Impact of Employing Hybrid Nanofluids as Heat Carrier Fluid on the Thermal Performance of a Borehole Heat Exchanger

Abstract

1. Introduction

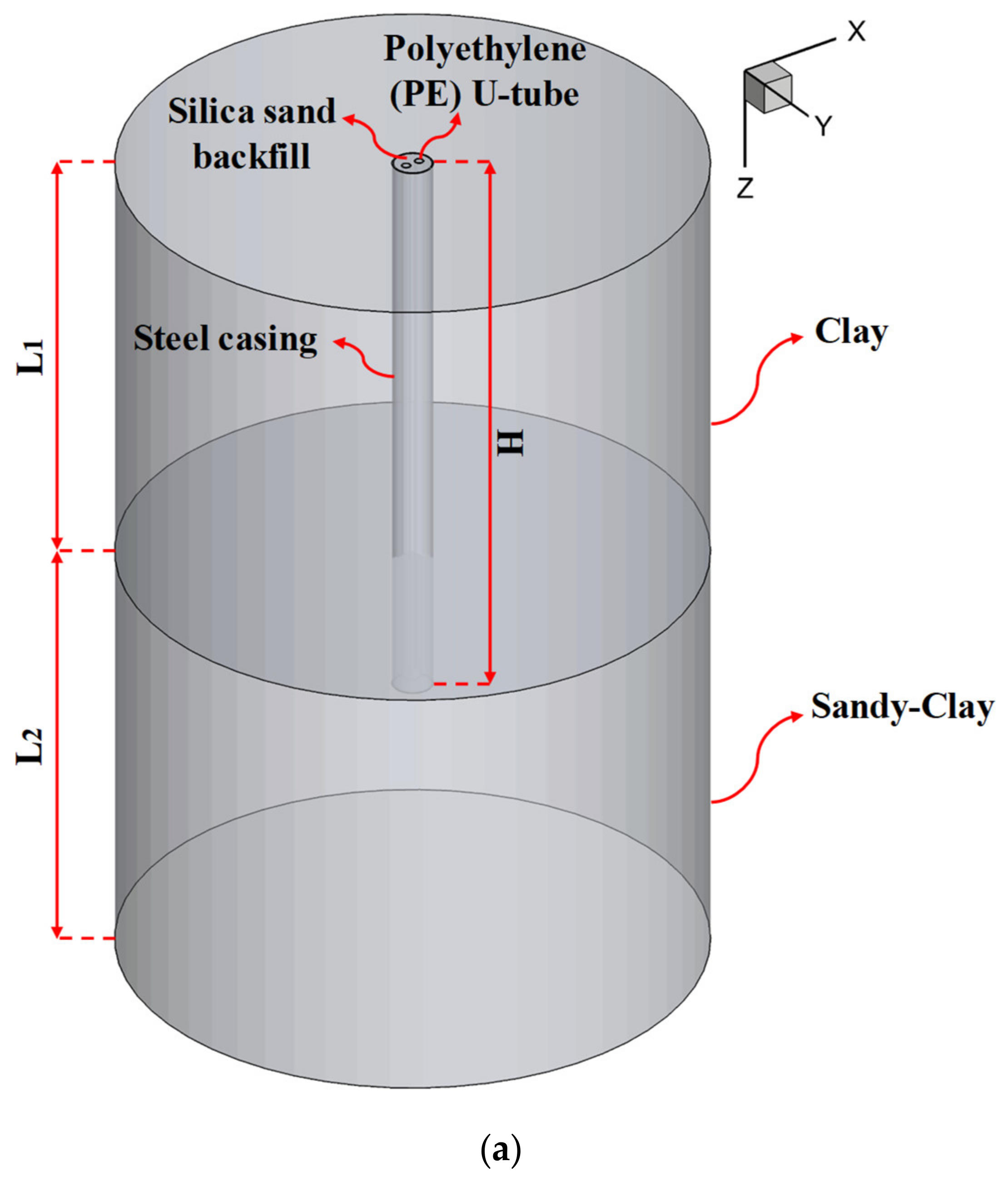

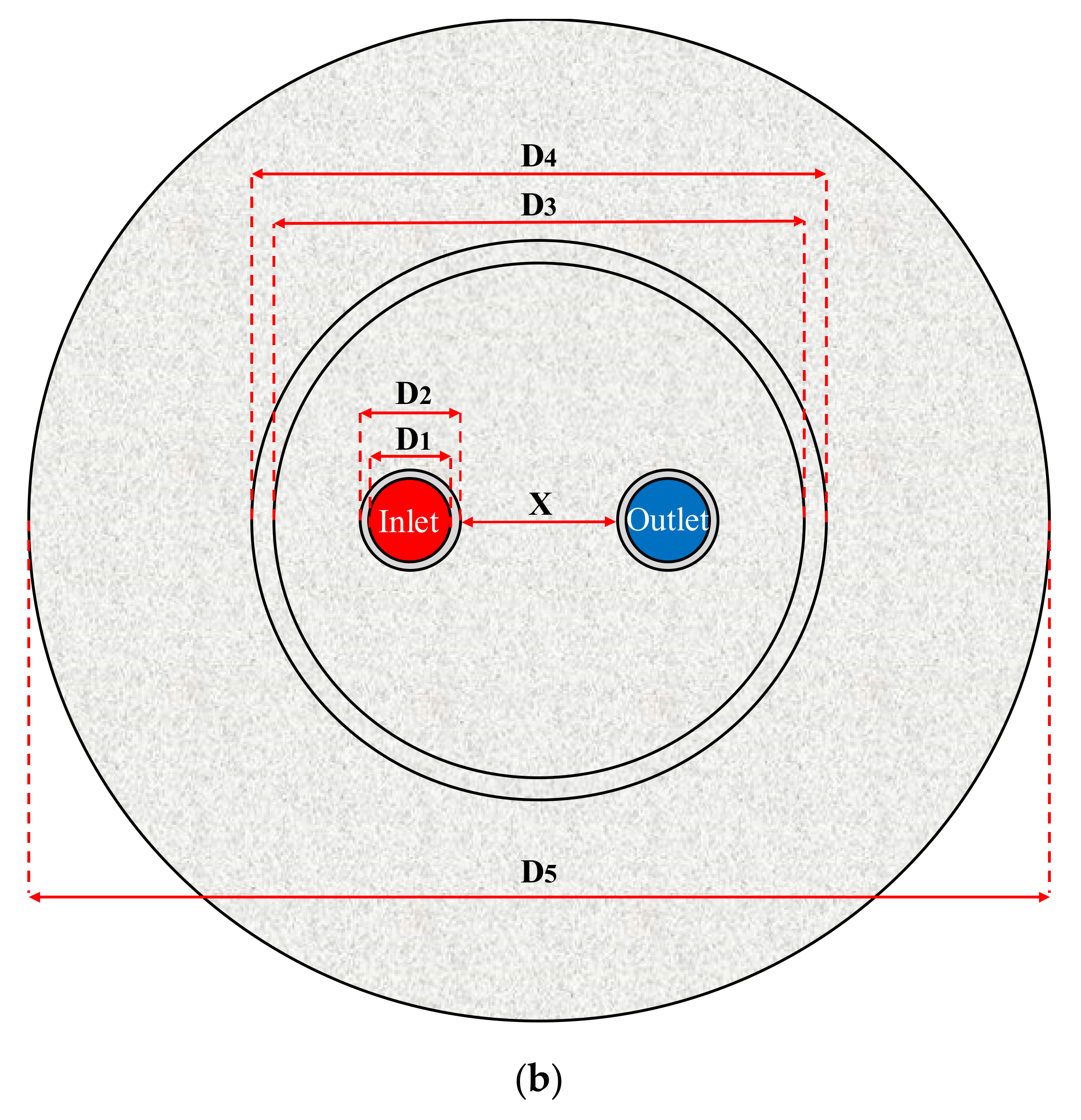

2. Geometry and Boundary Conditions

3. Thermo-Physical Properties and Studied Factors

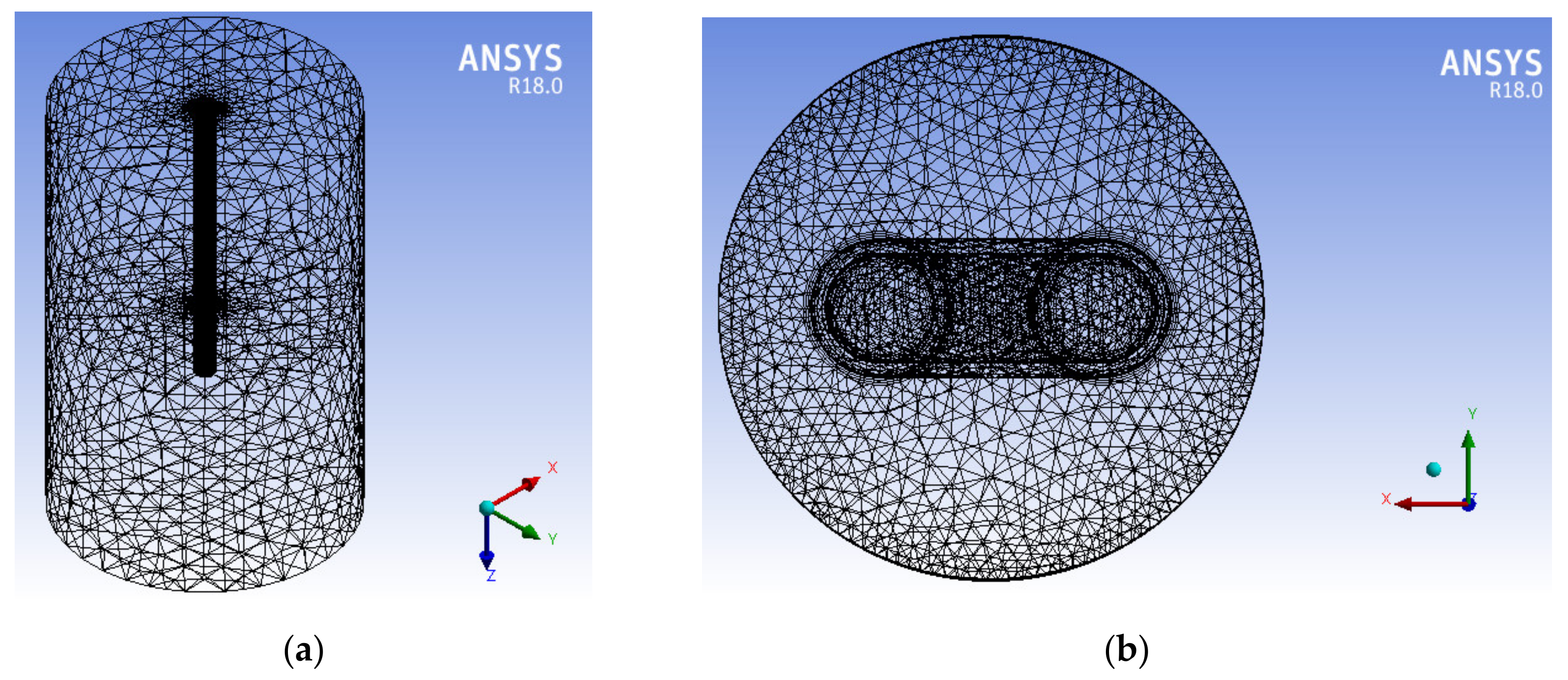

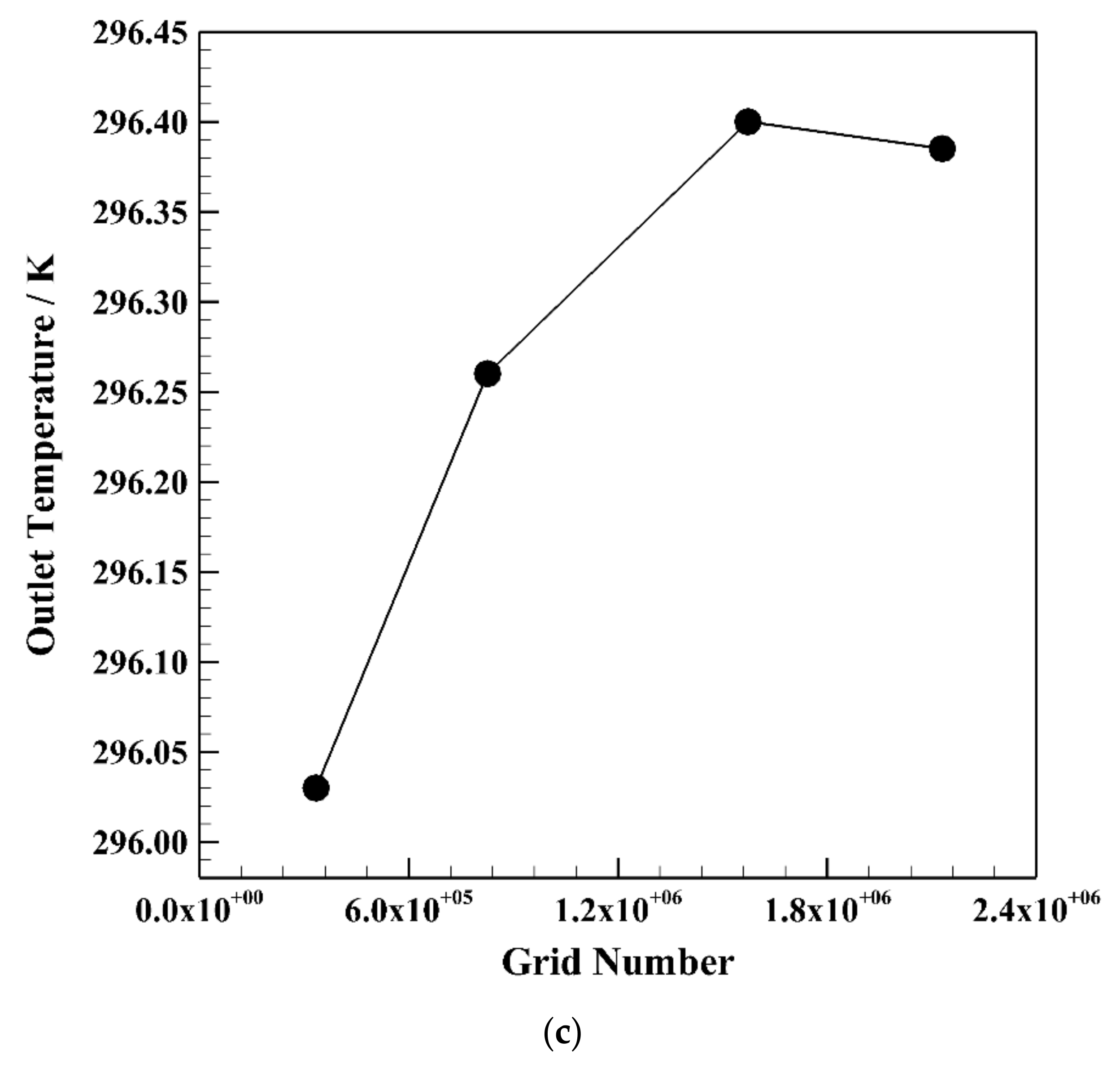

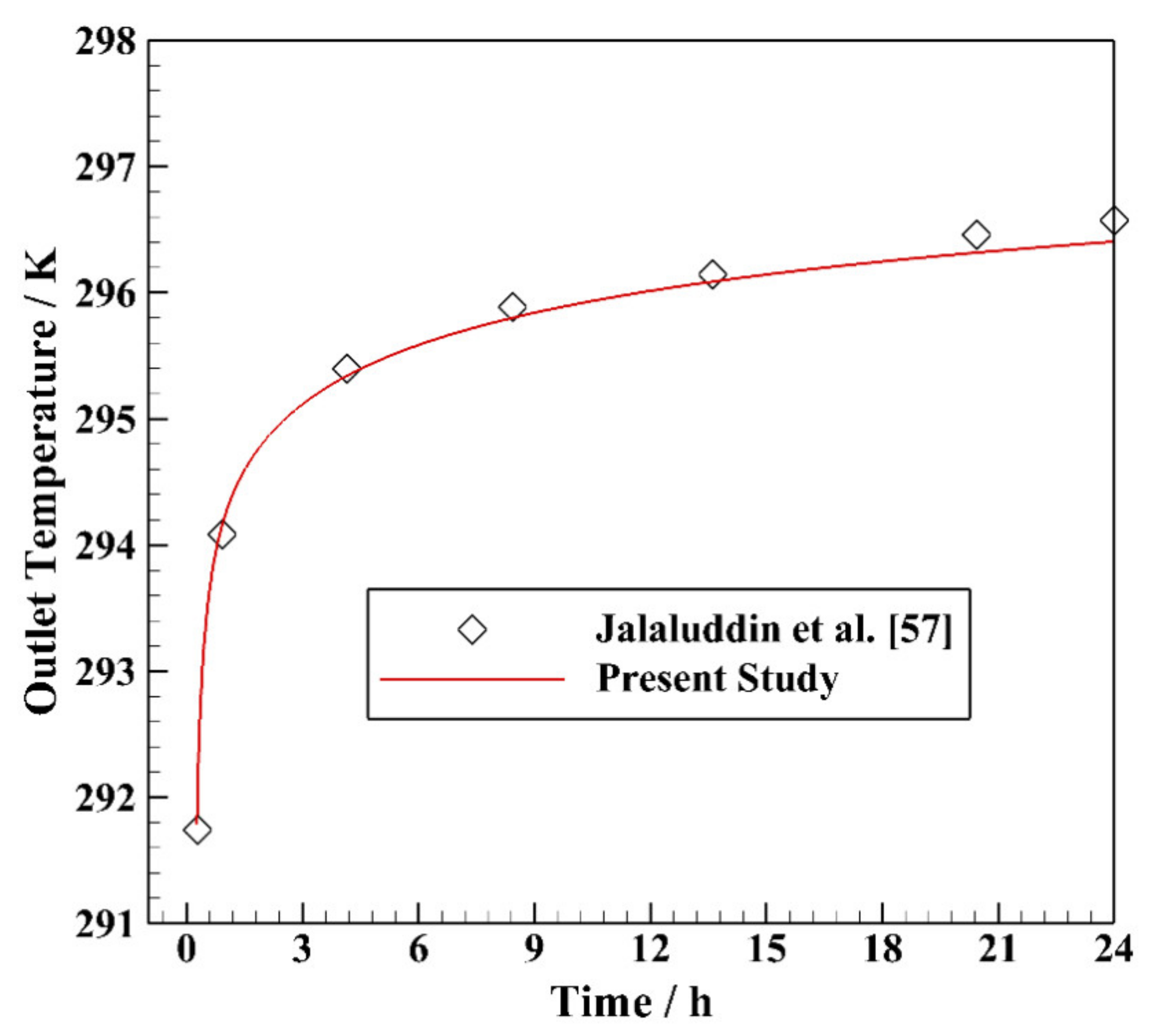

