1. Introduction

Solar energy is the most important renewable energy source and could represent 13–15% of the total energy mix in the year 2035 [

1,

2], due to the progress of photovoltaic (PV) technologies and the increasing scarcity of non-renewable sources. Solar energy-based projects offer a wide range of possibilities for both standalone and combined applications [

3,

4].

The evolution of photovoltaic panels has made possible the development of water pumps powered by solar energy, allowing irrigation of the soil without the need to connect to the electrical grid. The use of PV pumping systems for irrigation in different rural areas is also a more efficient method of storing the potential energy of water [

5,

6,

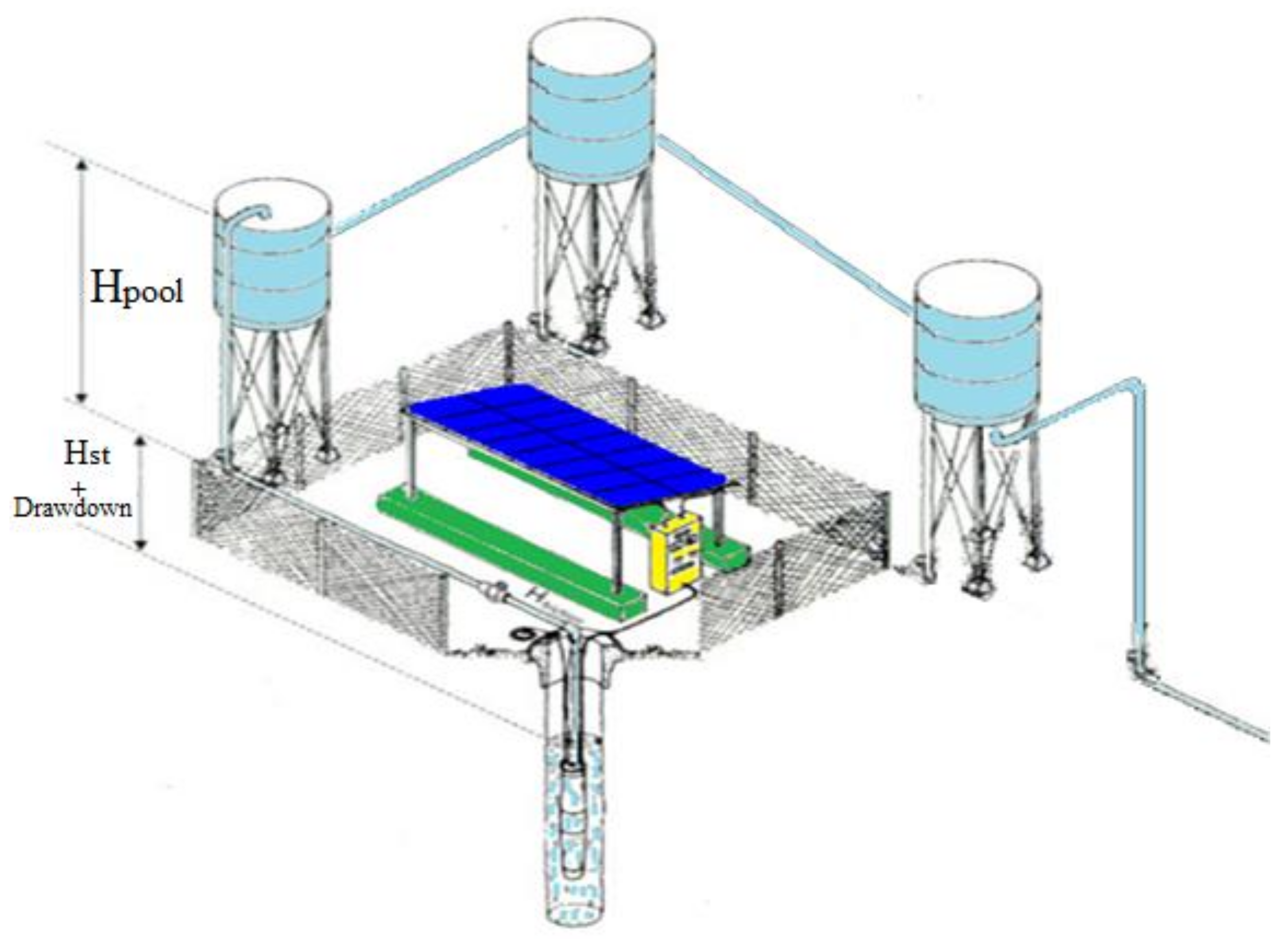

7]. The concept of such a pumping system is presented in

Figure 1.

It should be noted that solar pumps offer the possibility of delivering water for both irrigation and local drinking water supply. These pumps usually have DC motors that can use the current produced by the PV panels or the current in the storage batteries [

8].

It is possible also to equip solar pumps with AC motors, but this involves the use of advanced control systems based on inverters, converters, etc. [

9].

Modeling and simulation of the PV pumping has been studied until now by various authors. Muñoz et al. [

10] implemented the SISIFO simulator that allows forecasting pumped water flow, depending on the characteristics and performance of the PV generator used.

Taufik et al. [

11] has developed a simple and efficient photovoltaic pumping system by using two MPPT algorithms and control methods; the results of the simulations showed the performance parameters of the PV pumping system, respectively the total energy daily produced and the pumped water flow per day.

Kumar [

12] has developed a photovoltaic pumping system using the MPPT method and a boost converter, which has enabled the optimized operation of a permanent magnetic direct current (PMDC) motor.

Glasnovic and Margeta [

13] studied an integrated PV pumping system, analyzing the influences of the local climate, the soil used, the harvests obtained and the irrigation method considered; on this basis it was proposed a hybrid optimized model for irrigation which has been tested satisfactorily.

Shebani and Iqbal [

14] studied the modeling of a photovoltaic pumping system based on Homer software; the performance of the system was evaluated using the MPPT technique, resulting an improvement in the efficiency of the PV pump.

El-Shimy [

15] studied the optimization of a stand-alone photovoltaic pumping system for irrigation from the point of view of the impact of the tilt angle of PV array. The results indicated the capability and accuracy of the method used to size PV stand-alone pumping systems.

The present article adopted an original method of optimizing of a PV pumping system through the operation scheme introduced in the Matlab/Simulink working environment, respectively the syntax developed by the authors for the simulation and dynamic operation of such PV installation.

The achievement and highlighting of a case study for a site established and delimited on the South of Romania in terms of production/need for electricity depending on the solar irradiance related to the area of interest, as well as its comparison with a site from the South of Turkey were discussed.

The potential of artificial intelligence (AI) technique in the context of the development and operational optimization of PV pumping systems is highlighted too.

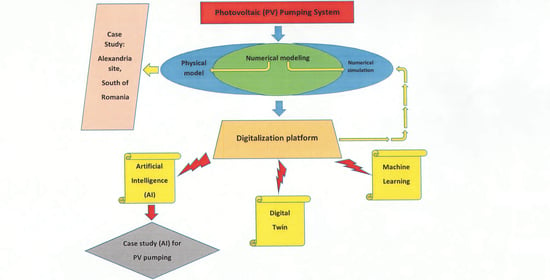

The authors have proposed the following objectives within this article: (1) performing numerical modeling for evaluation of the main parameters of a PV pumping system, (2) analyzing of the influence of the main meteorological parameters, respectively solar irradiance and temperature for performance evaluation of the PV pumping system operated for the specific case studied in the South of Romania, (3) the conceptual digitalization platform development based on the three digital technologies: machine learning (ML), digital twin (DT) and artificial intelligence (AI), and (4) the AI optimization of the PV pumping system based on an advanced MPPT algorithm.

2. Mathematical Model and Simulation Tool

2.1. Mathematical Model of the PV Pumping System

The mathematical model of the photovoltaic pumping system is considered by the characterization of all its components [

16,

17,

18,

19,

20,

21]. A correlation between the electrical parameters (specific parameters of the PV panels, motor and inverter, the supplied energy by the structure, as well as respectively the PV system power) and the non-electric ones (flow rate and pumping height) taking into account the main meteorological data (solar irradiance and temperature) is established. On this basis, it is possible to correctly estimate the irrigable potential of the PV pumping system. The equations defining the studied PV pumping system are presented below.

