the boiler and record them, the SCADA PROCES2 system was used (the control panel screen can be seen in

Figure 4).

During each test the combustion and thermal efficiency of the boiler was calculated. Combustion efficiency was calculated according to Formula (1):

where qA represents flue gas loses calculated according to Equation (2):

where:

Tg—flue gas temperature [°C],

Ta—ambient temperature [°C],

CO2—carbon dioxide concentration in the flue gas [%],

A1, B—Siegert coefficient characteristics, for biomass A1—0.65, B—0.

Thermal efficiency was calculated with using Formula (3):

where:

P—heating capacity of the boiler [kW], calculated according Formula (4),

B—fuel consumption rate [kg/h],

NCW—net calorific value of fuel [kWh/kg].

V—volumetric flow rate [L/h],

ρ—water density [kg/L],

T2—boiler’s outlet temperature [°C],

T1—boiler’s inlet temperature [°C],

cw—water specific heat capacity [kJ/(kg·K)].

Each measurement for every pellet type started from stabilizing the temperatures of the boiler’s inlet and outlet water. Then, feeding parameters and pause parameters for the fuel conveyors was set up in the controller. Setting up these parameters was important in order to reach the assumed heating capacity, regardless of the size and bulk density of the tested pellets. It was assumed that the boiler works on the nominal capacity—20 kW and with minimal capacity 6 kW, which is 30% of the nominal capacity. It was also necessary to set up the fan capacity to ensure proper primary and secondary air supply to the burner. After reaching the set capacity, emissions were checked (by the flue gas analyzers) and were checked the ash characteristics (visually), especially if it was powdery or melted and unburned burning parts were seen to be present in the ash. It was assumed that each pellet type and heating capacity test would last 2 h.

3. Results and Discussion

For laboratory testing, four types of pellets were used: wood pellet class A1 (according to ENplus requirements) and agrobiomass pellets made from sunflower husks, miscanthus straw, and corn stover, characterized in

Table 1. Wood pellets and sunflower husk pellets were standard commercial products. The miscanthus straw and corn stover pellets were prepared especially for testing purposes. The highest net calorific value was 17.65 MJ/kg for the wood pellet, while the lowest one, 14.44 MJ/kg, was found for the corn stover pellet. Most of the tested pellets had a similar moisture about 8.5%; only the corn stover pellet has a higher moisture content equal 13.7% (if the corn stover pellet have moisture content equal 8.5%, it will have 15.03 MJ/kg net calorific value). The lowest ash content was that of the wood pellet (0.4%), and the agrobiomass pellets all had much higher ash content. The miscanthus straw pellet had 1.6%, the sunflower husk pellet 3.4% and corn stover pellet had the highest ash content at 10.7%. The wood pellets has the highest bulk density (670 kg/m

3), followed by miscanthus pellet with 610 kg/m

3, sunflower husk with 580 kg/m

3, and the corn stover pellet has 570 kg/m

3. As reported, the weakest parameters were those of the corn stover pellets. The wood, miscanthus straw, and corn stover pellets were 6 mm in diameter, while the sunflower husk pellet was 8 mm in diameter. Photos of the tested pellets are shown in

Figure 5.

