The Possibility of a High-Efficiency Wave Power Generation System Using Dielectric Elastomers

Abstract

1. Introduction

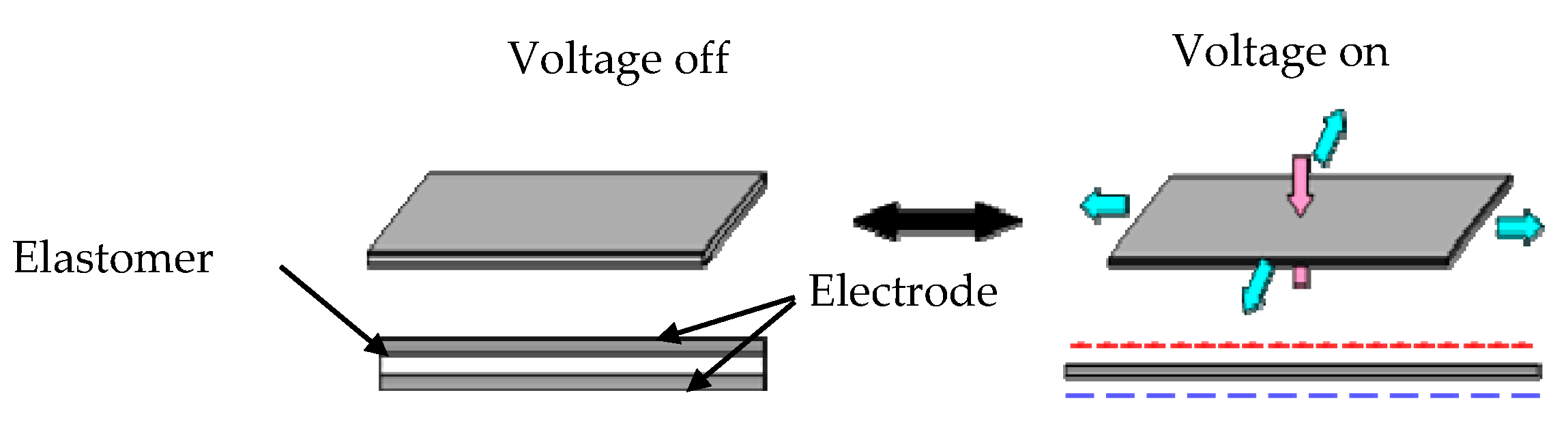

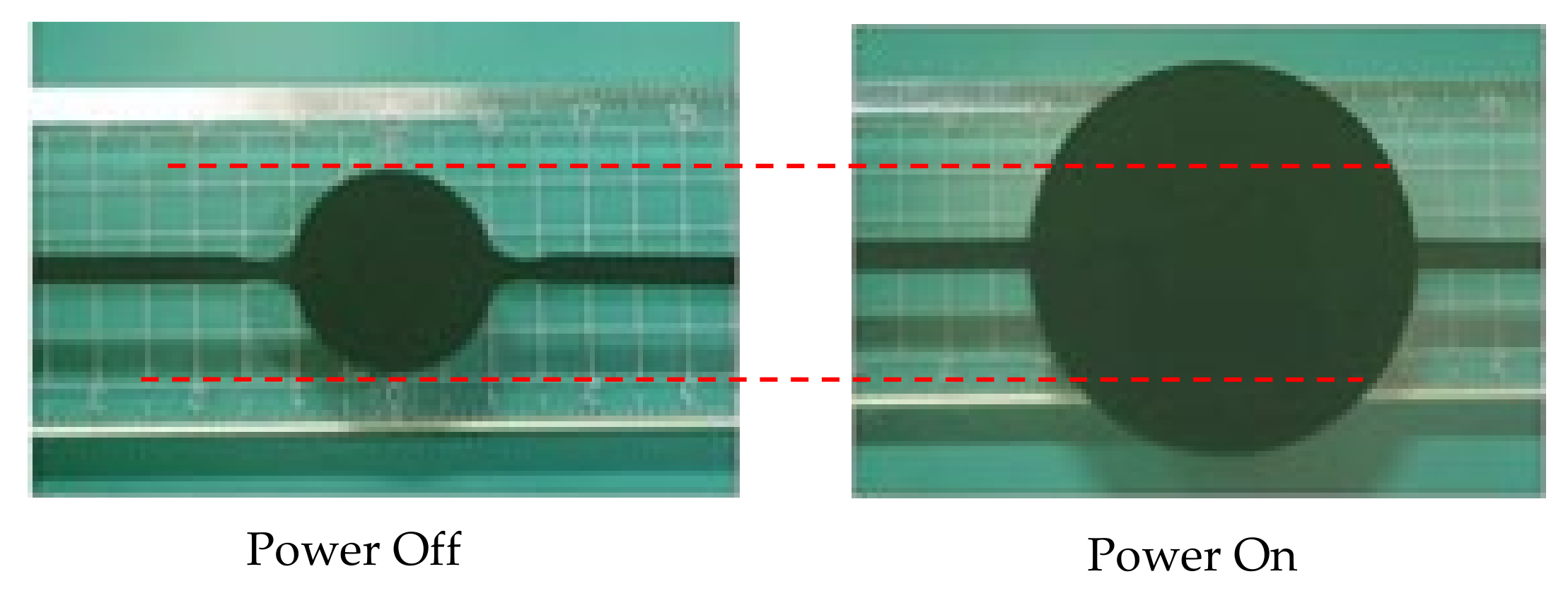

2. Background of Dielectric Elastomers

3. Dielectric Elastomer Generators (DEGs)

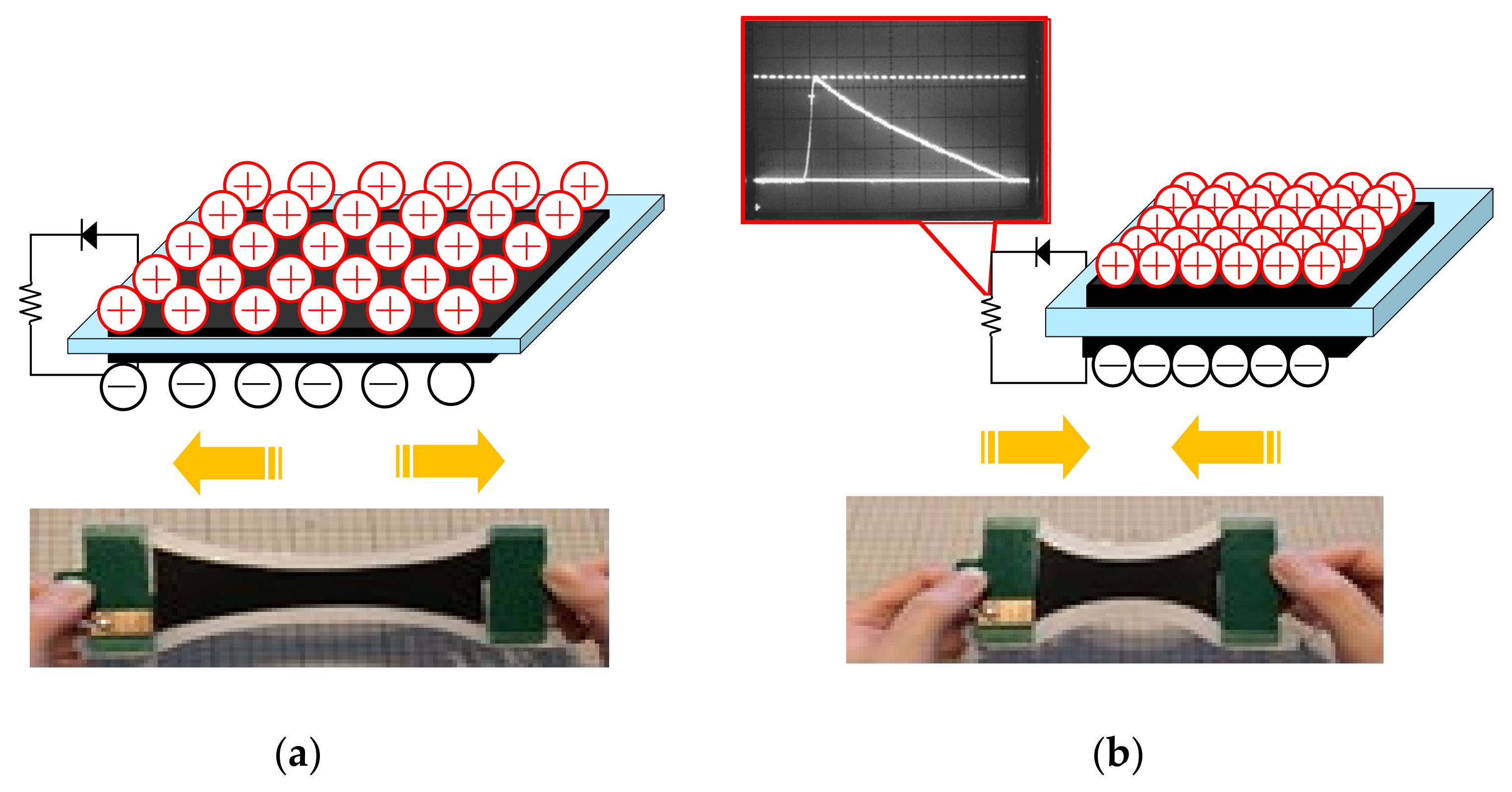

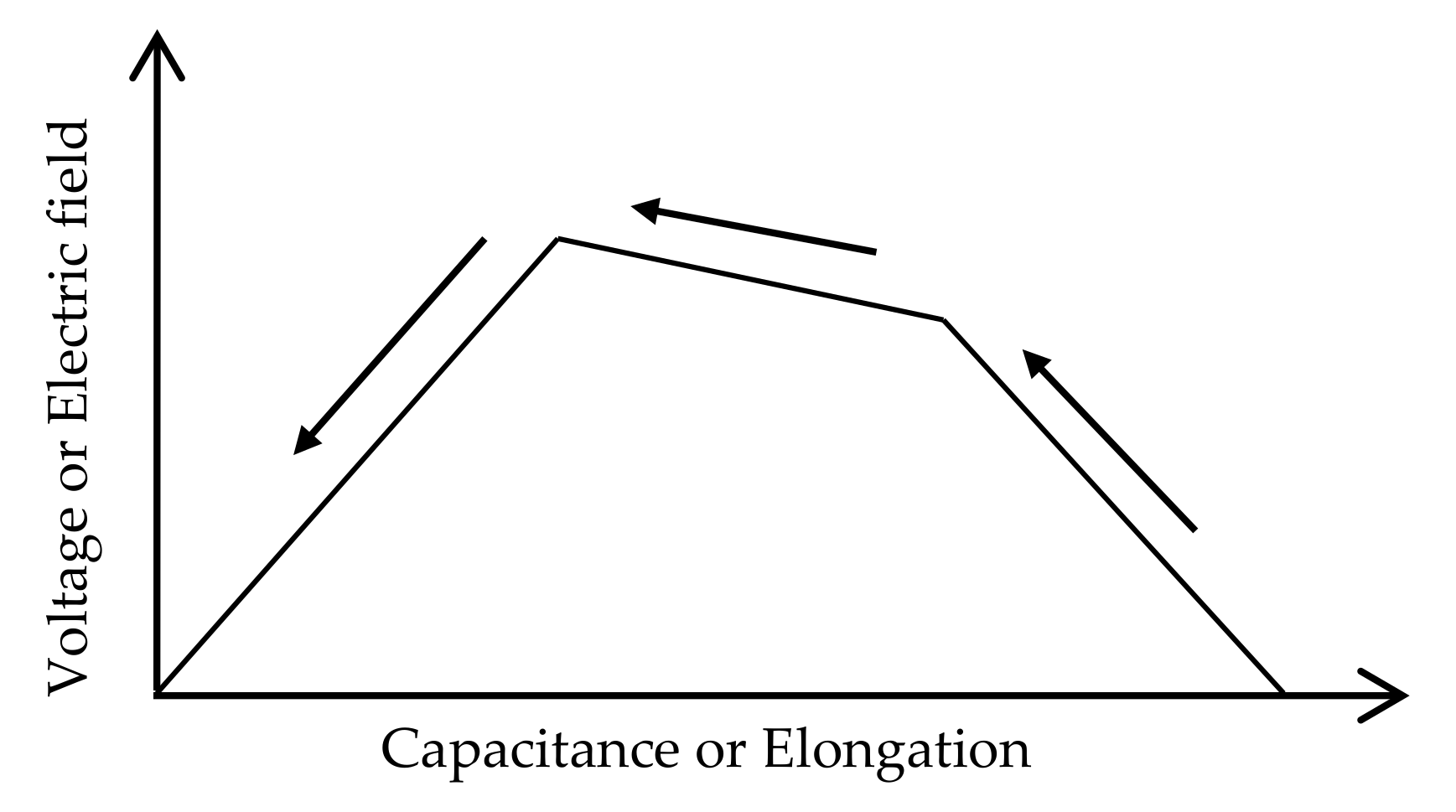

- (1)

- When mechanical energy is applied to the DE film and the film is stretched, the thickness of the film decreases and the surface area increases at the same time;

- (2)

- At this time, a voltage is applied to the film. The added electrical energy is stored in the membrane as an electric charge;

- (3)

