Determination of the Selected Wells Operational Power with Borehole Heat Exchangers Operating in Real Conditions, Based on Experimental Tests

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental and Measuring Site

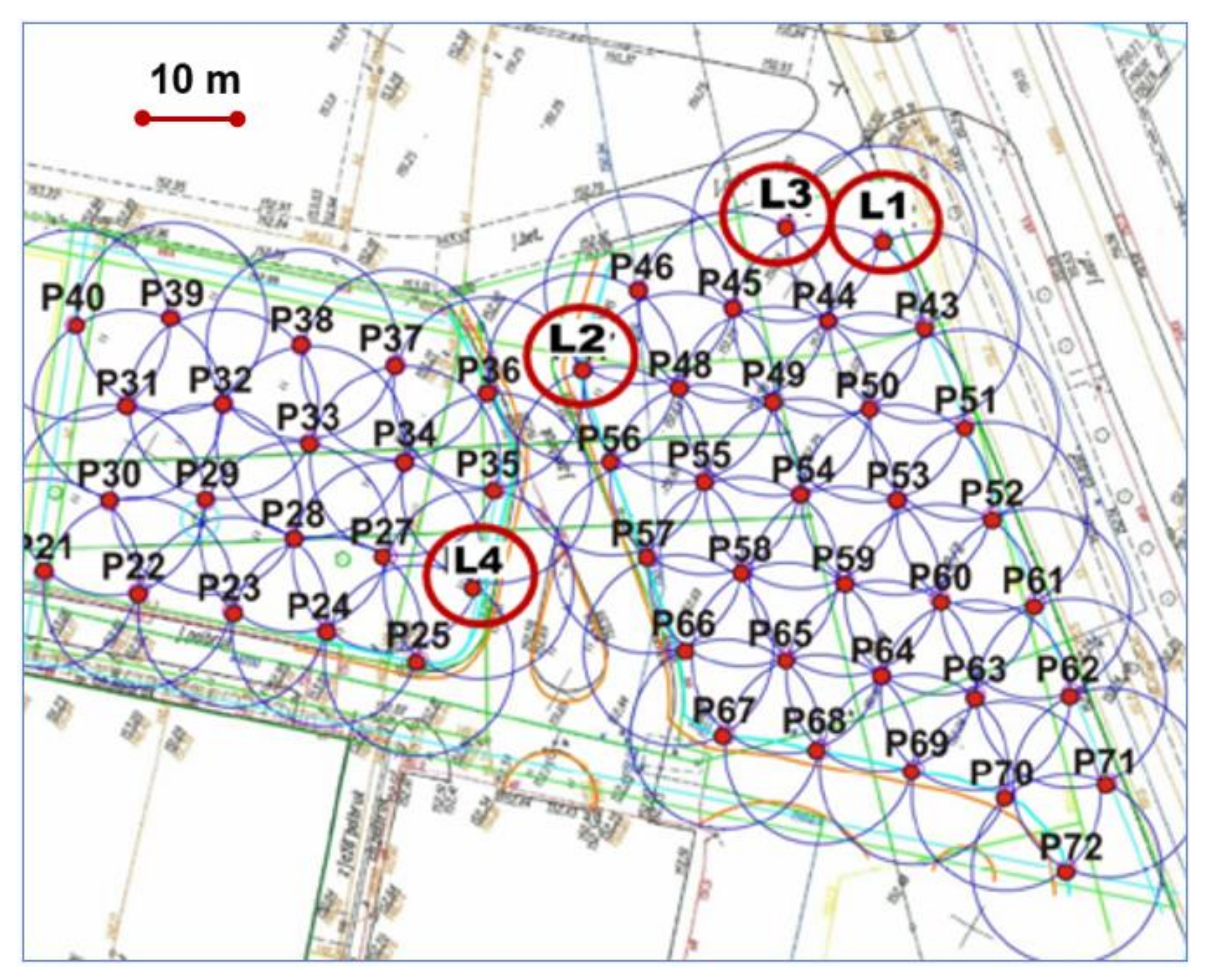

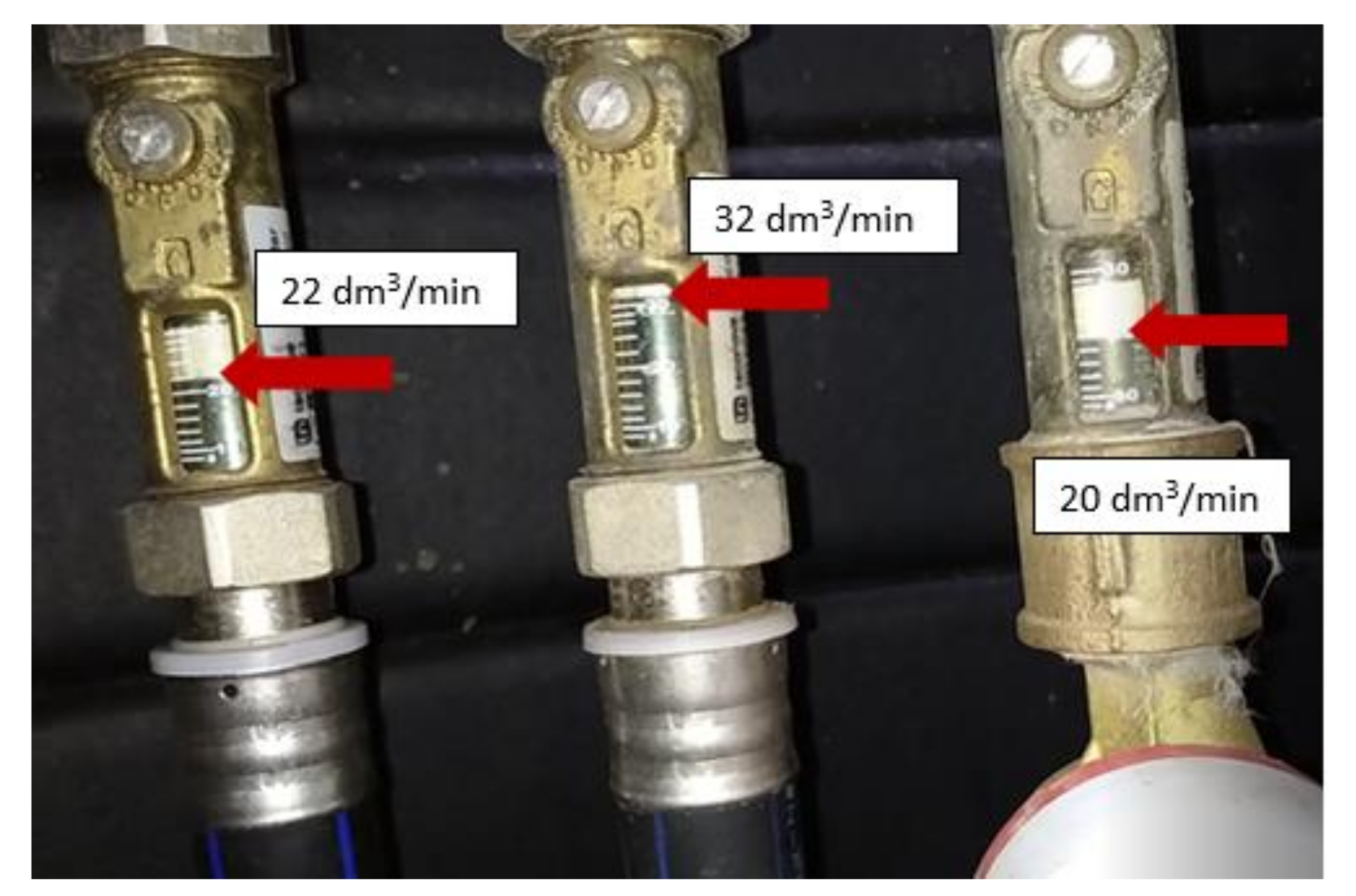

2.2. Description of the Experimental Setup and Location of the Tested Wells

2.3. Measurement Methodology

2.4. The Ground Profile

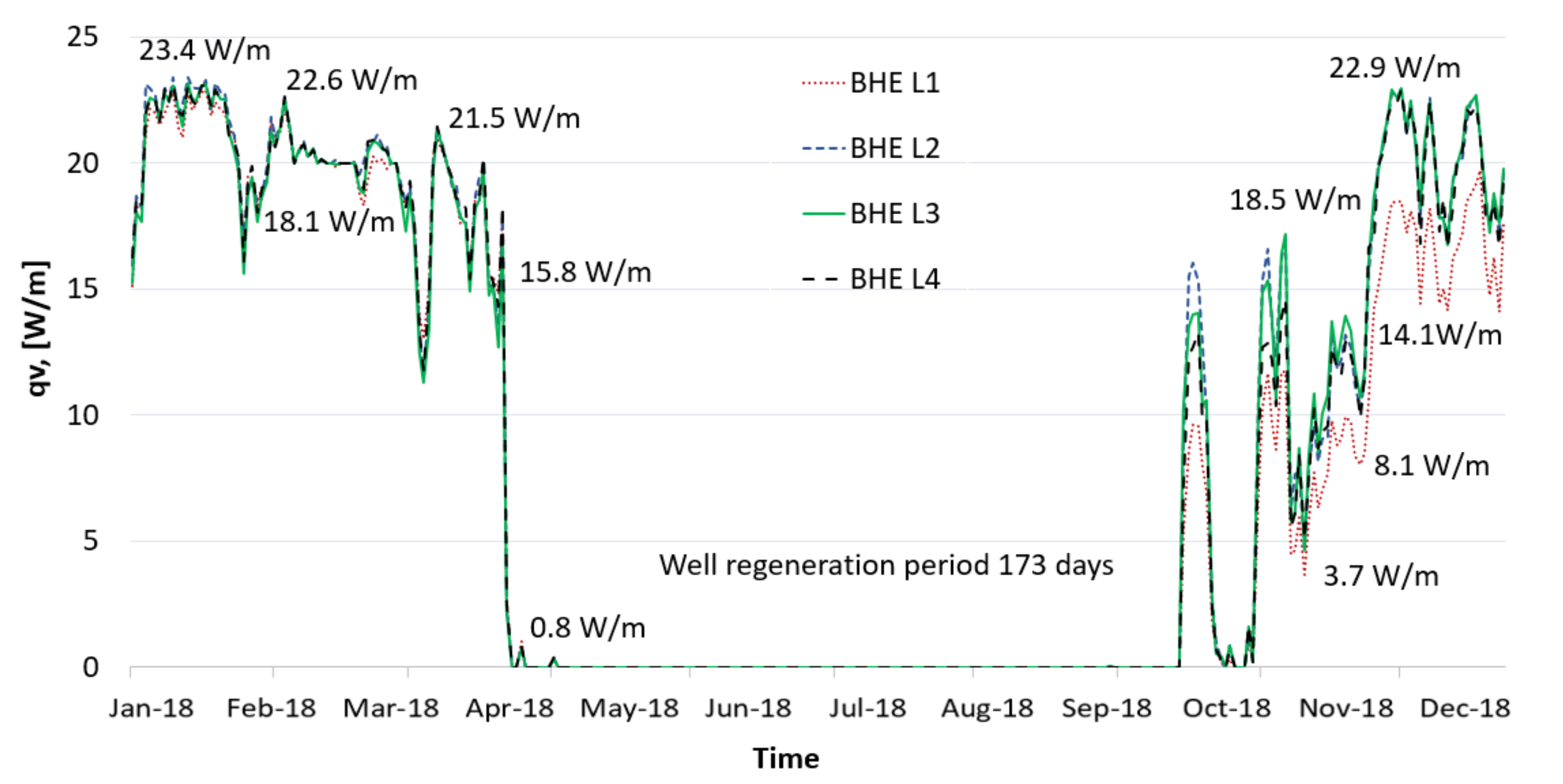

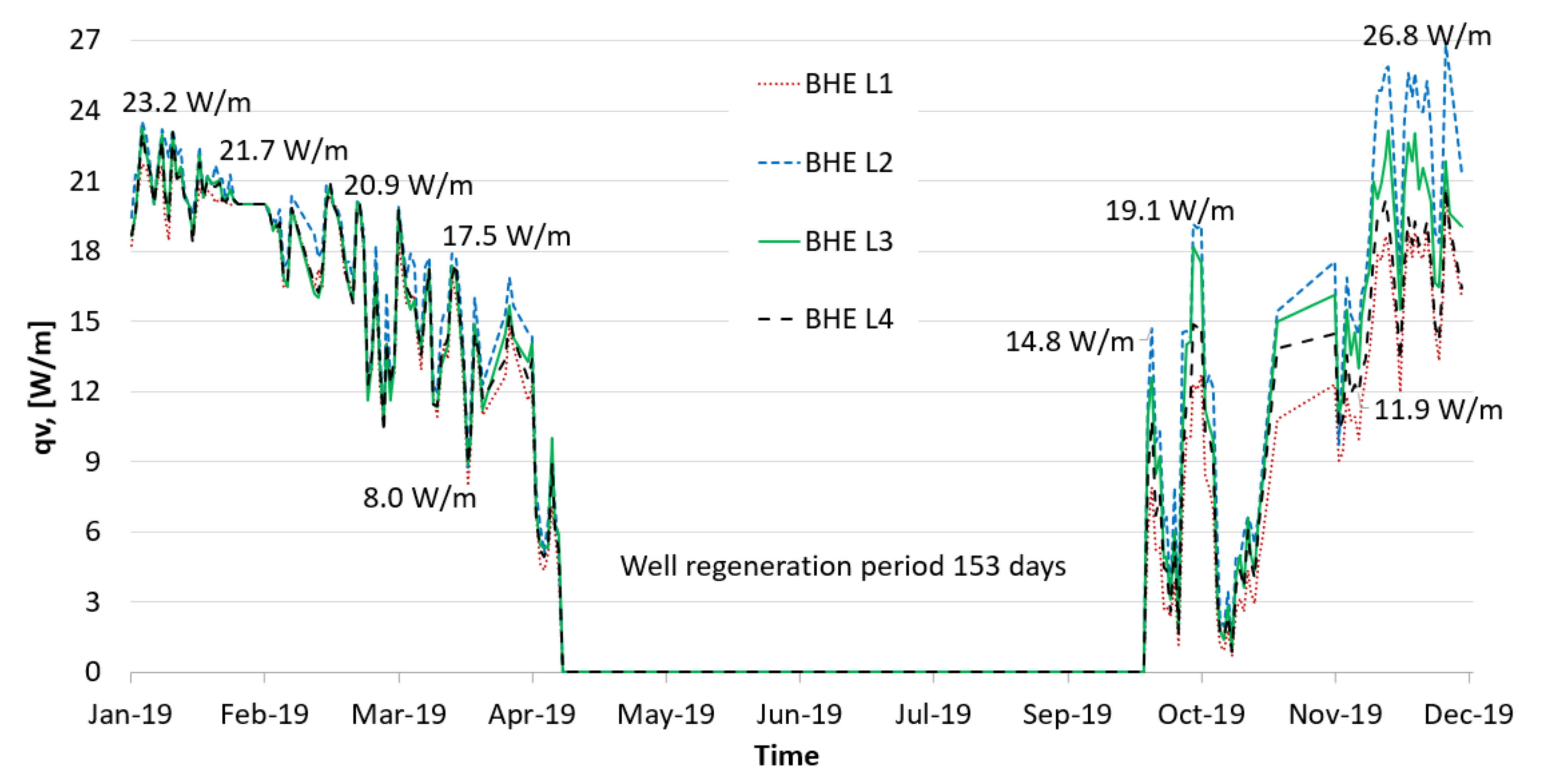

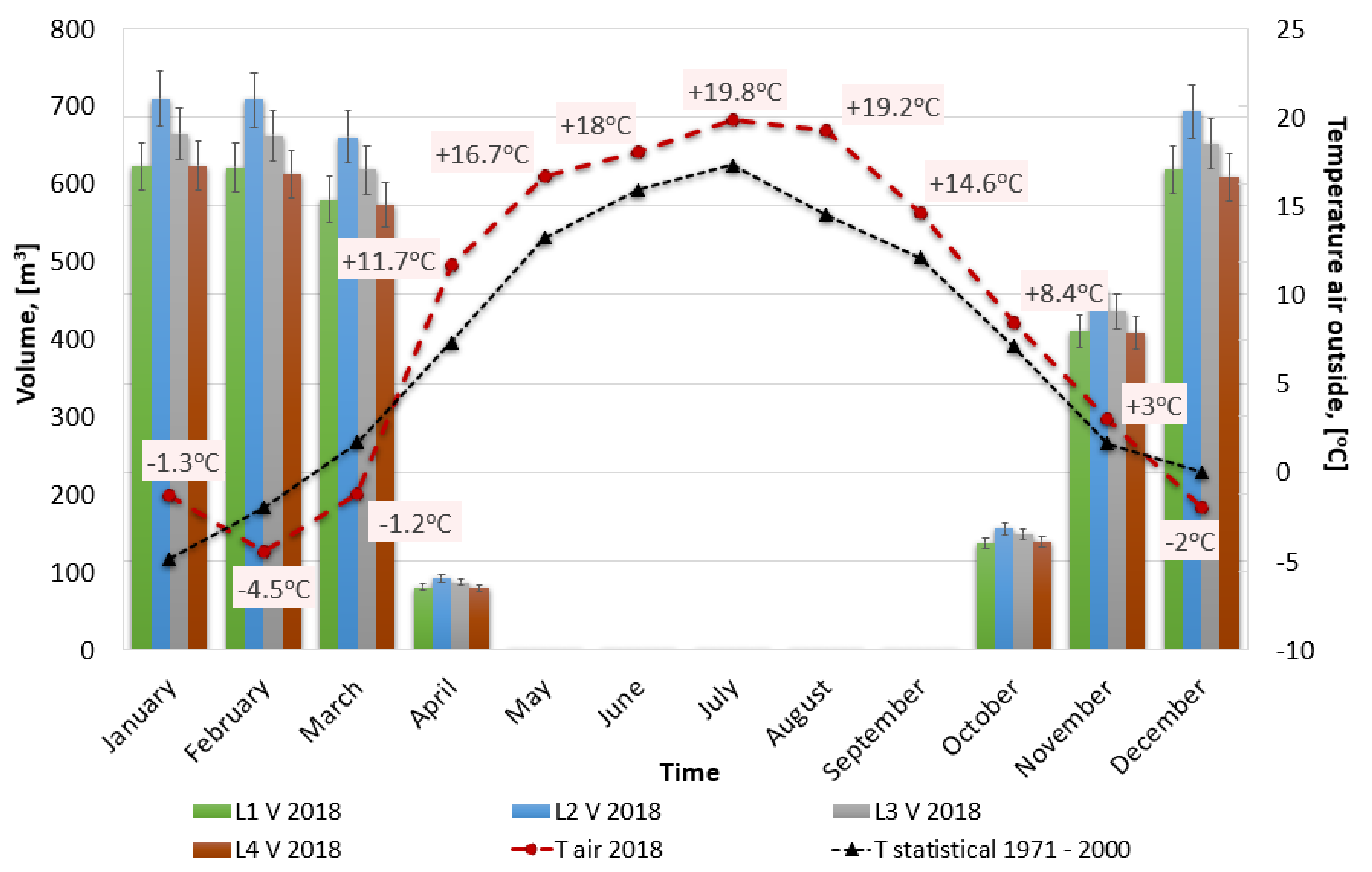

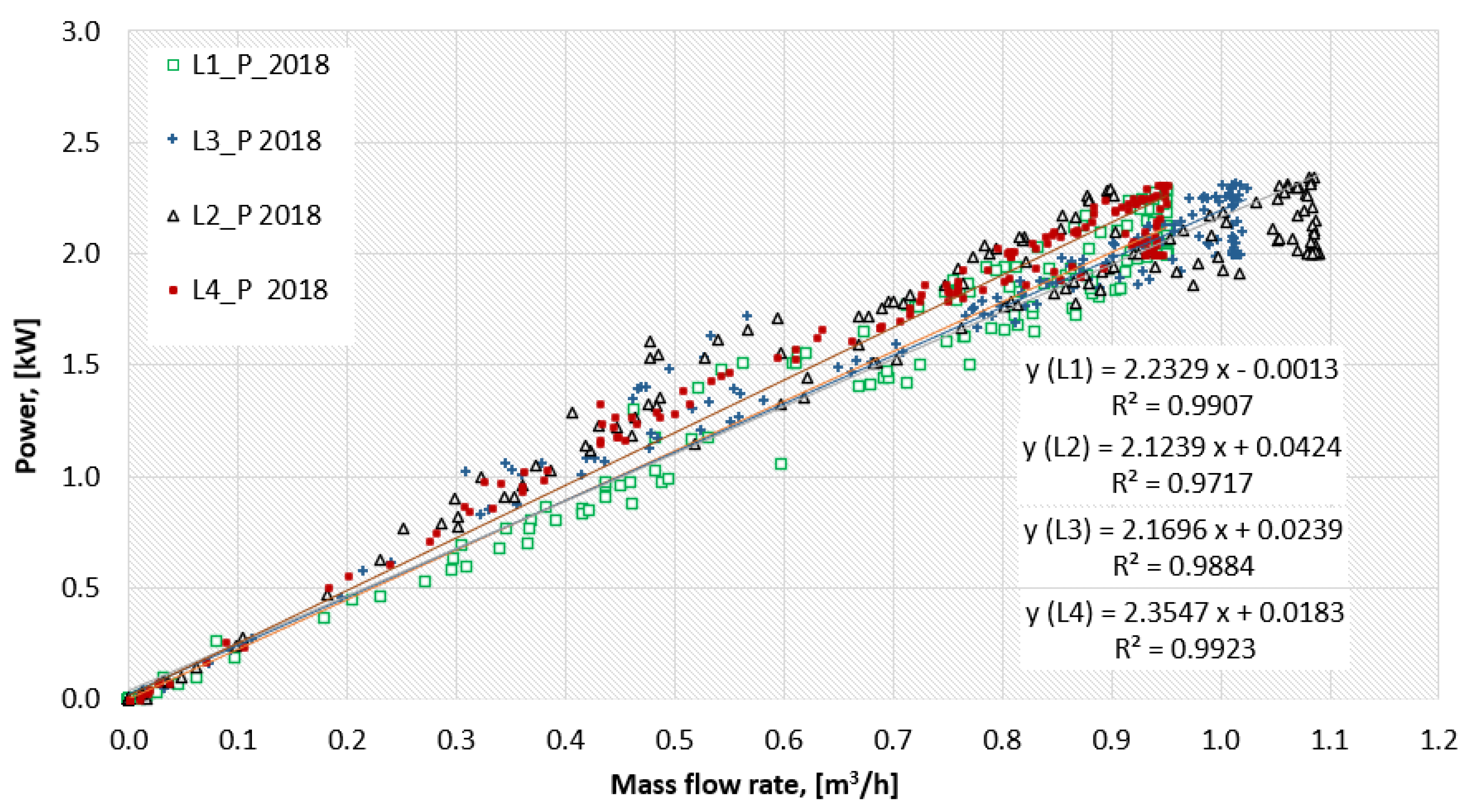

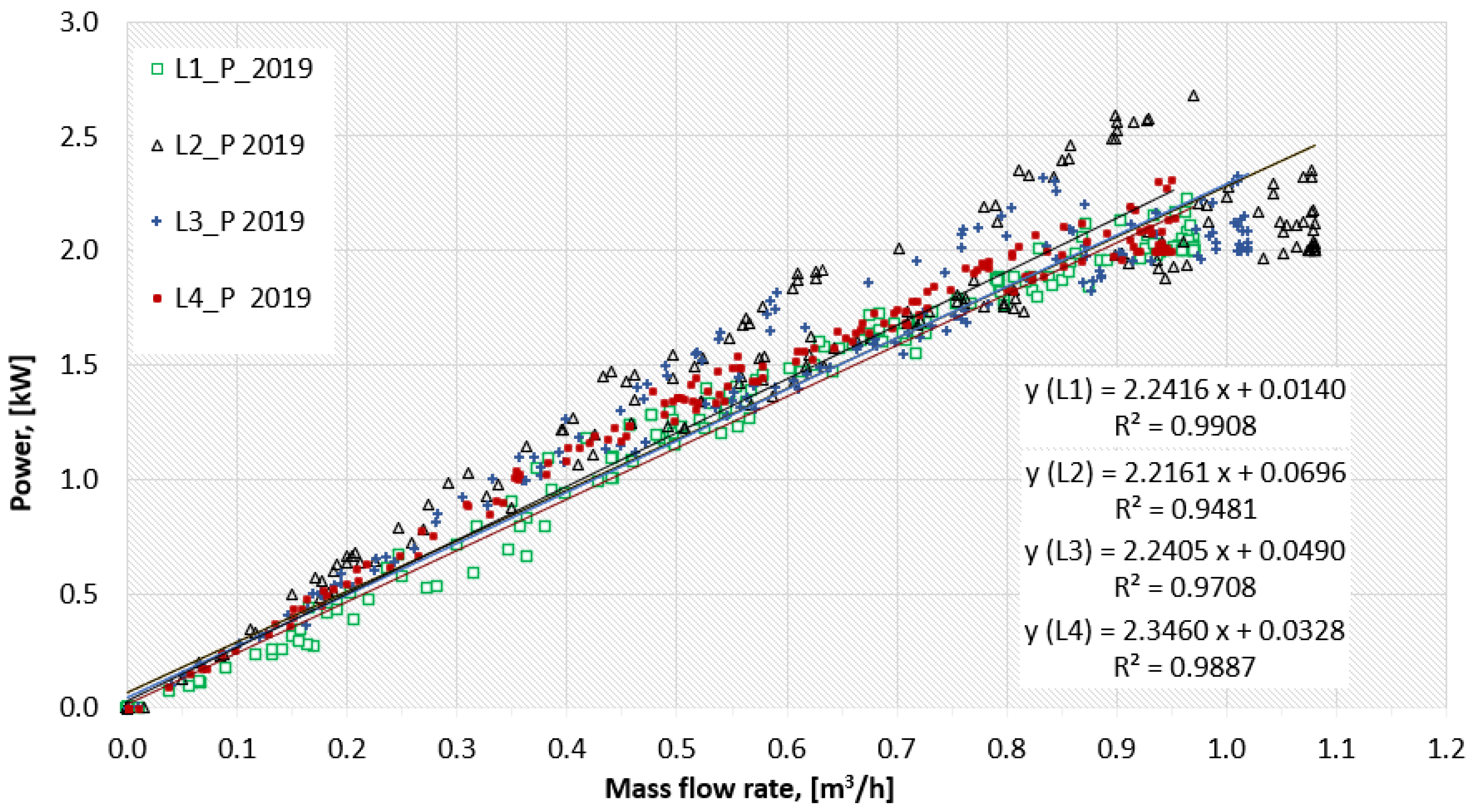

3. Results and Discussion

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Parliament. European Parliament Resolution of 15 January 2020 on the European Green Deal 2019, 2956 (RSP). Available online: https://www.europarl.europa.eu/doceo/document/TA-9-2020-0005_EN.%20html (accessed on 10 March 2021).

- European Parliament. European Parliament resolution of 14 March 2019 on Climate Change-A European Strategic Long-Term Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy in Accordance with the Paris Agreement 2019, 2582(RSP). Available online: https://www.europarl.europa.eu/%20doceo/document/TA-8-2019-0217_EN.html (accessed on 9 March 2021).

- International Energy Agency (IEA). Global Status Report for Buildings and Construction 2019; IEA: Paris, France, 2019; Available online: https://www.iea.org/reports/global-status-report-for-buildings-and-construction (accessed on 9 March 2021).

