Mechanical Behaviors of Granite after Thermal Shock with Different Cooling Rates

Abstract

:1. Introduction

2. Materials and Methods

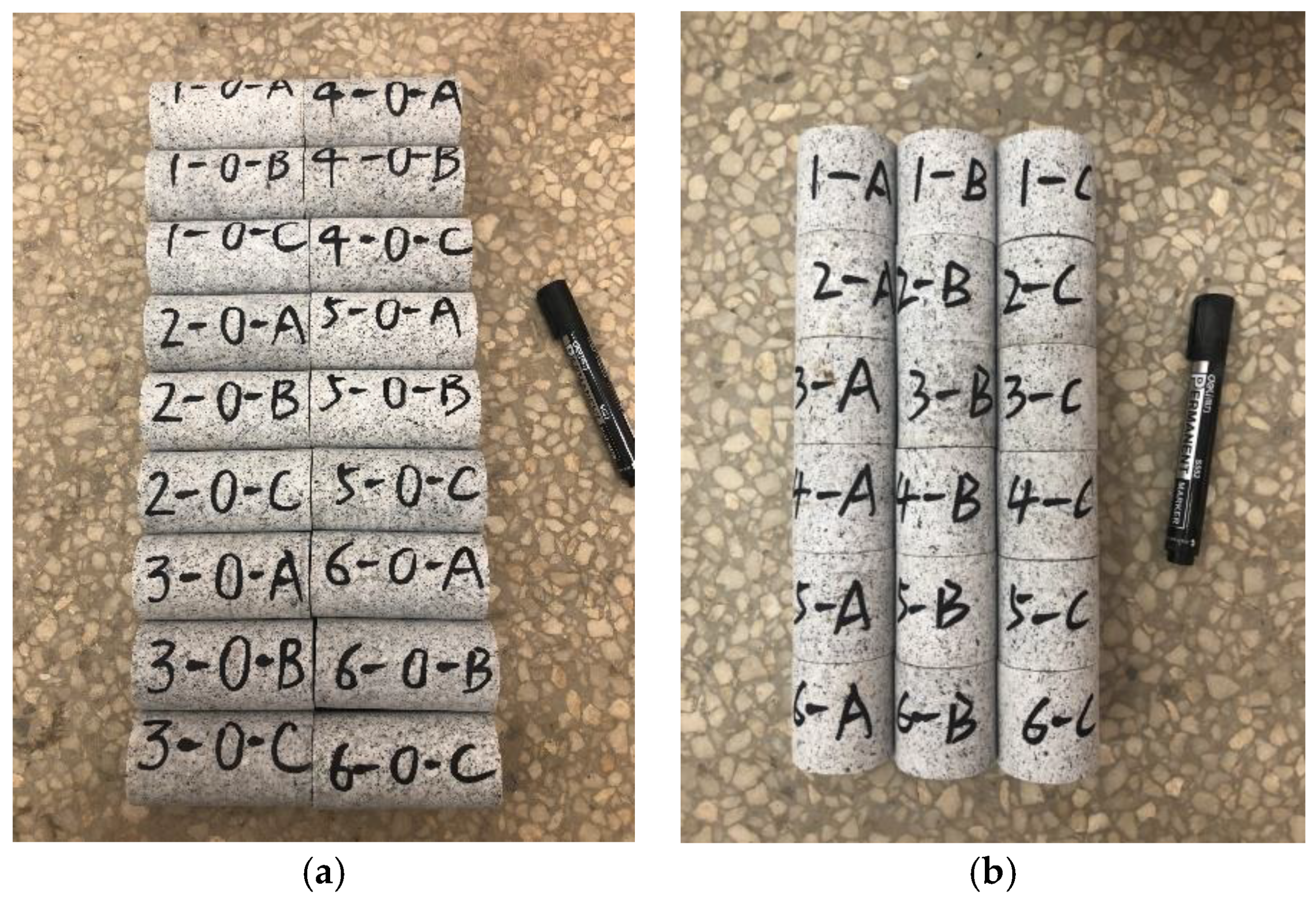

2.1. Sample Preparation

2.2. Test Equipment

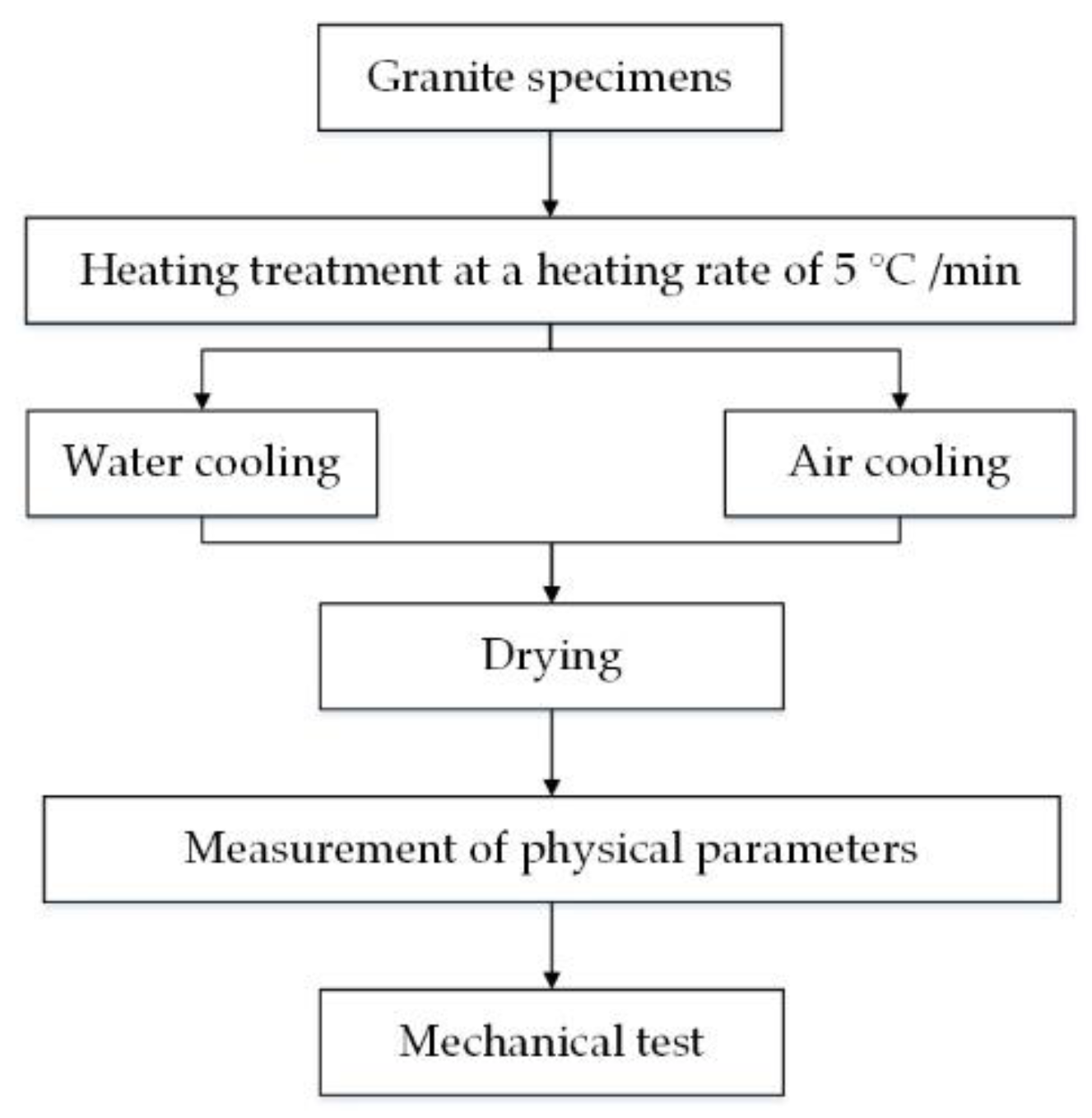

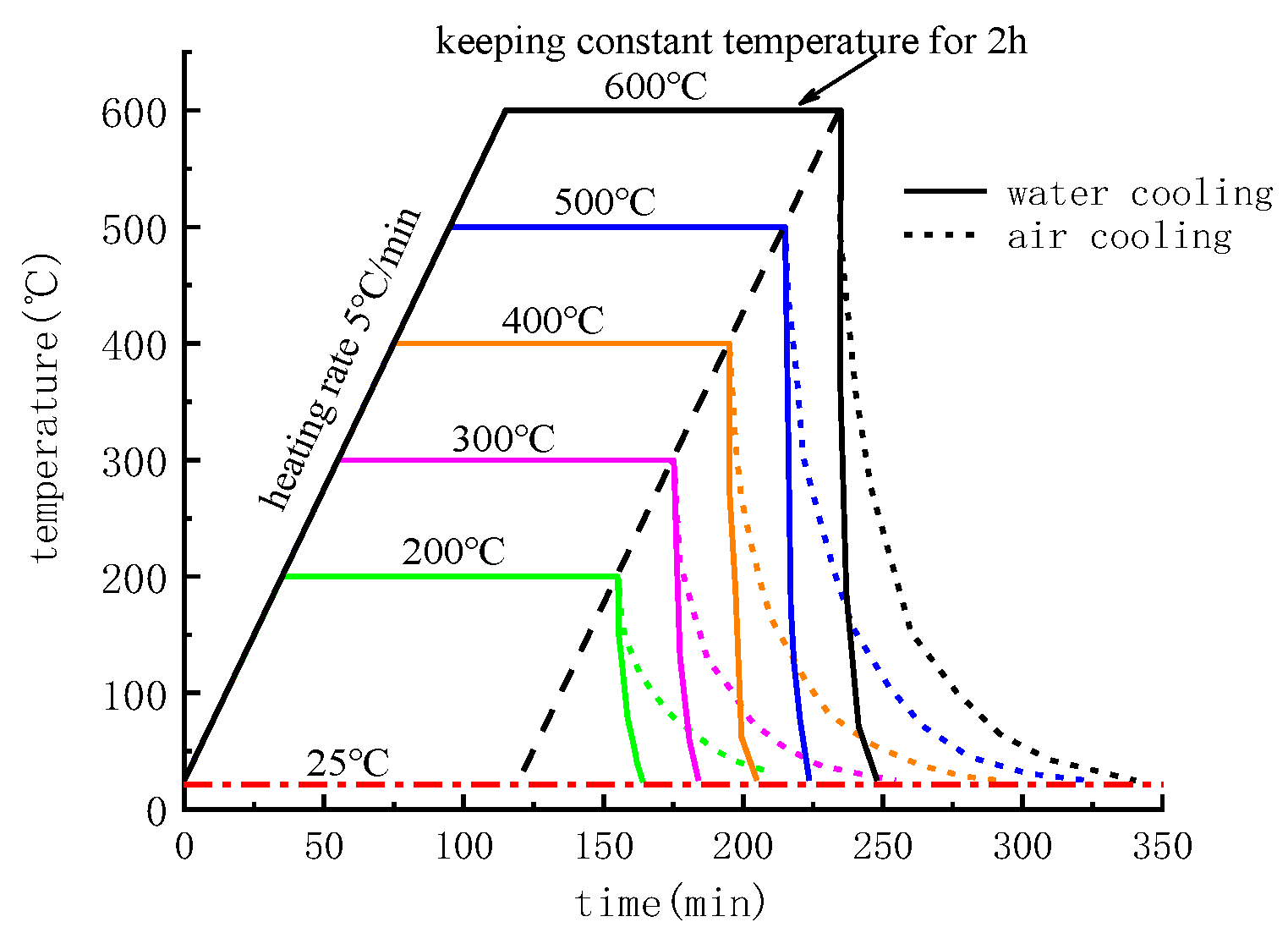

2.3. Experimental Procedure

3. Results

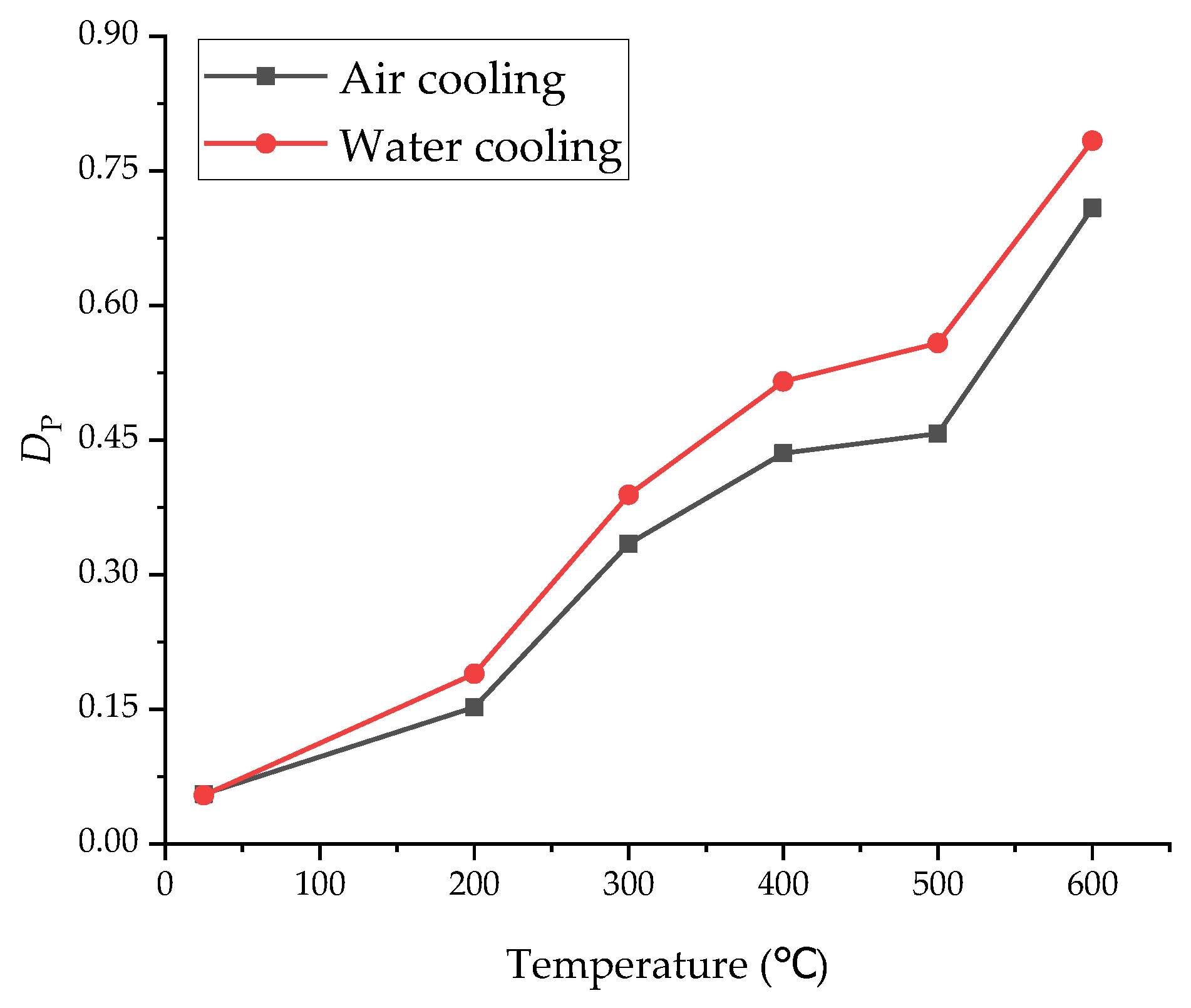

3.1. P-Wave Velocity

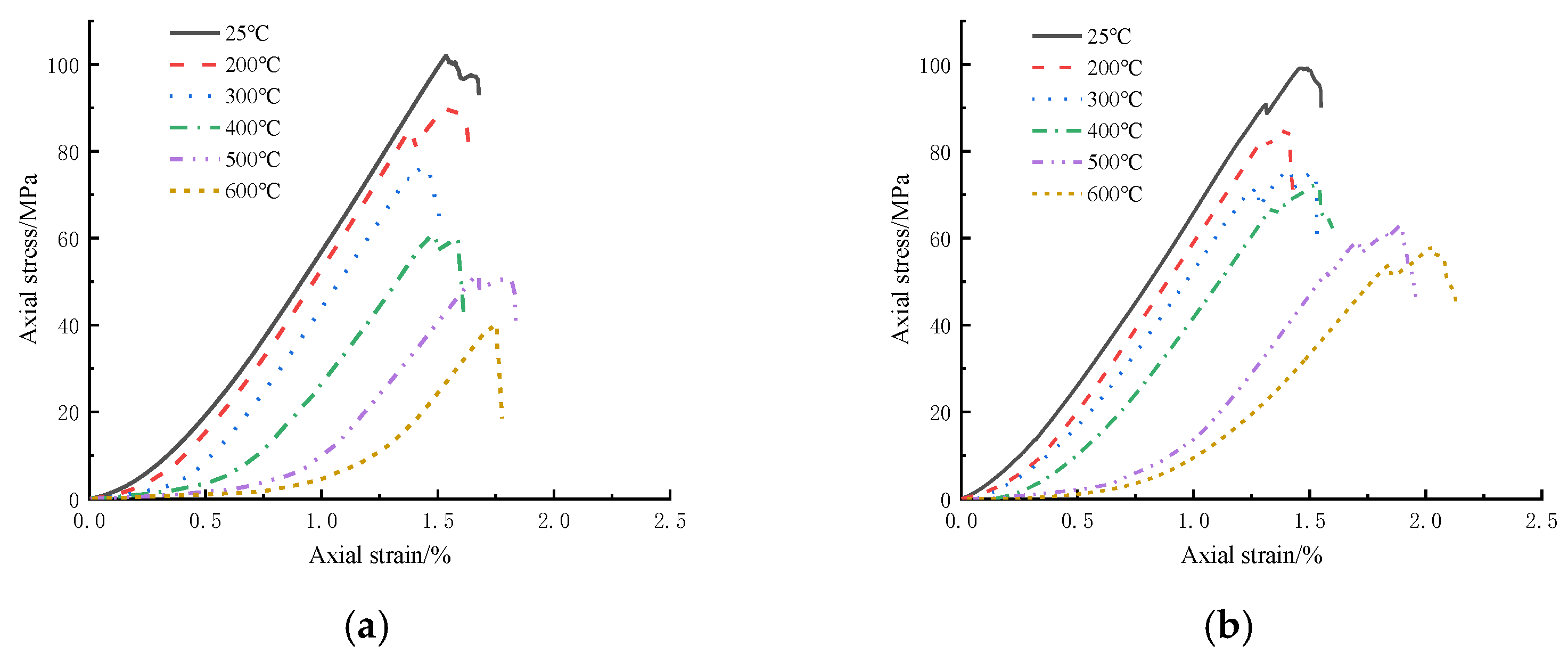

3.2. Stress–Strain Relations

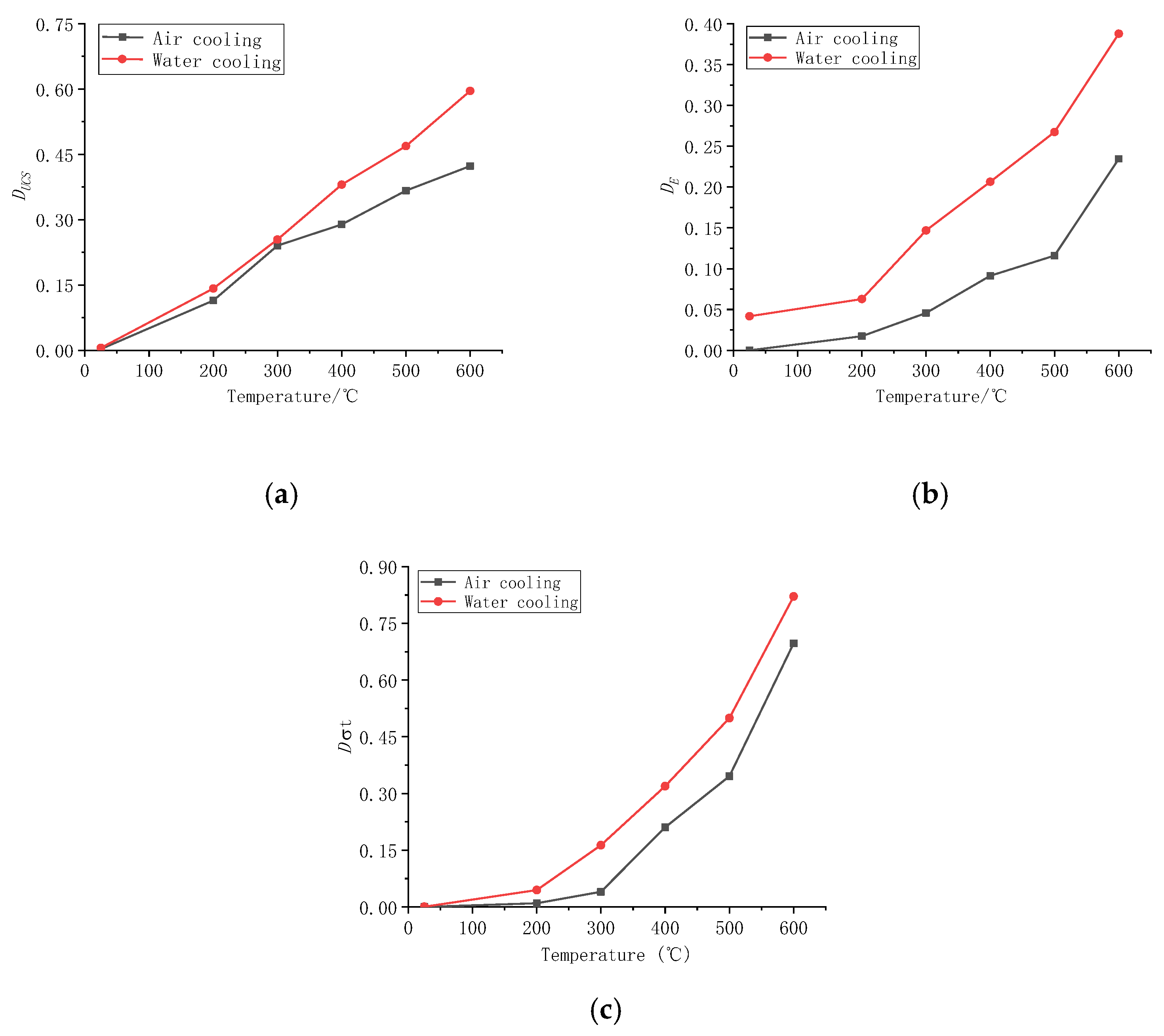

3.3. Mechanics Parameters

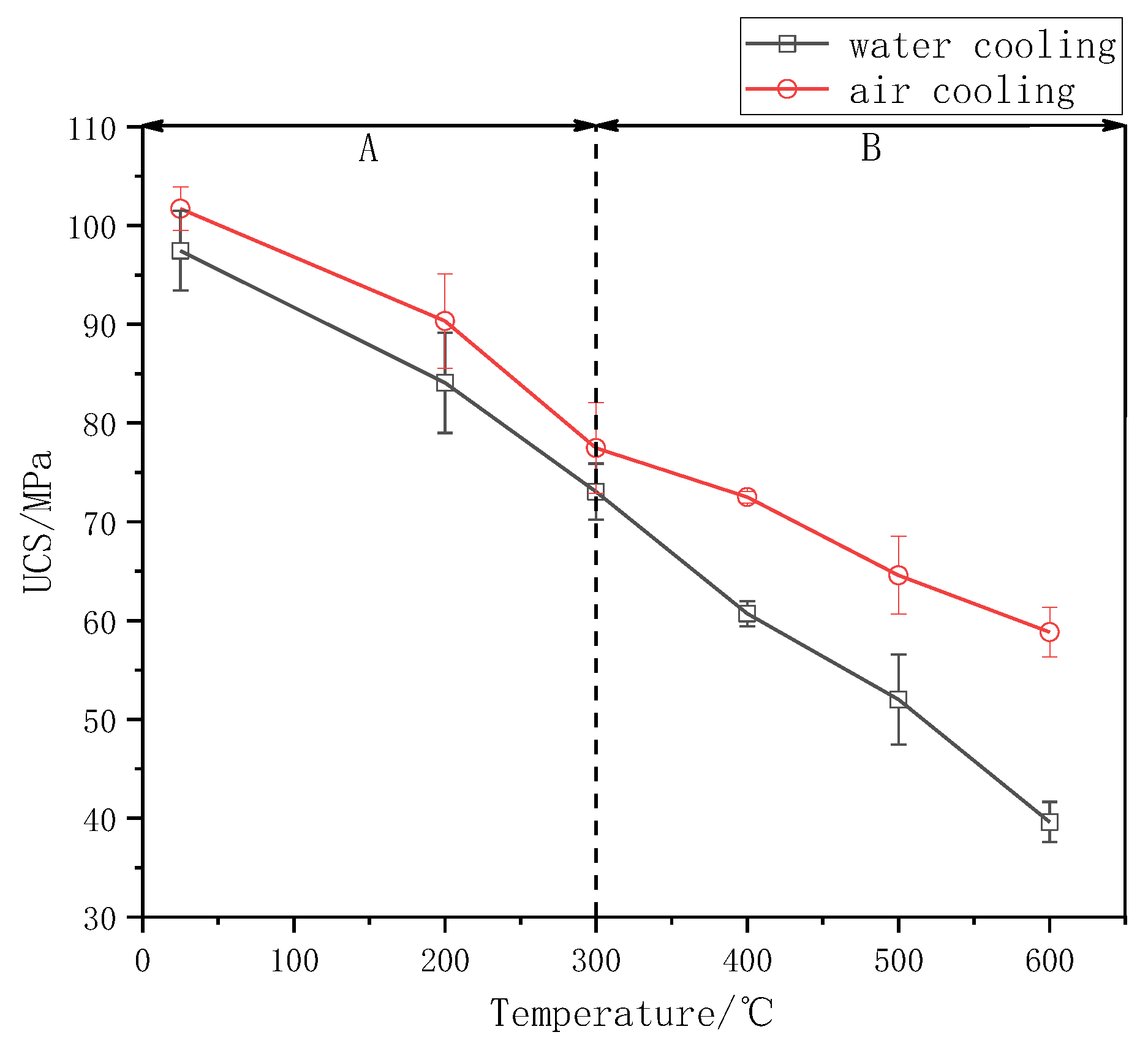

3.3.1. Uniaxial Compressive Strength

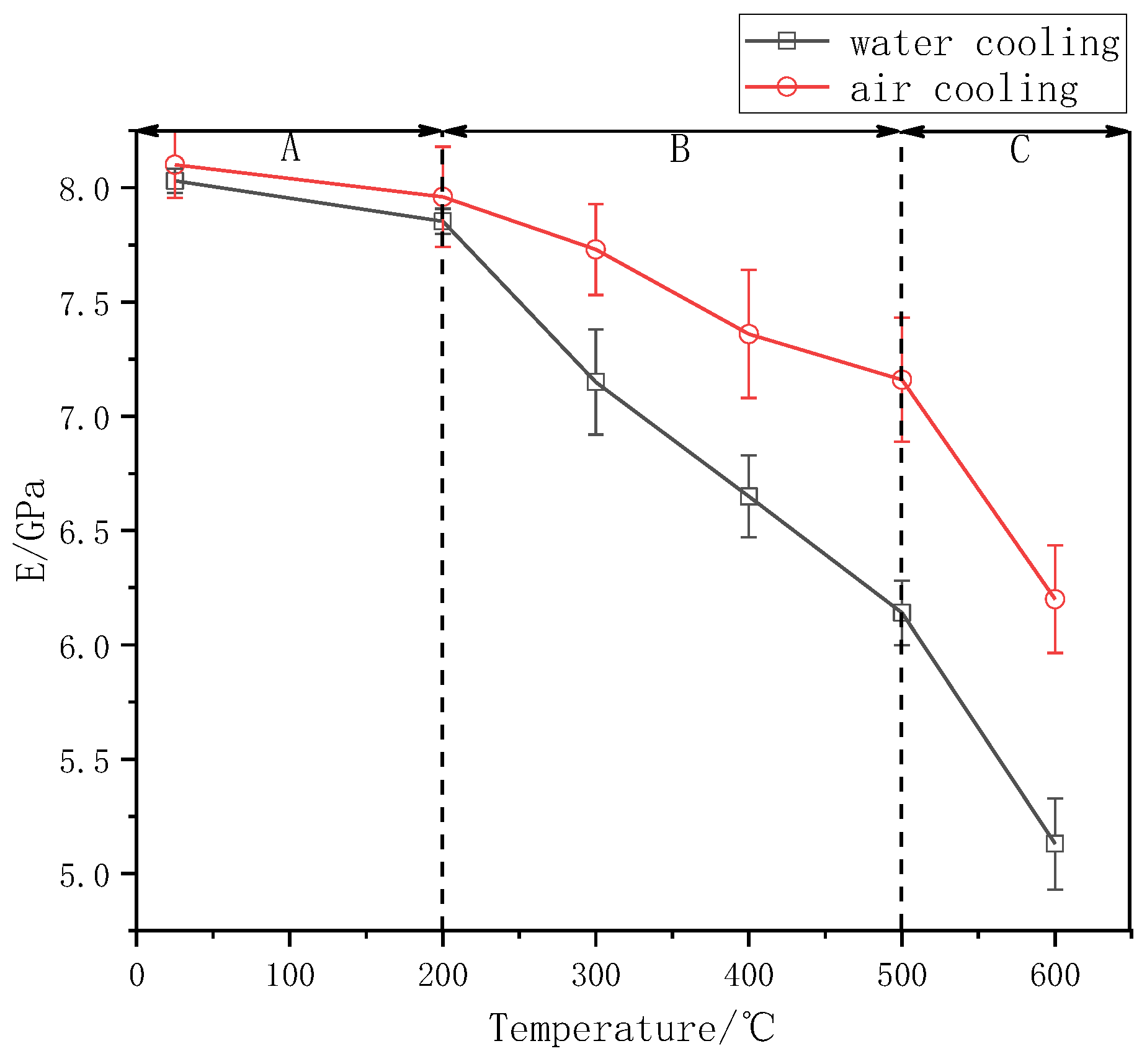

3.3.2. Elasticity Modulus

3.3.3. Tensile Strength

3.4. Failure Patterns

3.4.1. Failure Patterns under Uniaxial Compression Tests

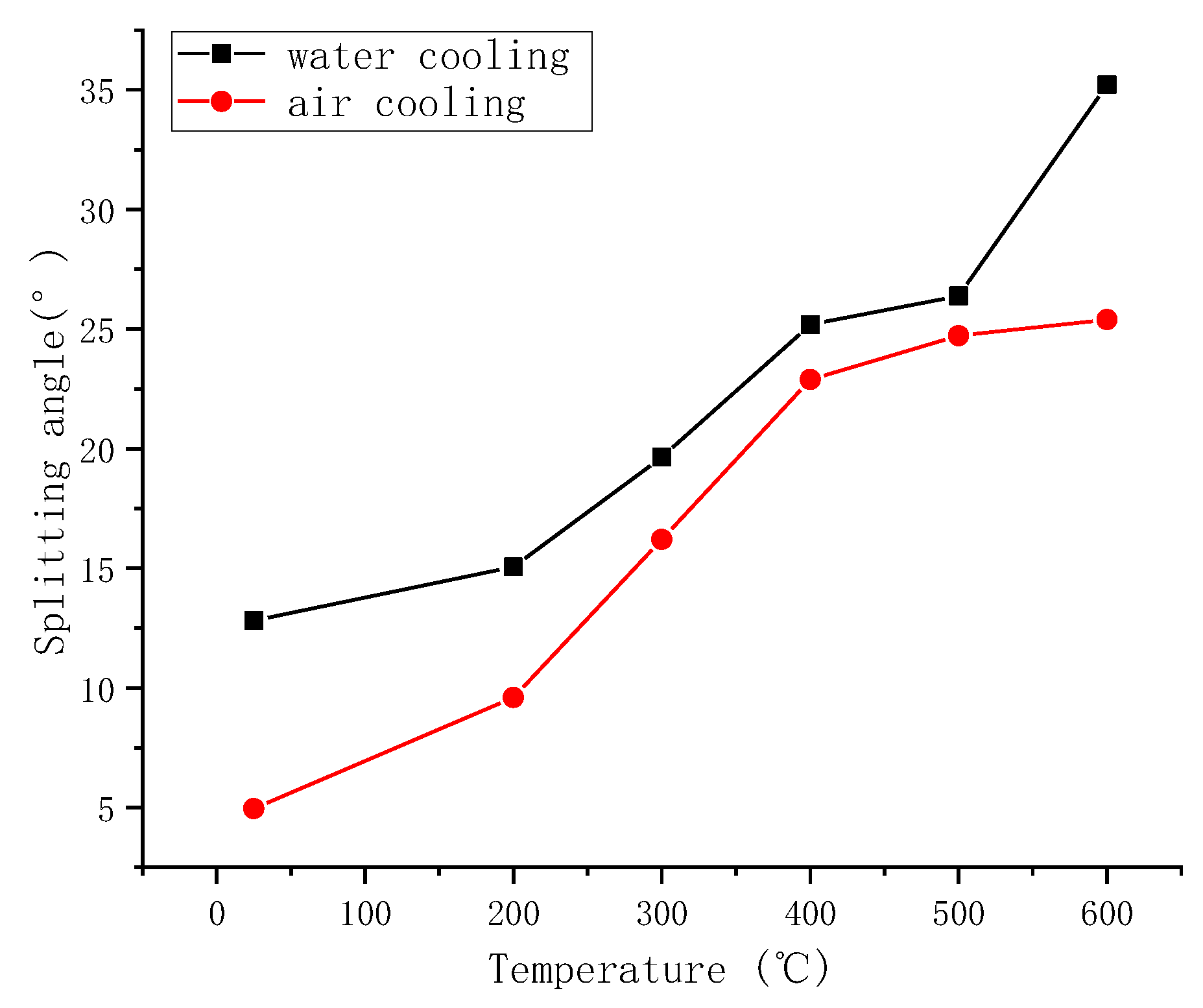

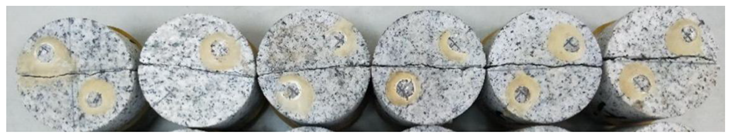

3.4.2. Failure Patterns under Brazil Splitting Tests

4. Discussion

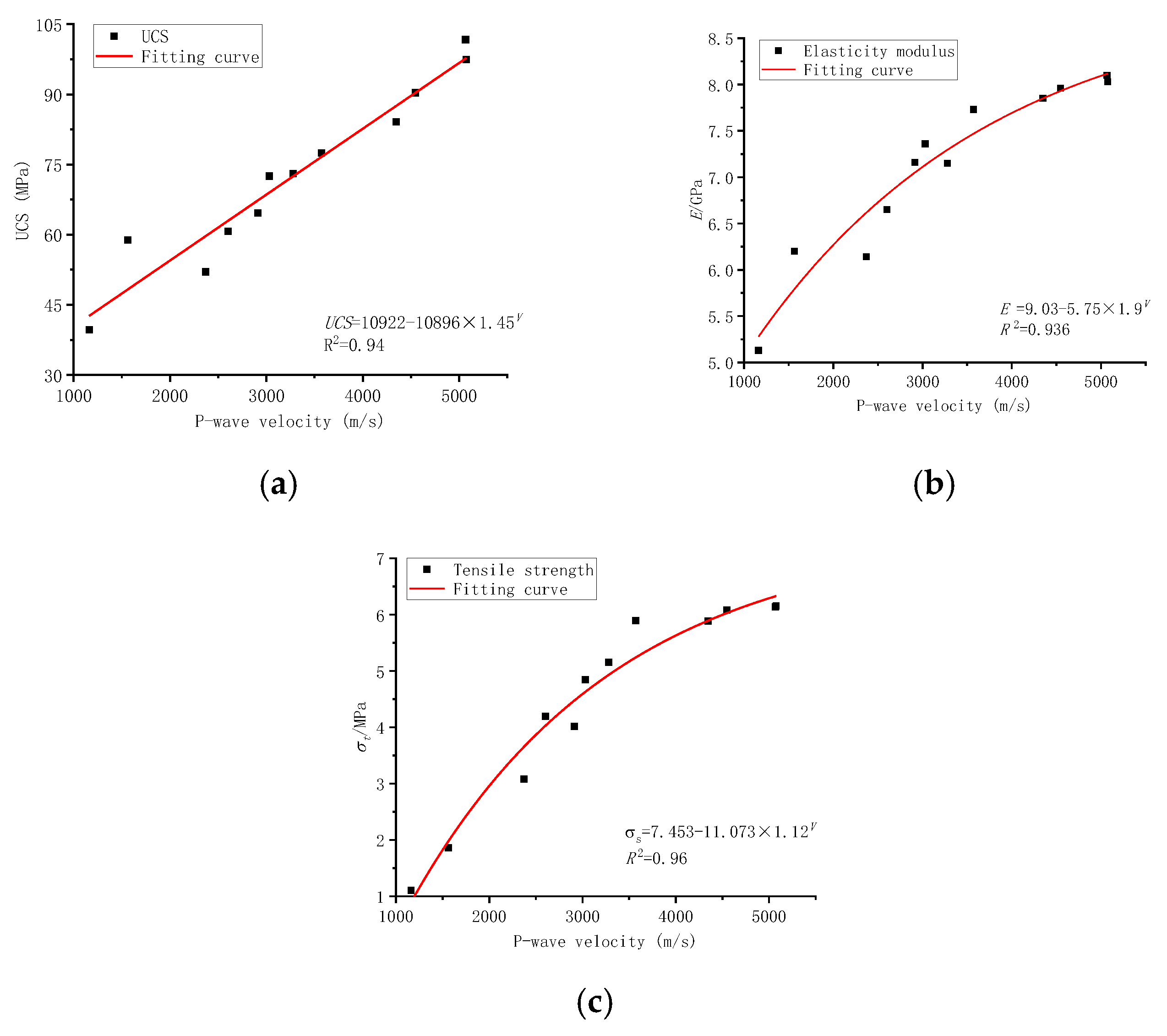

4.1. Relationship between VP and Mechanical Parameters of Granite

4.2. Effect of Temperature on Physical and Mechanics Behaviors

4.3. Effect of Thermal Shock on Failure Patterns of Rocks

