Thermo-Hydraulic Performance Characteristics and Optimization of Protrusion Rib Roughness in Solar Air Heater

Abstract

:1. Introduction

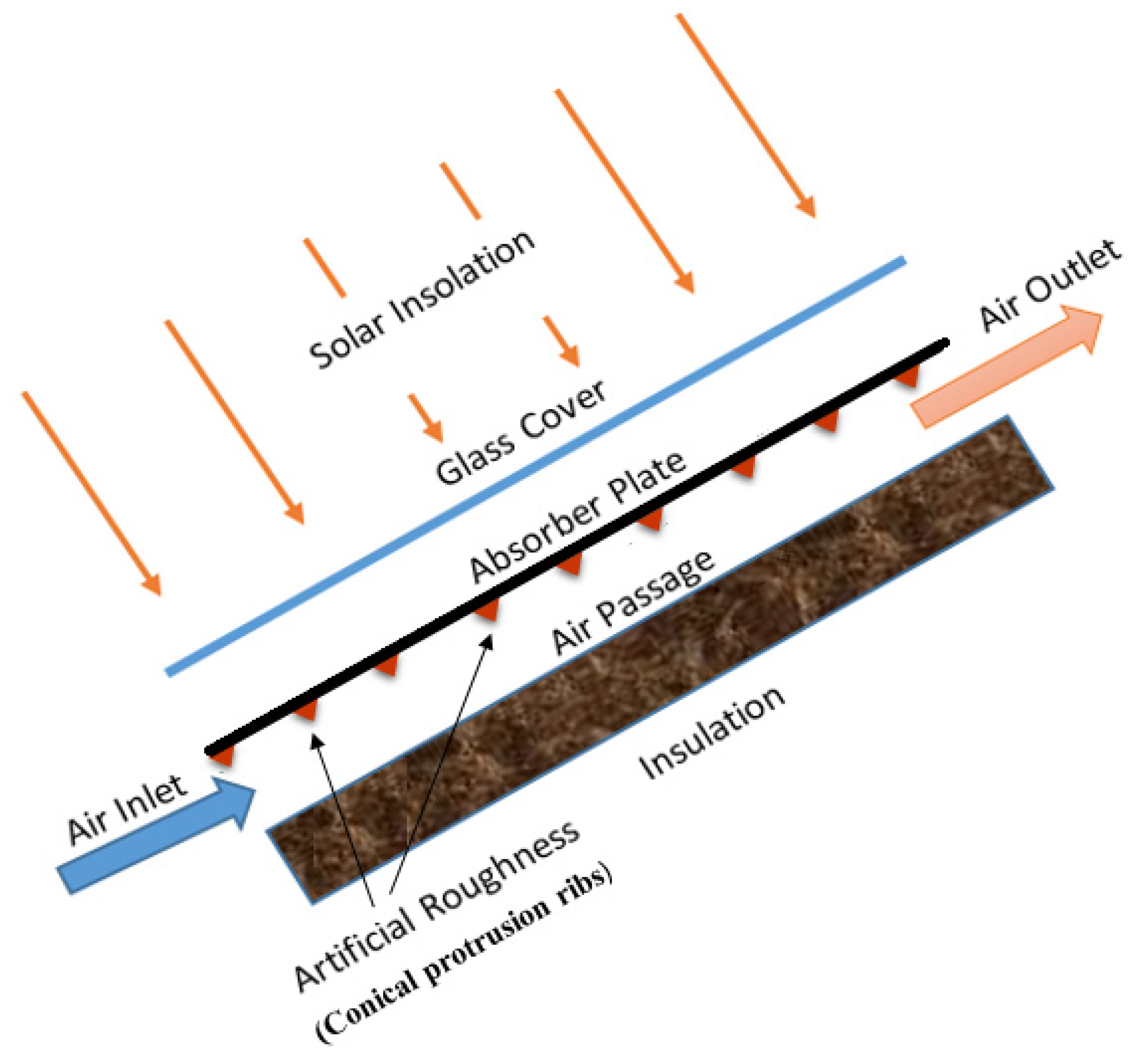

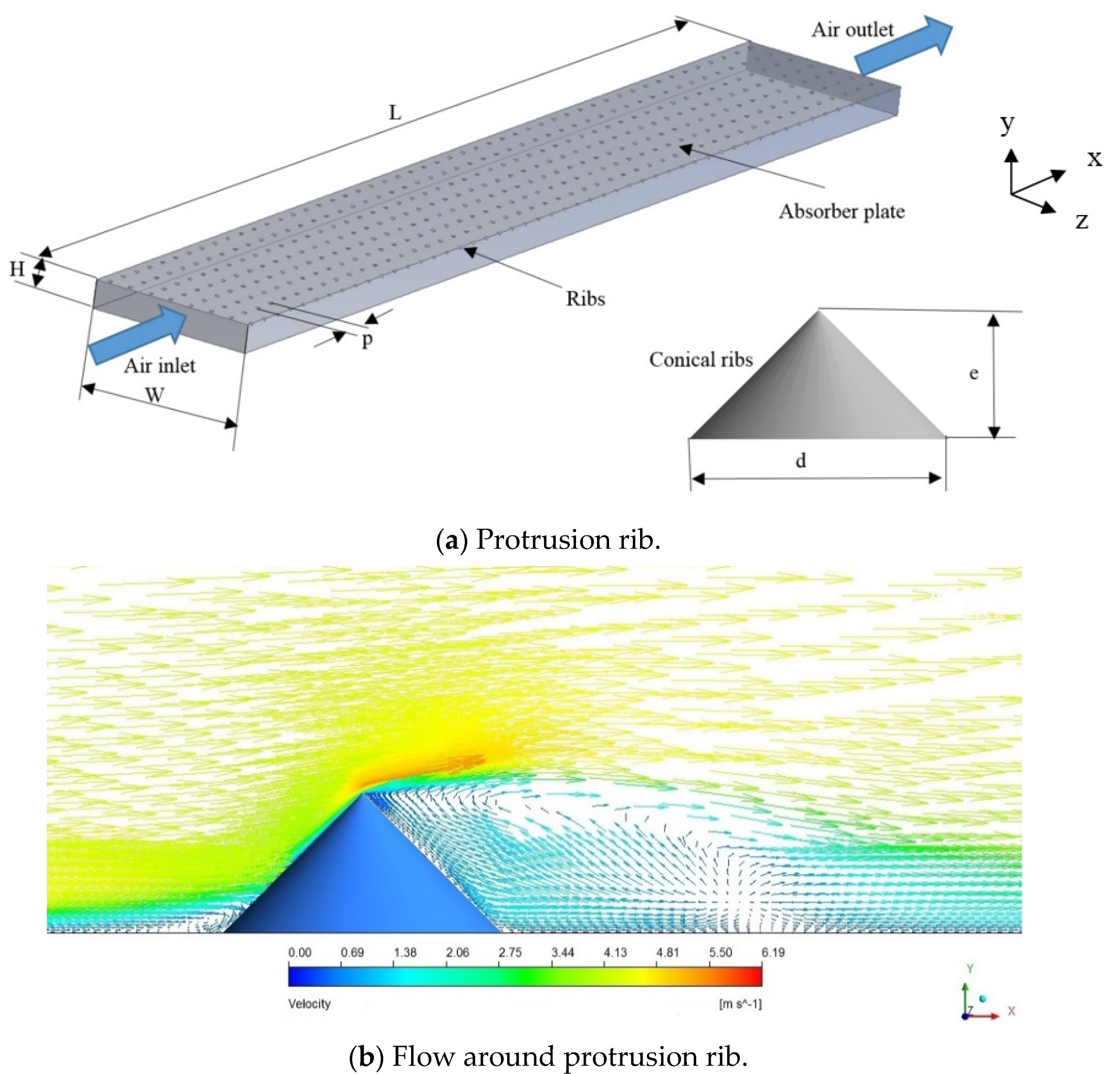

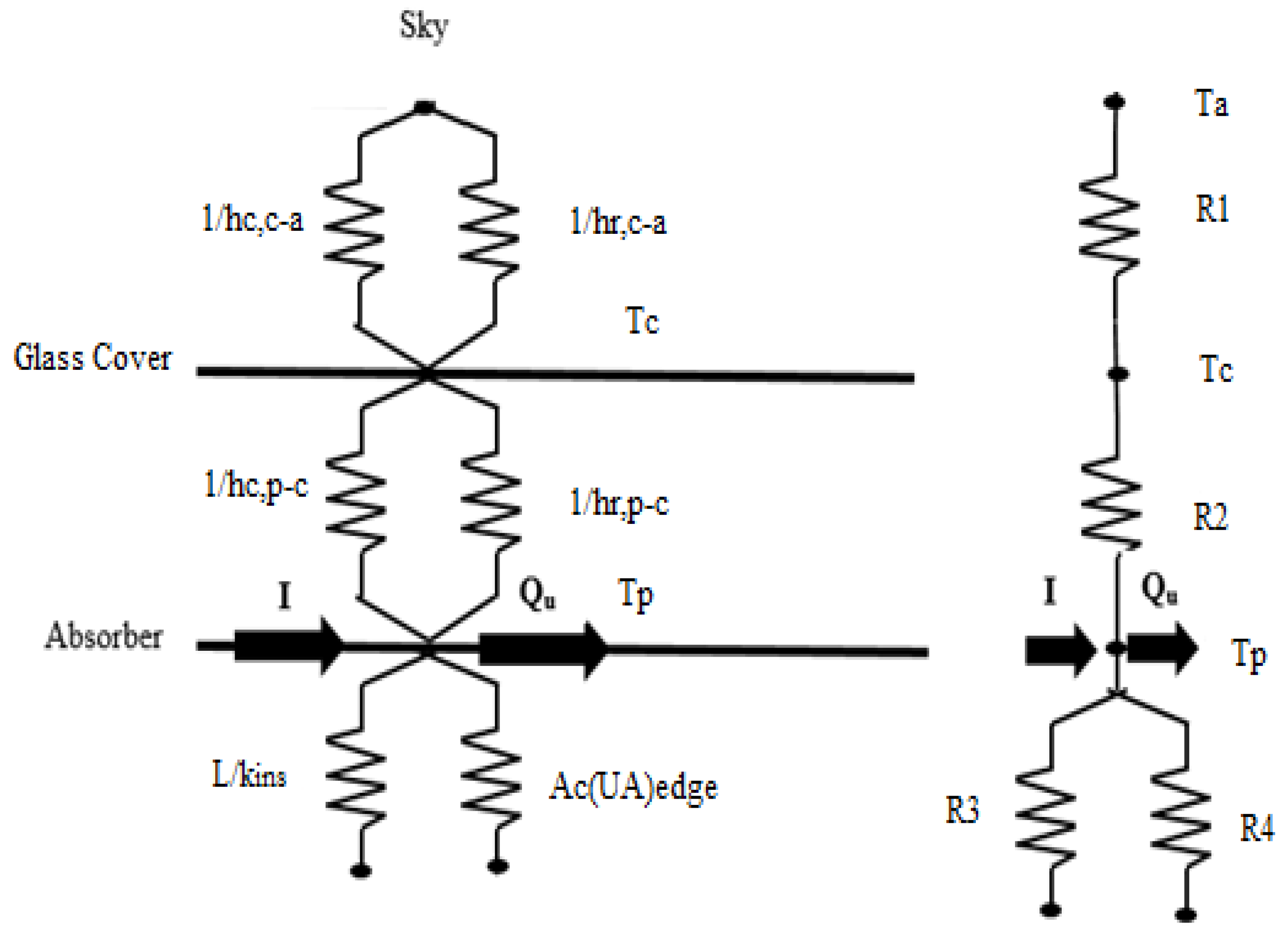

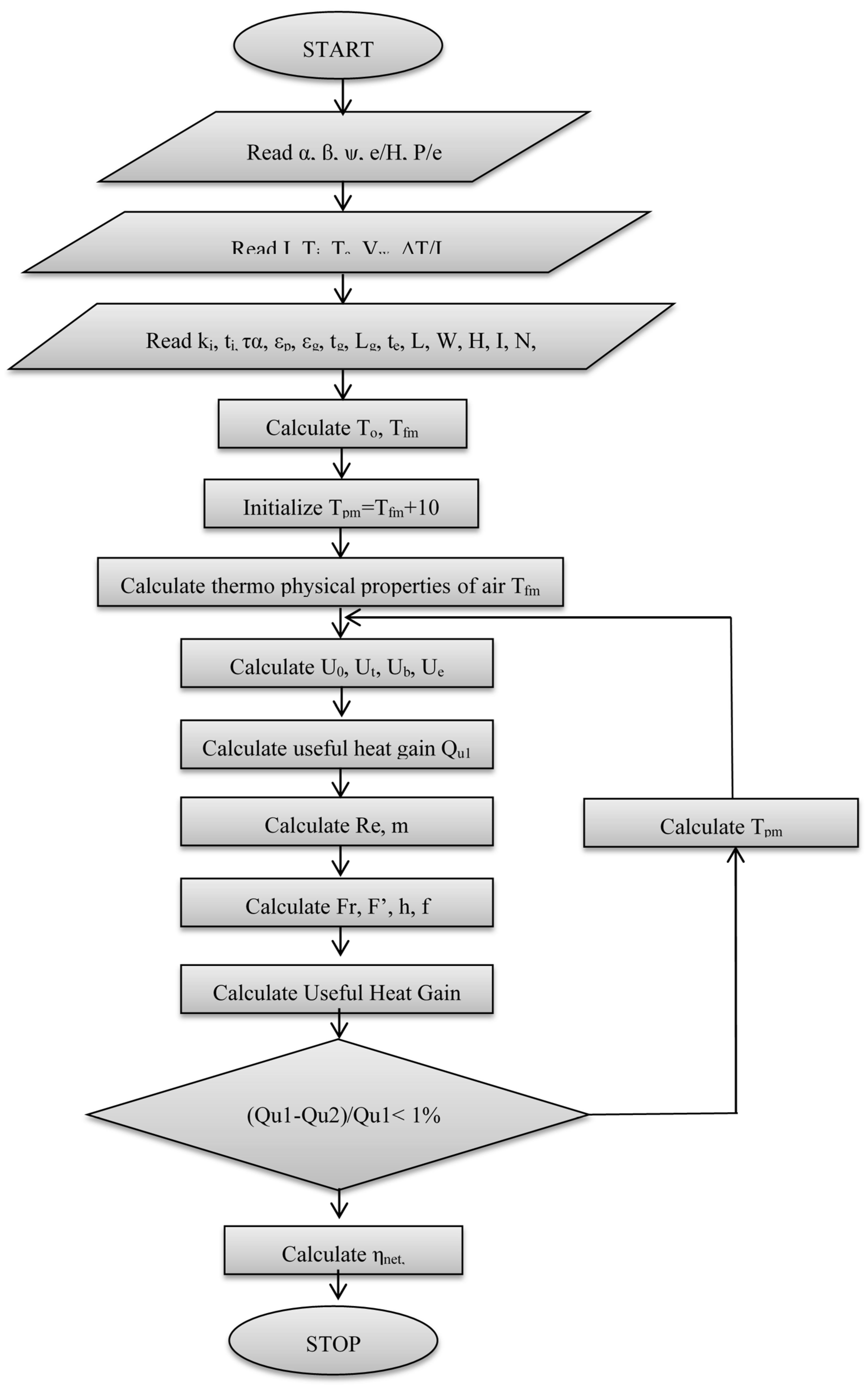

2. Conical Protrusion-Roughened SAH

3. Steps to Calculate the Thermo-Hydraulic Performance

- The rib parameters—i.e., the relative rib pitch and relative rib height—were identified in the entire study for which the characteristic of the net effective efficiency needed to be evaluated. System parameters of the SAH and operating parameters such as the solar insolation, inlet air temperature, ambient temperature, sky temperature, mass flow rate and wind speed needed to be kept fixed;

- The outlet temperature of air was determined using insolation and temperature increase parameters, while the inlet air temperature was considered as ambient temperature:

- 3.

