Open-Circuit Fault-Tolerant Control of Multi-Phase PM Machines by Compensating the d-q Axes Currents

Abstract

1. Introduction

2. Methodology

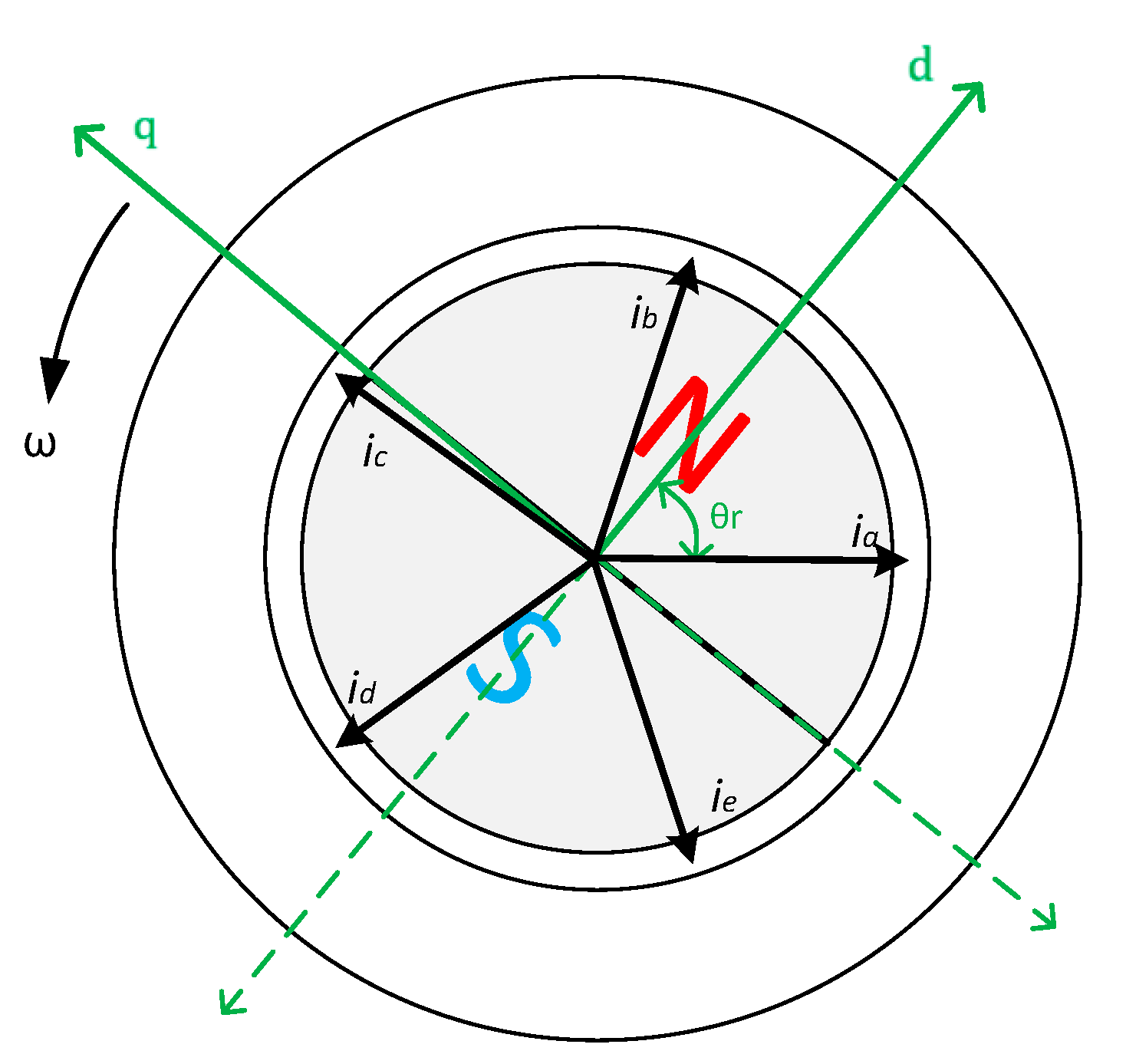

2.1. Direct and Quadrature Axes Currents

