Extended Permanent Magnet Synchronous Motors Speed Range Based on the Active and Reactive Power Control of Inverters

Abstract

1. Introduction

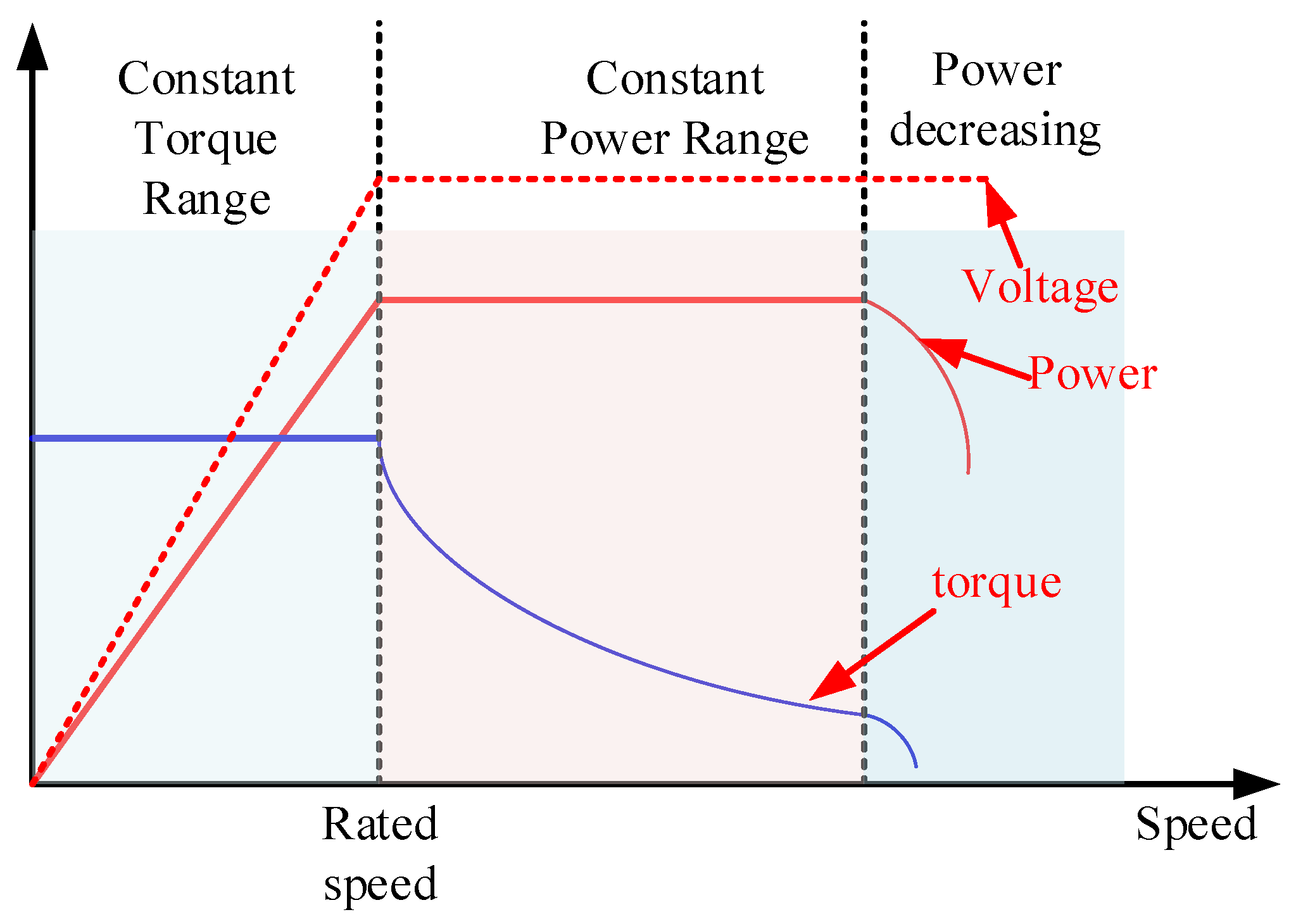

2. Speed Control of PMSM Drive Systems

2.1. PMSM Model and Its Limitations

- J: The inertia of motor and load combined referred to the motor shaft.

- F: The combined viscous friction coefficient of rotor and load.

- θ: Rotor angular position.

- TL: Shaft load torque.

- θm: Angular velocity of the rotor (mechanical speed)