- Zhao, Y.; Pang, Z.; Huang, Y.; Ma, Z. An efficient hybrid model for thermal analysis of deep borehole heat exchangers. Geotherm. Energy 2020, 8, 1–31. [Google Scholar] [CrossRef]

- Zarrella, A.; Emmi, G.; Graci, S.; De Carli, M.; Cultrera, M.; Santa, G.D.; Galgaro, A.; Bertermann, D.; Müller, J.; Pockelé, L.; et al. Thermal Response Testing Results of Different Types of Borehole Heat Exchangers: An Analysis and Comparison of Interpretation Methods. Energies 2017, 10, 801. [Google Scholar] [CrossRef]

- Minaei, A.; Maerefat, M. A new analytical model for short-term borehole heat exchanger based on thermal resistance capacity model. Energy Build. 2017, 146, 233–242. [Google Scholar] [CrossRef]

- Neuberger, P.; Adamovský, R. Analysis and Comparison of Some Low-Temperature Heat Sources for Heat Pumps. Energies 2019, 12, 1853. [Google Scholar] [CrossRef]

- Blázquez, C.S.; Martín, A.F.; Nieto, I.M.; García, P.C.; Pérez, L.S.S.; González-Aguilera, D. Efficiency Analysis of the Main Components of a Vertical Closed-Loop System in a Borehole Heat Exchanger. Energies 2017, 10, 201. [Google Scholar] [CrossRef]

- Rad, F.M.; Fung, A.S.; Rosen, M.A. An integrated model for designing a solar community heating system with borehole thermal storage. Energy Sustain. Dev. 2017, 36, 6–15. [Google Scholar] [CrossRef]

