Striated Tire Yaw Marks—Modeling and Validation

Abstract

:1. Introduction

- determination of subsequent vehicle positions and orientation during critical movement by matching the position of individual wheels to the corresponding marks;

- estimation of the vehicle’s speed at the start of yawing.

- Camber angle of the wheel (which in turn depends on the suspension kinematics);

- Structure to the tire;

- Cornering, longitudinal and vertical stiffnesses of the tire (which depend among others things on tire pressure);

- Tire aspect ratio (sidewall height divided by tire width);

- Tire tread depth;

- Dynamic tire offset (pneumatic trail);

- Composition of rubber compound;

- Road surface properties; and

- Temperature in the contact patch.

2. Assumptions to the Model

- To describe the tired wheel–road interaction, a semi-physical, non-linear tire model TMeasy was used [17,18]. All its features, such as longitudinal and lateral forces, aligning moment, other moments resulting from the wheel kinematics, first-order dynamics for longitudinal, lateral and torsional strain, and dynamic tire offset are taken into account.

- The yaw mark creation model is universal, i.e., it applies to any curvilinear motion of a tire in lateral drift, when the wheel moves along any trajectory with variable curvature, and the wheel is subject to an unsteady force and moment as to the value and direction, calculated by solving the system of non-linear differential equations of vehicle dynamics.