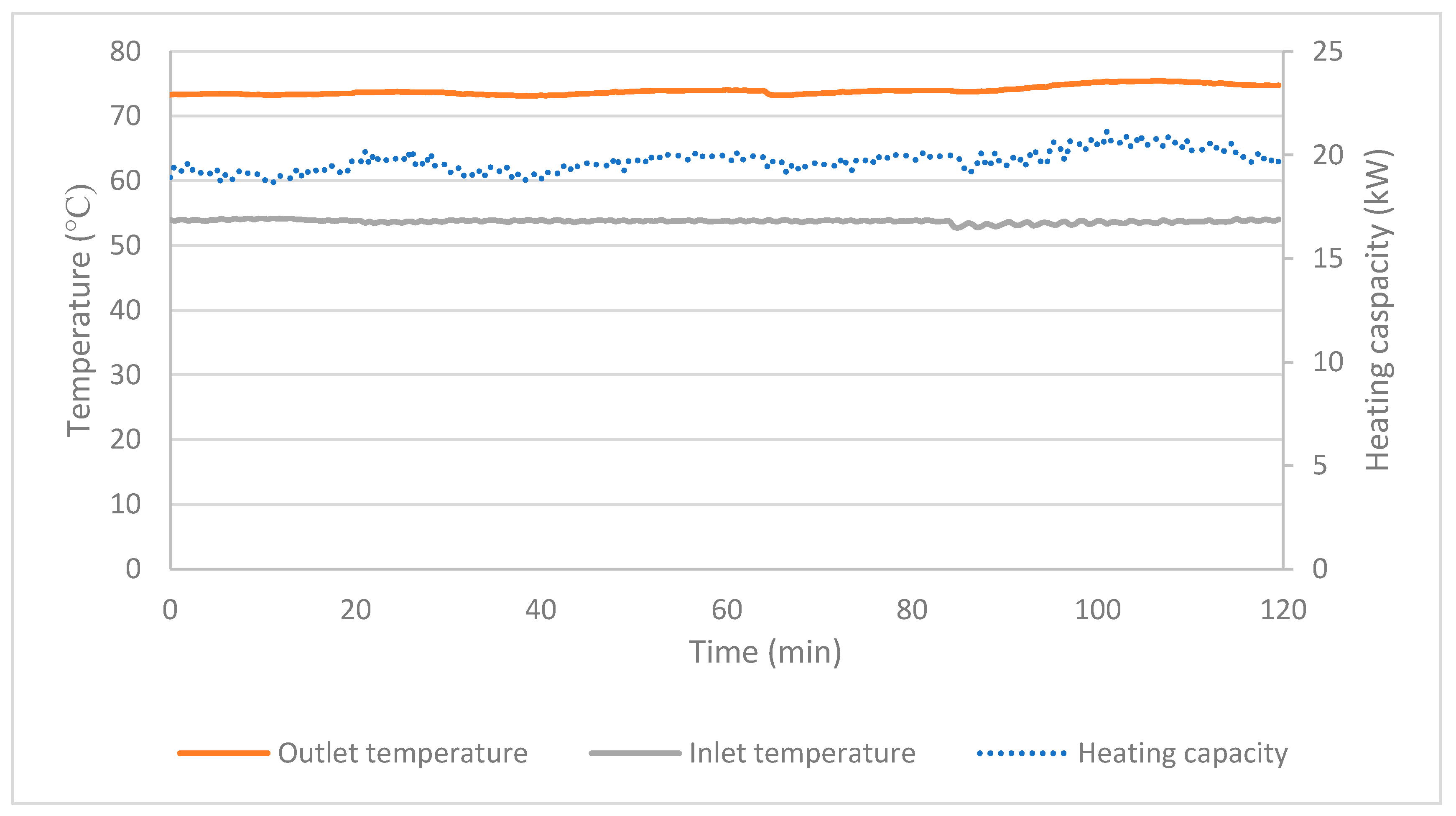

First, the parameters of the burner such as fuel feeding time, fuel feeding brake time, fan speed, and break of grate operation were adjusted (listed in

Table 2). Adjusting was done to reach the set value of heating capacity (20 kW for maximal heating capacity and 6 kW for minimal heating capacity) in correlation with the lowest possible burner emissions and stability of work connected with potential ash deposits on the grate. Ultimately, it was impossible to attain 20 kW for the miscanthus and corn stover pellets due to the falling of unburned pellets to the ashpan. For miscanthus pellets, ash had a tendency to sinter and it was necessary to reduce the break of grate operation and the heating capacity to 18 kW. For the corn stover pellets, no problems with sintering were encountered. However, their lower calorific value affected the lower heating capacity. The highest stable value of heating capacity without the fuel loss was 17.6 kW. For minimal heating capacity in each case it was about 6 kW. Established controller settings (listed in

Table 2) could be used for the end user in the case of agrobiomass pellets such as miscanthus straw, sunflower husk, and corn stover pellets. In each case, for both maximal and minimal heating capacity, outlet temperatures were between 70 and 80 °C and the heating capacity was as stable as the wood pellets, as shown in

Figure 6.

