Hydraulic Fracturing Simulations with Real-Time Evolution of Physical Parameters

Abstract

1. Introduction

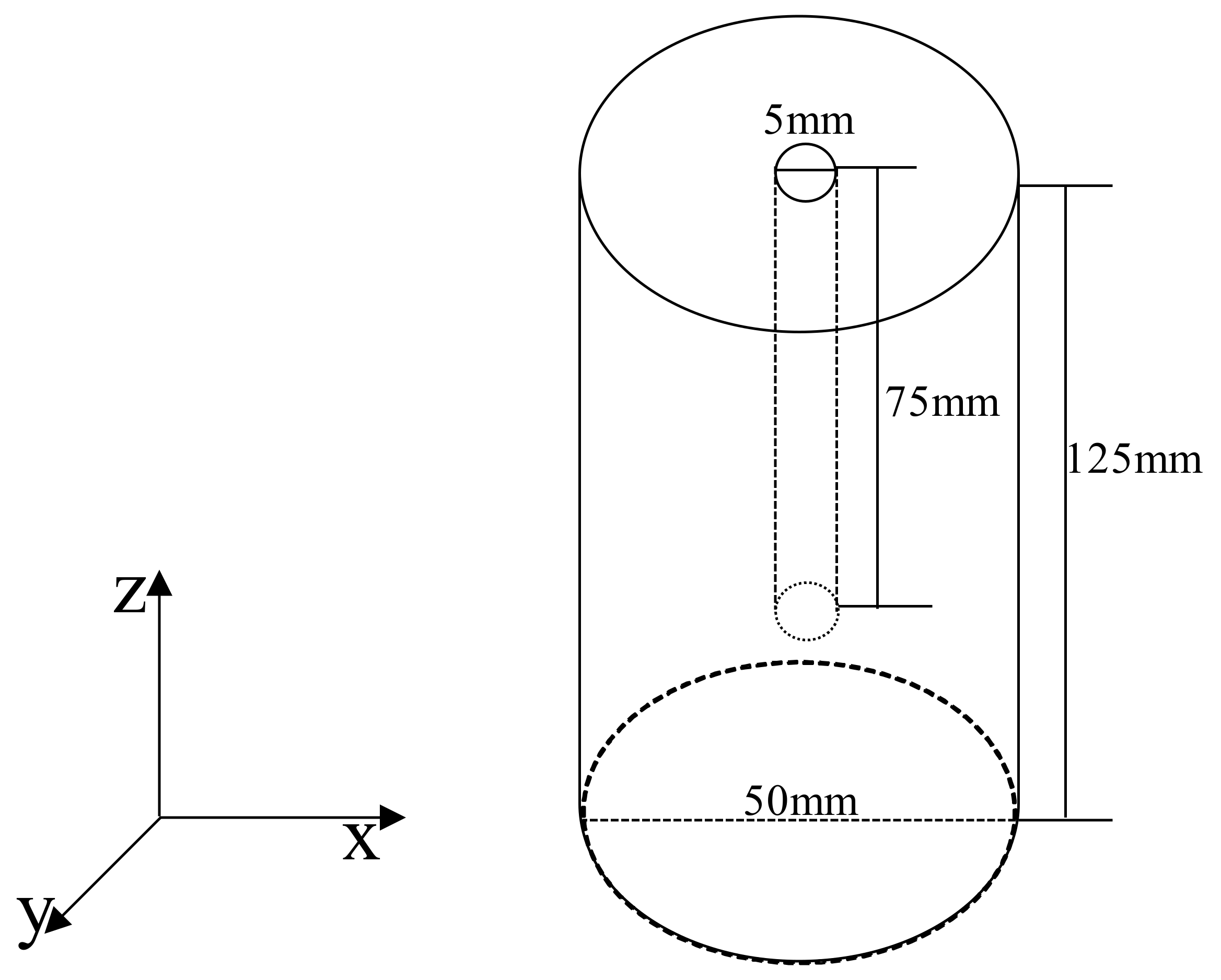

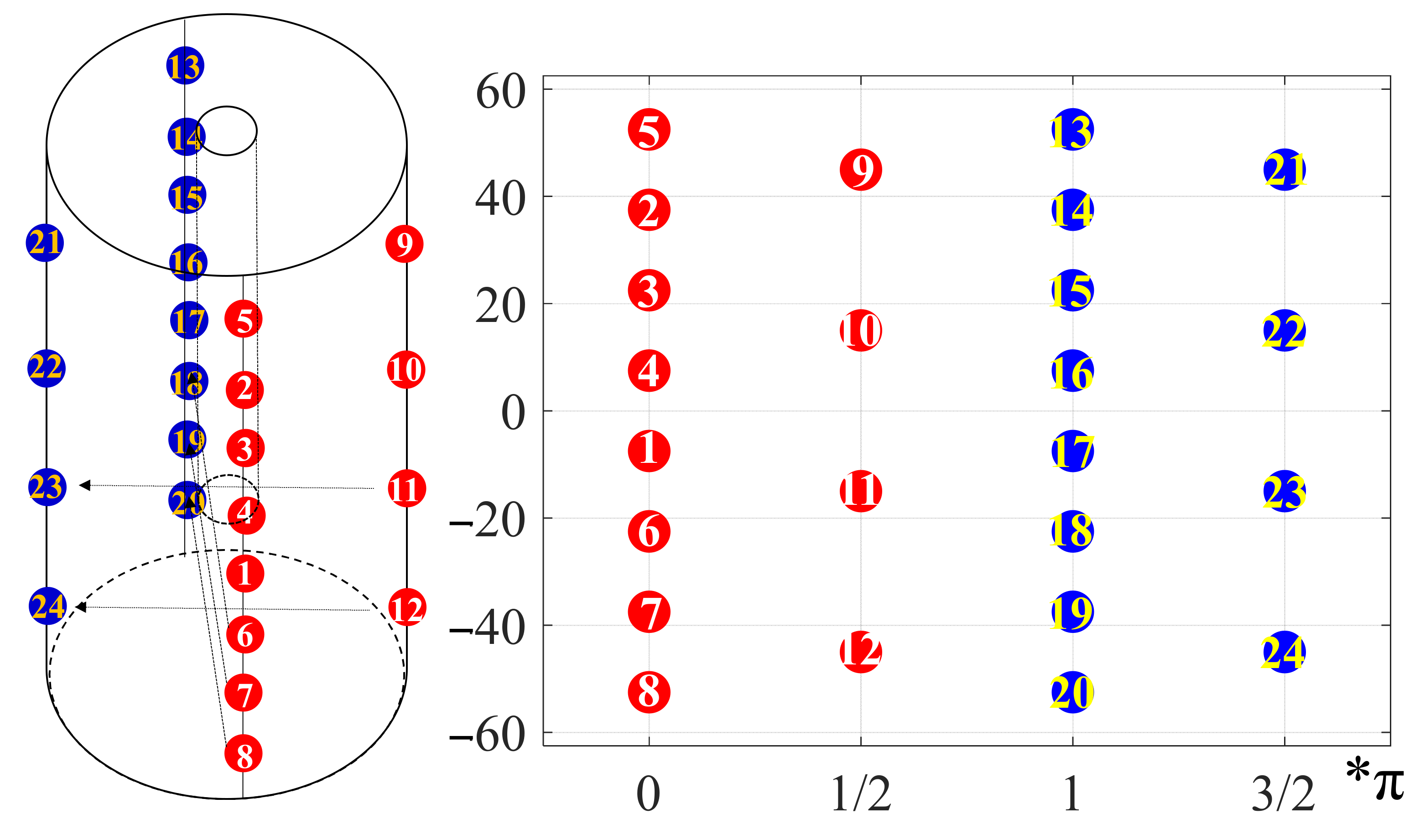