4. Mesh Topology and Validation

5. Results and Discussion

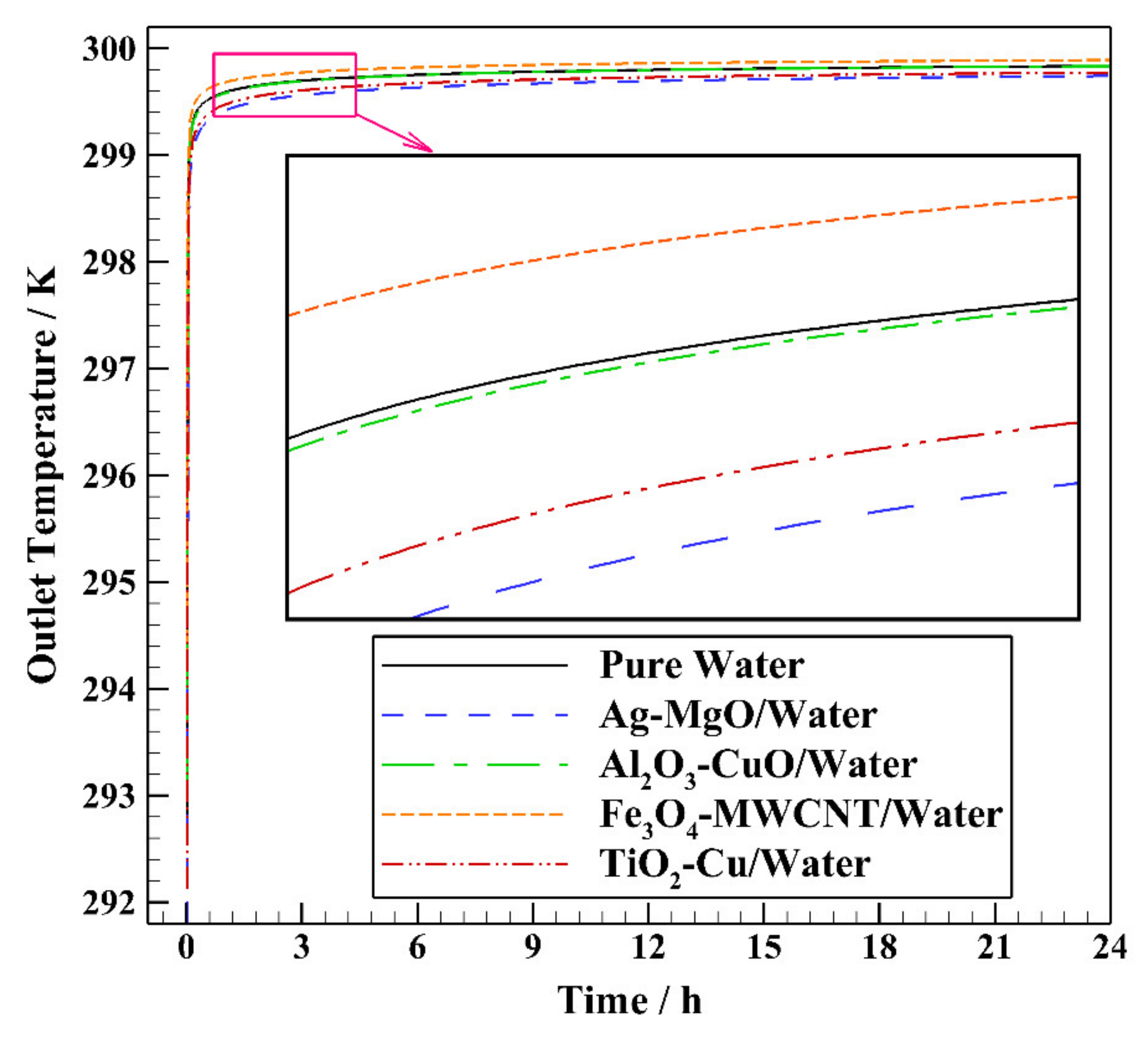

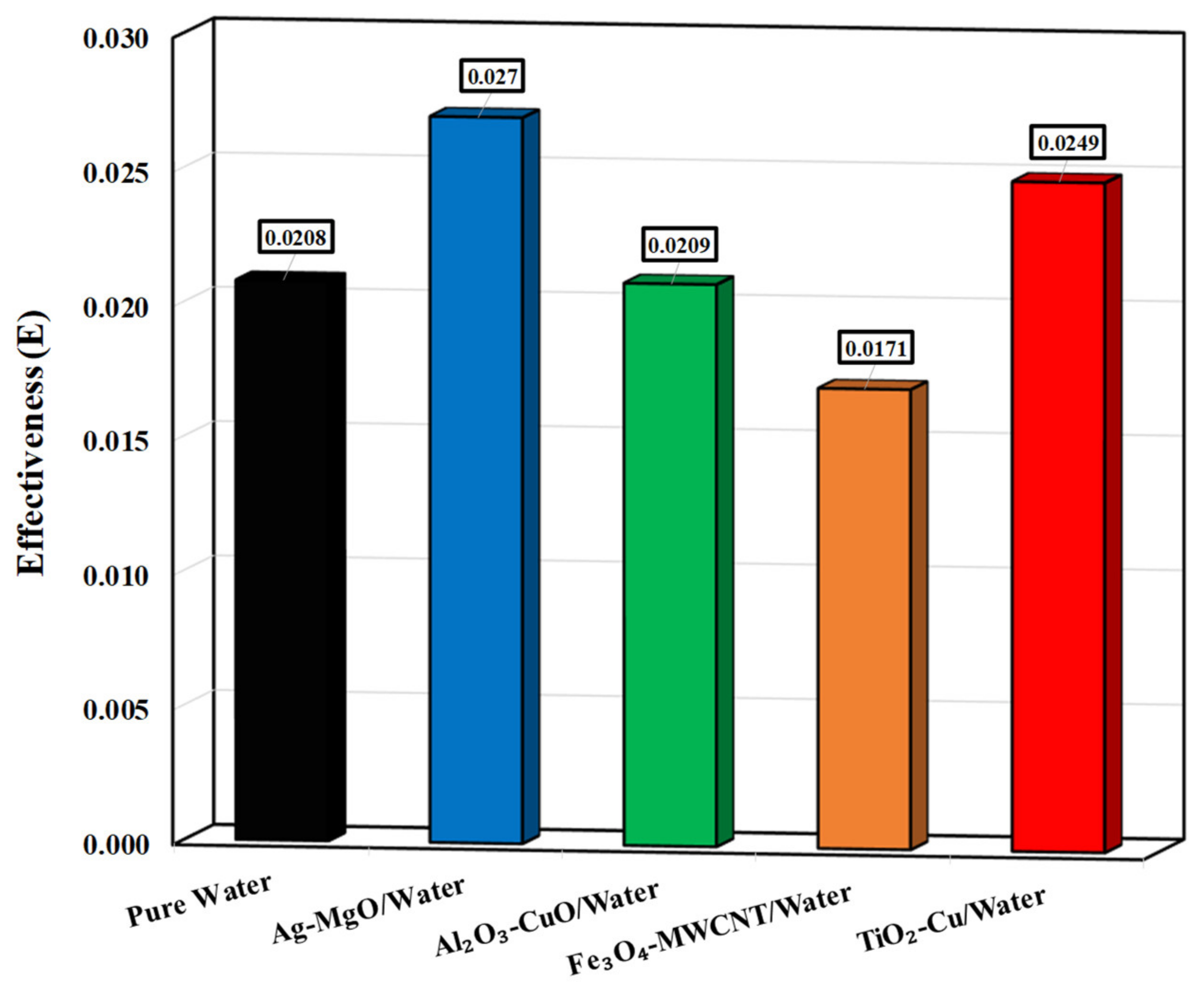

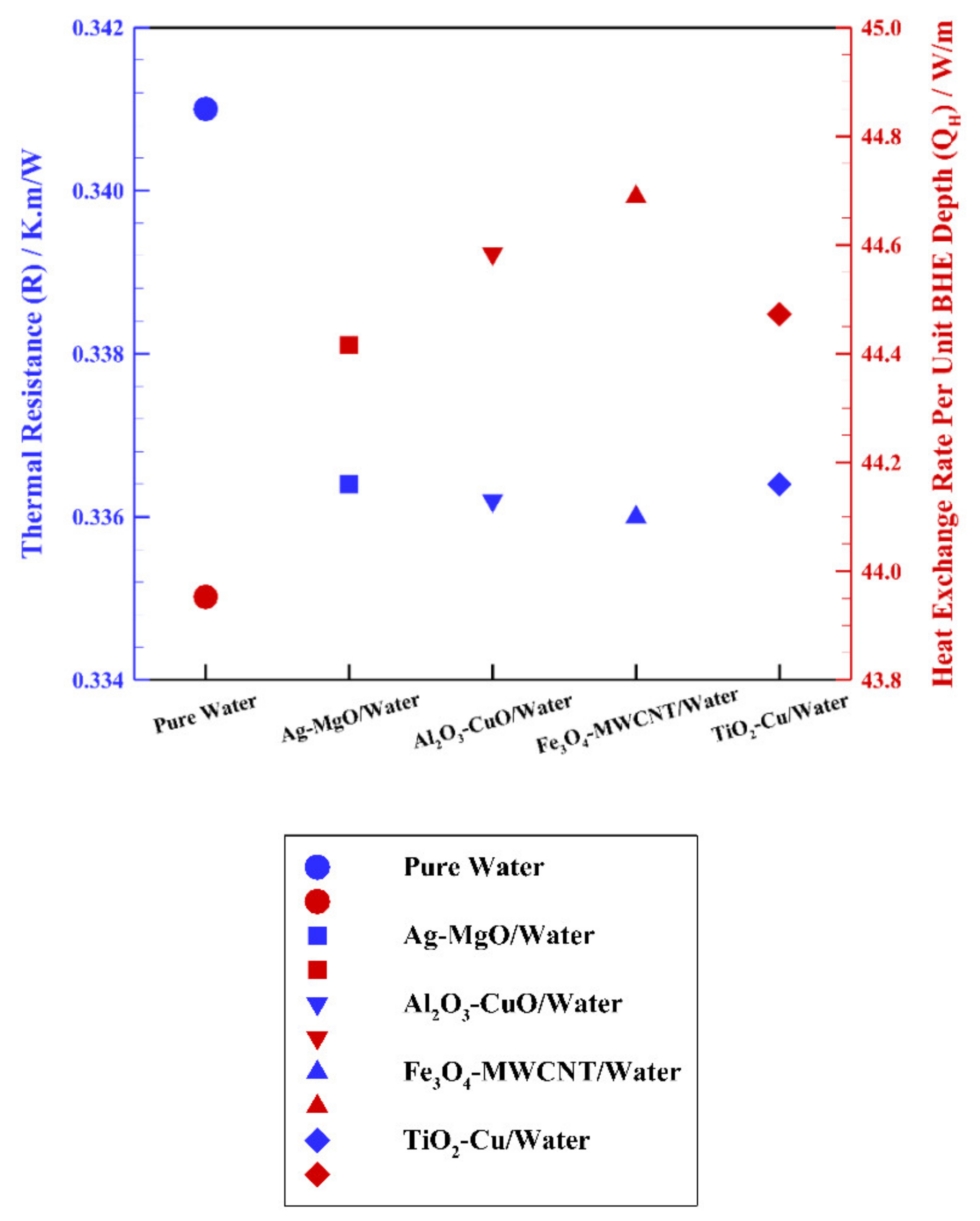

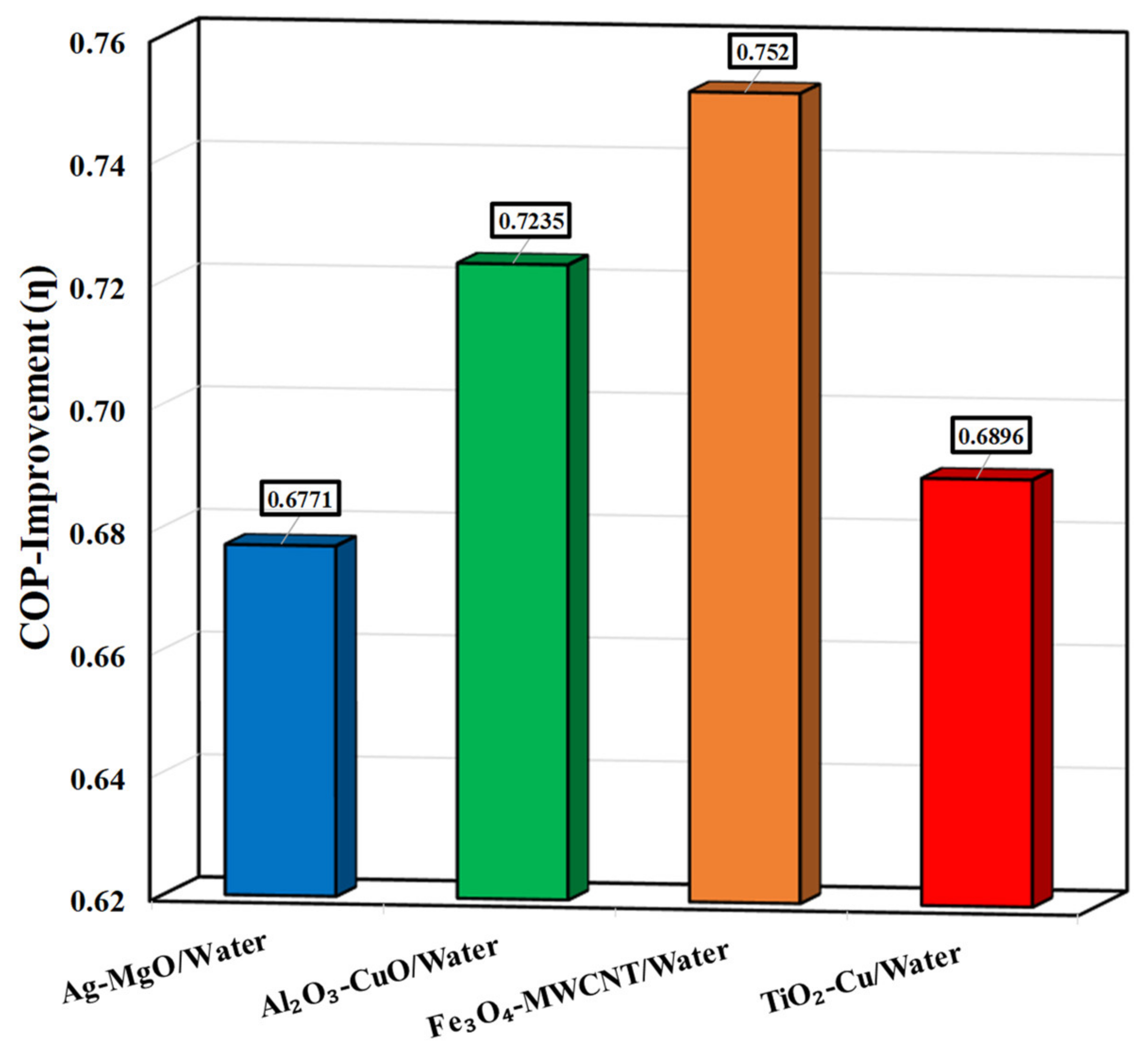

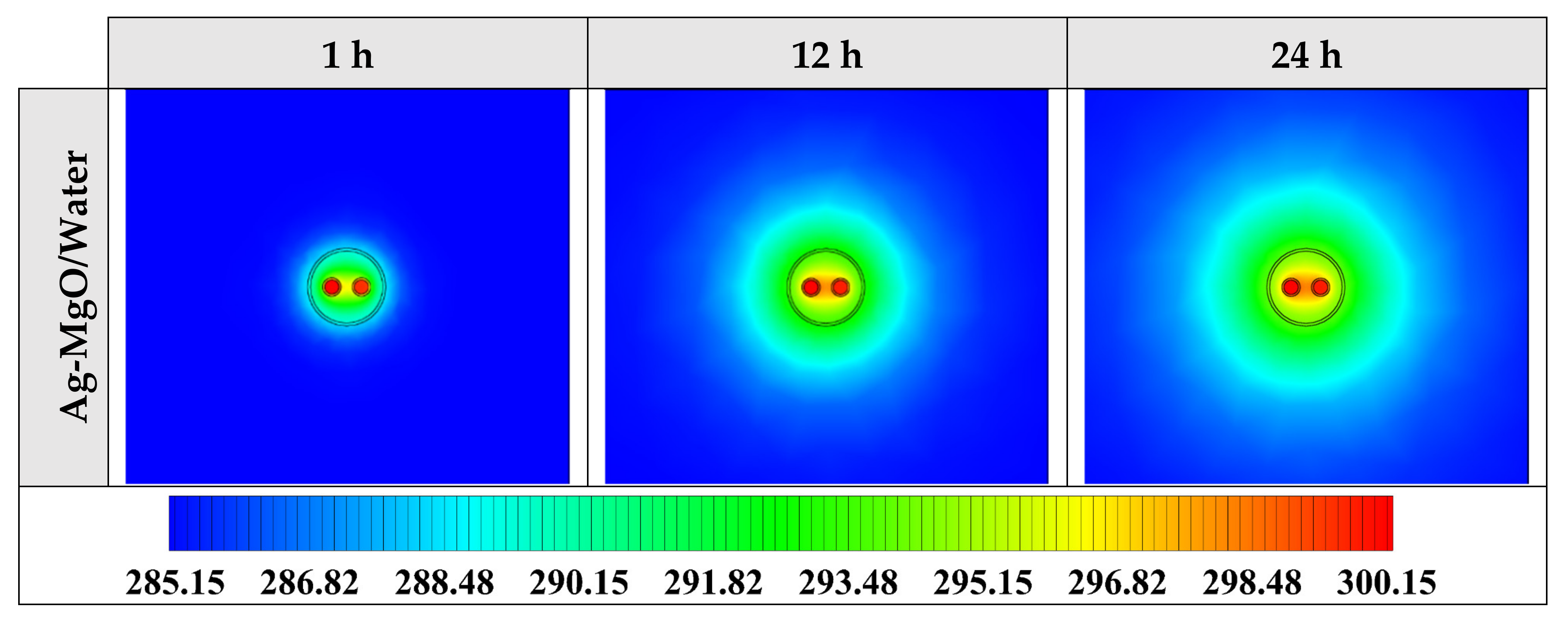

5.1. Comparing Various Types of Hybrid Nanofluid

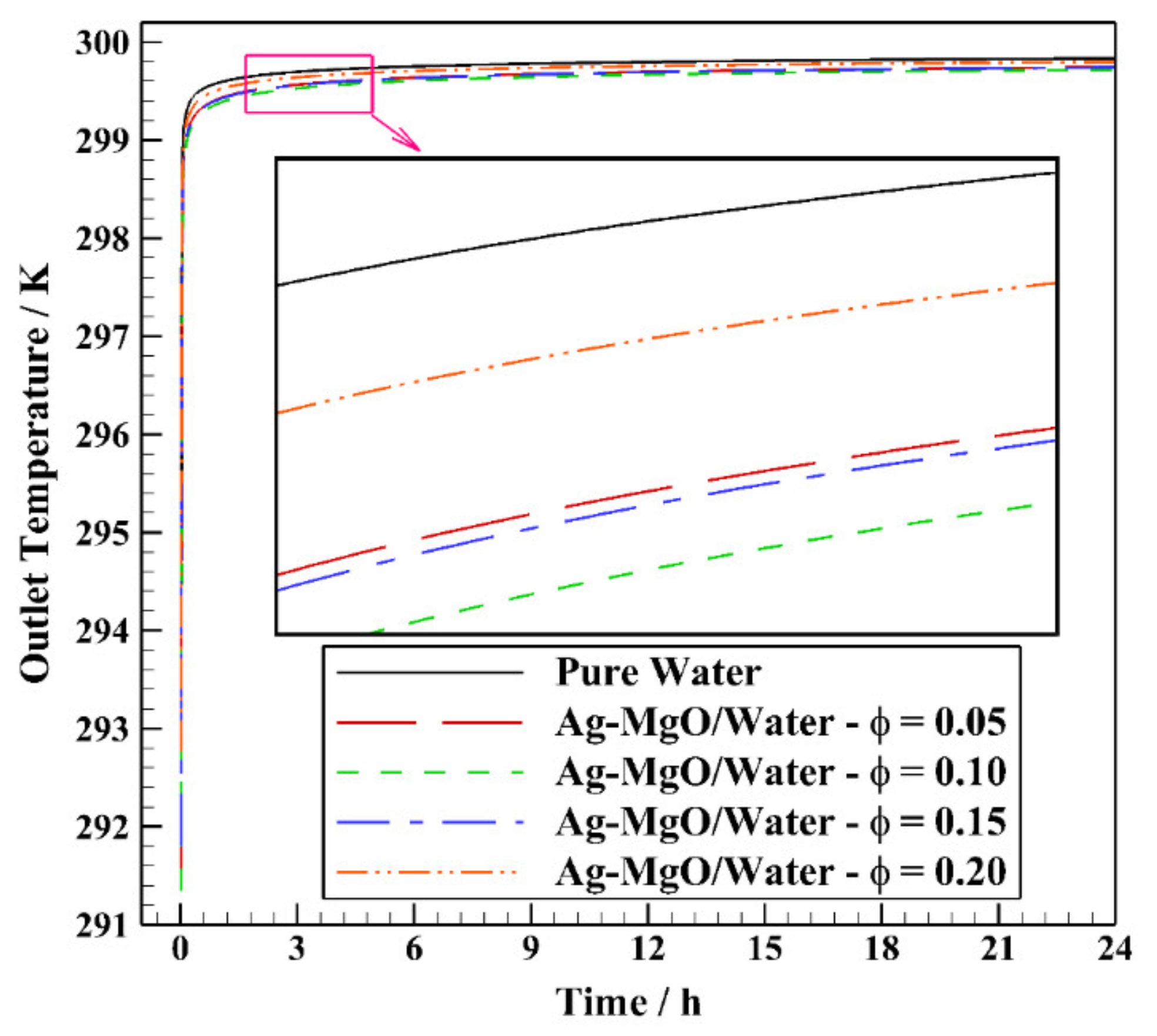

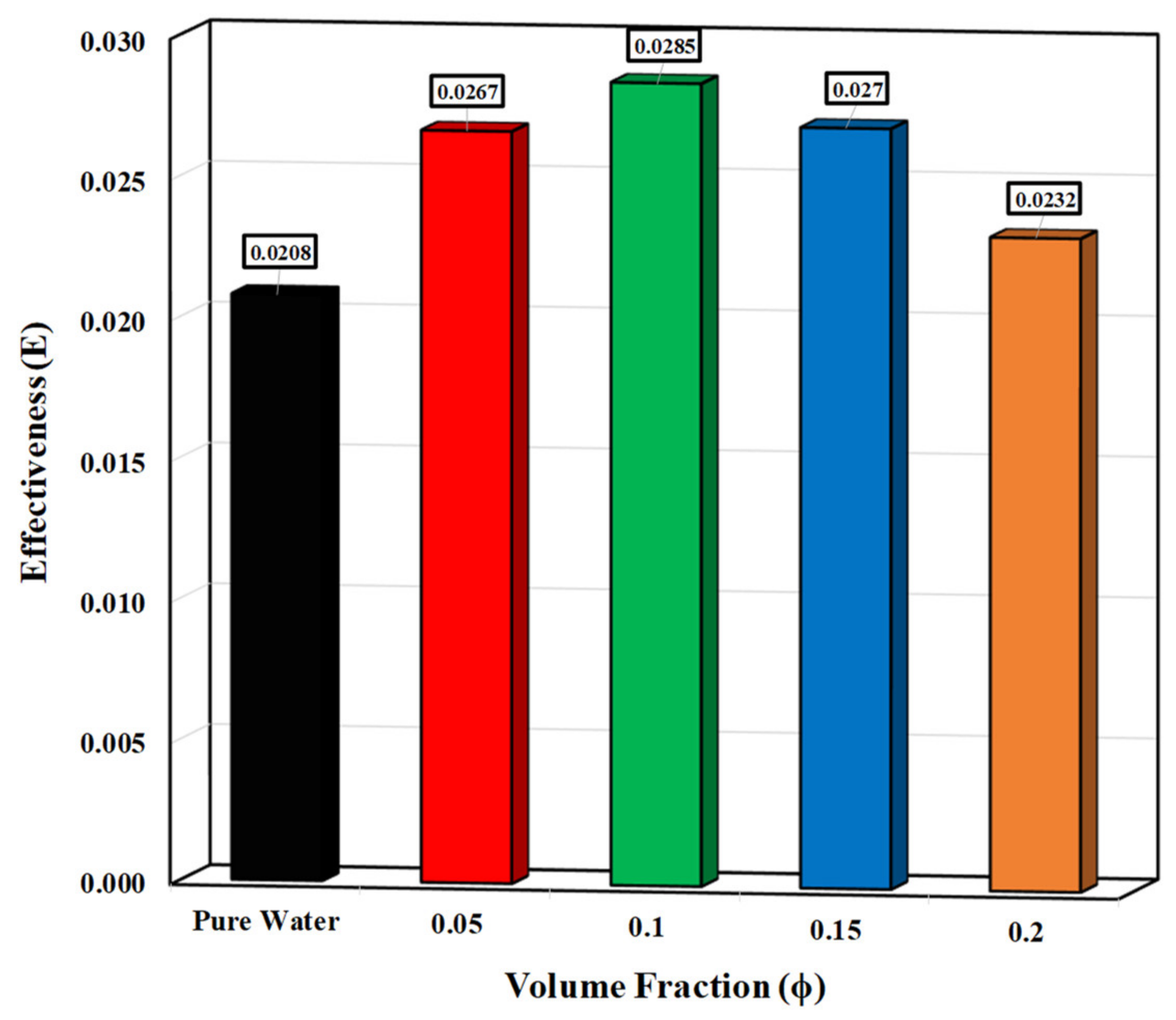

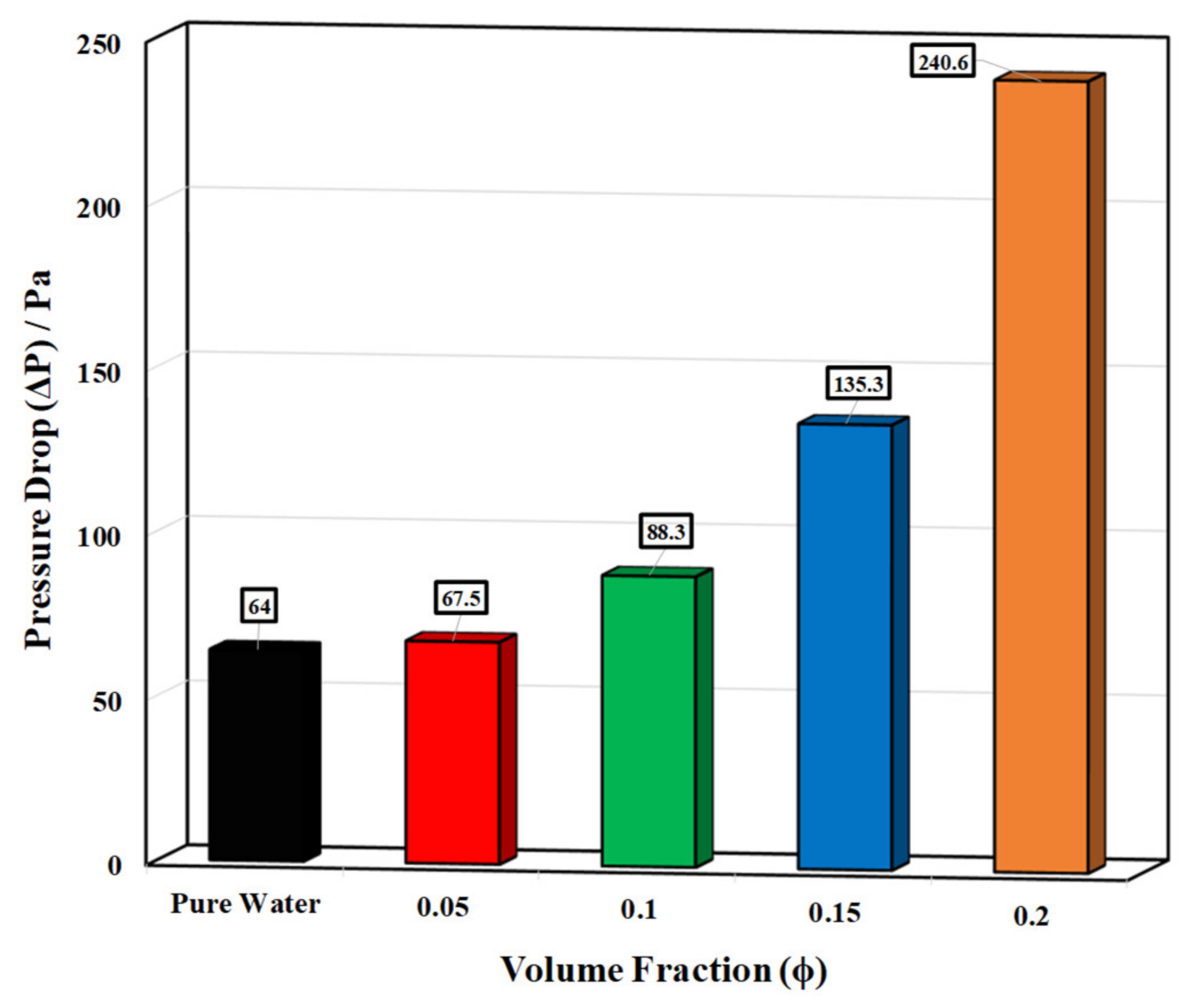

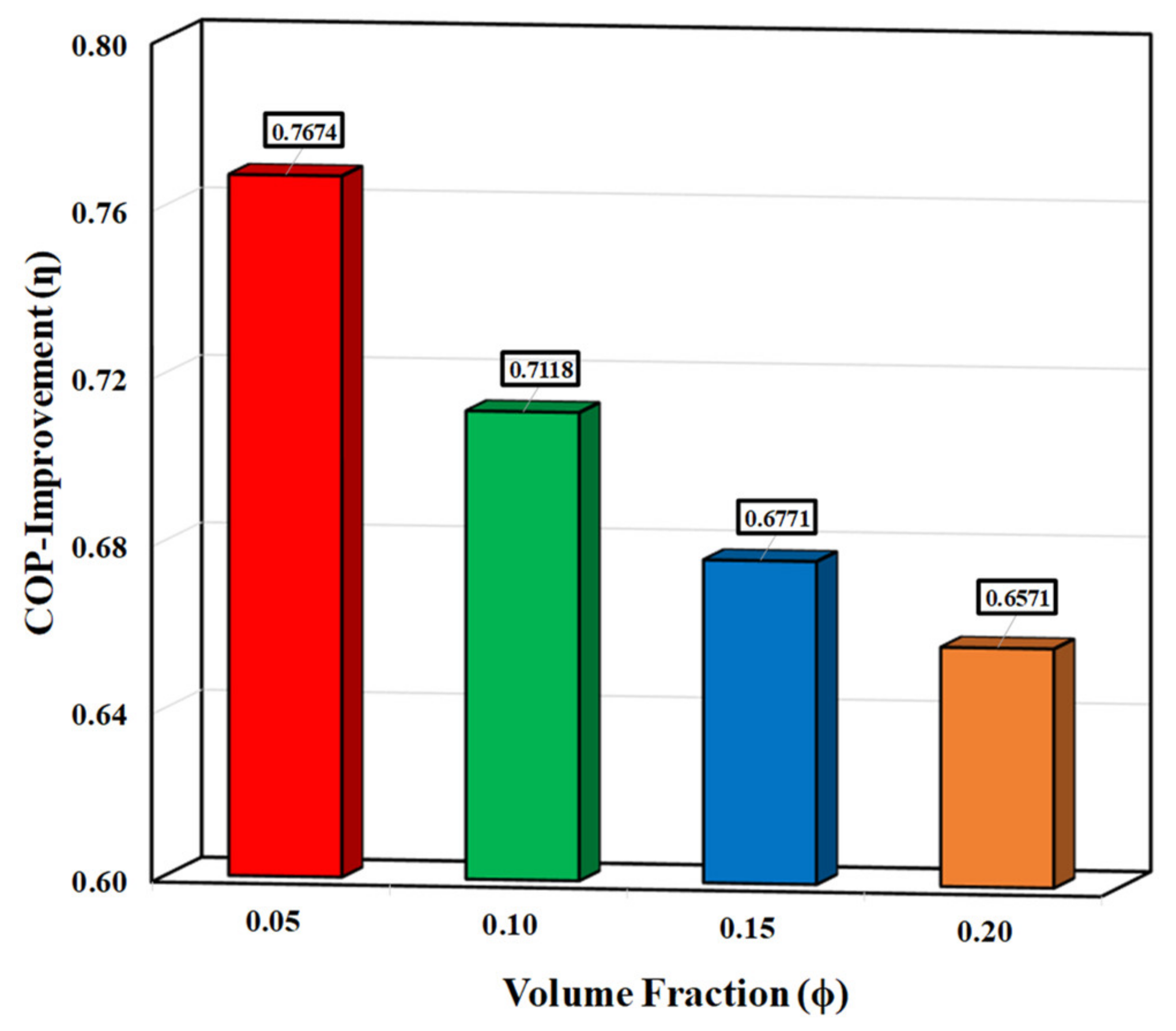