4.4. Application of the Present Experimental Investigation

5. Conclusions

- (1)

- Thermal shock has a great influence on the physical and mechanical parameters of granite. VP, UCS, E, and σt of heated granite after two cooling methods all show a decreasing trend with temperature. There is a great asymptote fitting between mechanical strength and the P-wave of heated granite after two cooling methods.

- (2)

- High temperature causes uneven expansion of different minerals and further induces the development of microcracks. The degradation of physical and mechanical properties can be attributed to the generation and propagation of microcracks.

- (3)

- Water cooling further degrades the physical and mechanical behaviors of granite, compared with air cooling. Thermal shock caused by water cooling induces more microcracks, and water permeating into granite also further causes the propagation of microcracks.

- (4)

- Thermal shock can change the mechanical behavior of granite specimens. The splitting angle gradually increases with treatment temperature, and the rock failure pattern gradually transforms from longitudinal fracture to shear failure. A rapid cooling rate can exaggerate the damage degree of the granite specimens.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Majorowicz, J.; Grasby, S.E. Deep Geothermal Heating Potential for the Communities of the Western Canadian Sedimentary Basin. Energies 2021, 14, 706. [Google Scholar] [CrossRef]

- Noorollahi, Y.; Shabbir, M.S.; Siddiqi, A.F.; Ilyashenko, L.K.; Ahmadi, E. Review of two decade geothermal energy development in Iran, benefits, challenges, and future policy. Geothermics 2019, 77, 257–266. [Google Scholar] [CrossRef]

- Mahlia, T.M.I.; Yanti, P.A.A. Cost efficiency analysis and emission reduction by implementation of energy efficiency standards for electric motors. J. Clean. Prod. 2010, 18, 365–374. [Google Scholar] [CrossRef]

- Isaka, B.L.A.; Gamage, R.P.; Rathnaweera, T.D.; Perera, M.S.A.; Chandrasekharam, D.; Kumari, W.G.P. An Influence of Thermally-Induced Micro-Cracking under Cooling Treatments: Mechanical Characteristics of Australian Granite. Energies 2018, 11, 13386. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Z.; Tian, H.; Kempka, T.; Jiang, G.; Dou, B.; Mei, G. Mechanical Behaviors of Granite After Thermal Treatment Under Loading and Unloading Conditions. Nat. Resour. Res. 2021, 30, 2733–2752. [Google Scholar] [CrossRef]

