Stress Reversals near Hydraulically Fractured Wells Explained with Linear Superposition Method (LSM)

Abstract

1. Introduction

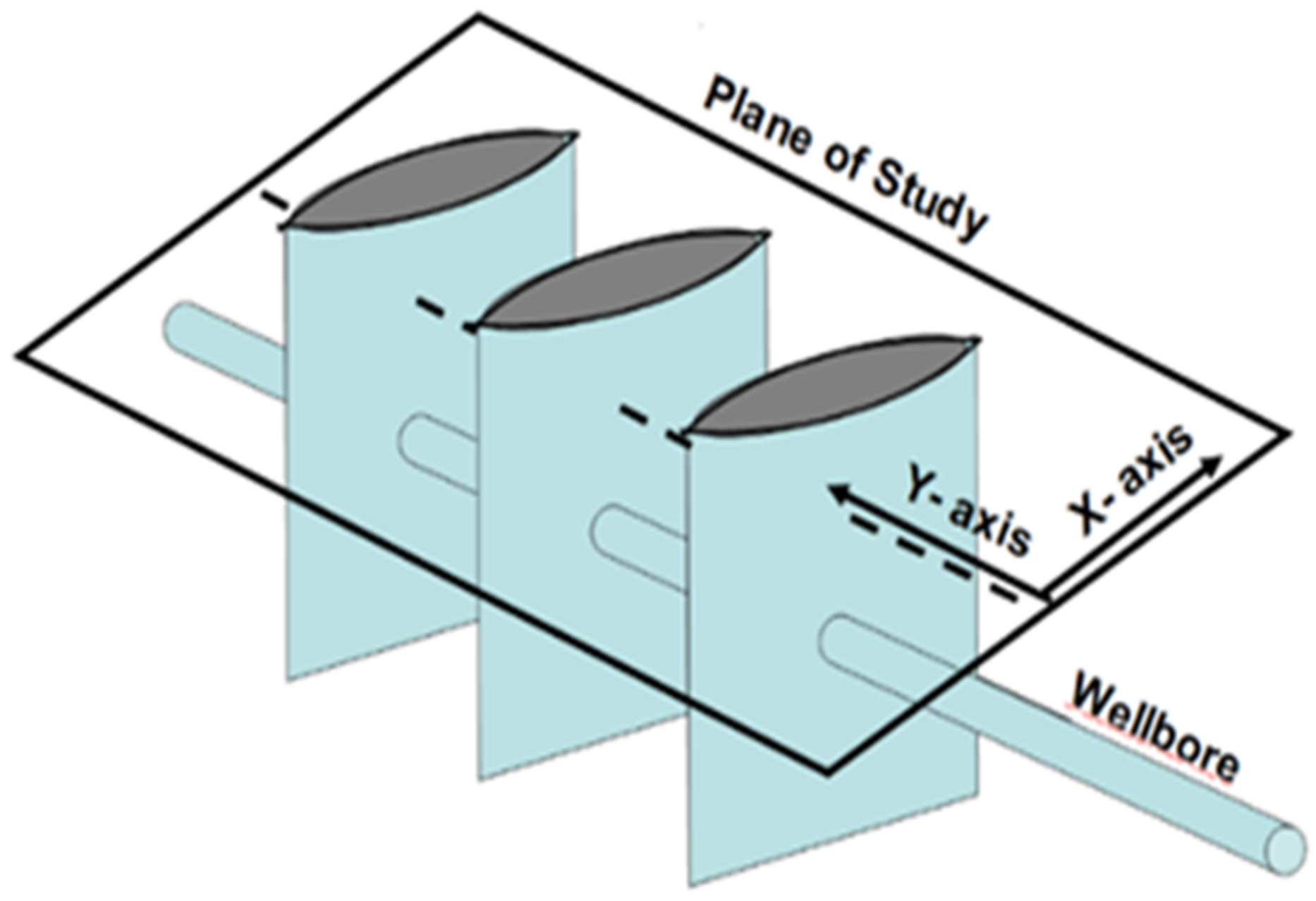

2. Methodology

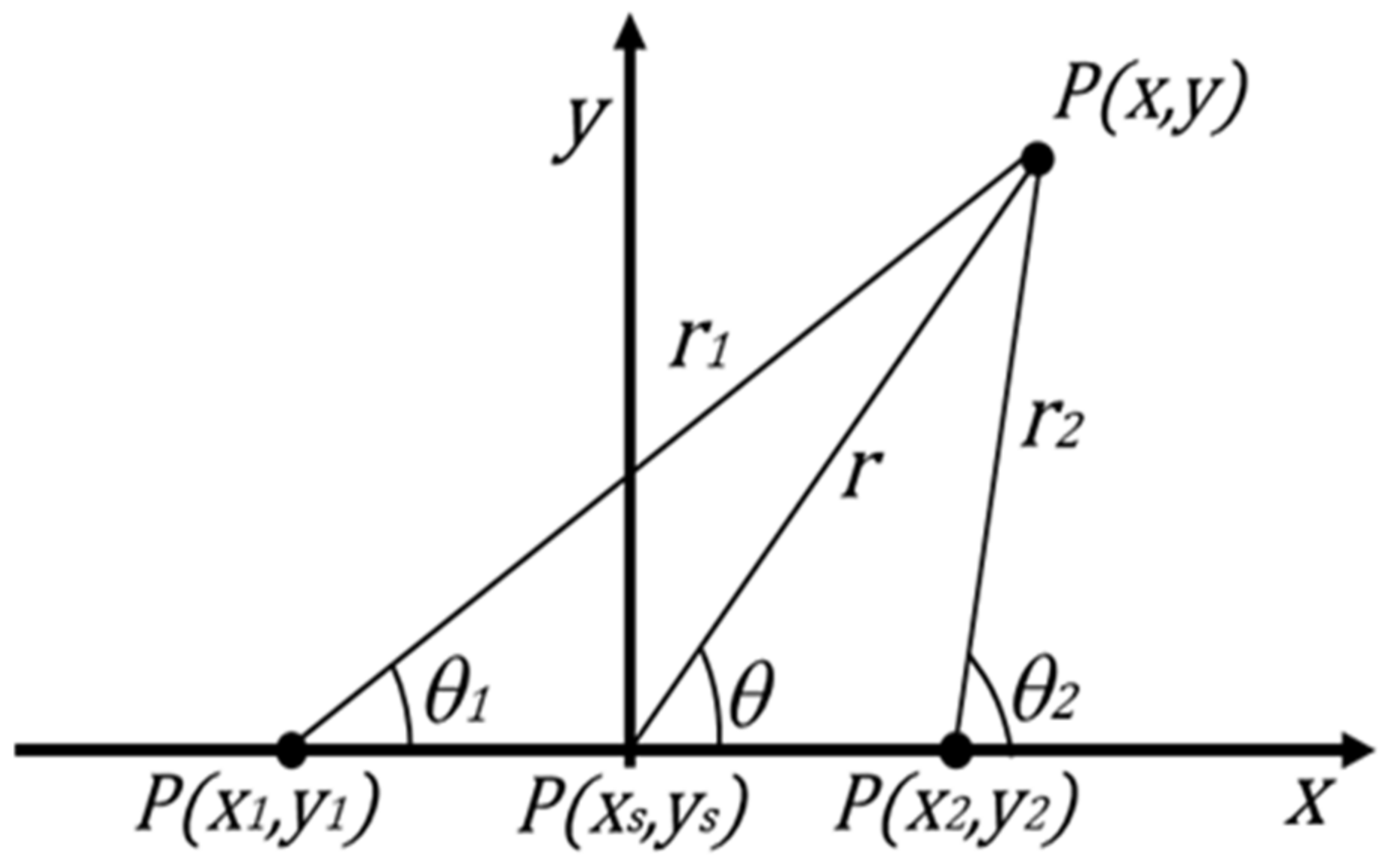

2.1. Linear Superposition Method (LSM)

2.2. Principal Stress Trajectories

2.3. Computing Initial Stress State and Reservoir Pressure

2.4. Computing Impact of Fracture Treatment on Stress State and Reservoir Pressure

2.5. Computing Impact of Leak-Off and Flow-Back on Stress State and Pressure Changes

2.6. Computing Impact of Pressure Depletion during Production

3. Results

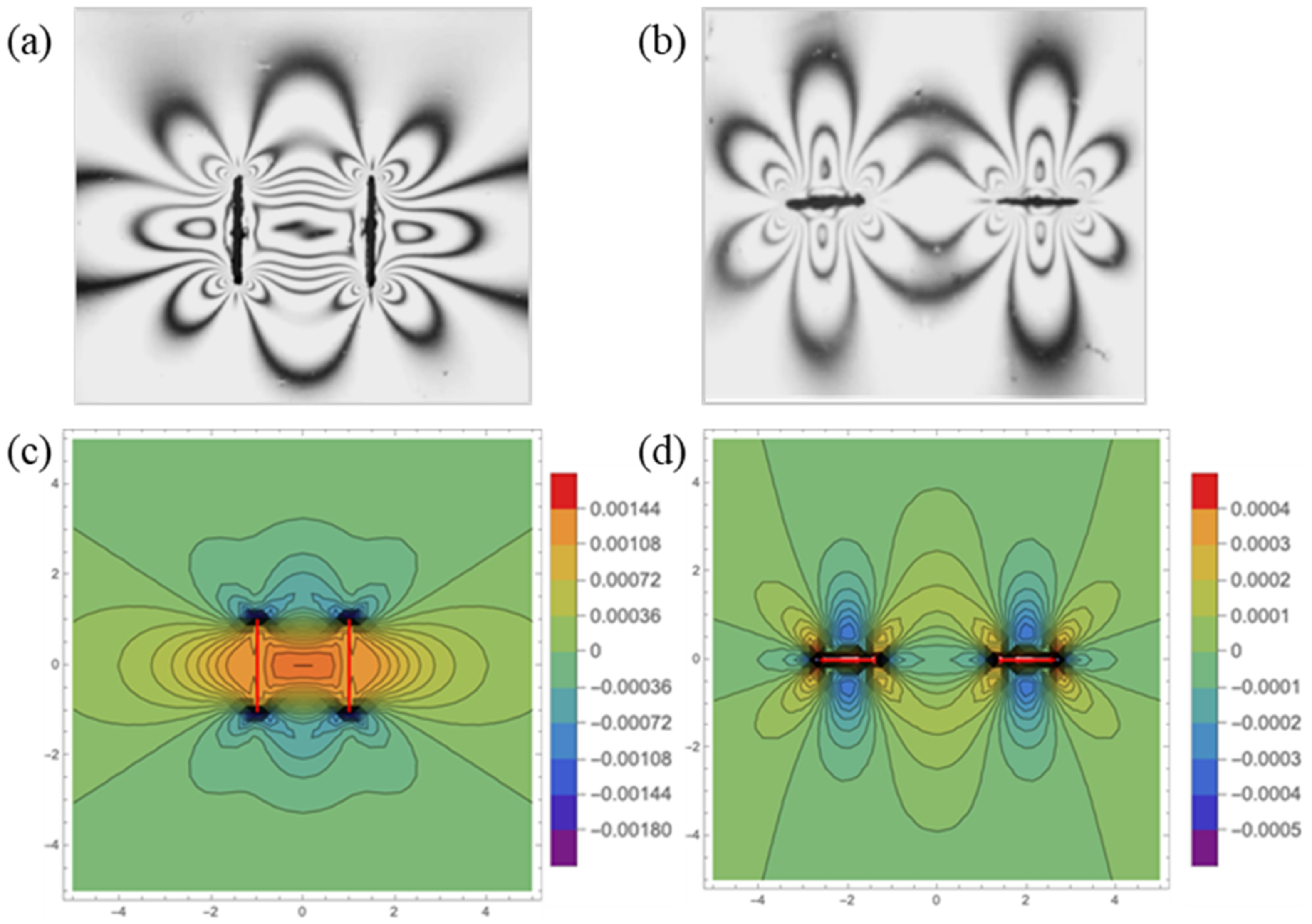

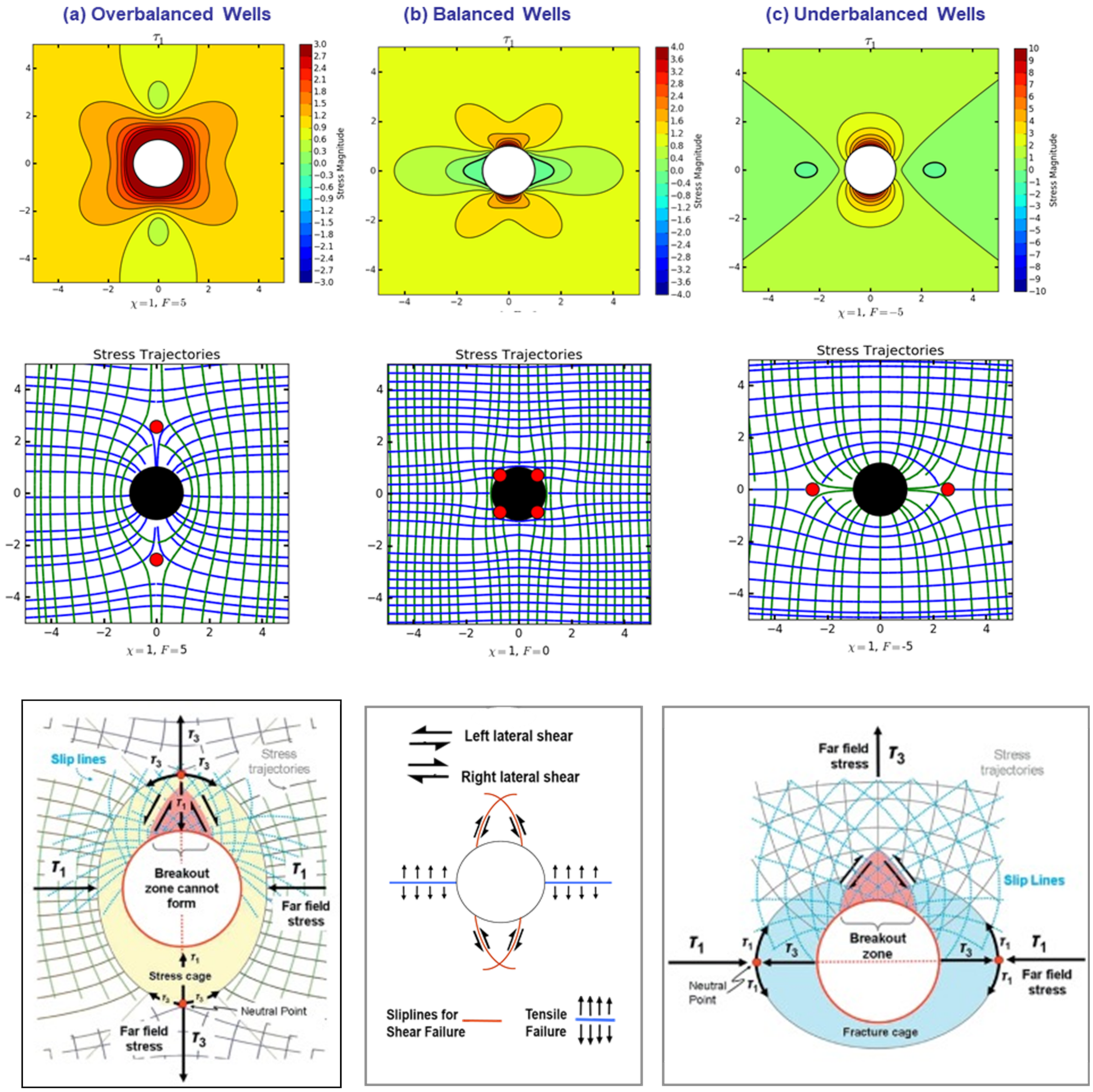

3.1. Fracture Treatment-Induced Stress Changes

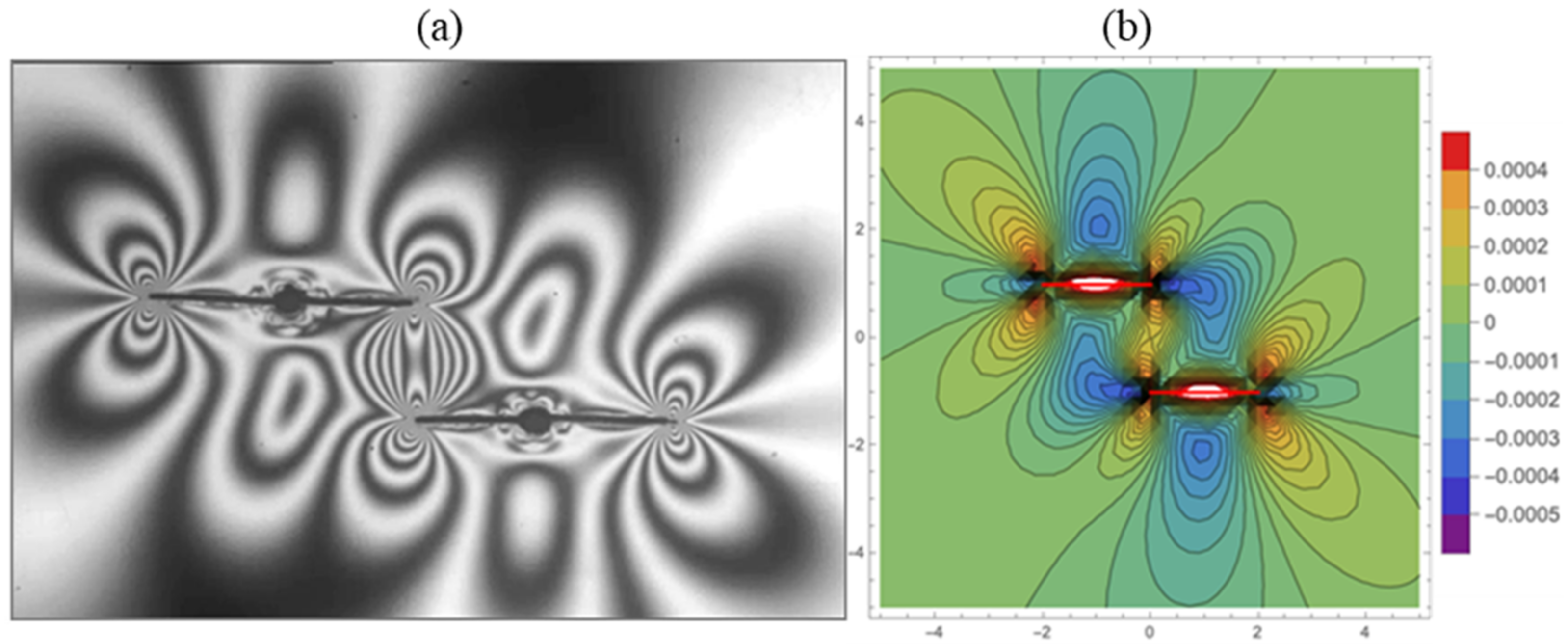

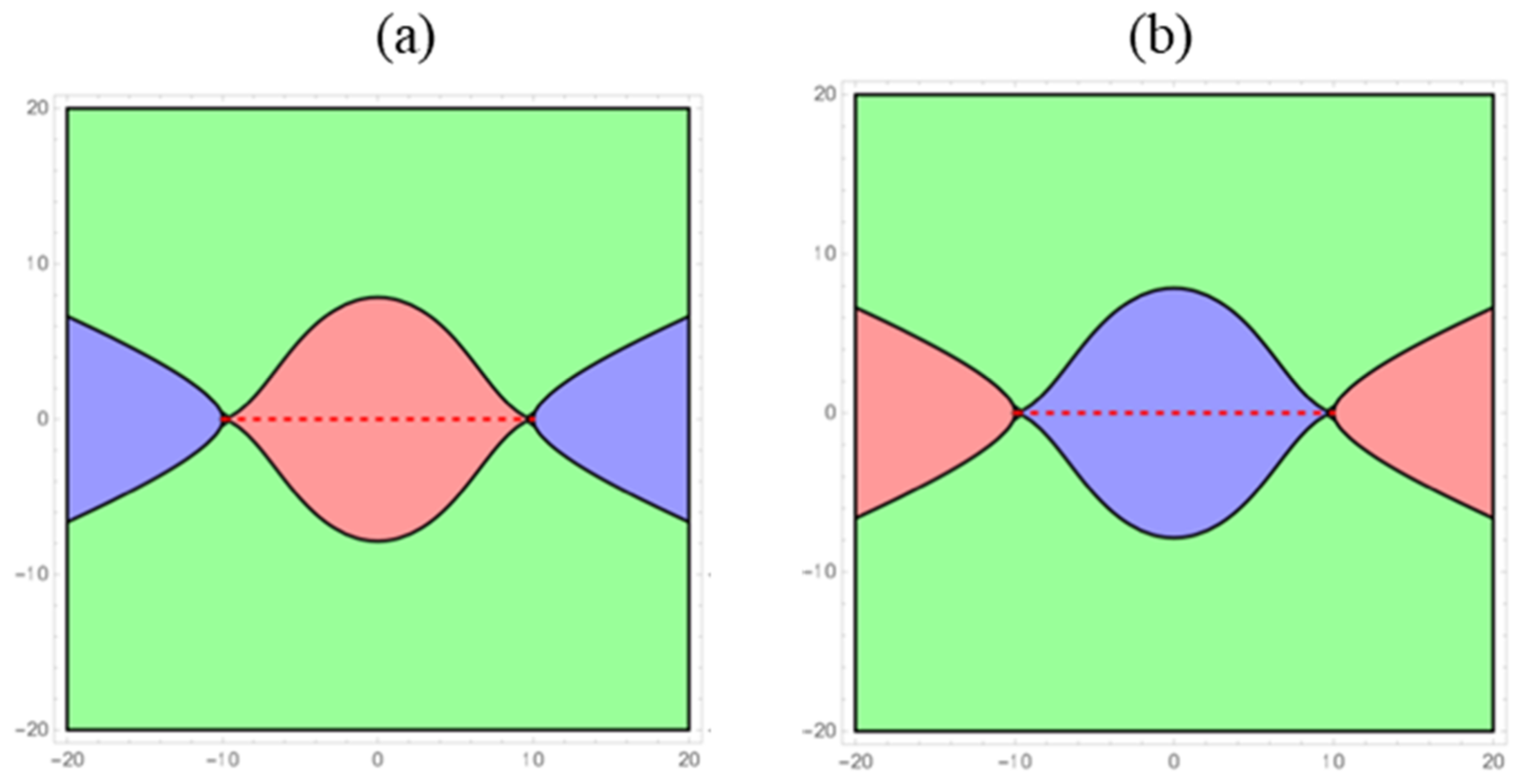

3.2. Leak-Off- and Flow-Back-Induced Stress Changes

3.3. Production-Induced Stress Changes

4. Discussion

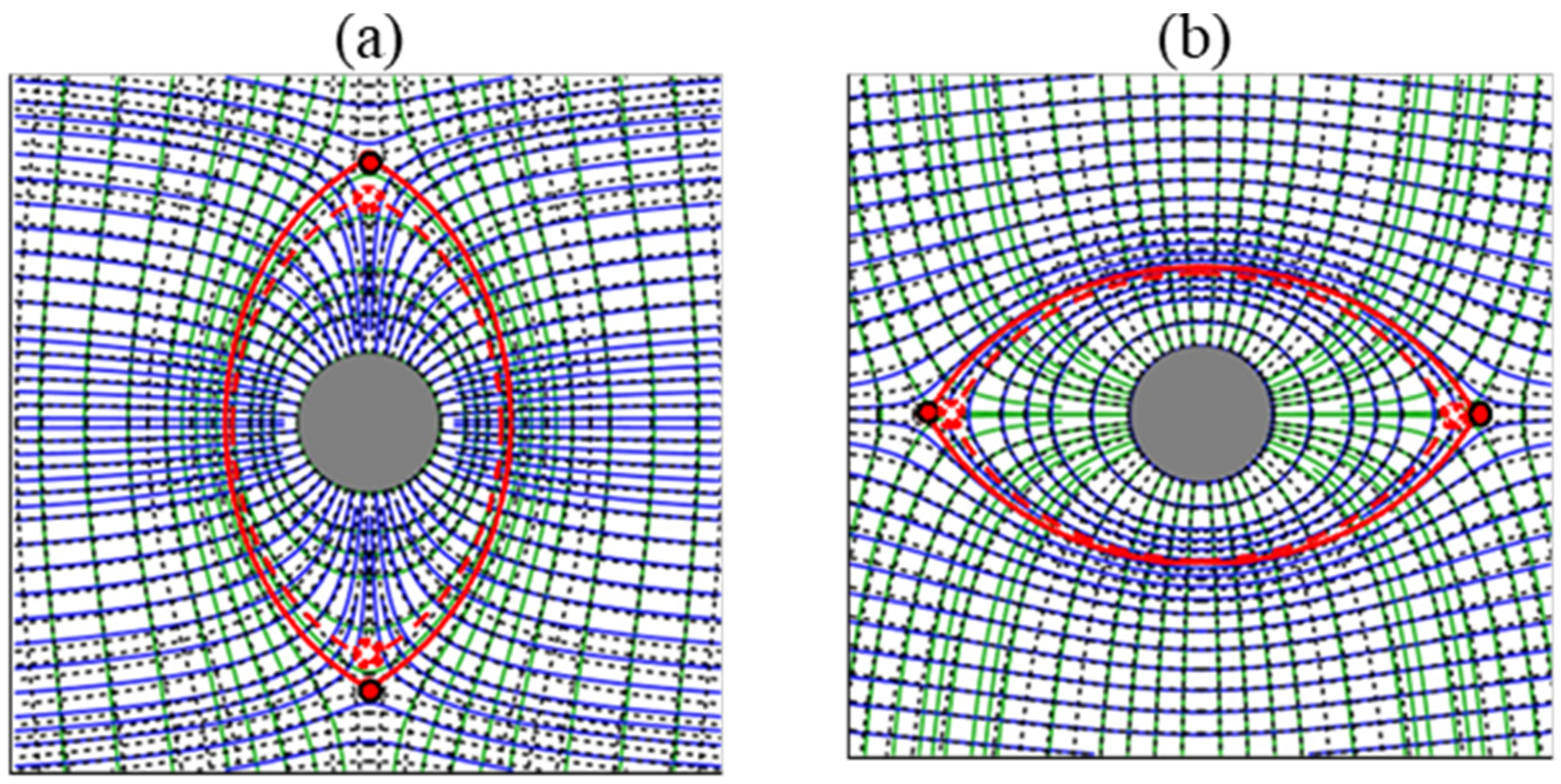

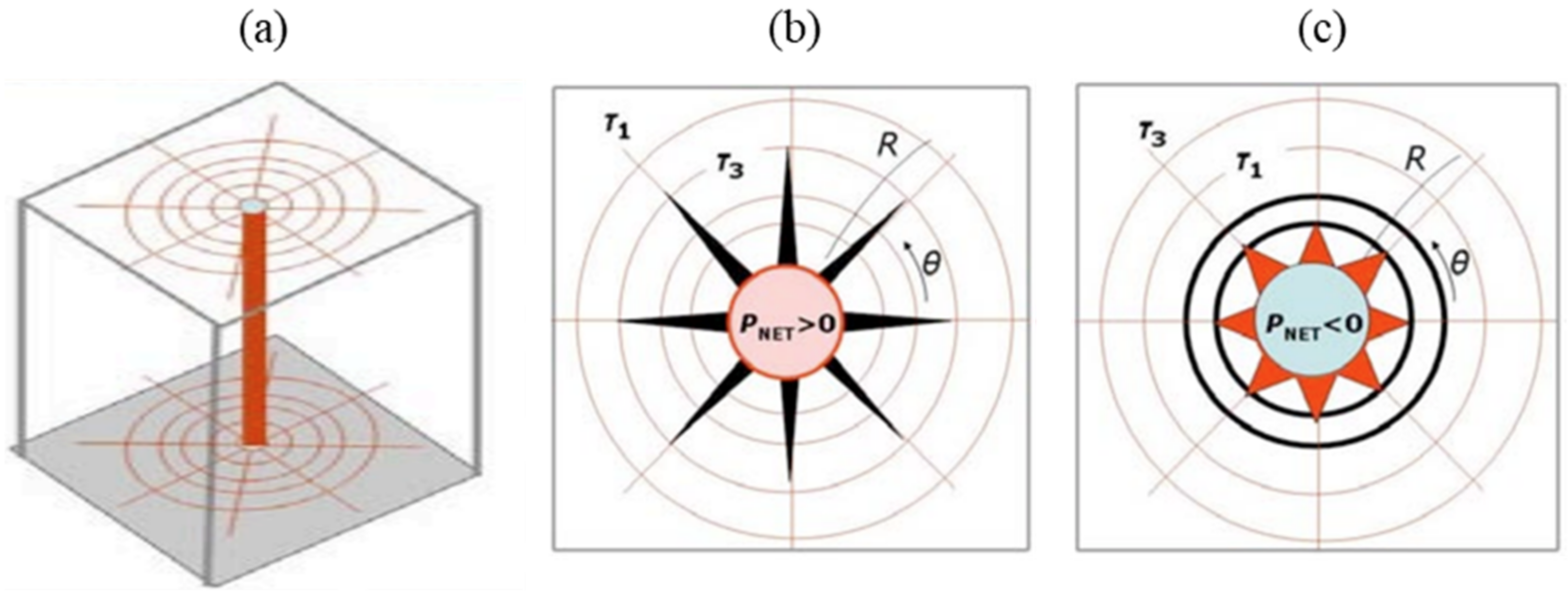