5.2. Impact of Volume Fraction of Hybrid Nanofluid

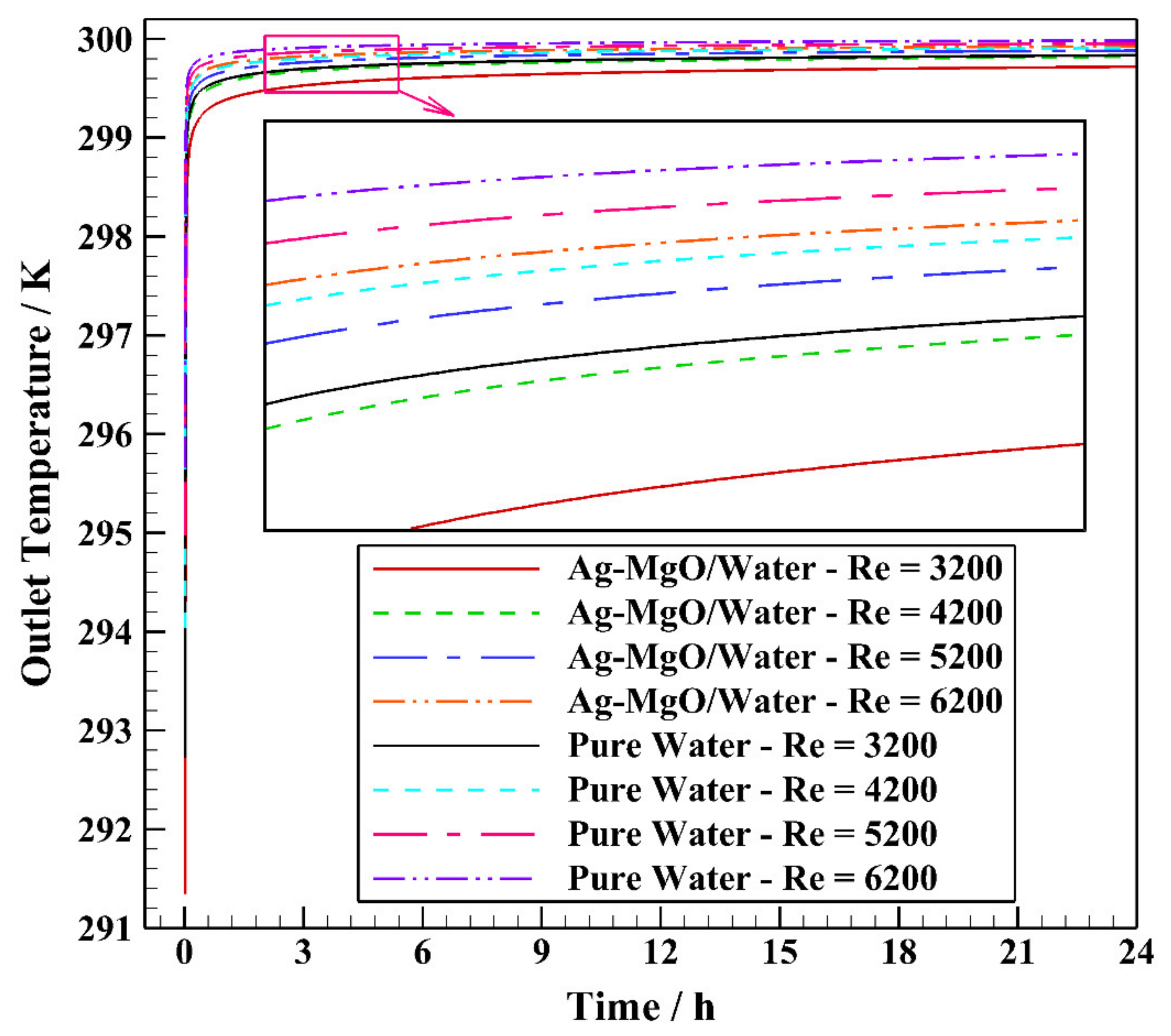

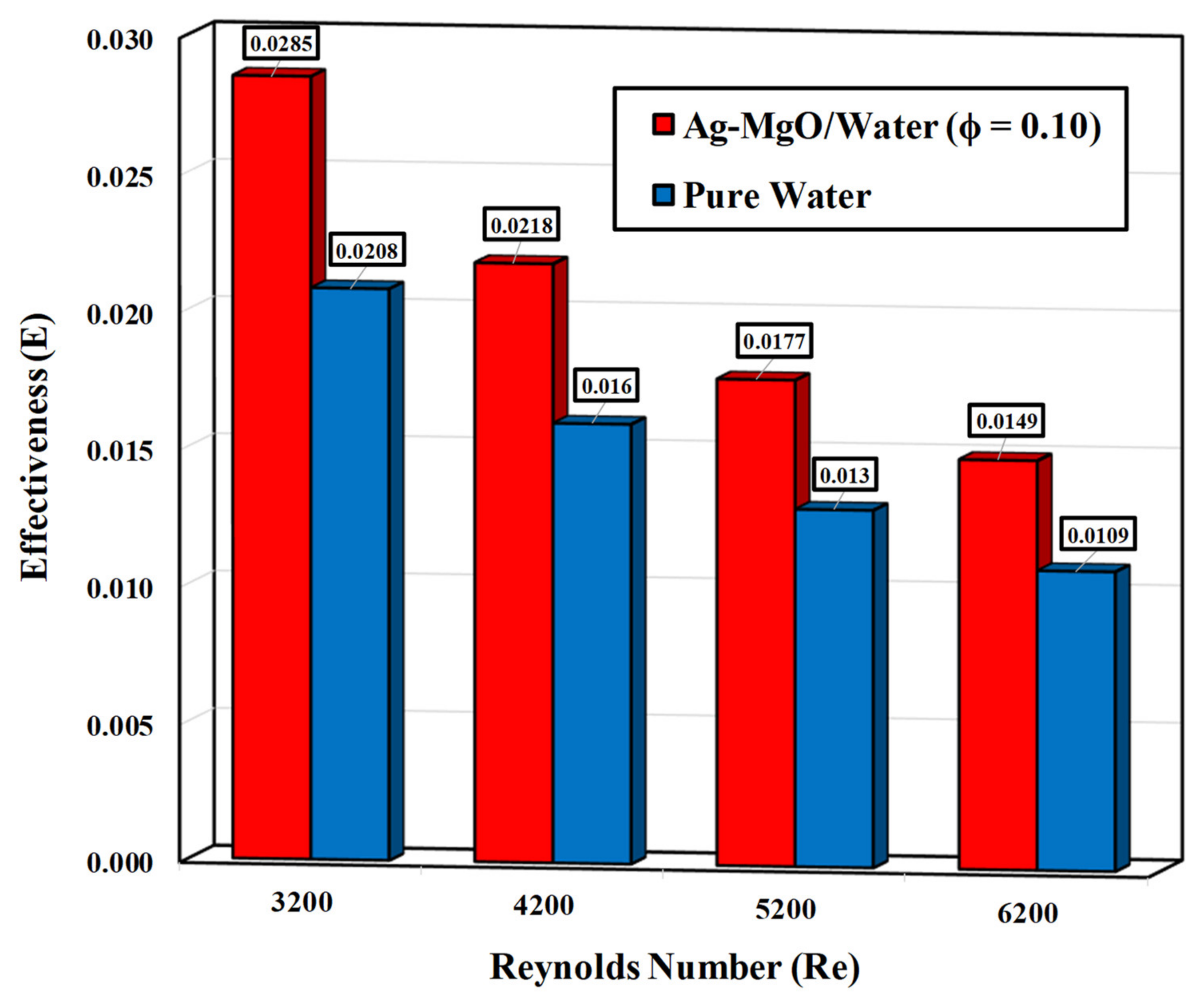

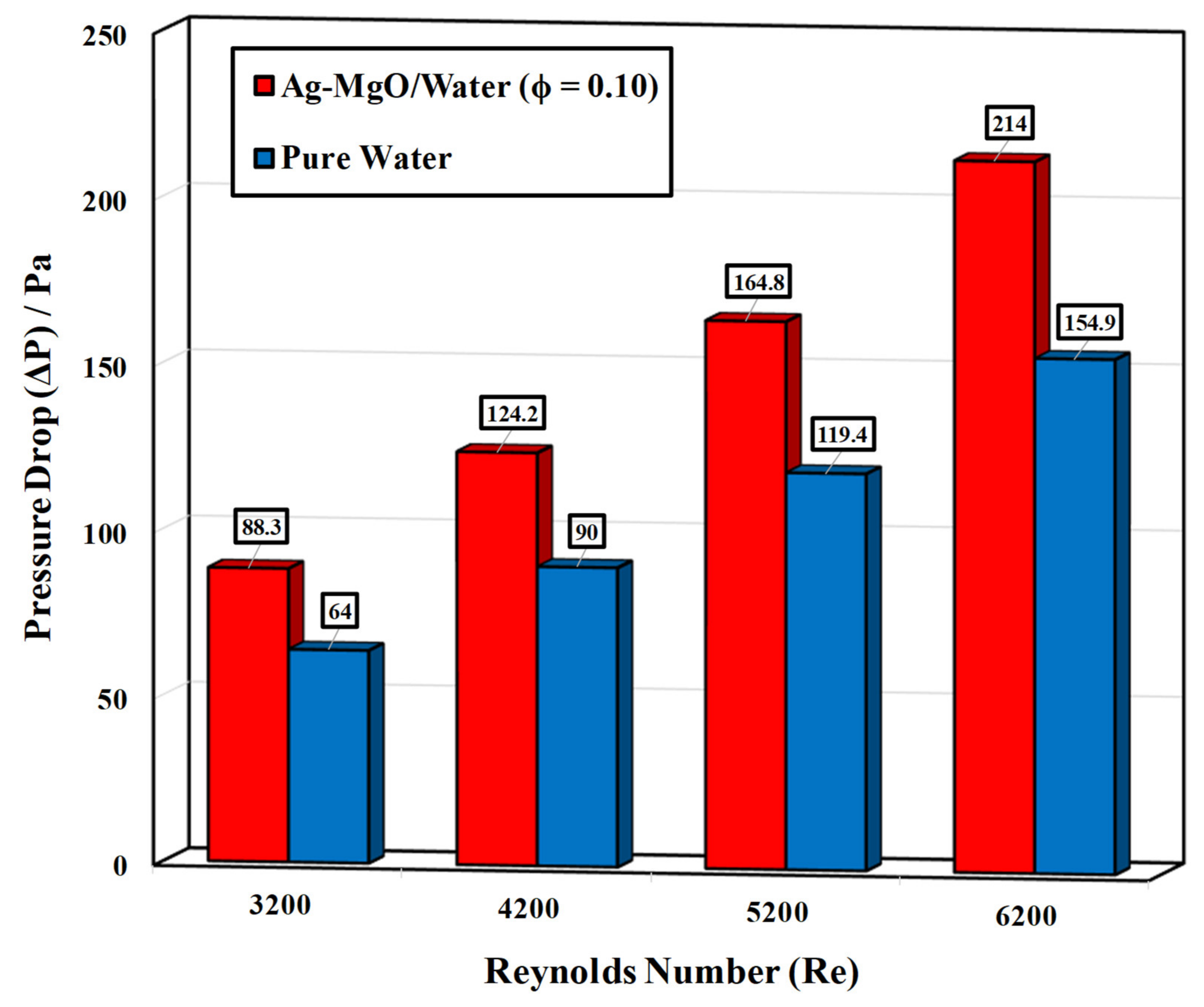

5.3. Impact of Reynolds Number of Hybrid Nanofluid

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Cp | Specific heat (J·kg−1·K−1) |

| E | Effectiveness |

| Gravitational acceleration (m·s−2) | |

| H | Borehole depth (m) |

| k | Thermal conductivity (W·m−1·K−1) |