- Li, K.; Bian, H.; Liu, C.; Zhang, D.; Yang, Y. Comparison of geothermal with solar and wind power generation systems. Renew. Sust. Energy Rev. 2015, 42, 1464–1474. [Google Scholar] [CrossRef]

- Bakhoda, H.; Almassi, M.; Moharamnejad, N.; Moghaddasi, R.; Azkia, M. Energy production trend in Iran and its effect on sustainable development. Renew. Sust. Energy Rev. 2012, 16, 1335–1339. [Google Scholar] [CrossRef]

- Zeng, Y.; Su, Z.; Wu, N. Numerical simulation of heat production potential from hot dry rock by water circulating through two horizontal wells at Desert Peak geothermal field. Energy 2013, 56, 92–107. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, Z.; Xi, B.; Wan, Z.; Yang, D.; Liang, W. Deformation and instability failure of borehole at high temperature and high pressure in Hot Dry Rock exploitation. Renew. Energy 2015, 77, 159–165. [Google Scholar] [CrossRef]

- Siratovich, P.A.; Villeneuve, M.C.; Cole, J.W.; Kennedy, B.M.; Begue, F. Saturated heating and quenching of three crustal rocks and implications for thermal stimulation of permeability in geothermal reservoirs. Int. J. Rock Mech. Min. Sci. 2015, 80, 265–280. [Google Scholar] [CrossRef]