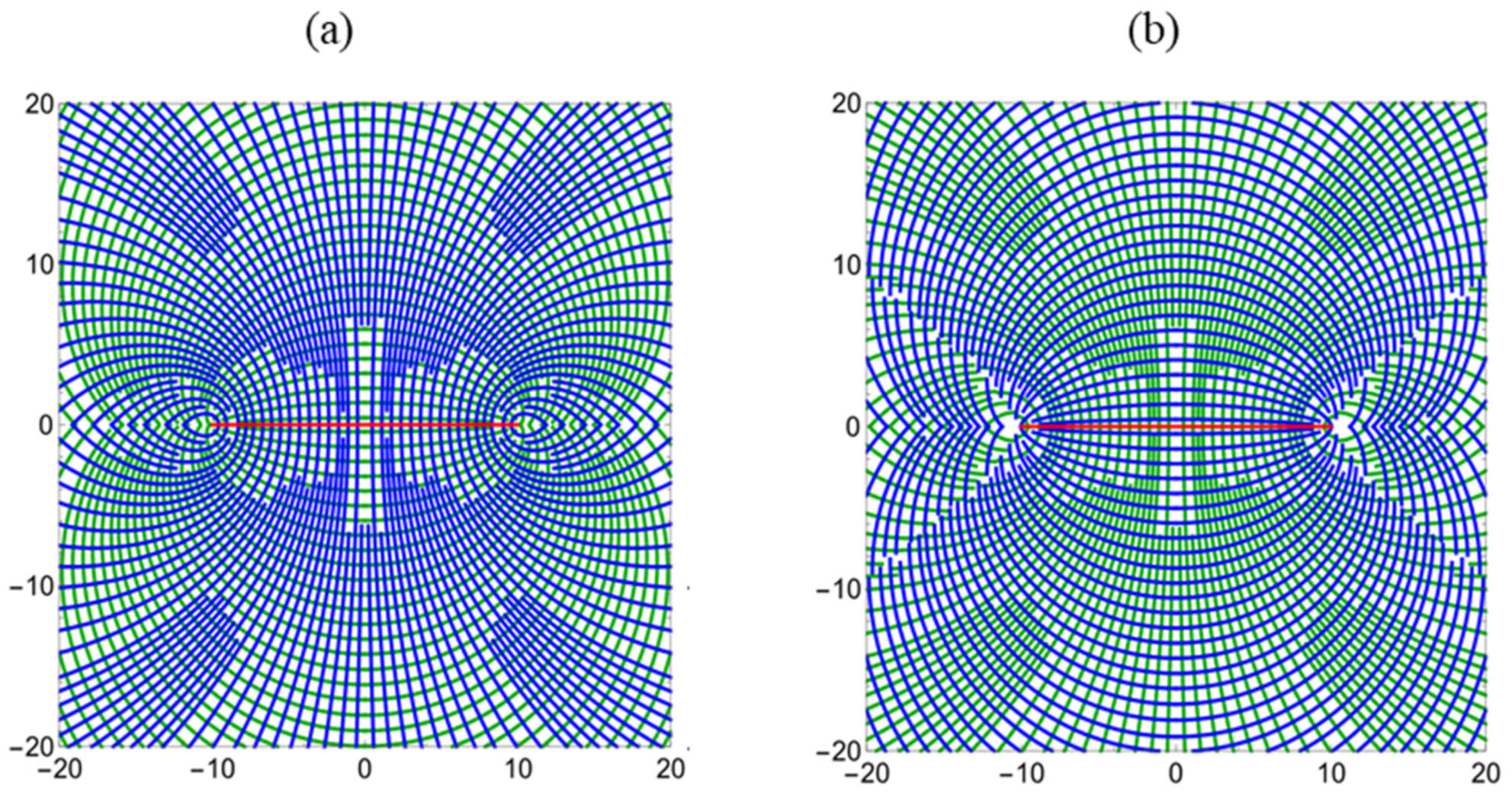

4.1. Analogy between Wellbores and Hydraulic Fractures

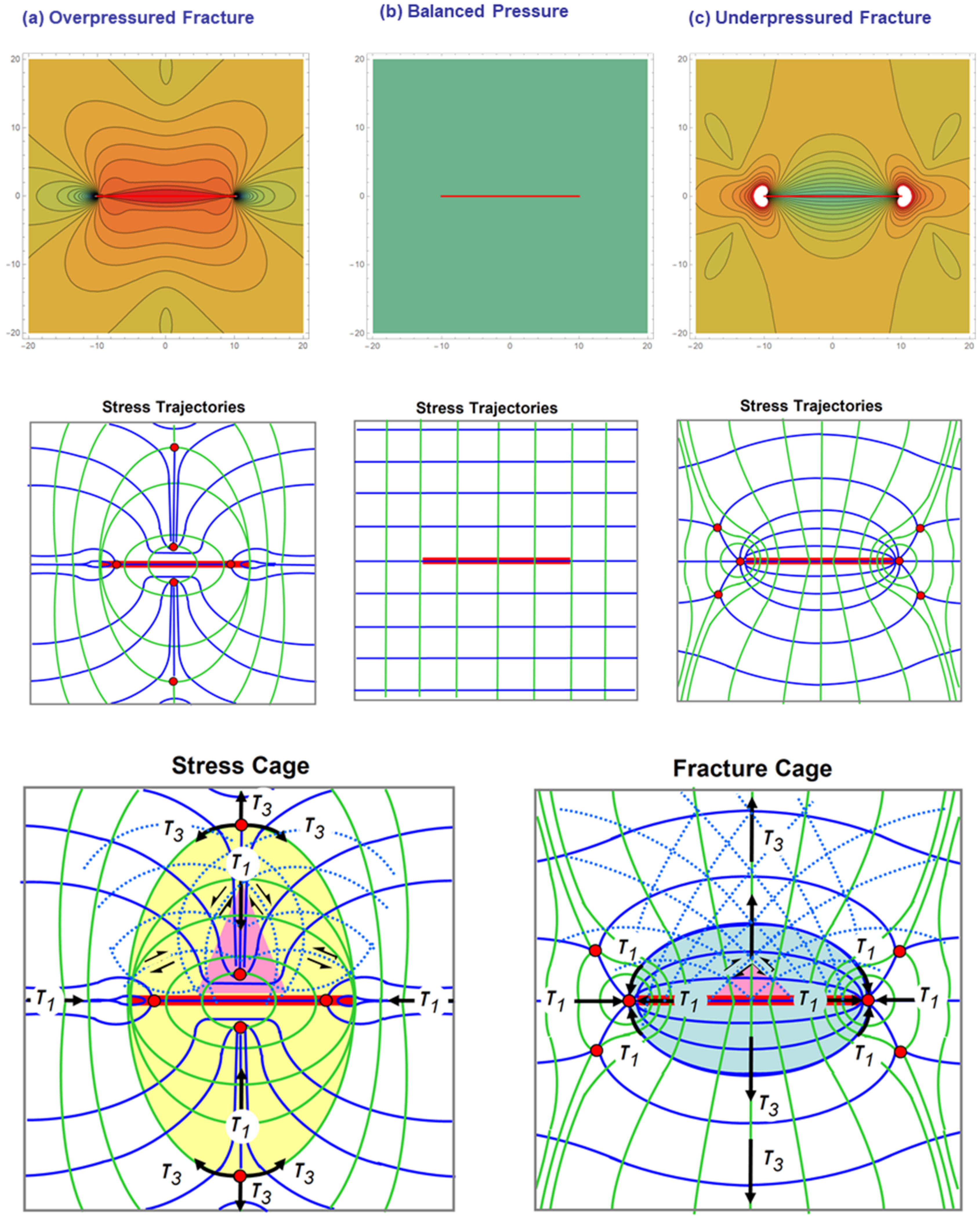

4.2. Stress Cages and Fracture Cages around Wellbores

4.3. Stress Cages and Fracture Cages around Hydraulic Fractures

4.4. Stress Regime Reversals

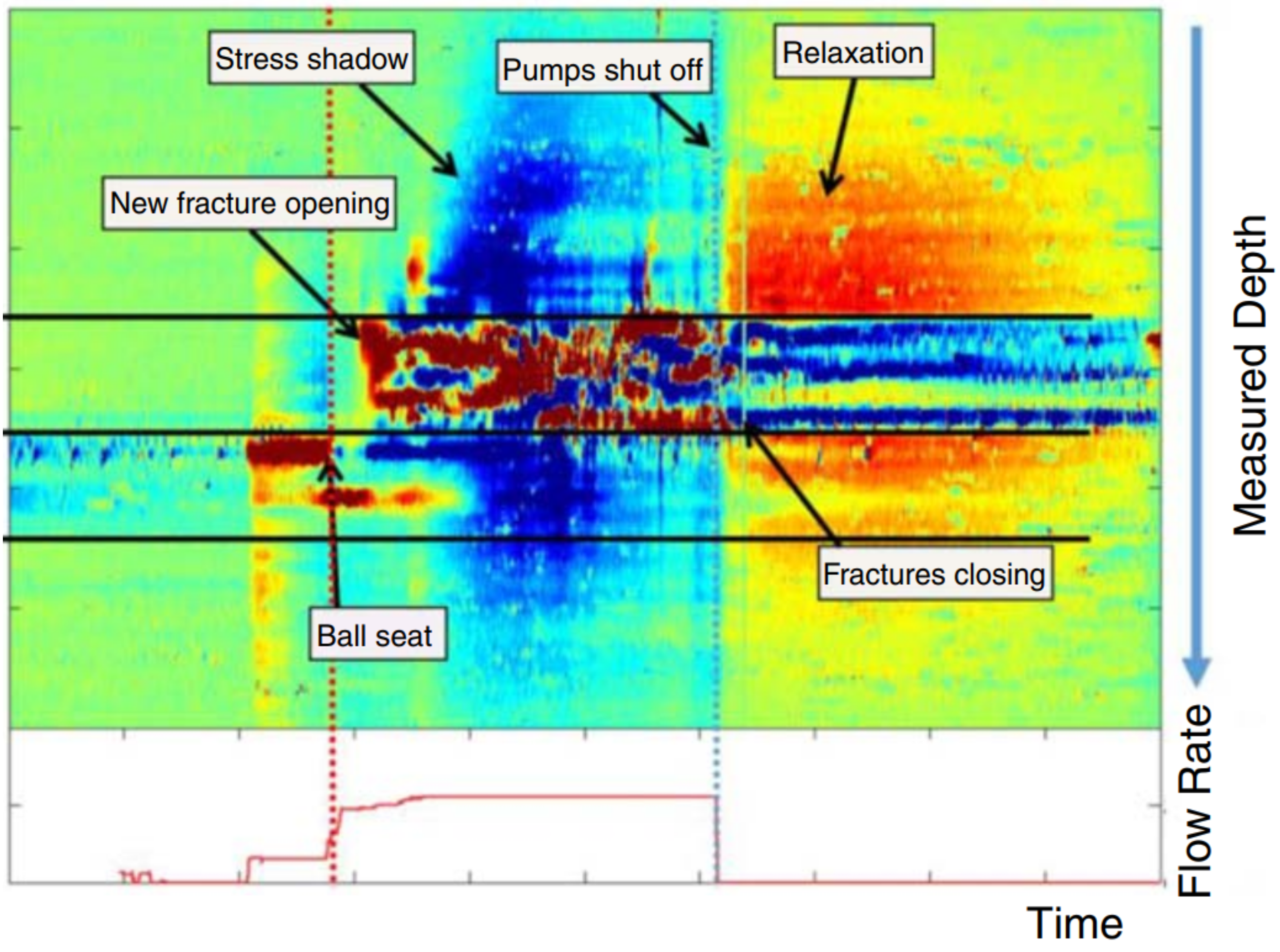

4.5. Field Observations of Stress Regime Changes during Fracture Treatment

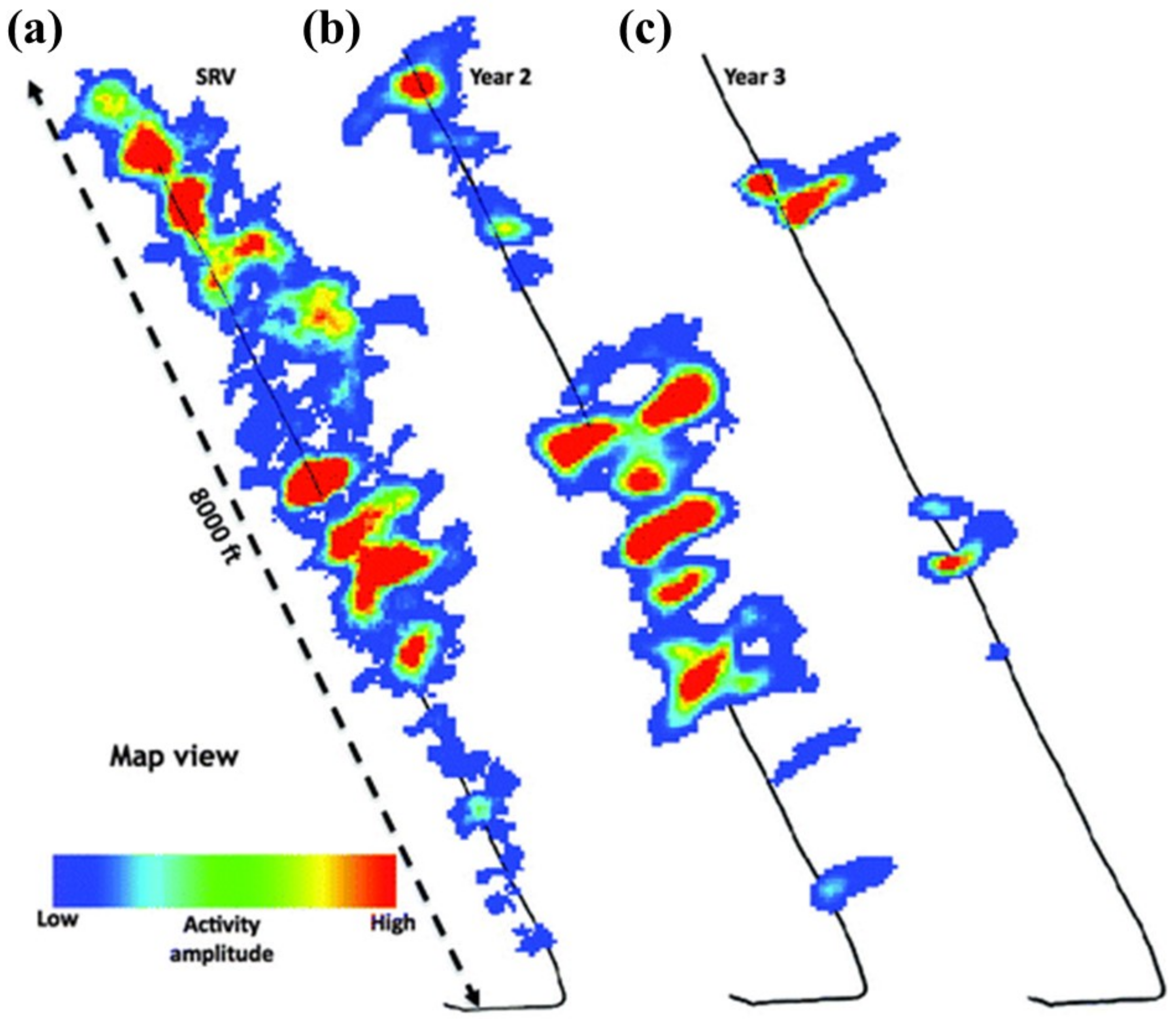

4.6. Field Observations of Stress Regime Changes during Production

5. Recommendations

- First, place a limited set of first-generation perforation clusters, PF1.

- Create the first generation of hydraulic fractures from PF1, termed HF1.

- Next, create a second generation of perforation clusters PF2, between the prior PF1.

- Keep HF1 pressurized, and then initiate, from PF2, the second-generation fractures, HF2.

- The above schedule results in HF2 fractures curving transverse to HF1.

