Comparison of Two Energy Management Strategies Considering Power System Durability for PEMFC-LIB Hybrid Logistics Vehicle

Abstract

1. Introduction

2. Powertrain System Modeling

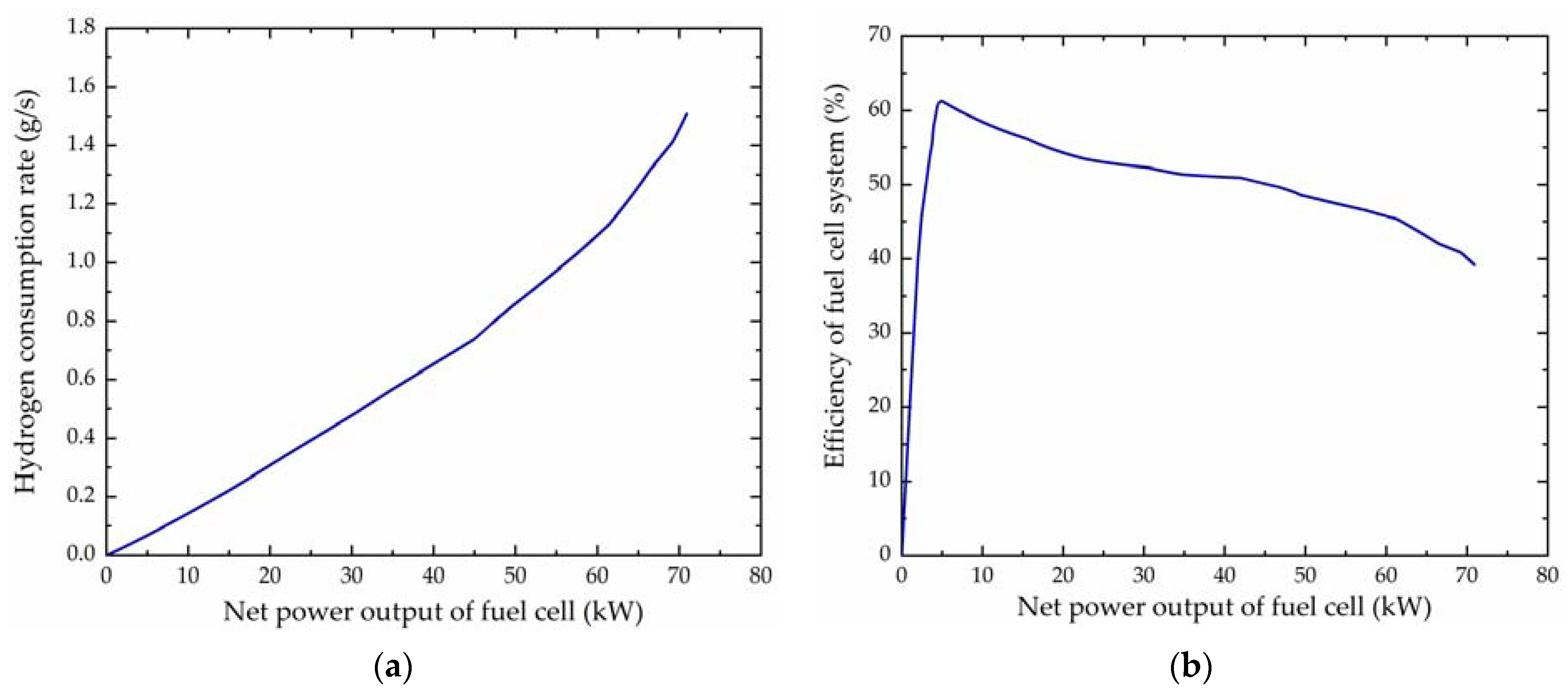

2.1. Model of PEMFC

2.2. Model of Lithium-Ion Battery

2.3. Model of the Vehicle

3. Energy Management Strategy Considering Power System Durability

3.1. Energy Management Strategy under Qualitative Generalized Economy

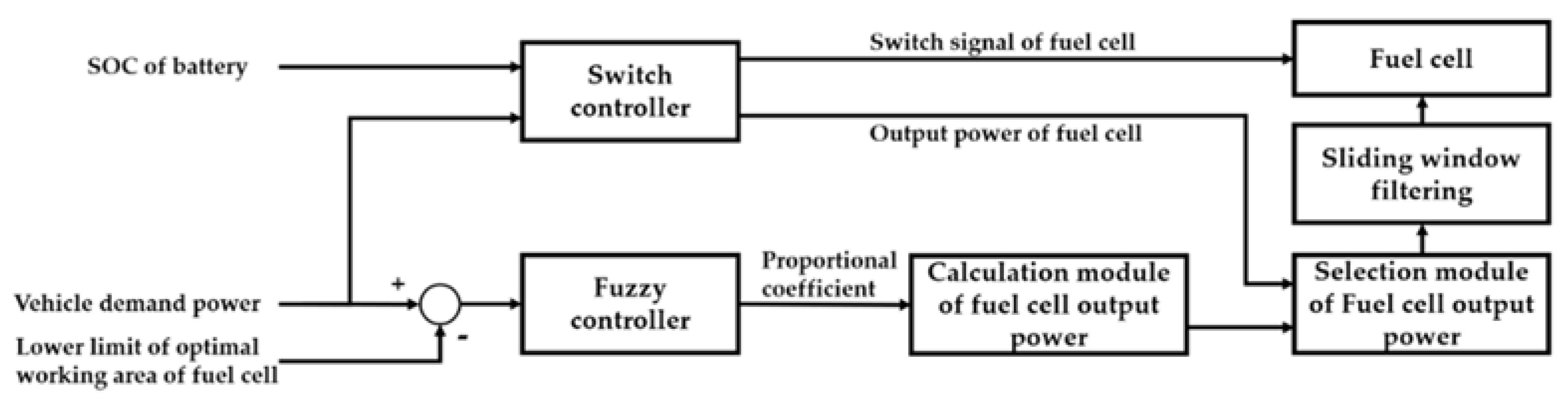

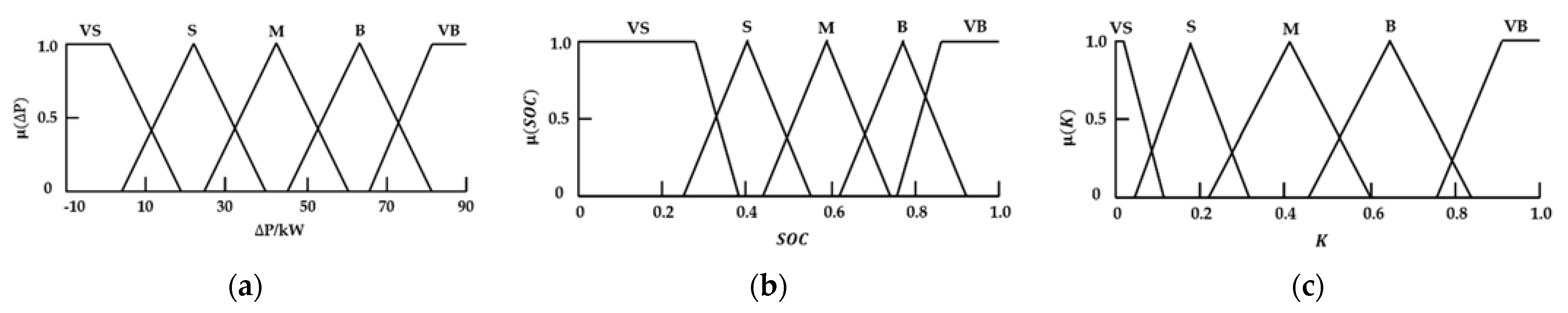

3.1.1. Composite Fuzzy Control Strategy

- Try to avoid the fuel cell working at idling condition;

- Try to reduce the number of fuel cell start-up and shut-down;

- Make the fuel cell work in a high efficiency area; and

- Keep the SOC of the battery in a reasonable range, which was 40~80% in this paper [33].