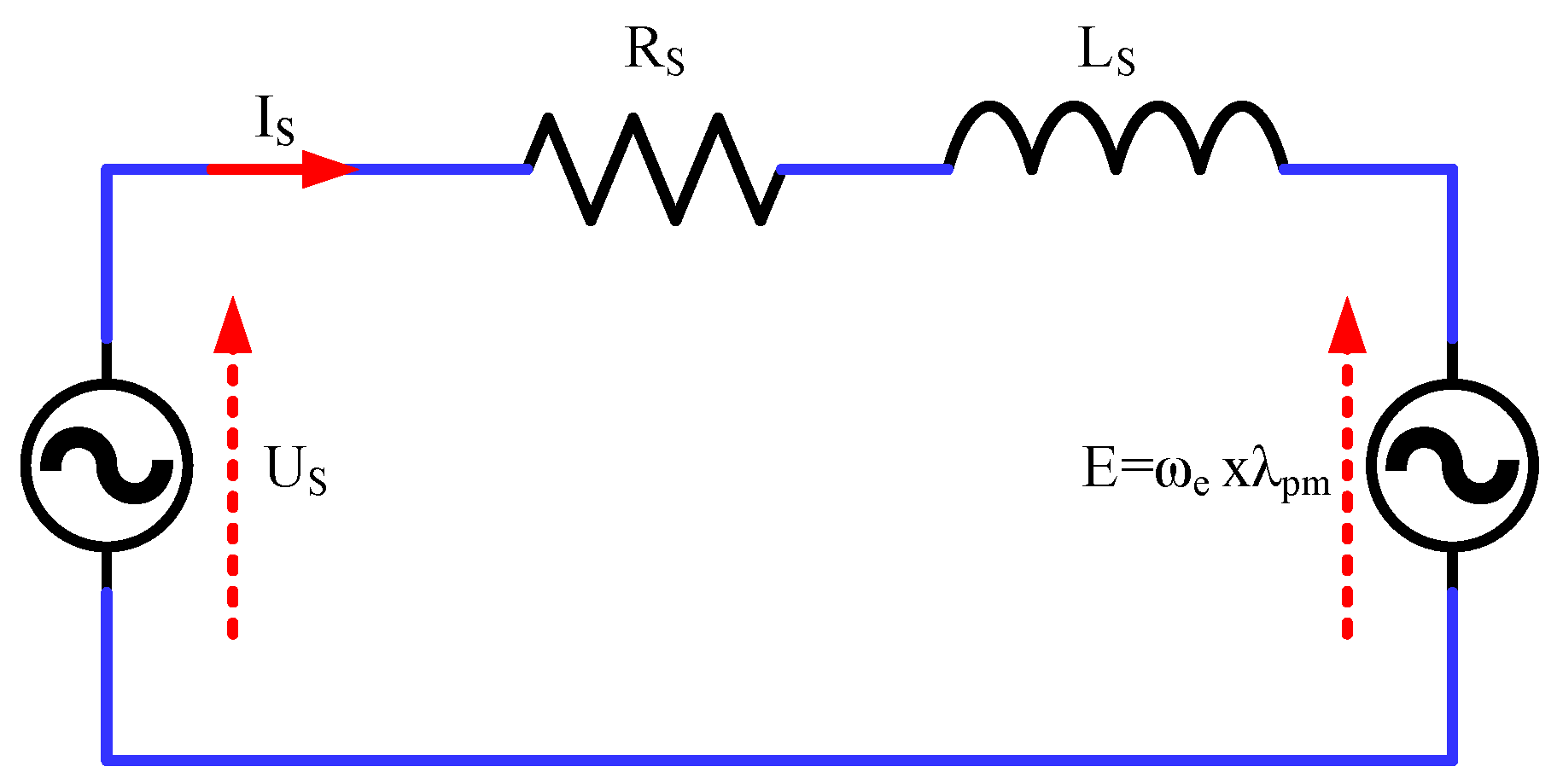

2.2. Principle of Transferring Power from the Inverter to the Motor

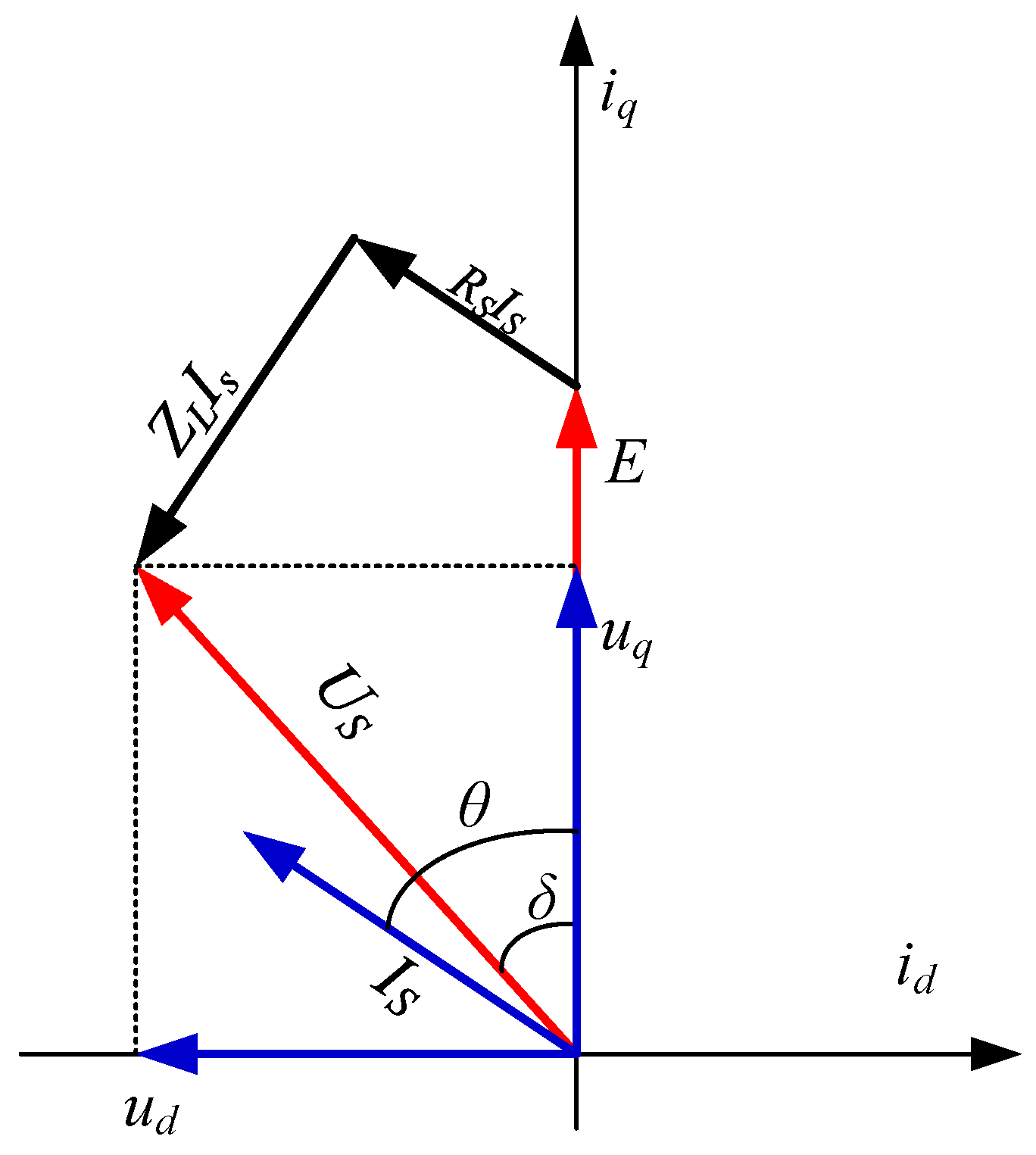

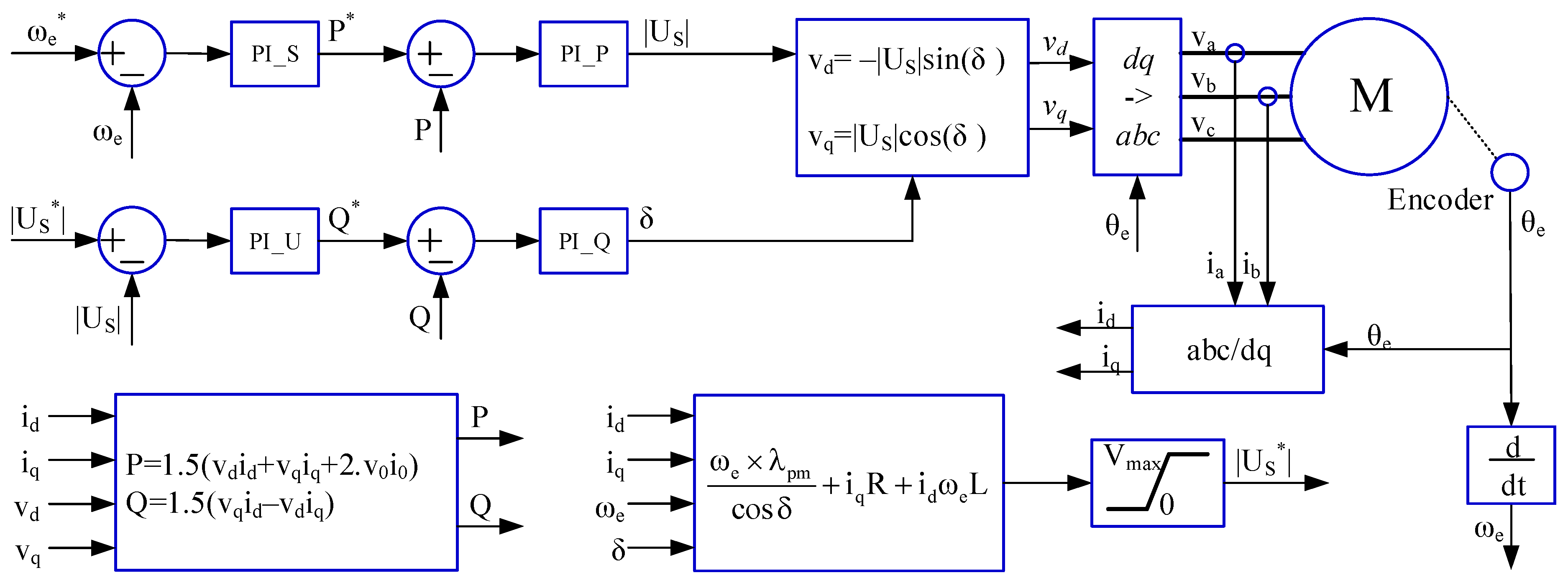

3. The Principle of Controlling the Speed of a PMSM Motor Is Based on the Power Control PQ

- The active power is adjusted through the speed PI controller (PI_S) from the actual speed difference compared to the reference speed.