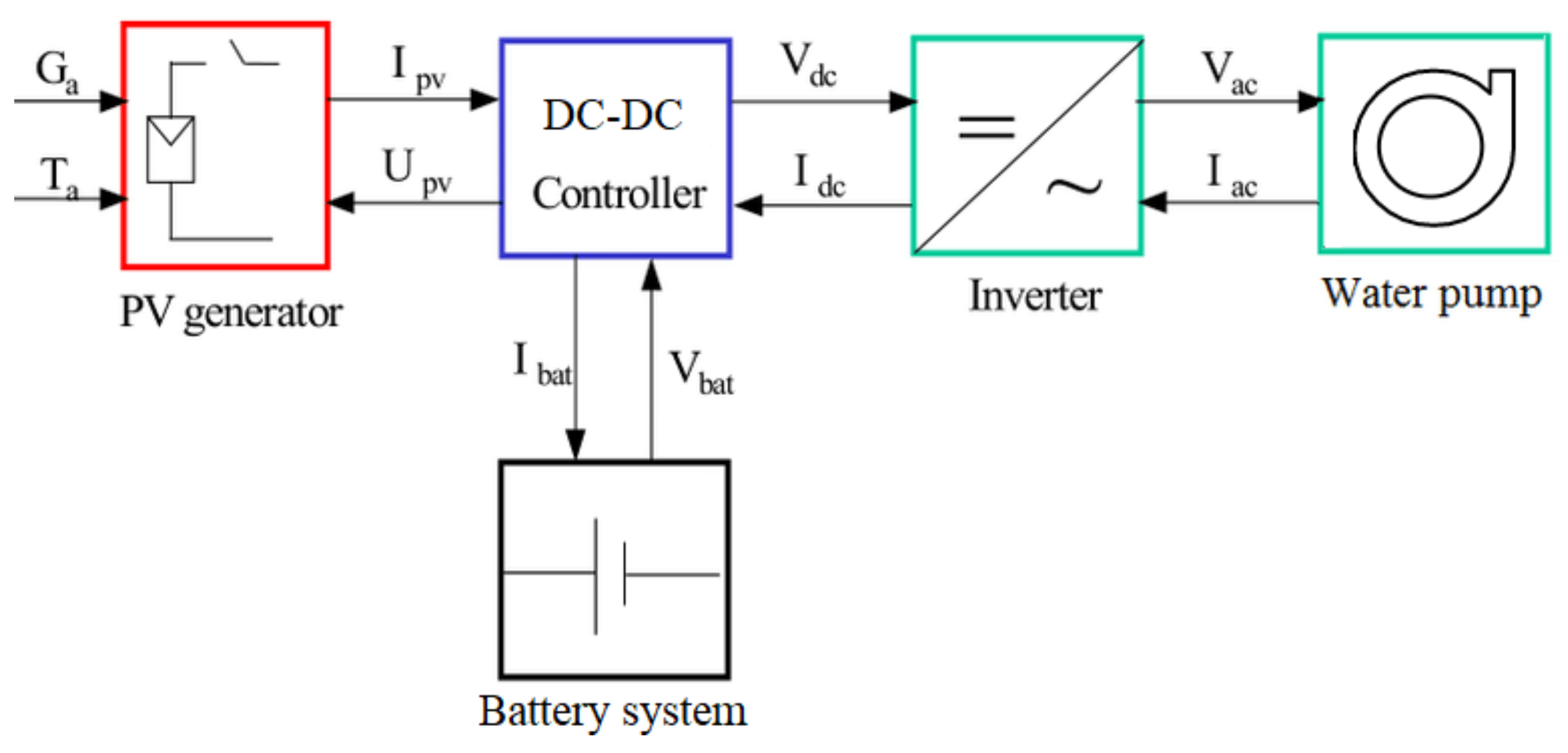

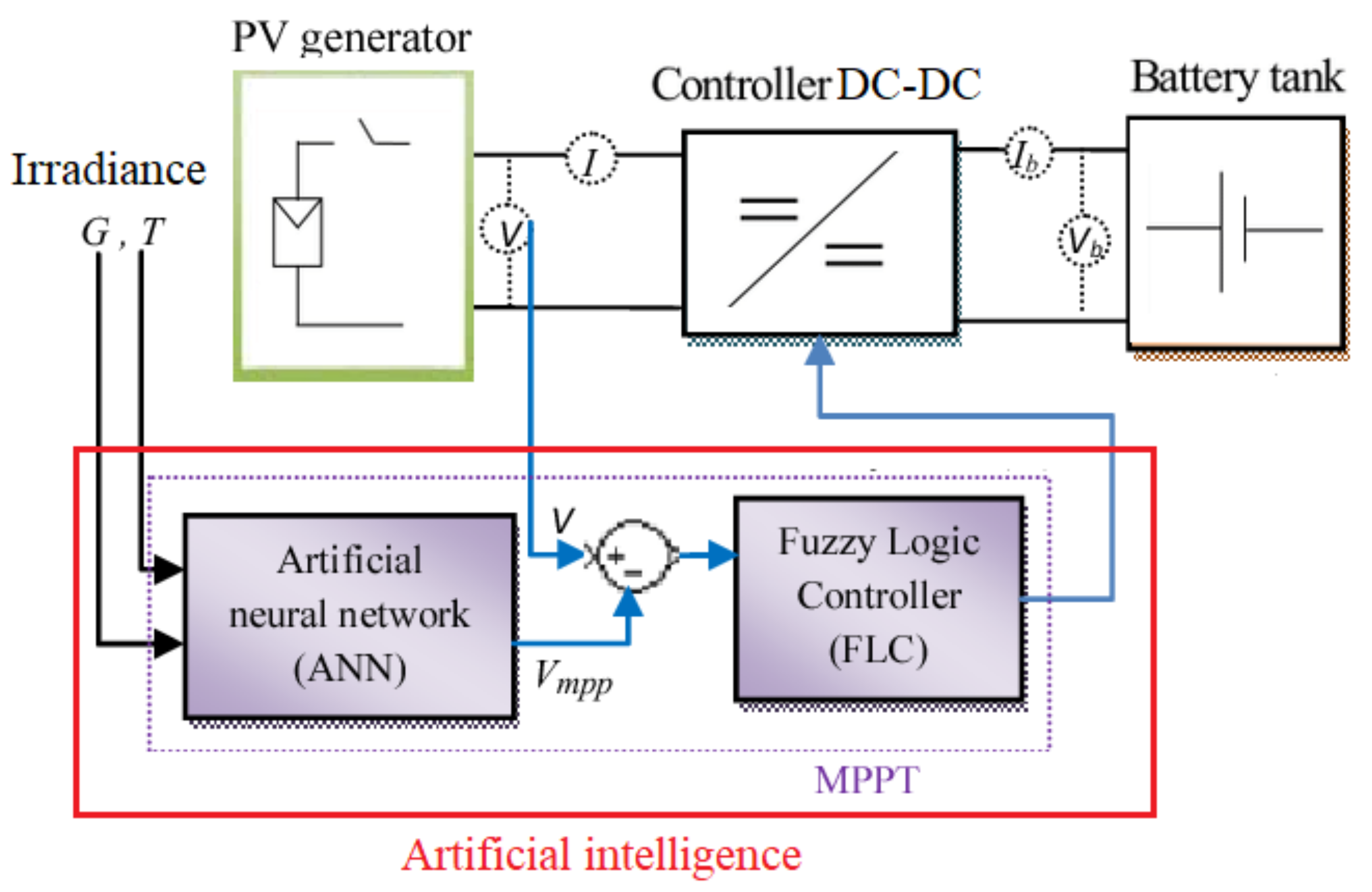

In

Figure 2 it is presented the block diagram of the PV pumping system architecture constituted from the following main components :(1) PV Generator; (2) DC-DC Controller; (3) Inverter; (4) Battery system; (5) Water pump.

2.1.1. PV Generator

The output maximum DC power,

PDC, is obtained using the following relationship [

17]:

where

is the maximum power under standard test conditions (STC, defined by normal solar irradiance of

= 1000 W/m

2, normal solar cell temperature of

= 25 °C, and AM1.5 spectrum),

η = η (

G,

TC) is the conversion efficiency as a function of the incident solar irradiance,

G, and cell temperature,

, and

is the conversion efficiency under STC,

, where

A is the active area of the PV generator.

The calculation of the conversion efficiency, η is based on an “Only temperature effect” model, namely:

where

is the coefficient of variation of power with temperature, in [°C

−1], and

is calculated from the ambient temperature,

, using the equation with the nominal operation cell temperature, (

), obtained from the manufacturer’s data sheet:

where

and

are given in °C,

G is given in W·m

−2, and

k is a thermal resistance called Ross coefficient, which is given in °C∙m

2/W. The 0.9 factor is an experimental correction factor.

2.1.2. Inverter

The inverter conversion efficiency

() could be calculated knowing its nominal power (

), its maximum output power (

) and three experimental parameters

(k0, k1 and

k2), associated to the inverter losses, as follows, [

18]:

where

=

/

,

is the AC output power of the inverter, which can be determined from

(power at the inverter input) and parameters

k0, k1 and k2, which must be fitted, either from the conversion efficiency curve provided by the manufacturer, or from experimental measurements.

2.1.3. Current Transformer

The ratio low voltage/medium voltage transformer (LV/MV) is characterized by its nominal power, copper and core losses. The conversion efficiency of this transformer,

, is calculated as a ratio between the output power

and the input power

, [

19]:

where

represents the core losses, and

represents copper losses.

2.1.4. Pumping

The calculation of the pumping parameters, respectively the motor efficiency ), the pumping height (H) and the pumping flow rate (Q), takes into account the input power of the motor , the available electric power , and the power developed at the shaft of the motor (Pshaft).

Thus, the motor efficiency could be calculated with the equation:

where

,and k

m0, k

m1 and k

m2 are the losses coefficients.

The pumping height

H(Q) and shaft power

depending on flow rate (

Q) could be fitted with second order polynomials, as follows [

20,

21]:

where

H is the pump height, and

kB0, kB1, and kB2 are the second degree polynomial coefficients that represent the best fit for

H, while

kP0, kP1, and kP2 are the coefficients for

.

The pumping height is computed using the static height (

kS0) and friction losses (

kS2) of the system; it is also a second order polynomial:

Equations (6)–(9) characterize system operation at nominal frequency. Since the system can operate at different frequencies, as the pump’s operating point depends on the available PV generator power, it is necessary to obtain different PV pump curves, according to frequency, in order to determine the optimum operating points. To achieve this goal, the affinity laws for the optimum operation of PV pumping are considered, namely:

where ω

1 and ω

2 represent instantaneous frequencies for two different points on the same affinity curve. The essential objective of the photovoltaic pumping modeling is to establish the relationship between flow rate

(Q) and motor shaft power (

Pshaft); under the terms of (12) affinity law; this relationship has the expression:

where

kQ0, kQ1, kQ2 and

kQ3 are the third-degree polynomial coefficients.

3. Numerical Modeling: Results and Discussions

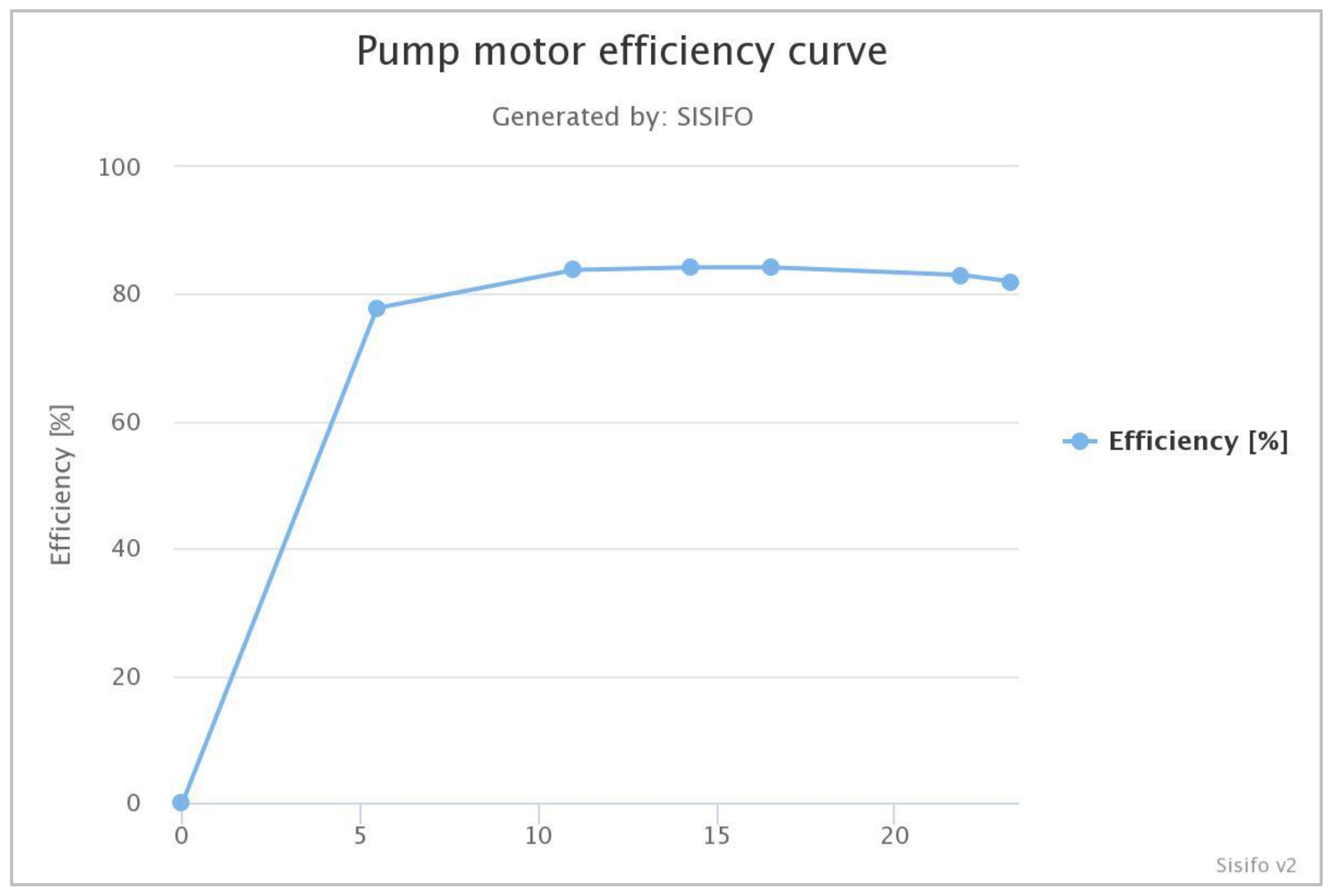

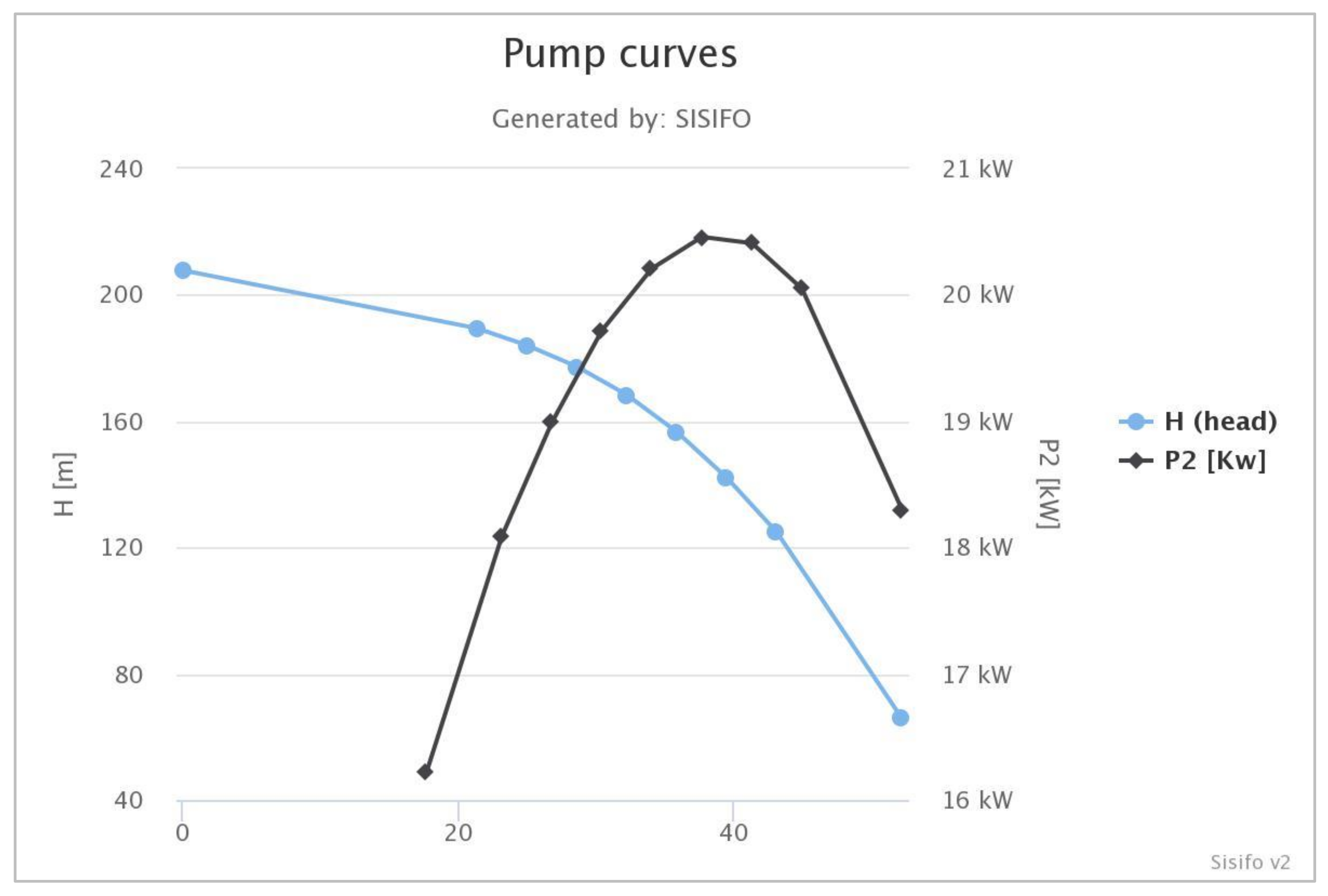

3.1. Simulation the Performance of the Mechanical Components for the PV Pumping System

The analyzed pumping system was based on the Caprari online database [

22]. In

Table 1 and

Table 2 the pump and motor input data were shown, respectively, based on the models E6P35/15A and MAC630A-8V.

Using the input data of the two essential components of the PV pumping system for irrigation, as well as the Equations (9)–(13) of the mathematical model discussed in

Section 2, the authors established: (1) the operating characteristics of the PV pump (the pumping height and the power to the shaft depending on the rate flow), see

Figure 3, and (2) the pump motor operation characteristics (efficiency of the pump motor depending on the power), see

Figure 4.