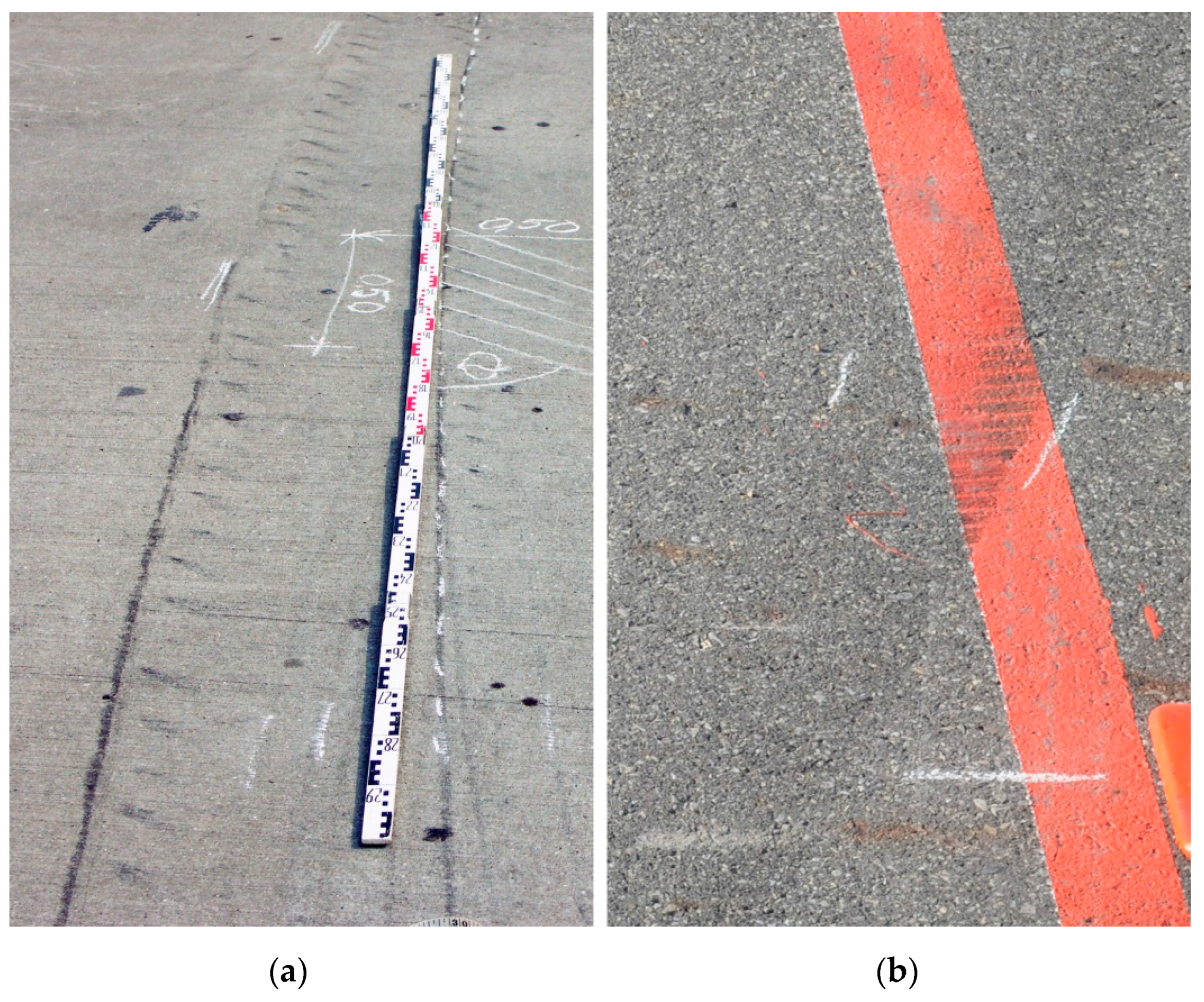

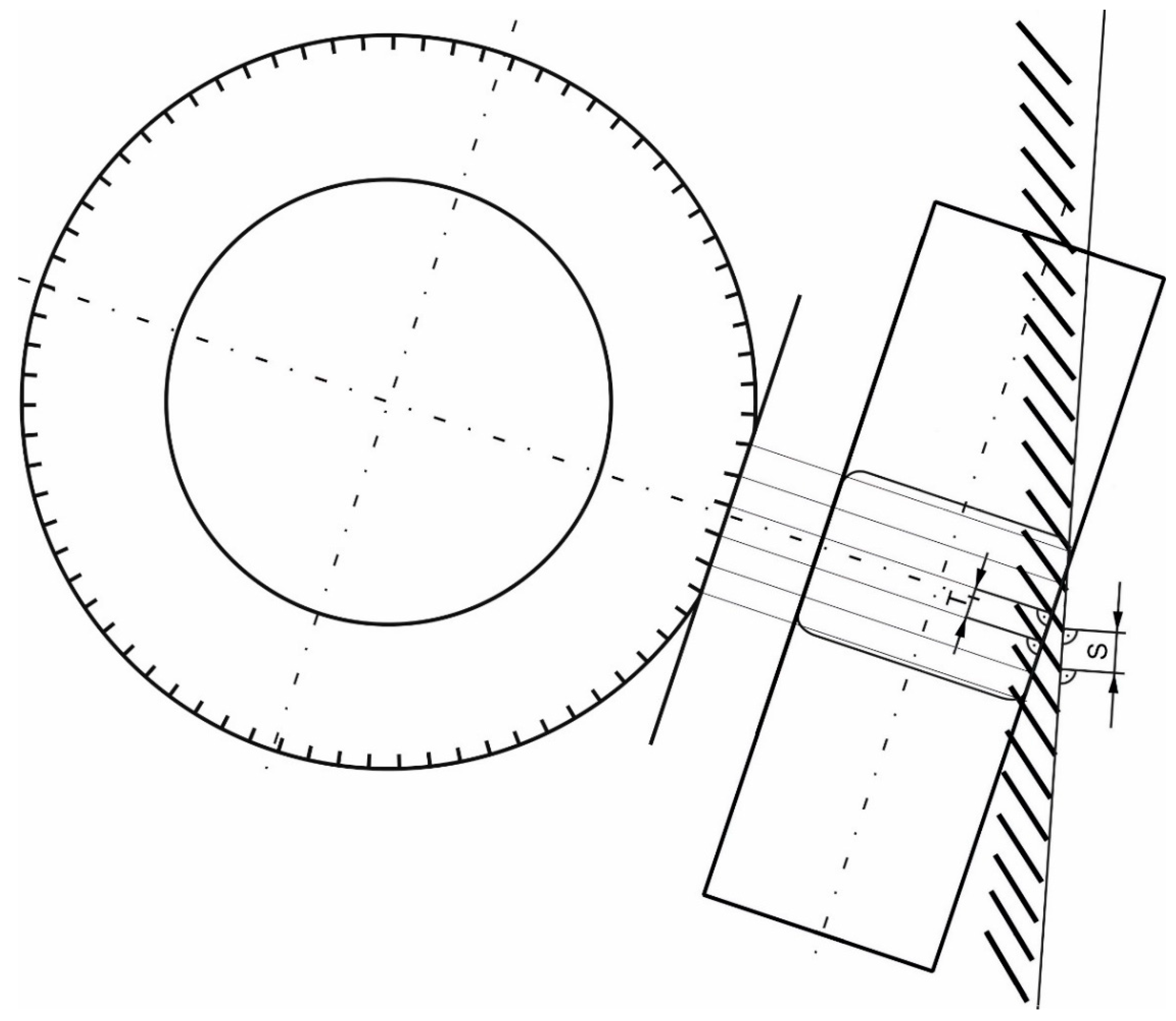

- As this area is in fact the dominant one, the yaw mark will be created by the tread elements of the tire shoulder forming the outer border (during curvilinear movement of the vehicle) of the patch in contact with the road. For the yaw mark curved to the left these will be the right patch border, and for the mark curved to the right the left patch border. As the striations being deposited by the internal tread elements of the patch are usually not very clear, they have been omitted; however, if necessary, it will be easy to extend the algorithm by following the model described.

- It is possible to define any, including non-uniform, pitch of the tread shoulder blocks of the tire.

- Semi-physical tire models of class TMeasy, Magic Formula [19], HSRI [20] etc. do not describe the tire in-plane buckling, therefore this phenomenon can instead be analyzed in two ways:

- (a)

- partially, i.e., as to the tire mark course and the striations direction only; it is then sufficient to enter any pitch of the tread shoulder blocks;

- (b)

- fully, i.e., as to the tire mark course, and striations direction and pitch, if the buckling pitch in the patch is known in some other way, which can be manually entered into the program.

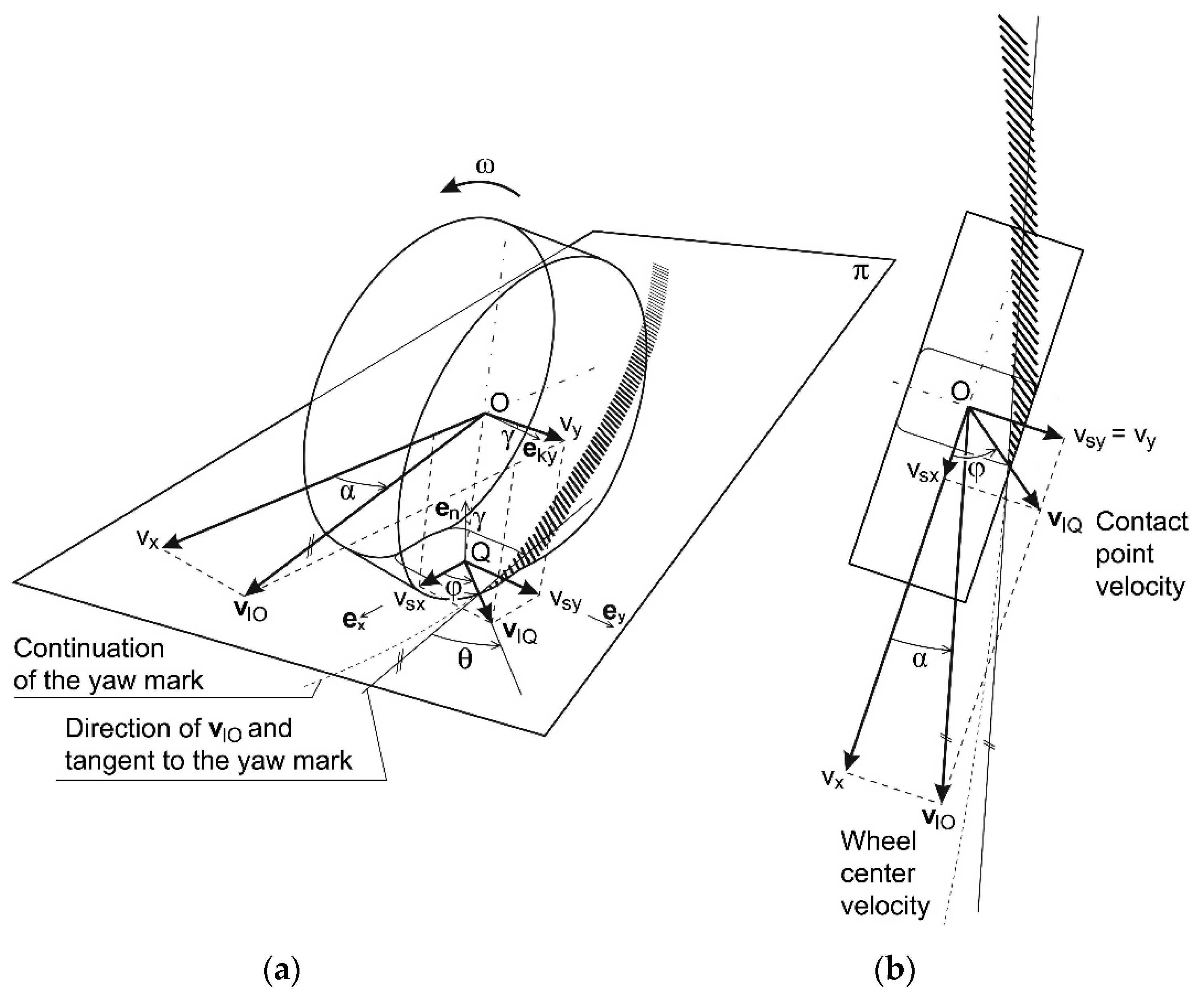

3. Basic Terms Concerning Movement of a Wheel in a Bend

- {}

- the symbol of a reference frame, e.g., the term {I} should be read “in the reference frame I”;

- {I}

- the ground-fixed inertial (global) reference frame with the origin at point I; the axis is parallel to the gravitational acceleration vector and points upward;

- vector from point I to wheel center O; the subscript after the comma denotes the reference frame in which this vector is observed—here {I};

- vector of absolute velocity of wheel center O, with respect to {I}.