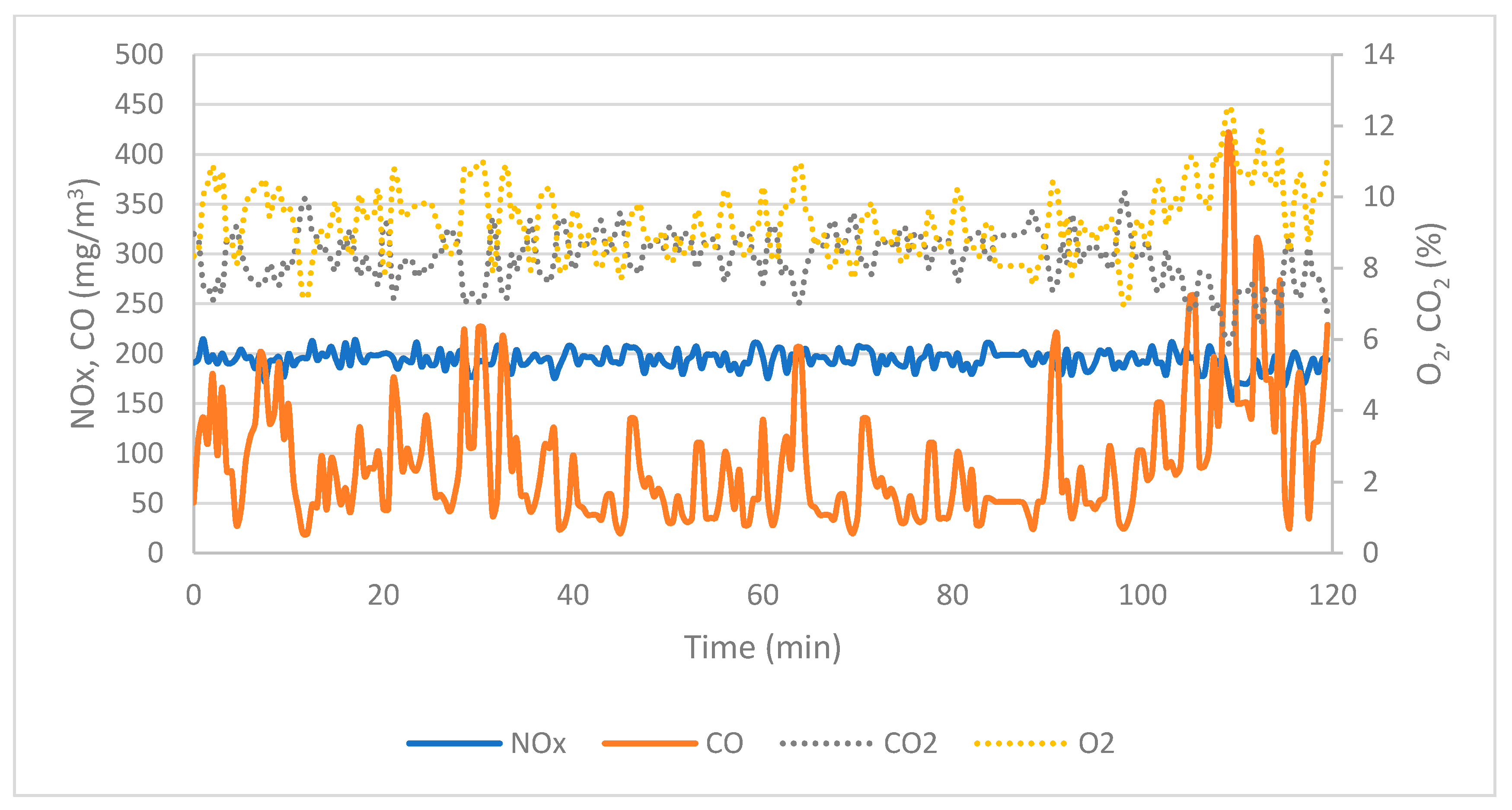

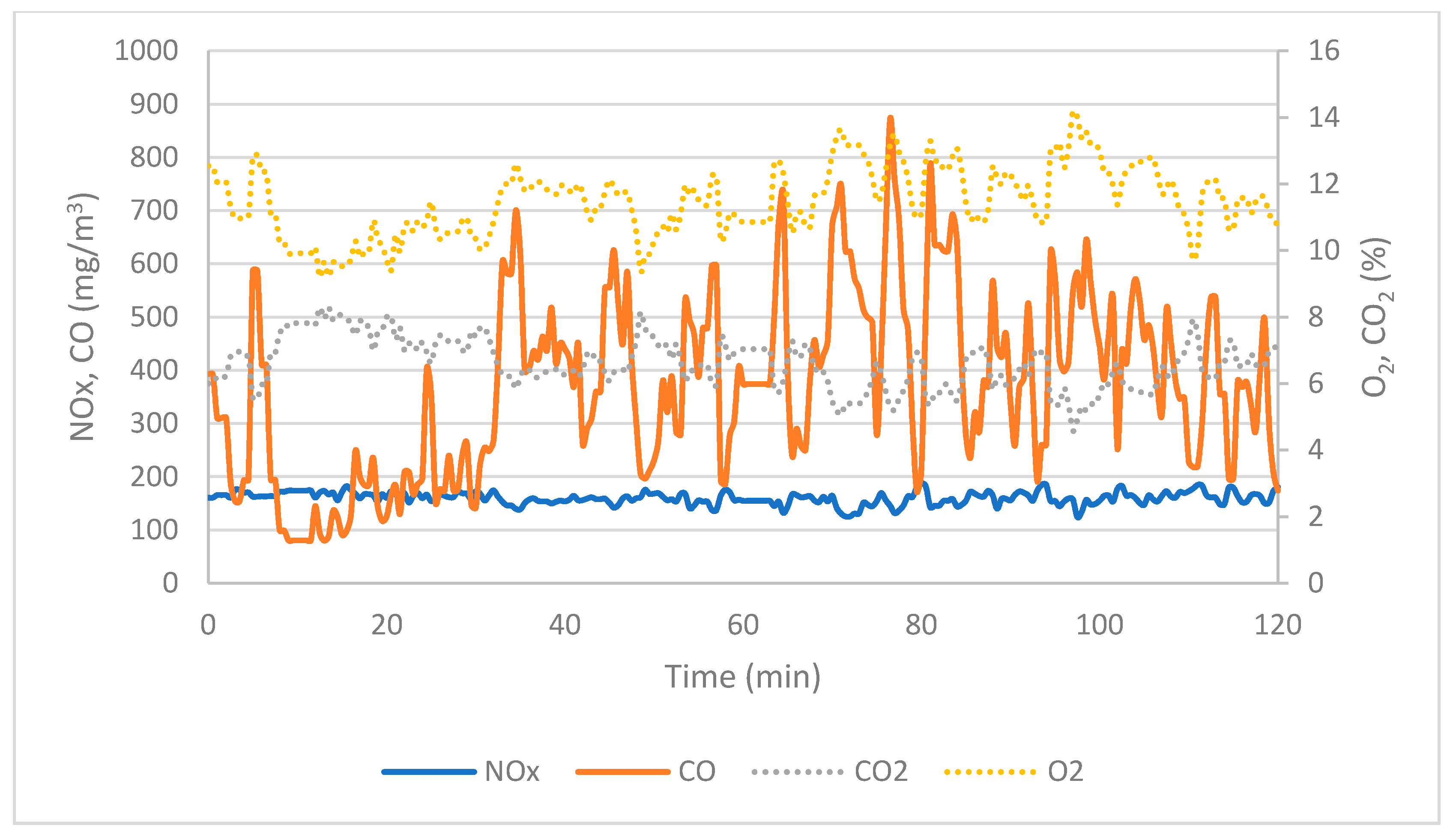

Significant differences between the various types of pellets in the volume of pollutant emission values during combustion was observed. In

Figure 7 and

Figure 8, CO, NOx, CO

2 emissions, and also O

