The Structure and Optimal Gear Tooth Profile Design of Two-Speed Transmission for Electric Vehicles

Abstract

:1. Introduction

2. The Necessity and the Purpose of the Study

2.1. The Necessity of the Study

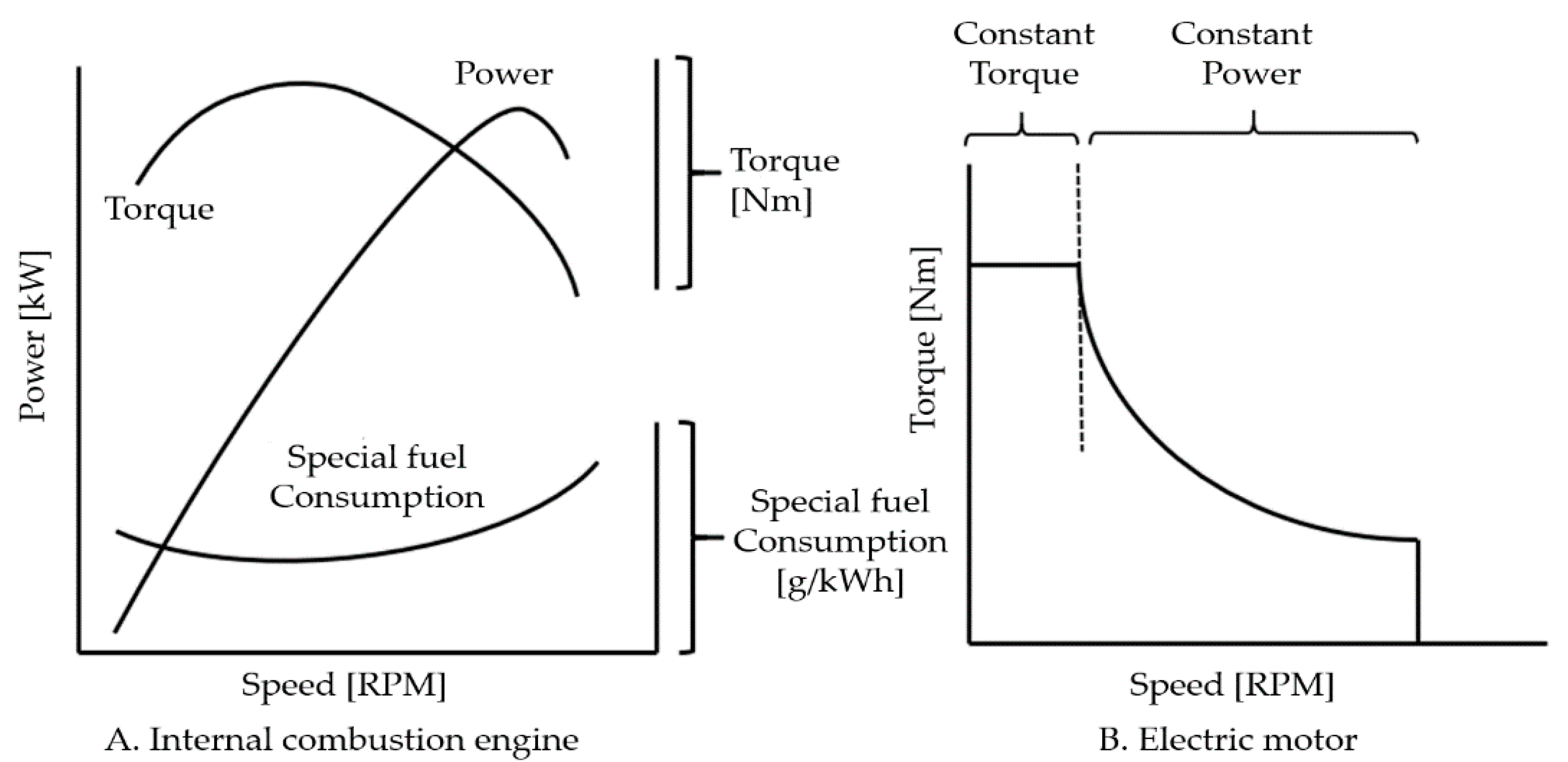

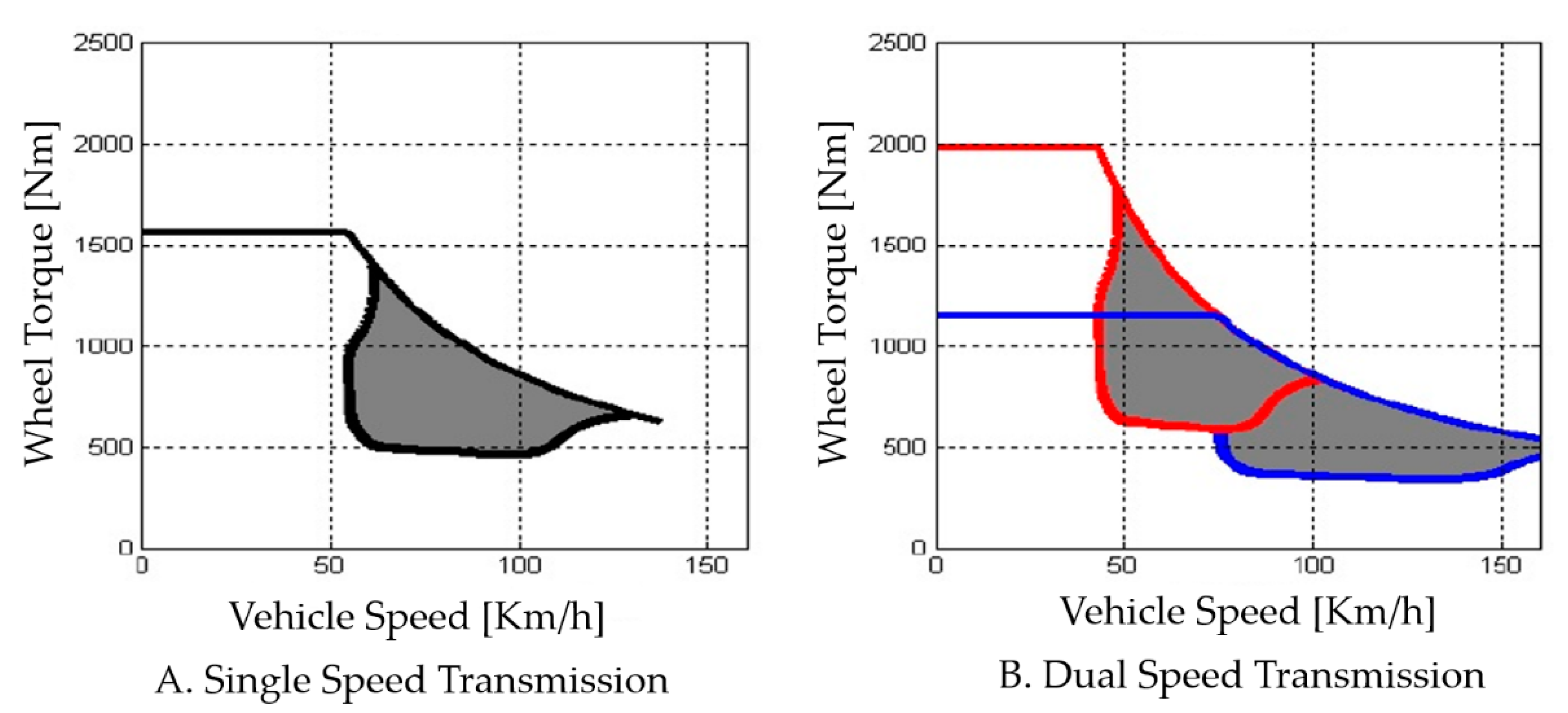

2.1.1. Necessity of Study on Electric Vehicle Two-Speed Transmission

2.1.2. Problems with Conventional Transmissions

2.2. The Purpose of the Study

3. Transmission Structure Design and Tooth Profile Design

3.1. Design of Transmission Planetary Gear Module

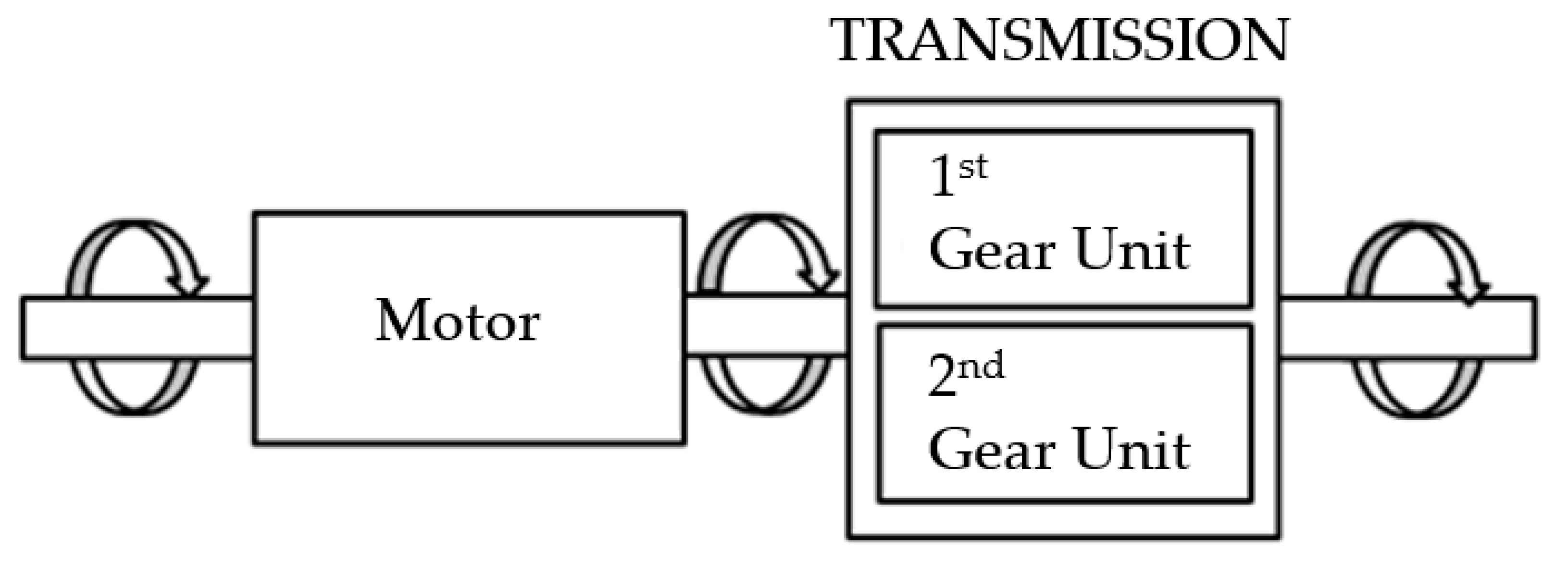