2.2. Resultant (Rotating) Magnetomotive Force of the Sinusoidal Distributed Five-Phase Machine

2.3. Open-Circuit Fault-Tolerant Control of a Sinusoidal Distributed Winding Five-Phase Machine

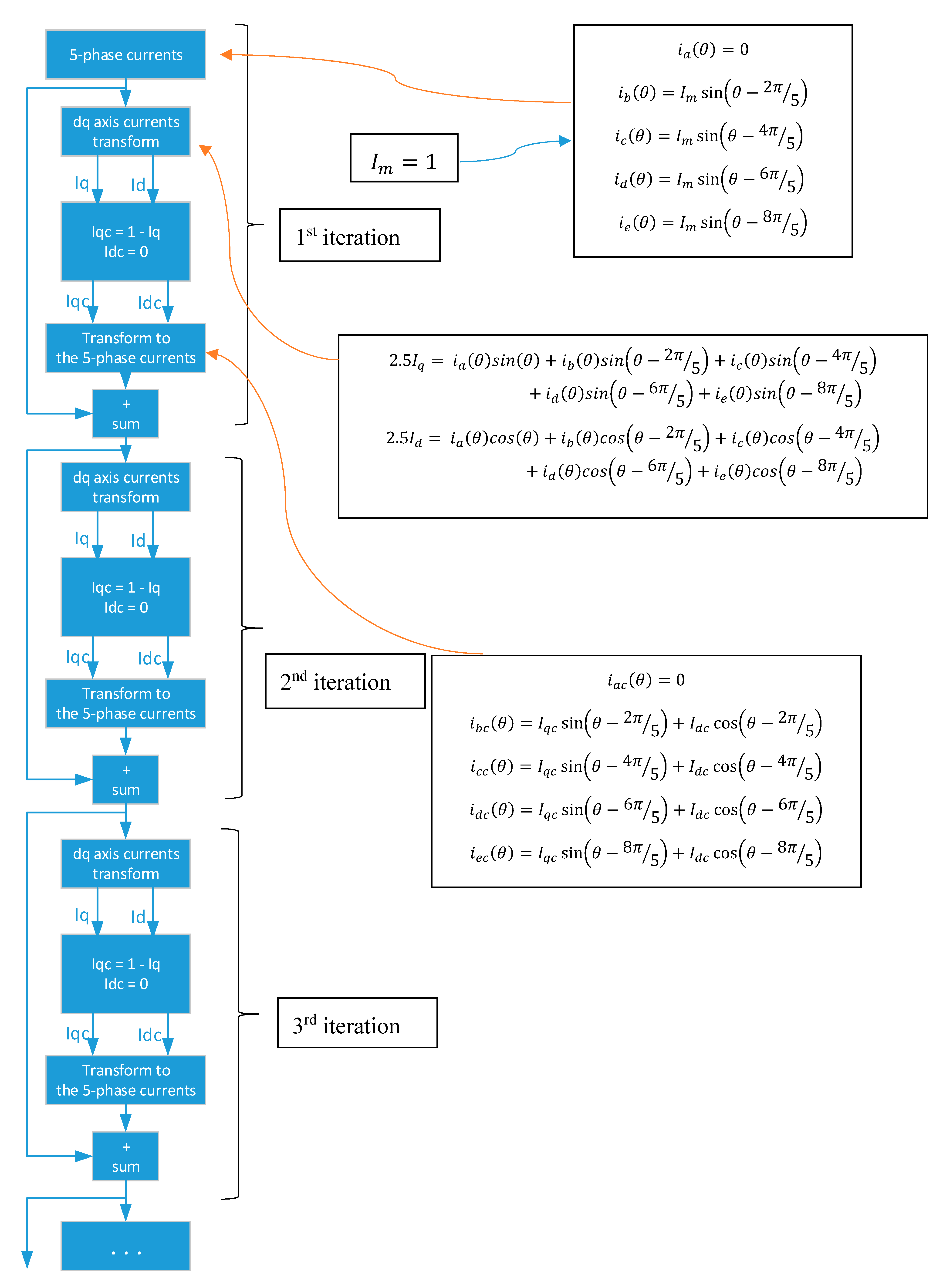