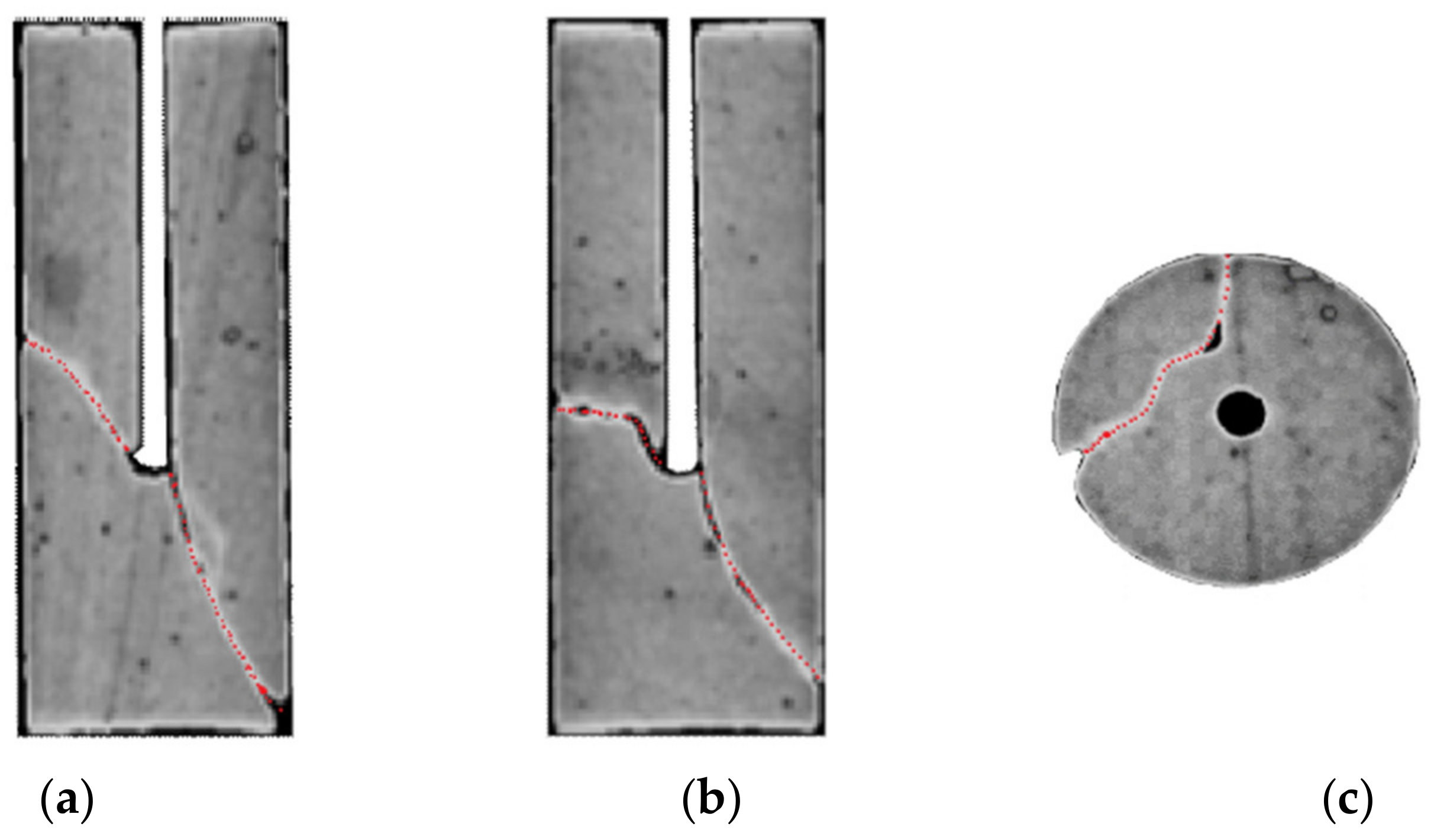

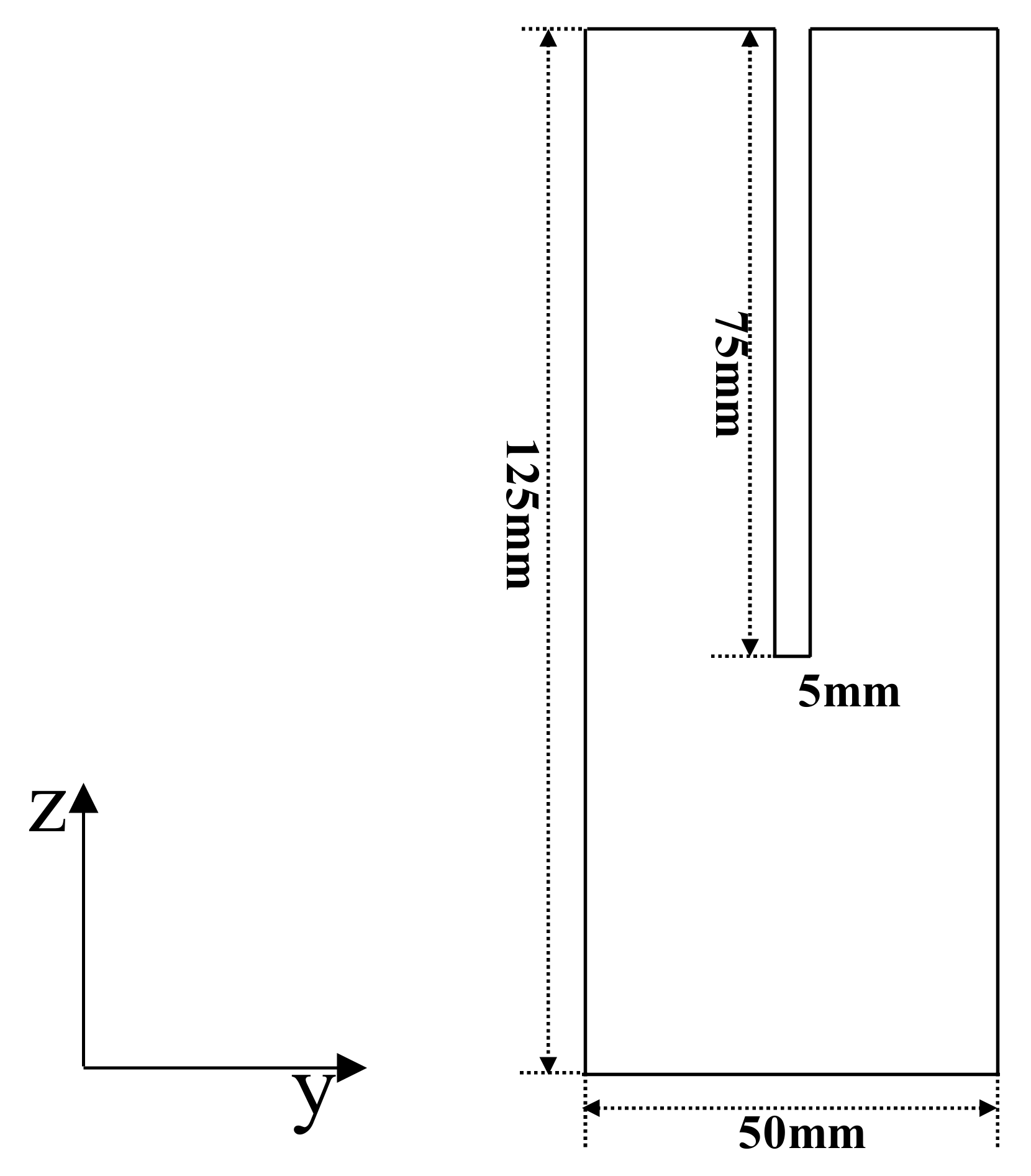

2. Laboratory Hydraulic Fracturing Experiment

3. Methodology

4. Numerical Examples

4.1. Fracturing Simulation with Constant Physical Parameter

4.2. Fracturing Simulation Considering Real-Time Evolution of Velocity

5. Discussions and Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Zhang, Z.; Li, X. Numerical Study on the Formation of Shear Fracture Network. Energies 2016, 9, 299. [Google Scholar] [CrossRef]