- When the mechanical energy of the membrane decreases, the elastic resilience of the membrane acts to restore the original thickness and reduce the area. At this time, the electric charge is pushed out toward the electrode. This change in the position of the charge increases the voltage difference and results in an increase in electrostatic energy;

- (4)

- The charge is removed from the membrane and the membrane returns to its original length.

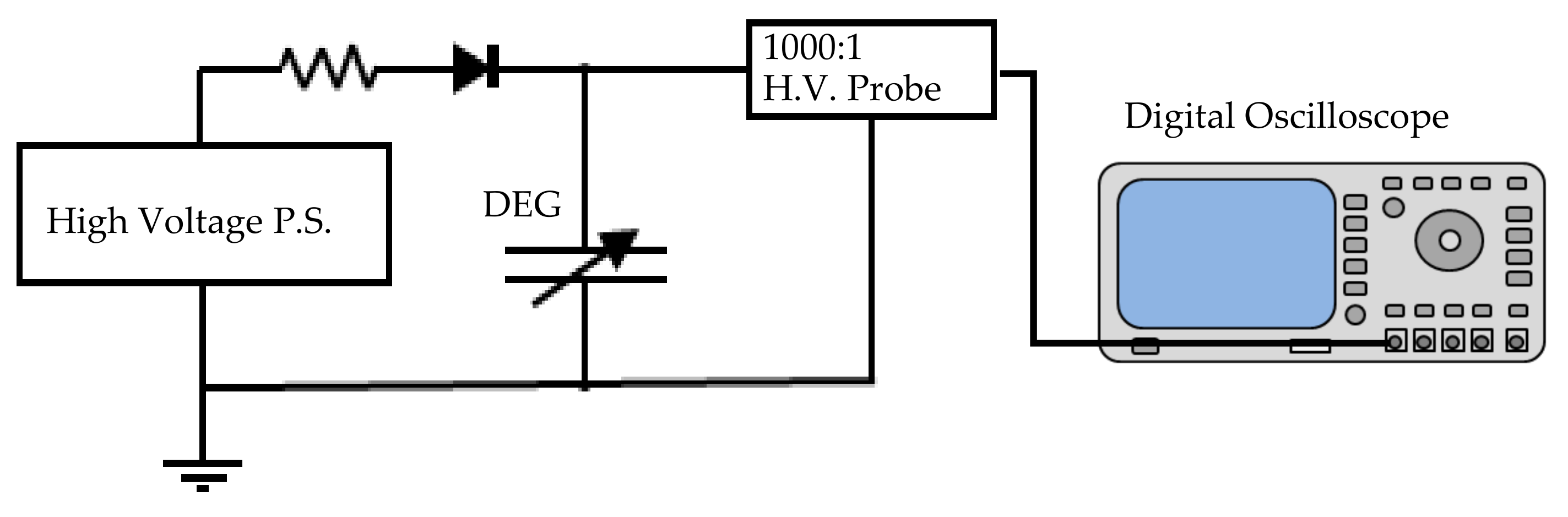

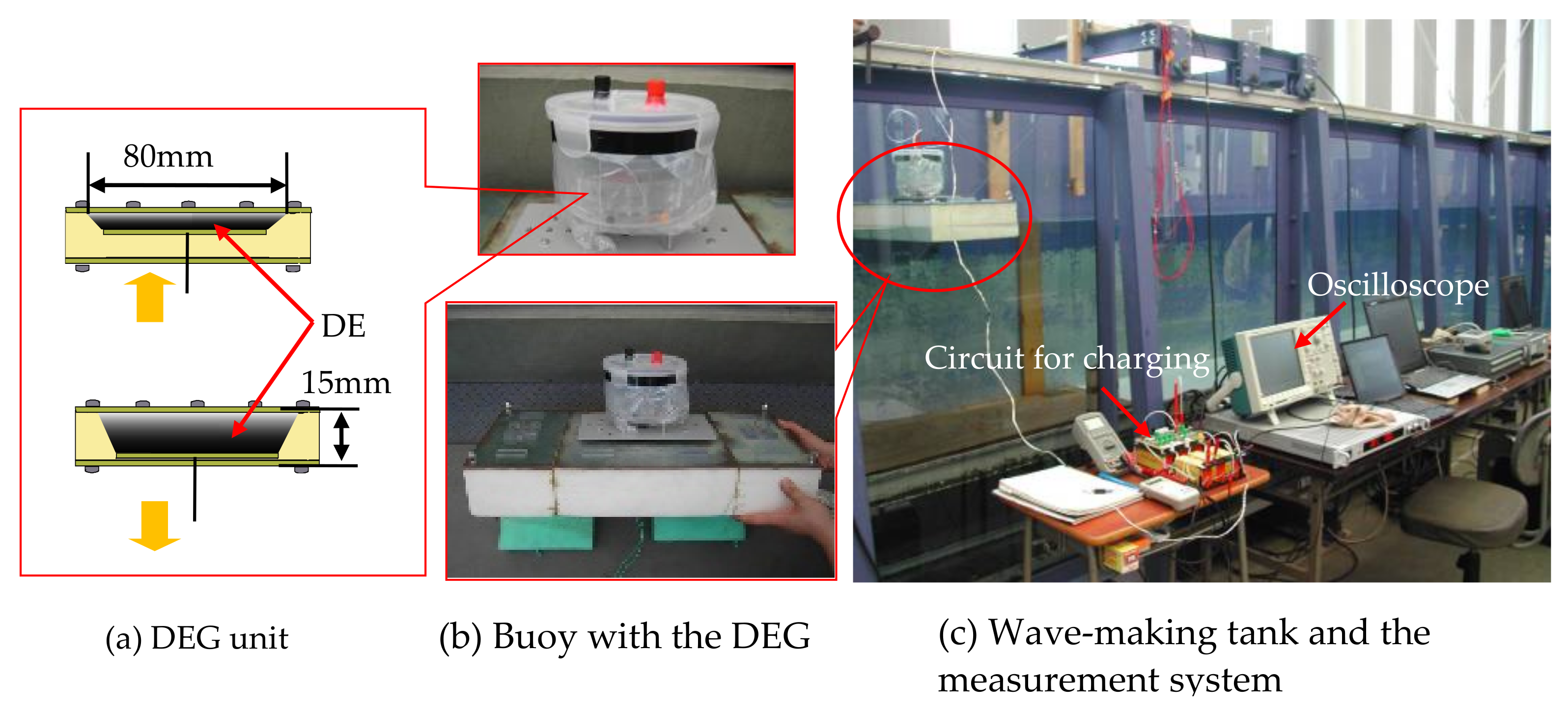

- (1)

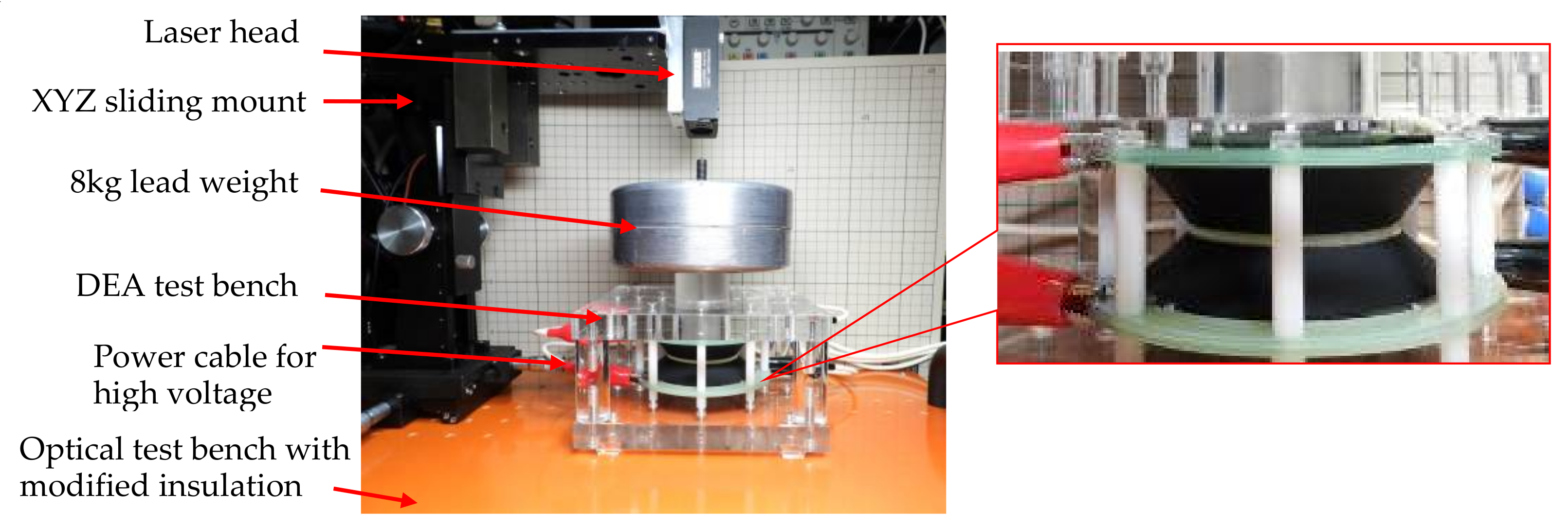

- The voltage (V2) between the electrodes on both sides of the DEG in the contracted state can be measured for each wave frequency using a digital oscilloscope (see Figure 6).