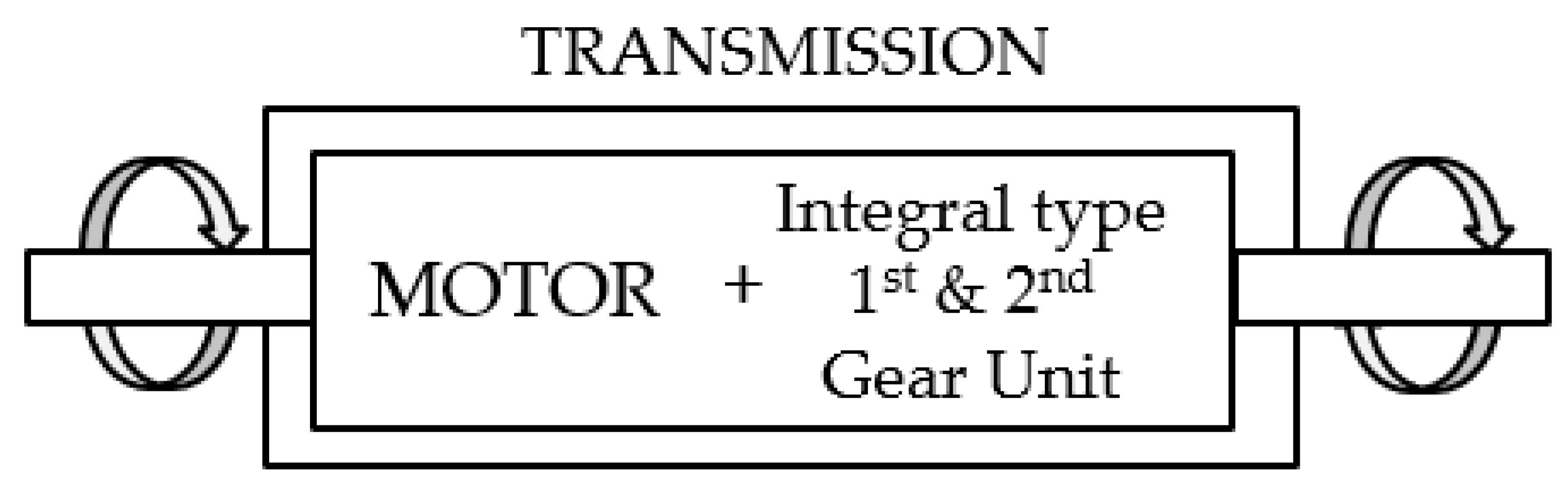

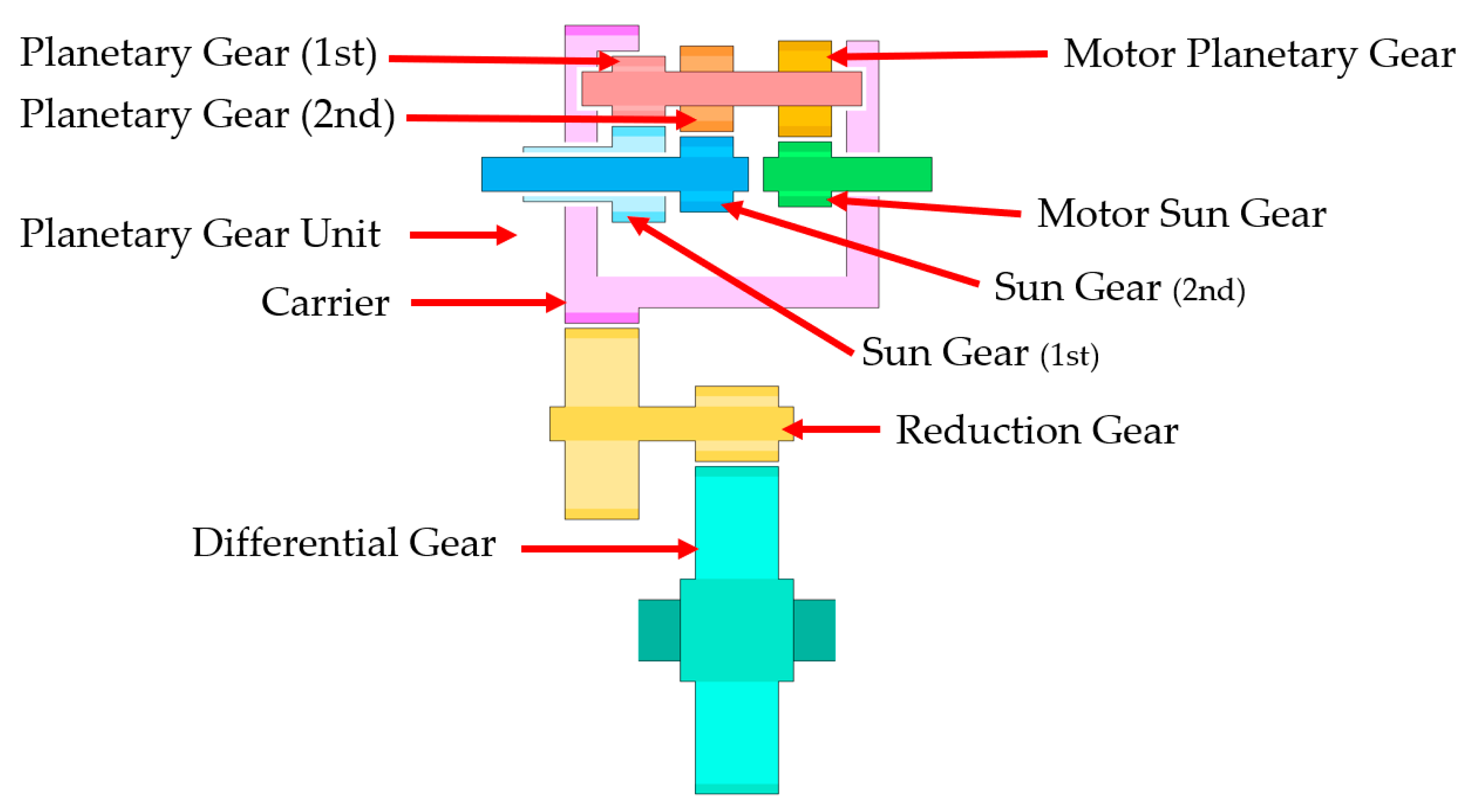

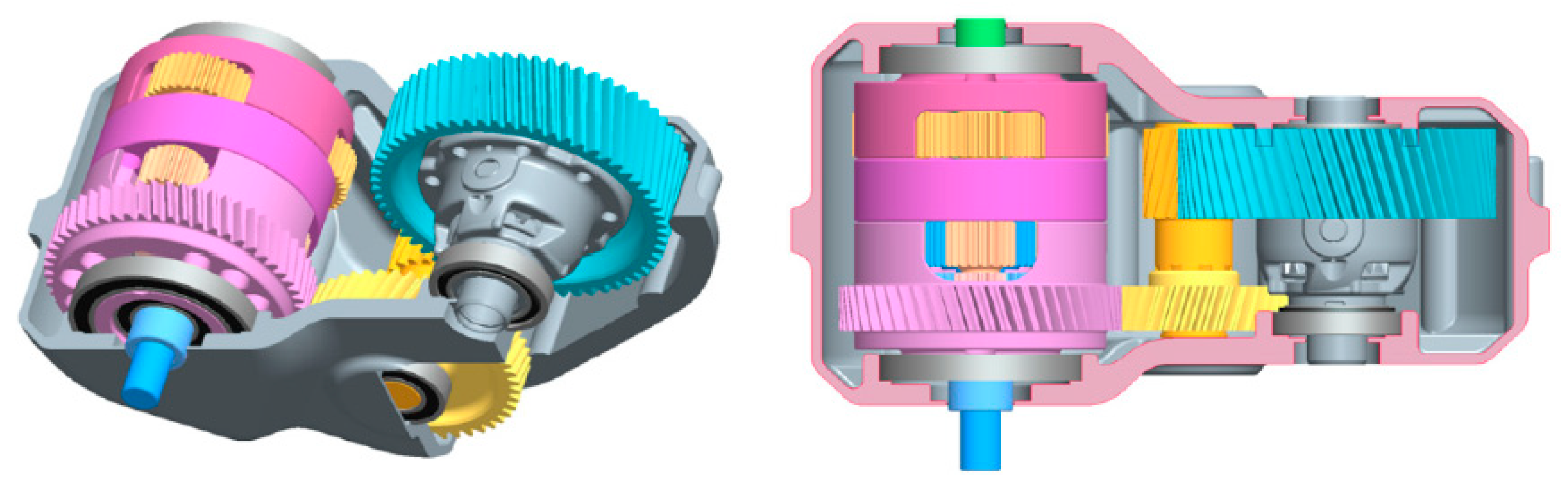

3.2. Design of 2-Speed Transmission

3.2.1. 3D Modeling 2-Speed Transmission

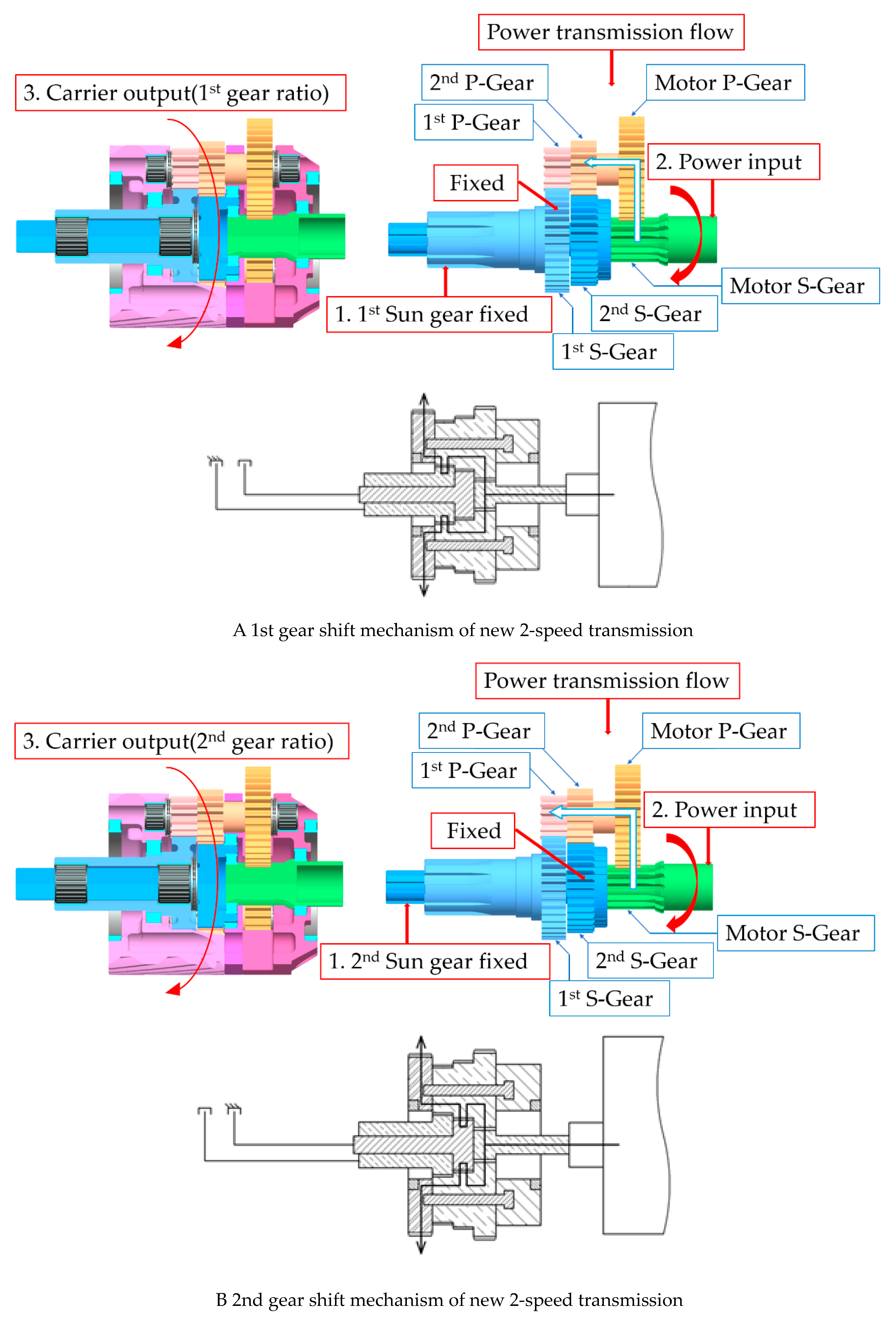

3.2.2. Shift Mechanism of New Type Transmission

3.2.3. Calculate Planetary Gear Reduction Ratio

3.3. Evaluation of Gears Strength

3.3.1. Calculation of Bending Strength and Surface Durability

3.3.2. Final Gear Specification

3.4. Meshing Efficiency Analysis of Transmission

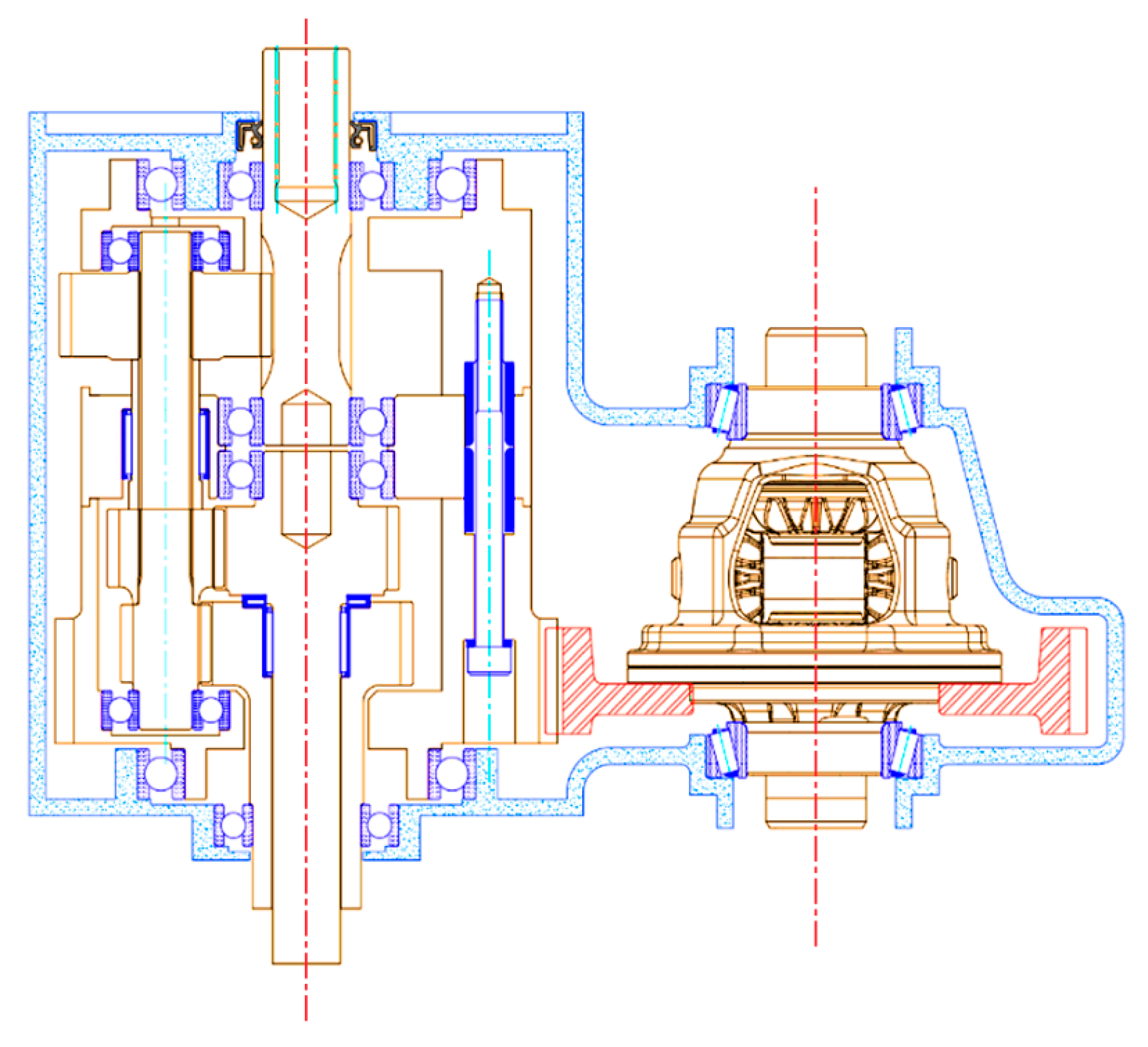

3.5. Two-Speed Transmission Housing Design