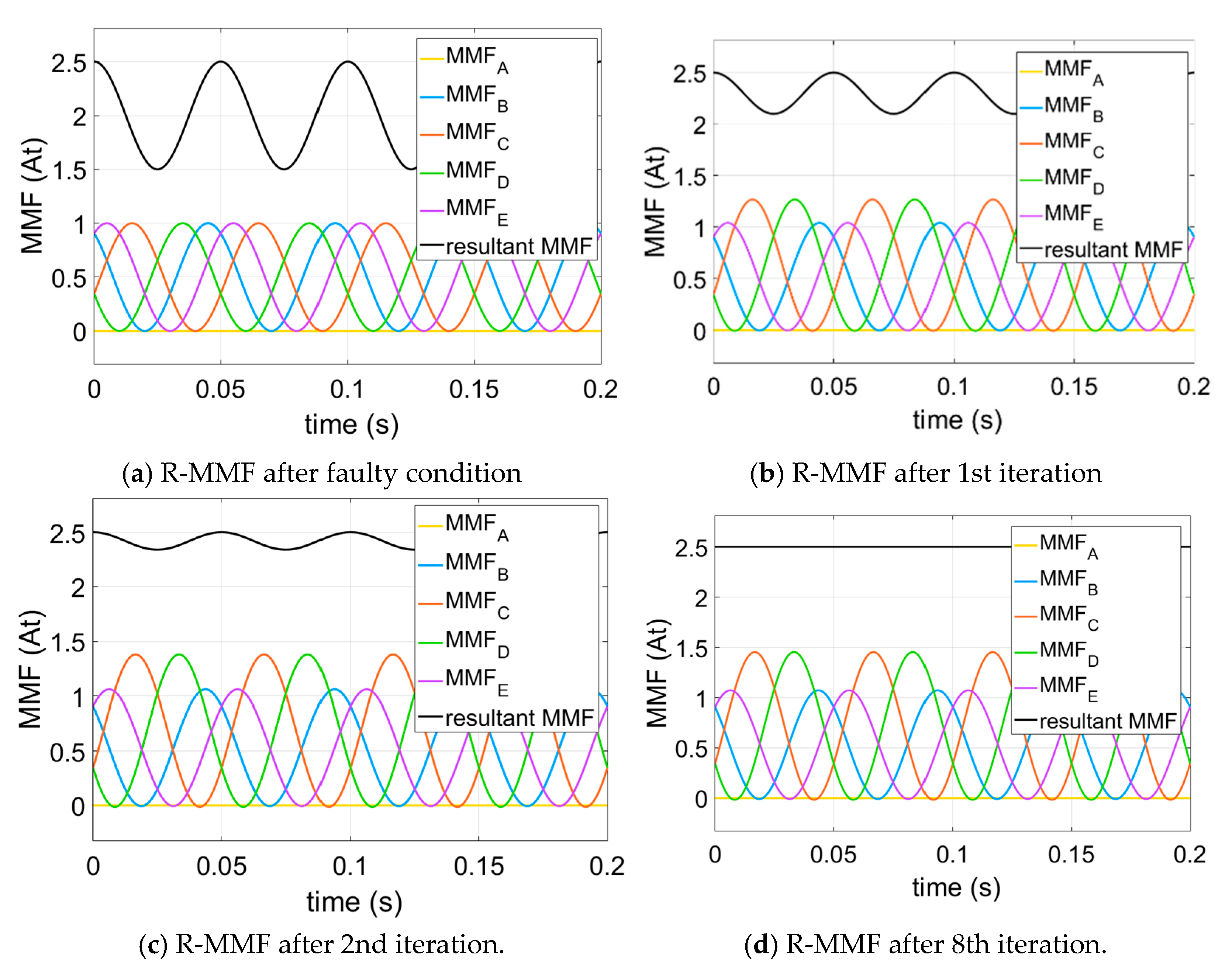

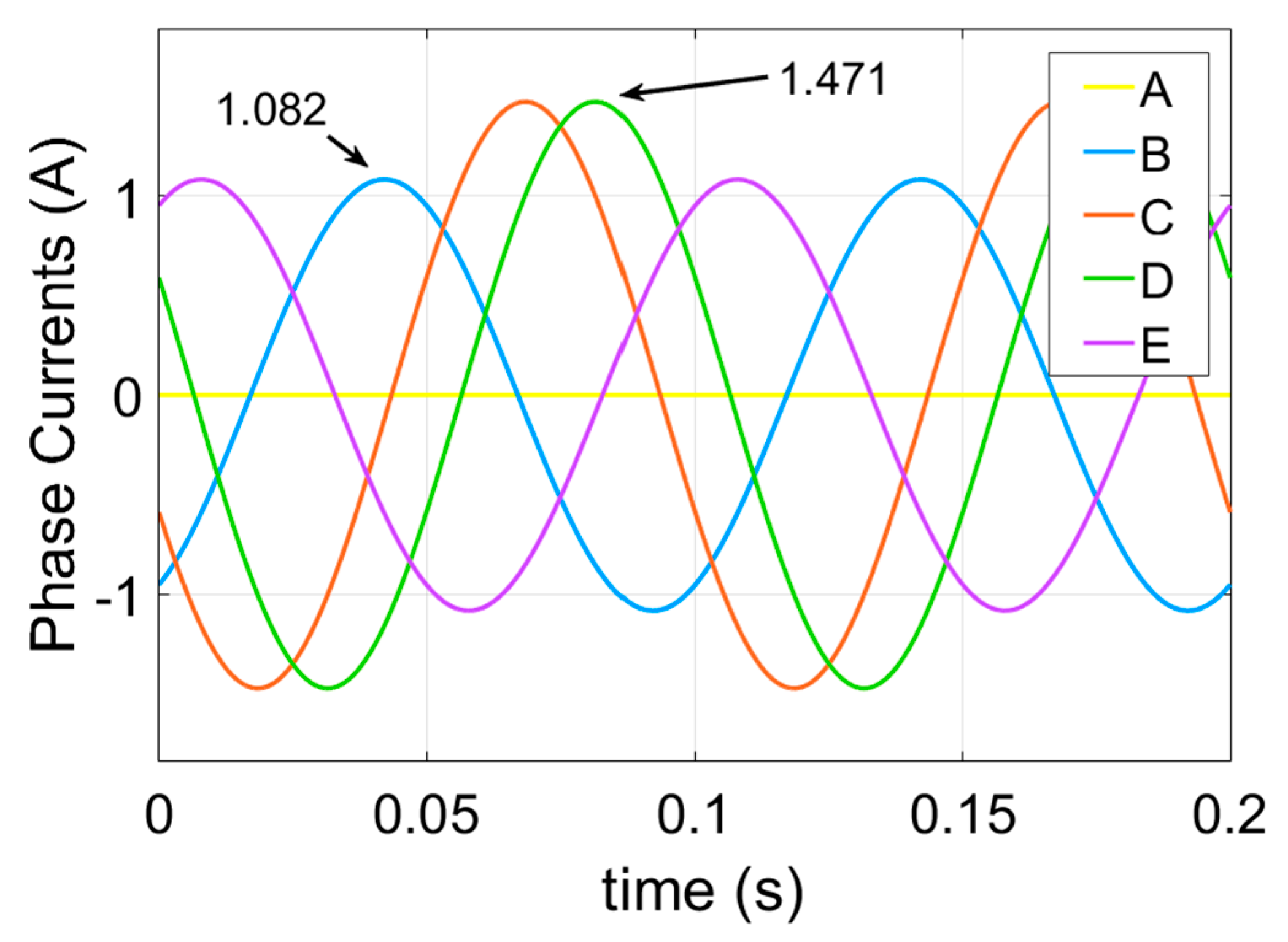

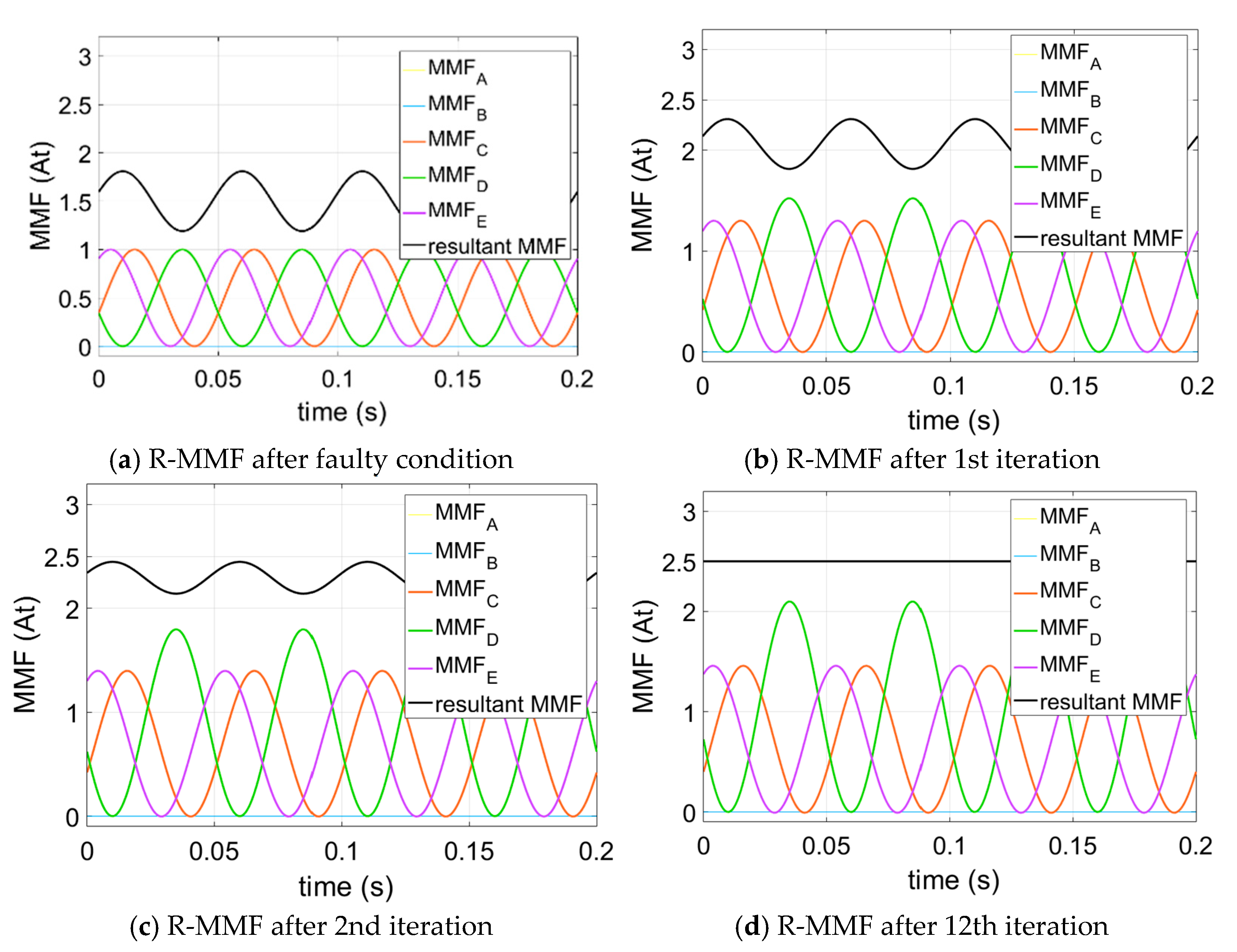

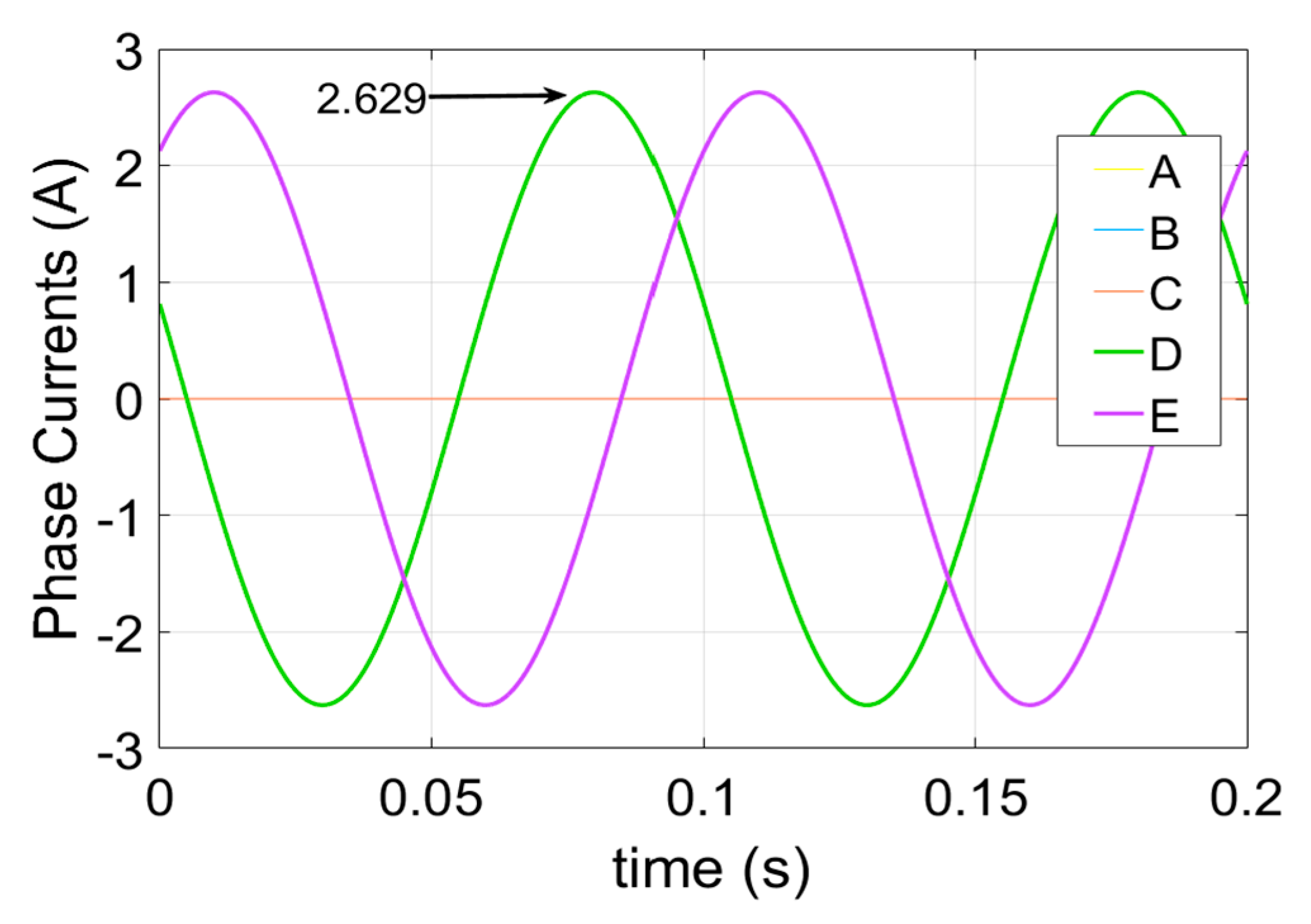

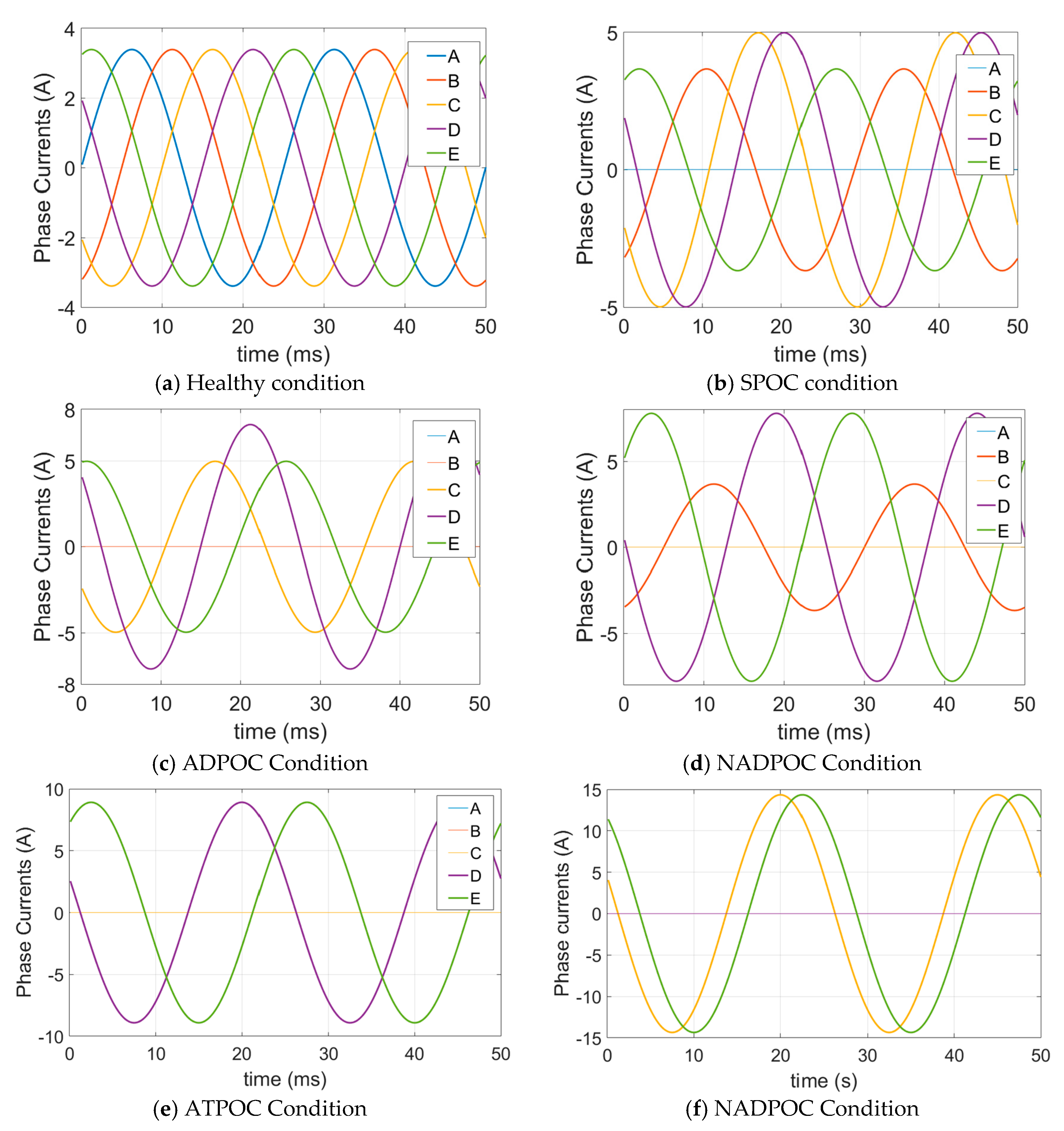

2.3.1. Single-Phase Open-Circuit Condition