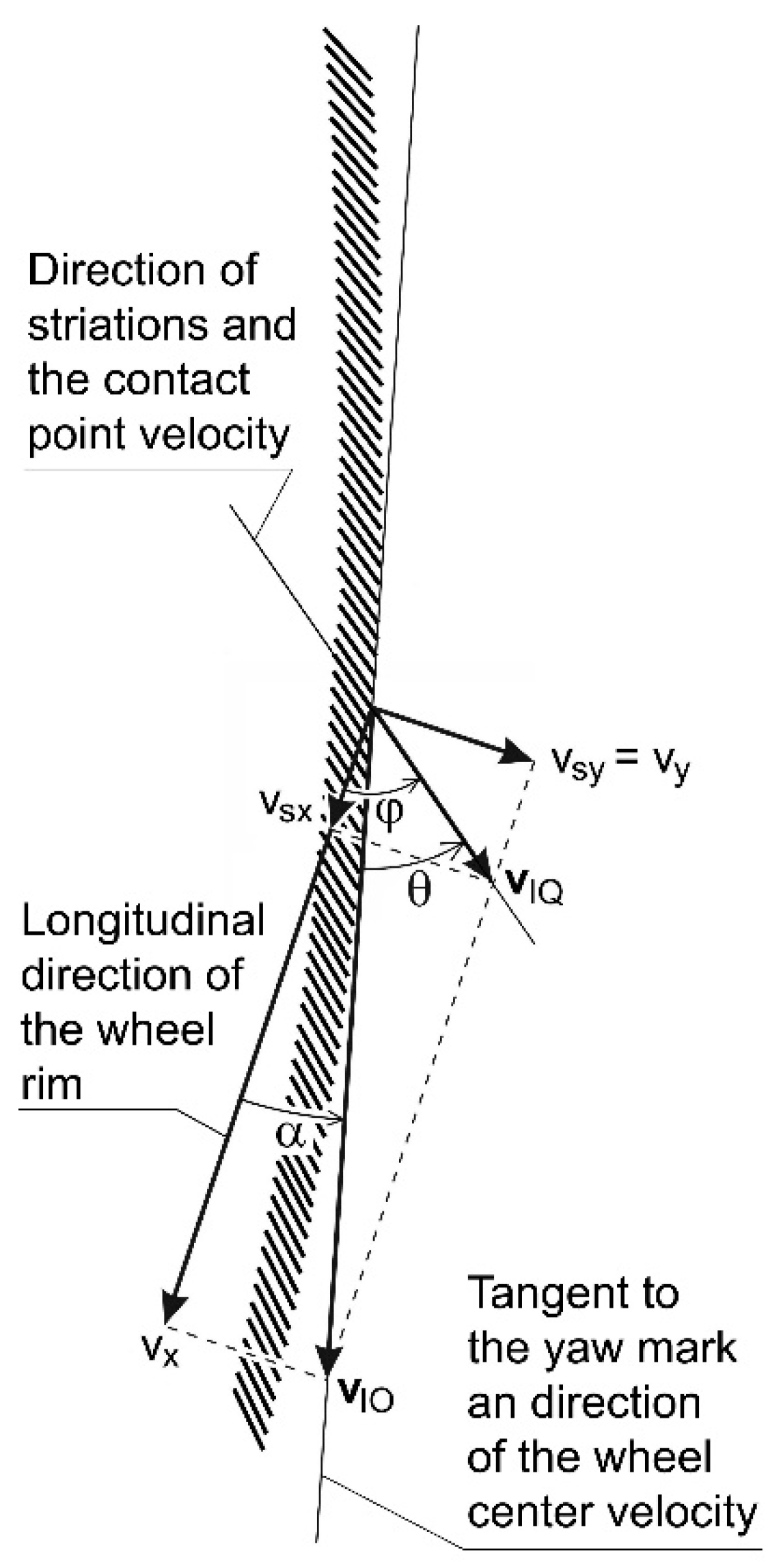

- and —components of the wheel center velocity vector parallel to π, the first of which lies on the direction of the longitudinal axis of the rim, and the other is perpendicular to it;

- —camber angle;

- —wheel slip angle;

- —wheel angular velocity about its spin axis given by the unit vector ;

- and —components of the absolute velocity vector of the contact point (wheel slip velocity); and are parallel to and , and read:

- —dynamic tire radius;

- —direction of the contact point velocity against the longitudinal axis of the wheel (rim).

4. Wheel Velocities and Slips Versus Geometry of the Striated Tire Mark

- S—the striation pitch measured along the yaw mark;

- T—the pitch of the tread shoulder blocks measured on the tire circumference.

- Measure the angle and distance S on the mark;

- Measure the distance T at the tire shoulder;

- Calculate the angles and from the formulae (11) and (12) respectively (note: in the case of non-steered rear wheels, when, in addition, the marks of other wheels allow one to discover successive angular positions of the vehicle by matching the corresponding wheels, the orientation of the rear wheel relative to the yaw mark is known, therefore angles and can be measured directly on the mark—see Figure 3);

- Calculate and from formulae (9) and (10).