- The overall heat loss coefficient was the sum of the back cover heat loss coefficient, side-edge heat loss coefficient and top heat loss coefficient, which were evaluated in the following manner:

- 4.

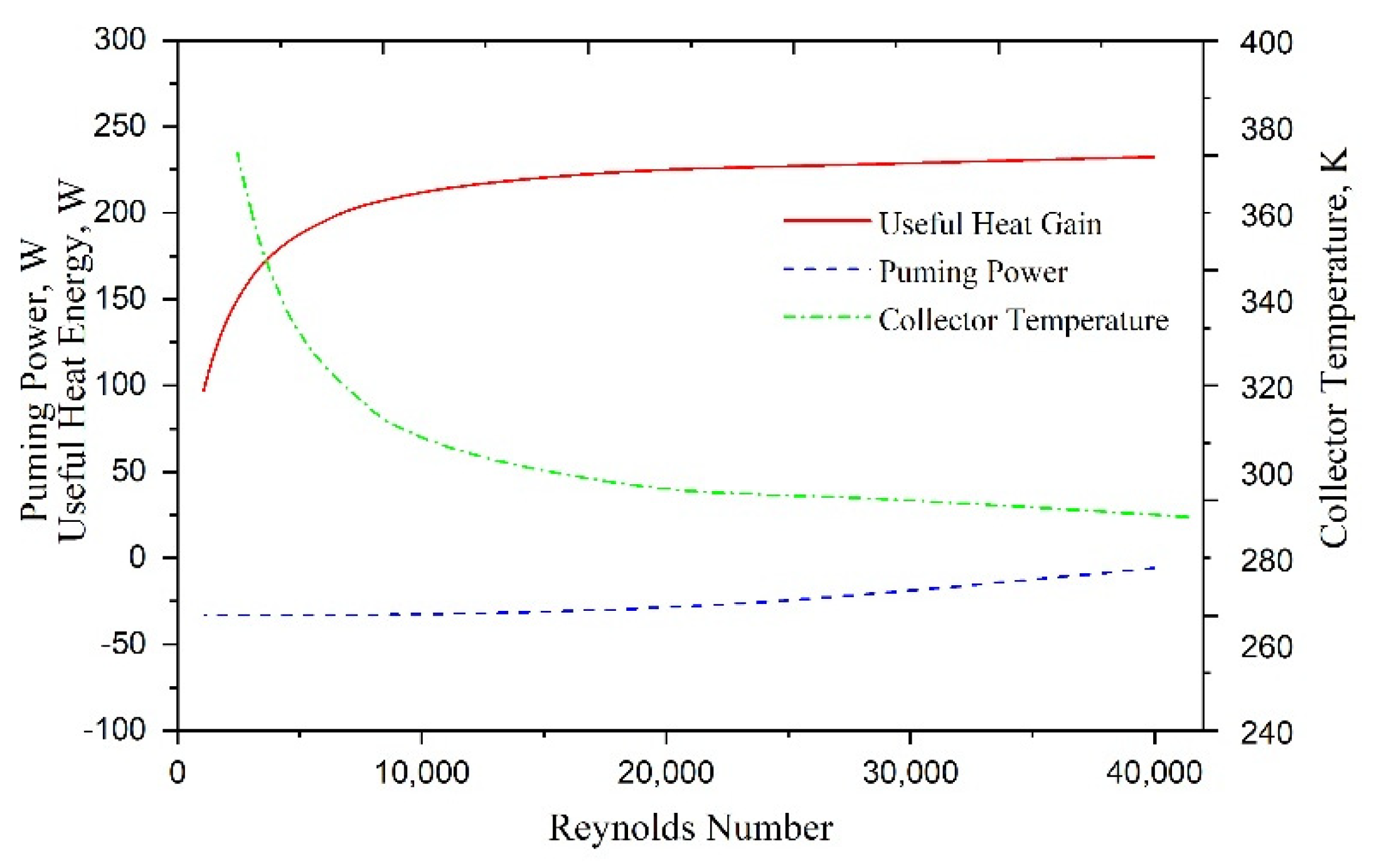

- Useful heat gain was estimated by determining the overall heat loss coefficient. Then, the Reynolds number of air was evaluated in the following manner:

- 5.

- The Nusselt number was estimated by the correlation of the conical protrusion rib roughness in the air passage [28]; then, the convective heat transfer of the absorber plate was estimated as follows:

- 6.

- Again, the heat gain by air was determined by estimating the heat removal factor and collector fin efficiency as follows [32]:where

- 7.

- Qu1 and Qu2 were compared; if these values deviated from each other, the new value of Tpm was determined using the value of heat gain, Qu2, from Equation (17). Iterations continued until the values of Qu1 and Qu2 became nearly equal :

- 8.

- The friction factor was estimated by the correlation of the conical protrusion rib roughness [28]. Then, the pressure drop and mechanical power needed to propel the air through SAH were calculated:

4. Result and Discussion

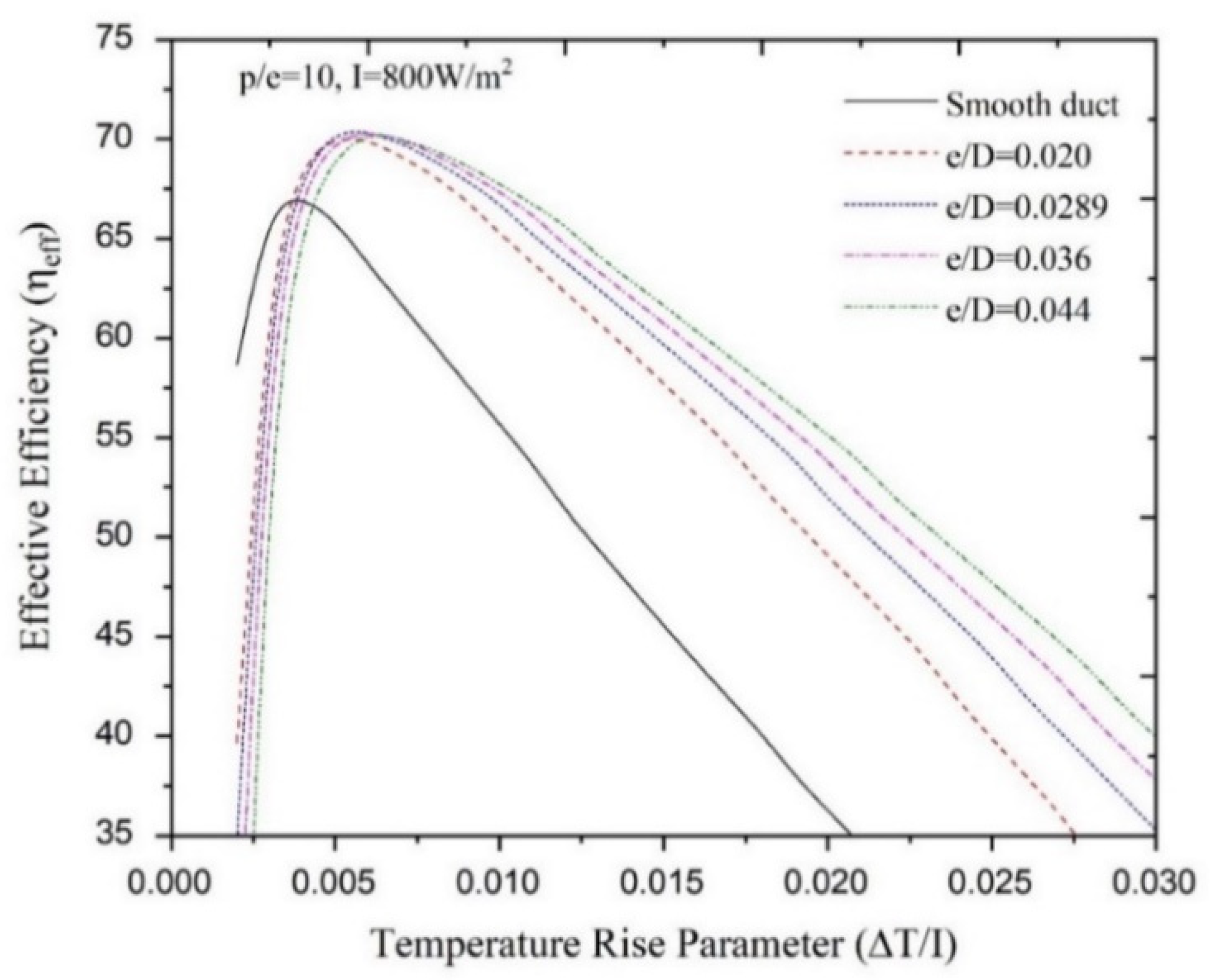

4.1. Effect of Relative Height

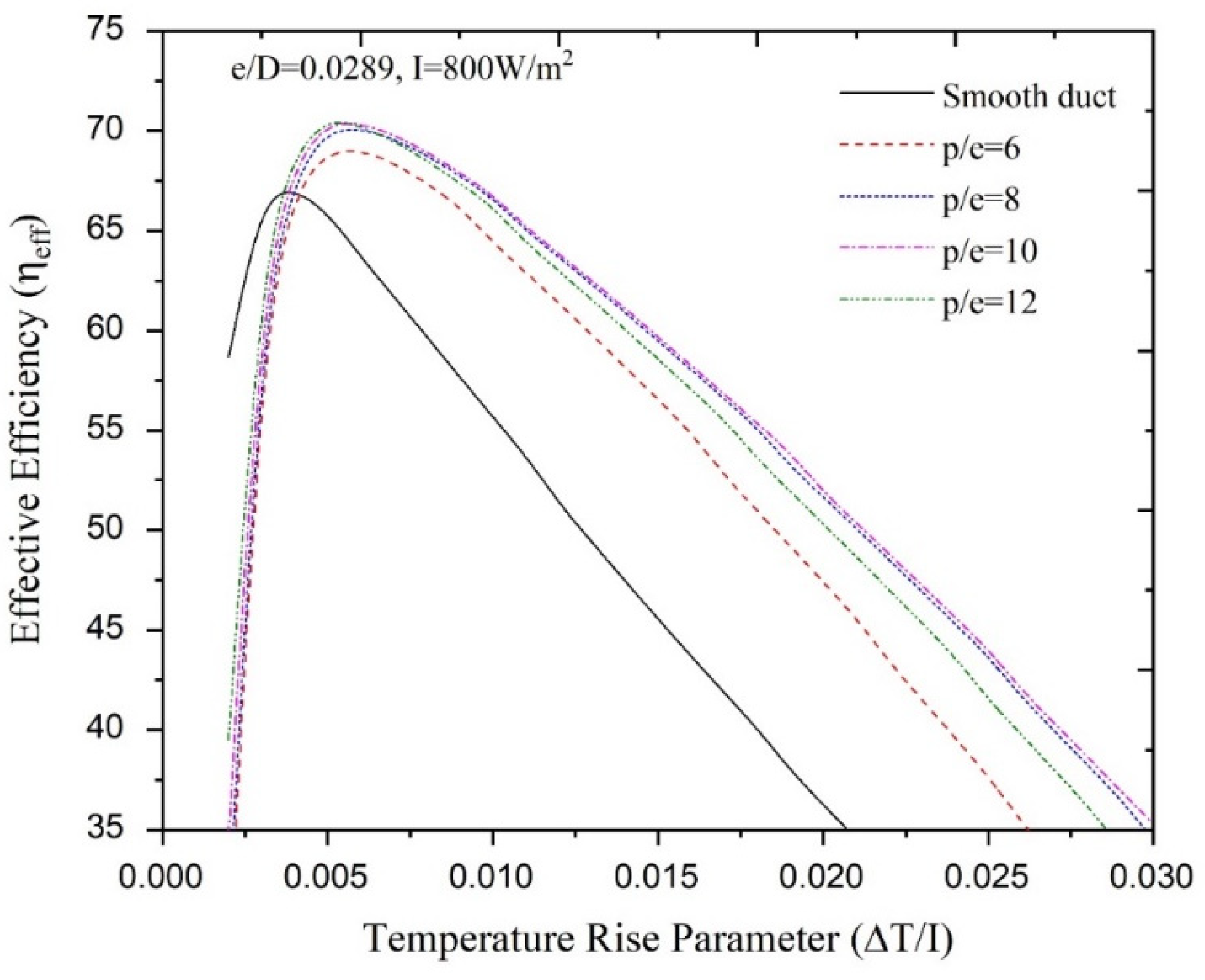

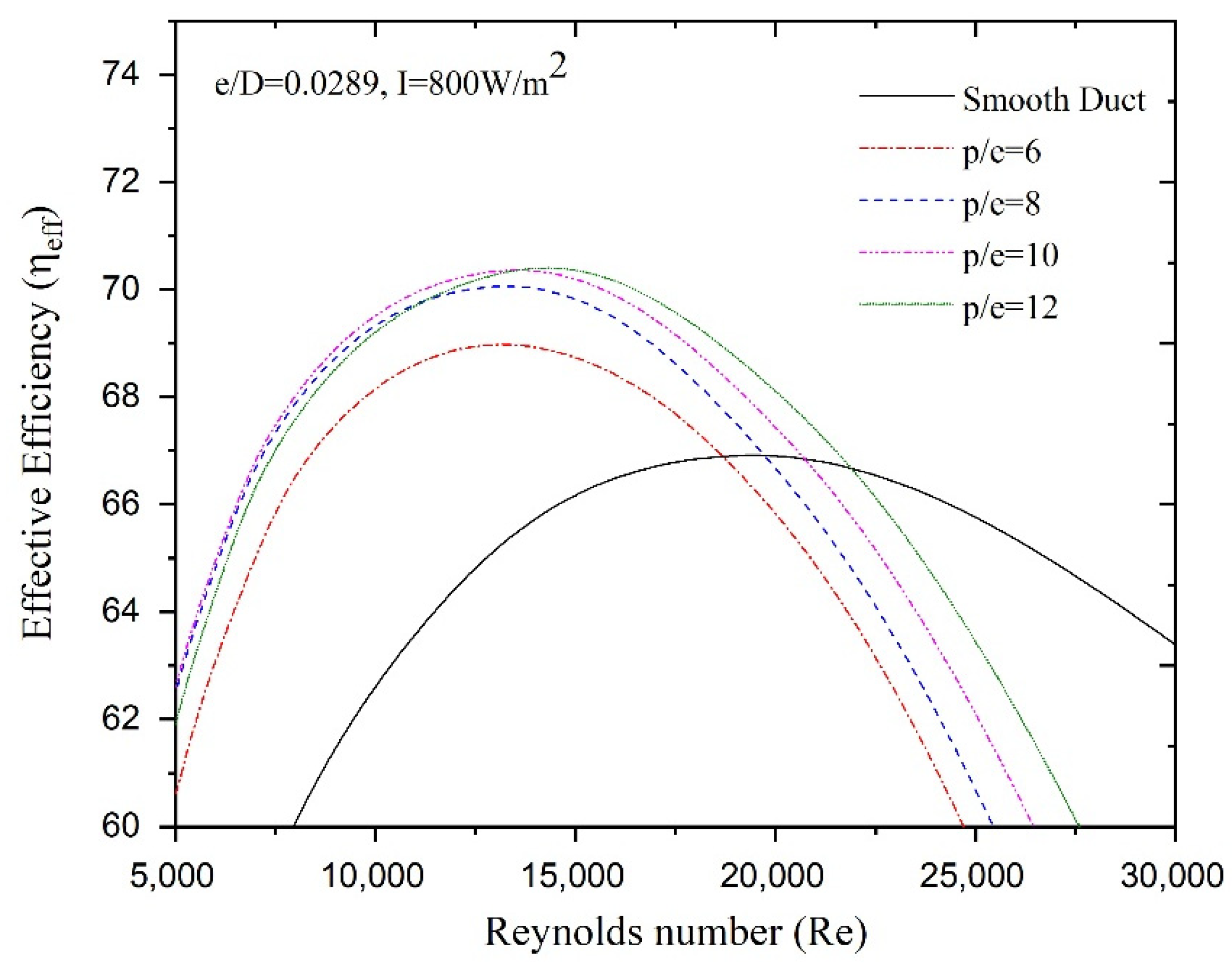

4.2. Effect of Relative Pitch

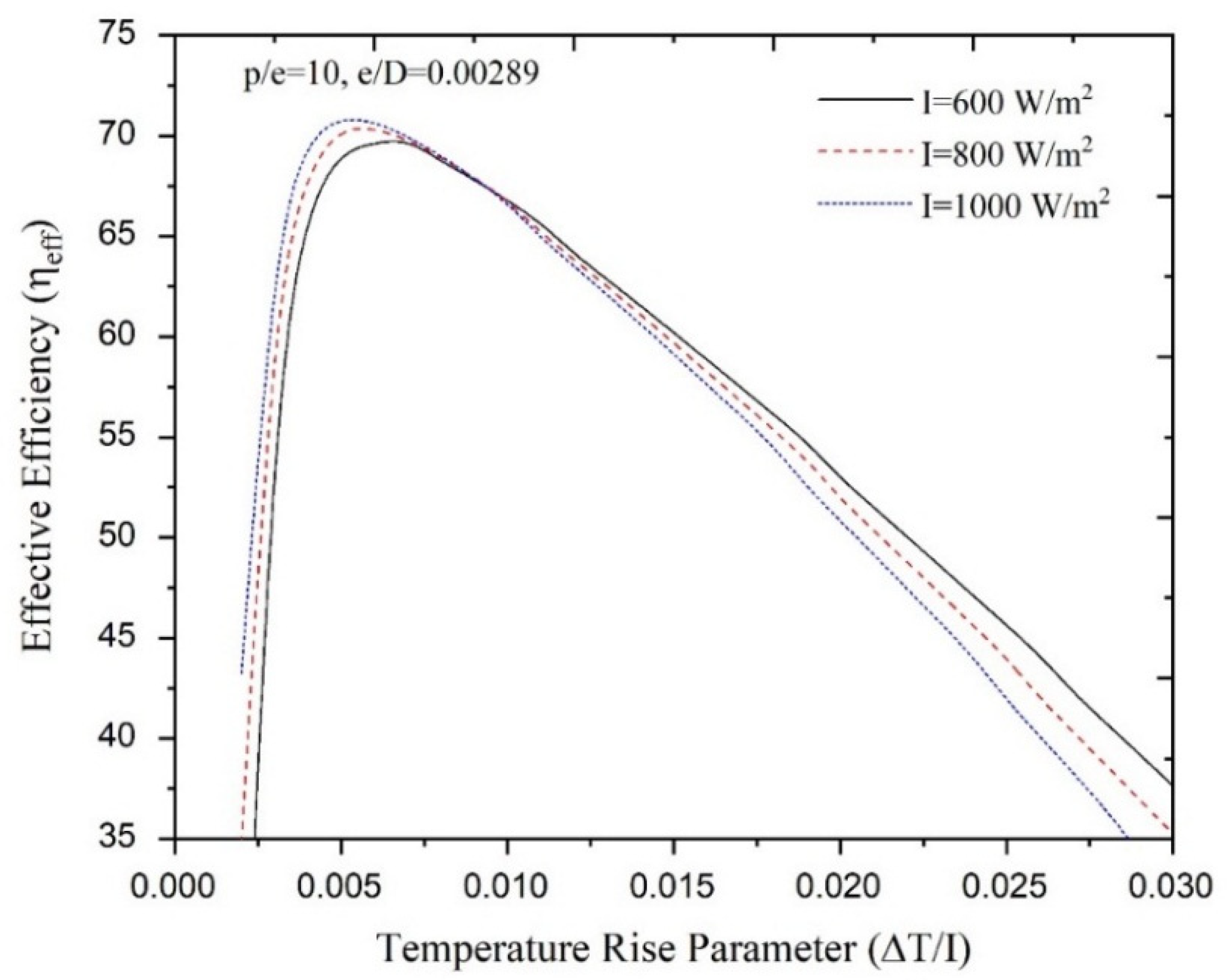

4.3. Effect of Solar Insolation

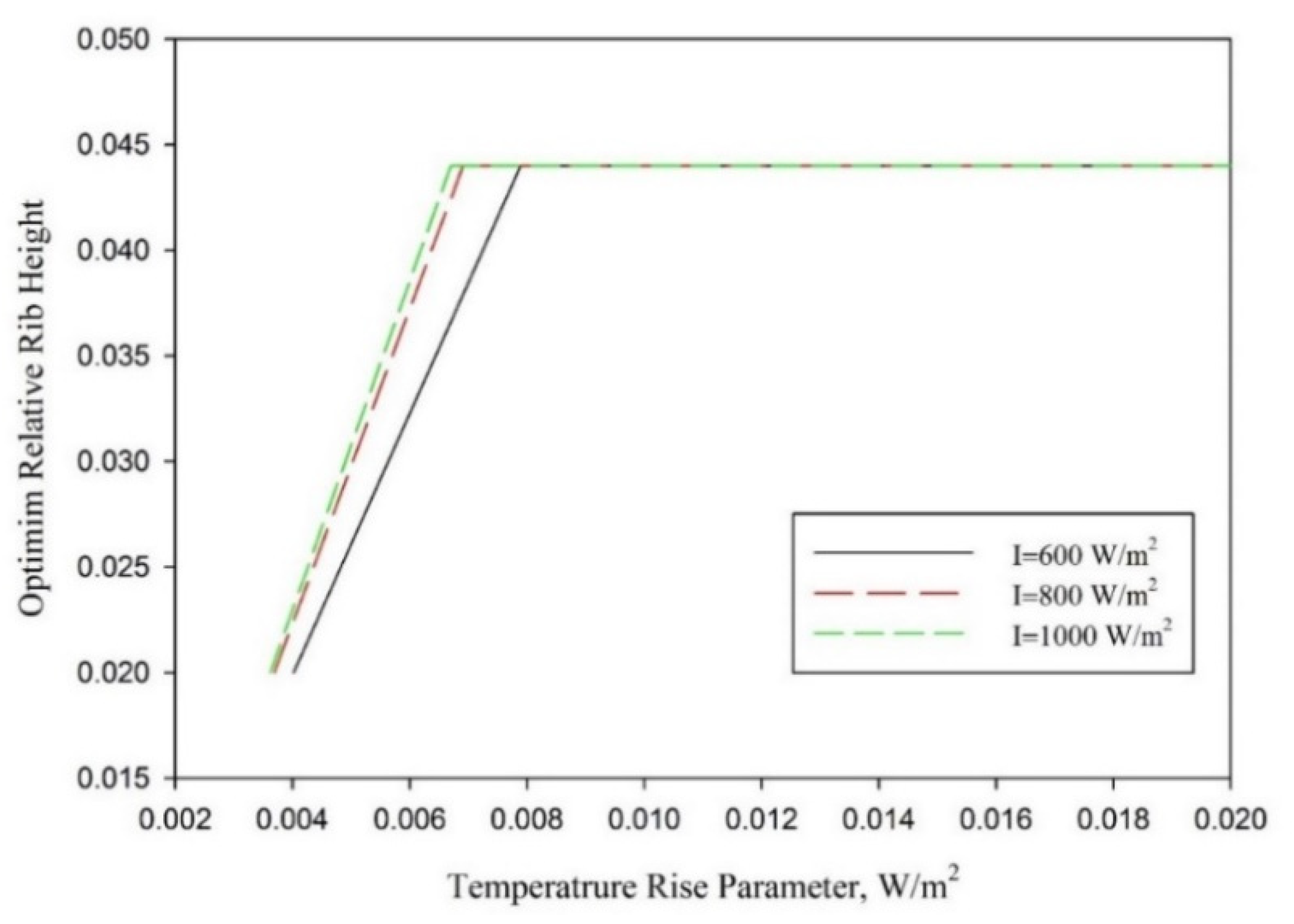

5. Optimization of Conical Protrusion Roughness Parameters

6. Conclusions

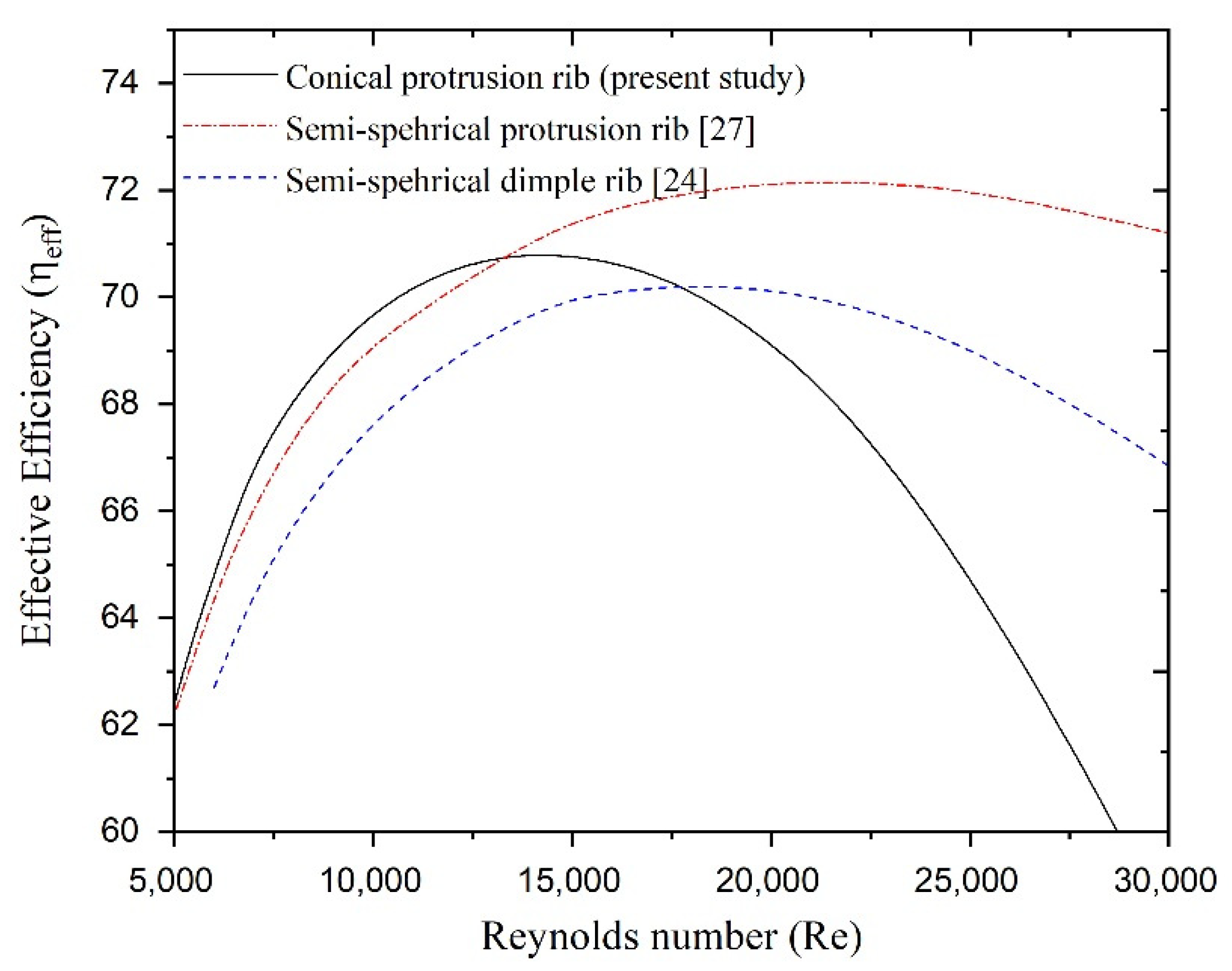

- A conical protrusion rib roughness significantly affects the net effective efficiency of an SAH duct. An effective efficiency increase of up to 70.92% was obtained at an e/D of 0.0289 and p/e of 10;

- Net effective efficiency is observed to depend strongly on the Reynolds number: a higher Reynolds number always results in a relatively