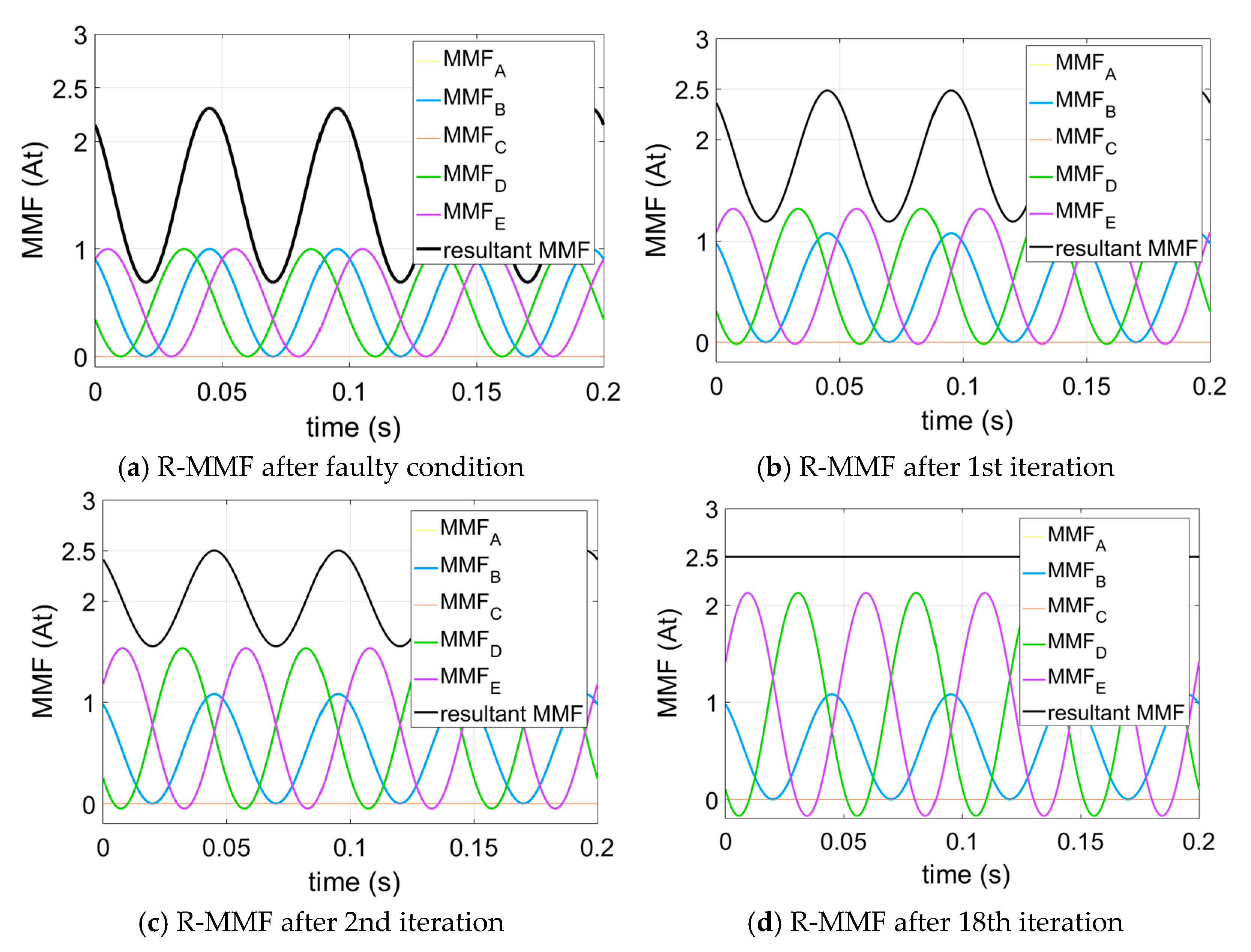

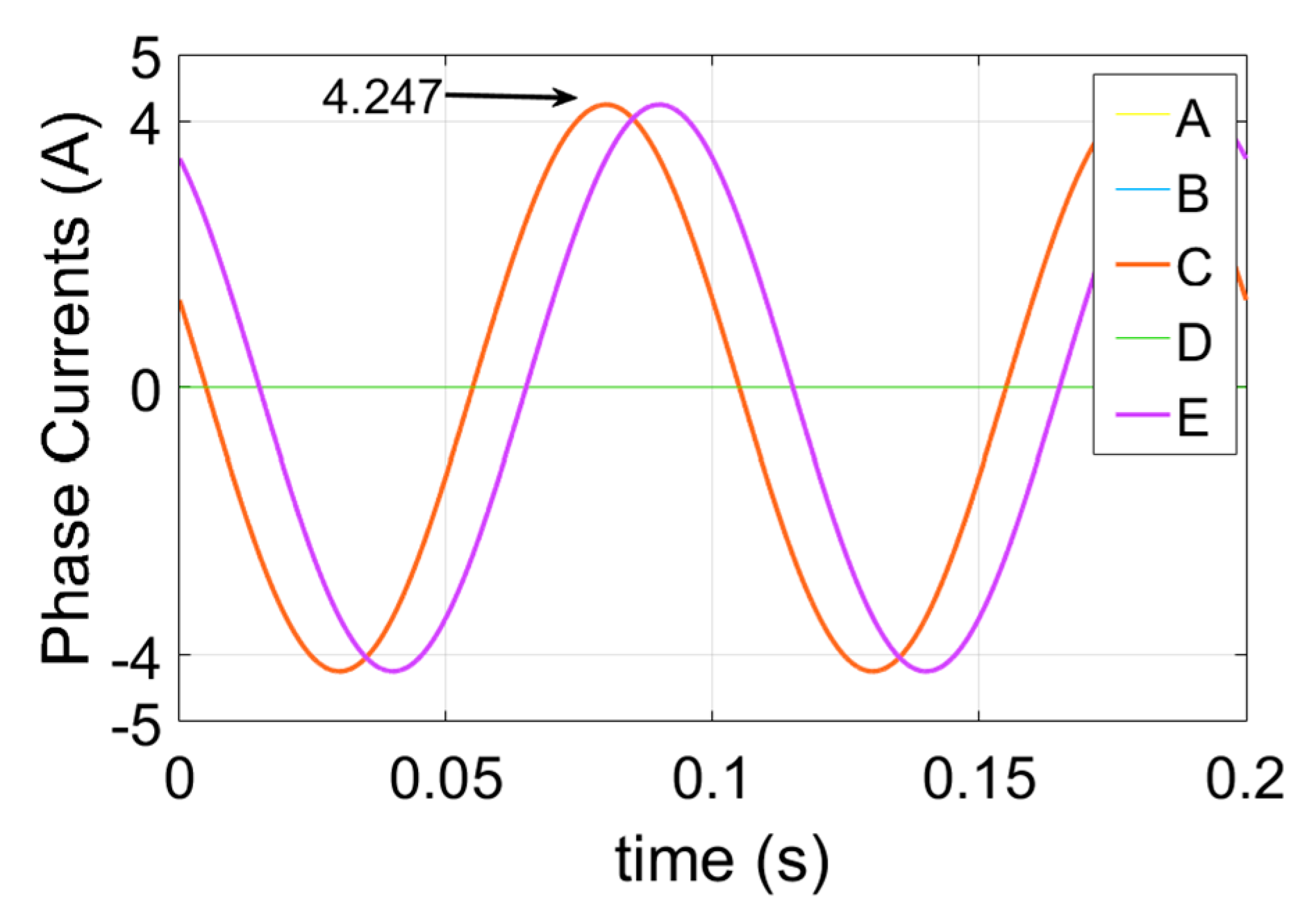

2.3.2. Adjacent Double-Phase Open-Circuit Condition

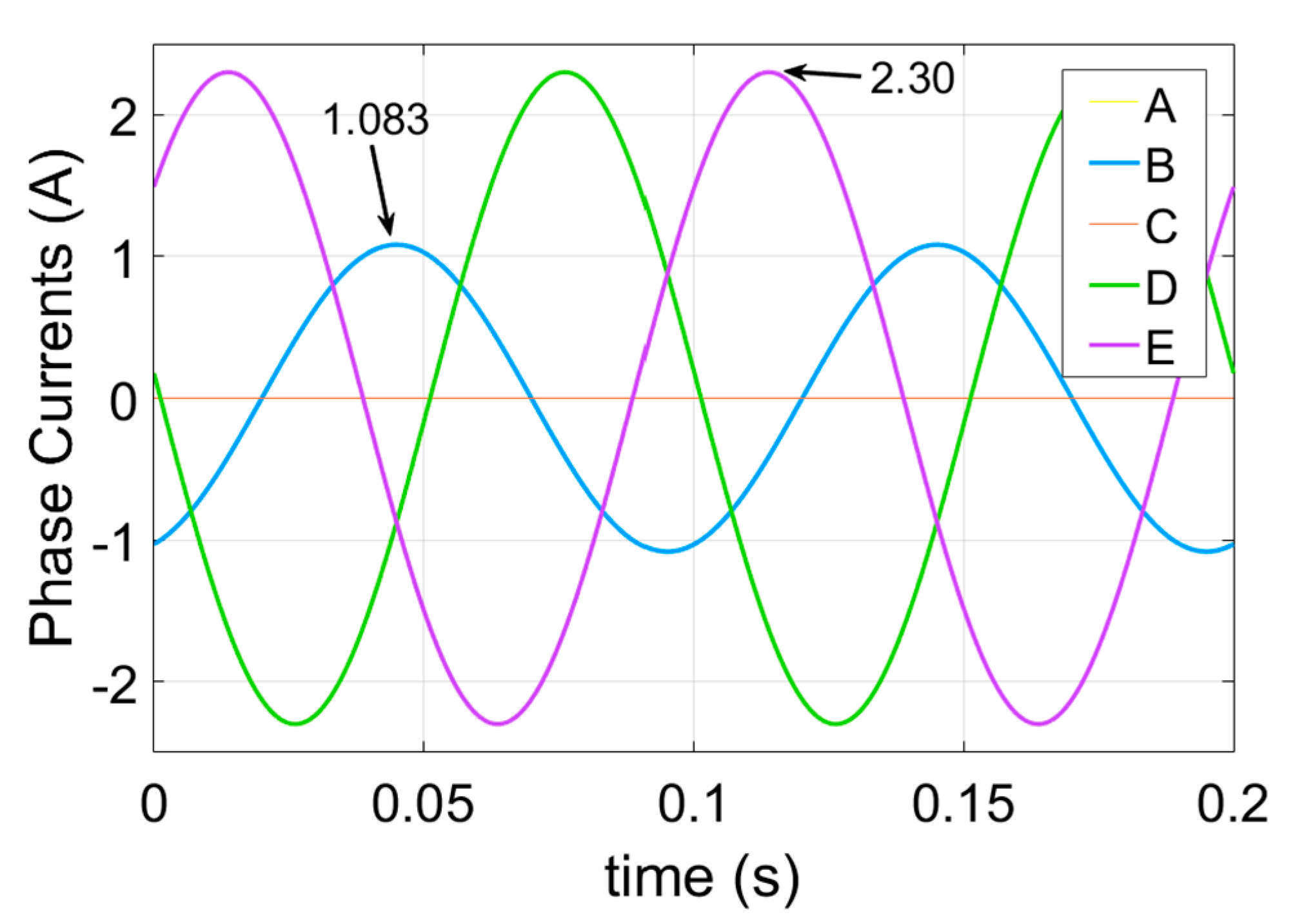

2.3.3. Non-Adjacent Double-Phase Open-Circuit Condition