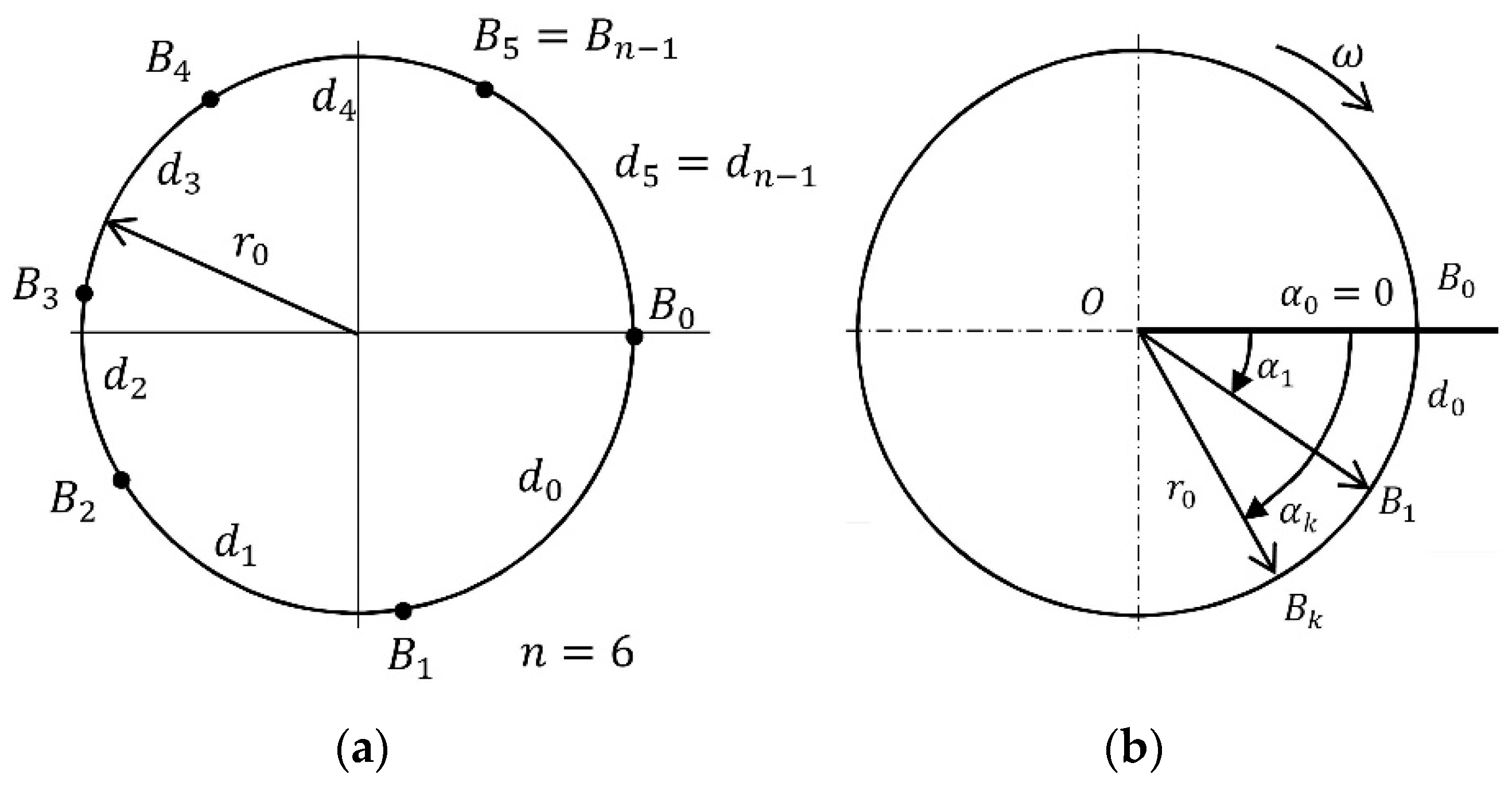

5. Model of Deposition of the Yaw Mark Striations on the Road Surface

- —number of blocks or grooves on the tread shoulder (consistently keeping to the chosen convention);

- , —point indicating the -th block (or groove);

- —distances between adjacent points measured along an arc: with typical tires, without making a significant error, these can be measured in a straight line;

- —number of simulation step;

- —current simulation time;

- —simulation timestep.