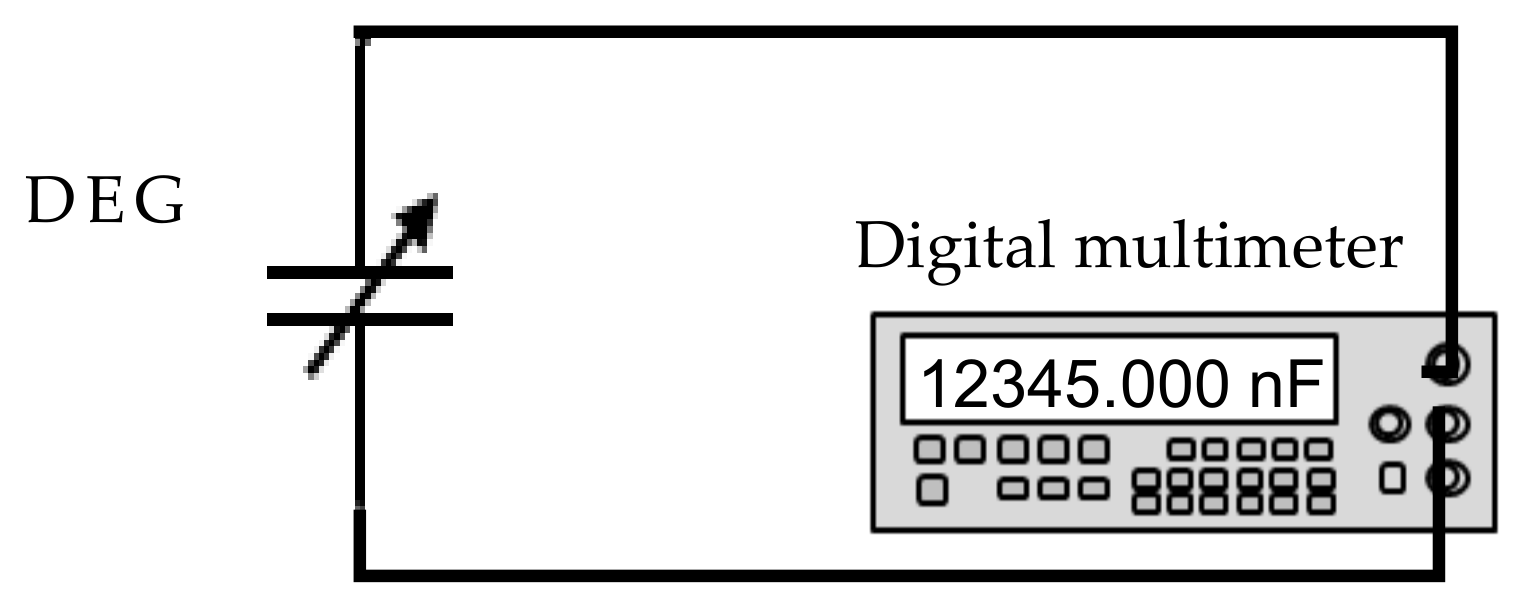

- (2)

- The capacitance (C2) of the transducer in the contracted state is measured with a digital multimeter (see Figure 7).

- (3)

- Using the values of Equations (1) and (2), and C2 and V2, the amount of power generation is calculated as follows:

- (a)

- The relationship C1 = V2C2/V1 is derived from Equation (1).

- (b)

- Next, by introducing C1 into Equation (2), the generated electric power can be obtained:E = 0.5V1V2C2(V2/V1 − 1)

- (c)

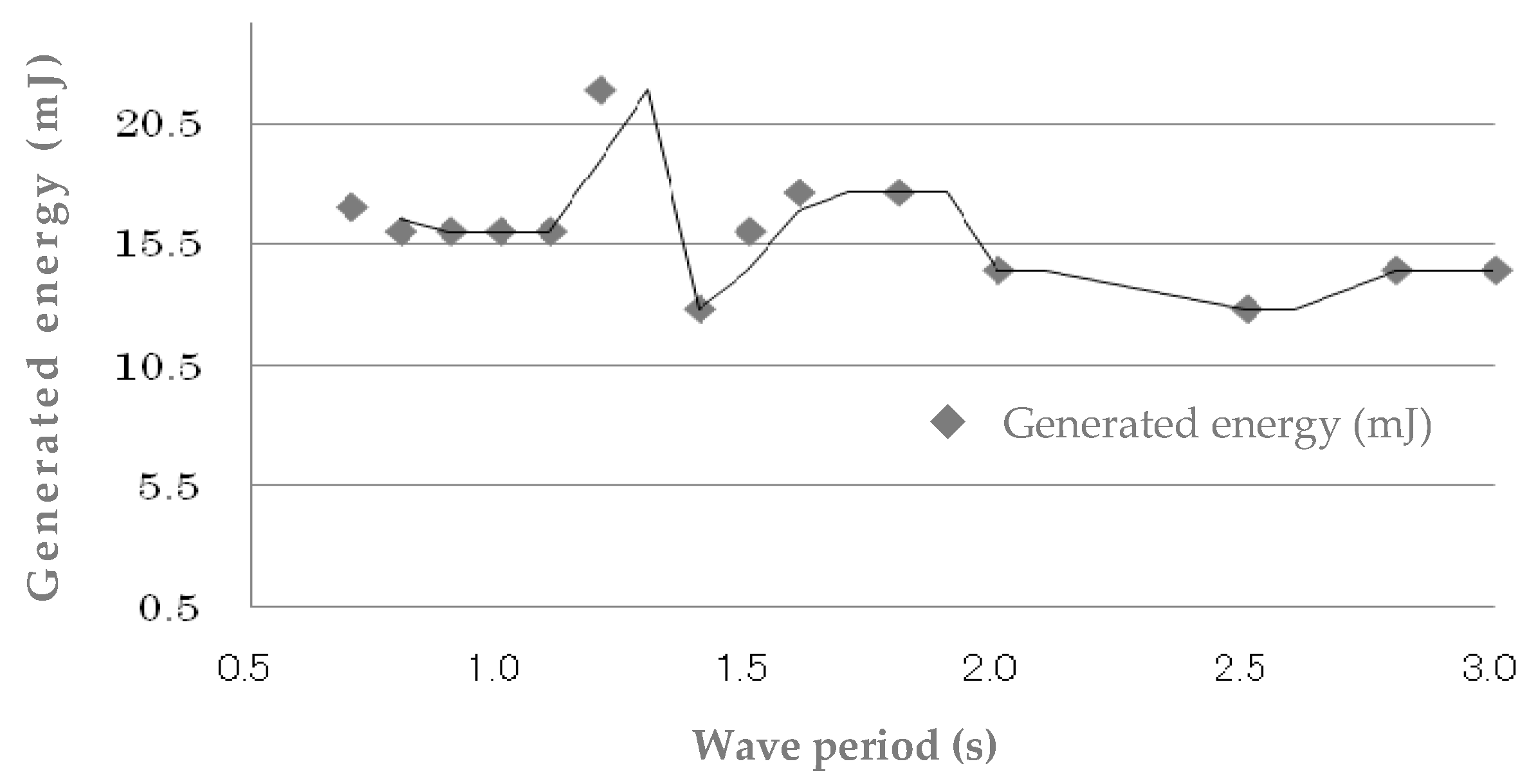

- Using Equation (4) and the values of C2 and V2, the power generated at the frequency of each wave of the transducer can be calculated