- Zhu, M.; Yu, L.; Zhang, X.; Davarpanah, A. Application of Implicit Pressure-Explicit Saturation Method to Predict Filtrated Mud Saturation Impact on the Hydrocarbon Reservoirs Formation Damage. Mathematics 2020, 8, 1057. [Google Scholar] [CrossRef]

- Gens, A.; Guimaraes, L.D.N.; Garcia-Molina, A.; Alonso, E.E. Factors controlling rock–clay buffer interaction in a radioactive waste repository. Eng. Geol. 2002, 64, 297–308. [Google Scholar] [CrossRef] [Green Version]

- Davarpanah, A.; Shirmohammadi, R.; Mirshekari, B.; Aslani, A. Analysis of hydraulic fracturing techniques: Hybrid fuzzy approaches. Arab. J. Geosci. 2019, 12, 402. [Google Scholar] [CrossRef]

- Zhu, Z.; Tian, H.; Chen, J.; Jiang, G.; Dou, B.; Xiao, P.; Mei, G. Experimental investigation of thermal cycling effect on physical and mechanical properties of heated granite after water cooling. Bull. Eng. Geol. Environ. 2020, 79, 2457–2465. [Google Scholar] [CrossRef]

- Fox, D.B.; Sutter, D.; Beckers, K.F.; Lukawski, M.Z.; Koch, D.L.; Anderson, B.J.; Tester, J.W. Sustainable heat farming: Modeling extraction and recovery in discretely fractured geothermal reservoirs. Geothermics 2013, 46, 42–54. [Google Scholar] [CrossRef]