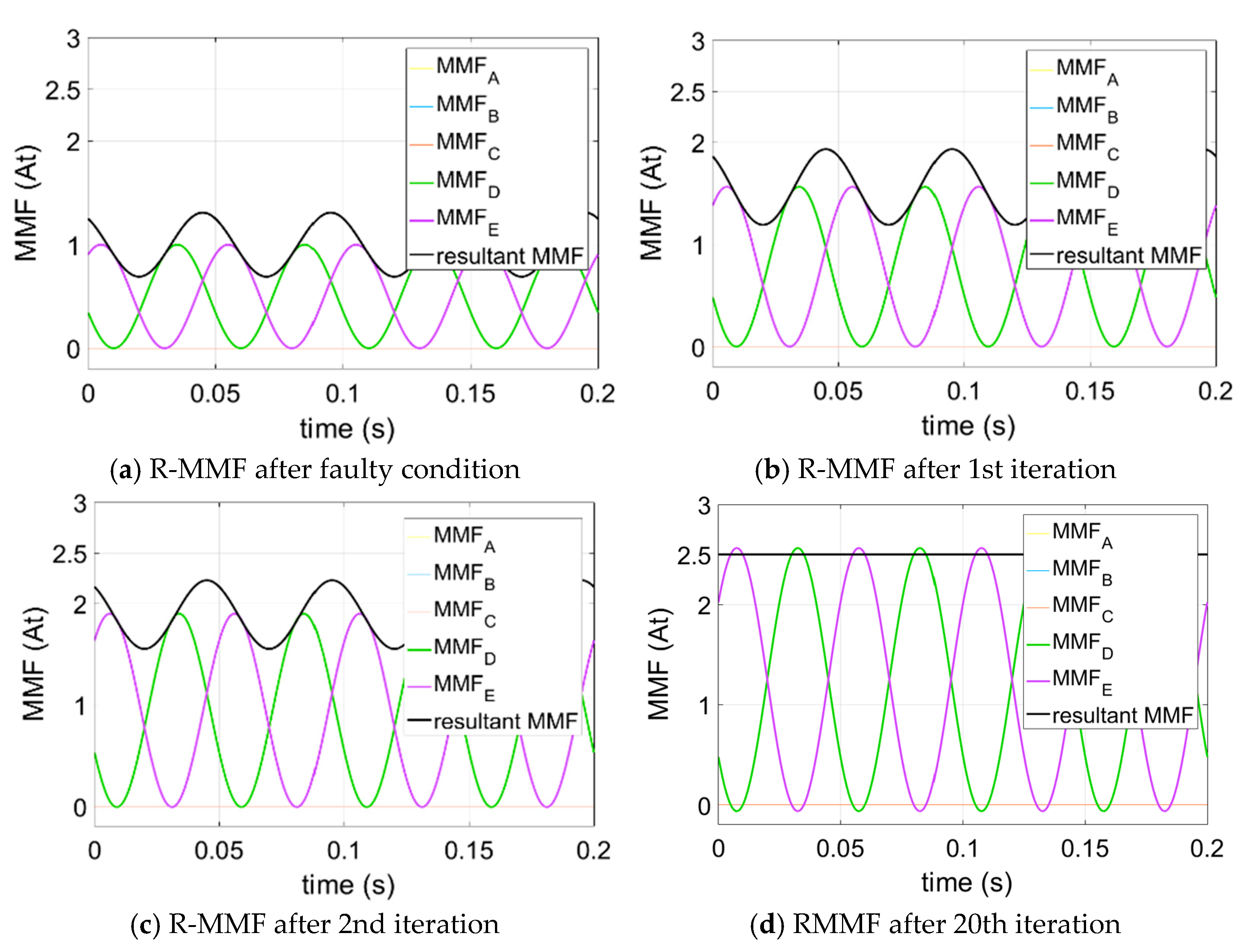

2.3.4. Adjacent Three-Phase Open Circuit Condition

2.3.5. Non-Adjacent Three-Phase Open Circuit Condition

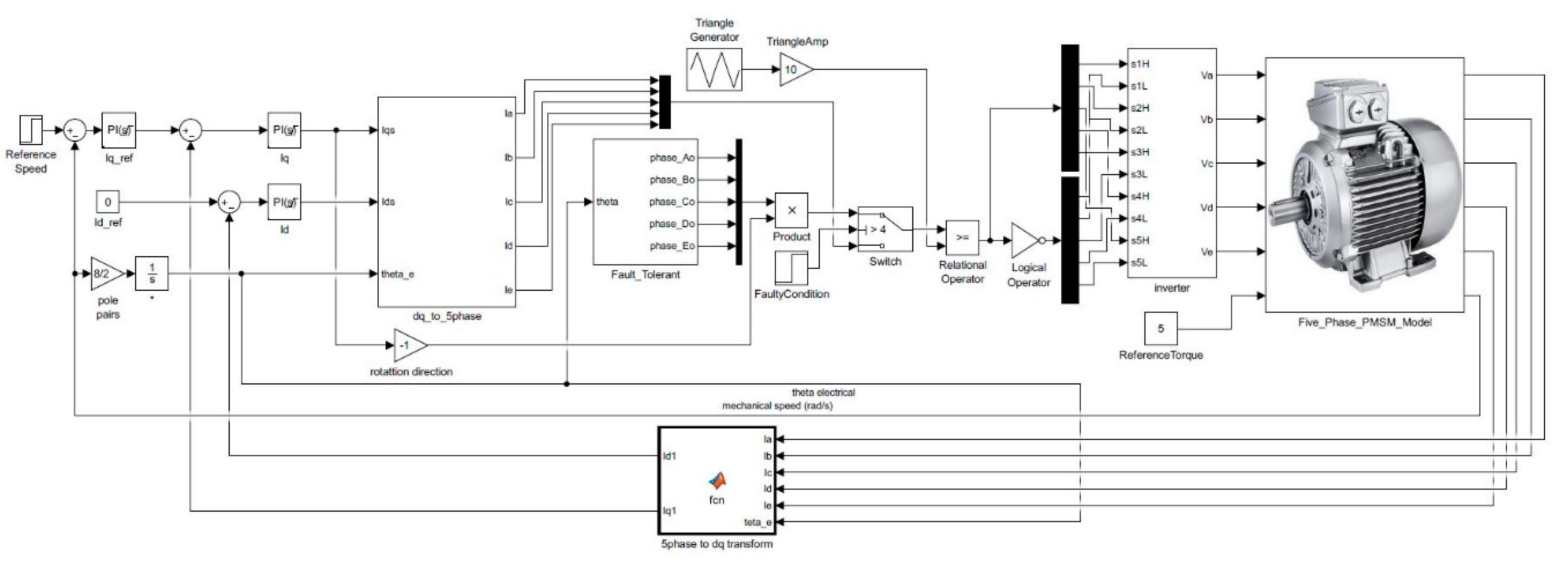

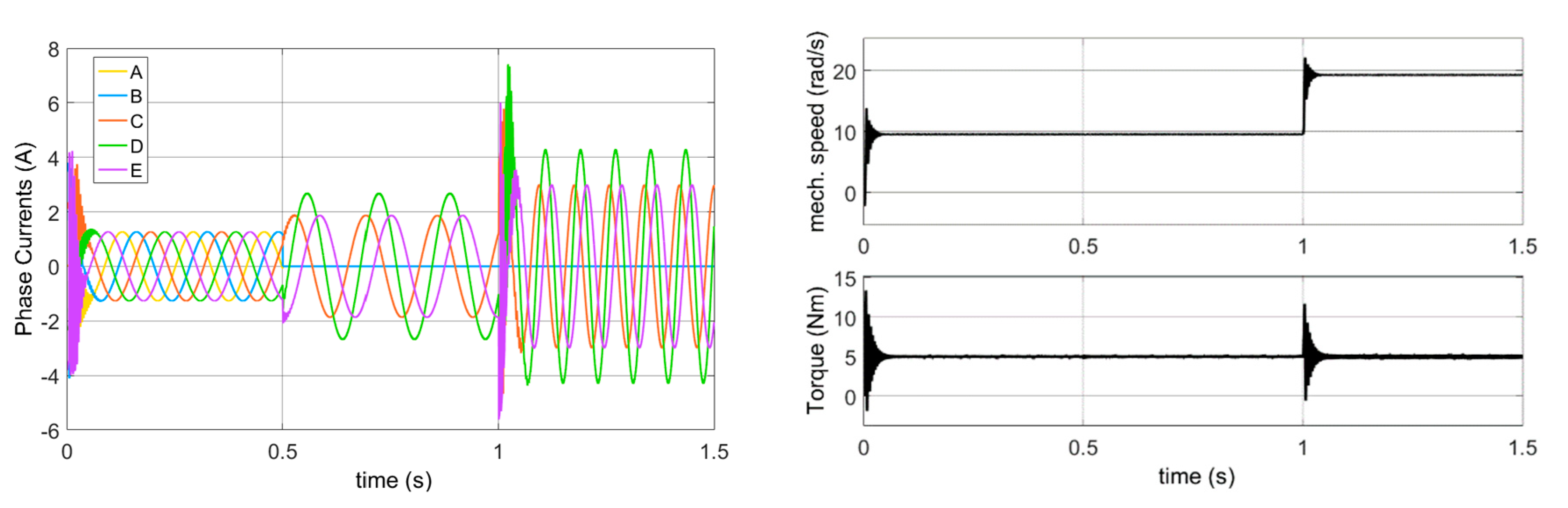