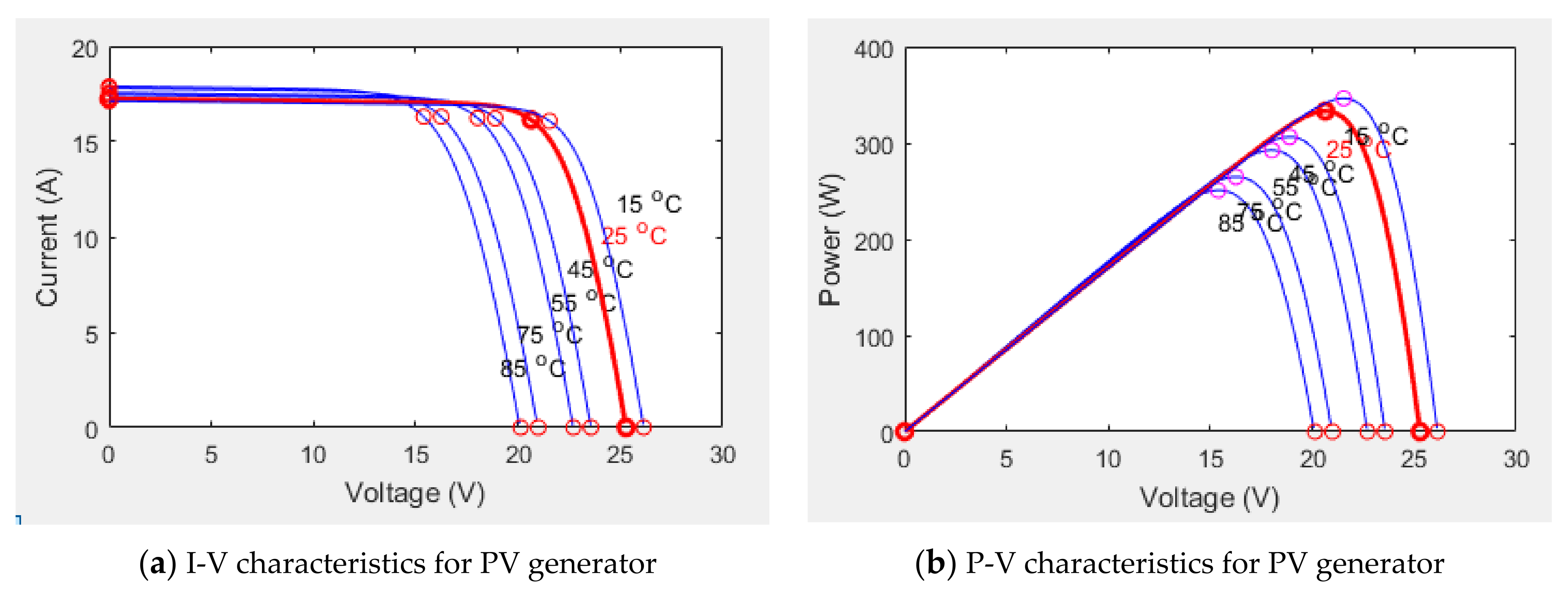

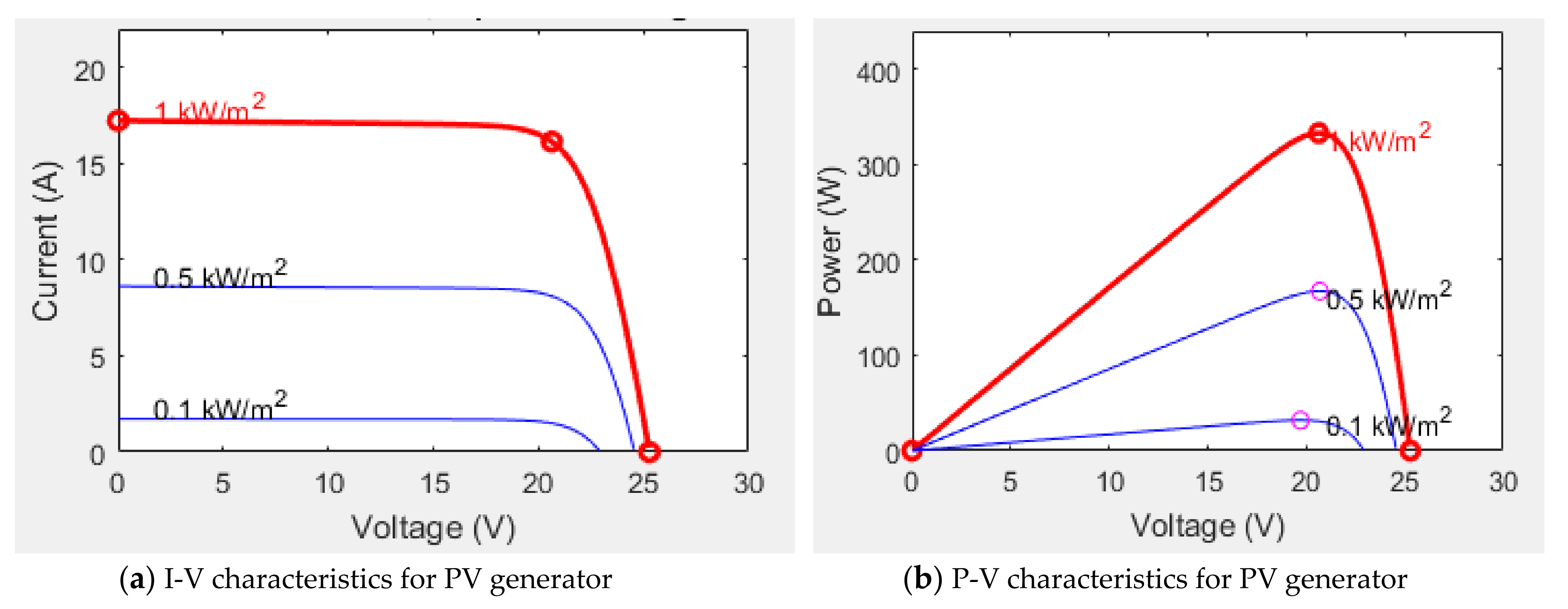

3.2. Simulation the Performance of the Electrical Components for the PV Pumping System

The characteristics and performance of the PV generator were determined form the point of view of two main meteorological parameters: (1) solar irradiance (the range 100–1000 W/m

2) (see

Figure 5a,b), and (2) temperature (in the range between 15–85 °C) (see

Figure 6a,b). The obtained results are in good agreement with literature [

23,

24].

The performance of the inverter for the PV pumping system is obtained using the input data from the catalog (nominal power, output power, and inverter losses) and the Equation (4) of the mathematical model discussed. As it was expected the inverter efficiency for the operation range (see

Figure 7) is very high, in good agreement with literature values [

25,

26].

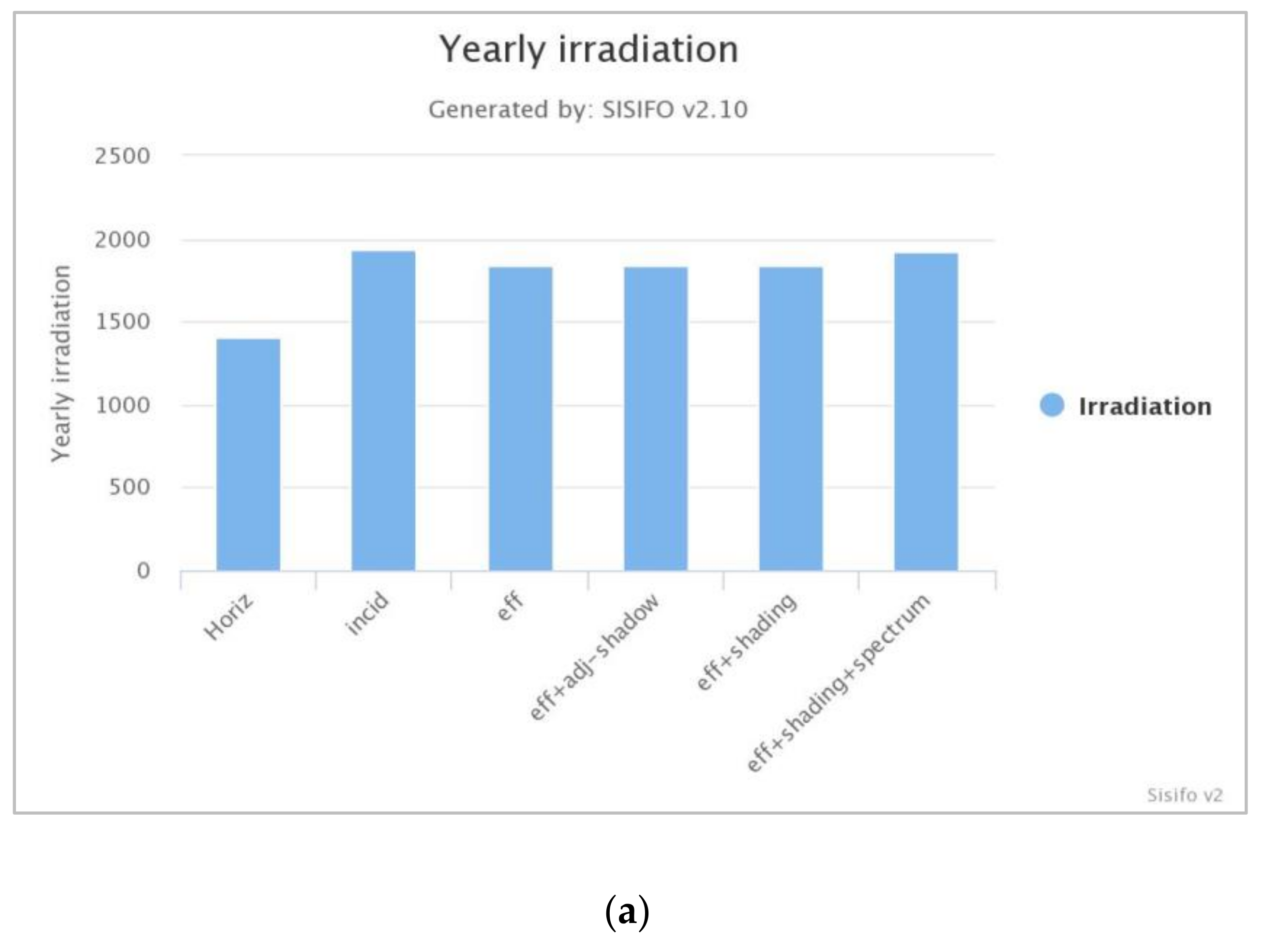

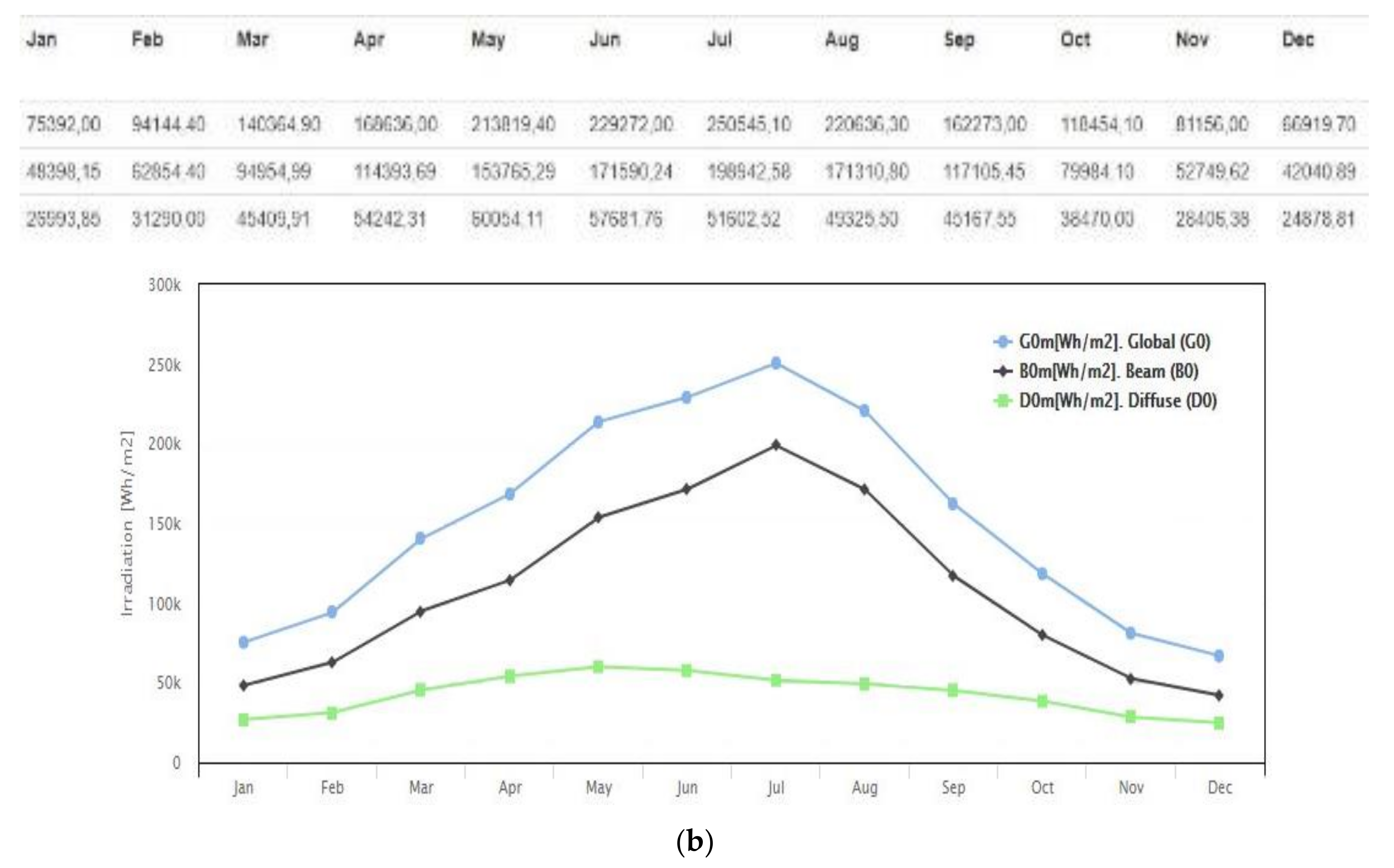

3.3. Meteorological Characteristics of the Proposed Site

The PV pumping system for irrigation considered was studied for the specific analyzed site in meteorological conditions that are favorable for exploiting solar potential and in a region with high irrigation potential, namely the Romanian Plain, in the South of the country. The main meteorological parameters, namely the solar irradiance and the ambient temperature, were extracted from the SISIFO-PVGIS platform database [

22]. This simulation platform takes into account the real operating conditions of photovoltaic panels, including both the influence of dust and shading, separately and by mixing of these factors.