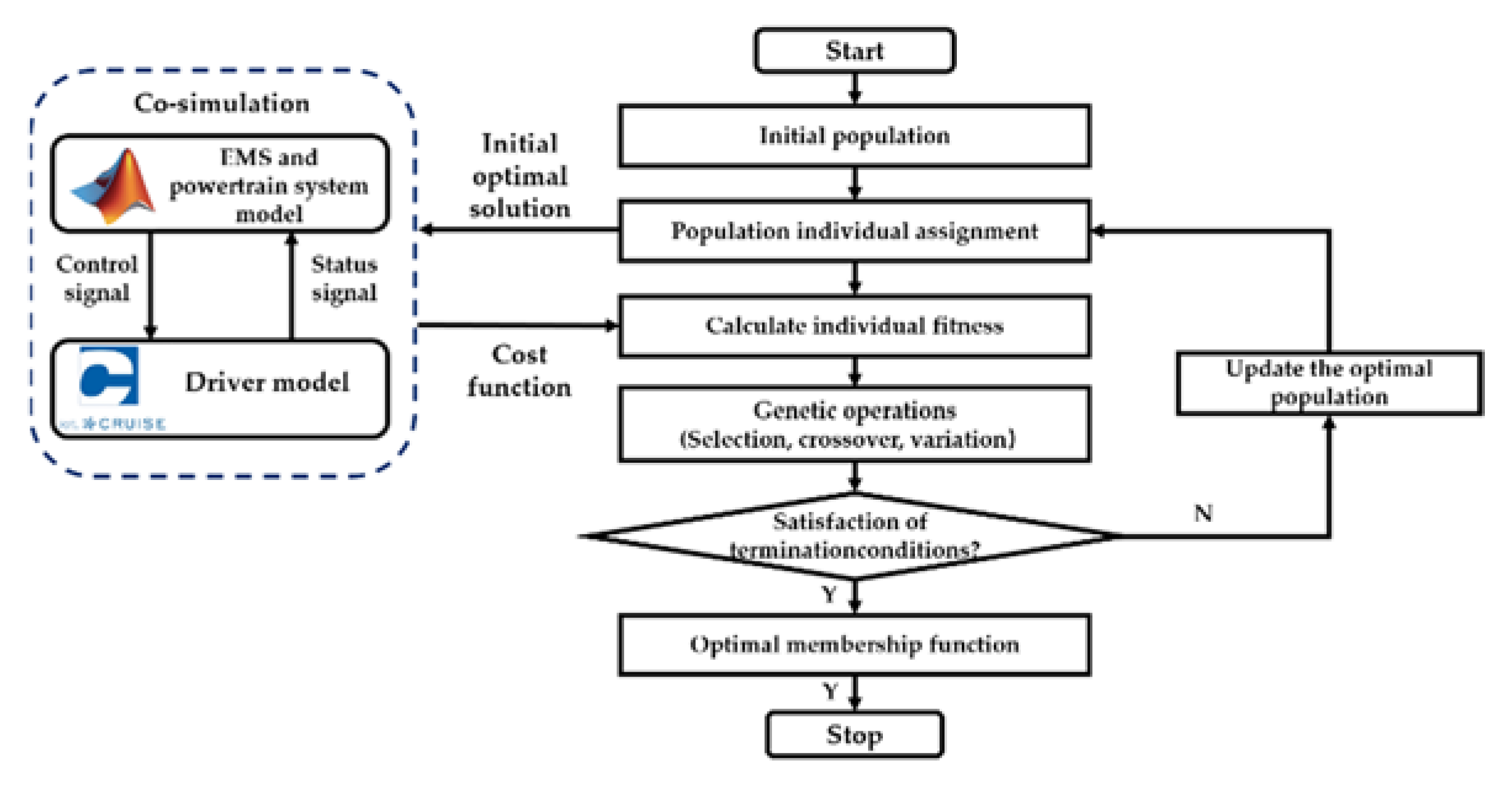

3.1.2. Improved Composite Fuzzy Control Strategy Using Genetic Algorithm (GA)

3.2. Energy Management Strategy under Quantitative Generalized Economy

3.2.1. Optimization Problem Formation and Basic Optimization Goal Setting

3.2.2. Improved Optimization Objective Based on Fuel Cell Power Change Rate

4. Results and Discussion

4.1. Results of Energy Management Strategy under Qualitative Generalized Economy

4.1.1. Verification of Optimization Effect of Composite Fuzzy Control Strategy

- Compared with the switch control strategy, the hydrogen consumption per 100 km was increased by 5.250%, while the cost was reduced by 5.825%. This is because in the switching control strategy, the fuel cell is in a constant power operating point for a long time, and the frequency of the dynamic load change condition is almost zero. In order to fill the power demand of the bus, the battery is in a state of deep charge/discharge for a long time, which causes great damage to the battery. The composite fuzzy strategy greatly alleviates the fluctuation of the battery and is beneficial to the extension of the battery life; and

- Compared with the sliding window filtering strategy, the hydrogen consumption per 100 km was significantly reduced, and the cost was decreased by 0.618%. At the same time, the total degradation rate of the fuel cell was reduced.