- Guo, T.; Qu, Z.; Gong, F.; Wang, X. Numerical Simulation of Hydraulic Fracture Propagation Guided by Single Radial Boreholes. Energies 2017, 10, 1680. [Google Scholar] [CrossRef]

- Figueiredo, B.; Tsang, C.F.; Rutqvist, J.; Niemi, A. The effects of nearby fractures on hydraulically induced fracture propagation and permeability changes. Eng. Geol. 2017, 228, 197–213. [Google Scholar] [CrossRef]

- Remij, E.W.; Remmers, J.J.; Huyghe, J.M.; Smeulders, D.M. On the numerical simulation of crack interaction in hydraulic fracturing. Comput. Geosci. 2018, 22, 423–437. [Google Scholar] [CrossRef]

- Warpinski, N.R.; Teufel, L.W. Influence of geologic discontinuities on hydraulic fracture propagation. J. Pet. Technol. 1987, 39, 209–220. [Google Scholar] [CrossRef]

- Bahorich, B.; Olson, J.E.; Holder, J. Examining the effect of cemented natural fractures on hydraulic fracture propagation in hydrostone block experiments. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012. [Google Scholar]

- Nguyen, V.P.; Lian, H.; Rabczuk, T.; Bordas, S. Modelling hydraulic fractures in porous media using flow cohesive interface elements. Eng. Geol. 2017, 225, 68–82. [Google Scholar] [CrossRef]

- Xie, J.; Huang, H.; Ma, H.; Zeng, B.; Tang, J.; Yu, W.; Wu, K. Numerical investigation of effect of natural fractures on hydraulic-fracture propagation in unconventional reservoirs. J. Natl. Gas Sci. Eng. 2018, 54, 143–153. [Google Scholar] [CrossRef]

- Tuttle, S.; Grechka, V.; Jahan, I.; Zhang, Z. Spatiotemporal Gyration from Microseismicity in the Permian Basin. In Proceedings of the Unconventional Resources Technology Conference (URTEC), Houston, TX, USA, 20–22 July 2020. [Google Scholar]

- Liu, R.; Jiang, Y.; Huang, N.; Sugimoto, S. Hydraulic properties of 3D crossed rock fractures by considering anisotropic aperture distributions. Adv. Geo-Energy Res. 2018, 2, 113–121. [Google Scholar] [CrossRef]

- Zhu, W.S.; Zhao, C.L.; Zhou, H. Discussion on several key issues in current rock mechanics. J. Rock Mech. Eng. 2015, 34, 649–658. [Google Scholar]

- Bazan, L.W.; Brinzer, B.C.; Meyer, B.R.; Brown, E.K. Key Parameters Affecting Successful Hydraulic Fracture Design and Optimized Production in Unconventional Wells. Soc. Pet. Eng. 2013. [Google Scholar] [CrossRef]

- Youcai, T.A.; Fenglin, N.I. Recent advances in microseismic monitoring and implications for hydraulic fracturing mapping. Pet. Sci. Bull. 2016, 1, 198–208. [Google Scholar]

- Hu, L.; Ghassemi, A. Heat production from lab-scale enhanced geothermal systems in granite and gabbro. Int. J. Rock Mech. Min. Sci. 2019, 126, 104205. [Google Scholar] [CrossRef]

- Hu, L.; Ghassemi, A.; Pritchett, J.; Garg, S. Characterization of laboratory-scale hydraulic fracturing for EGS. Geothermics 2019, 83, 101706. [Google Scholar] [CrossRef]

- Lei, X.; Funatsu, T.; Ma, S.; Liu, L. A laboratory acoustic emission experiment and numerical simulation of rock fracture driven by a high-pressure fluid source. J. Rock Mech. Geotech. Eng. 2016, 8, 27–34. [Google Scholar] [CrossRef]