Figure 8a shows the annual solar irradiance for different actual operating conditions of photovoltaic panels in the analyzed site.

Figure 8b represents the fitted monthly solar irradiance for the specific location over a year under real operating conditions (dust, shadow and mix of these factors).

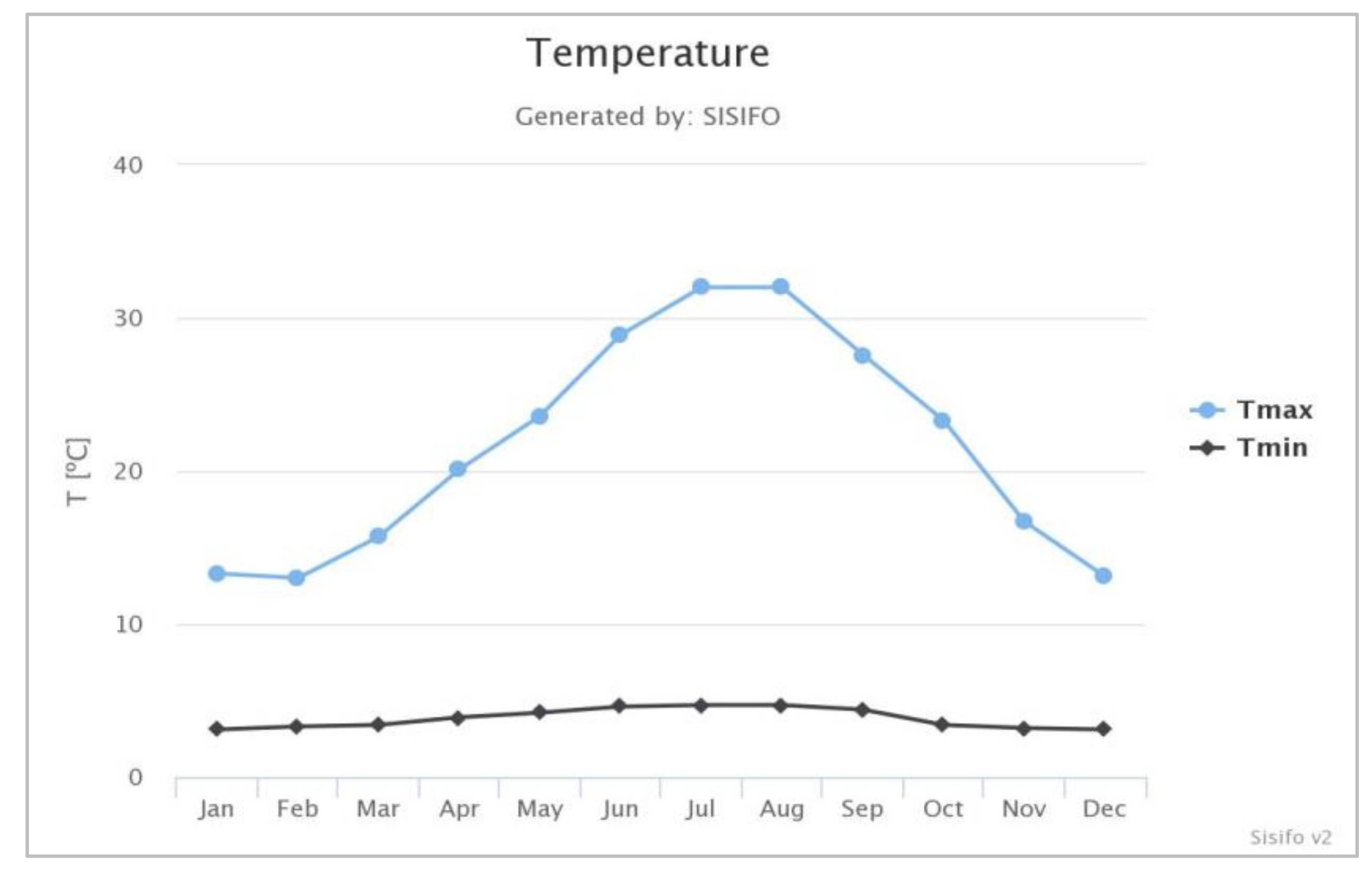

Figure 8 shows the minimum and maximum monthly temperature values over a year.The results obtained in

Figure 9 and

Figure 10 based on the characteristics of the solar irradiance and ambient temperature for the analyzed site are used to determine the performance of the irrigation pumping photovoltaic system.

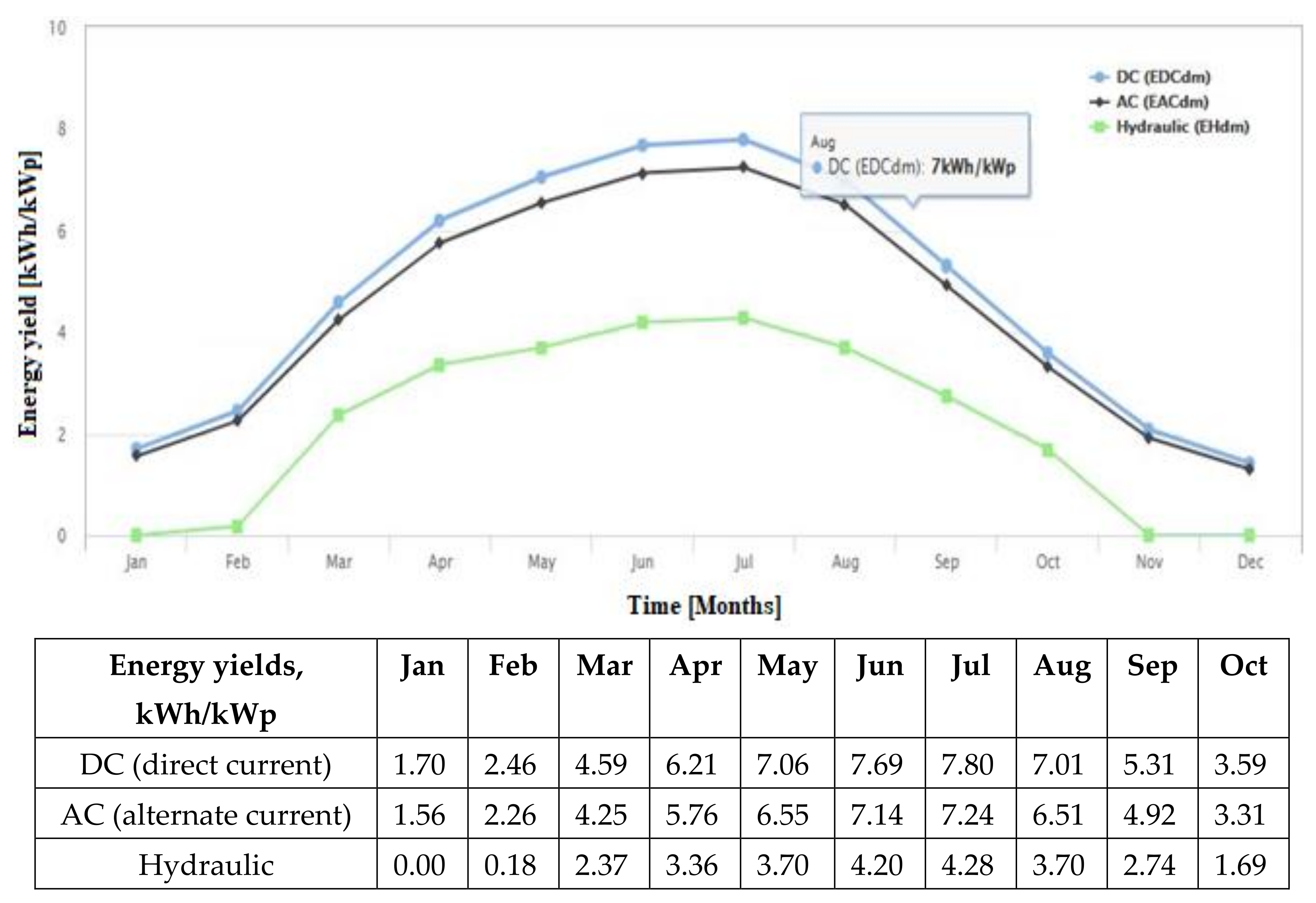

3.4. Global Performance of the PV Pumping System

Using the input data from the

Section 3.1,

Section 3.2 and

Section 3.3, as well as the SISIFO simulation platform we could obtain the main performances of the analyzed photovoltaic pumping system.