4. Conclusions

- (1)

- An electric vehicle two-speed transmission mechanism was envisioned, and 3D modeling was undertaken. The number of parts is reduced by means of a mechanism different from a conventional transmission with each planetary gear and sun gear coaxially configured to eliminate unnecessary space. The design was made even more compact by eliminating the ring gear.

- (2)

- The characteristics of the two-speed transmission mechanism, detailed in this paper, allows for the speed and acceleration of the sun gear to be fixed to “0”. Thus, it is judged to be an advantageous structure for automobiles powered by batteries because of the low shift shock and the low energy required for shifting.

- (3)

- Gear strength calculations were performed both inside and outside the transmission. The bending strength and the surface durability strength of the gear were calculated, and it was confirmed that each gear meets JGMA standard safety factors. Thus, the safety of the transmission is confirmed.

- (4)

- The transmission meshing efficiency was analyzed. It was calculated to allow for the meshing efficiency of the involute external gear to be calculated. Based on this calculated result, the reference efficiency of the transmission was then calculated. A result of 97% of reference efficiency in the transmission was obtained. The reference efficiency for the first gear shift was 96.4466%, while for the second gear the reference efficiency was calculated as 96.5712%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, E.Y. Policy Challenges to Strengthen the Competitiveness of the Battery Industry in the Electric Vehicle Era KERI Brief 19-01. Available online: http://scholar.dkyobobook.co.kr/searchDetail.laf?barcode=4010027039886 (accessed on 4 April 2021).