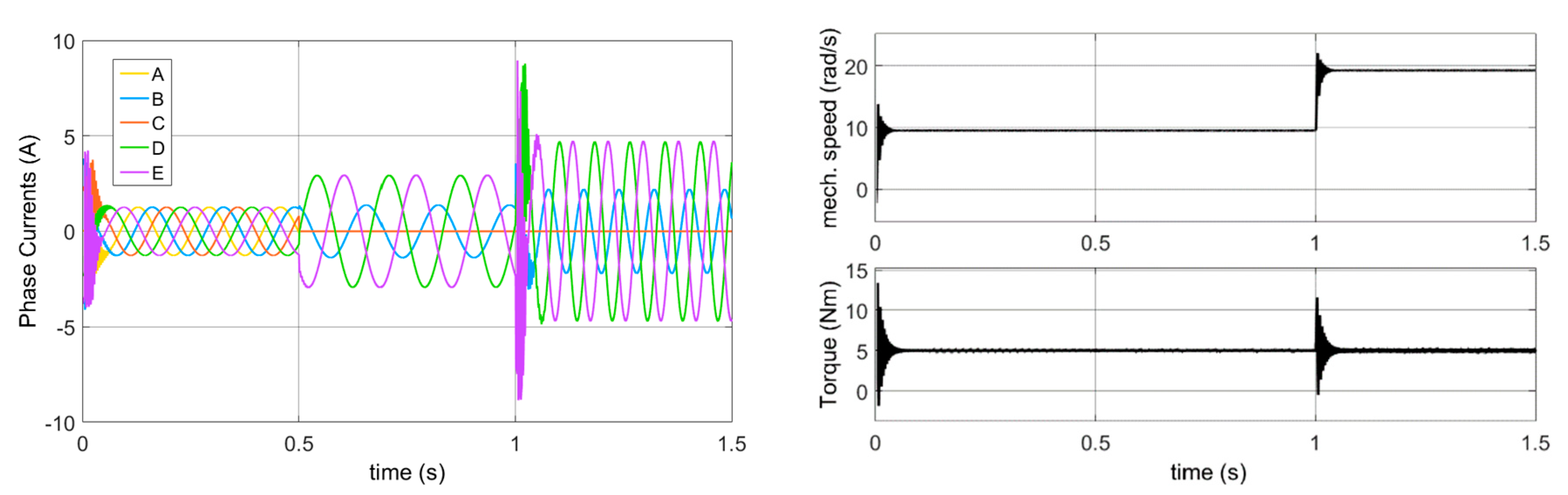

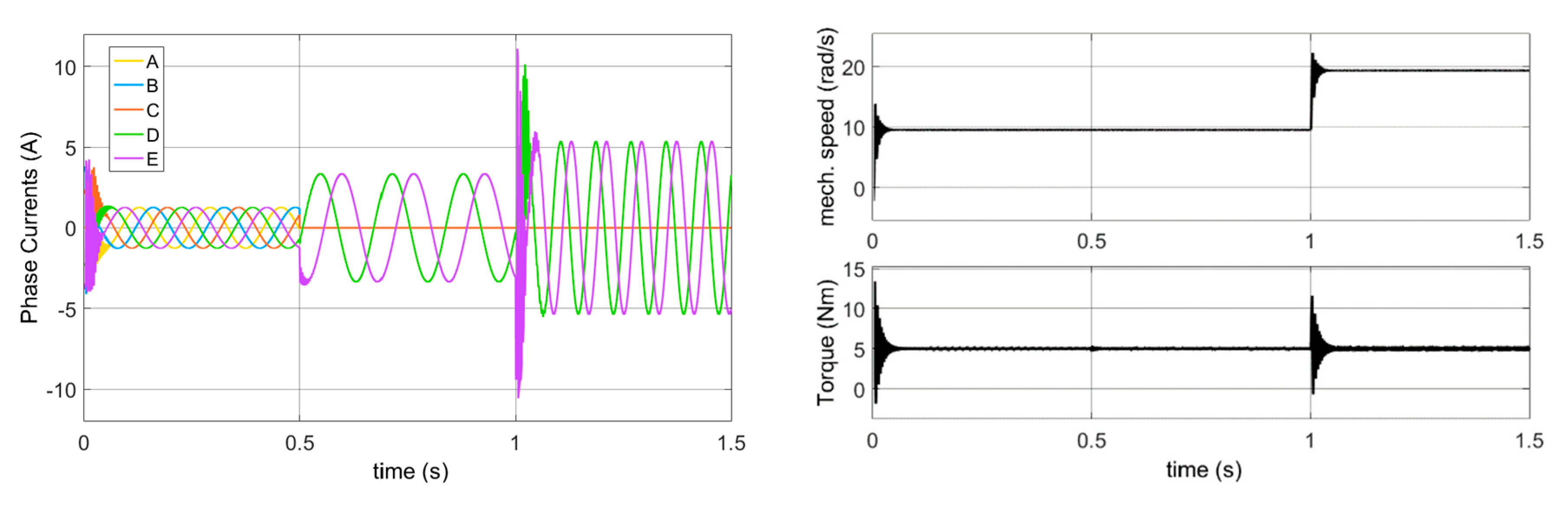

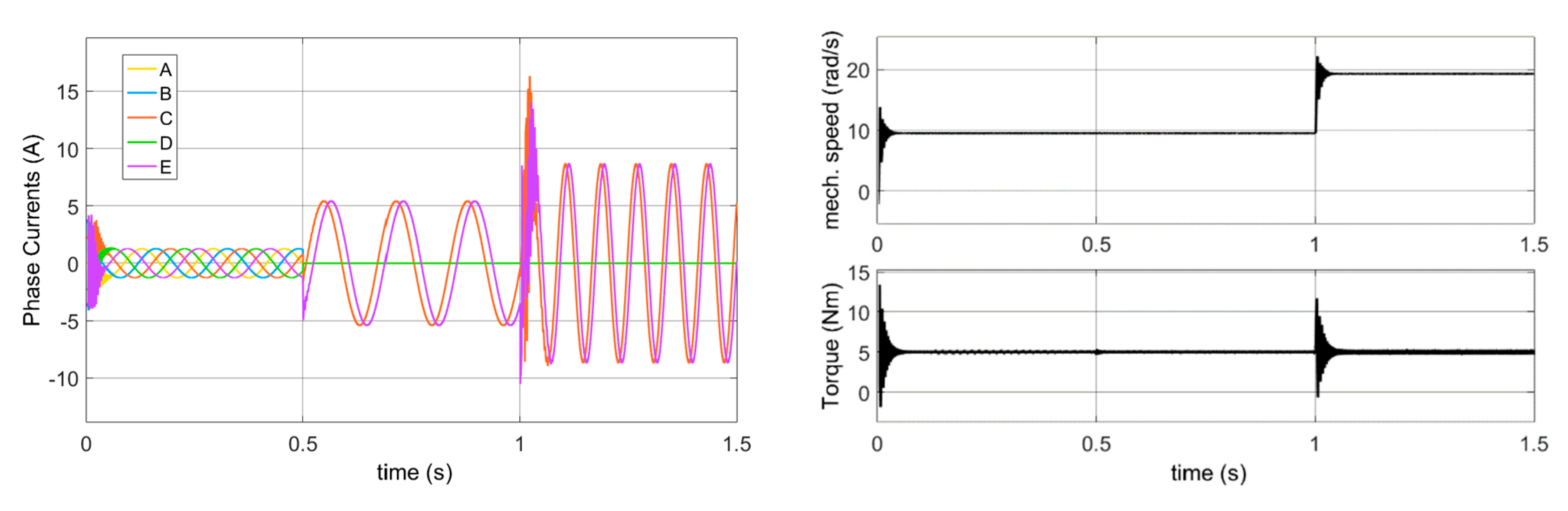

3. MATLAB/Simulink Simulation of the Proposed Method

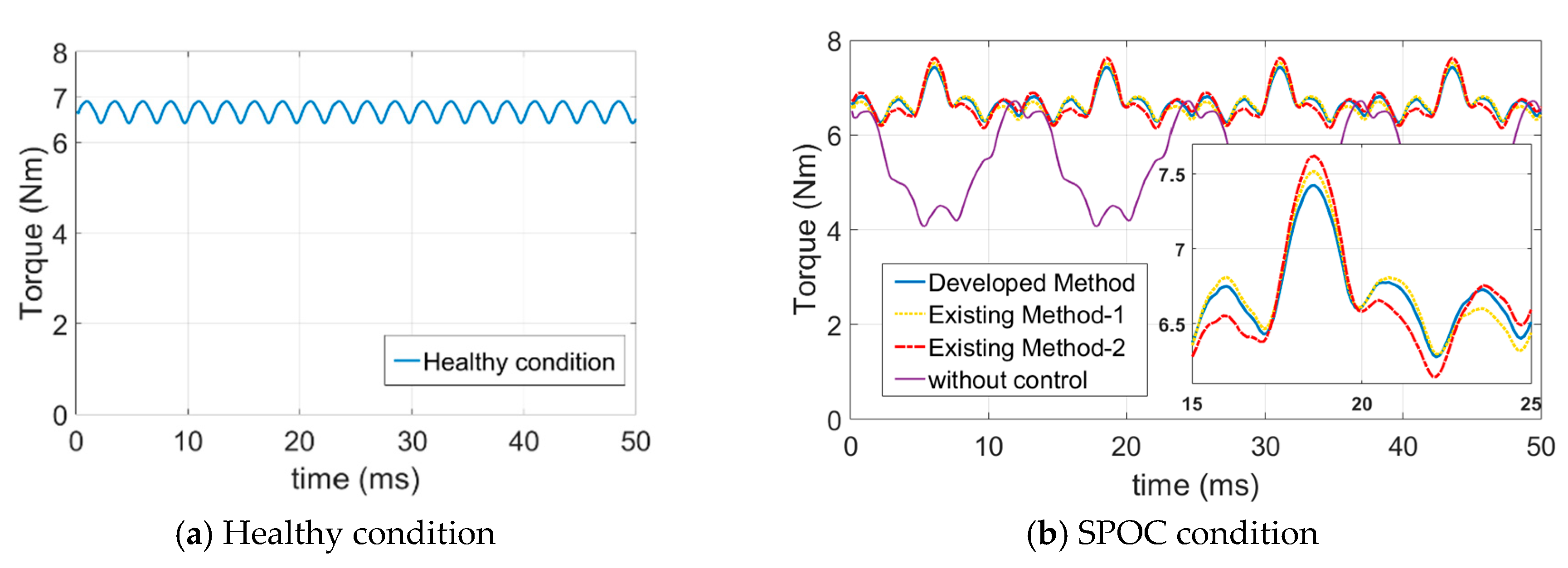

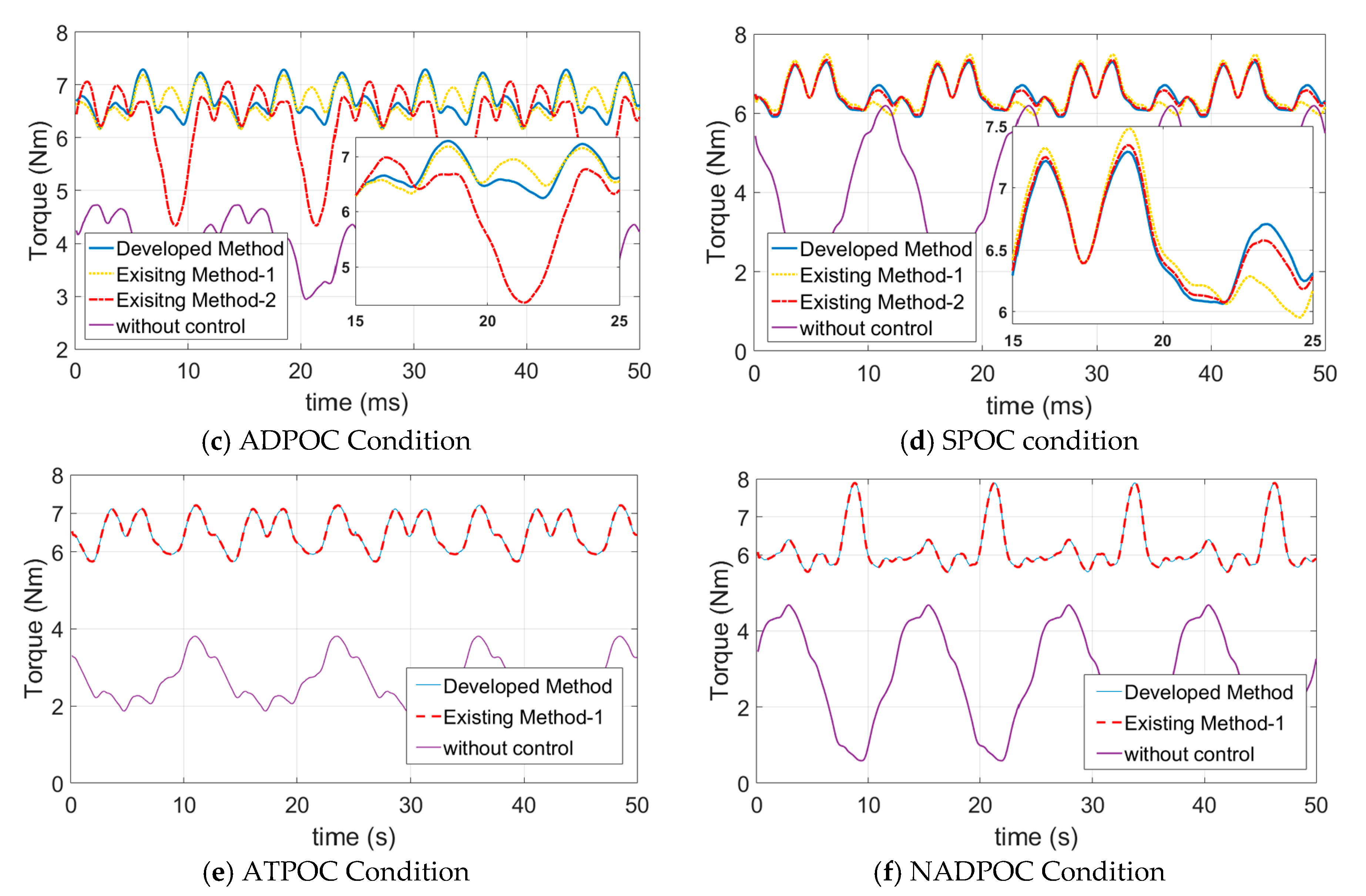

4. Simulation on an FEA Model

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Levi, E. Multiphase Electric Machines for Variable-Speed Applications. IEEE Trans. Ind. Electron. 2008, 55, 1893–1909. [Google Scholar] [CrossRef]