- The bottomhole pressure should not be lowered further than needed for lift, because the hydraulic conductivity of the HF1 and HF2 will deteriorate with increased pressure differential between the reservoir and the bottomhole.

- Keeping the well on natural flow, for as long as possible, will be best to prevent premature closure of HF1 and HF2.

- When artificial lift is required, the bottomhole pressure (BHP) in the well should be gradually lowered, staying just below the threshold pressure to lift the fluid to the surface.

- In undersaturated oil wells, the added advantage of keeping the BHP as high as possible for as long as possible, is that near-wellbore bubble-point effects will be minimized.

- Although the time value of money concept urges operators to pump wells as quickly as possible, the insight gained from our study suggests that such pumping should be moderated to prevent premature decline of the well rate.

6. Conclusions

- Stress trajectories can be rapidly visualized with LSM.

- Principal stress orientations near hydraulic fractures may wander over time.

- We show that two generations of such stress reversals occur.

- A first reversal occurs during the fracture treatment intervention.

- A second reversal occurs during production due to pressure depletion.

- This new insight is important for improving fracture treatment operations.

Author Contributions

Funding

Conflicts of Interest

References

- Fisher, M.K.; Heinze, J.R.; Harris, C.D.; Davidson, B.M.; Wright, C.A.; Dunn, K.P. Optimizing Horizontal Completion Techniques in the Barnett Shale Using Microseismic Fracture Mapping. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26 September 2004. [Google Scholar]

- Guo, B.; Liu, X.; Tan, X. Petroleum Production Engineering, 2nd ed.; Gulf Professional Publishing: Houston, TX, USA, 2017. [Google Scholar]

- Parsegov, S.G.; Nandlal, K.; Schechter, D.S.; Weijermars, R. Physics-Driven Optimization of Drained Rock Volume for Multistage Fracturing: Field Example From the Wolfcamp Formation, Midland Basin. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018. [Google Scholar]