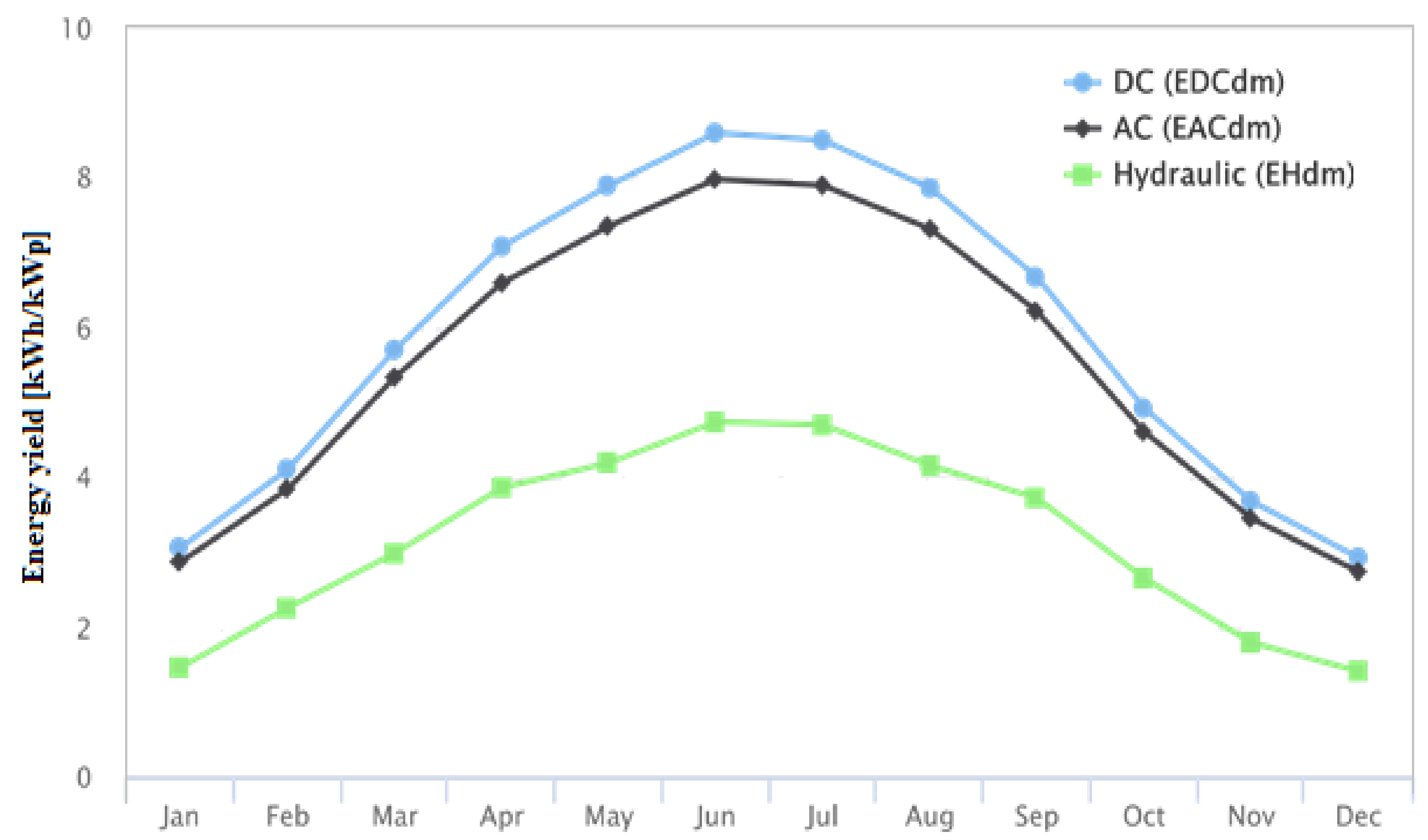

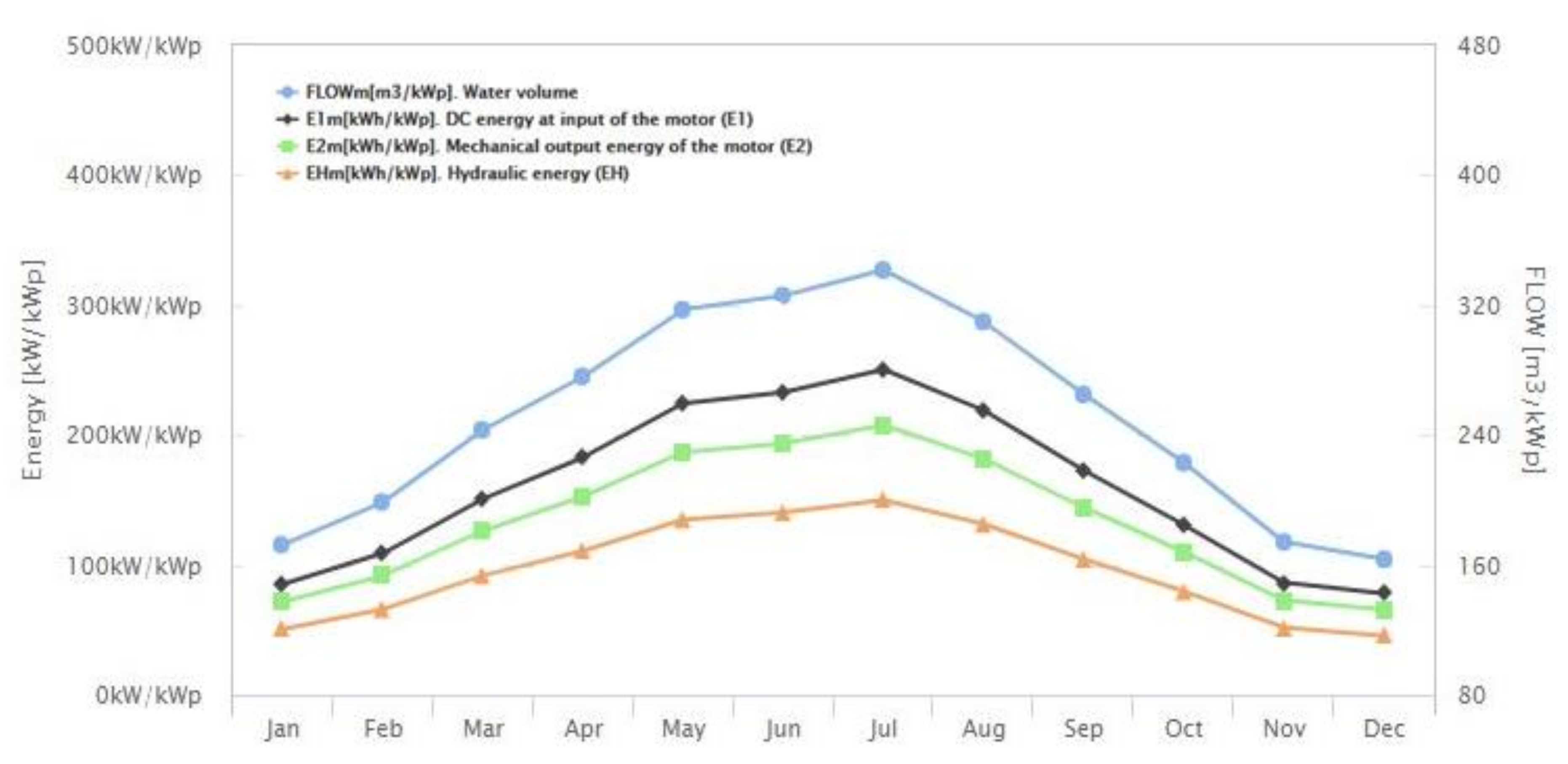

Thus, the monthly energy yield of the photovoltaic pumping system over a period of a year, i.e., the DC energy yield, AC energy yield and hydraulic energy, respectively, is plotted in

Figure 9. We could see that the significant period for irrigation is the interval March—October what is confirmed by the values obtained for the energy yield. The maximum value of the DC energy

yield of 8 kWh/kWp, an AC energy yield of 7 kWh/kWp for the PV pumping system is obtained in July, respectively. The maximum value of the hydraulic energy yield is roughly 4.2 kWh/kWp.

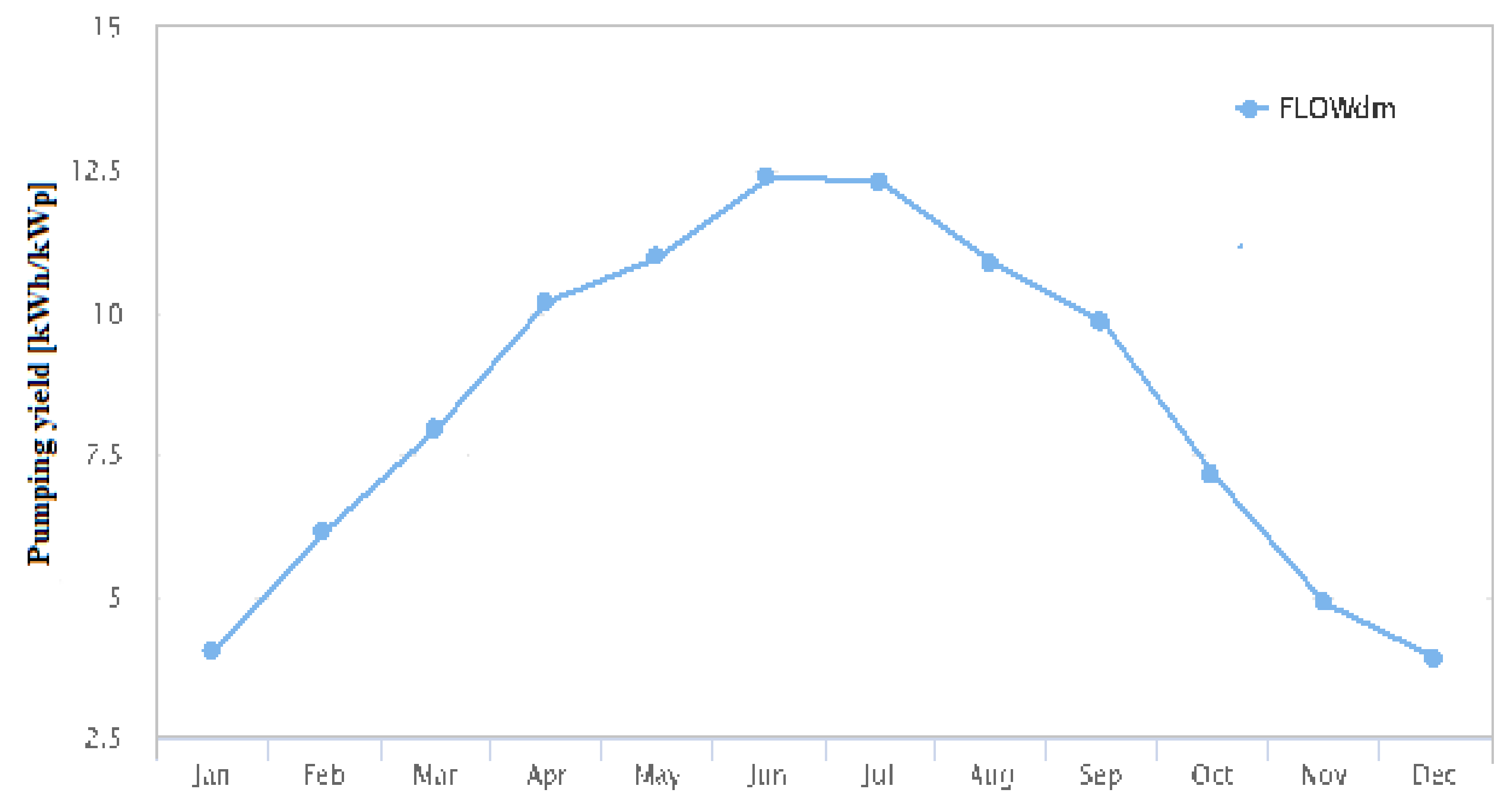

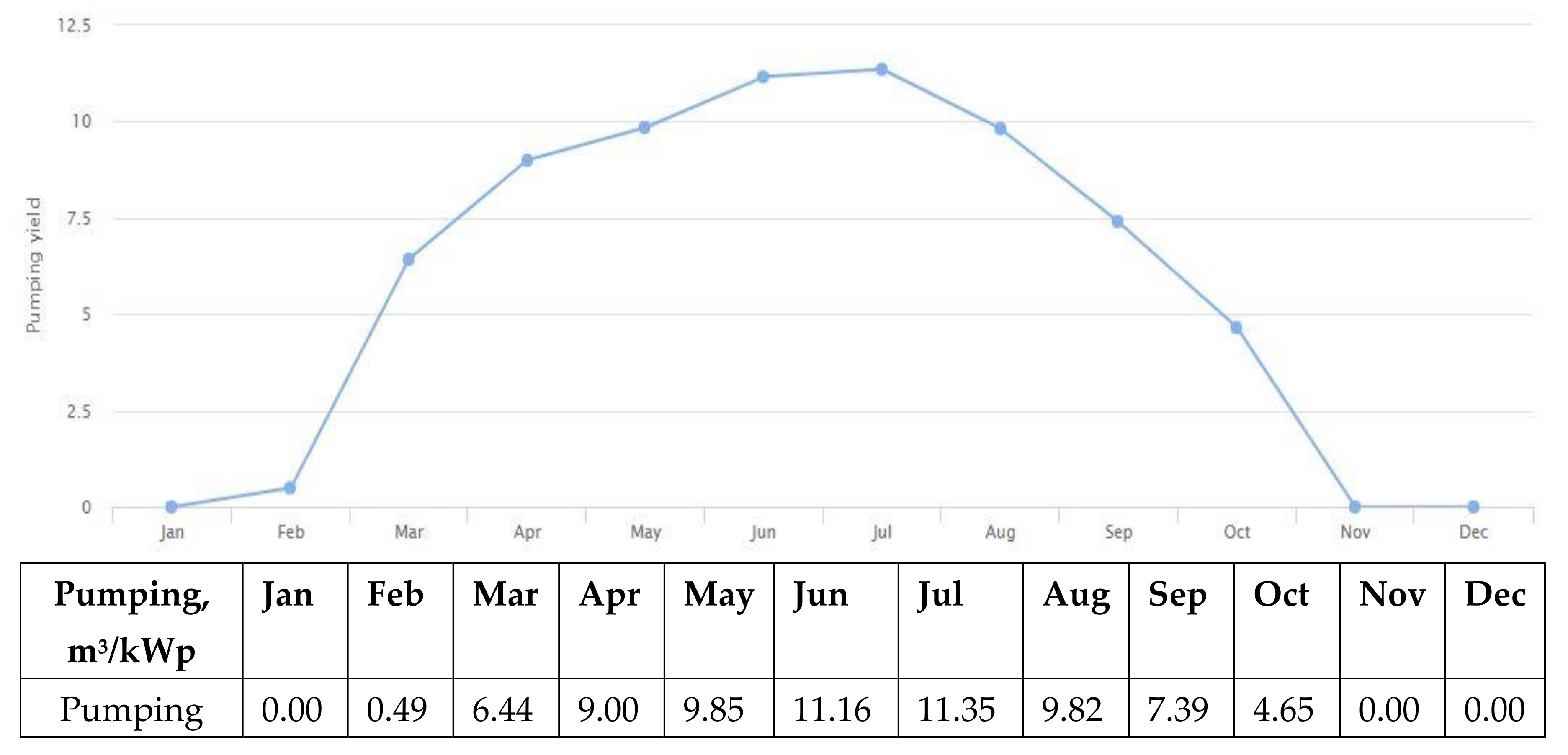

Another important performance of the PV pumping system is the monthly pumping yield presented in the

Figure 11. The maximum value of this performance is 12.5 m

3/kWp and is obtained in July.

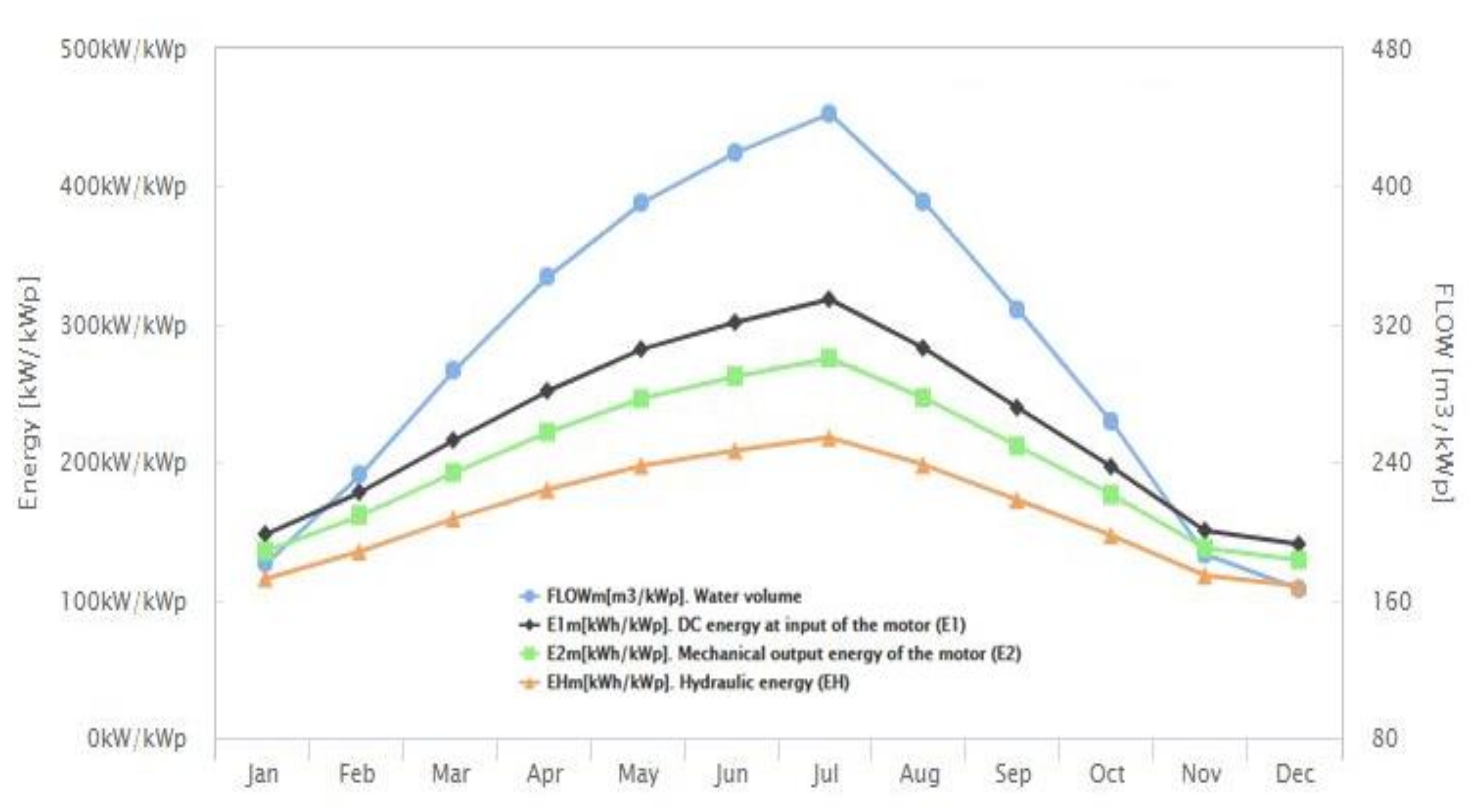

The total performances of the PV pumping system analyzed are plotted in

Figure 12. They are: the monthly flow rate, the monthly DC energy at the input of the pump motor, the monthly mechanical energy of the pump motor and the monthly hydraulic energy, all of them divided by the electrical energy produced by the PV generator. The maximum values of these quantities are obtained in July. All these performances define the best operation period of the PV pumping system, namely from March to October.