low value of effective efficiency irrespective of roughness parameters because of the very high frictional power requirements. Furthermore, in the lower Reynolds number range, the actual value of rib parameter determines the value of the effective efficiency;

- Net effective efficiency is also observed to be a function of insolation. The maximum effective efficiency increased from 69.82% to 70.92% when the insolation increased from 600 W/m2 to 1000 W/m2;

- A set optimum values of conical protrusion rib parameters exists that corresponds to specified operating conditions, resulting in maximum effective efficiency. The optimum relative rib heights have been found to be 0.020, 0.0289, 0.036 and 0.044 for temperature increase parameter ranges of 0.00369 < ∆T/I <0.00463 K·m2/W, 0.00463 < ∆T/I 0.00608 K·m2/W, 0.00608 < ∆T/I 0.00691 K·m2/W and 0.00691 < ∆T/I K·m2/W, respectively. Similarly, ranges of temperature increase parameters of 0.00365 < ∆T/I < 0.00562 K·m2/W and 0.00365 < ∆T/I K·m2/W have been found in which relative rib pitches of 12 and 10, respectively, exhibit the best net effective efficiency;

- Optimum values of the relative rib pitch and relative rib height vary with the temperature increase parameter, and ranges of the temperature increase parameter for optimum roughness parameters change slightly with insolation;

- A unique combination of an optimum relative rib height of 0.44 and relative rib pitch of 10 are observed regardless of the insolation value when ∆T/I > 0.00789 K·m2/W.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Disclosure