- Warpinski, N.R.; Branagan, P.T. Altered-Stress Fracturing. J. Pet. Technol. 1989, 41, 990–997. [Google Scholar] [CrossRef]

- Palmer, I.D. Induced Stresses Due to Propped Hydraulic Fracture in Coalbed Methane Wells. In Proceedings of the Low Permeability Reservoirs Symposium, Denver, CO, USA, 26–28 April 1993. [Google Scholar]

- Elbel, J.L.; Mack, M.G. Refracturing: Observations and Theories. In Proceedings of the SPE Production Operations Symposium, Oklahoma City, OK, USA, 21–23 March 1993. [Google Scholar]

- Siebrits, E.; Elbel, J.L.; Detournay, E.; Detournay-Piette, C.; Christianson, M.; Robinson, B.M.; Diyashev, I.R. Parameters Affecting Azimuth and Length of a Secondary Fracture During a Refracture Treatment. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 27–30 September 1998. [Google Scholar]

- Siebrits, E.; Elbel, J.L.; Hoover, R.S.; Diyashev, I.R.; Griffin, L.G.; Demetrius, S.L.; Wright, C.A.; Davidson, B.M.; Steinsberger, N.P.; Hill, D.G. Refracture Reorientation Enhances Gas Production in Barnett Shale Tight Gas Wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 1–4 October 2000. [Google Scholar]

- Peirce, A.P.P.; Bunger, A.P.P. Interference Fracturing: Nonuniform Distributions of Perforation Clusters That Promote Simultaneous Growth of Multiple Hydraulic Fractures. SPE J. 2014, 20, 384–395. [Google Scholar] [CrossRef]

- Roussel, N.P.; Sharma, M.M. Strategies to Minimize Frac Spacing and Stimulate Natural Fractures in Horizontal Completions. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 30 October–2 November 2011. [Google Scholar]

- Sesetty, V.; Ghassemi, A. Numerical Simulation of Sequential and Simultaneous Hydraulic Fracturing. In Proceedings of the ISRM International Conference for Effective and Sustainable Hydraulic Fracturing, Brisbane, QLD, Australia, 20–22 May 2013. [Google Scholar]

- Roussel, N.P.; Sharma, M.M. Role of Stress Reorientation in the Success of Refracture Treatments in Tight Gas Sands. SPE Prod. Oper. 2012, 27, 346–355. [Google Scholar] [CrossRef]

- Mutalik, P.N.; Gibson, R.W. Case History of Sequential and Simultaneous Fracturing of the Barnett Shale in Parker County. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. [Google Scholar]

- Waters, G.A.; Dean, B.K.; Downie, R.C.; Kerrihard, K.J.; Austbo, L.; McPherson, B. Simultaneous Hydraulic Fracturing of Adjacent Horizontal Wells in the Woodford Shale. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 19–21 January 2009. [Google Scholar]

- Pham, T.; Weijermars, R. Solving stress tensor fields around multiple pressure-loaded fractures using a linear superposition method (LSM). Appl. Math. Model. 2020, 88, 418–436. [Google Scholar] [CrossRef]

- Pham, T.; Weijermars, R. Development of Hydraulic Fracture Hits and Fracture Redirection Visualized for Consecutive Fracture Stages with Fast Time-stepped Linear Superposition Method (TLSM). In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, TX, Texas, 20–22 July 2020. [Google Scholar]