- Rad, F.M.; Fung, A.S. Solar community heating and cooling system with borehole thermal energy storage—Review of systems. Renew. Sustain. Energy Rev. 2016, 60, 1550–1561. [Google Scholar] [CrossRef]

- Liu, Z.; Li, R.; Wang, D.; Li, H.; Shi, L. Multilayer quasi-three-dimensional model for the heat transfer inside the borehole wall of a vertical ground heat exchanger. Geothermics 2020, 83, 101711. [Google Scholar] [CrossRef]

- Al-Temeemi, A.; Harris, D. The generation of subsurface temperature profiles for Kuwait. Energy Build. 2001, 33, 837–841. [Google Scholar] [CrossRef]

- Ouzzane, M.; Eslami-Nejad, P.; Aidoun, Z.; Lamarche, L. Analysis of the convective heat exchange effect on the undisturbed ground temperature. Sol. Energy 2014, 108, 340–347. [Google Scholar] [CrossRef]

- Pan, A.; Lu, L.; Tian, Y. A new analytical model for short vertical ground heat exchangers with Neumann and Robin boundary conditions on ground surface. Int. J. Therm. Sci. 2020, 152, 106326. [Google Scholar] [CrossRef]

- Nian, Y.-L.; Wang, X.-Y.; Xie, K.; Cheng, W.-L. Estimation of ground thermal properties for coaxial BHE through distributed thermal response test. Renew. Energy 2020, 152, 1209–1219. [Google Scholar] [CrossRef]

- Boban, L.; Soldo, V.; Fujii, H. Investigation of heat pump performance in heterogeneous ground. Energy Convers. Manag. 2020, 211, 112736. [Google Scholar] [CrossRef]

- Ahmadfard, M.; Bernier, M. A review of vertical ground heat exchanger sizing tools including an inter-model comparison. Renew. Sustain. Energy Rev. 2019, 110, 247–265. [Google Scholar] [CrossRef]