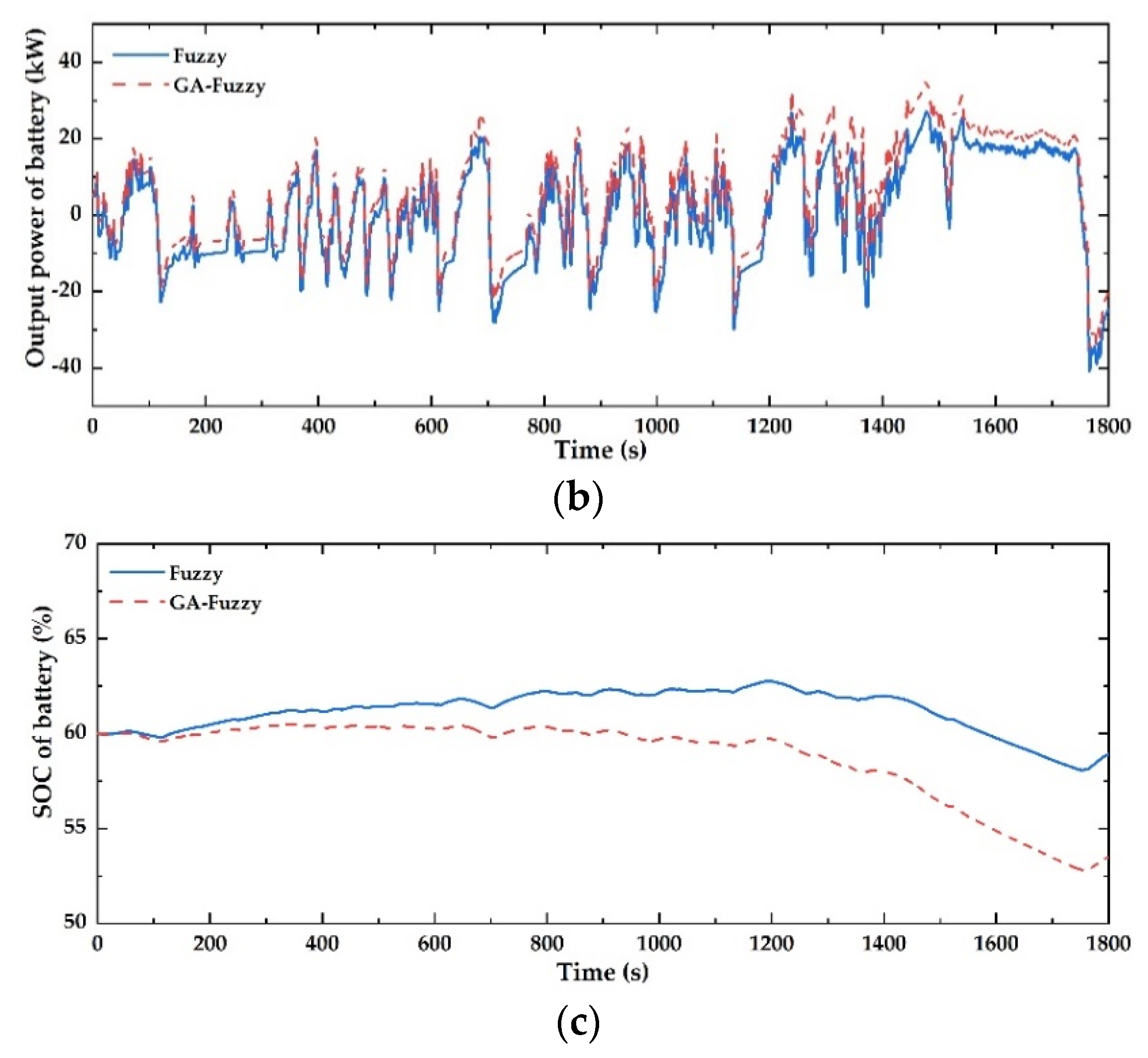

4.1.2. Verification of Effect of the Improved Composite Fuzzy Control Strategy by Using Genetic Algorithm

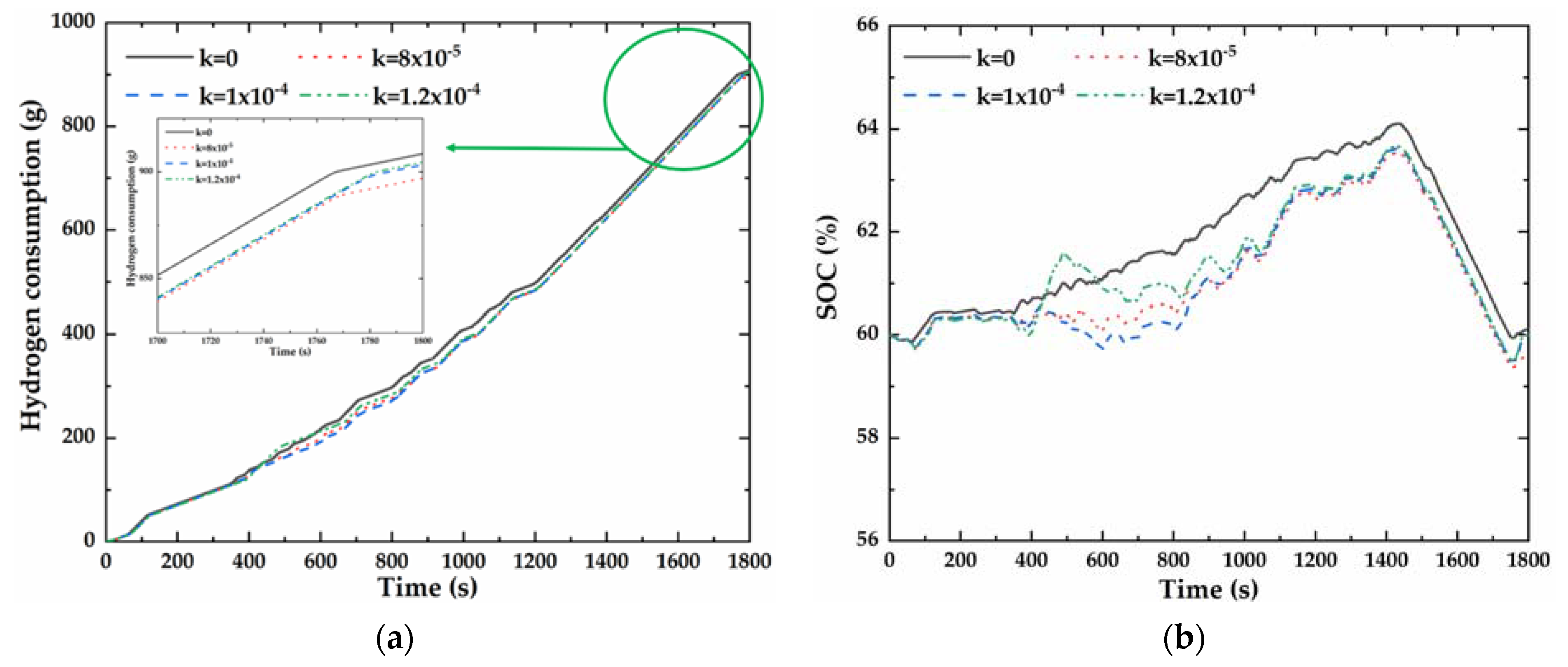

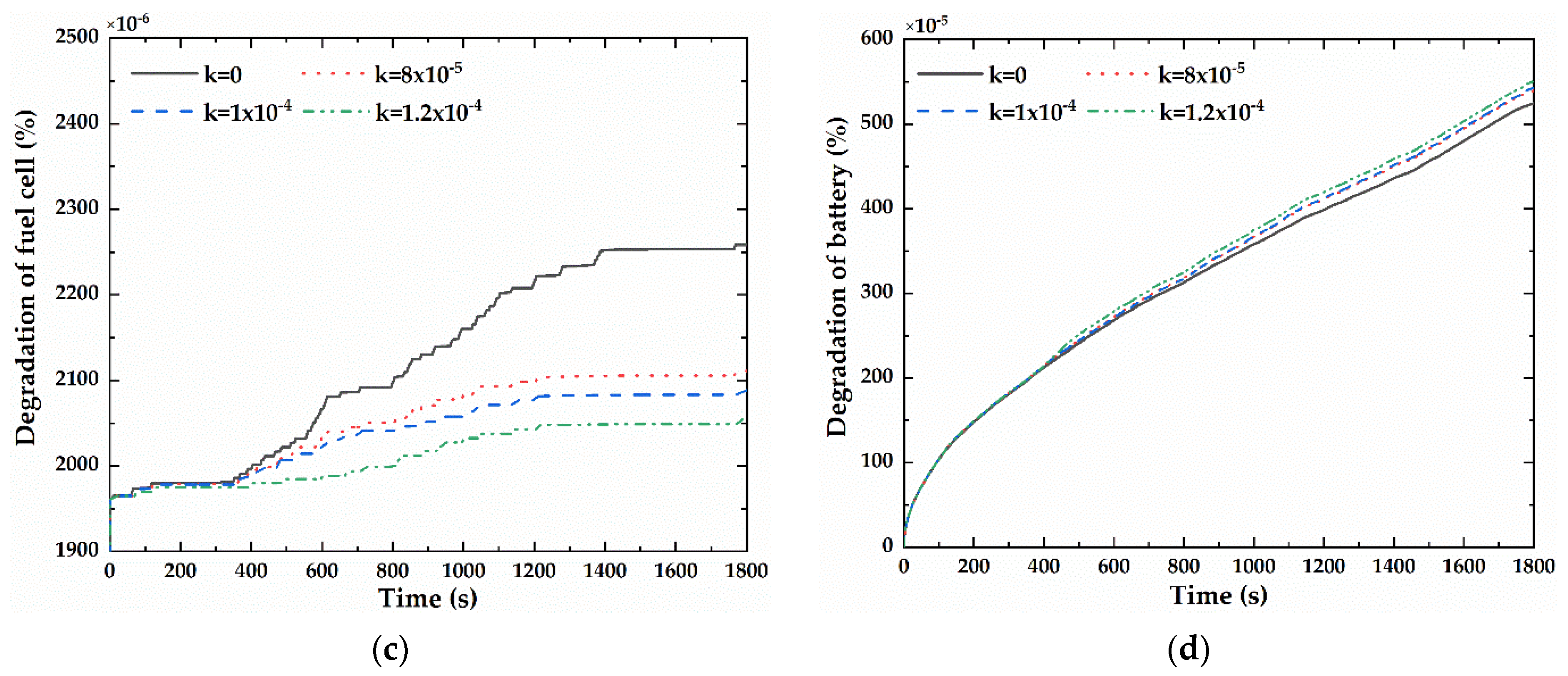

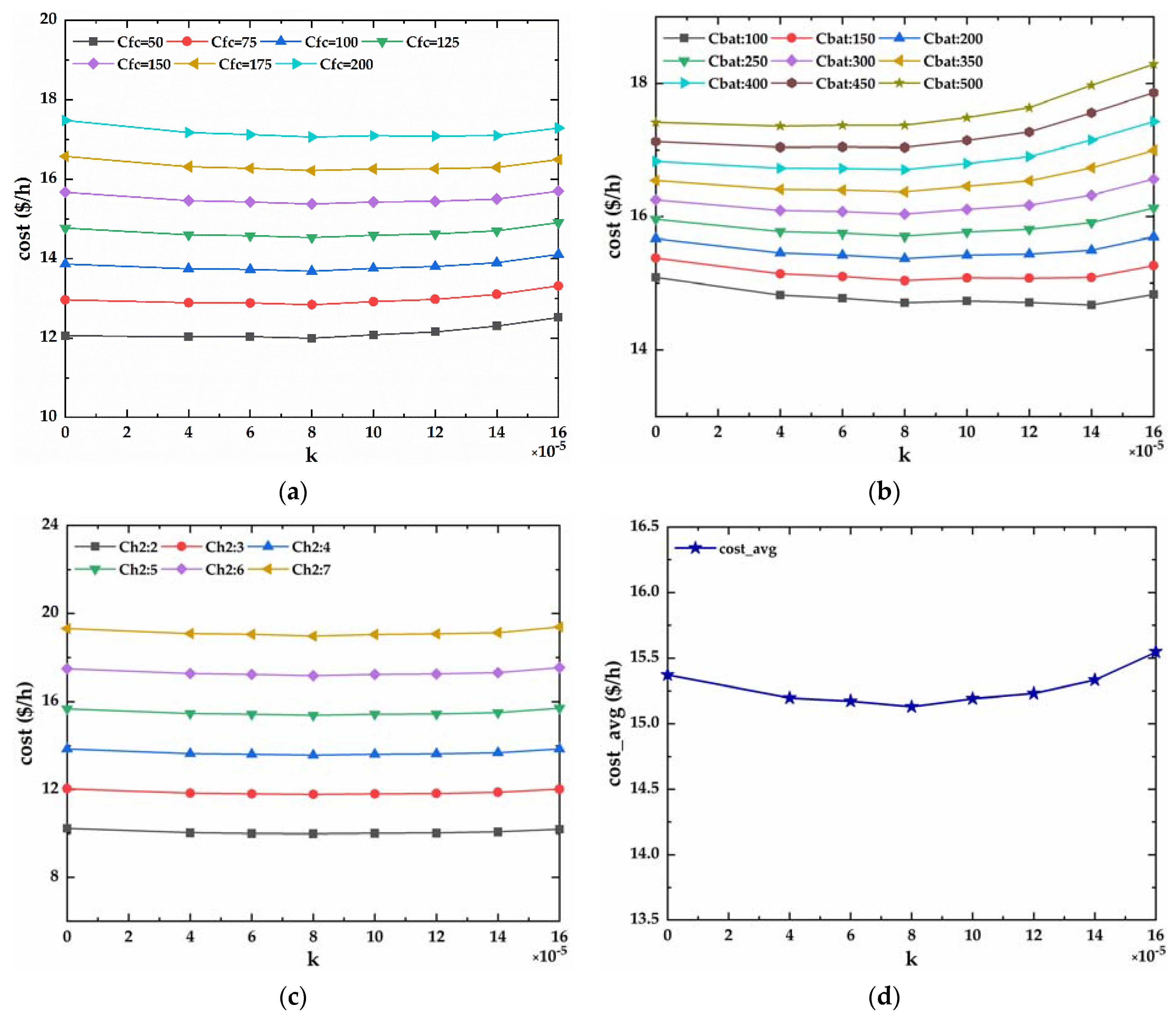

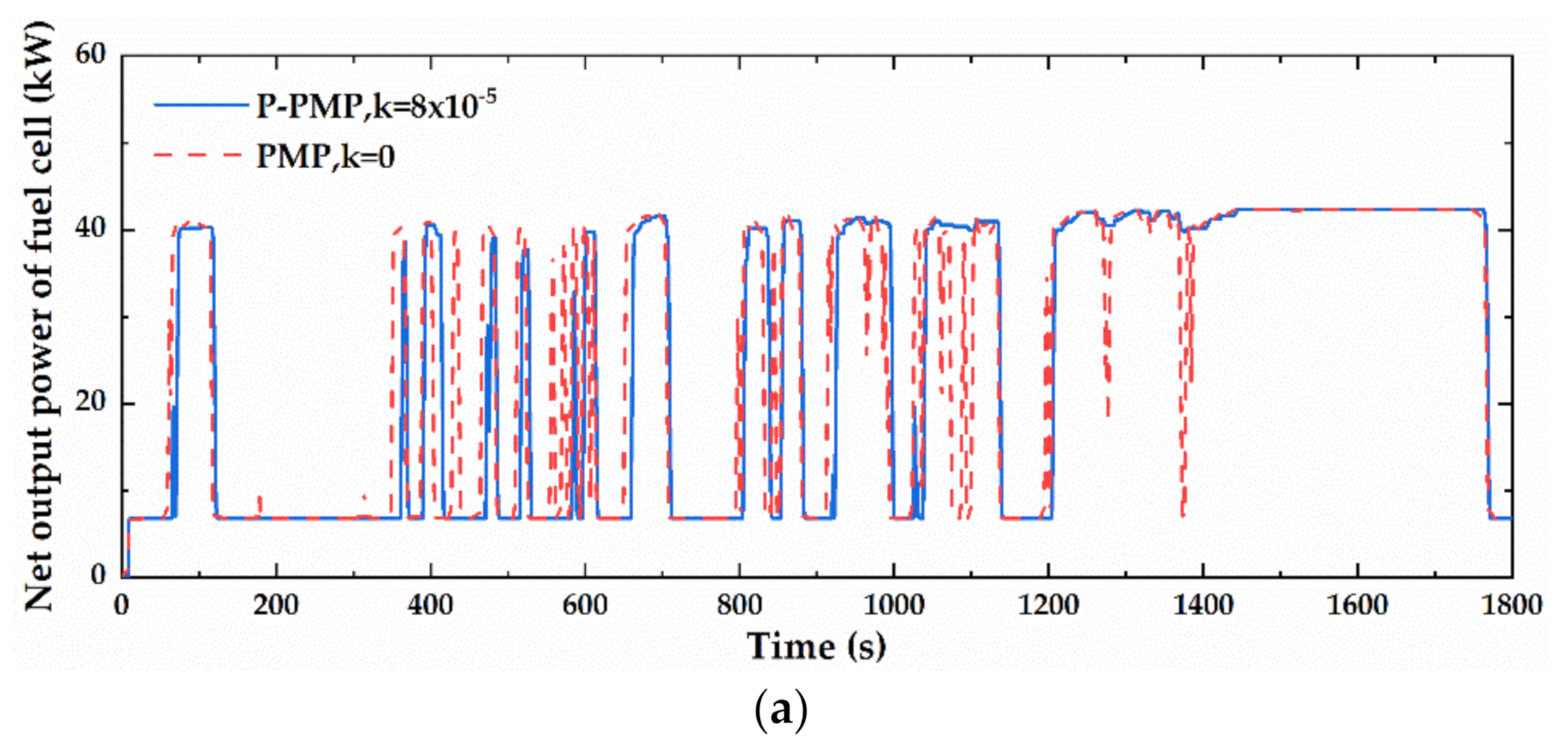

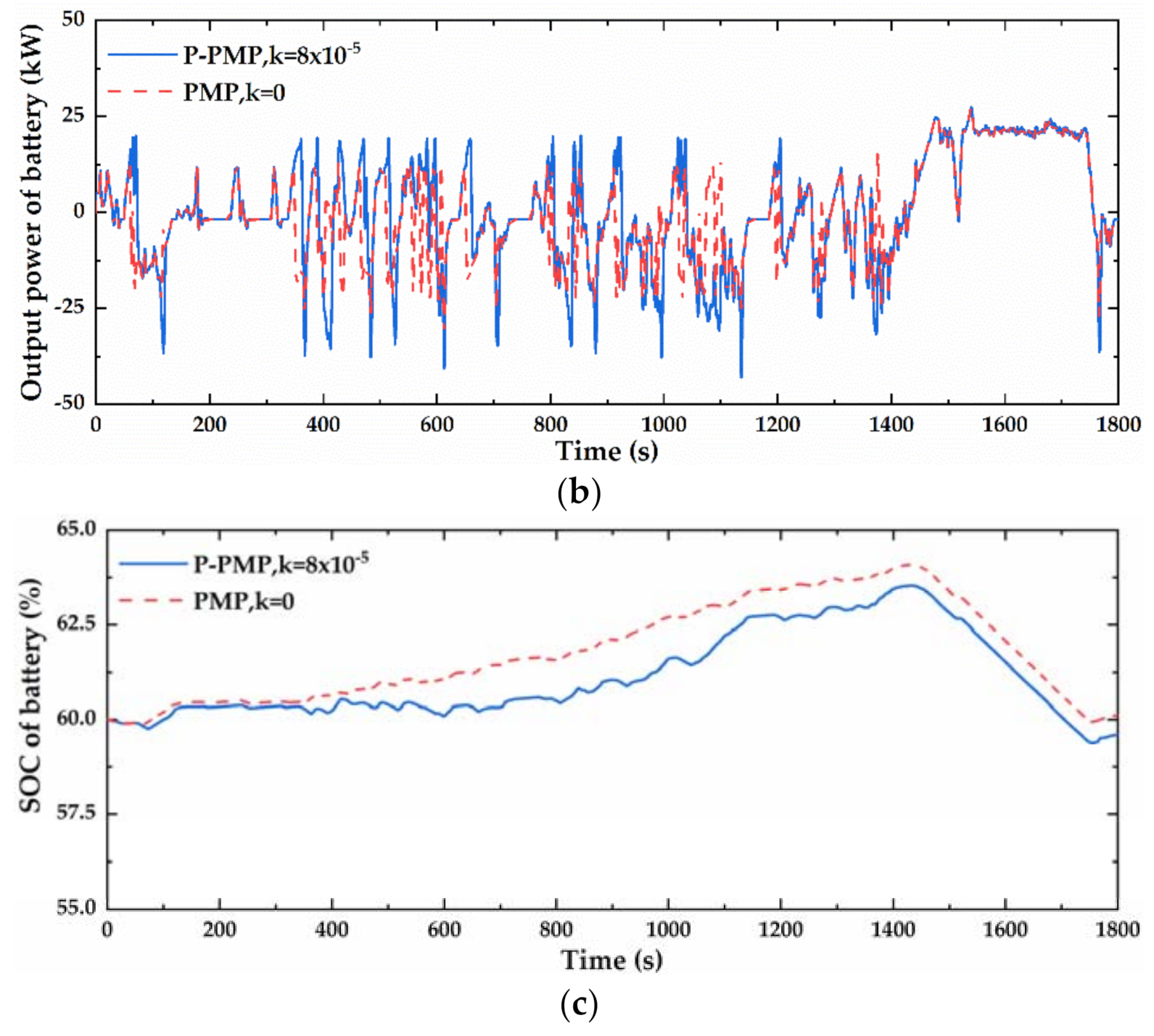

4.2. Results of Energy Management Strategy under Quantitative Generalized Economy

- The fuel economy was improved under the three k values;

- The difference between the peak and valley of SOC under three k values decreased, but the degradation degree of the battery increased, which indicates that the small fluctuation of SOC during working condition is relatively larger than that before improvement, which is not conducive to the maintenance of battery life;

- The degradation of fuel cell under three k values was lower than that before improvement, which indicates that the improvement strategy has a significant effect on improving the fuel cell durability; and

- It can be seen from Figure 11c,d that the larger the value of k, the less impact the dynamic load change condition has on the degradation of the fuel cell, which is more conducive to improving the fuel cell durability, despite the battery durability being relatively poor. This reflects that different values of k have different effects on the durability of thee fuel cell and battery, so the concept of total cost function is helpful to further select the best value of k, which makes the fuel economy and power system durability relatively better.

- The output power of the fuel cell was smoother, and the influence of the dynamic load change condition on fuel cell degradation was reduced;

- The absolute value of the SOC fluctuation of the battery |ΣΔSOC| was smaller;

- The total hydrogen consumption was smaller and the fuel economy was better; and

- The total degradation of the fuel cell was smaller. Although the total degradation rate of the battery was slightly larger, the lifetime cost was lower.