- Fairhurst, C. Nuclear waste disposal and rock mechanics: Contributions of the Underground Research Laboratory (URL), Pinawa, Manitoba, Canada. Int. J. Rock Mech. Min. Sci. 2004, 41, 1221–1227. [Google Scholar] [CrossRef]

- Géraud, Y.; Mazerolle, F.; Raynaud, S. Comparison between connected and overall porosity of thermally stressed granites. J. Struct. Geol. 1992, 14, 981–990. [Google Scholar] [CrossRef]

- Zhu, Z.; Tian, H.; Mei, G.; Jiang, G.; Dou, B.; Xiao, P. Experimental investigation on mechanical behaviors of Nanan granite after thermal treatment under conventional triaxial compression. Environ. Earth Sci. 2021, 80, 46. [Google Scholar] [CrossRef]

- Zhang, W.; Sun, Q.; Hao, S.; Geng, J.; Lv, C. Experimental study on the variation of physical and mechanical properties of rock after high temperature treatment. Appl. Therm. Eng. 2016, 98, 1297–1304. [Google Scholar] [CrossRef]

- Vazquez, P.; Shushakova, V.; Gomez-Heras, M. Influence of mineralogy on granite decay induced by temperature increase: Experimental observations and stress simulation. Eng. Geol. 2015, 189, 58–67. [Google Scholar] [CrossRef]