5.1. Determining the Position of Each Point Relative to the Wheel-Fixed Reference Frame {O}

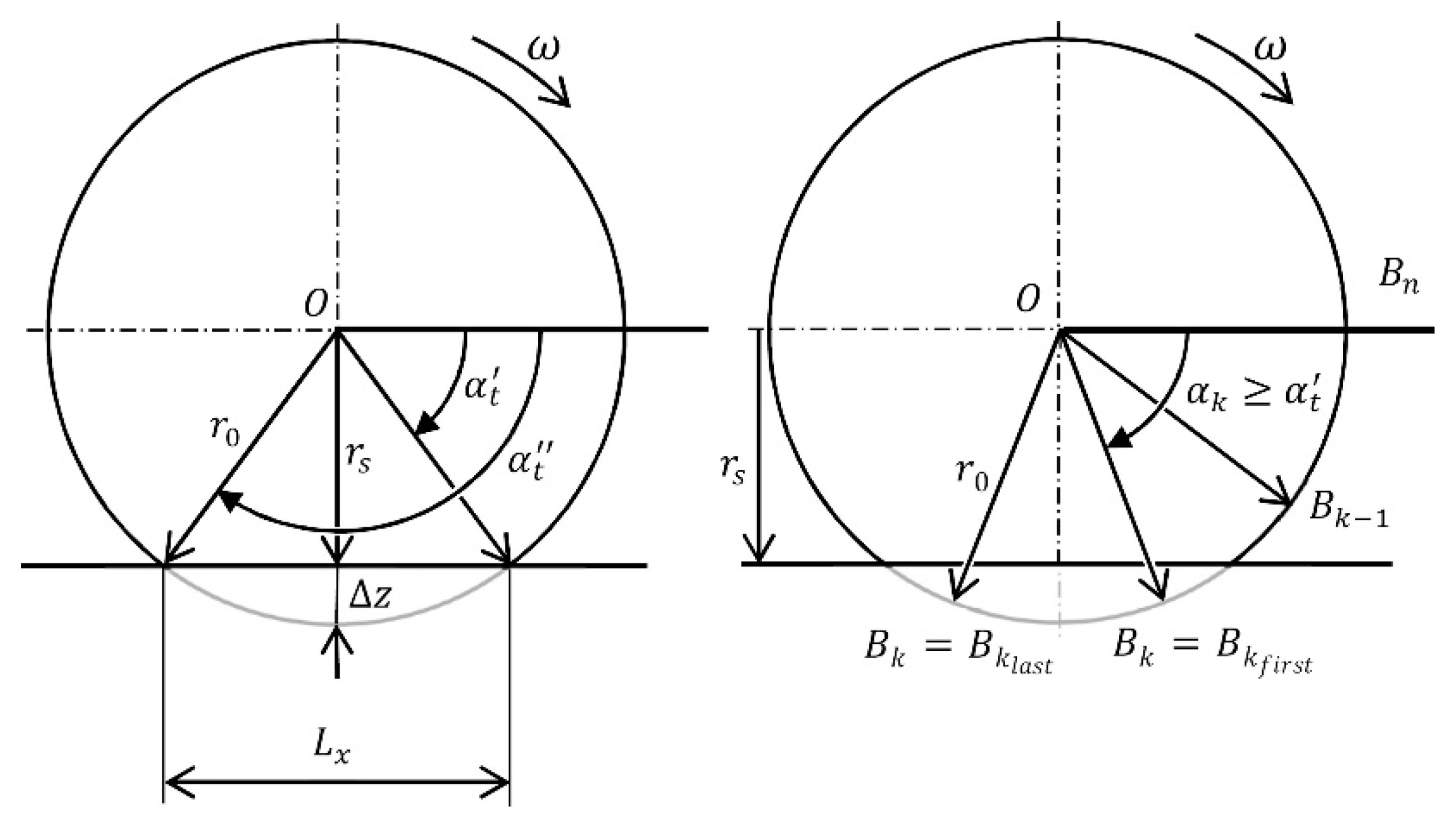

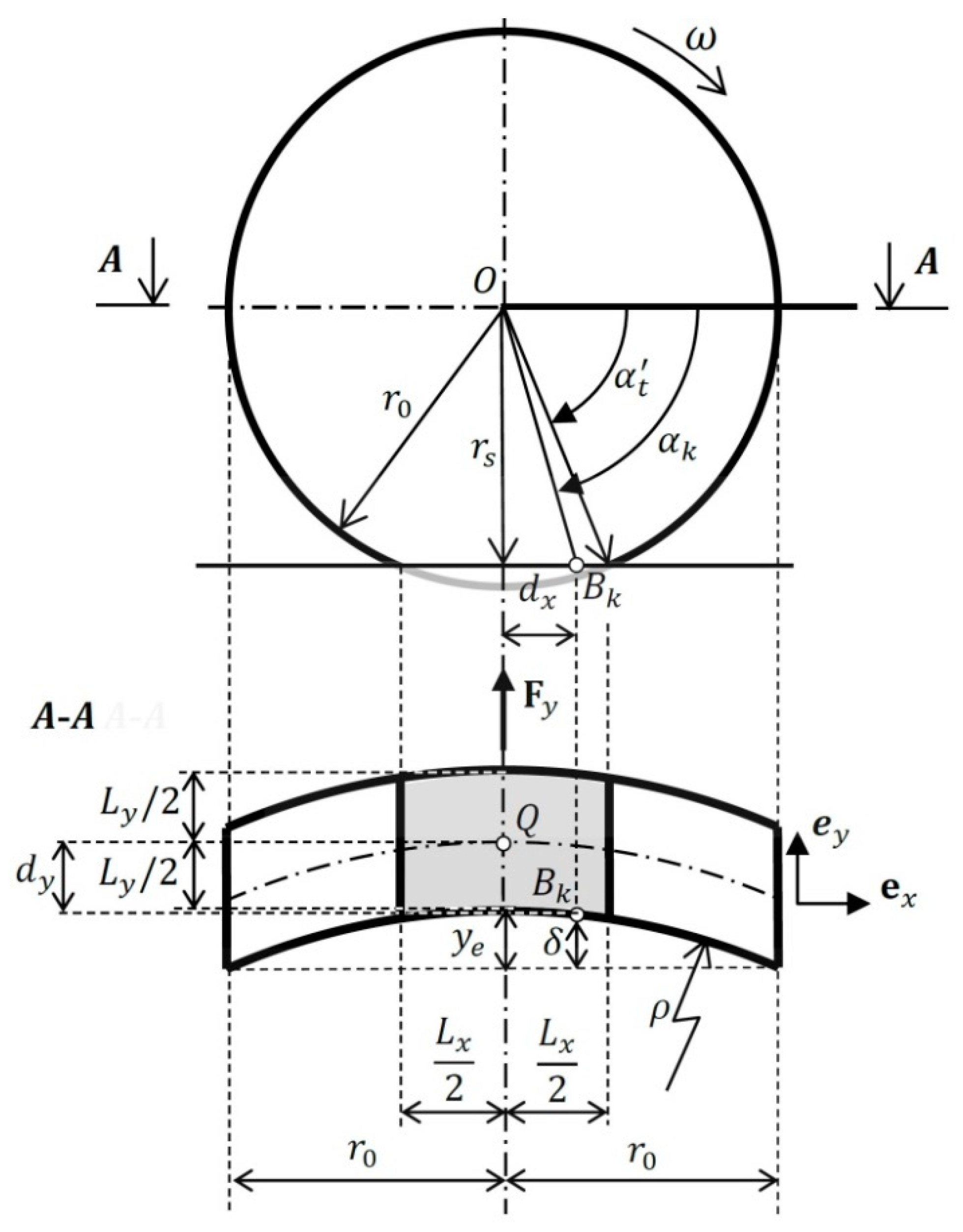

5.2. Calculation of the Characteristic Dimensions of the Contact Patch

- is the total tire deflection given by the formula:

- —the normal reaction of the roadway to the tire at the contact point;

- —the radial stiffness of the tire;

- —the loaded (static) tire radius;

- —the tire camber angle, i.e., the inclination of the rim center plane against the roadway normal.

5.3. Calculating the Geometry of Striations

- —current lateral force acting on the tire, calculated according to the TMeasy (or any other) tire model;

- —current normal force to the roadway acting on the tire;

- —tire-road friction coefficient; in general ;

- —percentage of the maximum horizontal force at which the yaw mark is to be made; by default 95% can be adopted.

- Incrementation of the index indicating the simulation step ;

- Time incrementation ;

- Calculation of the new angular position of the point ;where is the current angular velocity of the wheel about its spin in [rad];

- Checking if the wheel has not already made a full rotation—See Code 5 in Appendix A.

- Repeating the calculations from the formula (14)—strictly from the function Angular_position_of_block() (section Code 1 in Appendix A)—to formula (26);

- Archiving the coordinates of the patch points drawing the striations.

6. Validation and Discussion

6.1. Stage 1. Measurement of Time Histories of Vehicle Motion Parameters (Actual Data)

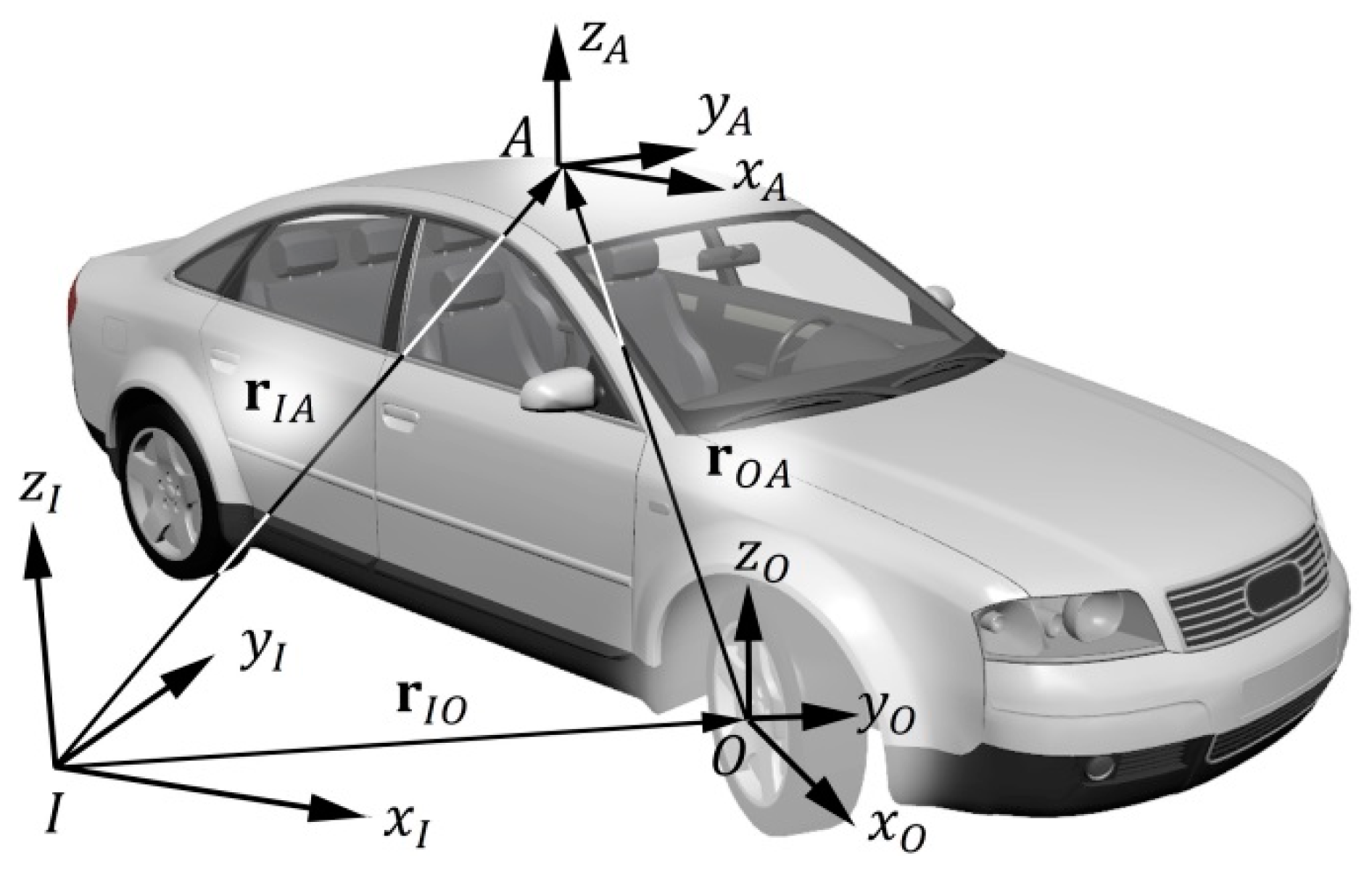

- A set of kinematic data fully describing the spatial movement of the vehicle, and, first of all, time histories of three components of the CG position vector and quasi-Euler body angles (transformations—see [23]);

- Time histories of the actual longitudinal and lateral slip of the front right wheel (transformations—see Appendix of [14]).