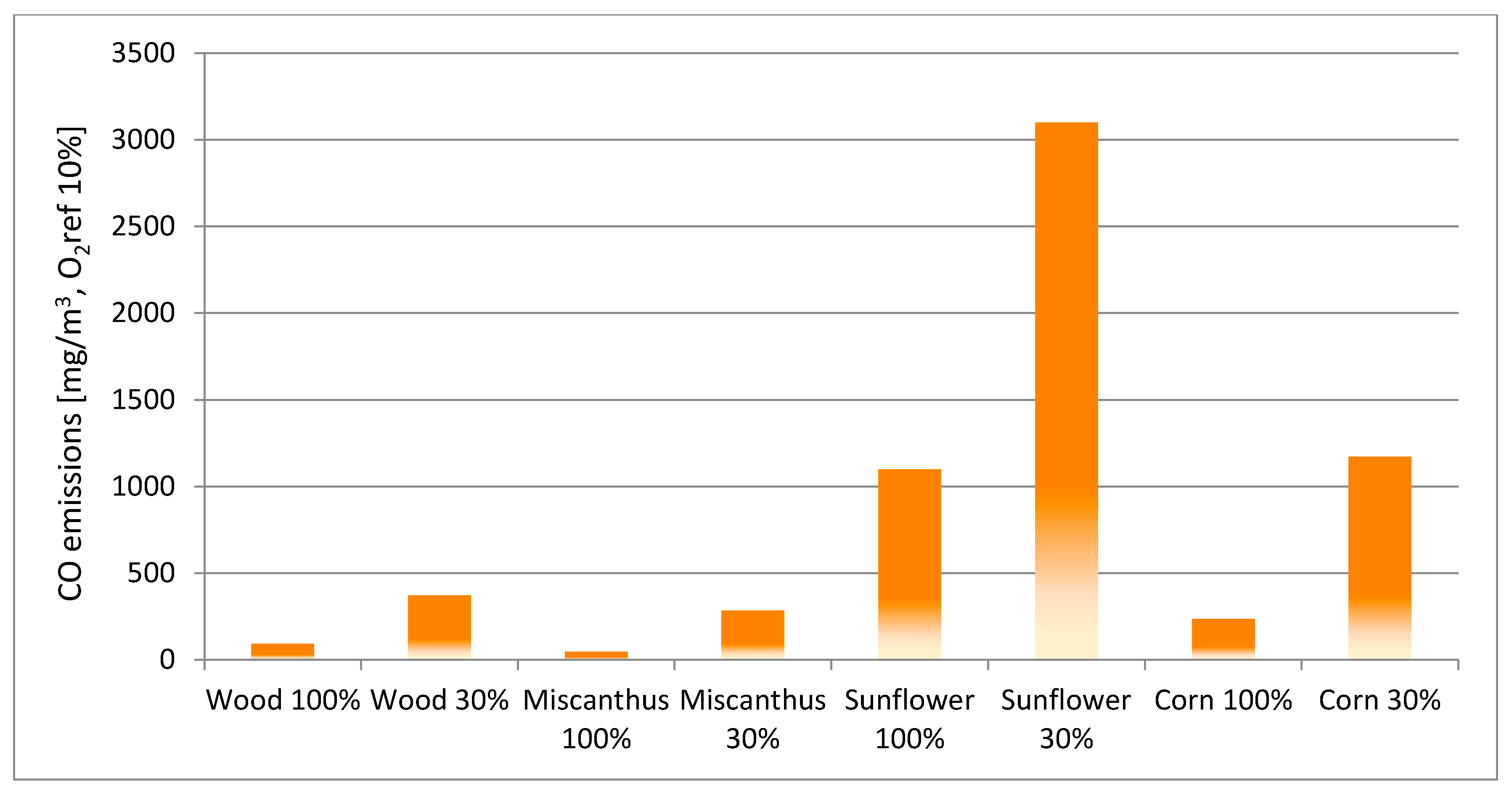

2 concentrations during the testing of wood pellets in full and minimal load are presented. In the case of carbon monoxide emissions, higher level of pollutants were reported during combustion with a minimum load than with a full load (