Based on these simulations it is possible to obtain a clear characterization of the system from the point of view of the electrical and hydraulic performances. This approach could be useful to forecast both the sizing, and operation of a such PV pumping system for different meteorological conditions.

3.5. Comparison of the Two Case Studies for PV Pumping System Placed in the South of Romania and South of Turkey

We have analysed two case studies for the PV pumping system based on two sites, namely:

- (a)

Alexandria, in the South of Romania

- (b)

Antalya, in the South of Turkey

For comparison we have considered by simulation the main performances of the PV pumping system, namely:

- (1)

- (2)

- (3)

The global performances of the PV pumping system for Antalya (

Figure 15) and Alexandria (

Figure 12).

The results indicate a higher irrigation potential for Antalya in comparison with that for Alexandria; so, the maximum value of flow rate, indicated by the

Figure 12 and

Figure 15, is 450 m

3/kWp for Antalya, respectively 340 m

3/kWp for Alexandria. This difference is due to the solar higher irradiance potential measured (for Antalya) by the SISIFO—PVGIS platform tools.

All other performances have the same trend, showing a significant increase for Antalya in comparison with that for Alexandria.

Figure 13.

Monthly energy yield of the PV pumping system (Antalya, Turkey).

Figure 13.

Monthly energy yield of the PV pumping system (Antalya, Turkey).

Figure 14.

Monthly pumping yield of the PV pumping system (Antalya, Turkey).

Figure 14.

Monthly pumping yield of the PV pumping system (Antalya, Turkey).

Figure 15.

The global performances of the PV pumping system for Antalya, Turkey.

Figure 15.

The global performances of the PV pumping system for Antalya, Turkey.

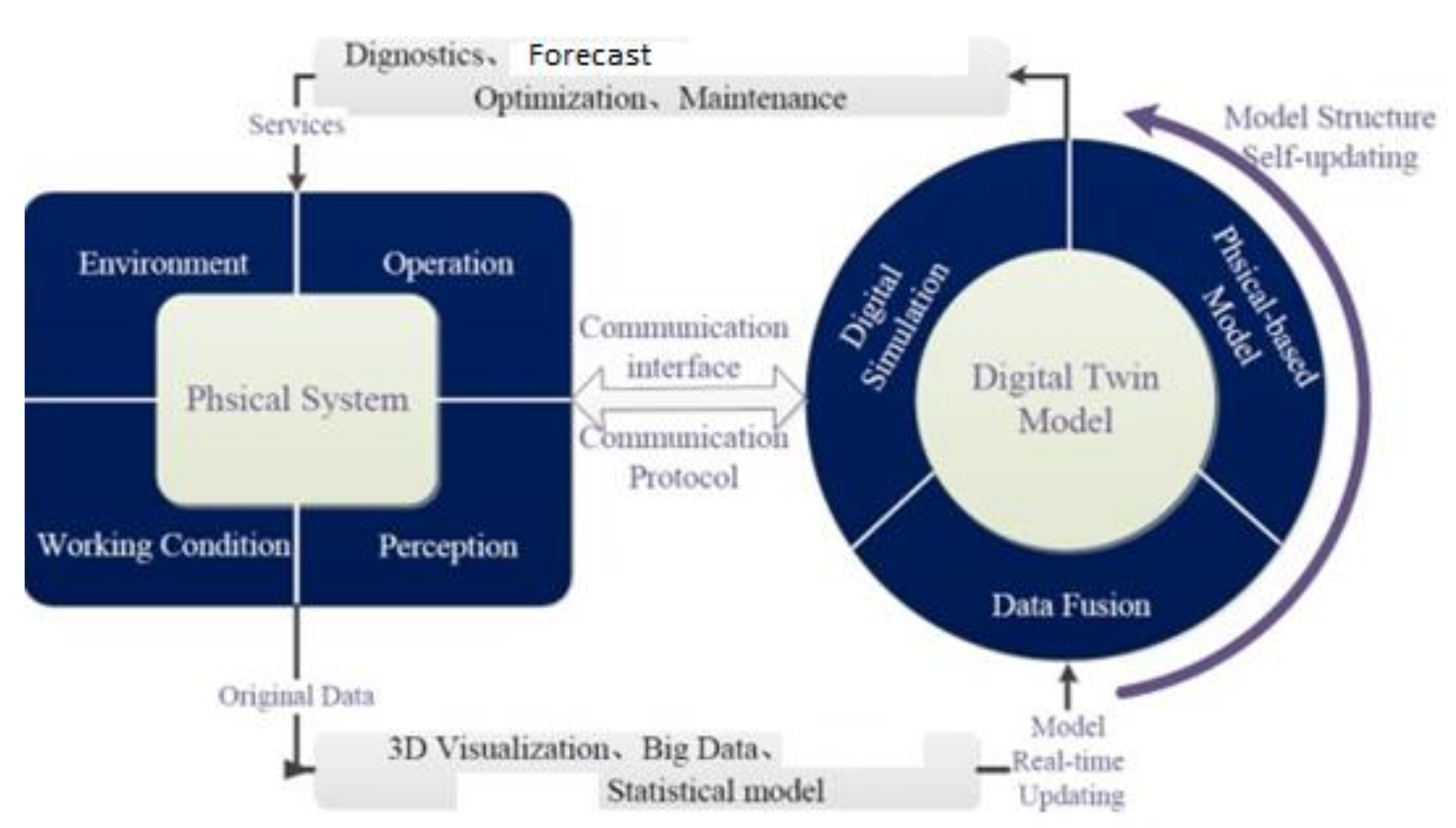

4. Digitalization Platform: General Case

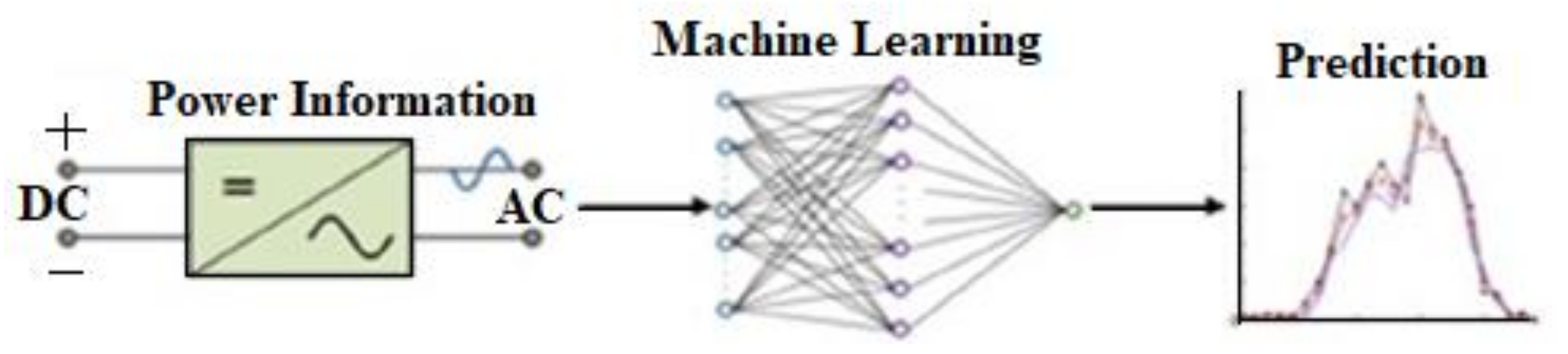

Digitalization Platform is based on three advanced technologies that could be introduced in the analysis of PV pumping system: machine learning (ML), digital twin (DT) and artificial intelligence (AI).

4.1. Machine Learning (ML) for PV Systems

Short-term PV production forecasting (intra-hour) is necessary for power and voltage prediction as well as control operations and dispatch management. On the other hand, mid-term PV production forecasting (intra-day and day-ahead) is used for load consumption and production monitoring to control voltage and frequency levels and reduce secondary reserve.

For improving the forecasting accuracy of the power produced, adaptive machine learning approaches that can capture system behavior without the need of datasheet and installation parameters have been introduced, [

26]. In this respect, ML models that do not require knowledge of the physical parameters but construct relationships between input and output variables based on data driven approaches could be developed. A primary objective would be to establish a methodology that extends the forecasting accuracy beyond the state-of-the-art pursuing minimal computational, as well as data complexity.

Parametric models are driven by the performance of the component models and parameters. Three main models could be explored: (1) artificial neural networks (ANN); (2) support vector regression (SVR); (3) regression trees (RT) with different parameters and features.

The comparative analysis of the three models showed that ANN is the most performant model with the lowest errors [

27], respectively for: mean absolute percentage error (MAPE) and normalized root mean square error (nRMSE). The prediction capabilities of the SVR and RT models can be considered equivalent since then RMSE results are roughly the same. In this way, the ANN model could predict the output power of the PV pumping system more accurately compared to SVR and RT models.

4.2. Digital Twin (DT) for PV Systems

Digital twin technology is based on the pairing of the physical PV pumping system with the virtual one; it allows the analysis of huge quantity of data and monitoring of PV pumping installations. Data gathering and its in-depth analysis prove to be useful in predictive and preventive analysis and actions. The digital twin-based analytics engine can have important effects on the performance and output of PV systems. This digital twin technology acts as follows [

28]:

- (a)

Close monitoring help prove the predictability of all the components of the PV system. With the use of real-time simulation, it becomes to assess the present condition of each part of the grid. The operator scan do predictive maintainace in the grid.

- (b)

The digital twin technology is effective in closely analyzing how the PV system works during various meteorological conditions. The virtual PV system also allows administrators to replicate different scenarios and figure out how the upgraded PV components of the system would respond to them.

- (c)

Forecasting is one of the key aspects of the digital twin technology, which ensures optimum solar PV system performance. It enables the mapping of the solar grid to a virtual program ensuring better utilization of the whole system.

- (d)

Auto-generated alarms and performance benchmarks help minimize the losses and improve output at the same time.

4.3. Artificial Intelligence (AI) for PV Systems

The artificial intelligence (AI) technology developed for PV systems is represented by the following algorithms, [

29]: (1) neural network (NN); (2) fuzzy logic (FL); (3) simulated annealing (SA); (4) genetic algorithm (GA); (5) ant colony (ACO); (6) particle swarm optimization (PSO); and (7) hybrid techniques like adaptive-neuron fuzzy inference systems (ANFIS), GA-fuzzy and NN-fuzzy. Several applications of artificial intelligence (AI) for PV systems could be discussed:

- (1)

The detection of incidences, either using unsupervised learning or comparing the measured data with simulated electrical measurements;

- (2)

Short-circuit fault detection of PV-arrays by using artificial neural networks (ANN);

- (3)

Hierarchical context-aware anomaly diagnosis methods to identify operating states of individual strings automatically;

- (4)

Prediction of soiling effects with a Bayesian neural network and polynomial regressions.

Based on these applications there were established the following qualities of the AI algorithms, [

25]:

- (a)

ANFIS has higher accuracy in the parameter identification application than GA and SA.

- (b)

NN achieves the highest accuracy in sizing PV systems and maximum power point tracking (MPPT).

- (c)

fuzzy controllers and hybrid fuzzy controllers are the most widely used controllers in MPPT and inverter control.

- (d)

GA achieves the highest accuracy in Sun tracking applications.

- (e)

NN is the most widely used algorithm for fault diagnosis.

AI algorithms could offer an alternative method for sizing PV pumping systems in many regions that lack complete data [

30].