- —rotation matrix from the local, body fixed reference frame {A} to the global reference frame {I};

- —rotation matrix from from {A} to {O};

- —absolute velocity of the wheel center O in {I};

- —velocity of the GPS receiver mounting point A in {I};

- —angular velocity of the body in {A};

- —position vector from point O to A in {A}.

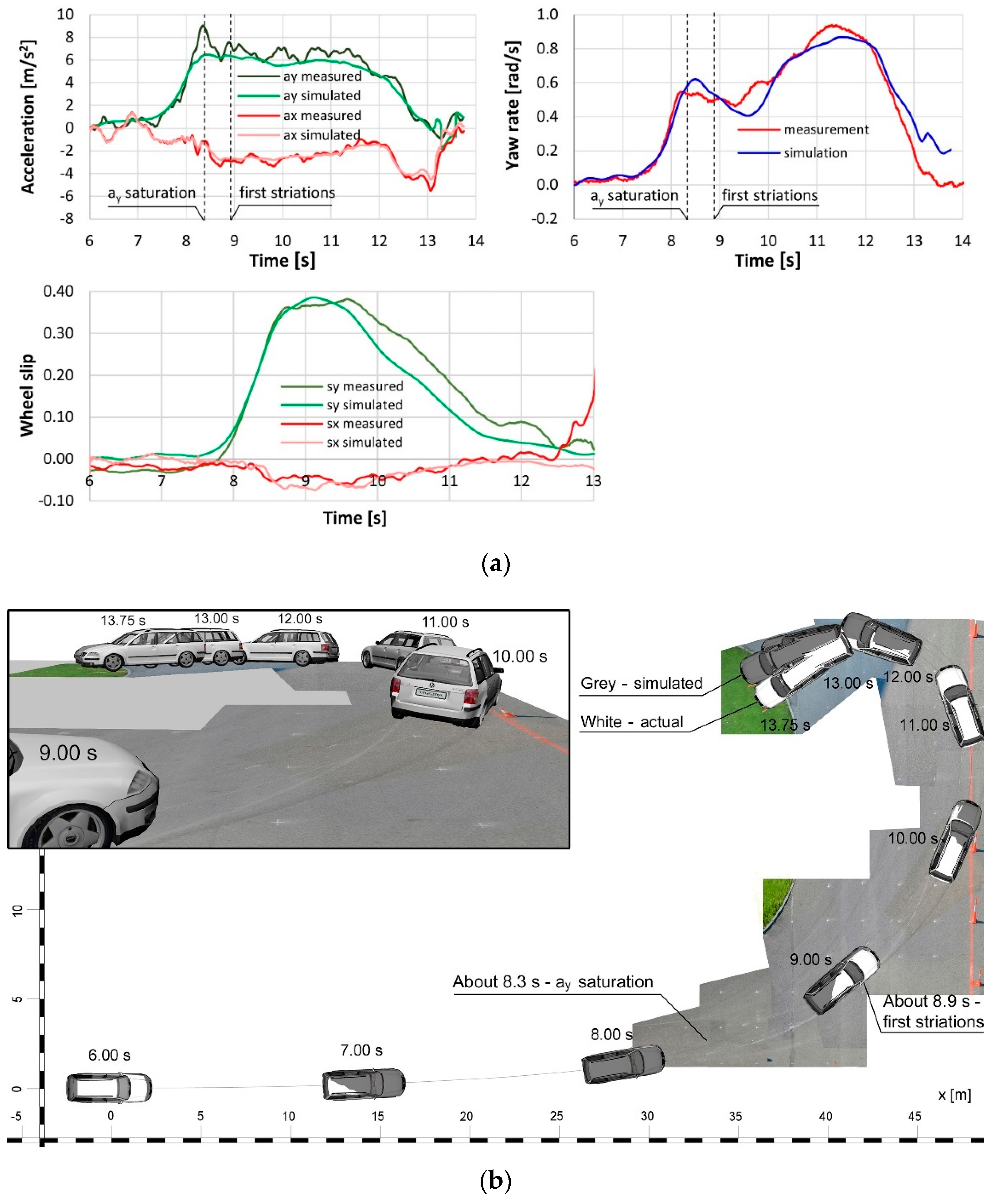

6.2. Stage 2. Vehicle Movement Simulation and Its Verification

- (a)

- steering wheel angle ;

- (b)

- external torques acting on the front wheels (left and right respectively) relative to their self-rotation axes.