- Shin, D.H.; Sharma, M.M. Factors Controlling the Simultaneous Propagation of Multiple Competing Fractures in a Horizontal Well. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 4–6 February 2014. [Google Scholar]

- Roussel, N.P. Analyzing ISIP Stage-by-Stage Escalation to Determine Fracture Height and Horizontal-Stress Anisotropy. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 24–26 January 2017. [Google Scholar]

- Soliman, M.Y.; East, L.E.; Adams, D.L. Geomechanics Aspects of Multiple Fracturing of Horizontal and Vertical Wells. SPE Drill. Completion 2008, 23, 217–228. [Google Scholar] [CrossRef]

- Weijermars, R.; Pham, T.; Ettehad, M. Linear superposition method (LSM) for solving stress tensor fields and displacement vector fields: Application to multiple pressure-loaded circular holes in an elastic plate with far-field stress. Appl. Math. Comput. 2020, 381, 125234. [Google Scholar] [CrossRef]

- Stepanova, L.; Computation Pavel, R.; Pavel, L. A Photoelastic Study for Multiparametric Analysis of the Near Crack Tip Stress Field Under Mixed Mode Loading. Procedia Struct. Integr. 2016, 2, 1797–1804. [Google Scholar]

- Sneddon, I.N. The distribution of stress in the neighbourhood of a crack in an elastic solid. Proc. R. Soc. A 1946, 187, 32. [Google Scholar]

- Lowengrub, M.; Sneddon, I.N. The distribution of stress in the vicinity of an external crack in an infinite elastic solid. Int. J. Eng. Sci. 1965, 3, 451–460. [Google Scholar] [CrossRef]

- Lowengrub, M.; Sneddon, I.N. Crack Problems in the Classical Theory of Elasticity. Soc. Ind. Appl. Math. 1969, 13, 2. [Google Scholar]

- Ramesh, K.; Sasikumar, S. Digital photoelasticity: Recent developments and diverse applications. Optics and Lasers in Engineering 2020, 135, 106186. [Google Scholar] [CrossRef]

- Weijermars, R.; Poliakov, A. Stream functions and complex potentials: Implications for development of rock fabric and the continuum assumption. Tectonophysics 1993, 220, 33–50. [Google Scholar] [CrossRef]

- Weijermars, R. Stress cages and fracture cages in stress trajectory models of wellbores: Implications for pressure management during drilling and hydraulic fracturing. J. Nat. Gas Sci. Eng. 2016, 36, 986–1003. [Google Scholar] [CrossRef]

- Thomas, N.; Weijermars, R. Comprehensive atlas of stress trajectory patterns and stress magnitudes around cylindrical holes in rock bodies for geoscientific and geotechnical applications. Earth-Sci. Rev. 2018, 179, 303–371. [Google Scholar] [CrossRef]

- Wang, J.; Weijermars, R. New Interface for Assessing Wellbore Stability at Critical Mud Pressures and Various Failure Criteria: Including Stress Trajectories and Deviatoric Stress Distributions. Energies 2019, 12, 4019. [Google Scholar] [CrossRef]

- Weijermars, R.; Schultz-Ela, D. Visualizing Stress Trajectories around Hydraulically Pressurized Wellbores. In Proceedings of the SPE/EAGE European Unconventional Resources Conference and Exhibition, Vienna, Austria, 20–22 March 2012. [Google Scholar]

- Weijermars, R.; Zhang, X.; Schultz-Ela, D. Unrecognized ‘fracture caging’ could make shale gas drilling safer and more profitable. First Break 2012, 30, 2. [Google Scholar] [CrossRef]

- Weijermars, R.; Zhang, X.; Schultz-Ela, D. Geomechanics of fracture caging in wellbores. Geophys. J. Int. 2013, 193, 1119–1132. [Google Scholar] [CrossRef]

- Wang, J.; Weijermars, R. Expansion of Horizontal Wellbore Stability Model for Elastically Anisotropic Shale Formations With Anisotropic Failure Criteria: Permian Basin Case Study. In Proceedings of the 53rd U.S. Rock Mechanics/Geomechanics Symposium, New York, NY, USA, 23–26 June 2019. [Google Scholar]

- Weijermars, R.; Wang, J.; Nelson, R. Stress concentrations and failure modes in horizontal wells accounting for elastic anisotropy of shale formations. Earth-Sci. Rev. 2020, 200, 102957. [Google Scholar] [CrossRef]

- Weijermars, R.; Wang, J.; Pham, T. Borehole Failure Mechanisms in Naturally and Hydraulically Fractured Formations Investigated With a Fast Time-Stepped Linear Superposition Method (TLSM). In Proceedings of the 54th U.S. Rock Mechanics/Geomechanics Symposium, On-line; 2020. [Google Scholar]

- Raterman, K.T.; Farrell, H.E.; Mora, O.S.; Janssen, A.L.; Gomez, G.A.; Busetti, S.; McEwen, J.; Friehauf, K.; Rutherford, J.; Reid, R.; et al. Sampling a Stimulated Rock Volume: An Eagle Ford Example. SPE Reserv. Eval. Eng. 2018, 21, 927–941. [Google Scholar] [CrossRef]

- Sicking, C.; Vermilye, J.; Lacazette, A. Predicting Frac Performance and Active Producing Volumes Using Microseismic Data. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, San Antonio, TX, USA, 20–22 July 2015. [Google Scholar]

- Sicking, C.; Vermilye, J.; Yaner, A. Forecasting reservoir performance by mapping seismic emissions. Interpretation 2015, 5, 9. [Google Scholar] [CrossRef]

- Weijermars, R.; Wang, J. Analyzing Data from the Hydraulic Fracture Test Site (Permian Basin) with the Linear Superposition Method (LSM). In Proceedings of the 55th US Rock Mechanics/ Geomechanics Symposium, Houston, TX, USA, 20–23 June 2021. [Google Scholar]

| Property | Andersonian Stress State: Strike-Slip Basin |

|---|---|

| (kPa/m) | 22.6 |

| (kPa/m) | 24.9 |

| (kPa/m) | 20.4 |

| Pore pressure gradient (kPa/m) | 10.2 |

| Assumed TVD (m) | 2000 |

| Fracture spacing (m) | 10 |

| Fracture half-length (m) | 10 |

| Poisson’s ratio, ν | 0.25 |

| Young’s modulus, E (GPa) | 40 |

| Typical Stress Gradients | Strike-Slip Basin |

|---|---|

| (kPa/m) | |

| (kPa/m) | |

| (kPa/m) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weijermars, R.; Wang, J. Stress Reversals near Hydraulically Fractured Wells Explained with Linear Superposition Method (LSM). Energies 2021, 14, 3256. https://doi.org/10.3390/en14113256

Weijermars R, Wang J. Stress Reversals near Hydraulically Fractured Wells Explained with Linear Superposition Method (LSM). Energies. 2021; 14(11):3256. https://doi.org/10.3390/en14113256

Chicago/Turabian StyleWeijermars, Ruud, and Jihoon Wang. 2021. "Stress Reversals near Hydraulically Fractured Wells Explained with Linear Superposition Method (LSM)" Energies 14, no. 11: 3256. https://doi.org/10.3390/en14113256

APA StyleWeijermars, R., & Wang, J. (2021). Stress Reversals near Hydraulically Fractured Wells Explained with Linear Superposition Method (LSM). Energies, 14(11), 3256. https://doi.org/10.3390/en14113256