Nomenclature

| βti | Tilt angle, ° |

| β′ | Coef of thermal expansion of air, 1/K |

| εg | Emissivity of glass cover |

| εp | Emissivity of absorber plate |

| ηth | Thermal efficiency |

| ηnet | Net effective efficiency |

| ρ | Density of air, kg/m3 |

| σ | Stefan–Boltzmann Constant, W/m2.K4 |

| τ | Trasnmissivity of glass cover |

| µ | Dynamic viscosity of air, Kg/m·s |

| υ | Kinematic viscosity of air, m2/s |

| (τα) | Transmittance-absorbent product of glass cover |

| Ap | Area of absorber plate, m2 |

| Cp | Specific heat of air at constant pressure, J/Kg.K |

| D | Duct height, mm |

| e | Rib height, mm |

| e/D | Relative rib height |

| F′ | Flat efficiency factor, |

| Fo | Heat removal factor |

| f | Friction factor of roughened duct |

| fs | Friction factor of smooth duct |

| h | Heat transfer coefficient, W/m2.K |

| hr | Radiative heat transfer coefficient, W/m2.K |

| hc | Convective heat transfer coefficient, W/m2.K |

| hw | Wind convective heat transfer coeff., W/m2.K |

| Gr | Grashoff number, |

| I | Solar insolation, W/m2 |

| Lg | Air gap b/w absorber plate and glass cover, m |

| ka | Thermal conductivity of air, W/m/K |

| kg | Thermal conductivity of glass, W/m/K |

| m | Mass flow rate, Kg/s |

| N | Number of glass cover |

| Nu | Nusselt number of roughened duct |

| Nus | Nusselt number of smooth duct |

| P | Pitch of ribs, mm |

| Pm | Pumping power, W |

| P/e | Relative pitch ratio |

| Pr | Prandtl number |

| Qu | Useful heat gain, J |

| R | Thermal Resistance, K/W |

| Ra | Rayleigh number |

| Re | Reynolds number |

| Ta | Ambient temperature, K |

| Ti | Inlet temperature, K |

| To | Outlet temperature of air, K |

| Tpm | Average plate mean temperature, K |

| Ts | Sun temperature, K |

| ΔT | Air temperature rise, K |

| ΔT/I | Temperature rise parameter, K.m2/W |

| ti | Thickness of insulation, mm |

| tg | Thickness of glass cover, mm |

| tg | Height of collector edge, mm |

| Ub | Back heat loss coefficient, W/m2.K |

| Ue | Edge heat loss coefficient, W/m2.K |

| Ut | Top heat loss coefficient, W/m2.K |

| V | Air velocity, m/s |

| Vw | Wind speed, m/s |

References

- Statistical Review of World Energy, 68th Edition. 2019. Available online: www.bp.com (accessed on 21 May 2021).

- Sukhatme, S.P. Solar Energy: Principles of Thermal Collection and Storage, 9th ed.; Tata McGraw-Hill: New Delhi, India, 2003. [Google Scholar]

- Duffie, J.A.; Beckman, W.A. Solar Engineering Thermal Processes; John Wiley: Hoboken, NJ, USA, 1991. [Google Scholar]

- Alam, T.; Kim, M.H. A critical review on artificial roughness provided in rectangular solar air heater duct. Renew. Sustain. Energy Rev. 2017, 69, 387–400. [Google Scholar] [CrossRef]

- Prasad, B.N.; Saini, J.S. Optimal thermohydraulic performance of artficially roughened solar air heaters. Solar Energy 1991, 47, 91–96. [Google Scholar] [CrossRef]

- Prasad, B.; Saini, J. Effect of artificial roughness on heat transfer and friction factor in a solar air heater. Sol. Energy 1988, 41, 555–560. [Google Scholar] [CrossRef]

- Gupta, D.; Solanki, S.; Saini, J. Heat and fluid flow in rectangular solar air heater ducts having transverse rib roughness on absorber plates. Sol. Energy 1993, 51, 31–37. [Google Scholar] [CrossRef]

- Momin, A.-M.E.; Saini, J.; Solanki, S. Heat transfer and friction in solar air heater duct with V-shaped rib roughness on absorber plate. Int. J. Heat Mass Transf. 2002, 45, 3383–3396. [Google Scholar] [CrossRef]

- Hans, V.; Saini, R.; Saini, J. Heat transfer and friction factor correlations for a solar air heater duct roughened artificially with multiple v-ribs. Sol. Energy 2010, 84, 898–911. [Google Scholar] [CrossRef]

- Aharwal, K.; Gandhi, B.; Saini, J. Experimental investigation on heat-transfer enhancement due to a gap in an inclined continuous rib arrangement in a rectangular duct of solar air heater. Renew. Energy 2008, 33, 585–596. [Google Scholar] [CrossRef]

- Kumar, A.; Saini, R.; Saini, J. Experimental investigation on heat transfer and fluid flow characteristics of air flow in a rectangular duct with Multi v-shaped rib with gap roughness on the heated plate. Sol. Energy 2012, 86, 1733–1749. [Google Scholar] [CrossRef]

- Gawande, V.B.; Dhoble, A.; Zodpe, D.; Chamoli, S. Experimental and CFD investigation of convection heat transfer in solar air heater with reverse L-shaped ribs. Sol. Energy 2016, 131, 275–295. [Google Scholar] [CrossRef]

- Kumar, R.; Goel, V.; Singh, P.; Saxena, A.; Kashyap, A.S.; Rai, A. Performance evaluation and optimization of solar assisted air heater with discrete multiple arc shaped ribs. J. Energy Storage 2019, 26, 100978. [Google Scholar] [CrossRef]

- Wang, D.; Liu, J.; Liu, Y.; Wang, Y.; Li, B.; Liu, J. Evaluation of the performance of an improved solar air heater with “S” shaped ribs with gap. Sol. Energy 2020, 195, 89–101. [Google Scholar]

- Jaurker, A.; Saini, J.; Gandhi, B. Heat transfer and friction characteristics of rectangular solar air heater duct using rib-grooved artificial roughness. Sol. Energy 2006, 80, 895–907. [Google Scholar] [CrossRef]

- Juarker, A.R. Heat and Fluid Flow Characteristics of Rib-Groove Artificially Roughened Solar Air Heater; Indian Institute of Technology: Roorkee, India, 2005. [Google Scholar]

- Layek, A.; Saini, J.; Solanki, S. Effect of chamfering on heat transfer and friction characteristics of solar air heater having absorber plate roughened with compound turbulators. Renew. Energy 2009, 34, 1292–1298. [Google Scholar] [CrossRef]

- Layek, A.; Saini, J.; Solanki, S. Heat transfer and friction characteristics for artificially roughened ducts with compound turbulators. Int. J. Heat Mass Transf. 2007, 50, 4845–4854. [Google Scholar] [CrossRef]

- Alam, T.; Saini, R.; Saini, J. Effect of circularity of perforation holes in V-shaped blockages on heat transfer and friction characteristics of rectangular solar air heater duct. Energy Convers. Manag. 2014, 86, 952–963. [Google Scholar] [CrossRef]

- Chamoli, S. Preference selection index approach for optimization of V down perforated baffled roughened rectangular channel. Energy 2015, 93, 1418–1425. [Google Scholar] [CrossRef]

- Alam, T.; Saini, R.; Saini, J. Heat transfer enhancement due to V-shaped perforated blocks in a solar air heater duct. Appl. Mech. Mater. 2014, 619, 125–129. [Google Scholar] [CrossRef]

- Saini, R.; Verma, J. Heat transfer and friction factor correlations for a duct having dimple-shape artificial roughness for solar air heaters. Energy 2008, 33, 1277–1287. [Google Scholar] [CrossRef]