5. Case Study for Digitalization Platform: The AI Approach of a PV Pumping System to Achieve an Optimized Operation

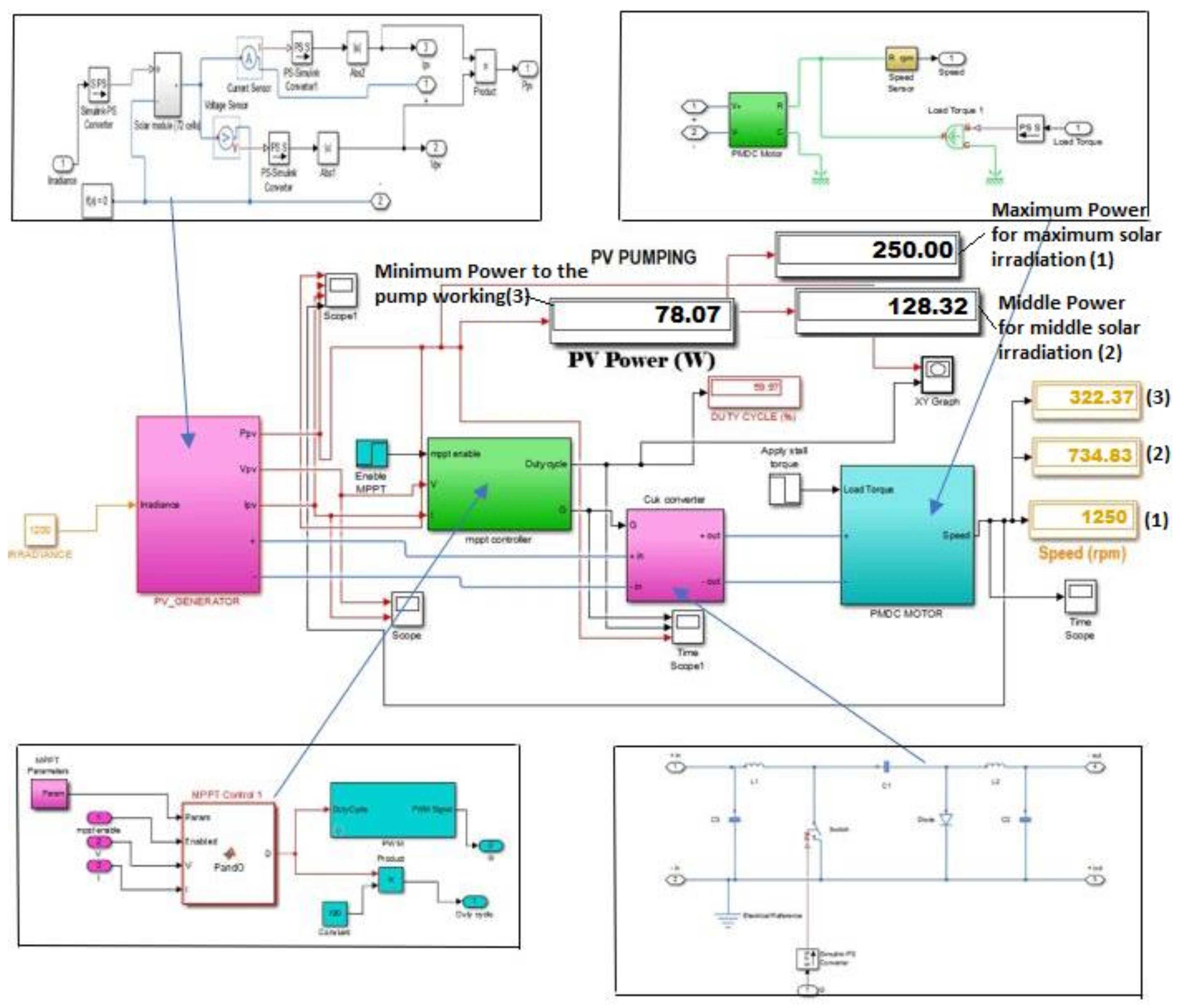

In order to analyze an optimized operation of the PV pumping system the authors proposed an intelligent (AI) approach based on MPPT algorithm and frequency converter (pulse width modulation or PWM); it was developed and implemented in MATLAB/ Simulink software [

32]. An operation and control block diagram based on these concepts was presented in

Figure 20. All the components of the PV pumping system, respectively PV generator, pump motor, MPPT controller and PWM were also represented using the electronic layouts; they included all sub-systems belonging to each block component.

This AI approach achieved a performing control and monitoring of the parameters for the PV generator and pump motor. These analyses could be implemented for real applications using suitable sensors and Arduino platform, what would allow a further improvement of the operation for the PV pumping system.

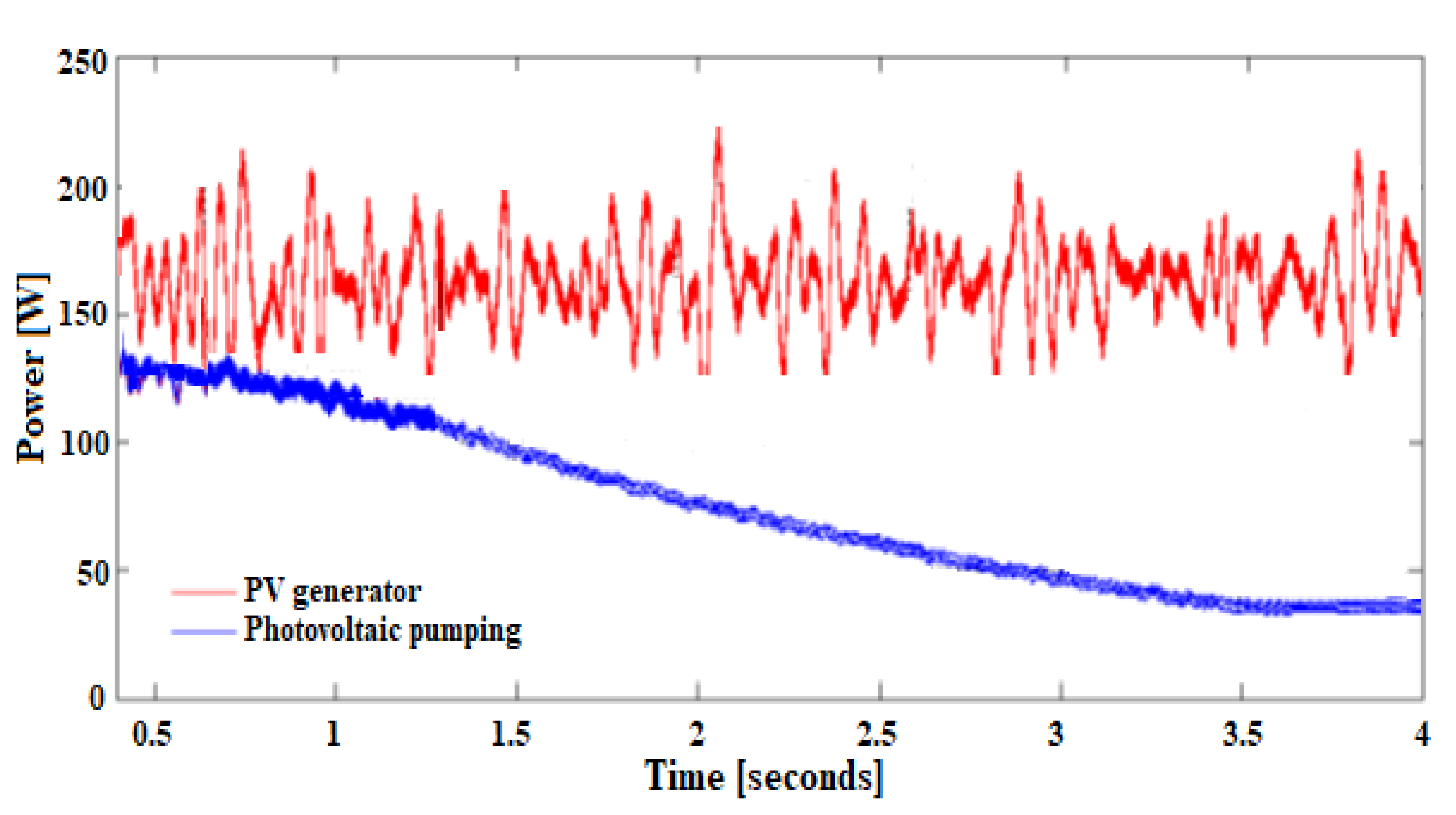

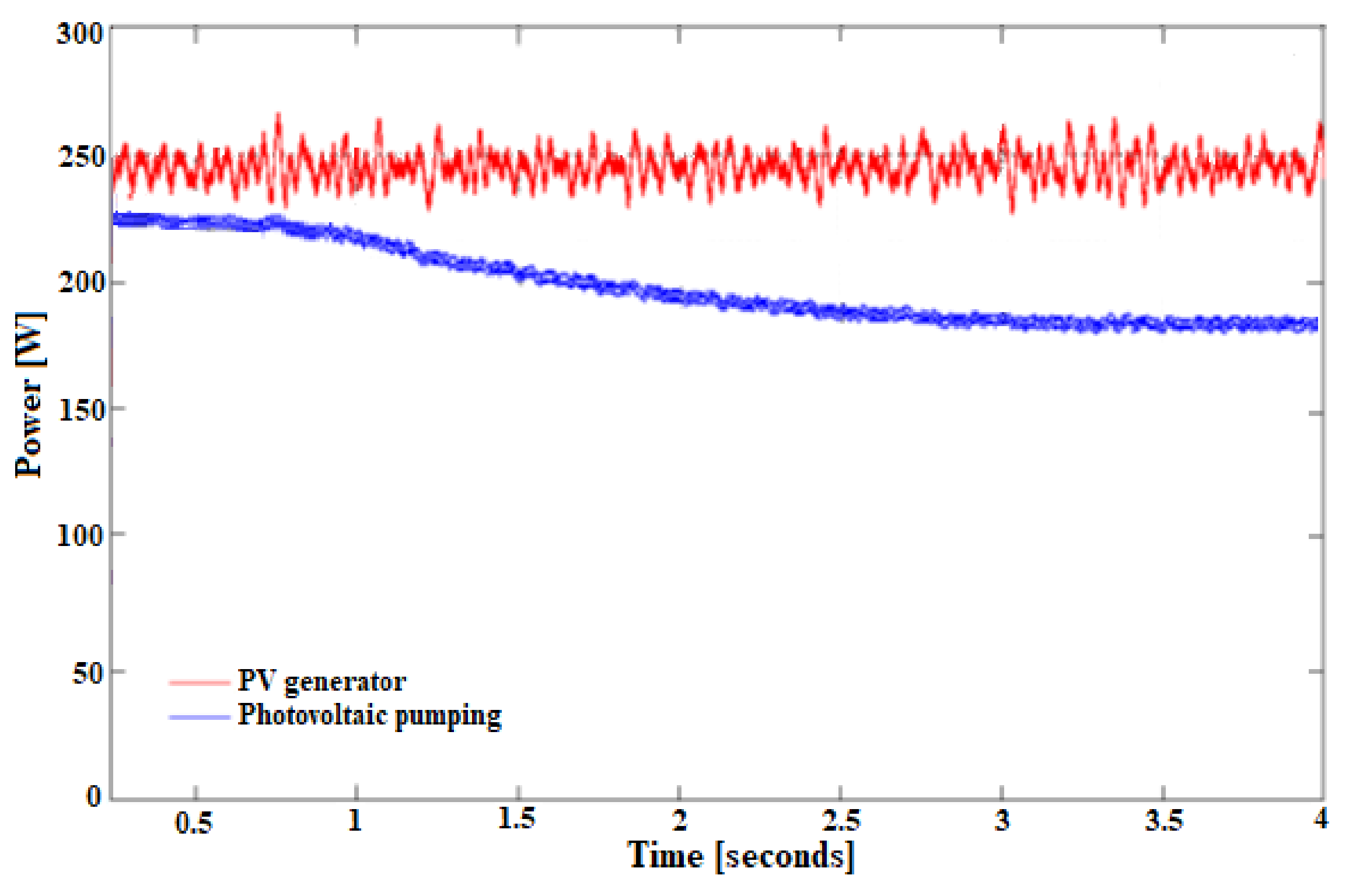

Using the operation and control block diagram based on MPPT controller and PWM frequency converter, as well as MATLAB/Simulink software the authors obtained the behavior of the PV pumping system for two cases, namely:

- (a)

without MPPT controller (according to

Figure 21)

- (b)

with MPPT controller (according to

Figure 22)

The output power of the PV generator, respectively of the pump motor for these two cases are presented in the

Figure 21 and

Figure 22. It is remarked that:

- (1)

The fluctuations of the output power for the PV generator are important in the case when the MPPT controller is not used and are significantly reduced when the MPPT controller is used.

- (2)

The output power of the pump motor is much influenced by the fluctuations of the output power of the PV generator and could determine non-functionality of the system in the case without MPPT. It is significantly increased in the case when the MPPT controller is used.

This analysis shows the importance of utilization of the MPPT controller and PWM frequency converter for the PV pumping. The devices ensure the stability of the PV pumping system throughout its operation duration.

Figure 21.

The performances of the PV pumping system in the case without MPPT.

Figure 21.

The performances of the PV pumping system in the case without MPPT.

Figure 22.

The performances of the PV pumping system in the case with MPPT.

Figure 22.

The performances of the PV pumping system in the case with MPPT.

6. Conclusions

The main novelty of this article consisted in: (1) a unified approach of all the components of the PV pumping system using the SISIFO simulation software, and (2) an optimized functionality and operation of the system using a performed controller based on digital intelligent approach. It was also conceived an original block diagram of the PV pumping system developed in the MATLAB/Simulink.

The significant conclusions obtained by the authors in the present study could be synthesized as follows:

- (a)

Analysis of the advanced system was developed based on a specific simulation software and a mathematical model that allowed to establish specific equations for all system components.

- (b)

The numerical modeling has led to a complete characterization of the investigated photovoltaic structure through clear defined performance indicators, which highlight its irrigation potential. The results obtained by simulations are consistent with different models developed in specialized literature [

1,

7,

8,

9,

10,

17,

18,

19,

20].

- (c)

A case study has been proposed for the implementation of the advanced pumping system at the Alexandria site (in southern Romania), which have been assessed through the essential meteorological parameters (solar irradiance and ambient temperature), which dictated the irrigation potential for this case study.

- (d)

The conceptual digitalization platform was discussed based on three advanced digital technologies, namely machine learning, digital twin and artificial intelligence; it could be used for different PV applications, including PV pumping systems.