- Sailer, E.; Taborda, D.M.; Zdravković, L. A new approach to estimating temperature fields around a group of vertical ground heat exchangers in two-dimensional analyses. Renew. Energy 2018, 118, 579–590. [Google Scholar] [CrossRef]

- Hu, J. An improved analytical model for vertical borehole ground heat exchanger with multiple-layer substrates and groundwater flow. Appl. Energy 2017, 202, 537–549. [Google Scholar] [CrossRef]

- Morchio, S.; Fossa, M. On the ground thermal conductivity estimation with coaxial borehole heat exchangers according to different undisturbed ground temperature profiles. Appl. Therm. Eng. 2020, 173, 115198. [Google Scholar] [CrossRef]

- Beier, R.A. Thermal response tests on deep borehole heat exchangers with geothermal gradient. Appl. Therm. Eng. 2020, 178, 115447. [Google Scholar] [CrossRef]

- Gónzález-Santander, J.L. Asymptotic expansions for the ground heat transfer due to a borehole heat exchanger with a Neumann boundary condition. J. Eng. Math. 2019, 117, 47–64. [Google Scholar] [CrossRef]

- Kerme, E.D.; Fung, A.S. Heat transfer simulation, analysis and performance study of single U-tube borehole heat exchanger. Renew. Energy 2020, 145, 1430–1448. [Google Scholar] [CrossRef]

- Claesson, J.; Javed, S. Explicit Multipole Formulas for Calculating Thermal Resistance of Single U-Tube Ground Heat Exchangers. Energies 2018, 11, 214. [Google Scholar] [CrossRef]