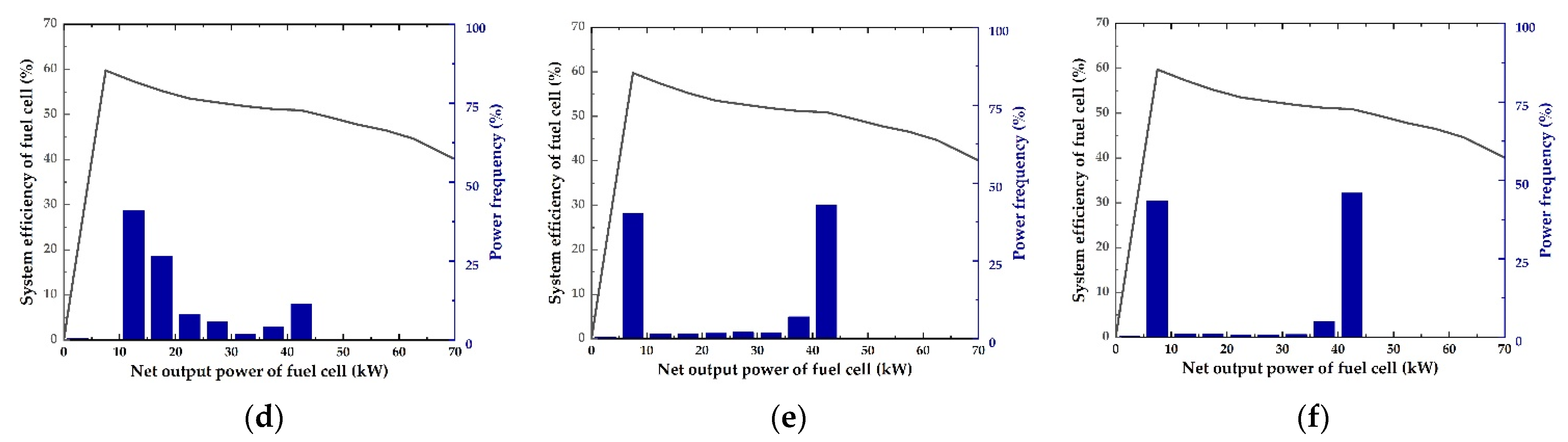

4.3. Comparison of Fuel Economy and Power System Durability under Different Strategies

- The hydrogen consumption per 100 km was the lowest under the P-PMP strategy, which was 3.481 kg/100 km. At the same time, the lifetime cost was also the lowest among all strategies, which was 13.042 $/h;

- The total fuel cell degradation was low under the switch control strategy, because the fuel cell has been working at some fixed power point, so the frequency of the dynamic load change condition was very small. According to the power distribution diagram of the fuel cell, the frequency of fuel cell working in the high efficiency area was higher under this strategy, and the heat loss of hydrogen in the process of energy conversion was less. Therefore, the hydrogen consumption per 100 km was relatively low. However, it also led to frequent fluctuations and a high degradation rate in the batteries. It ended with a relatively high lifetime cost compared with the other strategies;

- Under the sliding window filtering strategy, the total degradation of the fuel cell and battery were at the middle level. At the same time, the hydrogen consumption was higher. According to the efficiency distribution of the fuel cell, the working point of the fuel cell was more scattered under this strategy. Compared with the other strategies, the fuel cell worked more frequently at low efficiency, so the energy loss of hydrogen during energy conversion was larger;

- Compared with the GA-fuzzy strategy, the total fuel cell degradation was increased by 5.79% in the P-PMP strategy. In addition, the battery degradation decreased, the hydrogen consumption per 100 km was smaller, and the final cost was 2.23% smaller; and

- Compared with the PMP strategy, the frequency of thee fuel cell working in the high efficiency zone was higher and the hydrogen consumption per 100 km was lower under the P-PMP strategy. In addition, the total degradation of the fuel cell was greatly improved, and the cost was also 1.14% lower.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Acronyms | |

| EMS | Energy management strategy |

| PMP | Pontryagin’s minimum principle |

| PEMFCs | Proton exchange membrane fuel cells |

| ECMS | Equivalent consumption minimization strategy |

| DP | Dynamic programming |

| FCE | Fuel cell engine |

| OCV | Open circuit voltage |

| NREL | National Renewable Energy Laboratory |

| SOC | State of charge |

| GA | Genetic algorithm |

| P-PMP | Improved Pontryagin’s minimum principle |

| Symbols | |

| Output current of fuel cell | |

| Moles of electrons | |

| F | Faraday constant |

| Hydrogen consumption rate of fuel cell | |

| Number of fuel cell units | |

| Molar mass of hydrogen | |

| Utilization rate of hydrogen | |

| Output power of fuel cell system | |

| Lower heat value of hydrogen | |

| Efficiency of fuel cell system | |

| Total degradation of fuel cell | |

| Degradation rate under start-stop condition | |

| Degradation rate under dynamic load change condition | |

| Degradation rates under idling condition | |

| Degradation rates under high-power condition | |

| Low-power threshold of fuel cell under idling condition | |

| High-power threshold of fuel cell under high-power condition | |

| On/off state of the fuel cell engine | |

| Duration time of the off state of fuel cell engine | |

| Output voltage of battery | |

| Open circuit voltage of battery | |

| Output power of battery | |

| Equivalent internal resistance of battery | |

| Current of battery | |

| Current state of charge of battery | |

| Residual state of charge of battery at the initial time | |

| Capacity of battery | |

| Charged/discharged in the battery calculated at the dc bus | |

| Charge/discharge capacity of battery | |

| Average voltage of battery | |

| Efficiency of dc/dc converter | |

| Internal charge resistance of battery | |

| Internal discharge resistance of battery | |

| Charge power of battery | |

| Discharge power of battery | |

| Average charge efficiency of battery | |

| Average discharge efficiency of battery | |

| Total degradation of battery | |

| Cycle degradation of battery | |

| Calendar degradation of battery | |

| Total traction force | |

| m | Vehicle mass |

| g | Acceleration due to gravity |

| f | Rolling resistance coefficient |

| u | Vehicle velocity |

| A | Front area |

| α | Road angle |

| Air drag coefficient | |

| Torque on the wheel | |

| Wheel rotation speed | |

| Total demanded power | |

| Degradation of battery | |

| Unit cost of fuel cell | |

| Unit cost of battery | |

| Peak power of the fuel cell system | |

| Total energy of the battery | |

| M | Total hydrogen consumption |

| Unit price of hydrogen | |

| Unit price of the electric charge/discharge | |

| SOC change rate of battery | |

| Co-state variable | |

| Start time | |

| End time | |

| Charge/discharge efficiency of battery | |

| Reference value of the SOC of battery | |

| Low limit power of fuel cell | |

| High limit power of fuel cell | |

| Low limit power of battery | |

| High limit power of battery | |

| Low limit state of charge of battery | |

| High limit state of charge of battery | |

| Allowable margin of error of the end SOC of battery | |

| Hydrogen consumption | |

| Fuel cell power fluctuation | |

| k | Weight factor of the power fluctuation of fuel cell |

| Subscripts | |

| st | Stable |

| fc | Fuel cell |

| H | Hydrogen |

| cell | Fuel cell units |

| start-stop | Start-stop condition |

| load-change | Dynamic load change condition |

| low | Idling condition |

| high | High-power condition |

| engine_on | On state of fuel cell engine |

| engine_off | Off state of fuel cell engine |

| b | Battery |

| oc | Open circuit |

| t | Current state |

| 0 | Initial state |

| bat | Battery |

| DC | DC/DC converter |

| chg | Charge |

| dis | Discharge |

| avg | Average |

| D | Drag |

| w | Wheel |

| req | Request |

| max | Maximum |

| ele | Electric |

| ref | Reference |

References

- Ma, T.C.; Lin, W.K.; Yang, Y.B.; Wang, K.; Jia, W. Water content diagnosis for proton exchange membrane fuel cell based on wavelet transformation. Int. J. Hydrogen Energy 2020, 45, 20339–20350. [Google Scholar] [CrossRef]

- Abaza, A.; Elsehiemy, R.A.; Mahmoud, K.; Lehtonen, M.; Darwish, M. Optimal Estimation of Proton Exchange Membrane Fuel Cells Parameter Based on Coyote Optimization Algorithm. Appl. Sci. 2021, 11, 2052. [Google Scholar] [CrossRef]

- Al-Gabalawy, M.; Mahmoud, K.; Darwish, M.M.F.; Dawson, J.; Lehtonen, M.; Hosny, N. Reliable and Robust Observer for Simultaneously Estimating State-of-Charge and State-of-Health of LiFePO4 Batteries. Appl. Sci. 2021, 11, 3609. [Google Scholar] [CrossRef]