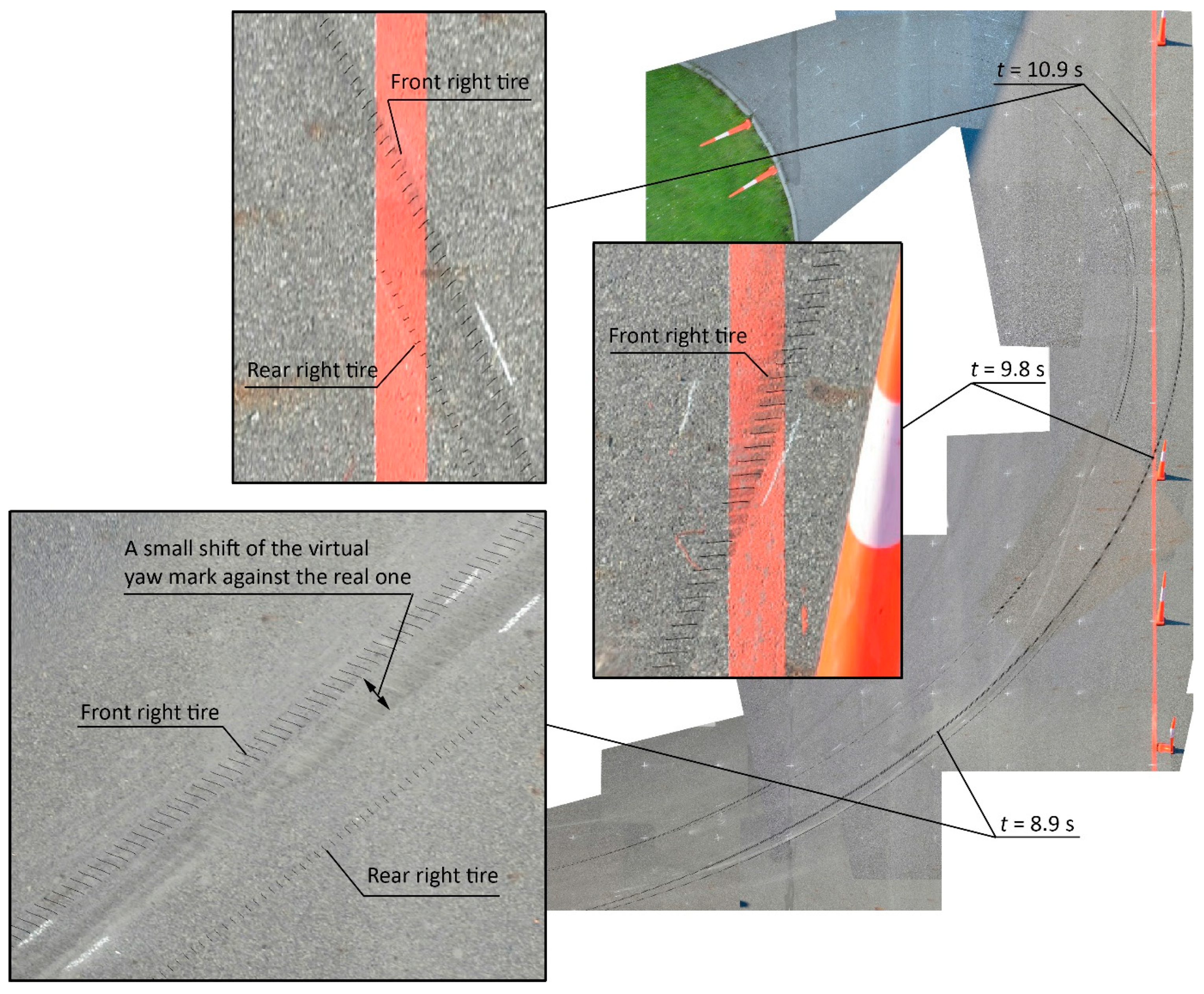

6.3. Stage 3. Verification of the Striation Creation Model

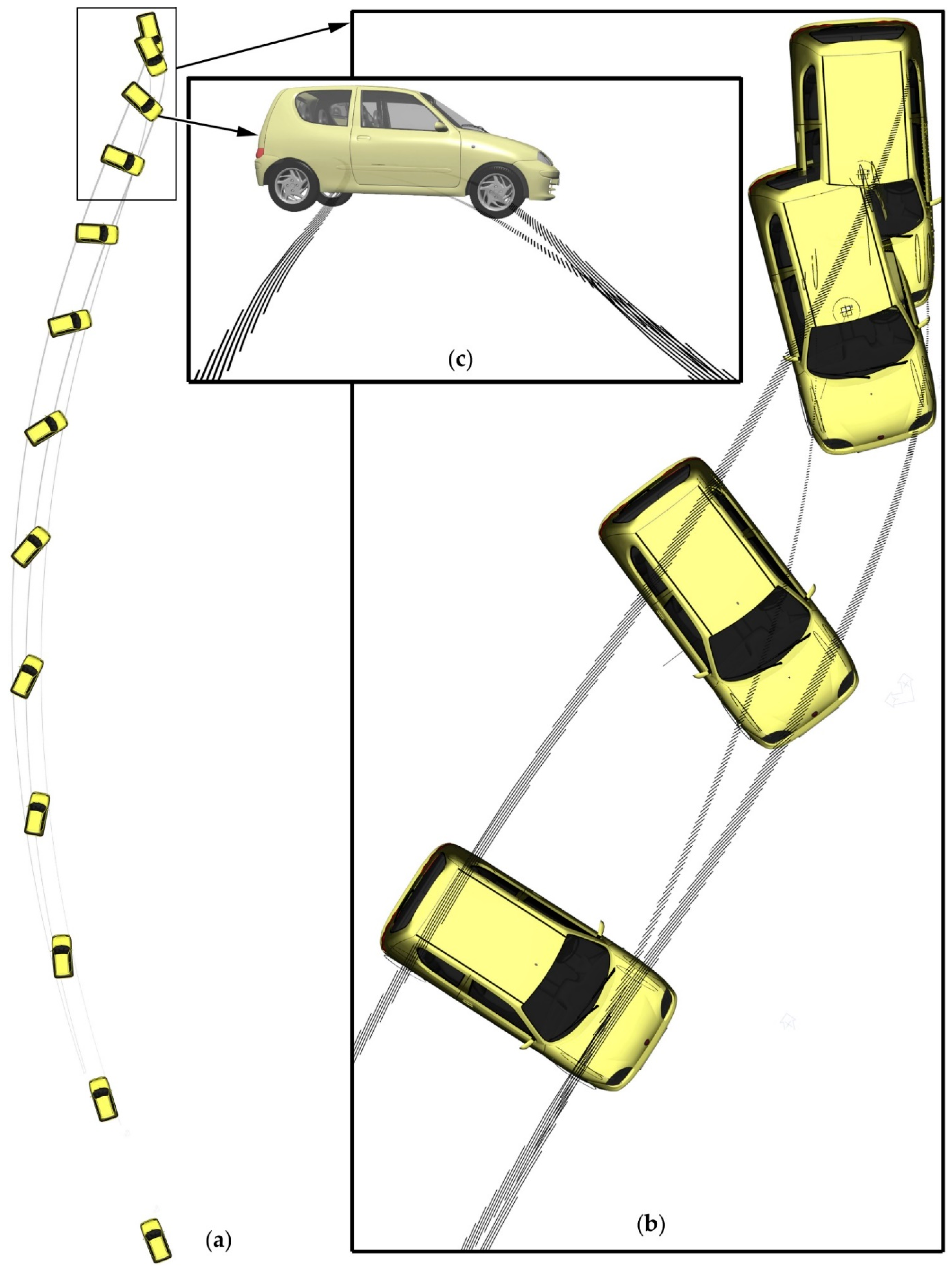

6.4. Example

7. Conclusions

- This work is, in some ways, a next step of the research of Beauchamp et al.—especially [13]. While they analyze striated yaw marks from the viewpoint of a reconstructionist who would like to know “what one can get from the marks uncovered at the accident scene” (deriving equations for calculation of longitudinal slip as a function of the striation marks angle and the slip angle ), this work focuses on development of a model to create striated tire marks, which can be used in programs for simulation of vehicle accidents. While their formulas apply to planar mechanics and kinematics, this model takes into account the spatial vehicle multi-body dynamics and tire model, including the relative movement of the wheel, its position and orientation, tire deformation, suspension kinematics as well as forces and torques acting on the wheel. A mathematical model of striated tire yaw mark creation has been developed, intended for programs for the simulation of vehicle accidents. It implements the main features of the topology of such marks.

- The application of the model is twofold. The first one is the simulation of the formation of striated yaw marks. The second one is to facilitate the understanding of the mechanics of the formation of such marks and the inference of the braking or acceleration state of the wheels based on the topology of the striations.

- The mark creation model is universal, i.e., it applies to a tire moving along any trajectory with variable curvature, and it is subjected to any forces and torques calculated by solving a system of non-linear equations of vehicle dynamics.

- The striated yaw mark is created by the tread shoulder blocks forming the outer border of the contact patch, as this area is actually dominant.

- It is possible to define any, including non-uniform, pitch of the tread shoulder blocks.