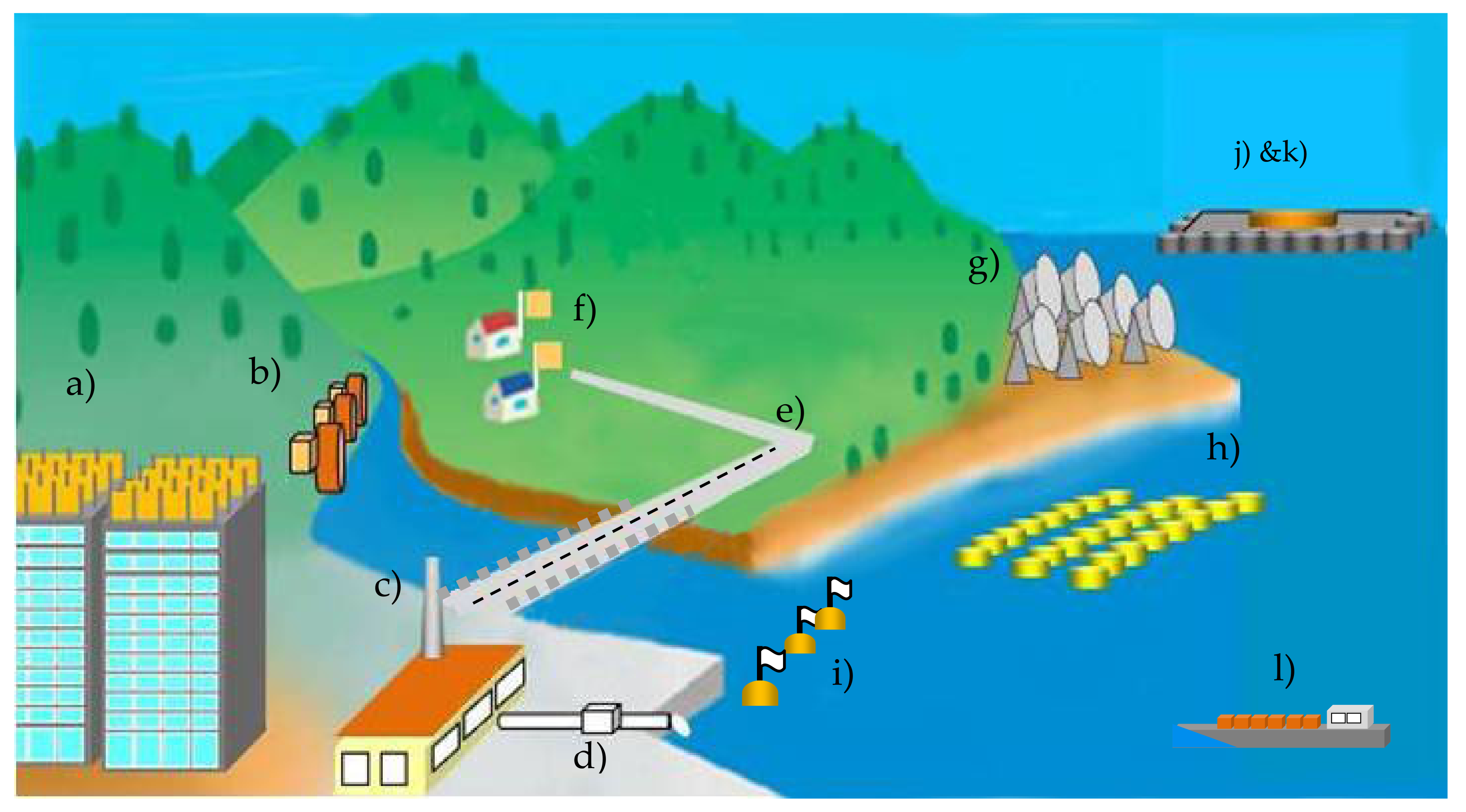

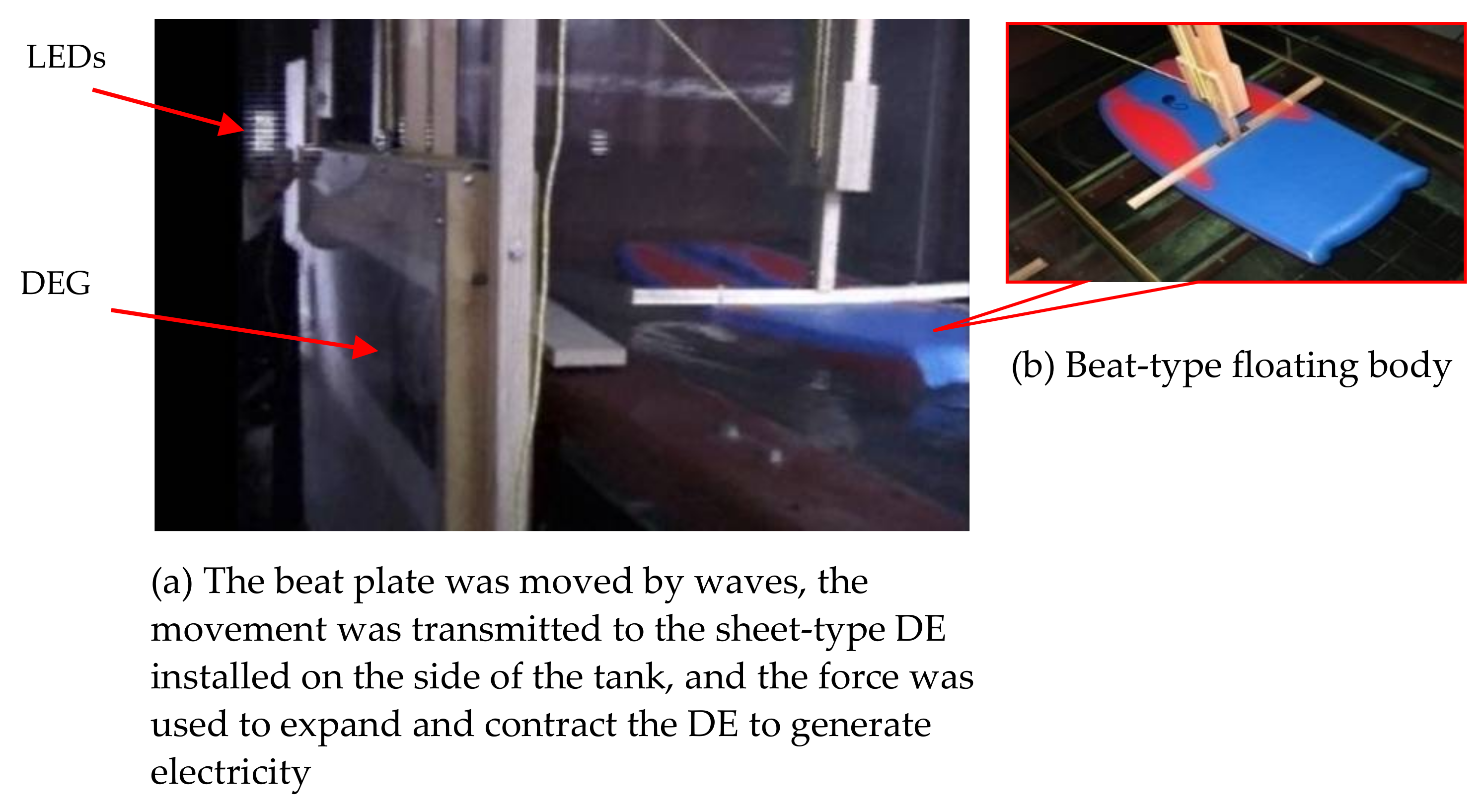

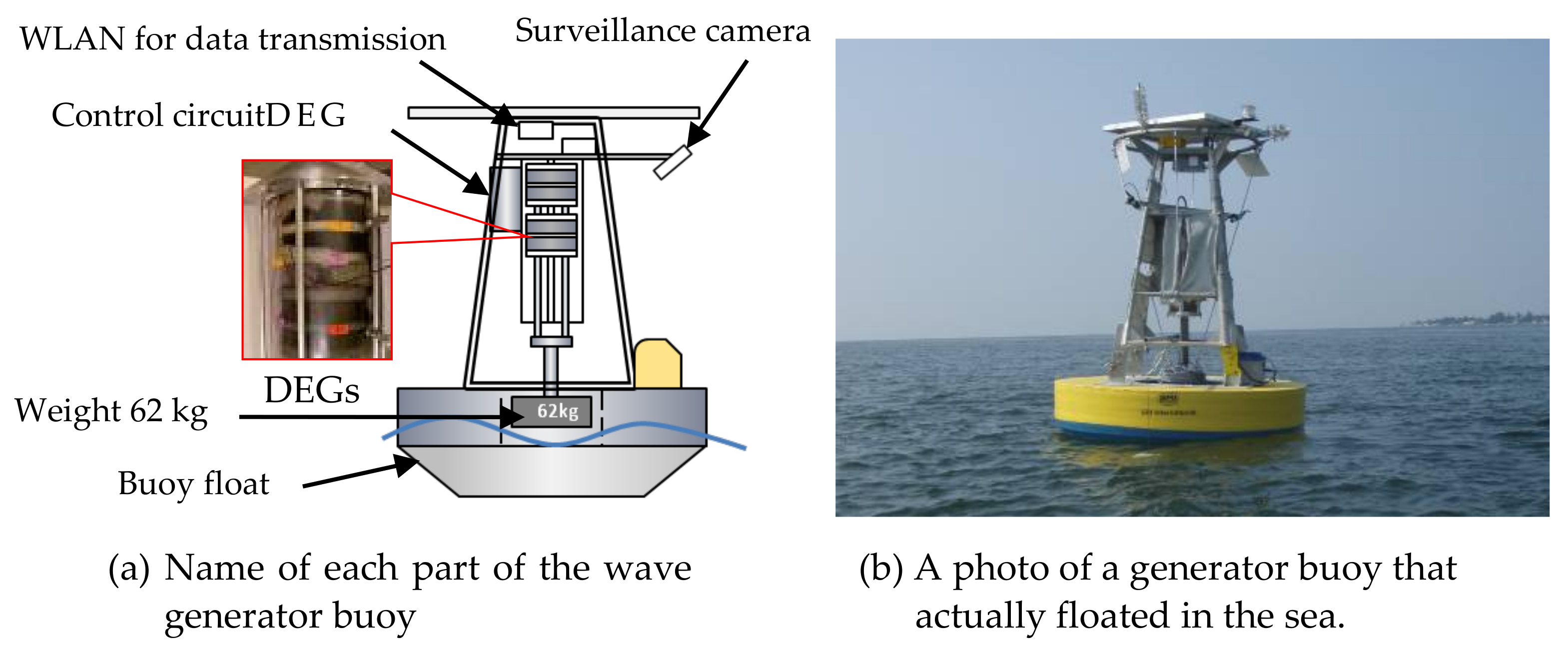

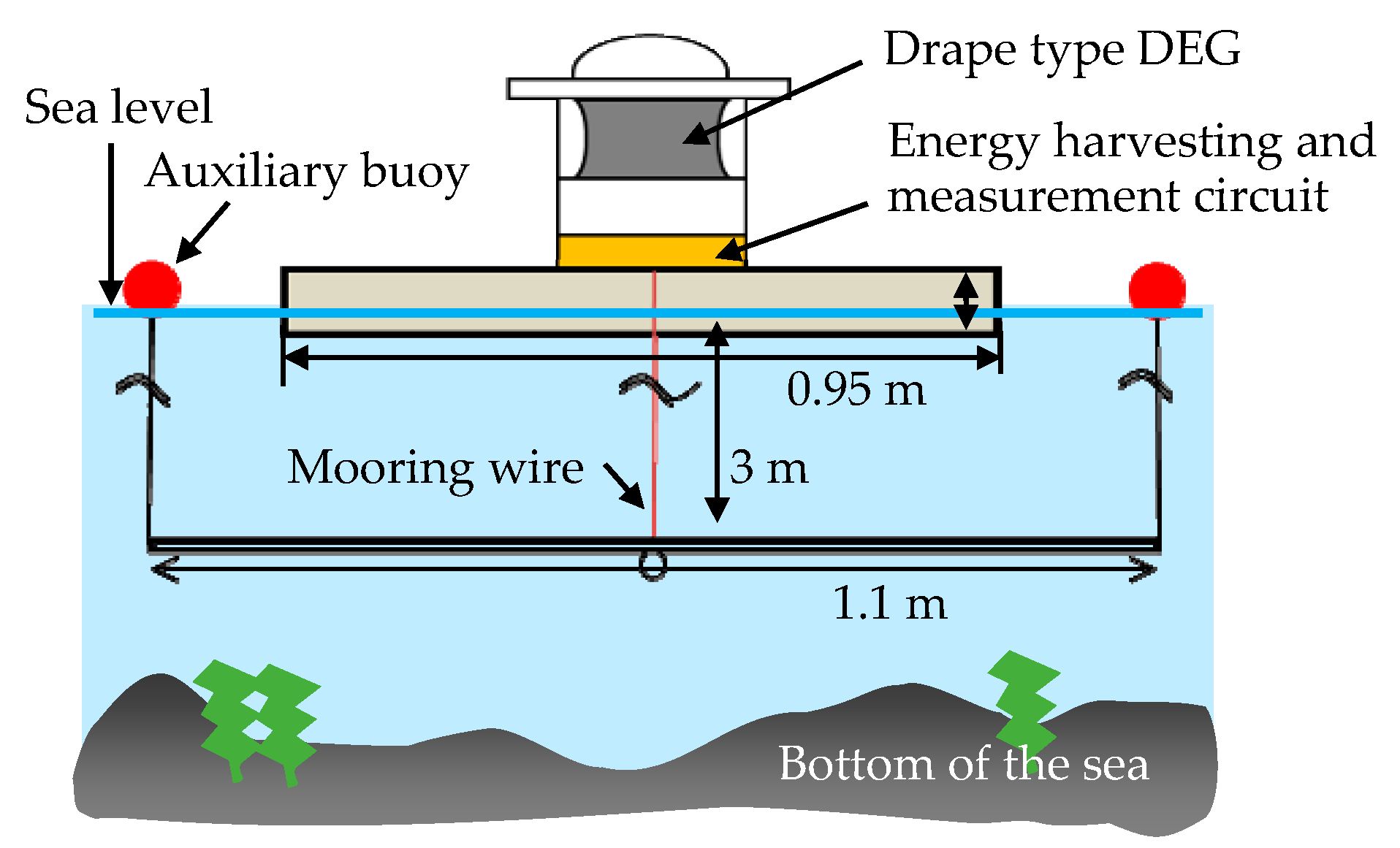

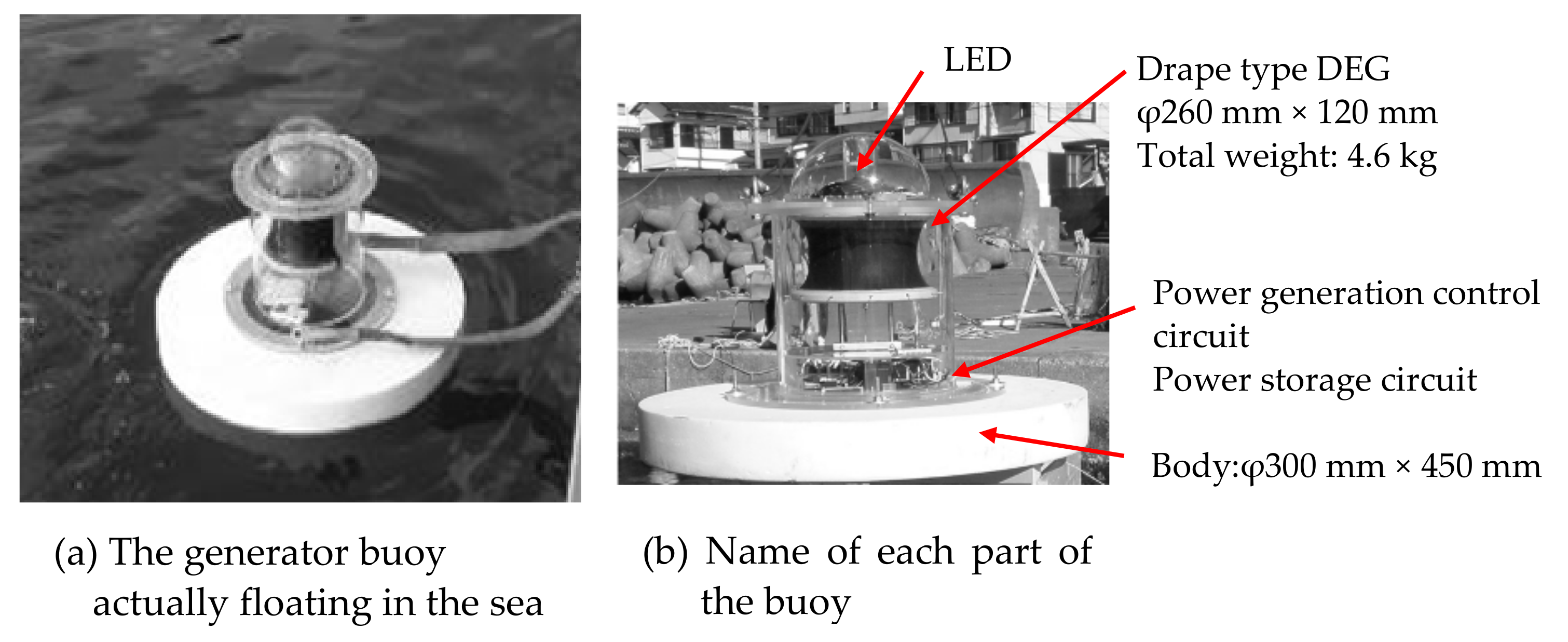

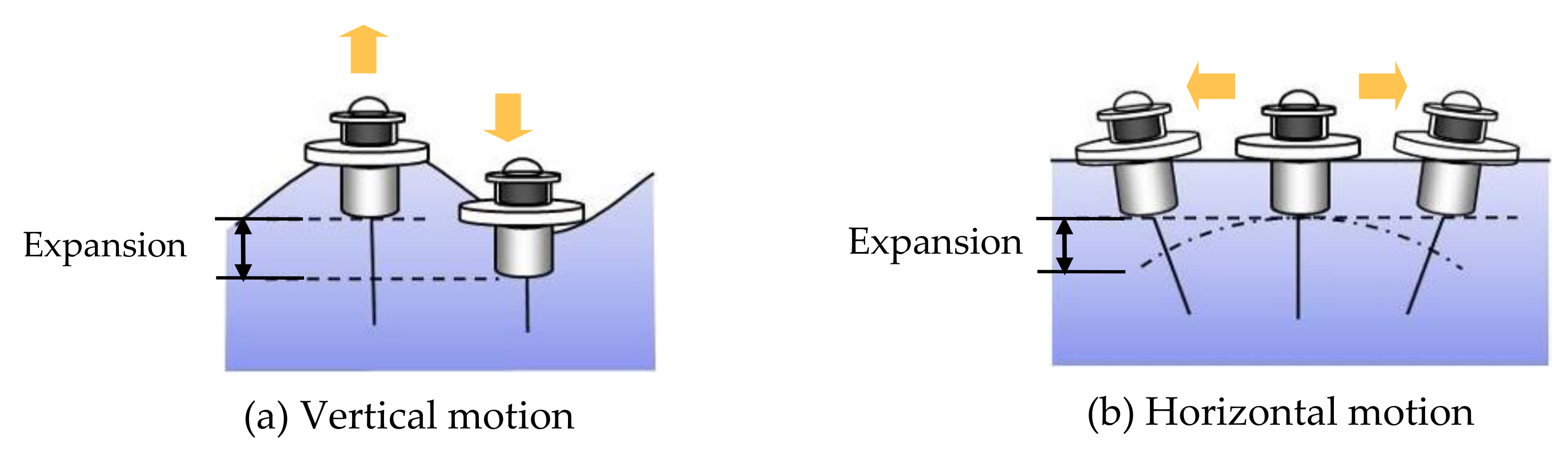

3.1. Buoy Power Generation Loaded with Dielectric Elastomer Generator