Figure 9). Such a dependence results from lower temperatures in the burner during a minimal load state, which leads to incomplete combustion whereby CO is created [

30]. During the sunflower husk pellet combustion at full boiler capacity, the highest CO emission (1098.1 mg/m

3) was registered. It was 12.1, 24.3, and 4.7 times higher than wood, miscanthus and corn stover pellets, respectively. The CO emissions of the other pellets during the full load state were lower than 500 mg/m

3, which is the limit for fifth class boilers according to PN-EN 303-5:2012, with the highest value for corn stover pellet equal to 233.9 mg/m

3. The lowest CO emission, at a value of 45.2 mg/m

3, was observed for miscanthus pellets. During the minimum boiler load tests, the CO emission from sunflower husk pellet combustion was almost three times higher (3099.3 mg/m

3) than in the full load case. The same regularity for other pellets is maintained. CO emission for wood pellets at minimum boiler load was 370 mg/m

3, for miscanthus pellet 283.5 mg/m

3 and for maize straw pellet 1171.2 mg/m

3, which is 4.1, 6.3, and 5.0 times higher than during the full boiler load combustion, respectively. For minimum capacity mode for carbon monoxide emission, two pellet types (sunflower husk pellet and corn stover pellet) did not meet the requirements of the PN-EN 303-5:2012 standard.

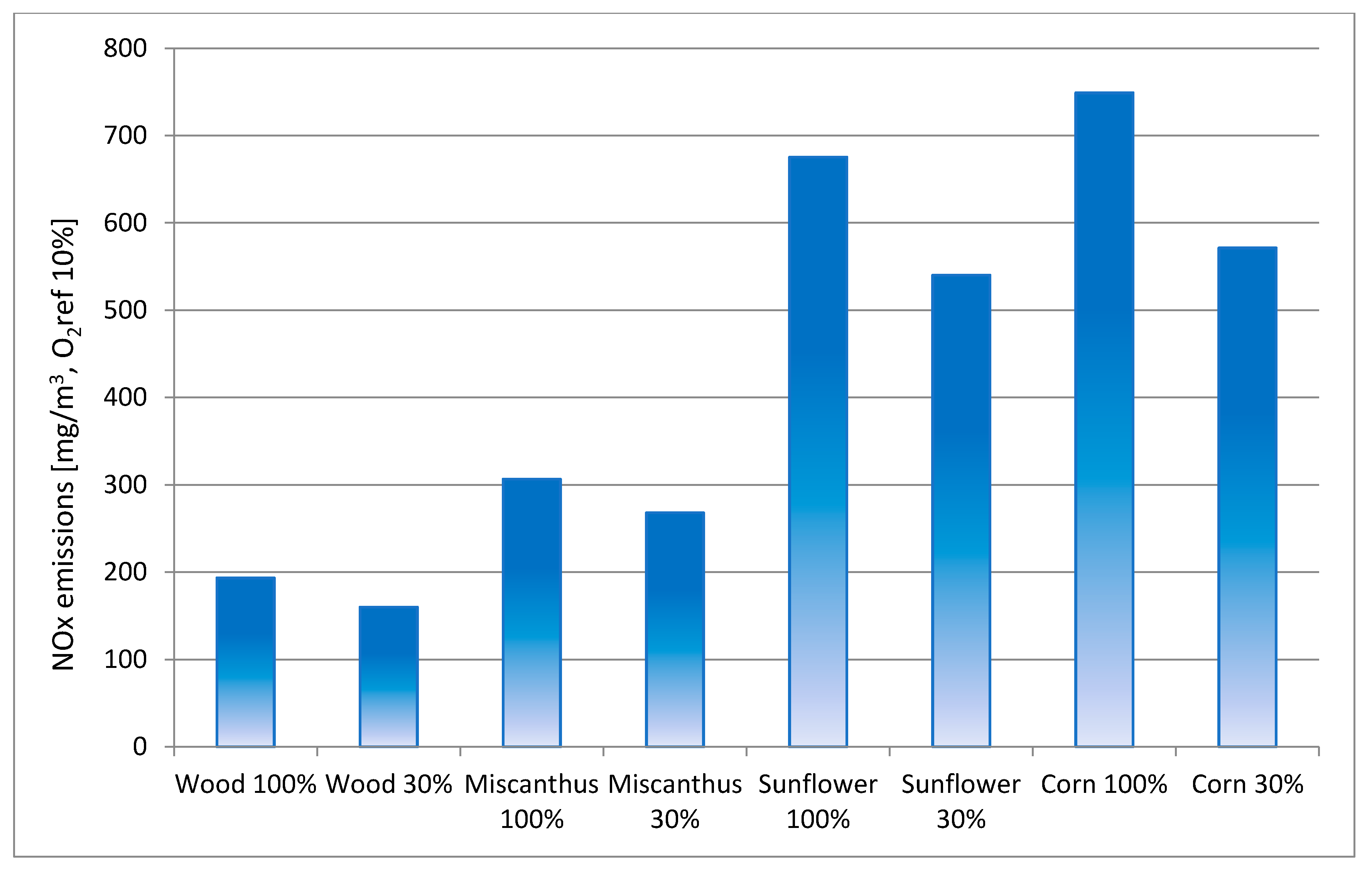

The highest NOx emission was registered during corn stover pellet combustion at both full and minimal load (