- (e)

In order to improve the performance and operational stability of the PV pumping system, the authors developed and implemented based on AI approach an original block diagram in the MATLAB/Simulink environment using a MPPT controller and a PWM frequency converter. In this way, an important increasing is achieved both in the use of the PV generator, and the pump motor.

- (f)

The digitalization analysis can contribute to the introduction of this type of PV pumping structure for advanced applications requiring monitoring and efficient control of the functioning of such installations in disadvantaged areas, both from the point of view of rain gauge regime, and from that of a poor electrical grid.

Author Contributions

Conceptualization, L.F.; methodology, L.F. and D.C.; formal analysis, L.F.; investigation, L.F. and D.C.; funding acquisition, L.F.; software, L.F. and D.C.; validation, L.F., D.C. and S.F.; resources, L.F., D.C. and S.F.; data curation, S.F.; writing—original draft preparation, L.F.; writing—review and editing, L.F.; visualization, L.F., D.C. and S.F.; supervision, L.F.; project administration, L.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Data supporting reported results could be found in the Proceedings of the International Conference CIGR 2018, Antalya, Turkey, 24–26 April 2018.

Acknowledgments

This work was supported by the project “Multiscale in modeling and validation for solar photovoltaics” (Multiscale Solar) MP1406, 2015–2019 for Polytechnic University of Bucharest. Funded by the European Commission through the COST program.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| Pv | Photovoltaic |

| Dp | Digital platform |

| Ml | Machine learning |

| Dt | Digital twin |

| Ai | Artificial intelligence |

| Mppt | Maximum power point tracking |

| Ac | Alternative current |

| Dc | Direct current |

| Pmdc | Permanent magnetic direct current |

| Stc | Standard test conditions |

| Am | Air mass |

| Lv/mv | Low voltage/medium voltage |

| Pvgis | Database |

| Sisifo | Simulation platform |

| I-v | Current-voltage characteristics |

| P-v | Power-voltage characteristics |

| Ann | Artificial neural networks |

| Svr | Support vector regressions |

| Rt | Regression trees |

| Mape | Mean absolute percentage error |

| Nrmse | Normalized root mean square error |

| Nn | Neural network |

| Fl | Fuzzy logic |

| Sa | Simulated annealing |

| Ga | Genetic algorithm |

| Aco | Ant colony |

| Pso | Particle swarm optimization |

| Anfis | Adaptive-neuron fuzzy inference systems |

| Iot | Internet of Things data |

| Pwm | Pulse width modulation |

References

- Fara, L.; Mitroi, R.; Cincu, C.; Iancu, V.; Zaharia, C.; Fara, S.; Finta, D.; Iancu, M.; Comaneci, D. Physics and Technology of Solar Cells and Photovoltaic Systems; AOSR: Bucharest, Romania, 2009. [Google Scholar]

- Kohle, M.; Joshi, J.C.; Kothtcaresary, D.P. Performance Analysis of a Directly Coupled Photovoltaic Water-Pumping System. IEEE Trans. Energy Convers. 2004, 19, 613–618. [Google Scholar]

- Taufik, A. The Designand Simulation of PV Water Pumping System. Master’s Thesis, California Polytechnic State University, San Luis Obispo, CA, USA, 2005. [Google Scholar]

- Martínez-Moreno, F.; Lorenzo, E.; Muñoz, J.; Moretón, R. On the testing of large PV arrays. Prog. Photovolt. Res. Appl. 2012, 20, 100–105. [Google Scholar] [CrossRef]

- Jantsch, M.; Schmidt, H.; Schmid, J. Results of the concerted action on power conditioning andcontrol. In Proceedings of the 11th European Photovoltaic Solar Energy Conference, Montreux, Switzerland, 12–16 October 1992; pp. 1589–1592. [Google Scholar]

- Chapman, S.J. Electric Machinery Fundamentals, 5th ed.; McGraw-Hill: New York, NY, USA, 2011. [Google Scholar]

- Lawrance, B.W.W.; Langridge, D. Simulation and performance of a photovoltaic pumping system. Proc. IEEE Int. Conf. Power Electron. Drive Syst. 1995, 1, 513–518. [Google Scholar]

- Hadj Arab, A.; Benghanem, M.; Chenlo, F. Motor-pump system modelization. Renew. Energy 2006, 31, 905–913. [Google Scholar] [CrossRef]

- Surendra, T.S.; Subbaraman, S.V.V. Solar PV water pumping comes of age in India. In Proceedings of the Conference Record of the Twenty-Ninth IEEE Photovoltaic Specialists Conference, New Orleans, LA, USA, 19–24 May 2002; pp. 1485–1488. [Google Scholar]

- Muñoz, J.; Carrillo, J.M.; Martínez-Moreno, F.; Carrasco, L.M.; Narvarte, L. Modeling and simulation of large PV pumping systems. In Proceedings of the European Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany, 14–18 September 2015; pp. 3882–3887. [Google Scholar]

- Taufik, A.; Makbul, A.; Taufik, M. Modeling and simulation of photovoltaic water pumping system. In Proceedings of the Third Asia International Conference on Modelling & Simulation, Bundang, Indonesia, 25–29 May 2009; pp. 497–502. [Google Scholar]

- Kumar, M. Modeling and simulation of solar photovoltaic dc water pumping system using MPPT. Int. Res. J. Eng. Technol. 2017, 4, 1914–1919. [Google Scholar]

- Glasnovic, Z.; Margeta, J. A model for optimal sizing of photovoltaic irrigation water pumping systems. Sol. Energy 2007, 81, 904–916. [Google Scholar] [CrossRef]

- Shebani, M.M.; Iqbal, T. Dynamic modeling, control, and analysis of a solar water pumping system for Libya. Hindawi J. Renew. Energy 2017, 2017, 8504283. [Google Scholar] [CrossRef]

- EL-Shimy, M. Sizing optimisation of stand-alone photovoltaic generators for irrigation water pumping systems. Int. J. Sustain. Energy 2013, 32, 333–350. [Google Scholar] [CrossRef]

- Suehrcke, H.; Appelbaum, J.; Breshef, B. Modelling a permanent magnet DC motor/centrifugal pump assembly in a photovoltaic energy system. Sol. Energy 1997, 59, 37–42. [Google Scholar] [CrossRef]

- Bakellia, Y.; Hadj Arabb, A.; Azouic, B. Optimal sizing of photovoltaic pumping system with water tank storage using LPSP. Sol. Energy 2011, 85, 288–294. [Google Scholar] [CrossRef]

- Kenge, K.; Hasija, M.; Tare, R.; Raghuwanshi, S. Mathematical Modelling and Implementation of Solar Based Water Pumping System for Irrigation. Int. J. Recent Technol. Eng. 2019, 8, 5596–5601. [Google Scholar]

- Shepovalova, O.V.; Belenov, A.T.; Chirkov, S.V. Review of photovoltaic water pumping system research. Energy Rep. 2020, 6, 306–324. [Google Scholar] [CrossRef]

- Cervera-Gascó, J.; Montero, J.; Moreno, M.A. I-Solar, a Real Time Photovoltaic Simulation Model for Accurate Estimation of Generated Power. Agronomy 2021, 11, 485. [Google Scholar] [CrossRef]

- Poompavai, T.; Kowsalya, M. Control and energy management strategies applied for solar photovoltaic and wind energy fed water pumping system: A review. Renew. Sustain. Energy Rev. 2019, 107, 108–122. [Google Scholar] [CrossRef]

- The Current Version of SISIFO Platformis Accessible through the Following Website. 2020. Available online: https://www.sisifo.info/en/default/ (accessed on 20 March 2021).

- Diaconu, A.; Craciunescu, D.; Fara, L.; Sterian, P.; Oprea, C.; Fara, S. Estimation of electricity production for a photovoltaic park using specialized advanced software. In Proceedings of the ISES EuroSun 2016 Conference, Palma de Mallorca, Spain, 18 August 2016; pp. 1180–1182. [Google Scholar]

- Fara, L.; Craciunescu, D. Output Analysis of Stand-Alone PV Systems: Modeling, Simulation and Control, Sustainable Solutions for Energy and Environment. Energy Procedia 2017, 112, 595–605. [Google Scholar] [CrossRef]

- Fara, L.; Craciunescu, D.; Diaconu, A. Results in performance improvement and operational optimization of photovoltaic components and systems. Ann. Acad. Rom. Sci. Ser. Phys. Chem. Sci. 2017, 2, 7–30. [Google Scholar]

- Diaconu, A.; Fara, L.; Sterian, P.; Craciunescu, D.; Fara, S. Results in sizing and simulation of PV applications based on different solar cell technologies. J. Power Energy Eng. 2017, 5, 63–74. [Google Scholar] [CrossRef][Green Version]

- Theocharides, S.; Makrides, G.; Georghiou, G.E.; Kyprianou, A. Machine Learning Algorithms for Photovoltaic System Power Output Prediction. In Proceedings of the 2018 IEEE International Energy Conference (ENERGYCON), Limassol, Cyprus, 3–7 June 2018. [Google Scholar] [CrossRef]

- How Digital Twin Technology is Changing the Solar Power. 2020. Available online: www.pratititech.com (accessed on 20 March 2021).

- Youssefa, A.; El-Telbanya, M.; Zekryb, A. The role of artificial intelligence in photovoltaic systems design and control: A review. Renew. Sustain. Energy Rev. 2017. [Google Scholar] [CrossRef]

- Mellit, A. Sizing of photovoltaic systems: A review. Rev. Des Energy Renouvelables 2007, 10, 463–472. [Google Scholar]

- Digital Platform. 2020. Available online: https://www.record-evolution.de/ (accessed on 20 February 2021).

- Craciunescu, D. Contributions to Development and Integration of Complex Photovoltaic Systems in Optoelectronic and Power Applications. Ph.D. Thesis, Polytechnic University of Bucharest, Bucharest, Romania, 2019. [Google Scholar]

Figure 1.

The concept of the PV pumping system for irrigation application (original conception).

Figure 1.

The concept of the PV pumping system for irrigation application (original conception).

Figure 2.

The block diagram of the PV pumping system architecture, off-grid type.

Figure 2.

The block diagram of the PV pumping system architecture, off-grid type.

Figure 3.

PV pump characteristics.

Figure 3.

PV pump characteristics.

Figure 4.

Pump motor characteristics.

Figure 4.

Pump motor characteristics.

Figure 5.

I-V (current—voltage) and P-V (power—voltage) characteristics for the analyzed PV generator for different values of temperatures.

Figure 5.

I-V (current—voltage) and P-V (power—voltage) characteristics for the analyzed PV generator for different values of temperatures.

Figure 6.

I-V (current—voltage) and P-V (power—voltage) characteristics for the analyzed PV generator for different values of solar irradiance.

Figure 6.

I-V (current—voltage) and P-V (power—voltage) characteristics for the analyzed PV generator for different values of solar irradiance.

Figure 7.

The inverter efficiency depending of the rated output power.

Figure 7.

The inverter efficiency depending of the rated output power.

Figure 8.

(a) Annual solar irradiance taking into account different actual operating conditions of PV panels and (b) Monthly solar irradiance for the specific site (South of Romania).

Figure 8.

(a) Annual solar irradiance taking into account different actual operating conditions of PV panels and (b) Monthly solar irradiance for the specific site (South of Romania).

Figure 9.

Minimum and maximum monthly ambient temperature.

Figure 9.

Minimum and maximum monthly ambient temperature.

Figure 10.

Monthly energy yield of the PV pumping system irrigation (a specific site, South of Romania).

Figure 10.

Monthly energy yield of the PV pumping system irrigation (a specific site, South of Romania).

Figure 11.

Monthly pumping yield of the PV pumping system (a specific site, South of Romania).

Figure 11.

Monthly pumping yield of the PV pumping system (a specific site, South of Romania).

Figure 12.

The global performances of the PV pumping system for a specific site in Romania.

Figure 12.

The global performances of the PV pumping system for a specific site in Romania.

Figure 16.

The concept of digitalization.

Figure 16.

The concept of digitalization.

Figure 17.

Artificial Intelligence (AI) approach.

Figure 17.

Artificial Intelligence (AI) approach.

Figure 18.

Machine learning approach.

Figure 18.

Machine learning approach.

Figure 19.

Digital twin approach.

Figure 19.

Digital twin approach.

Figure 20.

Intelligent block diagram based on MPPT and PWM.

Figure 20.

Intelligent block diagram based on MPPT and PWM.

Table 1.

Input data for PV pump.

Table 1.

Input data for PV pump.

| Pump Curve | Shaft Power Curve |

|---|

| Q [m3/h] | H [m] | Q [m3/h] | Pshaft [kW] |

| 0.00 | 207.75 | 17.68 | 16.23 |

| 21.33 | 189.44 | 23.13 | 18.09 |

| 24.97 | 184.06 | 26.76 | 18.99 |

| 28.57 | 177.30 | 30.40 | 19.72 |

| 32.21 | 168.33 | 34.03 | 20.21 |

| 35.85 | 156.58 | 37.67 | 20.46 |

| 39.48 | 142.05 | 41.30 | 20.41 |

| 43.12 | 124.74 | 44.93 | 20.05 |

| 52.20 | 65.80 | 52.20 | 18.30 |

Table 2.

Input data for pump motor.

Table 2.

Input data for pump motor.

| Pump Curve | Shaft Power Curve |

|---|

| Pshaft [kW] | Efficiency [%] |

| 0 | 0.00 |

| 5.45 | 77.80 |

| 10,97 | 83.80 |

| 14,24 | 84.20 |

| 16.55 | 84.20 |

| 21.86 | 83.08 |

| 22.22 | 83.53 |

| 22.87 | 83.00 |

| 23.13 | 82.00 |

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).