- Zhai, H.; Chang, X.; Wang, Y.; Xue, Z.; Lei, X.; Zhang, Y. Sensitivity analysis of seismic velocity and attenuation variations for longmaxi shale during hydraulic fracturing testing in laboratory. Energies 2017, 10, 1393. [Google Scholar] [CrossRef]

- Kong, B.; Fathi, E.; Ameri, S. Coupled 3-D numerical simulation of proppant distribution and hydraulic fracturing performance optimization in Marcellus shale reservoirs. Int. J. Coal Geol. 2015, 147, 35–45. [Google Scholar] [CrossRef]

- Xiao-Lin, Z.; Feng, Z.; Xiang-Yang, L.; Xu-Ri, H.; Shuang-Quan, C. The influence of hydraulic fracturing on velocity and microseismic location. Chin. J. Geophys. 2013, 56, 3552–3560. (In Chinese) [Google Scholar] [CrossRef]

- Urbancic, T.; Baig, A.; Viegas, G.; Thompson, J.M.; Anderson, D.; Rice, C.; Martin, L. Effective constraint of RTA models utilizing microseismicity derived flow attributes. In Proceedings of the Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2017; Society of Exploration Geophysicists, American Association of Petroleum Geologists, Society of Petroleum Engineers: Houston, TX, USA; pp. 2411–2426. [Google Scholar]

- Diao, R.; Hu, X.T.; Cui, Q.H. Precision analysis and application of equivalent velocity in micro-seismic monitor. Reserv. Eval. Dev. 2015, 5, 49–53. [Google Scholar]

- Viegas, G.; Bosman, K.; Urbancic, T.; Angus, D. Estimates of primary production volumes of unconventional shale reservoirs using dynamic-parameter analysis of microseismicity: Validation case study applying topology on discrete fracture networks. In Proceedings of the SEG International Exposition and Annual Meeting, Anaheim, CA, USA, 14–19 October 2018; pp. 2997–3001. [Google Scholar] [CrossRef]

- Javadpour, F.; McClure, M.; Naraghi, M.E. Slip-corrected liquid permeability and its effect on hydraulic fracturing and fluid loss in shale. Fuel 2015, 160, 549–559. [Google Scholar] [CrossRef]

- Maity, D.; Ciezobka, J. An Interpretation of Proppant Transport Within the Stimulated Rock Volume at the Hydraulic-Fracturing Test Site in the Permian Basin. Soc. Pet. Eng. 2019. [Google Scholar] [CrossRef]

- Gidley, J.L. A method for correcting dimensionless fracture conductivity for non-Darcy flow effects. SPE Prod. Eng. 1991, 6, 391–394. [Google Scholar] [CrossRef]

- Zhang, D.F.; Li, S.C. The modified tensile stress crack propagation criterion and influence of cranny hydraulic pressure on crack propagation. Chin. J. Comput. Mech. 2009, 26, 114–119. [Google Scholar]

- Zhang, J. Pore pressure prediction from well logs: Methods, modifications, and new approaches. Earth-Sci. Rev. 2011, 108, 50–63. [Google Scholar] [CrossRef]

- Liu, S.; Valkó, P. An Improved Equilibrium-Height Model for Predicting Hydraulic Fracture Height Migration in Multi-Layered Formations. Soc. Pet. Eng. 2015. [Google Scholar] [CrossRef]

- Oterkus, S.; Madenci, E.; Oterkus, E. Fully coupled poroelastic peridynamic formulation for fluid-filled fractures. Eng. Geol. 2017, 225, 19–28. [Google Scholar] [CrossRef]

- Rohmer, J.; Seyedi, D.M. Coupled large scale hydromechanical modelling for caprock failure risk assessment of CO2 storage in deep saline aquifers. Oil Gas Sci. Technol 2010, 65, 485–502. [Google Scholar] [CrossRef]