Figure 10). The average amount of pollutant emitted was equal to 748.9 mg/m

3 at nominal capacity of the boiler and 571.3 mg/m

3 at minimum capacity, that is 3.9 and 3.6 times higher than wood pellets which have the lowest reported NOx emissions, 193.4 mg/m

3 and 159.9 mg/m

3, respectively. The emission of NOx (from sunflower husk pellet combustion) was at a similar level to the corn stover pellets. The differences between full and part load were in range of 9.8% and 5.5%, respectively. It was noticed that NOx emissions were slightly lower during the minimum power combustion for every type of pellets. According to Lamberg [

31], the thermal oxidation of atmospheric nitrogen in small scale biomass boilers does not play a significant role due to relative low combustion temperatures (below 1300 °C). Therefore, the amount of fuel bound nitrogen is the most important mechanism of NOx formation in small scale biomass boilers. This is confirmed by the highest NOx emissions from corn stover and sunflower husk combustion, which are cultivated in an intensive way. Intensive fertilizing leads to high concentrations of nitrogen in the plants. Wood from forests has the lowest NOx emissions because it is grown in an extensive way and without the use of nitrogen fertilizers. The miscanthus pellet was produced from plants cultivated in an extensive manner near Krakow, but the proximity of other agricultural land meant a higher concentration of nitrogen than for wood. For sunflower husk pellets, the reported NOx emission was four times higher than emission reported by Verma et al. [

32] but at a similar level to those reported by Bala-Litwiniak and Zajemska [

33]. Pałaszyńska and Juszczak [

34] tested corn stover briquet emissions for an automatic boiler. They reported for nominal capacity CO emissions between 817 and 1364 mg/m

3 and NOx emissions between 404 and 429 mg/m

3 (10% O

2). The results for corn stover pellets show that CO emission is 3.5 to 5.8 times lower and NOx emission is almost two times higher. This could be the result of lower temperatures in the combustion chamber for burning briquets. Pałaszyńska and Juszczak [

34] also tested briquets made from corn stover and miscanthus, which decreased the emission of CO and NOx, respectively.