- Bakirci, K. Evaluation of the performance of a ground-source heat-pump system with series GHE (ground heat exchanger) in the cold climate region. Energy 2010, 35, 3088–3096. [Google Scholar] [CrossRef]

- Luo, J.; Rohn, J.; Bayer, M.; Priess, A.; Wilkmann, L.; Xiang, W. Heating and cooling performance analysis of a ground source heat pump system in Southern Germany. Geothermics 2015, 53, 57–66. [Google Scholar] [CrossRef]

- Sivasakthivel, T.; Murugesan, K.; Kumar, S.; Hu, P.; Kobiga, P. Experimental study of thermal performance of a ground source heat pump system installed in a Himalayan city of India for composite climatic conditions. Energy Build. 2016, 131, 193–206. [Google Scholar] [CrossRef]

- Sivasakthivel, T.; Philippe, M.; Murugesan, K.; Verma, V.; Hu, P. Experimental thermal performance analysis of ground heat exchangers for space heating and cooling applications. Renew. Energy 2017, 113, 1168–1181. [Google Scholar] [CrossRef]

- Zhai, X.; Cheng, X.; Wang, R. Heating and cooling performance of a minitype ground source heat pump system. Appl. Therm. Eng. 2017, 111, 1366–1370. [Google Scholar] [CrossRef]

- Atwany, H.; Hamdan, M.O.; Abu-Nabah, B.A.; Alami, A.H.; Attom, M. Experimental evaluation of ground heat exchanger in UAE. Renew. Energy 2020, 159, 538–546. [Google Scholar] [CrossRef]

- Vella, C.; Borg, S.P.; Micallef, D. The Effect of Shank-Space on the Thermal Performance of Shallow Vertical U-Tube Ground Heat Exchangers. Energies 2020, 13, 602. [Google Scholar] [CrossRef]

- Zarrella, A.; Zecchin, R.; Pasquier, P.; Guzzon, D.; Prataviera, E.; Vivian, J.; De Carli, M.; Emmi, G. Analysis of Retrofit Solutions of a Ground Source Heat Pump System: An Italian Case Study. Energies 2020, 13, 5680. [Google Scholar] [CrossRef]

- Bartolini, N.; Casasso, A.; Bianco, C.; Sethi, R. Environmental and Economic Impact of the Antifreeze Agents in Geothermal Heat Exchangers. Energies 2020, 13, 5653. [Google Scholar] [CrossRef]

- Badenes, B.; Pla, M.; Ángel, M.; Magraner, T.; Soriano, J.; Urchueguía, J.F. Theoretical and Experimental Cost-Benefit Assessment of Borehole Heat Exchangers (BHEs) According to Working Fluid Flow Rate. Energies 2020, 13, 4925. [Google Scholar] [CrossRef]

- Bae, S.M.; Nam, Y.; Choi, J.M.; Lee, K.H.; Choi, J.S. Analysis on Thermal Performance of Ground Heat Exchanger According to Design Type Based on Thermal Response Test. Energies 2019, 12, 651. [Google Scholar] [CrossRef]

- Naicker, S.S.; Rees, S.J. Long-term high frequency monitoring of a large borehole heat exchanger array. Renew. Energy 2020, 145, 1528–1542. [Google Scholar] [CrossRef]

- Spitler, J.D.; Bernier, M. 2-Vertical borehole ground heat exchanger design methods. In Advances in Ground-Source Heat Pump Systems; Rees, S.J., Ed.; Woodhead Publishing: Amsterdam, The Netherlands, 2016; pp. 29–61. ISBN 978-0-08-100311-4. [Google Scholar]

- Kusuda, T.; Achenbach, P.R. Earth temperature and thermal diffusivity at selected stations in the United States. Earth Temp. Therm. Diffus. Sel. Stn. 1965, 71. [Google Scholar] [CrossRef]

- Nian, Y.-L.; Cheng, W.-L. Analytical g-function for vertical geothermal boreholes with effect of borehole heat capacity. Appl. Therm. Eng. 2018, 140, 733–744. [Google Scholar] [CrossRef]

- Yu, X.; Li, H.; Yao, S.; Nielsen, V.; Heller, A. Development of an efficient numerical model and analysis of heat transfer performance for borehole heat exchanger. Renew. Energy 2020, 152, 189–197. [Google Scholar] [CrossRef]

- Wang, C.-L.; Li, H.; Huang, Z.-J.; Lu, Y.-H.; Huang, X.-J.; Gan, L. A new heat transfer model for single U-pipe ground heat exchanger. Appl. Therm. Eng. 2019, 154, 400–406. [Google Scholar] [CrossRef]

- Ghoreishi-Madiseh, S.A.; Kuyuk, A.F.; de Brito, M.A.R. An analytical model for transient heat transfer in ground-coupled heat exchangers of closed-loop geothermal systems. Appl. Therm. Eng. 2019, 150, 696–705. [Google Scholar] [CrossRef]

- Li, P.; Guan, P.; Zheng, J.; Dou, B.; Tian, H.; Duan, X.; Liu, H. Field Test and Numerical Simulation on Heat Transfer Performance of Coaxial Borehole Heat Exchanger. Energies 2020, 13, 5471. [Google Scholar] [CrossRef]

- Lee, S.-M.; Park, S.-H.; Jang, Y.-S.; Kim, E.-J. Proposition of Design Capacity of Borehole Heat Exchangers for Use in the Schematic-Design Stage. Energies 2021, 14, 822. [Google Scholar] [CrossRef]

- Javadi, H.; Urchueguia, J.F.; Ajarostaghi, S.S.M.; Badenes, B. Numerical Study on the Thermal Performance of a Single U-Tube Borehole Heat Exchanger Using Nano-Enhanced Phase Change Materials. Energies 2020, 13, 5156. [Google Scholar] [CrossRef]

- Katsura, T.; Sakata, Y.; Ding, L.; Nagano, K. Development of Simulation Tool for Ground Source Heat Pump Systems Influenced by Ground Surface. Energies 2020, 13, 4491. [Google Scholar] [CrossRef]

- Mitchell, M.S.; Spitler, J.D. An Enhanced Vertical Ground Heat Exchanger Model for Whole-Building Energy Simulation. Energies 2020, 13, 4058. [Google Scholar] [CrossRef]

- Jahanbin, A.; Semprini, G.; Impiombato, A.N.; Biserni, C.; Di Schio, E.R. Effects of the Circuit Arrangement on the Thermal Performance of Double U-Tube Ground Heat Exchangers. Energies 2020, 13, 3275. [Google Scholar] [CrossRef]

- Hałaj, E.; Pająk, L.; Papiernik, B. Finite Element Modeling of Geothermal Source of Heat Pump in Long-Term Operation. Energies 2020, 13, 1341. [Google Scholar] [CrossRef]

- Katsura, T.; Higashitani, T.; Fang, Y.; Sakata, Y.; Nagano, K.; Akai, H.; Oe, M. A New Simulation Model for Vertical Spiral Ground Heat Exchangers Combining Cylindrical Source Model and Capacity Resistance Model. Energies 2020, 13, 1339. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, T.; Li, B.; Jiang, Y. Comparison of Four Methods for Borehole Heat Exchanger Sizing Subject to Thermal Response Test Parameter Estimation. Energies 2019, 12, 4067. [Google Scholar] [CrossRef]

- Naldi, C.; Zanchini, E. Full-Time-Scale Fluid-to-Ground Thermal Response of a Borefield with Uniform Fluid Temperature. Energies 2019, 12, 3750. [Google Scholar] [CrossRef]

- Quaggiotto, D.; Zarrella, A.; Emmi, G.; De Carli, M.; Pockelé, L.; Vercruysse, J.; Psyk, M.; Righini, D.; Galgaro, A.; Mendrinos, D.; et al. Simulation-Based Comparison Between the Thermal Behavior of Coaxial and Double U-Tube Borehole Heat Exchangers. Energies 2019, 12, 2321. [Google Scholar] [CrossRef]

- Rivoire, M.; Casasso, A.; Piga, B.; Sethi, R. Assessment of Energetic, Economic and Environmental Performance of Ground-Coupled Heat Pumps. Energies 2018, 11, 1941. [Google Scholar] [CrossRef]

- Sun, X.-H.; Yan, H.; Massoudi, M.; Chen, Z.-H.; Wu, W.-T. Numerical Simulation of Nanofluid Suspensions in a Geothermal Heat Exchanger. Energies 2018, 11, 919. [Google Scholar] [CrossRef]