- Sethi, M.; Varun; Thakur, N. Correlations for solar air heater duct with dimpled shape roughness elements on absorber plate. Sol. Energy 2012, 86, 2852–2861. [Google Scholar] [CrossRef]

- Sethi, M.; Thakur, N.S.; Varun. Heat transfer and friction characteristics of dimple-shaped roughness element arranged in angular fashion (arc) on the absorber plate of solar air heater. J. Renew. Sustain. Energy 2012, 4, 023112. [Google Scholar] [CrossRef]

- Bhushan, B.; Singh, R. Nusselt number and friction factor correlations for solar air heater duct having artificially roughened absorber plate. Sol. Energy 2011, 85, 1109–1118. [Google Scholar] [CrossRef]

- Perwez, A.; Kumar, R. Thermal performance investigation of the flat and spherical dimple absorber plate solar air heaters. Sol. Energy 2019, 193, 309–323. [Google Scholar] [CrossRef]

- Yadav, S.; Kaushal, M.; Varun. Siddhartha Nusselt number and friction factor correlations for solar air heater duct having protrusions as roughness elements on absorber plate. Exp. Therm. Fluid Sci. 2013, 44, 34–41. [Google Scholar] [CrossRef]

- Alam, T.; Kim, M.-H. Heat transfer enhancement in solar air heater duct with conical protrusion roughness ribs. Appl. Therm. Eng. 2017, 126, 458–469. [Google Scholar] [CrossRef]

- Sharma, S.K.; Kalamkar, V. Thermo-hydraulic performance analysis of solar air heaters having artificial roughness—A review. Renew. Sustain. Energy Rev. 2015, 41, 413–435. [Google Scholar] [CrossRef]

- Cortés, A.; Piacentini, R. Improvement of the efficiency of a bare solar collector by means of turbulence promoters. Appl. Energy 1990, 36, 253–261. [Google Scholar] [CrossRef]

- Akhtar, N.; Mullick, S. Approximate method for computation of glass cover temperature and top heat-loss coefficient of solar collectors with single glazing. Sol. Energy 1999, 66, 349–354. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A.; Worek, W.M. Solar Engineering of Thermal Processes, 2nd ed.; Wiley: New York, NY, USA, 1980. [Google Scholar]

| Parameter | Value |

|---|---|

| System Parameters | |

| Tilt angle (βti) | 30° |

| Emissivity of absorber plate (εp) | 0.9 |

| Emissivity of transparent glass cover (εg) | 0.88 |

| Transmittance–absorptance product | 0.8 |

| Thickness of collector edge (te) | 0.1 m |

| Thickness of glass cover (tg) | 0.002 m |

| Thickness of back insulation (ti) | 0.05 m |

| Thermal conductivity of insulation (ki) | 0.037 W/m⋅K |

| Collector length (L) | 1.0 m |

| Gap between collector and glass cover (Lg) | 0.025 m |

| Collector duct height (H) | 0.025 m |

| Number of glass covers (N) | 1 |

| Collector width (W) | 0.3 m |

| Relative rib height (e/D) | 0.020–0.044 |

| Relative rib pitch (p/e) | 6–12 |

| Operating parameters | |

| Ambient temperature (Ta) | 285 K |

| Wind velocity (Vw) | 1.0 m/s |

| Temperature rise parameter (ΔT/I) | 0.002–0.030 K⋅m2/W |

| Insolation (I) | 600 W/m2–1000 W/m2 |

| I = 800 W/m2 and p/e = 10 | |||

|---|---|---|---|

| Roughness Parameter | Optimized Value of Parameter | Ranges of Temperature Increase Parameters (ΔT/I) | Ranges of Reynolds Numbers (Re) |

| Relative rib height (e/D) | Smooth | ∆T/I < 0.00369 | 21,640 < Re |

| e/D = 0.020 | 0.00369 < ∆T/I < 0.00463 | 16,812 < Re < 21,640 | |

| e/D = 0.0289 | 0.00463 < ∆T/I 0.00608 | 12,253 < Re < 16,812 | |

| e/D = 0.036 | 0.00608 < ∆T/I 0.00691 | 16,812 < Re < 21,640 | |

| e/D = 0.044 | 0.00691 < ∆T/I | Re < 11,095 | |

| P/e = 10, I = 800 W/m2 | e/D = 0.020 | e/D = 0.0289 | e/D = 0.036 | e/D = 0.044 | |

|---|---|---|---|---|---|

| Enhancement factor in effective efficiency (ηeff/ηeffs), | ΔT/I = 0.005 | 1.064 | 1.069 | 1.061 | 1.049 |

| ΔT/I = 0.010 | 1.172 | 1.199 | 1.209 | 1.217 | |

| ΔT/I = 0.015 | 1.267 | 1.310 | 1.333 | 1.353 | |

| ΔT/I = 0.020 | 1.353 | 1.432 | 1.486 | 1.52 | |

| ΔT/I = 0.025 | 1.413 | 1.559 | 1.629 | 1.69 | |

| ΔT/I = 0.030 | 1.437 | 1.677 | 1.797 | 1.900 | |

| I = 800 W/m2 and e/D = 0.0289 | |||

|---|---|---|---|

| Roughness Parameter | Optimized Value of Parameter | Ranges of Temperature Increase Parameters (ΔT/I) | Ranges of Reynolds Numbers (Re) |

| Relative rib pitch (p/e) | Smooth | ∆T/I < 0.00365 | 21,780 < Re |

| p/e = 12 | 0.00365 < ∆T/I < 0.00562 | 13,520 < Re < 21,780 | |

| p/e = 10 | <∆T/I 0.00562 | Re < 13,520 | |

| e/D = 0.0289, I = 800 W/m2 | p/e = 6 | p/e = 8 | p/e = 10 | p/e = 12 | |

|---|---|---|---|---|---|

| Enhancement factor in effective efficiency (ηeff/ηeffs), | ΔT/I = 0.005 | 1.046 | 1.063 | 1.069 | 1.072 |

| ΔT/I = 0.010 | 1.157 | 1.197 | 1.199 | 1.189 | |

| ΔT/I = 0.015 | 1.241 | 1.306 | 1.31 | 1.286 | |

| ΔT/I = 0.020 | 1.308 | 1.425 | 1.432 | 1.388 | |

| ΔT/I = 0.025 | 1.335 | 1.548 | 1.559 | 1.471 | |

| ΔT/I = 0.030 | 1.29 | 1.641 | 1.677 | 1.533 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alam, T.; Meena, C.S.; Balam, N.B.; Kumar, A.; Cozzolino, R. Thermo-Hydraulic Performance Characteristics and Optimization of Protrusion Rib Roughness in Solar Air Heater. Energies 2021, 14, 3159. https://doi.org/10.3390/en14113159

Alam T, Meena CS, Balam NB, Kumar A, Cozzolino R. Thermo-Hydraulic Performance Characteristics and Optimization of Protrusion Rib Roughness in Solar Air Heater. Energies. 2021; 14(11):3159. https://doi.org/10.3390/en14113159

Chicago/Turabian StyleAlam, Tabish, Chandan Swaroop Meena, Nagesh Babu Balam, Ashok Kumar, and Raffaello Cozzolino. 2021. "Thermo-Hydraulic Performance Characteristics and Optimization of Protrusion Rib Roughness in Solar Air Heater" Energies 14, no. 11: 3159. https://doi.org/10.3390/en14113159

APA StyleAlam, T., Meena, C. S., Balam, N. B., Kumar, A., & Cozzolino, R. (2021). Thermo-Hydraulic Performance Characteristics and Optimization of Protrusion Rib Roughness in Solar Air Heater. Energies, 14(11), 3159. https://doi.org/10.3390/en14113159