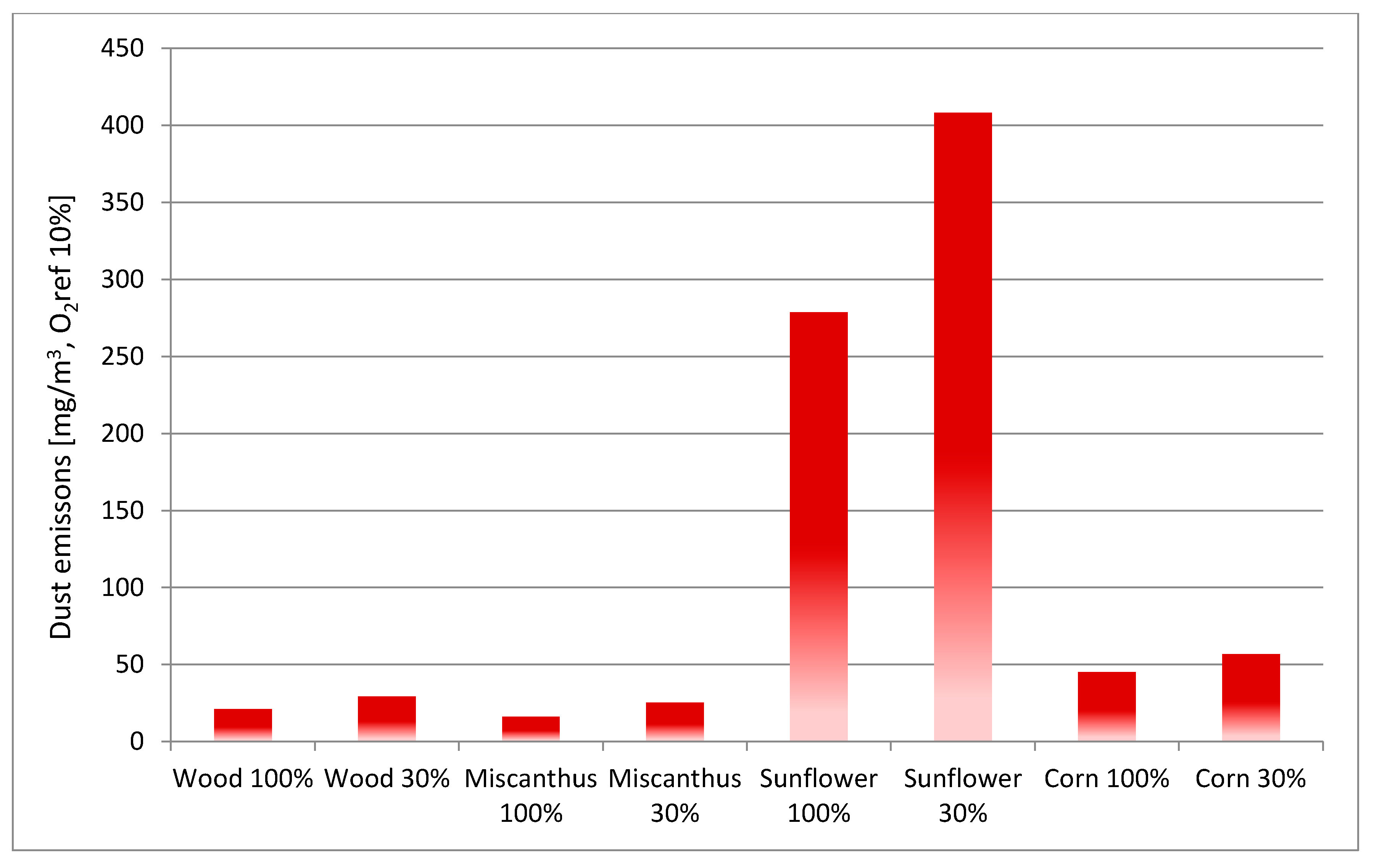

Particulate matter was measured as a total mass concentration using an MRU 7 FSM particular matter measurement equipment. The highest dust emission during sunflower pellet combustion was measured and the results are shown in

Figure 11. Emissions when operating at a nominal boiler load were 278.6 mg/m

3 and 408.1 mg/m

3 at minimum load. In comparison to the miscanthus pellets, which was characterized by the lowest emission with 16.1 mg/m

3 and 25.2 mg/m

3, respectively, sunflower husk pellet indicated even sixteen times higher dust emission. Moreover, the second highest recorded emission, during the corn stover pellet combustion, was 6.2 times lower (45.1 mg/m

3) at full boiler load and 7.2 times lower (56.8 mg/m

3) at minimum load. According to research, pellets made from agrobiomass tend to contain 50% of silicate as a total ash content [

35]. It was especially noticeable in the case of miscanthus, where the fireplace was constantly filled with high density sinter caused by the low sintering temperature of ash. It also could explain the lower dust emissions in comparison to sunflower husk and corn stover pellets. Contrastingly, the sunflower husk pellet shows a significantly higher fine content in the bottom ash that determines the highest dust emission. Wood pellets had the lowest ash content which results in very low dust emission, similar to the miscanthus pellet equal to 21.1 mg/m

3 and 29.3 mg/m

3 for the full and part load, respectively. According to the PN-EN 303-5:2012 standard requirements for fifth class boilers, maximal particulate matter emissions cannot exceed 40 mg/m

3. This means that only the utilization of wood and miscanthus pellets meet the requirements. For corn stover, particulate matter emissions slightly exceed 40 mg/m

3 for nominal capacity and for low heating capacity dust emission reached up to 56.8 mg/m

3. For sunflower husk pellets, the emissions were several times higher than for wood, miscanthus or corn stover pellets. The burner used for testing is not suitable for the ecological combustion of sunflower husk pellets.

The pollutant emissions results are only comparable for pellets made from plants cultivated in a similar manner, i.e., for sunflower husk and corn stover in intensive cultivation and for miscanthus straw from extensive cultivation.