| Mass flow rate (kg·s−1) | |

| Nu | Nusselt number |

| dh | Hydraulic diameter (m) |

| Q | Heat exchange rate (W) |

| R | Thermal resistance (K·m·W−1) |

| h | Heat transfer coefficient (W·m−2·K−1) |

| Source term of momentum equation | |

| τ | Time (s) |

| T | Temperature (K) |

| Velocity vector (m·s−1) | |

| u | Velocity (m·s−1) |

| l | Length of the U-tube (m) |

| Greek Symbols | |

| β | Thermal expansion coefficient (K−1) |

| ΔP | Pressure drop (Pa) |

| μ | Dynamic viscosity (Pa·s) |

| ρ | Density (kg·m−3) |

| ϕ | Volume fraction of nanoparticle |

| η | Coefficient of performance-improvement factor |

| f | Friction factor |

| Subscripts | |

| HNF | Hybrid nanofluid |

| NP | Nanoparticle |

| BF | Base fluid |

| s | Soil |

| a | Average |

| MAX | Maximum |

| 0 | Reference |

Abbreviations

| GSHP | Ground source heat pump |

| GHE | Ground heat exchanger |

| BHE | Borehole heat exchanger |

| MWCNT | Multi-wall carbon nanotube |

| COP | Coefficient of performance |

References

- Tsagarakis, K.P.; Efthymiou, L.; Michopoulos, A.; Mavragani, A.; Anđelković, A.S.; Antolini, F.; Bacic, M.; Bajare, D.; Baralis, M.; Bogusz, W.; et al. A review of the legal framework in shallow geothermal energy in selected European countries: Need for guidelines. Renew. Energy 2020, 147, 2556–2571. [Google Scholar] [CrossRef]