- Jahromi, M.M.; Heidary, H. Durability and economics investigations on triple stack configuration and its power management strategy for fuel cell vehicles. Int. J. Hydrogen Energy 2021, 46, 5740–5755. [Google Scholar] [CrossRef]

- Ma, T.C.; Lin, W.K.; Yang, Y.B.; Cong, M.; Yu, Z.; Zhou, Q. Research on Control Algorithm of Proton Exchange Membrane Fuel Cell Cooling System. Energies 2019, 12, 3692. [Google Scholar] [CrossRef]

- Xu, L.F.; Li, J.Q.; Hua, J.; Yang, G. Multi-mode control strategy for fuel cell electric vehicles regarding fuel economy and durability. Int. J. Hydrogen Energy 2014, 39, 2374–2389. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, Z.; Chen, Z. Rule-based energy management strategy of a lithium-ion battery, supercapacitor and PEM fuel cell system. Energy Procedia 2019, 158, 2555–2560. [Google Scholar] [CrossRef]

- Ji, R.H. Optimal Design and Energy Management of Power System for Full-power Fuel Cell Vehicle. Master’s Thesis, Jilin University, Changchun, China, 2020. [Google Scholar]

- Wang, Y.G.; Suresh, D.A.; Ajay, K.P. A comparison of rule-based and model predictive controller-based power management strategies for fuel cell/battery hybrid vehicles considering degradation. Int. J. Hydrogen Energy 2020, 45, 33948–33956. [Google Scholar] [CrossRef]

- Ahmadi, S.; Bathaee, S.M.T. Multi-objective genetic optimization of the fuel cell hybrid vehicle supervisory system: Fuzzy logic and operating mode control strategies. Int. J. Hydrogen Energy 2015, 40, 12512–12521. [Google Scholar] [CrossRef]

- Wang, Y.J.; Sun, Z.D.; Chen, Z.H. Energy management strategy for battery/supercapacitor/fuel cell hybrid source vehicles based on finite state machine. Appl. Energy 2019, 254, 113707. [Google Scholar] [CrossRef]

- Erdinc, O.; Vural, B.; Uzunoglu, M. A wavelet-fuzzy logic based energy management strategy for a fuel cell/battery/ultra-capacitor hybrid vehicular power system. J. Power Sources 2009, 194, 369–380. [Google Scholar] [CrossRef]

- Fu, Z.; Zhu, L.; Si, P.; Sun, L. Optimization based energy management strategy for fuel cell/battery/ultracapacitor hybrid vehicle considering fuel economy and fuel cell lifespan. Int. J. Hydrogen Energy 2020, 45, 8875–8886. [Google Scholar] [CrossRef]

- Ali, A.; Mahmoud, K.; Lehtonen, M. Multi-objective Photovoltaic Sizing with Diverse Inverter Control Schemes in Distribution Systems Hosting EVs. IEEE Trans. Ind. Inform. 2020. [Google Scholar] [CrossRef]

- Ferrario, A.M.; Manzano, F.S.; Bocci, E.; Andújar, J.M.; Bocci, E.; Martirano, L. Hydrogen vs. Battery in the Long-term Operation. A Comparative Between Energy Management Strategies for Hybrid Renewable Microgrids. IEEE Consum. Electron. Mag. 2020, 9, 1–128. [Google Scholar]

- Koubaa, R.; Bacha, S.; Smaoui, M. Robust optimization based energy management of a fuel cell/ultra-capacitor hybrid electric vehicle under uncertainty. Energy 2020, 200, 117530. [Google Scholar] [CrossRef]

- García, P.; Torreglosa, J.P.; Fernández, L.M.; Jurado, F. Control strategies for high-power electric vehicles powered by hydrogen fuel cell, battery and supercapacitor. Expert Syst. Appl. 2013, 40, 4791–4804. [Google Scholar] [CrossRef]

- Geng, B.; Mills, J.K.; Sun, D. Two-Stage Energy Management Control of Fuel Cell Plug-In Hybrid Electric Vehicles Considering Fuel Cell Longevity. IEEE Trans. Veh. Technol. 2012, 61, 498–508. [Google Scholar] [CrossRef]

- Xu, L.F.; Mueller, C.D.; Li, J.; Ouyang, M.; Hu, Z. Multi-objective component sizing based on optimal energy management strategy of fuel cell electric vehicles. Appl. Energy 2015, 157, 664–674. [Google Scholar] [CrossRef]

- Hu, Z.Y.; Li, J.Q.; Xu, L.F.; Song, Z.; Fang, C.; Ouyang, M.; Dou, G.; Kou, G. Multi-objective energy management optimization and parameter sizing for proton exchange membrane hybrid fuel cell vehicles. Energy Convers. Manag. 2016, 129, 108–121. [Google Scholar] [CrossRef]

- Zheng, C.H.; Kim, N.M.; Cha, S.W. Optimal control in the power management of fuel cell hybrid vehicles. Int. J. Hydrogen Energy 2012, 37, 655–663. [Google Scholar] [CrossRef]

- Li, Q.; Chen, W.; Liu, Z.; Li, M.; Ma, L. Development of energy management system based on a power sharing strategy for a fuel cell-battery-supercapacitor hybrid tramway. J. Power Sources 2015, 279, 267–280. [Google Scholar] [CrossRef]

- Florescu, A.; Bacha, S.; Munteanu, I.; Bratcu, A.I.; Rumeau, A. Adaptive frequency-separation-based Energy Management System for electric vehicles. J. Power Sources 2015, 280, 410–421. [Google Scholar] [CrossRef]

- Li, T.; Liu, H.; Zhao, D.; Wang, L. Design and analysis of a fuel cell supercapacitor hybrid construction vehicle. Int. J. Hydrogen Energy 2016, 41, 12307–12319. [Google Scholar] [CrossRef]

- Hou, Y.P.; Liu, Y.N.; Cai, Q.Z.; Sun, M. Study on efficiency characteristics of fuel cell engine during start-up. Chin. J. Automot. Eng. 2013, 3, 88–93. [Google Scholar]

- Zhai, J.X.; He, G.L.; Xiong, Y.L. Experimental study on hydrogen utilization of proton exchange membrane fuel cell system. Energy Storage Sci. Technol. 2020, 3, 684–687. [Google Scholar]

- Pei, P.C.; Chang, Q.; Tian, T. A quick evaluating method for automotive fuel cell lifetime. Int. J. Hydrogen Energy 2008, 33, 3829–3836. [Google Scholar] [CrossRef]

- Jiang, H.L.; Xu, L.F.; Li, J.Q.; Hu, Z.; Ouyang, M. Energy Management and Component Sizing for a Fuel Cell/Battery/Supercapacitor Hybrid Powertrain based on Two-Dimensional Optimization Algorithms. Energy 2019, 177, 386–396. [Google Scholar] [CrossRef]

- Liu, Y.G.; Liu, J.J.; Zhang, Y.J.; Wu, Y.; Chen, Z.; Ye, M. Rule learning based energy management strategy of fuel cell hybrid vehicles considering multi-objective optimization. Energy 2020, 207, 118212–118225. [Google Scholar] [CrossRef]

- Song, K.; Chen, H.; Wen, P.M.; Zhang, T.; Zhang, B.; Zhang, T. A comprehensive evaluation framework to evaluate energy management strategies of fuel cell electric vehicles. Electrochim. Acta 2018, 292, 960–973. [Google Scholar] [CrossRef]