- Alberti, L.; Angelotti, A.; Antelmi, M.; La Licata, I. A Numerical Study on the Impact of Grouting Material on Borehole Heat Exchangers Performance in Aquifers. Energies 2017, 10, 703. [Google Scholar] [CrossRef]

- Puttige, A.R.; Andersson, S.; Östin, R.; Olofsson, T. A Novel Analytical-ANN Hybrid Model for Borehole Heat Exchanger. Energies 2020, 13, 6213. [Google Scholar] [CrossRef]

- Lei, X.; Zheng, X.; Duan, C.; Ye, J.; Liu, K. Three-Dimensional Numerical Simulation of Geothermal Field of Buried Pipe Group Coupled with Heat and Permeable Groundwater. Energies 2019, 12, 3698. [Google Scholar] [CrossRef]

- Ma, Z.; Jia, G.; Cui, X.; Xia, Z.; Zhang, Y.; Jin, L. Analysis on variations of ground temperature field and thermal radius caused by ground heat exchanger crossing an aquifer layer. Appl. Energy 2020, 276, 115453. [Google Scholar] [CrossRef]

- Serageldin, A.A.; Radwan, A.; Sakata, Y.; Katsura, T.; Nagano, K. The Effect of Groundwater Flow on the Thermal Performance of a Novel Borehole Heat Exchanger for Ground Source Heat Pump Systems: Small Scale Experiments and Numerical Simulation. Energies 2020, 13, 1418. [Google Scholar] [CrossRef]

- Park, S.; Lee, S.; Lee, H.; Pham, K.; Choi, H. Effect of Borehole Material on Analytical Solutions of the Heat Transfer Model of Ground Heat Exchangers Considering Groundwater Flow. Energies 2016, 9, 318. [Google Scholar] [CrossRef]

- Badenes, B.B.; Pla, M.; Ángel, M.; Lemus-Zúñiga, L.-G.; Mauleón, B.S.; Urchueguía, J.F. On the Influence of Operational and Control Parameters in Thermal Response Testing of Borehole Heat Exchangers. Energies 2017, 10, 1328. [Google Scholar] [CrossRef]

- Witte, H.J. Error analysis of thermal response tests. Appl. Energy 2013, 109, 302–311. [Google Scholar] [CrossRef]

- Lamarche, L.; Raymond, J.; Pambou, C.H.K. Evaluation of the Internal and Borehole Resistances during Thermal Response Tests and Impact on Ground Heat Exchanger Design. Energies 2017, 11, 38. [Google Scholar] [CrossRef]

- Kurevija, T.; Strpić, K.; Koščak-Kolin, S. Applying Petroleum the Pressure Buildup Well Test Procedure on Thermal Response Test—A Novel Method for Analyzing Temperature Recovery Period. Energies 2018, 11, 366. [Google Scholar] [CrossRef]

- Jensen-Page, L.; Loveridge, F.; Narsilio, G.A. Thermal Response Testing of Large Diameter Energy Piles. Energies 2019, 12, 2700. [Google Scholar] [CrossRef]

- Blázquez, C.S.; Piedelobo, L.; Fernández-Hernández, J.; Nieto, I.M.; Martín, A.F.; Lagüela, S.; González-Aguilera, D. Novel Experimental Device to Monitor the Ground Thermal Exchange in a Borehole Heat Exchanger. Energies 2020, 13, 1270. [Google Scholar] [CrossRef]

- Zhang, C.; Guo, Z.; Liu, Y.; Cong, X.; Peng, D. A review on thermal response test of ground-coupled heat pump systems. Renew. Sustain. Energy Rev. 2014, 40, 851–867. [Google Scholar] [CrossRef]

- Data from the Institute of Meteorology and Water Management. Available online: https://danepubliczne.imgw.pl/ (accessed on 11 January 2021). (In Polish).

- Łapa, M. Executive project. In Reconstruction of the WBiIŚ Building of the Bialystok University of Technology Together with the Construction of An Internal Monitoring Installation under the Project “Improving the Energy Efficiency of the PB Infrastructure Using Renewable Heat Sources”; Scope: Construction of the heat pump installation; Office Technika Grzewcza Solarsystem: Myślenice, Poland, 2014. (In Polish) [Google Scholar]

- Piotrowska-Woroniak, J. Preliminary Results of the Temperature Distribution Measurements Around the Vertical Ground Heat Exchangers Tubes. Ecol. Chem. Eng. S 2020, 27, 509–528. [Google Scholar] [CrossRef]

- Earth Energy Designer ver.4.20 Software. BLOCON AB: Lund, Sweden, (license for g.woroniak@pb.edu.pl).

- Port, P.C. Guidelines for Designing, Realization and Receiving Installations Powered by Heat Pumps; Part 1; Polish Organization for the Development of Heat Pump Technology: Cracow, Poland, 2013. (In Polish) [Google Scholar]

- Bigaj, Z. Project of Geological Works for Drilling Boreholes to Use Heat from the Earth; Hydrogeological Company PANGEA: Chrzanów, Poland, 2013. (In Polish) [Google Scholar]

- Verlag des Vereins Deutscher Ingenieure. Standard VDI 4640 Thermal use of the underground-Ground source heat pump systems. In Verein Deutscher Ingenieure. Richtlinien VDI 4640; Part 2; Düsseldorf Verlag des Vereins Deutscher Ingenieure: Alexisbad, Harzgerode, Germany, 2001. (In German) [Google Scholar]

- Baumann, K. First experiences with the geophysical borehole examination of geothermal probes; bbr Wasser, Kanal- & Rohrleitungsbau, 2010, 5. wvgw Wirtschafts- und Verlagsgesellschaft Gas und Wasser mbH Available online: http://www.blm-storkow.de/fileadmin/user_upload/dokumente/veroeffentlichungen/bbr_2010_Erdwaermesonden.pdf (accessed on 11 January 2021). (In German).

- Mirowski, A. Ground source heat sources-how to study their thermal efficiency? Methods for determining the soil conduc-tivity coefficient. InstalReporter 2016, 2, 45–48. (In Polish) [Google Scholar]

- Baumann, K.; Tewes, S.; Lang, D.; Rogge, R. Subsequent sealing of the annular space for the dismantling of wells and groundwater measuring points; Energie wasser-praxis 2020, 8. and bbr Wasser, Kanal- & Rohrleitungsbau, 2020, 4. wvgw Wirtschafts- und Verlagsgesllschaft Gas und Wasser mbH. Available online: http://www.blm-storkow.de/fileadmin/user_upload/dokumente/veroeffentlichungen/Rueckbau_ewp.pdf (accessed on 12 January 2021). (In German).

- Mosch, S.; Pietzner, O.; Baumann, K.; Goldbeck, J. Impulse-based bulk Material Consolidation-hydraulic changes in the con-struction of a new well; Energie wasser-praxis 2020, 8 and bbr Wasser, Kanal- & Rohrleitungsbau 2020, 11. wvgw Wirtschafts- und Verlagsgesllschaft Gas und Wasser mbH. Available online: http://www.blm-storkow.de/fileadmin/user_upload/dokumente/veroeffentlichungen/Schuettgutkonsolidierung.pdf (accessed on 10 January 2021). (In German).