- Javadi, H.; Ajarostaghi, S.S.M.; Rosen, M.A.; Pourfallah, M. Performance of ground heat exchangers: A comprehensive review of recent advances. Energy 2019, 178, 207–233. [Google Scholar] [CrossRef]

- Philippe, M.; Bernier, M.; Marchio, D. Vertical geothermal borefields. Ashrae J. 2010, 52, 20–27. [Google Scholar]

- Fossa, M.; Rolando, D. Improving the Ashrae method for vertical geothermal borefield design. Energy Build. 2015, 93, 315–323. [Google Scholar] [CrossRef]

- Cullin, J.R.; Spitler, J.D.; Montagud, C.; Ruiz-Calvo, F.; Rees, S.J.; Naicker, S.S.; Konečný, P.; Southard, L.E. Validation of vertical ground heat exchanger design methodologies. Sci. Technol. Built Environ. 2015, 21, 137–149. [Google Scholar] [CrossRef]

- Rolando, D.; José, A.; Marco, F. A Web Application for Geothermal Borefield Design. In Proceedings of the World Geothermal Congress, Melbourne, Australia, 19–25 April 2015. [Google Scholar]

- Spitler, J.D.; Bernier, M. Vertical borehole ground heat exchanger design methods. In Advances in Ground-Source Heat Pump Systems; Woodhead Publishing: Cambridge, UK, 2016; pp. 29–61. [Google Scholar]

- Fossa, M.; Rolando, D. Improved Ashrae method for BHE field design at 10 year horizon. Energy Build. 2016, 116, 114–121. [Google Scholar] [CrossRef]

- Staiti, M.; Angelotti, A. Design of Borehole Heat Exchangers for Ground Source Heat Pumps: A Comparison between Two Methods. Energy Procedia 2015, 78, 1147–1152. [Google Scholar] [CrossRef]

- Fossa, M.; Davide, R.; Antonella, P. Investigation on the Effects of Different Time Resolutions in the Design and Simulation of BHE Fields. In Proceedings of the IGSHPA Technical/Research Conference and Expo, Denver, CO, USA, 14–16 March 2017. [Google Scholar]

- Capozza, A.; De Carli, M.; Zarrella, A. Design of borehole heat exchangers for ground-source heat pumps: A literature review, methodology comparison and analysis on the penalty temperature. Energy Build. 2012, 55, 369–379. [Google Scholar] [CrossRef]

- Fossa, M. Correct design of vertical borehole heat exchanger systems through the improvement of the ASHRAE method. Sci. Technol. Built Environ. 2017, 23, 1080–1089. [Google Scholar] [CrossRef]

- Ahmadfard, M.; Michel, B. Modifications to ASHRAE’s sizing method for vertical ground heat exchangers. Sci. Technol. Built Environ. 2018, 24, 803–817. [Google Scholar] [CrossRef]

- Fossa, M. The temperature penalty approach to the design of borehole heat exchangers for heat pump applications. Energy Build. 2011, 43, 1473–1479. [Google Scholar] [CrossRef]

- Badenes, B.; Burkhard, S.; Pla, M.Á.M.; Cuevas, J.M.; Bartoli, F.; Ciardelli, F.; González, R.M.; Ghafar, A.N.; Fontana, P.; Zuñiga, L.L.; et al. Development of advanced materials guided by numerical simulations to improve performance and cost-efficiency of borehole heat exchangers (BHEs). Energy 2020, 201, 117628. [Google Scholar] [CrossRef]

- Garbin, E.; Ludovico, M.; Eloisa, D.S.; Gilberto, A.; Javier, F.U.; Dimitris, M.; David, B.; Jacques, V.; Riccardo, P.; Adriana, B.; et al. Assessing Grouting Mix Thermo-Physical Properties for Shallow Geothermal Systems. In Proceedings of the 22nd EGU General Assembly Conference, Online. 4–8 May 2020. [Google Scholar]

- Javadi, H.; Ajarostaghi, S.S.M.; Rosen, M.A.; Pourfallah, M. A Comprehensive Review of Backfill Materials and Their Effects on Ground Heat Exchanger Performance. Sustainability 2018, 10, 4486. [Google Scholar] [CrossRef]

- Javadi, H.; Ajarostaghi, S.S.M.; Pourfallah, M.; Zaboli, M. Performance analysis of helical ground heat exchangers with different configurations. Appl. Therm. Eng. 2019, 154, 24–36. [Google Scholar] [CrossRef]

- Javadi, H.; Ajarostaghi, S.S.M.; Mousavi, S.S.; Pourfallah, M. Thermal analysis of a triple helix ground heat exchanger using numerical simulation and multiple linear regression. Geothermics 2019, 81, 53–73. [Google Scholar] [CrossRef]

- Javadi, H.; Urchueguia, J.F.; Ajarostaghi, S.S.M.; Badenes, B. Numerical Study on the Thermal Performance of a Single U-Tube Borehole Heat Exchanger Using Nano-Enhanced Phase Change Materials. Energies 2020, 13, 5156. [Google Scholar] [CrossRef]

- Bobbo, S.; Laura, C.; Antonella, B.; Stefano, R.; Laura, F. Characterization of Nanofluids Formed by Fumed Al2O3 in Water for Geothermal Applications. In Proceedings of the 16th International Refrigeration and Air Conditioning Conference, West Lafayette, IN, USA, 11–14 July 2016. [Google Scholar]

- Narei, H.; Ghasempour, R.; Noorollahi, Y. The effect of employing nanofluid on reducing the bore length of a vertical ground-source heat pump. Energy Convers. Manag. 2016, 123, 581–591. [Google Scholar] [CrossRef]

- Daneshipour, M.; Rafee, R. Nanofluids as the circuit fluids of the geothermal borehole heat exchangers. Int. Commun. Heat Mass Transf. 2017, 81, 34–41. [Google Scholar] [CrossRef]

- Sui, D.; Langåker, V.H.; Yu, Z. Investigation of thermophysical properties of Nanofluids for application in geothermal energy. Energy Procedia 2017, 105, 5055–5060. [Google Scholar] [CrossRef]

- Diglio, G.; Roselli, C.; Sasso, M.; Channabasappa, U.J. Borehole heat exchanger with nanofluids as heat carrier. Geothermics 2018, 72, 112–123. [Google Scholar] [CrossRef]

- Sun, X.-H.; Yan, H.; Massoudi, M.; Chen, Z.-H.; Wu, W.-T. Numerical Simulation of Nanofluid Suspensions in a Geothermal Heat Exchanger. Energies 2018, 11, 919. [Google Scholar] [CrossRef]

- Peng, Y.; Yong, W.; Ruiqing, D. The Effect of Nanofluid to Vertical Single U-Tube Ground Heat Exchanger. In Proceedings of the 4th Building Simulation and Optimization Conference, Cambridge, UK, 11–12 September 2018. [Google Scholar]

- Mishra, S.; Sikata, S.; Das, D.K. Theoretical analysis on application of nanofluids in ground source heat pumps for building cooling. Int. J. Recent Technol. Mech. Electr. Eng. 2018, 5, 28–37. [Google Scholar]

- Du, R.; Jiang, D.; Wang, Y.; Shah, K.W. An experimental investigation of CuO/water nanofluid heat transfer in geothermal heat exchanger. Energy Build. 2020, 227, 110402. [Google Scholar] [CrossRef]

- Du, R.; Jiang, D.; Wang, Y. Numerical Investigation of the Effect of Nanoparticle Diameter and Sphericity on the Thermal Performance of Geothermal Heat Exchanger Using Nanofluid as Heat Transfer Fluid. Energies 2020, 13, 1653. [Google Scholar] [CrossRef]

- Sarkar, J.; Ghosh, P.; Adil, A. A review on hybrid nanofluids: Recent research, development and applications. Renew. Sustain. Energy Rev. 2015, 43, 164–177. [Google Scholar] [CrossRef]

- Leong, K.; Ahmad, K.K.; Ong, H.C.; Ghazali, M.; Baharum, A. Synthesis and thermal conductivity characteristic of hybrid nanofluids-A review. Renew. Sustain. Energy Rev. 2017, 75, 868–878. [Google Scholar] [CrossRef]

- Hamzah, M.H.; Sidik, N.A.C.; Ken, T.L.; Mamat, R.; Najafi, G. Factors affecting the performance of hybrid nanofluids: A comprehensive review. Int. J. Heat Mass Transf. 2017, 115, 630–646. [Google Scholar] [CrossRef]

- Minea, A.A. Challenges in hybrid nanofluids behavior in turbulent flow: Recent research and numerical comparison. Renew. Sustain. Energy Rev. 2017, 71, 426–434. [Google Scholar] [CrossRef]

- Gupta, M.; Singh, V.; Kumar, S.; Kumar, S.; Dilbaghi, N.; Said, Z. Up to date review on the synthesis and thermophysical properties of hybrid nanofluids. J. Clean. Prod. 2018, 190, 169–192. [Google Scholar] [CrossRef]

- Sajid, M.U.; Hafiz, M.A. Thermal conductivity of hybrid nanofluids: A critical review. Int. J. Heat Mass Transf. 2018, 126, 211–234. [Google Scholar] [CrossRef]

- Kumar, D.D.; Arasu, A.V. A comprehensive review of preparation, characterization, properties and stability of hybrid nanofluids. Renew. Sustain. Energy Rev. 2018, 81, 1669–1689. [Google Scholar] [CrossRef]

- Suresh, S.; Venkitaraj, K.P.; Selvakumar, P.; Chandrasekar, M. Effect of Al2O3–Cu/water hybrid nanofluid in heat transfer. Exp. Therm. Fluid Sci. 2012, 38, 54–60. [Google Scholar] [CrossRef]

- Labib, M.N.; Nine, J.; Afrianto, H.; Chung, H.; Jeong, H. Numerical investigation on effect of base fluids and hybrid nanofluid in forced convective heat transfer. Int. J. Therm. Sci. 2013, 71, 163–171. [Google Scholar] [CrossRef]

- Takabi, B.; Salehi, S. Augmentation of the Heat Transfer Performance of a Sinusoidal Corrugated Enclosure by Employing Hybrid Nanofluid. Adv. Mech. Eng. 2014, 6, 147059. [Google Scholar] [CrossRef]

- Sundar, L.S.; Singh, M.K.; Sousa, A.C. Enhanced heat transfer and friction factor of MWCNT–Fe3O4/water hybrid nanofluids. Int. Commun. Heat Mass Transf. 2014, 52, 73–83. [Google Scholar] [CrossRef]

- Madhesh, D.; Parameshwaran, R.; Kalaiselvam, S. Experimental investigation on convective heat transfer and rheological characteristics of Cu–TiO2 hybrid nanofluids. Exp. Therm. Fluid Sci. 2014, 52, 104–115. [Google Scholar] [CrossRef]