- Shi, Y.Q.; He, B.; Cao, G.J.; Li, J.Q.; Ouyang, M.G. A study on the energy management strategy for fuel cell electric vehicle based on instantaneous optimization. Automot. Eng. 2008, 1, 30–35. [Google Scholar]

- Shi, Y.Q.; He, B.; Cao, G.J.; Li, J.Q.; Ouyang, M.G. Overview of NREL Battery Lifetime Models & Health Management R&D Health Management R&D for Electric Drive Vehicles; National Renewable Energy Laboratory: Golden, CO, USA, 2012. [Google Scholar]

- Li, F.; Yang, Z.P.; Wang, Y.; An, X.K.; Ling, F. Energy management strategy of tram with hybrid energy storage system based on pontryagin’s minimum principle. Trans. China Electrotech. Soc. 2019, 34, 752–759. [Google Scholar]

- Xu, L.F.; Ouyang, M.G.; Li, J.Q.; Yang, F.; Lu, L.; Hua, J. Application of Pontryagin’s Minimal Principle to the energy management strategy of plugin fuel cell electric vehicles. Int. J. Hydrogen Energy 2013, 38, 10104–10115. [Google Scholar] [CrossRef]

- Eudy, L. Technology Acceleration: Fuel Cell Bus Evaluations; National Renewable Energy Laboratory: Golden, CO, USA, 2019. [Google Scholar]

- Wilson, A.; Kleen, G.; Papageorgopoulos, D. Fuel Cell System Cost; Department of Energy: Washington, DC, USA, 2017. [Google Scholar]

- James, B.D. 2019 DOE Hydrogen and Fuel Cells Program Review Presentation; Strategic Analysis Inc.: Reading, PA, USA, 2019. [Google Scholar]

- AMPLY Power 2020. Unlocking the Cost-Saving Potential of Electric Fuel. Available online: https://amplypower.com/whitepaper2020 (accessed on 31 May 2020).

- Amwook, K.; Sukwon, C.; Huei, P. Optimal control of hybrid electric vehicles based on pontryagin’s minimum principle. IEEE Trans. Control Syst. Technol. 2011, 19, 1279–1287. [Google Scholar]

- Du, G.Q.; Xie, H.M.; Lu, Z.; Huang, Y. Analysis for the energy management problem of extended-range electric city buses based on pontryagin’s minimum principle. J. Chongqing Inst. Technol. 2018, 32, 10–17. [Google Scholar]

| Ref. | Classification | Control Algorithm |

|---|---|---|

| [7,10] | Rule-based | Operating mode control |

| [8,9] | Thermostat control | |

| [11] | State machine control | |

| [10,12,13,14] | Fuzzy control | |

| [16] | Optimization-based | Particle swarm optimization |

| [17,18] | ECMS | |

| [19,20] | DP | |

| [21] | PMP |

| Parameter | Parameter | Value |

|---|---|---|

| Fuel cell | Cell number | 380 |

| Effective area of cell | 227 cm2 | |

| Peak power of stack | 80 kW | |

| Battery | Cell capacity | 26.5 Ah |

| Parallel number | 3 | |

| Serial number | 85 | |

| Peak charge-discharge ratio | 4C | |

| Rated voltage | 320 V | |

| Motor | Peak power | 4000 kW |

| Peak speed | 1600 r/min | |

| Peak torque | 80 Nm | |

| Rated power | 800 kW | |

| Rated speed | 1024 r/min | |

| Rated torque | 4000 Nm | |

| Vehicle | Curb Weight | 5100 kg |

| Full Weight | 7900 kg | |

| Vehicle length | 6438 mm | |

| Rolling resistance coefficient | 0.01 | |

| Face area | 5.9 m2 | |

| Drag coefficient | 0.7 |

| SOC | VS | S | M | B | ||

|---|---|---|---|---|---|---|

| K | ||||||

| ΔP | ||||||

| VS | M | S | VS | VS | ||

| S | B | M | S | VS | ||

| M | VB | B | M | S | ||

| B | VB | B | B | M | ||

| VB | VB | VB | B | M | ||

| Strategy | SOC End Value/% | Hydrogen Consumption/(kg/100 km) | Cost/($/h) |

|---|---|---|---|

| 1. Switch control | 57.489 | 3.257 | 14.352 |

| 2. Sliding window filtering | 59.314 | 3.561 | 13.600 |

| 3. Composite fuzzy strategy | 58.929 | 3.428 | 13.516 |

| 3 vs. 1 | - | +5.250% | −5.825% |

| 3 vs. 2 | - | −3.735% | −0.618% |

| Strategy | SOC End Value/% | Hydrogen Consumption/ (kg/100 km) | Cost/($/h) |

|---|---|---|---|

| 1. Composite fuzzy | 58.929 | 3.428 | 13.516 |

| 2. GA-Fuzzy | 57.763 | 3.317 | 13.339 |

| 2 vs. 1 | - | −3.238% | −1.310% |

| Strategy | Degradation of Fuel Cell/ % × 10−5 | Degradation of Battery/ % × 10−5 | Hydrogen Consumption/ (kg/100 km) | Cost/($/h) | ||

|---|---|---|---|---|---|---|

| Dynamic Load Change | Total | Cycle | Total | |||

| 1. Switch control | 0.33 | 196.65 | 111.49 | 4319.55 | 3.257 | 14.352 |

| 2. Sliding window filtering | 4.45 | 213.28 | 63.45 | 4271.51 | 3.561 | 13.600 |

| 3. Composite fuzzy | 2.64 | 206.90 | 80.19 | 4288.25 | 3.428 | 13.516 |

| 4. GA-fuzzy | 2.28 | 198.60 | 81.47 | 4289.53 | 3.317 | 13.339 |

| 5. PMP | 26.78 | 223.26 | 46.33 | 4254.39 | 3.540 | 13.192 |

| 6. P-PMP | 13.63 | 210.10 | 53.15 | 4261.21 | 3.481 | 13.042 |

| 6 vs. 1 | - | +6.84% | - | −1.35% | +6.88% | −7.73% |

| 6 vs. 2 | - | −1.49% | - | −0.24% | −2.25% | −2.63% |

| 6 vs. 3 | - | +1.55% | - | −0.63% | +1.55% | −2.03% |

| 6 vs. 4 | - | +5.79% | - | −0.66% | +4.94% | −2.23% |

| 6 vs. 5 | - | −5.89% | - | +0.16% | −1.67% | −1.14% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, J.; Li, Y.; Jia, W.; Lin, W.; Ma, T. Comparison of Two Energy Management Strategies Considering Power System Durability for PEMFC-LIB Hybrid Logistics Vehicle. Energies 2021, 14, 3262. https://doi.org/10.3390/en14113262

Liang J, Li Y, Jia W, Lin W, Ma T. Comparison of Two Energy Management Strategies Considering Power System Durability for PEMFC-LIB Hybrid Logistics Vehicle. Energies. 2021; 14(11):3262. https://doi.org/10.3390/en14113262

Chicago/Turabian StyleLiang, Jianying, Yankun Li, Wenya Jia, Weikang Lin, and Tiancai Ma. 2021. "Comparison of Two Energy Management Strategies Considering Power System Durability for PEMFC-LIB Hybrid Logistics Vehicle" Energies 14, no. 11: 3262. https://doi.org/10.3390/en14113262

APA StyleLiang, J., Li, Y., Jia, W., Lin, W., & Ma, T. (2021). Comparison of Two Energy Management Strategies Considering Power System Durability for PEMFC-LIB Hybrid Logistics Vehicle. Energies, 14(11), 3262. https://doi.org/10.3390/en14113262