- Tran, D.-D.; Vafaeipour, M.; El Baghdadi, M.; Barrero, R.; Van Mierlo, J.; Hegazy, O. Thorough state-of-the-art analysis of electric and hybrid vehicle powertrains: Topologies and integrated energy management strategies. Renew. Sust. Energ. Rev. 2020, 119, 109596. [Google Scholar] [CrossRef]

- Szałek, A.; Pielecha, I. The Influence of Engine Downsizing in Hybrid Powertrains on the Energy Flow Indicators under Actual Traffic Conditions. Energies 2021, 14, 2872. [Google Scholar] [CrossRef]

- Chu, W.; Zhu, Z.; Zhang, J.; Liu, X.; Stone, D.; Foster, M. Investigation on Operational Envelops and Efficiency Maps of Electrically Excited Machines for Electrical Vehicle Applications. IEEE Trans. Magn. 2015, 51, 1–10. [Google Scholar] [CrossRef]

- IEA. Global EV Outlook 2018: Towards cross-modal electrification, IEA, Paris. 2018. Available online: https://doi.org/10.1787/9789264302365-en (accessed on 4 April 2021).

- Ren, Q.; Crolla, D.A.; Morris, A. Effect of transmission design on Electric Vehicle (EV) performance. In Proceedings of the 5th IEEE Vehicle Power and Propulsion Conference (VPPC’09), Dearborn, MI, USA, 7–11 September 2009; pp. 1260–1265. [Google Scholar]

- Walker, P.D.; Rahman, S.A.; Zhu, B.; Zhang, N. Modelling, simulations, and optimisation of electric vehicles for analysis of transmission ratioselection. Adv. Mech. Eng. 2013, 5, 340435. [Google Scholar] [CrossRef]

- Son, H.; Yoon, Y.S.; Kim, K.S.; Kim, S.J.; Song, C. Economic hybrid transmission system using clutchless geared manual transmission. In Proceedings of the 28th Electric Vehicle Symposium and Exhibition, Goyang, Korea, 3–6 May 2015. [Google Scholar]

- Walker, P.; Zhu, B.; Zhang, N. Powertrain dynamics and control of a two speed dual clutch transmission for electric vehicles. Mech. Syst. Signal Process. 2017, 85, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Naunheimer, H.; Bertsche, B.; Ryborz, J.; Novak, W.; Kuchle, A. Automotive Transmissions: Fundamentals, Selection, Design and Application, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Han, J.O.; Shin, J.W.; Kim, J.C.; Oh, S.H. Design 2-Speed Transmission for Compact Electric Vehicle Using Dual Brake System. Appl. Sci. 2019, 9, 1793. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Song, X.; Saltsman, B.; Hu, H. Comparative Studies of Drivetrain Systems for Electric Vehicles; SAE Technical Paper. Available online: https://www.sae.org/publications/technical-papers/content/2013-01-2467/ (accessed on 11 March 2021).

- Toyota. Toyota technical review.

- Shin, J.W.; Jung, H.Y.; Oh, S.H. A study on 2-speed transmission of electric vehicle by using inventogram. J. Mech. Sci. Technol. 2017, 31, 2543–2546. [Google Scholar] [CrossRef]

- Singh, K.V.; Bansal, H.O.; Singh, D. A comprehensive review on hybrid electric vehicles: Architectures and components. J. Mod. Transport. 2019, 27, 77–107. [Google Scholar] [CrossRef] [Green Version]

- Badin, F.; Scordia, J.; Trigui, R.; Vinot, E.; Jeanneret, B. Hybrid electric vehicles energy consumption decrease according to drive train architecture, energy management and vehicle use. In Proceedings of the IET—The Institution of Engineering and Technolgy Hybrid Vehicle Conference, Coventry, UK, 12–13 December 2006; pp. 213–224. [Google Scholar] [CrossRef]

- Thomas, C.E.S. Transportation options in a carbon-constrained world: Hybrids, plug-in hybrids, biofuels, fuel cell electric vehicles, and battery electric vehicles. Int. J. Hydrogen Energy 2009, 34, 9279–9296. [Google Scholar] [CrossRef]

- Panday, A.; Bansal, H.O. A review of optimal energy management strategies for hybrid electric vehicle. Int. J. Veh. Technol. 2014, 2014, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Mantriota, G.; Reina, G. Dual-Motor Planetary Transmission to Improve Efficiency in Electric Vehicles. Machines 2021, 9, 58. [Google Scholar] [CrossRef]

- Lee, T.-W.; Hong, D.-K. Electrical and Mechanical Characteristics of a High-Speed Motor for Electric Turbochargers in Relation to Eccentricity. Energies 2021, 14, 3340. [Google Scholar] [CrossRef]

- Nicola, F.D.; Sorniotti, A.; Holdstork, T.; Viotto, F.; Bertolotto, S. Optimization of a multiple-speed transmission for downsizing the motor of a fully electric vehicle. SAE Int. J. Alt. Power. 2012, 1, 134–143. [Google Scholar] [CrossRef]

- Park, S.U. A Study on the New Clutch Mechanism for the Electric Vehicles Transmission. Ph.D. Thesis, KAIST, Daejeon, Korea, February 2019. [Google Scholar]

- Rhodes, K.; Kok, D.; Sohoni, P.; Perry, E.; Kraska, M.; Wallace, M. Estimation of the Effects of Auxiliary Electrical Loads on Hybrid Electric Vehicle Fuel Economy; SAE Technical Paper 2017-01-1155; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Bajer, A.; Demkowicz, L. Dynamic contact/impact problems, energy conservation, and planetary gear trains. Comput. Methods Appl. Mech. Eng. 2002, 191, 4159–4191. [Google Scholar] [CrossRef]

- Kahraman, A. Planetary Gear Train Dynamics. ASME. J. Mech. Des. 1994, 116, 713–720. [Google Scholar] [CrossRef]

- Dudley, D.W. Handbook of Practical Gear Design; McGraw-Hill: New York, NY, USA, 1984; p. 656. [Google Scholar]

- Litvin, F.L. Gear Geometry and Applied Theory; Prentice-Hall: Hoboken, NJ, USA, 1994; pp. 331–345. [Google Scholar]

- Del Castillo, J.M. The analytical expression of the efficiency of planetary gear trains. Mech. Mach. Theory 2002, 37, 197–214. [Google Scholar] [CrossRef]

- Kissling, U.; Beermann, S. Face Gears: Geometry and strength. Gear Technol. 2007, 1, 54–61. [Google Scholar]

- Shin, J.W. Study of the 2-Speed Auto Transmission Structure of Micro Mobility. Ph.D. Thesis, Chung-ang University, Seoul, Korea, February 2017. [Google Scholar]

- KHK Stock Gears. Gear Technical Reference. Gear Knowledge. Available online: http://khkgears.net/gear-konwledge/gear-technical-reference/ (accessed on 4 April 2021).