3.2. Usefulness of Dielectric Elastomer Wave Power Generation

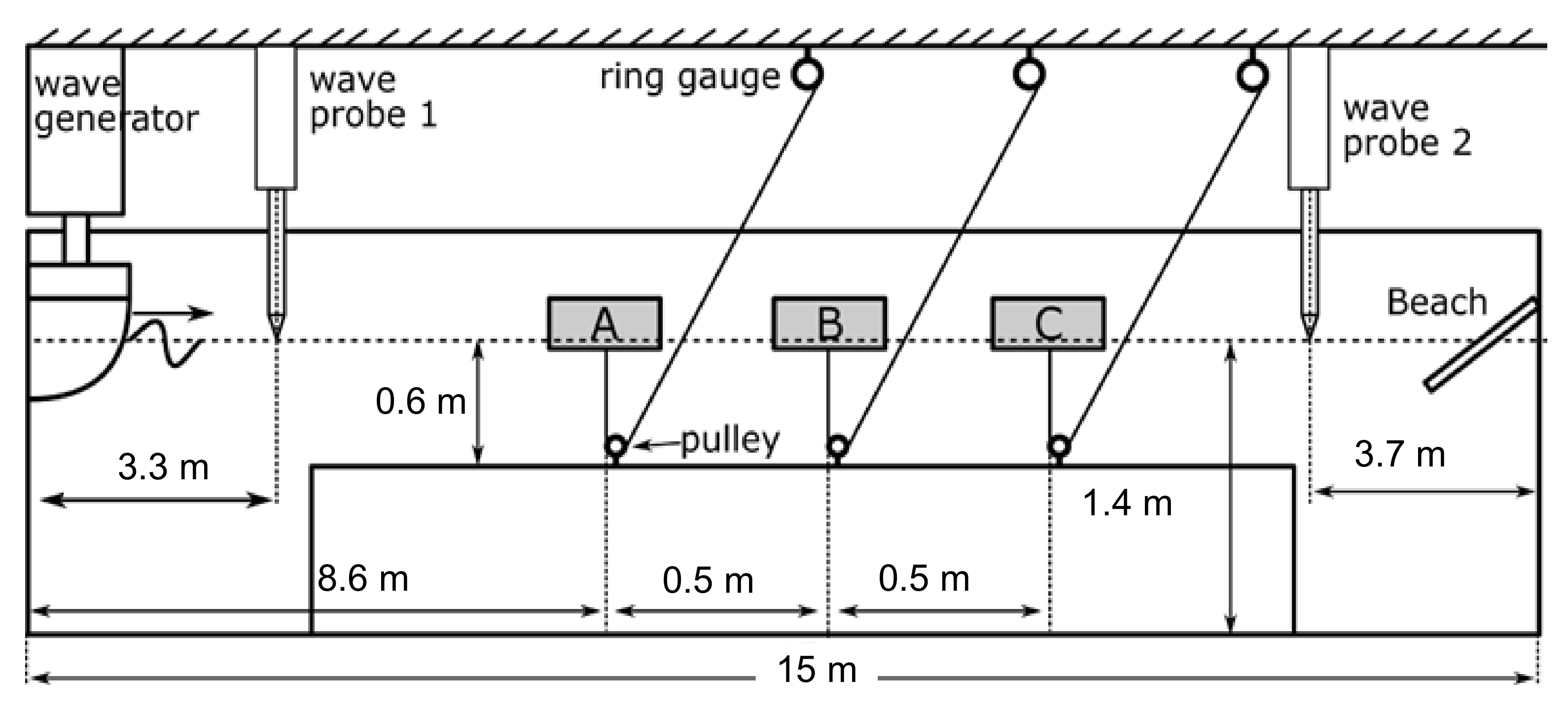

3.2.1. Buoy–Buoy Interaction

- (1)

- The calculated motion (surge, heave, pitch), mooring tension, and power generation efficiency were in good agreement with the experimental measurements.