- Zhu, Z.; Ranjith, P.G.; Tian, H.; Jiang, G.; Dou, B.; Mei, G. Relationships between P-wave velocity and mechanical properties of granite after exposure to different cyclic heating and water cooling treatments. Renew. Energy 2021, 168, 375–392. [Google Scholar] [CrossRef]

- Shen, Y.; Yuan, J.; Hou, X.; Hao, J.; Bai, Z.; Li, T. The strength changes and failure modes of high-temperature granite subjected to cooling shocks. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 23. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Chen, B.K.; Abdulagatov, I.M. Temperature-dependent mechanical behaviour of Australian Strathbogie granite with different cooling treatments. Eng. Geol. 2017, 229, 31–44. [Google Scholar] [CrossRef]

- Peng, J.; Yang, S. Comparison of Mechanical Behavior and Acoustic Emission Characteristics of Three Thermally-Damaged Rocks. Energies 2018, 11, 2350. [Google Scholar] [CrossRef] [Green Version]

- Martyushev, D.A.; Galkin, S.V.; Shelepov, V.V. The Influence of the Rock Stress State on Matrix and Fracture Permeability under Conditions of Various Lithofacial Zones of the Tournaisian–Fammenian Oil Fields in the Upper Kama Region. Mosc. Univ. Geol. Bull. 2019, 74, 573–581. [Google Scholar] [CrossRef]

- Martyushev, D.A. Rock stress state influence on permeability of carbonate reservoirs. Bull. Tomsk Polytech. Univ. 2020, 8, 24–33. [Google Scholar]

- David, C.; Menendez, B.; Darot, M. Influence of stress-induced and thermal cracking on physical properties and microstructure of La Peyratte granite. Int. J. Rock Mech. Min. Sci. 1999, 36, 433–448. [Google Scholar] [CrossRef]

- Griffiths, L.; Heap, M.J.; Baud, P.; Schmittbuhl, J. Quantification of microcrack characteristics and implications for stiffness and strength of granite. Int. J. Rock Mech. Min. Sci. 2017, 100, 138–150. [Google Scholar] [CrossRef]

- Fredrich, J.T.; Wong, T.F. Micromechanics of thermally induced cracking in three crustal rocks. J. Geophys. Res. Solid Earth 1986, 91, 12743–12764. [Google Scholar] [CrossRef]

- Tang, Z.C.; Sun, M.; Peng, J. Influence of high temperature duration on physical, thermal and mechanical properties of a fine-grained marble. Appl. Therm. Eng. 2019, 156, 34–50. [Google Scholar] [CrossRef]

- Chen, S.; Yang, C.; Wang, G. Evolution of thermal damage and permeability of Beishan granite. Appl. Therm. Eng. 2017, 110, 1533–1542. [Google Scholar] [CrossRef]

- Khamrat, S.; Thongprapha, T.; Fuenkajorn, K. Thermal effects on shearing resistance of fractures in Tak granite. J. Struct. Geol. 2018, 111, 64–74. [Google Scholar] [CrossRef]

- Peng, J.; Rong, G.; Cai, M.; Yao, M.; Zhou, C. Physical and mechanical behaviors of a thermal-damaged coarse marble under uniaxial compression. Eng. Geol. 2016, 200, 88–93. [Google Scholar] [CrossRef]

- Wu, Q.; Weng, L.; Zhao, Y.; Guo, B.; Luo, T. On the tensile mechanical characteristics of fine-grained granite after heating/cooling treatments with different cooling rates. Eng. Geol. 2019, 253, 94–110. [Google Scholar] [CrossRef]

- Zhao, F.; Shi, Z.; Sun, Q. Fracture Mechanics Behavior of Jointed Granite Exposed to High Temperatures. Rock Mech. Rock Eng. 2021, 54, 2183–2196. [Google Scholar] [CrossRef]

- Wang, X.; Schubnel, A.; Fortin, J.; Gueguen, Y.; Ge, H. Physical properties and brittle strength of thermally cracked granite under confinement. J. Geophys. Res. Solid Earth 2013, 118, 6099–6112. [Google Scholar] [CrossRef]

- Nasseri, M.H.B.; Schubnel, A.; Young, R.P. Coupled evolutions of fracture toughness and elastic wave velocities at high crack density in thermally treated Westerly granite. Int. J. Rock Mech. Min. Sci. 2007, 44, 601–616. [Google Scholar] [CrossRef]

- Alm, O.; Jaktlund, L.L.; Shaoquan, K. The influence of microcrack density on the elastic and fracture mechanical-properties of stripa granite. Phys. Earth Planet. Inter. 1985, 40, 161–179. [Google Scholar] [CrossRef] [Green Version]

- Zarei, V.; Mirzaasadi, M.; Davarpanah, A.; Nasiri, A.; Valizadeh, M.; Hosseini, M.J.S. Environmental Method for Synthesizing Amorphous Silica Oxide Nanoparticles from a Natural Material. Processes 2021, 9, 334. [Google Scholar] [CrossRef]

- Zhu, Z.; Tian, H.; Mei, G.; Jiang, G.; Dou, B. Experimental investigation on physical and mechanical properties of thermal cycling granite by water cooling. Acta Geotech. 2020, 15, 1881–1893. [Google Scholar] [CrossRef]

- Zhu, Z.; Tian, H.; Jiang, G.; Cheng, W. Effects of High Temperature on the Mechanical Properties of Chinese Marble. Rock Mech. Rock Eng. 2018, 51, 1937–1942. [Google Scholar] [CrossRef]

- Sun, W.; Wu, S.; Xu, X. Mechanical behaviour of Lac du Bonnet granite after high-temperature treatment using bonded-particle model and moment tensor. Comput. Geotech. 2021, 135, 104132. [Google Scholar] [CrossRef]

- Griffiths, L.; Lengline, O.; Heap, M.J.; Baud, P.; Schmittbuhl, J. Thermal Cracking in Westerly Granite Monitored Using Direct Wave Velocity, Coda Wave Interferometry, and Acoustic Emissions. J. Geophys. Res. Solid Earth 2018, 123, 2246–2261. [Google Scholar] [CrossRef]

- Shao, Z.; Tang, X.; Wang, X. The influence of liquid nitrogen cooling on fracture toughness of granite rocks at elevated temperatures: An experimental study. Eng. Fract. Mech. 2021, 246, 107628. [Google Scholar] [CrossRef]

- Yong, C.; Wang, C.Y. Thermally induced acoustic emission in westerly granite. Geophys. Res. Lett. 1980, 7, 1089–1092. [Google Scholar] [CrossRef]

- Shao, S.; Wasantha, P.L.P.; Ranjith, P.G.; Chen, B.K. Effect of cooling rate on the mechanical behavior of heated Strathbogie granite with different grain sizes. Int. J. Rock Mech. Min. Sci. 2014, 70, 381–387. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, Y.; Yu, Y.; Hu, D.; Shao, J. Influence of cooling rate on thermal degradation of physical and mechanical properties of granite. Int. J. Rock Mech. Min. Sci. 2020, 129, 104285. [Google Scholar] [CrossRef]

- Heap, M.J.; Coats, R.; Chen, C.; Varley, N.; Lavallee, Y.; Kendrick, J.; Xu, T.; Reuschle, T. Thermal resilience of microcracked andesitic dome rocks. J. Volcanol. Geoth. Res. 2018, 367, 20–30. [Google Scholar] [CrossRef]