- Stefanowicz, E.; Szulgowska-Zgrzywa, M.; Fidorów-Kaprawy, N. Analysis of the ground-source heat pump operation with various heat-carrier fluids in the lower heat source. E3S Web Conf. 2018, 44, 00168. [Google Scholar] [CrossRef]

| Month | Average Outside Air Temperature [°C] | The Number of Degree-Days [Day/K·Year] | Minimum Temperature Near the Ground [°C] | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Statistical 1971–2000 | 2018 | 2019 | Statistical 1971–2000 | 2018 | 2019 | 1971–2000 | 2018 | 2019 | |

| I | −4.9 | −1.3 | −3.7 | 709.9 | 598.3 | 672.7 | −21.0 | −13.3 | −22.2 |

| II | −2.0 | −4.5 | 1.8 | 560.0 | 630.0 | 453.6 | −20.7 | −18.6 | −10.3 |

| III | 1.7 | −1.2 | 4.2 | 505.3 | 595.2 | 427.8 | −15.9 | −21.8 | −7.2 |

| IV | 7.3 | 11.7 | 8.9 | 321.0 | 63.0 | 209.3 | −7.9 | −6.7 | −8.7 |

| V | 13.2 | 16.7 | 12.9 | 48.0 | 0 | 0 | −4.0 | 0.5 | −6.3 |

| VI | 15.9 | 18.0 | 20.8 | 0 | 0 | 0 | 0.3 | −0.6 | 5.4 |

| VII | 17.3 | 19.8 | 17.3 | 0 | 0 | 0 | 3.4 | 8.7 | 2.6 |

| VIII | 14.5 | 19.2 | 17.8 | 0 | 0 | 0 | 2.0 | 3.8 | 5.9 |

| IX | 12.1 | 14.6 | 13.0 | 59.0 | 0 | 35 | −3.4 | −3.2 | −3.8 |

| X | 7.1 | 8.4 | 9.8 | 337.9 | 297.6 | 254.2 | −8.1 | −3.4 | −6.0 |

| XI | 1.6 | 3.0 | 5.4 | 492.0 | 450.0 | 378.0 | −12.3 | −12.0 | −4.5 |

| XII | −1.3 | −2.0 | 2.3 | 598.3 | 620.0 | 486.7 | −19.8 | −17.1 | −7.4 |

| No. | Layer | Participation in the Structure of the Ground | Lithology [74] | Thermal Conductivity λ, [W/(m·K)] | Volumetric Specific Heat [MJ/(m3·K)] | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Top | Bottom | Min | Max | Recommended | Min | Max | Recommended | |||

| 1 | 0 m | 2 m | 2/100 | Native soil | 0.27 | 0.75 | 0.40 | 1.31 | 1.59 | 1.40 |

| 2 | 2 m | 4 m | 2/100 | Clay dry | 0.40 | 0.90 | 0.40 | 1.51 | 1.62 | 1.60 |

| 3 | 4 m | 12 m | 8/100 | Sand and Gravel, saturated | 0.75 | 0.90 | 0.80 | 1.40 | 1.65 | 1.62 |

| 4 | 12 m | 40 m | 28/100 | Clay, moist-wet | 0.90 | 2.22 | 1.60 | 1.60 | 3.40 | 2.40 |

| 5 | 40 m | 45 m | 5/100 | Muds | 1.73 | 5.02 | 2.40 | 2.20 | 2.85 | 2.50 |

| 6 | 45 m | 100 m | 55/100 | Clay, moist-wet | 0.90 | 2.22 | 1.60 | 1.60 | 3.40 | 2.40 |

| Average weighted factor | 0.91 | 2.20 | 1.53 | 1.61 | 3.16 | 2.31 | ||||

| Variant | Thermal Conductivity λavg [W/(m·K)] | The Unit thermal Efficiency qv [W/m] | 100 m Borehole Power [kW] |