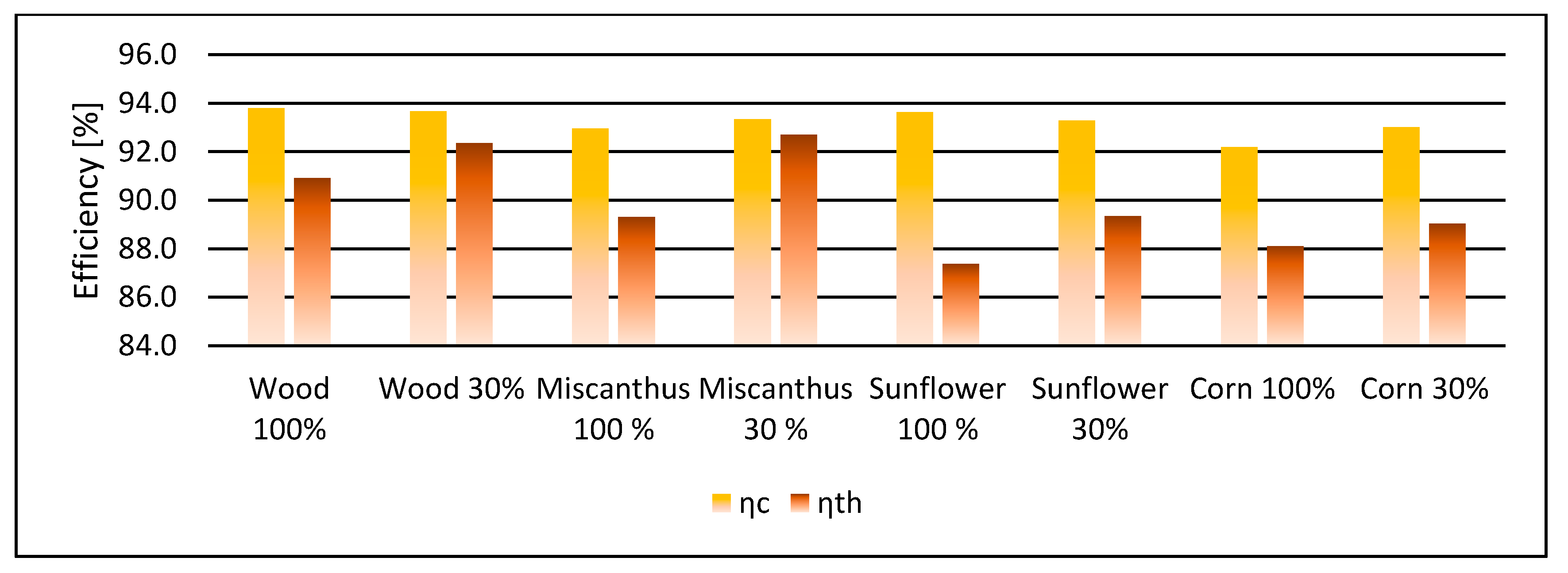

During test combustion, efficiency and thermal efficiency was calculated (

Figure 12 and

Table 3).

Table 3 summarizes the test parameters and emission levels. The highest combustion efficiency was achieved for wood pellets (93.8% for full heating capacity and 93.7% for low heating capacity). The lowest one was for corn stover pellets when burning with full heating capacity. It was 92.2%. For minimal heating capacity the lowest combustion efficiency had ex aequo corn stover and miscanthus straw burning. It was 93%. Thermal efficiency in all cases was lower than combustion efficiency because unburned matter loss, unburned gases in flue gas and heat loss in the boiler room all occur. For 100% heating capacity, the highest thermal efficiency was for wood pellets (90.9%) and the lowest one was for sunflower husk pellets (87.4%). For 30% heating capacity, the highest thermal efficiency was for the miscanthus straw pellets (92.7%) and the lowest was for the corn stover pellets (89%). Both for combustion efficiency as well as thermal efficiency, the highest values were observed for the same fuel at 30% heating capacity. For minimal thermal efficiency requirements, according to the PN-EN 303-5:2012 standard (minimal thermal efficiency for 20 kW boiler, measured for nominal capacity should not be less than 88%) only the combustion of sunflower husk pellets did not meet it since, in that case, the thermal efficiency was 87.4%. The values of combustion efficiencies and thermal efficiencies achieved during the tests are comparable to results from other publications [

32].

4. Conclusions

The decarbonization process and the goal of achieving climate neutrality by 2050 in EU countries requires the search for solutions to replace fossil energy sources. For agriculture and food and non-food industries that use coal, fuel oil, or natural gas in their production processes, the use of agro-biomass represents a solution to achieve the objectives of a closed circular economy and also to reduce its carbon footprint.

The energy clusters and energy cooperatives that have begun to emerge in Poland are ideal places to implement such solutions for heat production from locally available and climate-neutral renewable sources [

36].

Agropellets are the cheapest substitute for wood pellets. For moving grate burners there is the technical possibility to utilize miscanthus straw, sunflower husk and corn stover pellets. In terms of efficiencies, they have quite similar results, with thermal efficiencies differing by no more than four percentage points. From an end user point of view, such a difference would be negligible. However, from an ecological point of view, there are larger differences, especially in terms of the CO and NOx emissions for sunflower husk and corn stover pellets. CO emissions in that case are the highest for low heating capacity and NOx emission is the highest for maximal capacities. From the PN-EN 303-5:2012 requirements for wood pellets, of the agrobiomass alternatives, only miscanthus pellets (burning in nominal and minimal capacity) met the ecological requirements. For the sunflower husk pellets, none of the requirements are met. For the corn stover pellets, only the nominal capacity CO emissions were met. Finally, dust emissions did not meet the requirements. Nevertheless the obtained results of pollutants emissions can be comparable only for pellets made from plants cultivating in a similar manner.

A key issue is the quality of the raw materials used to produce pellets, which do not contain prohibited additives to improve their calorific value or adhesive additives. Methods for precise analysis of the raw material composition of the biomass from which the pellets are produced are well known and used. These are not physio-chemical methods, which in simple analyses of the calorific value, moisture, ash, sulphur, and chlorine content do not give results indicative of prohibited additives (for example, plastics). Precision methods for compositional analysis are microscopic methods borrowed from petrographic studies. On their basis, it is possible to quickly determine quantitatively and qualitatively the content of components such as glass, slag, stone powder, rust, mineral matter, metal pieces, plastics, and polymers of inorganic origin [

37,

38,

39].