- Zhou, Z.Y.; Kuang, S.B.; Chu, K.W.; Yu, A.B. Discrete particle simulation of particle–fluid flow: Model formulations and their applicability. J. Fluid Mech. 2010, 661, 482–510. [Google Scholar] [CrossRef]

- Salimzadeh, S.; Khalili, N. A Fully Coupled XFEM Model for Flow and Deformation in Fractured Porous Media with Explicit Fracture Flow. Int. J. Geomech. 2015, 16, 04015091. [Google Scholar] [CrossRef]

- Davydzenka, T.; Fagbemi, S.; Tahmasebi, P. Coupled fine-scale modeling of the wettability effects: Deformation and fracturing. Phys. Fluids 2020, 32, 083308. [Google Scholar] [CrossRef]

- Li, X.Y.; Lei, X.L.; Li, Q.; Cui, Y.X. Characteristics of acoustic emission during deformation and failure of typical reservoir rocks under triaxial compression: An example of Sinian dolomite and shale in the Sichuan Basin. Chin. J. Geophys. Chin. Ed. 2015, 58, 982–992. [Google Scholar] [CrossRef]

- Shen, H.; Li, X.; Li, Q.; Wang, H. A method to model the effect of pre-existing cracks on P-wave velocity in rocks. J. Rock Mech. Geotech. Eng. 2019, 12, 493–506. [Google Scholar] [CrossRef]

- ABAQUS. ABAQUS Documentation; ABAQUS: Palo Alto, CA, USA, 2017. [Google Scholar]

- Dolbow, J.E. An Extended Finite Element Method with Discontinuous Enrichment for Applied Mechanics. Ph.D. Thesis, Theoretical and Applied Mechanics, Northwestern University, Evanston, IL, USA, 1991. [Google Scholar]

- Moës, N.; Dolbow, J.; Belytschko, T. A finite element method for crack growth without remeshing. Int. J. Numer. Methods Eng. 1999, 46, 131–150. [Google Scholar] [CrossRef]

- Lecampion, B. An extended finite element method for hydraulic fracture problems. Commun. Numer. Methods Eng. 2009, 25, 121–133. [Google Scholar] [CrossRef]

- Dong, Z.Q.; Jun, Y. Numerical Simulation of Shale Hydraulic Fracturing Based on the Extended Finite Element Method. Appl. Math. Mech. 2014, 35. [Google Scholar] [CrossRef]

| Unit | Value | |

|---|---|---|

| Young’s modulus | GPa | 47 |

| Poisson’s ratio | - | 0.23 |

| Leak-off coefficient | m/Pa | 1 × 1014 |

| Fluid viscosity | Pas | 0.001 |

| Density | g/cm3 | 2.42 |

| Tensile strength of rock | MPa | 10 |

| Velocity (km/s) | % |

|---|---|

| 4.77 | 0 |

| 4.17 | −13 |

| 3.82 | −20 |

| 3.34 | −30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Q.; Xue, Q.; Ma, Z.; Zheng, Y.; Zhai, H. Hydraulic Fracturing Simulations with Real-Time Evolution of Physical Parameters. Energies 2021, 14, 1678. https://doi.org/10.3390/en14061678

Qin Q, Xue Q, Ma Z, Zheng Y, Zhai H. Hydraulic Fracturing Simulations with Real-Time Evolution of Physical Parameters. Energies. 2021; 14(6):1678. https://doi.org/10.3390/en14061678

Chicago/Turabian StyleQin, Qiuping, Qingfeng Xue, Zizhuo Ma, Yikang Zheng, and Hongyu Zhai. 2021. "Hydraulic Fracturing Simulations with Real-Time Evolution of Physical Parameters" Energies 14, no. 6: 1678. https://doi.org/10.3390/en14061678

APA StyleQin, Q., Xue, Q., Ma, Z., Zheng, Y., & Zhai, H. (2021). Hydraulic Fracturing Simulations with Real-Time Evolution of Physical Parameters. Energies, 14(6), 1678. https://doi.org/10.3390/en14061678