|---|---|---|---|

| V1 | 0.91 | 21.8 | 2.18 |

| V2 | 2.20 | 38.6 | 3.86 |

| V3 | 1.53 | 29.9 | 2.99 |

| V TRT | 1.76 ± 0.03 | 35.4 | 3.54 |

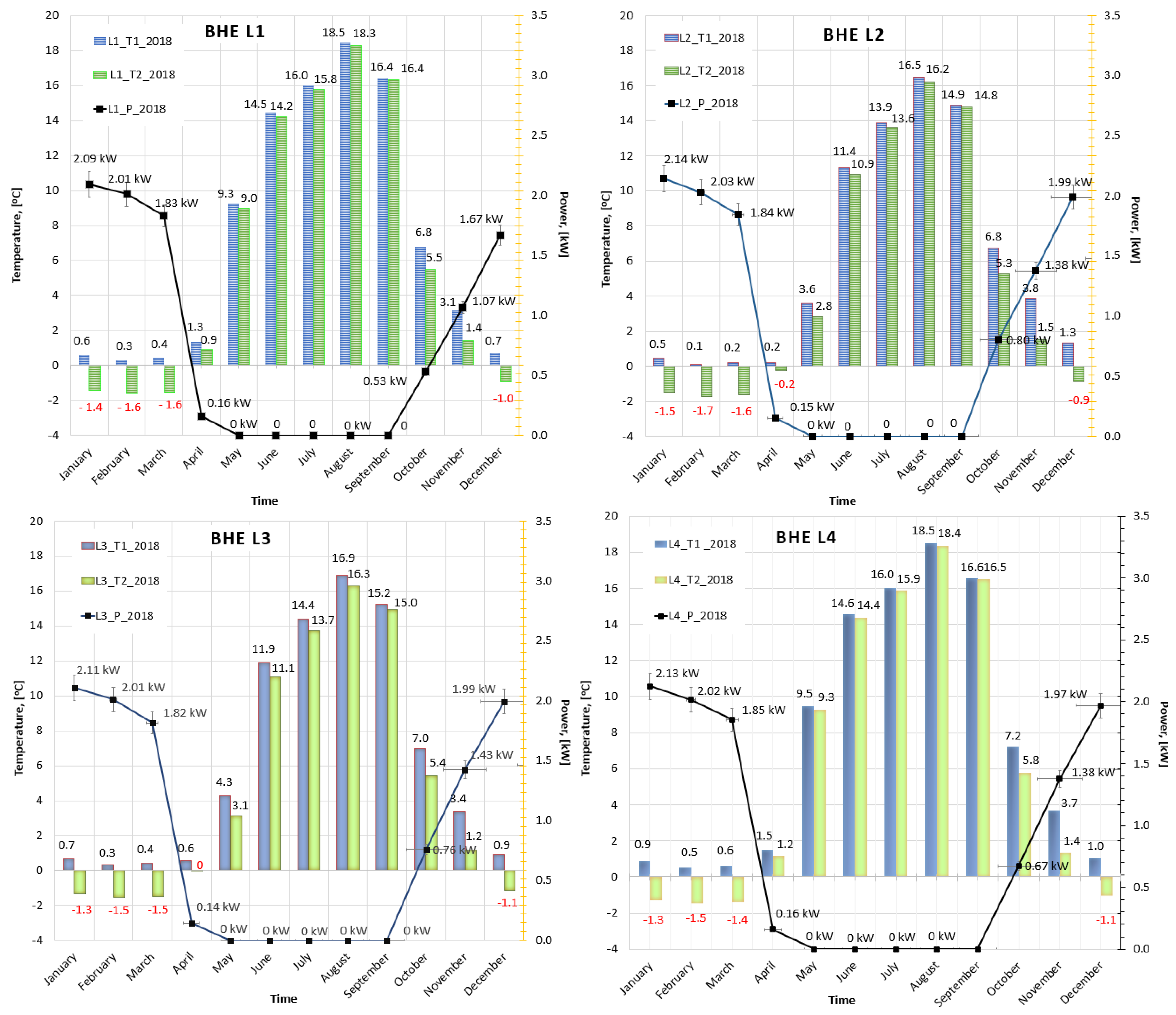

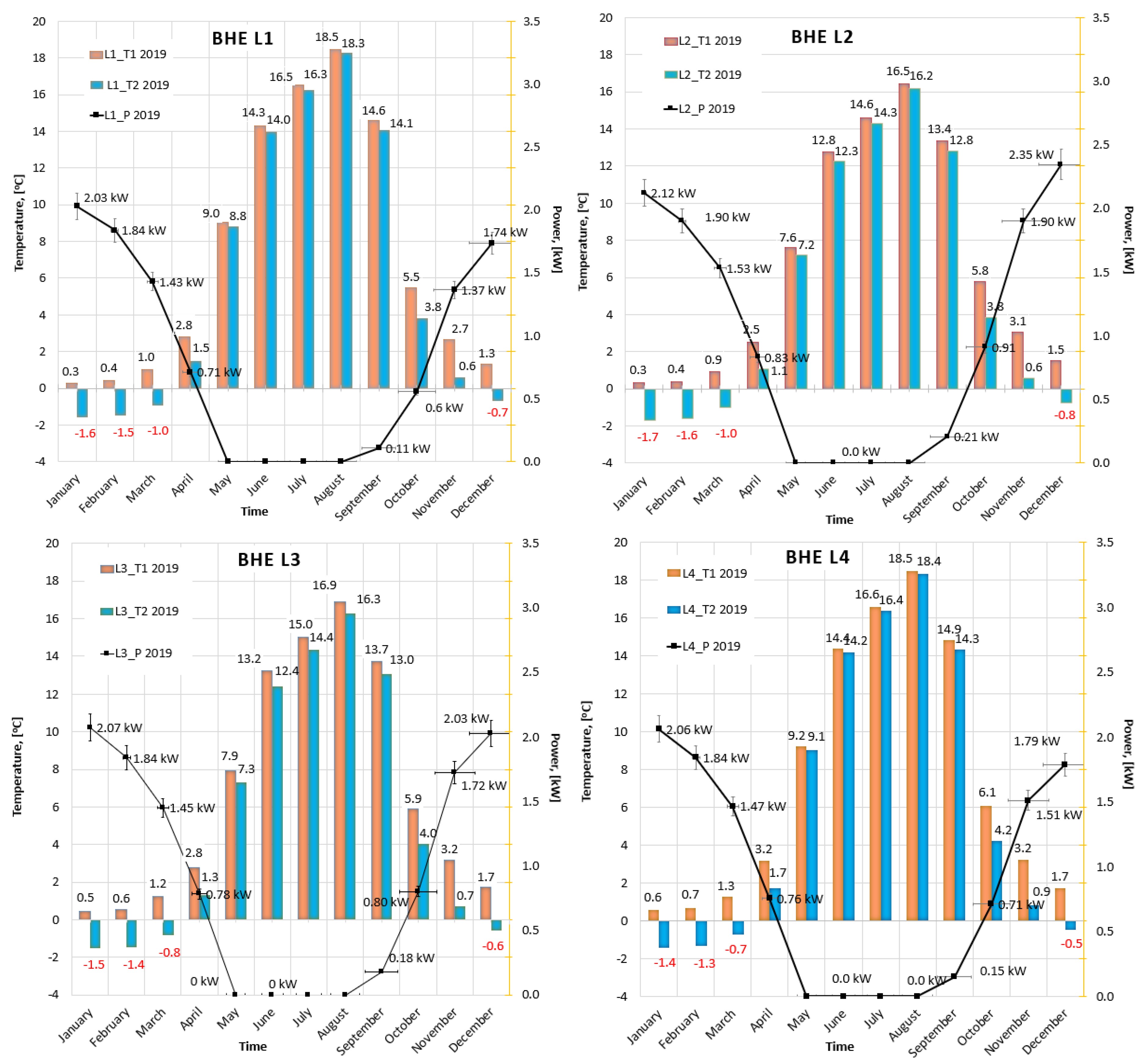

| No. | Date | Heat Pumps Work |

|---|---|---|

| 1 | 1 January 2018–10 April 2018 | duty cycle-on |

| 2 | 11 April 2018–30 September 2018 | duty cycle-off |

| 3 | 1 October 2018–23 April 2019 | duty cycle-on |

| 4 | 24 April 2019–23 September 2019 | duty cycle-off |

| 5 | 24 September 2019–31 December 2019 | duty cycle-on |

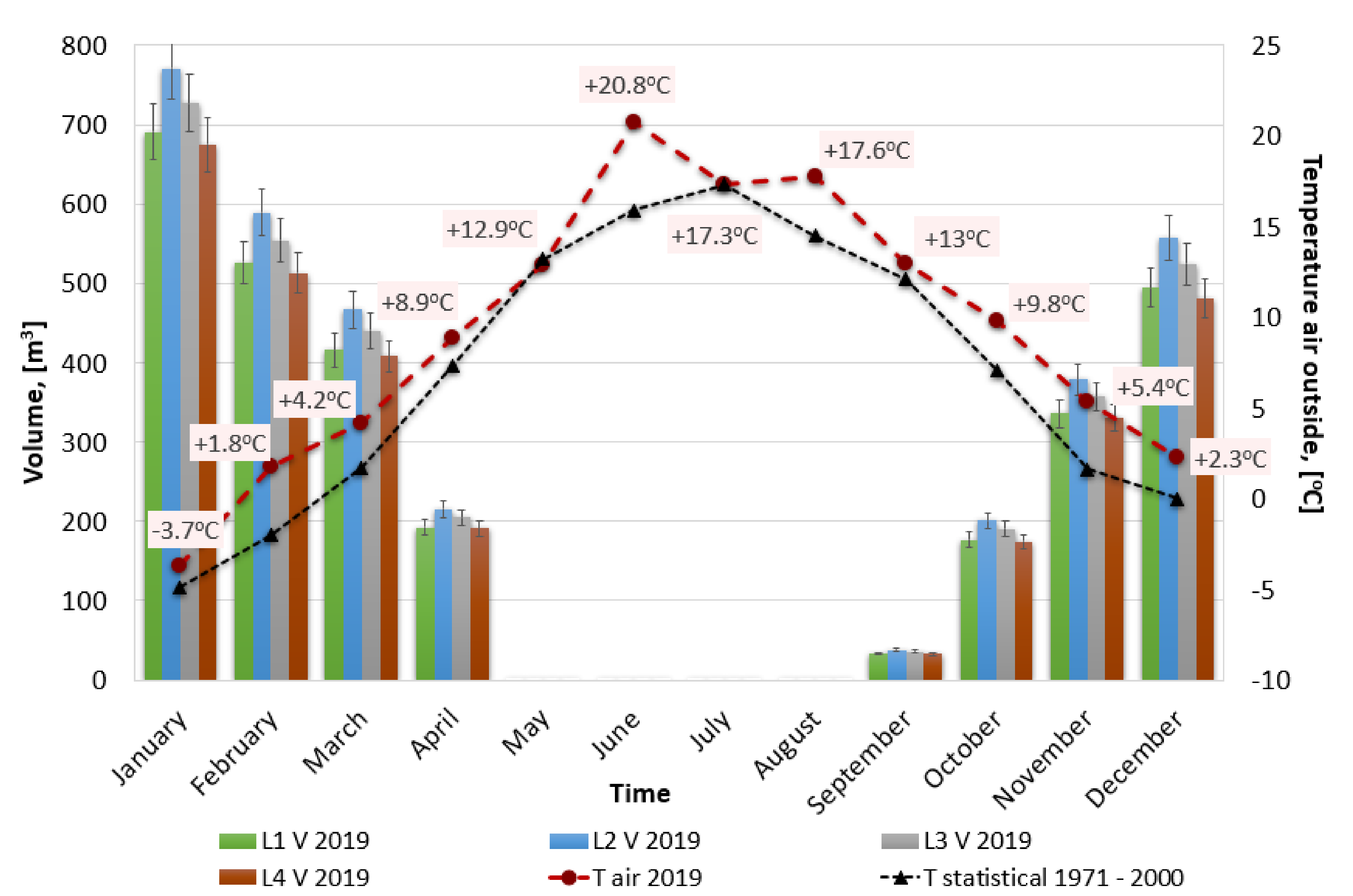

| BHE | Annual Energy Extracted from the Ground E [MJ] | Annual Brine Flow V [m3] | ||

|---|---|---|---|---|

| 2018 | 2019 | 2018 | 2019 | |

| L1 | 25530  | 25521  | 3069.64 | 2866.30 |

| L2 | 29921  | 29839  | 3480.88 | 3217.54 |

| L3 | 27941 | 27640 | 3265.18 | 3034.10 |

| L4 | 27141 | 25790 | 3043.57 | 2806.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piotrowska-Woroniak, J. Determination of the Selected Wells Operational Power with Borehole Heat Exchangers Operating in Real Conditions, Based on Experimental Tests. Energies 2021, 14, 2512. https://doi.org/10.3390/en14092512

Piotrowska-Woroniak J. Determination of the Selected Wells Operational Power with Borehole Heat Exchangers Operating in Real Conditions, Based on Experimental Tests. Energies. 2021; 14(9):2512. https://doi.org/10.3390/en14092512

Chicago/Turabian StylePiotrowska-Woroniak, Joanna. 2021. "Determination of the Selected Wells Operational Power with Borehole Heat Exchangers Operating in Real Conditions, Based on Experimental Tests" Energies 14, no. 9: 2512. https://doi.org/10.3390/en14092512

APA StylePiotrowska-Woroniak, J. (2021). Determination of the Selected Wells Operational Power with Borehole Heat Exchangers Operating in Real Conditions, Based on Experimental Tests. Energies, 14(9), 2512. https://doi.org/10.3390/en14092512