- ANSI/AGMA 2001—C95. Fundamental Rating Factors and Calculation Methods for Involute Spur and Helical Gear Teeth.

- DIN 3990. Grundlagen für die Tragfähigkeitsberechnung von Gerad-und Schrägstirnrädern; Beuth Verlag GmbH: Berlin, Germany, 1987. [Google Scholar]

- JGMA 6101—02. Calculation of Bending Strength for Spur and Helical Gears.

- KS B ISO 6336-1. Calculation of load capacity of spur and helical gears—Part 1: Basic principles, introduction and general influence factors.

- KS B ISO 6336-3. Calculation of load capacity of spur and helical gears—Part 3: Calculation of tooth bending strength.

- JGMA 6102—02. Calculation of Surface Durability (Pitting Resistance) for Spur and Helical Gears.

- TGL 10545. Tragfähigkeitsberechnung von außenverzahnten Stirnrädern.

- KS B ISO 6336-2. Calculation of load capacity of spur and helical gears—Part 2: Calculation of Surface Durability(pitting).

- Irimescu, A.; Mihon, L.; Pãdure, G. Automotive Transmission Efficiency Measurement Using A Chassis Dynamometer. Int. J. Automot. Technol. 2011, 12, 555–559. [Google Scholar] [CrossRef]

- Toshio, A. Cylindrical Gear Design—Design and Manufacture of Gears 1: Kinki Gear Conference Edition; Okawa Publishing: Okawa, Japan, 1974; pp. 63–116. [Google Scholar]

- Cho, S.; Ahn, K.; Lee, J.M. Efficiency of the planetary gear hybrid powertrain. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2006, 220, 1445–1454. [Google Scholar] [CrossRef]

- Saito, T.; Miyamoto, K. Prediction of CVT Transmission Efficiency by Metal V-Belt and Pulley Behavior with Feedback Control; SAE Technical Paper 2010-01-0855; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Shinbori, I.; Muto, A.; Takeo, H.; Takahashi, T.; Saito, Y.; Tsubata, Y. High Efficiency 6-speed Automatic Transmission; SAE Technical Paper 2010-01-0858; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Lee, J.; Jeong, W.; Han, J.; Kim, T.; Oh, S. Barrier-Free Wheelchair with a Mechanical Transmission. Appl. Sci. 2021, 11, 5280. [Google Scholar] [CrossRef]

| Sun Gear | All Rotates | All Rotates | |||

|---|---|---|---|---|---|

| Motor Sun Gear | |||||

| Motor Planetary Gear | |||||

| 1st and 2nd Planetary Gear | |||||

| 1st Sun Gear | 0 | 0 | |||

| 2nd Sun Gear | 0 | 0 | |||

| Carrier | 0 |

| Base Formulas | ||

|---|---|---|

| Tangential force | (3) | |

| Torque | (4) | |

| Power | (5) | |

| Main speed | (6) | |

| (7) | ||

| Allowable tangential force | (8) | |

| Root bending stress | (9) | |

| Safety factor (Root bending stress) | (10) | |

| (11) | ||

| Allowable tangential force | (12) | |

| Tooth contact stress | (13) | |

| Safety factor (Surface durability) | (14) | |

| Motor Sun Gear | Motor Planetary Gear | 1st Sun Gear | 1st Planetary Gear | 2nd Sun Gear | 2nd Planetary Gear | |

|---|---|---|---|---|---|---|

| Abbreviation | ||||||

| Type of gear | Spur | Spur | Spur | |||

| Module (M) | ||||||

| Pressure angle (Degree) | ||||||

| Number of teeth (Z ea) | ||||||

| Profile shift coefficient () | ||||||

| Face width (B mm) | ||||||

| Center circle distance (mm) | ||||||

| Pitch diameter ( mm) | .000 | 74.000 | 28.000 | 38.000 | ||

| Base diameter ( mm) | ||||||

| Tip diameter ( mm) | ||||||

| Root diameter ( mm) | ||||||

| Motor Sun Gear | Motor Planetary Gear | 1st Sun Gear | 1st Planetary Gear | 2nd Sun Gear | 2nd Planetary Gear | ||

|---|---|---|---|---|---|---|---|

| Abbreviation | |||||||

| Deep hardness | |||||||

| Allowable bending stress ( | |||||||

| Tooth profile coefficient () | |||||||

| Load Distribution Factor () | 0.73 | 0.75 | 0.73 | ||||

| Life factor () | 1.50 | 1.50 | 1.50 | ||||

| Dimension factor ( | 1.0 | 1.0 | |||||

| Dynamic Load Factor | |||||||

| Overload factor | |||||||

| Bending safety breakage rate () | |||||||

| Bending strength safety factor | 1set | 0.915 | |||||

| 3set | |||||||

| Motor Sun Gear | Motor Planetary Gear | 1st Sun Gear | 1st Planetary Gear | 2nd Sun Gear | 2nd Planetary Gear | ||