- The power PI controller is used to change the inverter voltage amplitude, to change the power supplied to the inverter according to the reference power,

- To ensure that reactive power Q is not fed to the BEMF source, the inverter voltage must be kept at a value according to (18) and must not exceed the inverter limit value to optimize motor operation. Inverter voltage must be kept at a determined value; some reactive power must be added (or drawn) from the inverters. The determination of reactive power Q is done via a voltage controller with the input of the error between the reference voltage and the actual voltage at the inverter output.

- The reactive power PI controller corrects the voltage angle δ between U and E, respectively, to change the reactive power to the reference value. The BEMF vector angle is always perpendicular to the direction of the d-axis current component, as shown in Figure 4; the voltage across the inverters’ coordinate system dq is determined according to (19) and (20).

4. Simulation Validation

4.1. Simulation IPMSM Speed Control Model

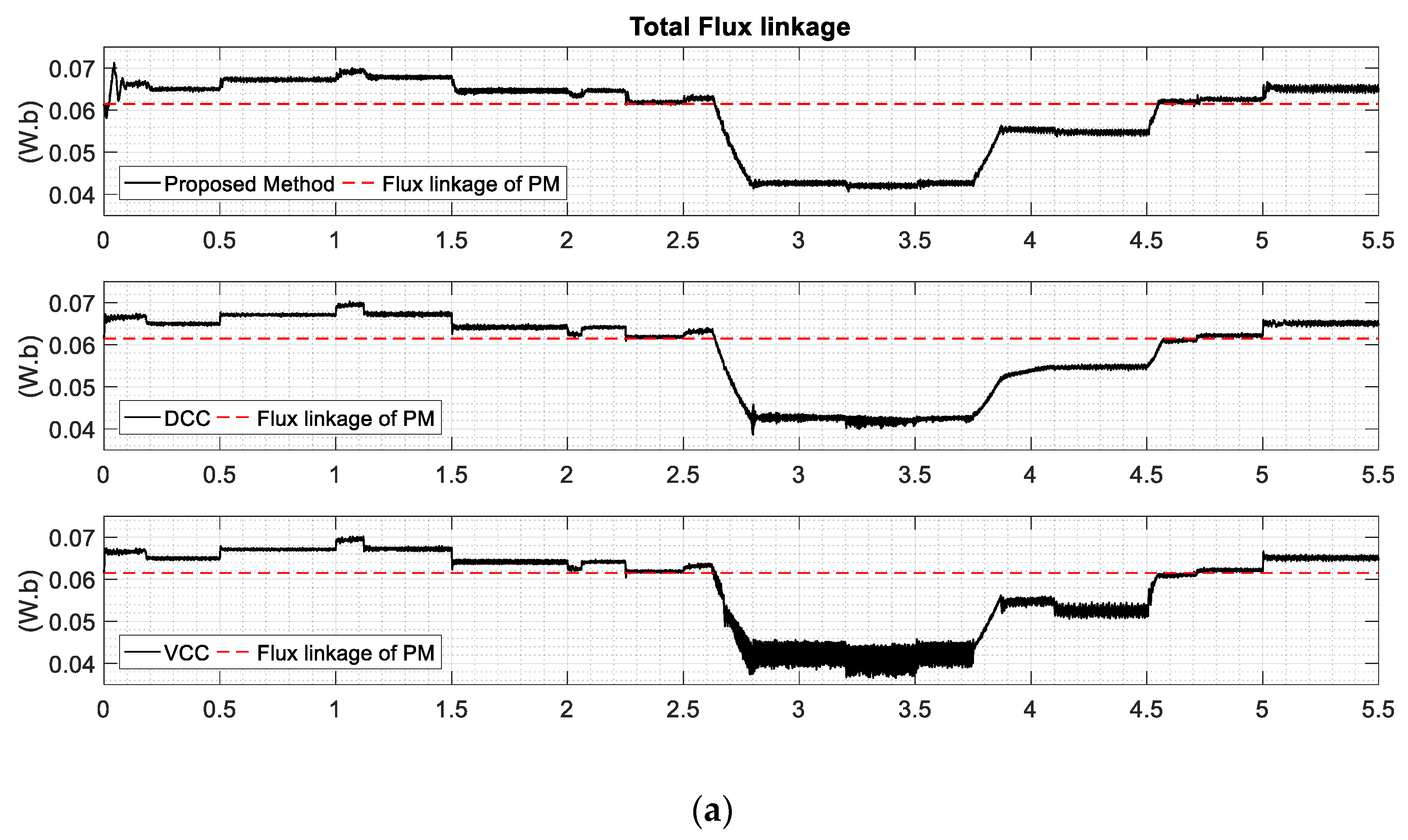

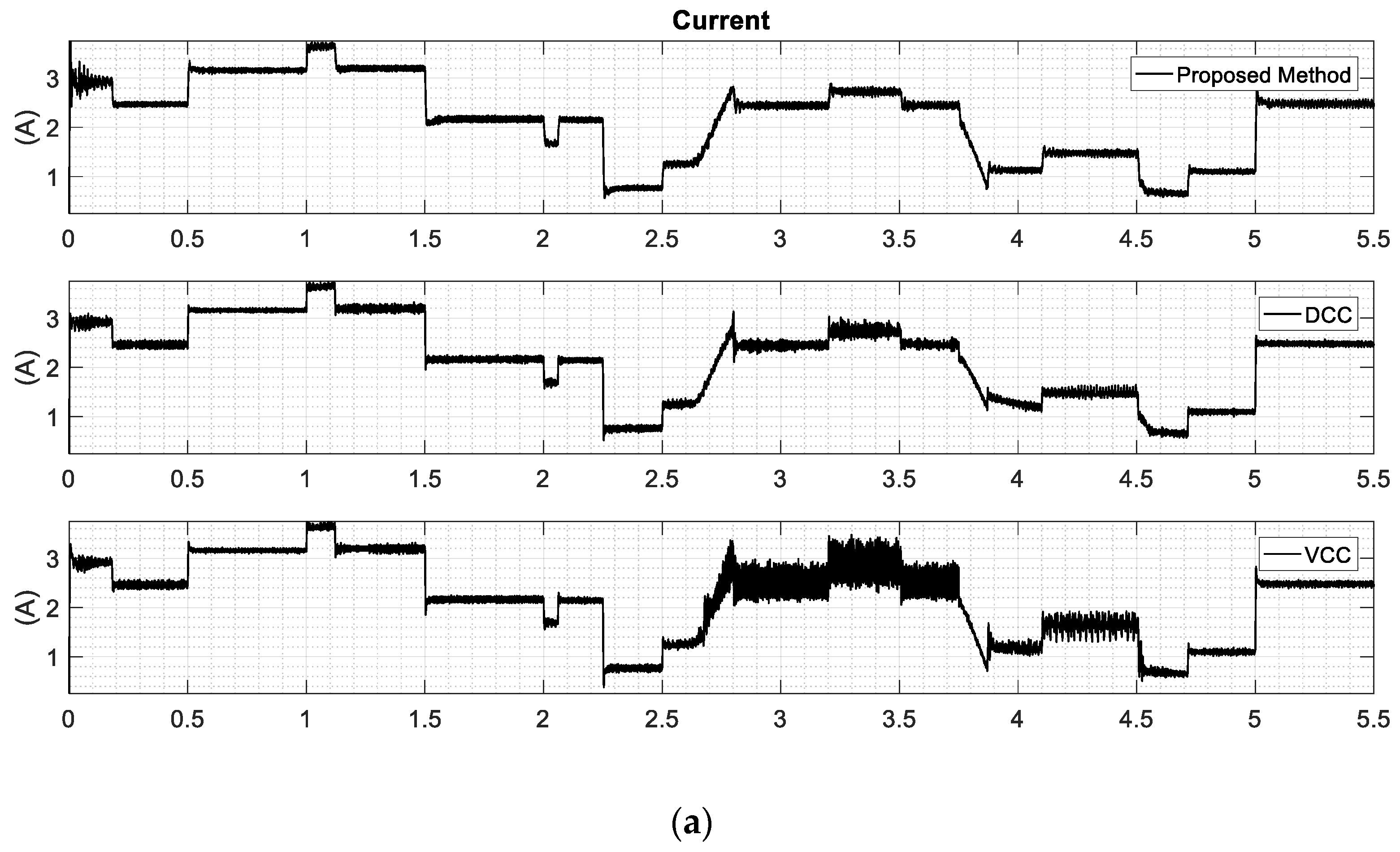

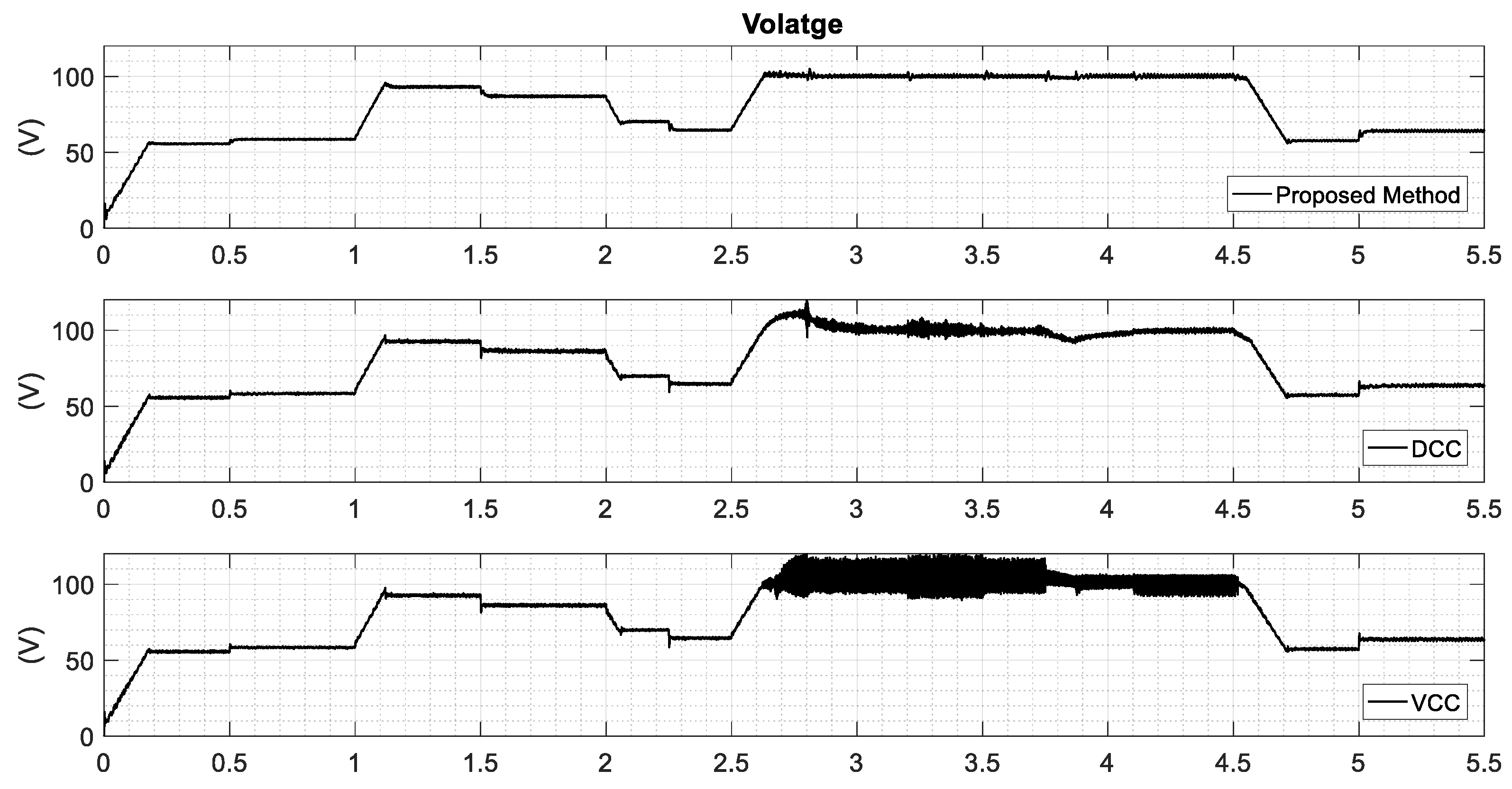

4.2. Simulation Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| vd (vq) | Stator voltage in d–q coordinate system |