- (2)

- In the case where double bodies are placed next to each other: when the wave frequency is high, the associated response amplitude operators (RAO) of surge, heave, and tension are small, but the RAO of pitch motion is large. That is, the RAO of body B is smaller than the RAO of body A, and it can be seen that the movement and mooring tension of body B are weakened by the presence of the body A. Due to the presence of the body, the wave is diffracted and a part of the wave energy is converted to electrical energy using the power-take-off system.

- (3)

- The efficiency of floating body A reduces at the low wave frequencies, but increases at high wave frequencies when the interval is increased from 0.5 m to 1 m from the case above. On the other hand, there was no significant difference in the efficiency of floating body B. It seems that the effects of the diffracted waves from body B on body A are more pronounced than the other way around. Apart from the reason that the floating body A with a DE extracts some of the wave energy, the results might show differences within the results of a 3D experimental work or high-fidelity simulations.

- (4)

- The power generation efficiency was calculated for the wave frequency in the case where the triple bodies were arranged side by side. In general, the power generation efficiency of the first body (A) that encounters the incident waves first is largest; the associated efficiency of the second body (B) is somewhat less than that of the first body, and so on. This can also be interpreted as the DE attached to the floating body absorbing part of the wave energy. In a particular wave frequency range, all wave energy converters (OWSs) can reach relatively high efficiencies; about 0.9 Hz for this studied case. The reason for this is that lower wave frequencies naturally reduce buoy-to-buoy interaction.

3.2.2. System That Incorporates a Dielectric Elastomer into Oscillating Water Column Wave Energy Converter Buoys Is Arranged

- (1)

- By arranging the DEG around the OWC, it is possible to handle waves with a period that OWSs are not good at. This is because, as discussed above, the wave period in which the DEGs can generate is very wide.

- (2)