|---|---|---|---|---|---|---|---|

| Abbreviation | |||||||

| Surface hardness | |||||||

| Allowable hertz stress | |||||||

| Area coefficient ( | |||||||

| Material constant coefficient () | |||||||

| Meshing rate coefficient () | 0 | 0 | 0 | ||||

| Life factor () | |||||||

| Lubricant factor () | 0 | 0 | 0 | ||||

| Roughness coefficient () | 0 | 0 | 0 | ||||

| Lubricant speed factor | |||||||

| Hardness ratio coefficient | |||||||

| Load distribution coefficient | |||||||

| Gear surface damage safety factor | |||||||

| Surface durability safety factor | 1set | ||||||

| 3set | |||||||

| Carrier Gear | Input Reducer Gear | Output Reducer Gear | Differential Gear | |

|---|---|---|---|---|

| Abbreviation | ||||

| Type of gear | Helical | Helical | ||

| Module (M) | ||||

| Pressure angle (Degree) | ||||

| Reference cylinder helical angle (Degree) | ||||

| Helical direction | L | R | L | R |

| Number of teeth (Z ea) | ||||

| Modified center distance (mm) | 142.50 | 130.00 | ||

| Backlash | 0.226 | 0.171 | ||

| Profile shift coefficient () | 0.1 | 0.2 | 0.2 | 0.1 |

| Axis perpendicular potential coefficient | 0.09659 | 0.19318 | 0.19318 | 0.09659 |

| Front module | 3.10582 | 3.10582 | ||

| Front pressure angle | 20.6468 | 20.6468 | ||

| Pitch diameter ( mm) | 211.194 | |||

| Base diameter ( mm) | ||||

| Tip diameter ( mm) | ||||

| Root diameter ( mm) | ||||

| Carrier Gear | Input Reducer Gear | Output Reducer Gear | Differential Gear | ||

|---|---|---|---|---|---|

| Abbreviation | |||||

| Deep hardness | |||||

| Allowable bending stress ( | |||||

| Tooth profile coefficient () | |||||

| Load Distribution Factor () | 0.66 | 0.70 | |||

| Torsion angle coefficient | 0.88 | 0.88 | |||

| Life factor () | 1.50 | 1.50 | |||

| Dimension factor ( | 1.0 | ||||

| Dynamic Load Factor | |||||

| Overload factor | |||||

| Bending safety breakage rate () | |||||

| Bending strength safety factor | 1set | ||||

| 3set | |||||

| Carrier Gear | Input Reducer Gear | Output Reducer Gear | Differential Gear | ||

|---|---|---|---|---|---|

| Abbreviation | |||||

| Surface hardness | |||||

| Allowable hertz stress ( | |||||

| Area coefficient ( | |||||

| Material constant coefficient () | |||||

| Meshing rate coefficient () | |||||

| Life factor () | |||||

| Lubricant factor () | 0 | 0 | |||

| Roughness coefficient () | 0 | 0 | |||

| Lubricant speed factor | 0.990 | ||||

| Hardness ratio coefficient | |||||

| Load distribution coefficient | |||||

| Gear surface damage safety factor | |||||

| Surface durability safety factor | 1st | ||||

| 2nd | |||||

| Formulas | Gear Reference Efficiency Formulas | ||

|---|---|---|---|

| Spur | Contact of involute external gear | ||

| Spur & Rack | |||

| Spur & Internal | Contact of involute internal gear | ||

| Helical | |||

| (23) |

| (24) |

| (25) |

| (26) |

| (27) |

| Abbreviation | C | D | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of teeth | 19 | 32 | 37 | 14 | 32 | 19 | 54 | 37 | 15 | 68 | ||

| Profile shift coefficient | 0.25 | 0.25 | 0.2 | 0.3 | 0.25 | 0.25 | 0.1 | 0.25 | 0.25 | 0.05 | ||

| Pitch diameter ( mm) | .00 | 74.00 | 28.00 | 38.00 | 167.7 | 114.9 | 46.58 | 211.1 | ||||

| Tip diameter ( mm) | 174.5 | 122.3 | 53.99 | 218.0 | ||||||||

| Root diameter ( mm) | 34.20 | 59.40 | 69.40 | 24.20 | 59.40 | 34.20 | 160.5 | 108.3 | 40.02 | 204.0 | ||

| Center distance | 52 | 52 | 52 | 142.5 | 130.0 | |||||||

| Module | 2.0 | 2.0 | 2.0 | 3.10 | 3.105 | |||||||

| Pressure angle | 20 | 20 | 20 | 20.64 | 20.64 | |||||||

| Friction coefficient | 0.05 | 0.05 | 0.05 | 0.08 | 0.08 | |||||||

| Addendum pressure angle | 26.49 | 29.25 | 37.46 | 25.42 | ||||||||

| Gear meshing ratio | 0.96 | 0.88 | 0.841 | 0.879 | ||||||||

| Efficiency (%) | 99.05 | 98.92 | 99.05 | 99.38 | 99.03 | |||||||

| 1st Gear Train | 2nd Gear Train | |

|---|---|---|

| Efficiency |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, J.-O.; Jeong, W.-H.; Lee, J.-S.; Oh, S.-H. The Structure and Optimal Gear Tooth Profile Design of Two-Speed Transmission for Electric Vehicles. Energies 2021, 14, 3736. https://doi.org/10.3390/en14133736

Han J-O, Jeong W-H, Lee J-S, Oh S-H. The Structure and Optimal Gear Tooth Profile Design of Two-Speed Transmission for Electric Vehicles. Energies. 2021; 14(13):3736. https://doi.org/10.3390/en14133736

Chicago/Turabian StyleHan, Jae-Oh, Won-Hyeong Jeong, Jong-Seok Lee, and Se-Hoon Oh. 2021. "The Structure and Optimal Gear Tooth Profile Design of Two-Speed Transmission for Electric Vehicles" Energies 14, no. 13: 3736. https://doi.org/10.3390/en14133736

APA StyleHan, J.-O., Jeong, W.-H., Lee, J.-S., & Oh, S.-H. (2021). The Structure and Optimal Gear Tooth Profile Design of Two-Speed Transmission for Electric Vehicles. Energies, 14(13), 3736. https://doi.org/10.3390/en14133736