| id (iq) | Stator current in d–q coordinate system |

| Ld (Lq) | stator inductance in dq coordinate system |

| λpm | Magnet flux linkage |

| RS | Stator resistance |

| Ω | rotor speed |

| ωe | magnetic field speed |

| Pp | number of pole pairs |

| Te | Electromagnetic torque |

| J | The inertia of motor and load combined reduced to the motor shaft. |

| F | The combined viscous friction coefficient of rotor and load. |

| θ | Rotor angular position |

| TL | Shaft load torque |

| θm | Angular velocity of the rotor (mechanical speed) |

| P1, P2 | Power at the inverter output |

| E | back electromotive force in the stator winding |

| S | transparent power transmitted to the back electromotive force terminal |

| P | Active power transmitted to the back electromotive force terminal |

| Q | Reactive power transmitted to the back electromotive force terminal |

| |Us| | Voltage amplitude at the inverter output |

| φus | the phase of inverters voltage vector |

| φE | the phase of back electromotive force in the stator winding |

| δ | angular deviation between φus and φE |

| β | Phase of winding impedance |

| XL | Winding impedance |

| L | winding inductance |

| ΔU | voltage drop across the winding |

References

- Tang, Z.; Akin, B. A New LMS Algorithm Based Deadtime Compensation Method for PMSM FOC Drives. IEEE Trans. Ind. Appl. 2018, 54, 6472–6484. [Google Scholar] [CrossRef]

- Cash, S.; Olatunbosun, O. Fuzzy logic field-oriented control of an induction motor and a permanent magnet synchronous motor for hybrid/electric vehicle traction applications. Int. J. Electr. Hybrid Veh. 2017, 9, 269–284. [Google Scholar] [CrossRef]

- Lara, J.; Chandra, A. Performance investigation of two novel HSFSI demodulation algorithms for encoderless FOC of PMSMs intended for EV propulsion. IEEE Trans. Ind. Electron. 2017, 65, 1074–1083. [Google Scholar] [CrossRef]

- Lu, D.; Ouyang, M.; Gu, J.; Li, J. Optimal Velocity Control for a Battery Electric Vehicle Driven by Permanent Magnet Synchronous Motors. Math. Probl. Eng. 2014, 2014, 1–14. [Google Scholar] [CrossRef]

- Samat, A.A.A.; Zainal, M.; Ismail, L.; Saidon, W.S.; Tajudin, A.I. Current PI-Gain Determination for Permanent Magnet Synchronous Motor by using Particle Swarm Optimization. Indones. J. Electr. Eng. Comput. Sci. 2017, 6, 412. [Google Scholar] [CrossRef]

- Amin, F.; Sulaiman, E.B.; Utomo, W.M.; Soomro, H.A.; Jenal, M.; Kumar, R. Modelling and Simulation of Field Oriented Control based Permanent Magnet Synchronous Motor Drive System. Indones. J. Electr. Eng. Comput. Sci. 2017, 6, 387. [Google Scholar] [CrossRef]