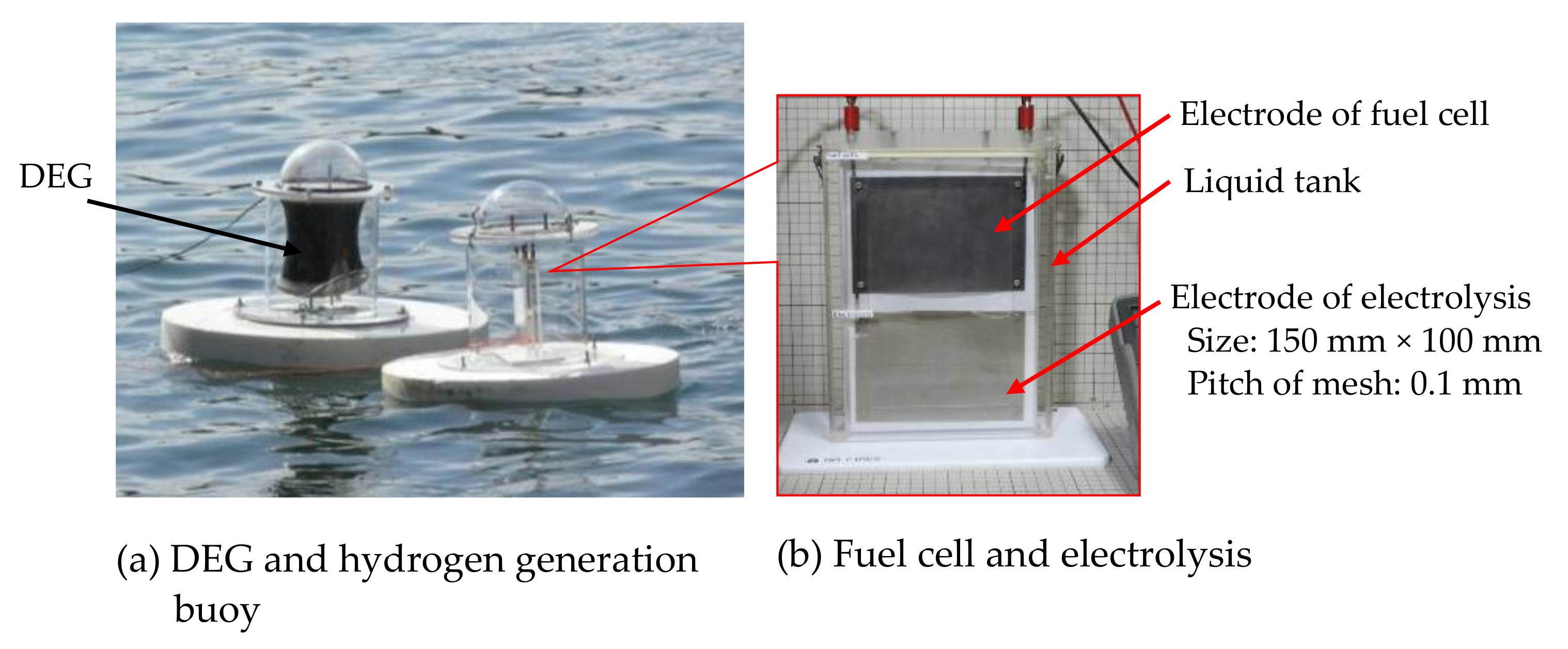

3.2.3. Production of Hydrogen

3.2.4. Combination of a Piezoelectric Power Generation System and Dielectric Elastomer Generator

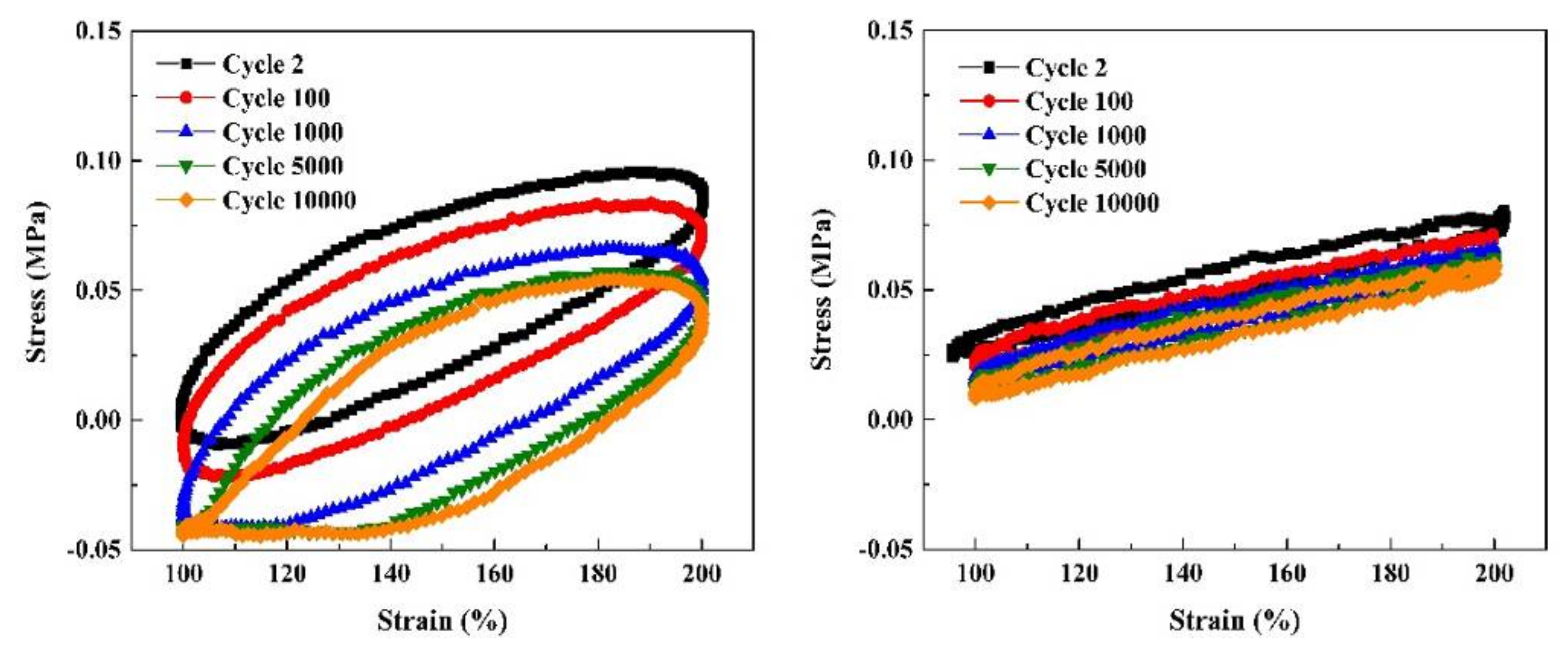

4. Dielectric Elastomer Material

4.1. Material Used for Dielectric Elastomers

4.2. Electrode Material Used for Dielectric Elastomers

| Type of Electrode | Power Obtained (mJ) |

|---|---|

| carbon black 1 | 274 |

| multi-walled carbon nanotube | 445 |

| single-walled carbon nanotube | 630 |

| high crystalline SWCNT 2 | 819 |

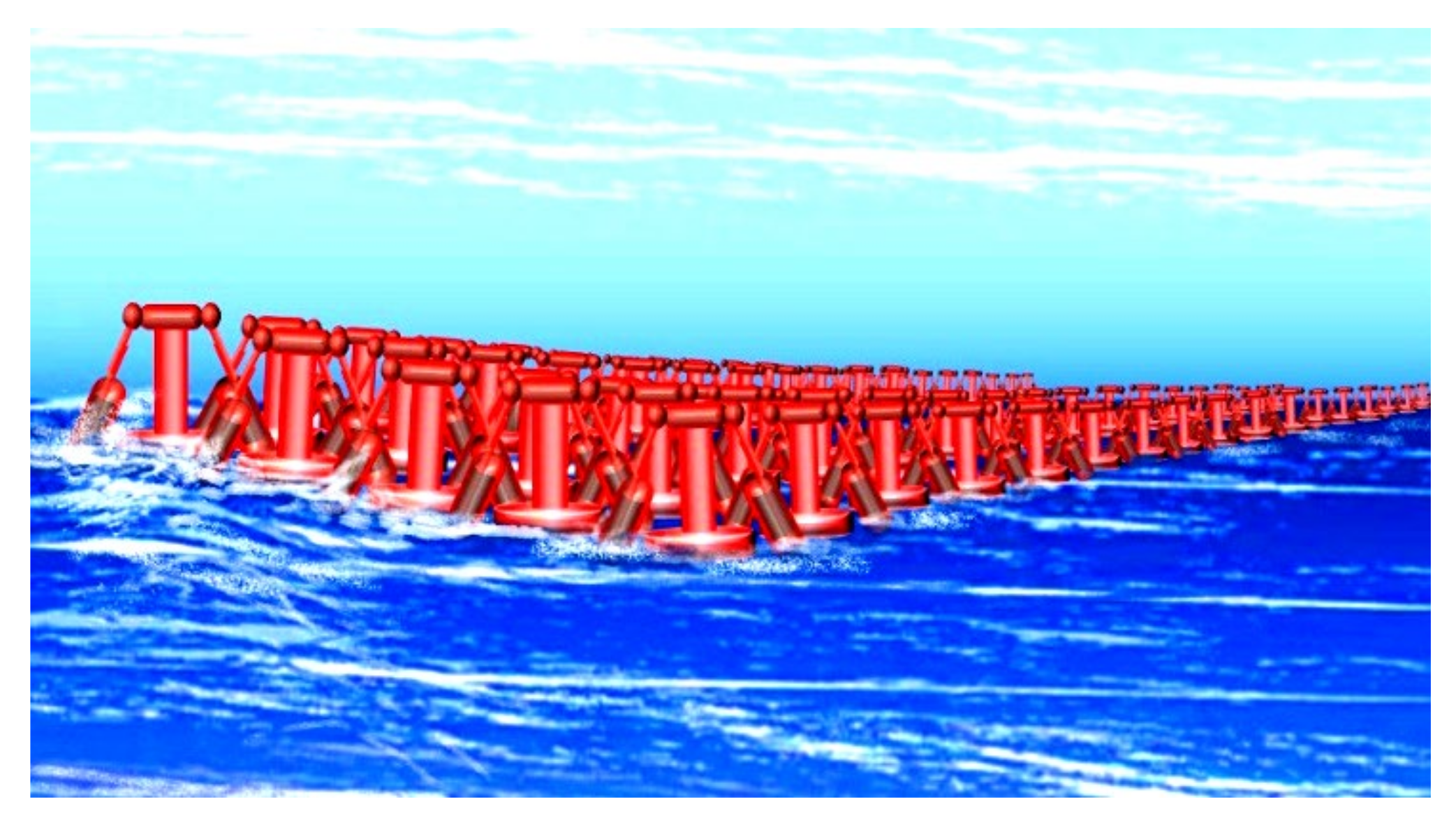

5. Summary and Conclusions

- A buoy generator equipped with DEs could be able to generate electricity with high efficiency.

- A generator equipped with DEs could be able to generate electricity in response to waves of a wide frequency range.

- If multiple generators are placed perpendicular to the wave, each generator could absorb some of the wave energy and convert it into electricity, which in turn could weaken the wave energy. In extreme cases, it is possible to reduce the wave height to zero by deploying a significant number of generators.

- By using a highly conductive material such as SWCNTs, the power generation capacity of the DEG is improved.

- At a super mega power plant in the ocean, hydrogen is produced by electricity, and by tanker, the hydrogen is transported by tankers to large consumption areas. It is efficient to use the hydrogen for carbon dioxide-free fuel and/or power generation at those sites.

- The power generation cost of an OWC equipped with a DEG on a buoy or an OWC could be about 5 US cents per 1kW.

- Pursuing a high-performance DE is important, since by driving the DE at a lower level, it is possible to extend its lifespan.

Author Contributions

Funding

Conflicts of Interest

References

- Institute for Sustainable Energy Policies. White Paper on Renewable Energy 2016. Available online: https://www.isep.or.jp/wp/wp-content/uploads/2017/03/JSR2016 (accessed on 20 April 2021).

- Proceedings of the 23rd Conference of the Parties to the United Nations Framework Convention on Climate Change (COP23), Bonn, Germany, 6–17 November 2017. Available online: www.c2es.org/content/cop-23-bonn (accessed on 20 April 2021).

- Carbon Dioxide Emissions Virtually Zero in 2050; Ministry of the Environment: Tokyo, Japan, 2020.

- Miyazaki, T.; Osawa, H. Search Report of Wave Power Devices. In Proceedings of the 2007 Spring Conference of the Japan Society of Naval Architects and Ocean Engineers, Kanazawa, Japan, 31 July–3 August 2007; pp. 43–46. [Google Scholar]

- Ashida, K.; Ichiki, M.; Tanaka, M.; Kitahara, T. Power Generation Using Piezo Element: Energy Conversion Efficiency of Piezo Element. In Proceedings of the JAME Annual Meeting, Tokyo, Japan, 1–4 August 2000; pp. 139–140. [Google Scholar]

- Asaka, K.; Okuzaki, H. (Eds.) Soft Actuators: Materials, Modeling, Applications, and Future Perspectives; Springer: Berlin/Heidelberg, Germany, 2014; Volume 13, pp. 183–195. [Google Scholar] [CrossRef]

- Yuan, X.; Changgeng, S.; Yan, G.; Zhenghong, Z. Application review of dielectric electroactive polymers (DEAPs) and piezoelectric materials for vibration energy harvesting. J. Phys. Conf. Ser. 2016, 744, 12077. [Google Scholar] [CrossRef]

- Pelrine, R.; Chiba, S. Review of Artificial Muscle Approaches. In Proceedings of the Third International Symposium on Micromachine and Human Science, Nagoya, Japan, 14–16 October 1992; pp. 1–9. [Google Scholar]

- Chiba, S.; Stanford, S.; Pelrine, R.; Kornbluh, R.; Prahlad, H. Electroactive Polymer Artificial Muscle. JRSJ 2006, 24, 38–42. [Google Scholar] [CrossRef]

- Chiba, S.; Waki, M.; Kormbluh, R.; Pelrine, R. Innovative Power Generators for Energy Harvesting Using Electroactive Polymer Artificial Muscles, 2008, Electroactive Polymer Actuators and Devices (EAPAD) 2008. In Proceedings of the SPIE; Bar-Cohen, Y., Ed.; SPIE: Bellingham, WA, USA, 2008; Volume 6927, pp. 1–9. [Google Scholar]

- Chiba, S.; Waki, M.; Ono, K.; Hatano, R.; Taniyama, Y.; Tanaka, S.; Okada, E.; Ohyama, K. Challenge of creating high performance dielectric elastomers. In Proceedings of the SPIE 2021 (Smart Structures and Materials Symposium and its 23rd Electroactive Polymer Actuators and Devices (EAPAD) Conference), Virtual, Online, 22–26 March 2021; pp. 1157–1162. [Google Scholar]

- Chiba, S.; Waki, M. The Challenge of Controlling a Small Mars Plane. In Solar Planets and Exoplanets; InTech: London, UK, 2021. [Google Scholar]

- Koh, S.J.; Zhao, X.; Suo, Z. Maximal Energy That Can Be Converted by a Dielectric Elastomer Generator. Appl. Phys. Lett. 2009, 94, 262902–262903. [Google Scholar] [CrossRef]

- Carpi, F.; Anderson, I.; Bauer, B.; Frediani Gallone, G.; Gei, M.; Graaf, C. Standards for dielectric transducers. Smart Mater. Struct. 2015, 24, 105025. [Google Scholar] [CrossRef]

- Jean-Mistral, C.; Basrour, S.; Chaillout, J.-J. Comparison of electroactive polymers for energy scavenging applications. Smart Mater. Struct. 2010, 19, 085012. [Google Scholar] [CrossRef]

- Zhong, X. Dielectric Elastomer Generators for Wind Energy Harvesting. Ph.D. Thesis, University of California Los Angeles, Los Angeles, CA, USA, 2010. [Google Scholar]

- Yurchenko, D.; Lai, Z.; Thomson, G.; Val, D.; Bobryk, R. Parametric study of a novel vibro-impact energy harvesting system with dielectric elastomer. Appl. Energy 2017, 208, 456–470. [Google Scholar] [CrossRef]

- Thomson, G.; Lai, Z.; Val, D.; Yurchenko, D. Advantages of nonlinear energy harvesting with dielectric elastomers. J. Sound Vib. 2019, 442, 167–182. [Google Scholar] [CrossRef]

- Moretti, G.; Papini, G.P.R.; Righi, M.; Forehand, D.; Ingram, D.; Vertechy, R.; Fontana, M. Resonant wave energy harvester based on dielectric elastomer generator. Smart Mater. Struct. 2018, 27, 035015. [Google Scholar] [CrossRef]

- Chiba, S.A.; Waki, M.; Tanaka, Y.; Tsurumi, N.; Okamoto, K.; Nagase, K.; Honma, M.; Yokota, H.; Odagiri, K.; Sato, H.; et al. Elastomer Transducers. Adv. Sci. Technol. 2016, 97, 61–74. [Google Scholar] [CrossRef]

- Huang, J.; Shian, S.; Suo, Z.; Clarke, D. Maximizing the Energy Density of Dielectric Elastomer Generators Using Equi-Biaxial Loading. Adv. Funct. Mater. 2013, 23, 5056–5061. [Google Scholar] [CrossRef]

- Lin, G.; Chen, M.; Song, D. Large-train, rigid-to-rigid deformation of bistable elctroactive polymers. In Proceedings of the International Conference on Energy and Environment Technology, ICEET 2009, Guilin, China, 16–18 October 2009; pp. 782–786. [Google Scholar]

- Brouchu, P.A.; Li, H.; Niu, X.; Pei, Q. Factors Influencing the Performance of Dielectric Elastomer Energy Harvesters. In Proceedings of the SPIE; SPIE: San Diego, CA, USA, 2010. [Google Scholar]

- Vertechy, R.; Papini, G.P.; Rosati, P.; Fontana, M. Reduced Model and Application of Inflating Circular Diaphragm Dielectric Elastomer Generators for Wave Energy Harvesting. J. Vib. Acoust. Trans. ASME 2015, 137, 11–16. [Google Scholar] [CrossRef]

- Bortot, E.; Gei, M. Harvesting Energy with Load-driven Dielectric Elastomer Annular Membranes Deforming Out-of-plane. Extreme Mech. Lett. 2015, 5, 62–73. [Google Scholar] [CrossRef]

- Moretti, G.; Fontana, M.; Vertechy, R. Parallelogram-shaped Dielectric Elastomer Generators: Analytical model and Experimental Validation. J. Intell. Mater. Syst. Struct. 2015, 26, 740–751. [Google Scholar] [CrossRef]

- Moretti, G.; Papini, G.P.R.; Daniele, L.; Forehand, D.; Ingram, D.; Vertechy, R.; Fontana, M. Modelling and testing of a wave energy converter based on dielectric elastomer generators. Proc. R. Soc. A Math. Phys. Eng. Sci. 2019, 475, 20180566. [Google Scholar] [CrossRef] [PubMed]

- Brochu, P.; Yuan, W.; Zhang, H.; Pei, Q. Dielectric Elastomers for Direct Wind-to-Electricity2009, Power Generation. In Proceedings of the ASME Conference on Smart Materials, Adaptive Structures and Intelligent System, Oxnard, CA, USA, 21–23 September 2009. [Google Scholar]