- Yarmand, H.; Gharehkhani, S.; Ahmadi, G.; Shirazi, S.F.S.; Baradaran, S.; Montazer, E.; Zubir, M.N.M.; Alehashem, M.S.; Kazi, S.; Dahari, M. Graphene nanoplatelets–Silver hybrid nanofluids for enhanced heat transfer. Energy Convers. Manag. 2015, 100, 419–428. [Google Scholar] [CrossRef]

- Esfe, M.H.; Arani, A.A.A.; Rezaie, M.; Yan, W.M.; Karimipour, A. Experimental determination of thermal conductivity and dynamic viscosity of Ag–MgO/water hybrid nanofluid. Int. Commun. Heat Mass Transf. 2015, 66, 189–195. [Google Scholar] [CrossRef]

- Toghraie, D.; Chaharsoghi, V.A.; Afrand, M. Measurement of thermal conductivity of ZnO–TiO2/EG hybrid nanofluid. J. Therm. Anal. Calorim. 2016, 125, 527–535. [Google Scholar] [CrossRef]

- Van Trinh, P.; Anh, N.N.; Thang, B.H.; Hong, N.T.; Hong, N.M.; Khoi, P.H.; Minh, P.N.; Hong, P.N. Enhanced thermal conductivity of nanofluid-based ethylene glycol containing Cu nanoparticles decorated on a Gr–MWCNT hybrid material. R. Soc. Chem. Adv. 2017, 6, 318–326. [Google Scholar] [CrossRef]

- Sundar, L.S.; Singh, M.K.; Ferro, M.; Sousa, A.C. Experimental investigation of the thermal transport properties of graphene oxide/Co3O4 hybrid nanofluids. Int. Commun. Heat Mass Transf. 2017, 84, 1–10. [Google Scholar] [CrossRef]

- Sahoo, R.R.; Sarkar, J. Heat transfer performance characteristics of hybrid nanofluids as coolant in louvered fin automotive radiator. Heat Mass Transf. 2016, 53, 1923–1931. [Google Scholar] [CrossRef]

- Ajarostaghi, S.S.M.; Zaboli, M.; Nourbakhsh, M. Numerical evaluation of turbulence heat transfer and fluid flow of hybrid nanofluids in a pipe with innovative vortex generator. J. Therm. Anal. Calorim. 2020, 143, 1–15. [Google Scholar]

- Karouei, S.H.H.; Ajarostaghi, S.S.M.; Gorji-Bandpy, M.; Fard, S.R.H. Laminar heat transfer and fluid flow of two various hybrid nanofluids in a helical double-pipe heat exchanger equipped with an innovative curved conical turbulator. J. Therm. Anal. Calorim. 2021, 143, 1455–1466. [Google Scholar] [CrossRef]

- Ajarostaghi, S.S.M.; Shirzad, M.; Rashidi, S.; Li, L.K.B. Heat transfer performance of a nanofluid-filled tube with wall corrugations and center-cleared twisted-tape inserts energy sources, part A recover. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 1–21. [Google Scholar] [CrossRef]

- Hamedani, F.A.; Ajarostaghi, S.S.M.; Hosseini, S.A. Numerical evaluation of the effect of geometrical and operational parameters on thermal performance of nanofluid flow in convergent–divergent tube. J. Therm. Anal. Calorim. 2020, 140, 1483–1505. [Google Scholar] [CrossRef]

- Noorbakhsh, M.; Ajarostaghi, S.S.M.; Zaboli, M.; Kiani, B. Thermal analysis of nanofluids flow in a double pipe heat exchanger with twisted tapes insert in both sides. J. Therm. Anal. Calorim. 2021, 1–12. [Google Scholar] [CrossRef]

- Khodadadi, J.M.; Fan, L. Expedited freezing of nanoparticle-enhanced phase change materials (NEPCM) exhibited through a simple 1-D stefan problem formulation. In Proceedings of the Heat Transfer Summer Conference, San Francisco, CA, USA, 19–23 July 2009. [Google Scholar]

- Hassan, M.; Marin, M.; Ellahi, R.; Alamri, S.Z. Exploration of convective heat transfer and flow characteristics synthesis by Cu–Ag/water hybrid-nanofluids. Heat Transf. Res. 2018, 49, 1837–1848. [Google Scholar] [CrossRef]

- Jalaluddin, J.; Miyara, A. Thermal performance and pressure drop of spiral-tube ground heat exchangers for ground-source heat pump. Appl. Therm. Eng. 2015, 90, 630–637. [Google Scholar] [CrossRef]

- Jalaluddin, J.; Miyara, A.; Tsubaki, K.; Inoue, S.; Yoshida, K. Experimental study of several types of ground heat exchanger using a steel pile foundation. Renew. Energy 2011, 36, 764–771. [Google Scholar] [CrossRef]

- Kadirgama, K.; Anamalai, K.; Ramachandran, K.; Ramasamy, D.; Samykano, M.; Kottasamy, A.; Rahman, M.M. Thermal analysis of SUS 304 stainless steel using ethylene glycol/nanocellulose-based nanofluid coolant. Int. J. Adv. Manuf. Technol. 2018, 97, 2061–2076. [Google Scholar] [CrossRef]

- Safiei, W.; Rahman, M.M.; Yusoff, A.R.; Radin, M.R. Preparation, stability and wettability of nanofluid: A review. J. Mech. Eng. Sci. 2020, 14, 7244–7257. [Google Scholar] [CrossRef]

- Urmi, W.T.; Shafiqah, A.; Rahman, M.; Kadirgama, K.; Maleque, A. Preparation Methods and Challenges of Hybrid Nanofluids: A Review. J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 78, 56–66. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Soil Diameter, D5 | 2 m |

| Casing Outer Diameter, D4 | 0.1398 m |

| Casing Inner Diameter, D3 | 0.1298 m |

| U-tube Outer Diameter, D2 | 0.033 m |

| U-tube Inner Diameter, D1 | 0.026 m |

| Clay Length, L1 | 1.5 m |

| Sandy-Clay Length, L2 | 1.5 m |

| Borehole Depth, H | 2 m |

| U-tube Length | 2 m |

| Leg Spacing of U-tube, X | 0.02 m |

| Inlet Temperature | 300.15 K |

| Operating Duration | 24 h |

| Operating Mode | Cooling |

| Hybrid Nanofluids | Ag-MgO (50:50 vol.%)/Water TiO2-Cu (50:50 vol.%)/Water Al2O3-CuO (50:50 vol.%)/Water Fe3O4-MWCNT (50:50 vol.%)/Water |

| Volume Fractions of Nanoparticles | 0.05, 0.10, 0.15, 0.20 |

| Reynolds Numbers | 3200, 4200, 5200, 6200 |

| Parameters | Value |

|---|---|

| Polyethylene (PE) | |

| Density (kg/m3) | 920 |

| Specific Heat Capacity (J/kg·K) | 2300 |

| Thermal Conductivity (W/m·K) | 0.35 |

| Steel | |

| Density (kg/m3) | 8030 |

| Specific Heat Capacity (J/kg·K) | 502.48 |

| Thermal Conductivity (W/m·K) | 16.27 |

| Silica Sand | |

| Density (kg/m3) | 2210 |

| Specific Heat Capacity (J/kg·K) | 750 |

| Thermal Conductivity (W/m·K) | 1.4 |

| Clay | |

| Density (kg/m3) | 1700 |

| Specific Heat Capacity (J/kg·K) | 1800 |

| Thermal Conductivity (W/m·K) | 1.2 |

| Sandy-Clay | |

| Density (kg/m3) | 1960 |

| Specific Heat Capacity (J/kg·K) | 1200 |

| Thermal Conductivity (W/m·K) | 2.1 |

| Property | Base Fluid | Nanoparticles | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Water | Cu [54] | CuO [54] | Al2O3 [54] | TiO2 [54] | Fe3O4 [41] | MWCNT [41] | Ag [44] | MgO [44] | |

| Density (kg/m3) | 998.2 | 8933 | 6510 | 3880 | 4175 | 5180 | 1600 | 10,500 | 3580 |

| Specific Heat Capacity (J/kg·K) | 4182 | 385 | 540 | 792 | 692 | 670 | 796 | 235 | 874 |

| Thermal Conductivity (W/m·K) | 0.6 | 401 | 18 | 42.34 | 8.4 | 9.7 | 3000 | 429 | 55 |

| Viscosity (Pa·s) | 0.001003 | - | - | - | - | - | - | - | - |

| Property | Hybrid Nanofluids | |||

|---|---|---|---|---|

| Ag-MgO (50:50 vol.%)/Water | TiO2-Cu (50:50 vol.%)/Water | Al2O3-CuO (50:50 vol.%)/Water | Fe3O4-MWCNT (50:50 vol.%)/Water | |

| Density (kg/m3) | 2810.74 | 2664.94 | 2257.24 | 1715.74 |

| Specific Heat Capacity (J/kg·K) | 1338.2930 | 1452.7067 | 1732.3743 | 2117.8970 |

| Thermal Conductivity (W/m·K) | 2.2769 | 2.2753 | 2.2183 | 2.2842 |

| Viscosity (Pa·s) | 0.0024 | 0.0024 | 0.0024 | 0.0024 |

| Property | Volume Fractions | |||

|---|---|---|---|---|

| ϕ = 0.05 | ϕ = 0.10 | ϕ = 0.15 | ϕ = 0.20 | |

| Density (kg/m3) | 1602.38 | 2206.56 | 2810.74 | 3414.92 |

| Specific Heat Capacity (J/kg·K) | 2519.2814 | 1767.1035 | 1338.2930 | 1061.2159 |

| Thermal Conductivity (W/m·K) | 1.3313 | 1.7452 | 2.2769 | 2.9852 |

| Viscosity (Pa·s) | 0.0013 | 0.0017 | 0.0024 | 0.0035 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Javadi, H.; Urchueguia, J.F.; Mousavi Ajarostaghi, S.S.; Badenes, B. Impact of Employing Hybrid Nanofluids as Heat Carrier Fluid on the Thermal Performance of a Borehole Heat Exchanger. Energies 2021, 14, 2892. https://doi.org/10.3390/en14102892

Javadi H, Urchueguia JF, Mousavi Ajarostaghi SS, Badenes B. Impact of Employing Hybrid Nanofluids as Heat Carrier Fluid on the Thermal Performance of a Borehole Heat Exchanger. Energies. 2021; 14(10):2892. https://doi.org/10.3390/en14102892

Chicago/Turabian StyleJavadi, Hossein, Javier F. Urchueguia, Seyed Soheil Mousavi Ajarostaghi, and Borja Badenes. 2021. "Impact of Employing Hybrid Nanofluids as Heat Carrier Fluid on the Thermal Performance of a Borehole Heat Exchanger" Energies 14, no. 10: 2892. https://doi.org/10.3390/en14102892

APA StyleJavadi, H., Urchueguia, J. F., Mousavi Ajarostaghi, S. S., & Badenes, B. (2021). Impact of Employing Hybrid Nanofluids as Heat Carrier Fluid on the Thermal Performance of a Borehole Heat Exchanger. Energies, 14(10), 2892. https://doi.org/10.3390/en14102892