- Mesloub, H.; Benchouia, M.T.; Goléa, A.; Goléa, N.; Benbouzid, M.E.H. Predictive DTC schemes with PI regulator and particle swarm optimization for PMSM drive: Comparative simulation and experimental study. Int. J. Adv. Manuf. Technol. 2016, 86, 3123–3134. [Google Scholar] [CrossRef]

- Ghamri, A.; Boumaaraf, R.; Benchouia, M.T.; Mesloub, H.; Goléa, A.; Goléa, N. Comparative study of ANN DTC and conventional DTC controlled PMSM motor. Math. Comput. Simul. 2020, 167, 219–230. [Google Scholar] [CrossRef]

- Guven, S.; Usta, M.A.; Okumus, H.I. An improved sensorless DTC-SVM for three-level inverter-fed permanent magnet synchronous motor drive. Electr. Eng. 2018, 100, 2553–2567. [Google Scholar] [CrossRef]

- Ouledali, O.; Meroufel, A.; Wira, P.; Bentouba, S. Direct Torque Fuzzy Control of PMSM based on SVM. Energy Procedia 2015, 74, 1314–1322. [Google Scholar] [CrossRef]

- Mendoza-Mondragõn, F.; Hernández-Guzmán, V.M.; Carrillo-Serrano, R.V. Velocity regulation in pmsms using standard field oriented control plus adaptation. Asian J. Control 2015, 17, 2382–2388. [Google Scholar] [CrossRef]

- Shihua, L.; Zhigang, L. Adaptive Speed Control for Permanent-Magnet Synchronous Motor System with Variations of Load Inertia. IEEE Trans. Ind. Electron. 2009, 56, 3050–3059. [Google Scholar] [CrossRef]

- Guan, Y.; Zhu, Z.; Afinowi, I.; Mipo, J. Influence of machine design parameters on flux-weakening performance of induction machine for electrical vehicle application. IET Electr. Syst. Transp. 2015, 5, 43–52. [Google Scholar] [CrossRef]

- Dong, Z.; Yu, Y.; Li, W.; Wang, B.; Xu, D. Flux-Weakening Control for Induction Motor in Voltage Extension Region: Torque Analysis and Dynamic Performance Improvement. IEEE Trans. Ind. Electron. 2018, 65, 3740–3751. [Google Scholar] [CrossRef]

- Xu, Y.; Morito, C.; Lorenz, R.D. Extending High-Speed Operating Range of Induction Machine Drives Using Deadbeat-Direct Torque and Flux Control With Precise Flux Weakening. IEEE Trans. Ind. Appl. 2019, 55, 3770–3780. [Google Scholar] [CrossRef]

- Aghdam, M.G.H. Z-Source Inverter with SiC Power Semiconductor Devices for Fuel Cell Vehicle Applications. J. Power Electron. 2011, 11, 606–611. [Google Scholar] [CrossRef][Green Version]

- Rahmani, F.; Quispe, D.; Agarwal, T.; Barzegaran, M. Speed Control of Brushless DC Motor by DC-DC Boost and Buck Converters Using GaN and SiC Transistors for Implementing the Electric Vehicles. MPRA 2020, 6, 70–75. [Google Scholar]

- Liu, T.-H.; Tseng, S.-K.; Lu, M.-B. Auto-tuning flux-weakening control for an IPMSM drive system using a predictive controller. In Proceedings of the 2017 IEEE 26th International Symposium on Industrial Electronics (ISIE), Edinburgh, UK, 19–21 June 2017; Volume 2, pp. 238–243. [Google Scholar] [CrossRef]

- Bedetti, N.; Calligaro, S.; Petrella, R. Analytical design and auto-tuning of adaptive flux-weakening voltage regulation loop in IPMSM drives with accurate torque regulation. IEEE Trans. Ind. Appl. 2019. [Google Scholar] [CrossRef]

- Agarwal, T.; Rahmani, F.; Zaman, I.; Gasbarri, F.; Davami, K.; Barzegaran, M. Comprehensive design analysis of a 3D printed sensor for readiness assessment applications. COMPEL-Int. J. Comput. Math. Electr. Electron. Eng. 2021. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, Z.Q. Fuzzy Logic Speed Control of Permanent Magnet Synchronous Machine and Feedback Voltage Ripple Reduction in Flux-Weakening Operation Region. IEEE Trans. Ind. Appl. 2020, 56, 1505–1517. [Google Scholar] [CrossRef]

- Wang, M.-S.; Hsieh, M.-F.; Lin, H.-Y. Operational Improvement of Interior Permanent Magnet Synchronous Motor Using Fuzzy Field-Weakening Control. Electronics 2018, 7, 452. [Google Scholar] [CrossRef]

- Cao, X.; Fan, L. Flux-Weakening Control Scheme Based on the Fuzzy Logic of PMSM Drive for Hybrid Electric Vehicle. In Proceedings of the 2009 IITA International Conference on Control, Automation and Systems Engineering (Case 2009), Zhangjiajie, China, 11–12 July 2009; pp. 287–290. [Google Scholar] [CrossRef]

- Uddin, M.N.; Rahman, M.A. High-Speed Control of IPMSM Drives Using Improved Fuzzy Logic Algorithms. IEEE Trans. Ind. Electron. 2007, 54, 190–199. [Google Scholar] [CrossRef]