- Zhou, J.; Jiang, L.; Khayat, R. Dynamic Analysis of a Tunable Viscoelastic Dielectric Elastomer Oscillator under External Excitation. Smart Mater. Struct. 2016, 25, 025005. [Google Scholar] [CrossRef]

- Jean-Mistral, C.; Basrour, S.; Chaillout, J.-J. Dielectric polymer: Scavenging energy from human motion. In Electroactive Polymer Actuators and Devices (EAPAD) 2008; International Society for Optics and Photonics: San Diego, CA, USA, 2008. [Google Scholar]

- Chiba, S.; Waki, M. Application to dielectric elastomer materials, power assist products, artificial muscle drive system. In Next-Generation Polymer/Polymer Development, New Application Development and Future Prospects; Technical Information Association: Tokyo, Japan, 2019; Section 3, Chapter 4; ISBN-10: 4861047382, ISBN-13: 978-4861047381. [Google Scholar]

- Arena, F.; Daniele, L.; Fiamma, V.; Fontana, M.; Malara, G.; Moretti, G.; Romolo, A.; Papini, G.P.R.; Scialò, A.; Vertechy, R. Field Experiments on Dielectric Elastomer Generators Integrated on a U-OWC Wave Energy Converter. In Proceedings of the Ocean Renewable Energy; ASME International: New York, NY, USA, 2018; Volume 10. [Google Scholar]

- Kovacs, G.M. Manufacturing polymer transducers: Opportunities and challenges. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, Denver, CO, USA, 4–8 March 2018. [Google Scholar]

- Pelrine, R.; Kornbluh, R.D.; Pei, Q. Dielectric elastomers: Past, present, and potential future. In Electroactive Polymer Actuators and Devices (EAPAD) XX; Bar-Cohen, Y., Ed.; SPIE: Washington, DC, USA, 2018. [Google Scholar]

- Chiba, S.; Waki, M.; Wada, T.; Hirakawa, Y.; Matsuda, K.; Ikoma, T. Consistent OceanWave Energy Harvesting Using Electroactive (Dielectric Elastomer) Artificial Muscle Generators. In Applied Energy; Elsevier: Amsterdam, The Netherlands, 2013; pp. 497–502. ISSN 0306-2619. [Google Scholar]

- McKay, T.; O’Brien, B.; Calius, E.; Anderson, I. Soft Generators Using Dielectric Elastomers. Appl. Phys. Lett. 2011, 98, 1–3. [Google Scholar] [CrossRef]

- Anderson, I.; Gisby, T.; McKay O’Brienl, B.; Calius, E. Multi-functional Dielectric Elas T.tomer Artificial Muscles for Soft and Smart Machines. J. Appl. Phys. 2012, 112, 041101. [Google Scholar] [CrossRef]

- Kessel, V.; Wattez, R.; Bauer, P. Analyses and Comparison of an Energy Harvesting System for Dielectric Elastomer Generators Using a Passive Harvesting Concept: The Voltage-clamped Multi-phase System. In Proceedings of the SPIE Smart Structures and Materials+ Nondestructive Evaluation and Health Monitoring, International Society for Optics and Photonics, San Diego, CA, USA, 8–12 March 2015; p. 943006. [Google Scholar]

- Zurkinden, A.; Campanile, F.; Martinelli, L. Wave Energy Converter through Piezoelectric Polymers. In Proceedings of the COMSOL User Conference 2007, Grenoble, France, 23–24 October 2007. [Google Scholar]

- Chiba, S.; Waki, M.; Fujita, K.; Song, Z.; Ohyama, K.; Zhu, S. Recent Progress on Soft Transducers for Sensor Networks. In Technologies and Eco-Innovation toward Sustainability II; Hu, A.H., Ed.; Springer Nature: London, UK, 2019. [Google Scholar] [CrossRef]

- Chiba, S.; Kornbluh, R.; Pelrine, R.; Waki, M. Low-cost Hydrogen Production from Electroactive Polymer Artificial Muscle Wave Power Generators. In Proceedings of the World Hydrogen Energy Conference 2008, Brisbane, Australia, 16–20 June 2008. [Google Scholar]

- Chiba, S.; Waki, M.; Masuda, K.; Ikoma, T.; Osawa, H.; Suwa, Y. Innovative 2012, Power Generation System for Harvesting Wave Energy, Design for Innovative Value Towards a Sustainable Society; Springer: Amsterdam, The Netherlands, 2012; pp. 1002–1007. ISBN 978-94-007-3010-6. [Google Scholar]

- Chiba, S.; Waki, M.; Masuda, K.; Ikoma, T.; Osawa, H.; Suwa, Y. Innovative Wave Power Generator Using Dielectric Elastomers Artificial Muscle. In Proceedings of the World Hydrogen Technologies Convention-2011, Glasgow, Scotland, UK, 14–16 September 2011. [Google Scholar]

- Chiba, S.; Hasegawa, K.; Waki, M.; Kurita, S. An Experimental Study on the Motion of Floating Bodies Arranged in Series for Wave Power Generation. J. Mater. Sci. Eng. A 2017, 7, 281–289. [Google Scholar] [CrossRef][Green Version]

- Jiang, C.; Chiba, S.; Waki, M.; Fujita, K.; Moctar, O. An Investigation of Novel Wave Energy Generator Using Die-Lectric Elastomers. In Proceedings of the ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineers, Virtual, Online, 3–7 August 2020. OMAE-18106. [Google Scholar]

- Mitsumasa, I.; Miyazaki, T.; Iida, M. Estimation of Cumulative Output Energy of Oscillating Water Colum Wave Energy Converter Considering Power Take Off Damping. In Proceedings of the ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineers, Virtual, Online, 3–7 August 2020. OMAE-19172. [Google Scholar]

- Sakano, T.; Ohyama, K.; Zhu, S.; Waki, M.; Chiba, S. Experimental verification of a self-excited power generation system for dielectric elastomer generation using piezoelectric elements. In Proceedings of the SPIE Smart Structures + Nondestructive Evaluation, Online, 27 April–9 May 2020. [Google Scholar]

- Pelrine, R.; Kornbluh, R.; Joseph, J.; Heydt, R.; Chiba, S. High-field defomation of elasomeric dielectrics for actuators. In Proceedings of the 6th SPIE Symposium on Smart Structure and Materials, Newport Beach, CA, USA, 1 March 1999. [Google Scholar]

- Kumamoto, H.; Hayashi, T.; Yonehara, Y.; Okui, M.; Nakamura, T. Development of a locomotion robot using deformable dielectric elastomer actuator without pre-stretch. In Proceedings of the SPIE Smart Structures + Nondestructive Evaluation, Online, 27 April–9 May 2020. [Google Scholar]

- Hu, P.; Huang, Q.; Madsen, J.; Skov, A.L. Soft silicone elastomers with no chemical cross-linking and unprecedented softness and stability. In Proceedings of the SPIE Smart Structures + Nondestructive Evaluation, Online, 27 April–9 May 2020. [Google Scholar]

- Li, W.; Zhu, S.; Ohyama, K.; Chiba, S.; Waki, M. Mechanical properties and viscoelasticity of dielectric elastomers. In Proceedings of the Materials and Mechanics Conference, Japan Society of Mechanical Engineers, Sapporo, Japan, 7–9 October 2017. [Google Scholar]

- Kornbluh, R.D.; Pelrine, R.; Prahlad, H.; Wong-Foy, A.; McCoy, B.; Kim, S.; Eckerle, J.; Low, T. From boots to buoys: Promises and challenges of dielectric elastomer energy harvesting. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 6–10 March 2011. [Google Scholar]

- Albuquerque, F.B.; Shea, H.R. Effect of humidity, temperature, and elastomer material on the lifetime of silicone-based dielectric elastomer actuators under a constant DC electric field (Conference Presentation). In Proceedings of the SPIE Smart Structures + Nondestructive Evaluation, Online, 27 April–9 May 2020. [Google Scholar]

- Chiba, S.; Waki, M.; Takeshita, M.; Uejima, M.; Arakawa, K. Dielectric elastomer using CNT as an electrode. In Proceedings of the SPIE Smart Structures + Nondestructive Evaluation, Online, 27 April–9 May 2020. [Google Scholar]

| Polymer (Specific Type) | Elastic Energy Density (J/cm3) | Pressure (MPa) | Strain (%) | Young’s Modulus (MPa) | Breakdown Electric Field (V/μm) | Dielectric Constant (at 1 kHz) | Coupling Efficiency, k2 (%) |

|---|---|---|---|---|---|---|---|

| Acrylic #a | 3.4 | 7.2 | 158 | 2.0 | 412 | 4.8 | 85 |

| Silicone #a | 0.22 | 1.36 | 102 | 1.0 | 235 | 2.8 | 54 |

| Polyurethane #a | 0.087 | 1.6 | 60 | 17.0 | 160 | 7.0 | 21 |

| Silicone #c | 0.082 | 0.51 | 32 | 0.7 | 144 | 2.8 | 54 |

| Fluorosilicone #1 | 0.055 | 0.39 | 28 | 0.5 | 80 | 6.9 | 48 |

| Silicone #b | 0.026 | 0.13 | 41 | 0.125 | 72 | 2.8 | 65 |

| Isoprene Natural Rubber #a | 0.0059 | 0.11 | 11 | 0.85 | 67 | 2.7 | 21 |

| Fluoroelastomer #a | 0.0046 | 0.11 | 8 | 2.5 | 32 | 12.7 | 15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiba, S.; Waki, M.; Jiang, C.; Takeshita, M.; Uejima, M.; Arakawa, K.; Ohyama, K. The Possibility of a High-Efficiency Wave Power Generation System Using Dielectric Elastomers. Energies 2021, 14, 3414. https://doi.org/10.3390/en14123414

Chiba S, Waki M, Jiang C, Takeshita M, Uejima M, Arakawa K, Ohyama K. The Possibility of a High-Efficiency Wave Power Generation System Using Dielectric Elastomers. Energies. 2021; 14(12):3414. https://doi.org/10.3390/en14123414

Chicago/Turabian StyleChiba, Seiki, Mikio Waki, Changqing Jiang, Makoto Takeshita, Mitsugu Uejima, Kohei Arakawa, and Kazuhiro Ohyama. 2021. "The Possibility of a High-Efficiency Wave Power Generation System Using Dielectric Elastomers" Energies 14, no. 12: 3414. https://doi.org/10.3390/en14123414

APA StyleChiba, S., Waki, M., Jiang, C., Takeshita, M., Uejima, M., Arakawa, K., & Ohyama, K. (2021). The Possibility of a High-Efficiency Wave Power Generation System Using Dielectric Elastomers. Energies, 14(12), 3414. https://doi.org/10.3390/en14123414