- The striated yaw mark creation model can be applied in programs for the simulation of vehicle dynamics with any degree of simplification and any tire model. In this paper, it was validated using the author-developed program Model.exe, in which the vehicle is represented by a 36 degree of freedom multi-body system with the TMeasy tire model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Brach, R.M.; Brach, M. Vehicle Accident Analysis and Reconstruction Methods, 2nd ed.; SAE International: Pittsburgh, PA, USA, 2011; pp. 79–83. [Google Scholar]

- Sledge, N.H., Jr.; Marshek, K.M. Formulas for Estimating Vehicle Critical Speed from Yaw Marks—A review; SAE Technical Paper 971147; SAE International: Pittsburgh, PA, USA, 1997. [Google Scholar] [CrossRef]

- Cannon, J.W. A Study of Errors in Yaw-Based Speed Estimates Due to Effective Braking; SAE Technical Paper 2003-01-0888; SAE International: Pittsburgh, PA, USA, 2003. [Google Scholar] [CrossRef]

- Cliff, W.E.; Lawrence, J.M.; Heinrichs, B.E.; Fricker, T.R. Yaw Testing of an Instrumented Vehicle with and without Braking; SAE Technical Paper 2004-01-1187; SAE International: Pittsburgh, PA, USA, 2004. [Google Scholar] [CrossRef]

- Amirault, G.; MacInnis, S. Variability of Yaw Calculations from Field Testing; SAE Technical Paper 2009-01-0103; SAE International: Pittsburgh, PA, USA, 2009. [Google Scholar] [CrossRef]

- Lambourn, R.F. The calculation of motor car speeds from curved tyre marks. J. For. Sci. Soc. 1989, 29, 371–386. [Google Scholar] [CrossRef]

- Lambourn, R.F. Braking and Cornering Effects with and without Anti-Lock Brakes; SAE Technical Paper 940723; SAE International: Pittsburgh, PA, USA, 1994. [Google Scholar] [CrossRef]

- Lambourn, R.F.; Jennings, P.; Knight, I. Critical speed yaw mark calculations with and without electronic stability control. In Proceedings of the 1st joint ITAI–EVU Conference (18th EVU and 9th ITAI Conference), Hinckley, UK, 25–27 September 2009; ITAI–EVU: Hinkley, UK, 2009; pp. 209–235. [Google Scholar]

- Cash, S.; Crouch, M. Calculating vehicle speed from yaw mark analysis. In Proceedings of the 24th EVU Conference, Edinburgh, UK, 15–17 October 2015; EVU: Edinburgh, UK, 2015; pp. 185–206. [Google Scholar]

- Yamazaki, S.; Akasaka, T. Buckling behavior in contact area of radial tire structure and skid marks left by tires. JSAE Rev. 1998, 9, 51–55. [Google Scholar]

- Yamazaki, S. Friction coefficients of tires and skid marks left by tires. In Proceedings of the International Workshop on Traffic Accident Reconstruction, Tokyo, Japan, 12–13 November 1998; National Research Institute of Police Science: Chiba, Japan, 1998; pp. 41–51. [Google Scholar]

- Beauchamp, G.; Pentecost, D.; Koch, D.; Rose, N. The relationship between tire mark striations and tire forces. SAE Int. J. Trans. Saf. 2016, 4, 134–150. [Google Scholar] [CrossRef] [Green Version]

- Beauchamp, G.; Hessel, D.; Rose, N.A.; Fenton, S.J.; Voitel, T. Determining vehicle steering and braking from yaw mark striations. SAE Int. J. Passeng. Cars Mech. Syst. 2009, 2, 91–307. [Google Scholar] [CrossRef] [Green Version]

- Zębala, J.; Wach, W.; Ciępka, P.; Janczur, R. Determination of Critical Speed, Slip Angle and Longitudinal Wheel Slip Based on Yaw Marks Left by a Wheel with Zero Tire Pressure; SAE Technical Paper No. 2016-01-1480; SAE International: Pittsburgh, PA, USA, 2016. [Google Scholar] [CrossRef]

- Beauchamp, G.; Thornton, D.; Bortles, W.; Rose, N. Tire mark striations: Sensitivity and uncertainty analysis. SAE Int. J. Trans. Saf. 2016, 4, 121–127. [Google Scholar] [CrossRef]

- Guzek, M.; Lozia, Z. Computing methods in the analysis of road accident reconstruction. Arch. Comp. Meth. Eng. 2020. [Google Scholar] [CrossRef]

- Hirschberg, W.; Rill, G.; Weinfurter, H. Tire model TMeasy. Veh. Syst. Dyn. 2007, 45, 101–119. [Google Scholar] [CrossRef]

- Rill, G. Simulation von Kraftfahrzeugen; Vieweg & Sohn Verlag: Braunschweig/Wiesbaden, Germany, 1994. [Google Scholar]

- Pacejka, H.B. Tire and Vehicle Dynamics, 2nd ed.; SAE: Pittsburgh, PA, USA, 2006. [Google Scholar]

- Dugoff, H.; Fancher, P.S.; Segel, L. An Analysis of Tire Traction Properties and Their Influence on Vehicle Dynamic Performance; SAE Technical Paper No. 700377; SAE International: Pittsburgh, PA, USA, 1970. [Google Scholar] [CrossRef]

- Rill, G. Road Vehicle Dynamics: Fundamentals and Modeling; CRC Press: New York, NY, USA, 2012. [Google Scholar]

- Mitschke, M. Dynamik der Kraftfahrzeuge, Band A: Antrieb und Bremsung; Springer: Berlin/Heidelberg, Germany, 1995. [Google Scholar]

- Wach, W. Reconstruction of Vehicle Kinematics by Transformations of Raw Measurement Data. In Proceedings of the XI International Scientific and Technical Conference Automotive Safety, Častá, Slovakia, 18–20 April 2018. [Google Scholar] [CrossRef]

- Wach, W.; Struski, J. Rear wheels multi-link suspension synthesis with the application of a ‘Virtual Mechanism’. In SAE Special Publication SP-2019 Steering & Suspension Technology and Tire & Wheel Technology 2006; SAE Technical Paper No. 2006-01-1376; SAE International: Pittsburgh, PA, USA, 2006. [Google Scholar] [CrossRef]

- Martini, A.; Bonelli, G.P.; Rivola, A. Virtual testing of counterbalance forklift trucks: Implementation and experimental validation of a numerical multibody model. Machines 2020, 8, 26. [Google Scholar] [CrossRef]

- Rebelle, J.; Mistrot, P.; Poirot, R. Development and validation of a numerical model for predicting forklift truck tip-over. Veh. Syst. Dyn. 2009, 47, 771–804. [Google Scholar] [CrossRef]

- Odabaşı, V.; Maglio, S.; Martini, A.; Sorrentino, S. Static stress analysis of suspension systems for a solar-powered car. FME Trans. 2019, 47, 70–75. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Value | |

|---|---|---|

| Vehicle mass distribution on wheels: | ||

| left front | 465 | kg |

| right front | 475 | kg |

| left rear | 345 | kg |

| right rear | 350 | kg |

| Distance of CG from front axle | 1.148 | m |

| CG height | 0.55 | m |

| Wheelbase | 2.703 | m |

| Steering system ratio | 16:1 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wach, W.; Zębala, J. Striated Tire Yaw Marks—Modeling and Validation. Energies 2021, 14, 4309. https://doi.org/10.3390/en14144309

Wach W, Zębala J. Striated Tire Yaw Marks—Modeling and Validation. Energies. 2021; 14(14):4309. https://doi.org/10.3390/en14144309

Chicago/Turabian StyleWach, Wojciech, and Jakub Zębala. 2021. "Striated Tire Yaw Marks—Modeling and Validation" Energies 14, no. 14: 4309. https://doi.org/10.3390/en14144309

APA StyleWach, W., & Zębala, J. (2021). Striated Tire Yaw Marks—Modeling and Validation. Energies, 14(14), 4309. https://doi.org/10.3390/en14144309