- Wang, H.; Wang, T.; Zhang, X.; Guo, L. Voltage feedback based flux-weakening control of IPMSMs with fuzzy-PI controller. Int. J. Appl. Electromagn. Mech. 2020, 62, 31–43. [Google Scholar] [CrossRef]

- Gu, X.; Li, T.; Li, X.; Zhang, G.; Wang, Z. An Improved UDE-Based Flux-Weakening Control Strategy for IPMSM. Energies 2019, 12, 4077. [Google Scholar] [CrossRef]

- Stojan, D.; Drevensek, D.; Plantic, Ž.; Grcar, B.; Stumberger, G. Novel Field-Weakening Control Scheme for Permanent-Magnet Synchronous Machines Based on Voltage Angle Control. IEEE Trans. Ind. Appl. 2012, 48, 2390–2401. [Google Scholar] [CrossRef]

- Xiaochun, F.; Fei, L.; Zhongping, Y. A modified flux-weakening control method of PMSM based on the d-q current cross-coupling effect. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, C.; Zhou, M.; You, X. Flux-Weakening in PMSM Drives: Analysis of Voltage Angle Control and the Single Current Controller Design. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 7, 437–445. [Google Scholar] [CrossRef]

- Li, X.; Liu, C.; Wu, S.; Chi, S.; Loh, P.C. Sliding-Mode Flux-Weakening Control With Only Single Current Regulator for Permanent Magnet Synchronous Motor. IEEE Access 2019, 7, 131616–131626. [Google Scholar] [CrossRef]

- Lei, Z.; Xuhui, W.; Feng, Z.; Liang, K.; Baocang, Z. Deep field-weakening control of PMSMs for both motion and generation operation. In Proceedings of the 2011 International Conference on Electrical Machines and Systems, Beijing, China, 20–23 August 2011; Volume 4, pp. 1–5. [Google Scholar] [CrossRef]

- Xu, W.; Ismail, M.M.; Liu, Y.; Islam, M.R. Parameter Optimization of Adaptive Flux-Weakening Strategy for Permanent-Magnet Synchronous Motor Drives Based on Particle Swarm Algorithm. IEEE Trans. Power Electron. 2019, 34, 12128–12140. [Google Scholar] [CrossRef]

- Dambrauskas, K.; Vanagas, J.; Zimnickas, T.; Kalvaitis, A.; Ažubalis, M. Method for Efficiency Determination of Permanent Magnet Synchronous Motor. Energies 2020, 13, 1004. [Google Scholar] [CrossRef]

- Wang, S.; Kang, J.; Degano, M.; Galassini, A.; Gerada, C. An Accurate Wide-Speed Range Control Method of IPMSM Considering Resistive Voltage Drop and Magnetic Saturation. IEEE Trans. Ind. Electron. 2020, 67, 2630–2641. [Google Scholar] [CrossRef]

- Bolognani, S.; Calligaro, S.; Petrella, R. Adaptive Flux-Weakening Controller for Interior Permanent Magnet Synchronous Motor Drives. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 236–248. [Google Scholar] [CrossRef]

- Fornari, R.; Franceschini, G.; David, D.; Torreggiani, A.; Bianchini, C.; Frigieri, M. Enhanced Internal Permanent-Magnet Machines Flux Weakening Control Strategies for Traction Applications. In Proceedings of the IECON 2019-45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; Volume 1, pp. 2682–2687. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Rated power | 400 | W | |

| Rated phase current | 2.7 | Arms | |

| Rated speed | 3000 | RPM | |

| Rated torque | 1.27 | N.m | |

| Number of poles pairs | P | 4 | |

| Stator resistance | 2.35 | Ω | |

| Stator inductance | 8.5 | mH | |

| Flux linkage | 0.0615 | Wb | |

| Inertia | J | 167 × 10−6 | Kg.m2 |

| Viscous friction | F | 106.9 × 10−6 | N.m.s/rad |

| DC Bus Voltage | 200 | V |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khanh, P.Q.; Truong, V.-A.; Anh, H.P.H. Extended Permanent Magnet Synchronous Motors Speed Range Based on the Active and Reactive Power Control of Inverters. Energies 2021, 14, 3549. https://doi.org/10.3390/en14123549

Khanh PQ, Truong V-A, Anh HPH. Extended Permanent Magnet Synchronous Motors Speed Range Based on the Active and Reactive Power Control of Inverters. Energies. 2021; 14(12):3549. https://doi.org/10.3390/en14123549

Chicago/Turabian StyleKhanh, Pham Quoc, Viet-Anh Truong, and Ho Pham Huy Anh. 2021. "Extended Permanent Magnet Synchronous Motors Speed Range Based on the Active and Reactive Power Control of Inverters" Energies 14, no. 12: 3549. https://doi.org/10.3390/en14123549

APA StyleKhanh, P. Q., Truong, V.-A., & Anh, H. P. H. (2021). Extended Permanent Magnet Synchronous Motors Speed Range Based on the Active and Reactive Power Control of Inverters. Energies, 14(12), 3549. https://doi.org/10.3390/en14123549