- Lu, G.; Zhou, J.; Li, Y.; Zhang, X.; Gao, W. The influence of minerals on the mechanism of microwave-induced fracturing of rocks. J. Appl. Geophys. 2020, 180, 104123. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, S.; Tian, W. Peridynamic simulation of fracture mechanical behaviour of granite specimen under real-time temperature and post-temperature treatments. Int. J. Rock Mech. Min. Sci. 2021, 138, 104573. [Google Scholar] [CrossRef]

- Zhang, B.; Tian, H.; Dou, B.; Zheng, J.; Chen, J.; Zhu, Z.; Liu, H. Macroscopic and microscopic experimental research on granite properties after high-temperature and water-cooling cycles. Geothermics 2021, 93, 102079. [Google Scholar] [CrossRef]

- Walsh, J.B. The effect of cracks on the compressibility of rock. J. Geophys. Res. 1965, 70, 381–389. [Google Scholar] [CrossRef]

- David, E.C.; Brantut, N.; Schubnel, A.; Zimmerman, R.W. Sliding crack model for nonlinearity and hysteresis in the uniaxial stress-strain curve of rock. Int. J. Rock Mech. Min. Sci. 2012, 52, 9–17. [Google Scholar] [CrossRef]

- Heap, M.J.; Lavallee, Y.; Laumann, A.; Hess, K.U.; Meredith, P.G.; Dingwell, D.B.; Huismann, S.; Weise, F. The influence of thermal-stressing (up to 1000 degrees C) on the physical, mechanical, and chemical properties of siliceous-aggregate, high-strength concrete. Constr. Build. Mater. 2013, 42, 248–265. [Google Scholar] [CrossRef]

- Jin, P.; Hu, Y.; Shao, J.; Zhao, G.; Zhu, X.; Li, C. Influence of different thermal cycling treatments on the physical, mechanical and transport properties of granite. Geothermics 2019, 78, 118–128. [Google Scholar] [CrossRef]

- Freire-Lista, D.M.; Fort, R.; Varas-Muriel, M.J. Thermal stress-induced microcracking in building granite. Eng. Geol. 2016, 206, 83–93. [Google Scholar] [CrossRef] [Green Version]

- Yang, F.; Wang, G.; Hu, D.; Liu, Y.; Zhou, H.; Tan, X. Calibrations of thermo-hydro-mechanical coupling parameters for heating and water-cooling treated granite. Renew. Energy 2021, 168, 544–558. [Google Scholar] [CrossRef]

- Glover, P.; Baud, P.; Darot, M.; Meredith, P.G.; Boon, S.A.; Leravalec, M.; Zoussi, S.; Reuschlé, T. α/β phase transition in quartz monitored using acoustic emissions. Geophys. J. Int. 1995, 120, 775–782. [Google Scholar] [CrossRef]

| Cooling Route | Water Cooling | Air Cooling | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature/°C | 25 | 200 | 300 | 400 | 500 | 600 | 25 | 200 | 300 | 400 | 500 | 600 | |

| UCS/MPa | No. 1 | 94.38 | 89.93 | 71.06 | 60.72 | 47.55 | 41.20 | 102.99 | 91.37 | 73.73 | 72.26 | 69.09 | 57.02 |

| No. 2 | 102.00 | 81.30 | 76.32 | 59.44 | 51.89 | 37.33 | 102.96 | 94.50 | 82.61 | 72.09 | 61.74 | 61.71 | |

| No. 3 | 95.91 | 81.02 | 71.81 | 61.98 | 56.64 | 40.34 | 99.13 | 85.11 | 76.07 | 73.17 | 62.96 | 57.80 | |

| Ave. | 97.43 | 84.08 | 73.06 | 60.71 | 52.03 | 39.62 | 101.70 | 90.33 | 77.47 | 72.51 | 64.6 | 58.84 | |

| E/GPa | No. 1 | 7.99 | 7.91 | 7.38 | 6.83 | 5.99 | 5.00 | 8.09 | 7.71 | 7.84 | 7.64 | 7.27 | 5.97 |

| No. 2 | 8.09 | 7.85 | 6.92 | 6.65 | 6.16 | 5.03 | 8.25 | 8.12 | 7.85 | 7.36 | 6.85 | 6.19 | |

| No. 3 | 8.01 | 7.8 | 7.15 | 6.47 | 6.27 | 5.36 | 7.96 | 8.05 | 7.5 | 7.08 | 7.36 | 6.44 | |

| Ave. | 8.03 | 7.85 | 7.15 | 6.65 | 6.14 | 5.13 | 8.1 | 7.96 | 7.73 | 7.36 | 7.16 | 6.20 | |

| σt/MPa | No. 1 | 6.16 | 5.89 | 5.15 | 4.19 | 3.08 | 1.10 | 6.14 | 6.08 | 5.89 | 4.85 | 4.02 | 1.90 |

| No. 2 | 6.18 | 5.89 | 5.09 | 4.27 | 3.09 | 1.15 | 6.14 | 6.10 | 5.87 | 4.86 | 4.02 | 1.89 | |

| No. 3 | 6.14 | 5.88 | 5.18 | 4.15 | 3.08 | 1.08 | 6.11 | 6.07 | 5.93 | 4.85 | 4.00 | 1.89 | |

| Ave. | 6.16 | 5.89 | 5.14 | 4.20 | 3.09 | 1.11 | 6.13 | 6.08 | 5.9 | 4.85 | 4.01 | 1.90 | |

| VP/m/s | No. 1 | 4.69 | 4.35 | 3.45 | 2.44 | 2.38 | 1.35 | 5.27 | 4.35 | 3.77 | 3.23 | 3.14 | 1.61 |

| No. 2 | 5.27 | 4.35 | 3.26 | 2.80 | 2.40 | 1.10 | 5.09 | 4.55 | 3.57 | 3.03 | 2.74 | 1.59 | |

| No. 3 | 5.26 | 4.35 | 3.13 | 2.56 | 2.33 | 1.04 | 4.84 | 4.75 | 3.37 | 2.83 | 2.86 | 1.49 | |

| Ave. | 5.08 | 4.35 | 3.28 | 2.60 | 2.37 | 1.16 | 5.07 | 4.55 | 3.57 | 3.03 | 2.91 | 1.56 | |

| Cooling Route | 25 °C | 200 °C | 300 °C | 400 °C | 500 °C | 600 °C |

|---|---|---|---|---|---|---|

| Water Cooling |  |  |  |  |  |  |

| Air Cooling |  |  |  |  |  |  |

| Cooling Method | 25 °C | 200 °C | 300 °C | 400 °C | 500 °C | 600 °C |

|---|---|---|---|---|---|---|

| Water Cooling |  | |||||

| Air Cooling |  | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, P.; Zheng, J.; Dou, B.; Tian, H.; Cui, G.; Kashif, M. Mechanical Behaviors of Granite after Thermal Shock with Different Cooling Rates. Energies 2021, 14, 3721. https://doi.org/10.3390/en14133721

Xiao P, Zheng J, Dou B, Tian H, Cui G, Kashif M. Mechanical Behaviors of Granite after Thermal Shock with Different Cooling Rates. Energies. 2021; 14(13):3721. https://doi.org/10.3390/en14133721

Chicago/Turabian StyleXiao, Peng, Jun Zheng, Bin Dou, Hong Tian, Guodong Cui, and Muhammad Kashif. 2021. "Mechanical Behaviors of Granite after Thermal Shock with Different Cooling Rates" Energies 14, no. 13: 3721. https://doi.org/10.3390/en14133721

APA StyleXiao, P., Zheng, J., Dou, B., Tian, H., Cui, G., & Kashif, M. (2021). Mechanical Behaviors of Granite after Thermal Shock with Different Cooling Rates. Energies, 14(13), 3721. https://doi.org/10.3390/en14133721