- Scuiller, F. Magnet Shape Optimization to Reduce Pulsating Torque for a Five-Phase Permanent-Magnet Low-Speed Machine. IEEE Trans. Magn. 2013, 50, 1–9. [Google Scholar] [CrossRef]

- Barrero, F.; Duran, M.J. Recent Advances in the Design, Modeling, and Control of Multiphase Machines—Part I. IEEE Trans. Ind. Electron. 2016, 63, 449–458. [Google Scholar] [CrossRef]

- Lipo, T.A.; Toliyat, H.A.; White, J.C. A Concentrated Winding Induction Machine. Energy 1991, 6, 1–5. [Google Scholar]

- Levi, E.; Barrero, F.; Duran, M.J. Multiphase machines and drives—Revisited. IEEE Trans. Ind. Electron. 2016, 63, 429–432. [Google Scholar] [CrossRef]

- Toliyat, H.; Waikar, S.; Lipo, T. Analysis and simulation of five-phase synchronous reluctance machines including third harmonic of airgap MMF. IEEE Trans. Ind. Appl. 1998, 34, 332–339. [Google Scholar] [CrossRef]

- Parsa, L. Performance Improvement of Permanent Magnet Ac Motors. J. Biol. Chem. 2005, 280, 33960–33967. [Google Scholar]

- Ding, S.; Chen, W.; Tong, M.; Xie, F.; Zheng, C. Fault tolerant control for a five-phase permanent magnet synchronous machine driving system. In Proceedings of the 2016 IEEE 11th Conference on Industrial Electronics and Applications (ICIEA), Hefei, China, 5–7 June 2016; pp. 2021–2025. [Google Scholar] [CrossRef]

- Shin, H.; Baek, S.K.; Lee, K. Five-Phase Induction Motor Driving System. In Proceedings of the 2016 IEEE 8th International Power Electronics and Motion Control Conference (IPEMC-ECCE Asia), Hefei, China, 22–26 May 2016; pp. 2487–2492. [Google Scholar]

- Jack, A.G.; Mecrow, B.C.; Haylock, J. A Comparative Study of Permanent Magnet and Switched Reluctance Motors for High Performance Fault Tolerant Applications. IEEE Trans. Ind. Appl. 1995, 32, 734–740. [Google Scholar]

- Lipo, T.A. A strategy for improving reliability of field oriented controlled induction motor drives. In Proceedings of the IEEE Idustry Applications Society Annual Meeting, Dearborn, MI, USA, 28 September–4 October 1991. [Google Scholar]

- Sui, Y.; Zheng, P.; Yin, Z.; Wang, M.; Wang, C. Open-Circuit Fault-Tolerant Control of Five-Phase PM Machine Based on Reconfiguring Maximum Round Magnetomotive Force. IEEE Trans. Ind. Electron. 2019, 66, 48–59. [Google Scholar] [CrossRef]

- Fu, J.; Lipo, T.A. Disturbance-Free Operation of a Multiphase Current-Regulated Motor Drive with an Opened Phase. IEEE Trans. Ind. Appl. 1994, 30, 5–12. [Google Scholar]

- Parsa, L.; Toliyat, H.A. Fault-Tolerant Five-Phase Permanent Magnet Motor Drives. In Proceedings of the Conference Record of the 2004 39th IEEE Industry Applications Conference, Seattle, WA, USA, 3–7 October 2004; Volume 2, pp. 1048–1054. [Google Scholar]

- Dwari, S.; Parsa, L. Open-circuit Fault Tolerant Control of Five-Phase Permanent Magnet Motors with Third-Harmonic Back-EMF. In Proceedings of the 34th Annual Conference of IEEE Industrial Electronics, Orlando, FL, USA, 10–13 November 2008. [Google Scholar]

- Dwari, S.; Parsa, L. Fault-Tolerant Control of Five-Phase Permanent-Magnet Motors With Trapezoidal Back EMF. IEEE Trans. Ind. Electron. 2011, 58, 476–485. [Google Scholar] [CrossRef]

- Mohammadpour, A.; Sadeghi, S.; Parsa, L. Fault-tolerant control of five-phase PM machines with pentagon connection of stator windings under open-circuit faults. In Proceedings of the 2012 Twenty-Seventh Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Orlando, FL, USA, 5–9 February 2012; pp. 1667–1672. [Google Scholar]

- Mohammadpour, A.; Gandhi, A.; Parsa, L. Design and control of fault-tolerant permanent magnet machines. In Proceedings of the 2013 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Paris, France, 11–12 March 2013; Volume 12180, pp. 108–116. [Google Scholar]

- Mohammadpour, A.; Parsa, L. Post-fault control technique for multi-phase PM motor drives under short-circuit faults. In Proceedings of the 2013 Twenty-Eighth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 17–21 March 2013; pp. 817–822. [Google Scholar]

- Mohammadpour, A.; Mishra, S.; Parsa, L. Fault-Tolerant Operation of Multiphase Permanent-Magnet Machines Using Iterative Learning Control. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 201–211. [Google Scholar] [CrossRef]

- Mohammadpour, A.; Sadeghi, S.; Parsa, L. A Generalized Fault-Tolerant Control Strategy for Five-Phase PM Motor Drives Considering Star, Pentagon, and Pentacle Connections of Stator Windings. IEEE Trans. Ind. Electron. 2014, 61, 63–75. [Google Scholar] [CrossRef]

- Mohammadpour, A.; Parsa, L. Global Fault-Tolerant Control Technique for Multiphase Permanent-Magnet Machines. IEEE Trans. Ind. Appl. 2015, 51, 178–186. [Google Scholar] [CrossRef]

| D-q Modelled Machine Parameters. | Values |

|---|---|

| Stator resistance (Rs) | 1.55 Ω |

| Number of poles (P) | 8 |

| q-axis inductance (Lq) | 3.88 mH |

| d-axis inductance (Ld) | 3.88 mH |

| Rotor PM Flux (λm) | 0.108 Wb |

| Rotational inertia (J) | 0.00128 kg⸱m2 |

| Viscous friction coefficient (B) | 0.000217 Nm⸱s/rad |

| Parameters. | Values |

|---|---|

| Rated Power | 1 kW |

| Rated Speed | 2000 rpm |

| Rated Current | 3.39 A (peak) |

| Rated Torque | 6.6966 Nm |

| Number of Poles | 8 |

| Number of slots | 10 |

| Ohmic Losses (W) | |||||

|---|---|---|---|---|---|

| SPOC | ADPOC | NADOPC | ATPOC | NATPOC | |

| Developed Method | 3.3346 | 4.3521 | 5.5593 | 6.9116 | 18.0625 |

| Existing Method-1 | 3.4553 | 4.6924 | 6.8604 | 6.9116 | 18.0625 |

| Existing Method-2 | 3.8198 | 11.5338 | 5.9547 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akay, A.; Lefley, P. Open-Circuit Fault-Tolerant Control of Multi-Phase PM Machines by Compensating the d-q Axes Currents. Energies 2021, 14, 192. https://doi.org/10.3390/en14010192

Akay A, Lefley P. Open-Circuit Fault-Tolerant Control of Multi-Phase PM Machines by Compensating the d-q Axes Currents. Energies. 2021; 14(1):192. https://doi.org/10.3390/en14010192

Chicago/Turabian StyleAkay, Ali, and Paul Lefley. 2021. "Open-Circuit Fault-Tolerant Control of Multi-Phase PM Machines by Compensating the d-q Axes Currents" Energies 14, no. 1: 192. https://doi.org/10.3390/en14010192

APA StyleAkay, A., & Lefley, P. (2021). Open-Circuit Fault-Tolerant Control of Multi-Phase PM Machines by Compensating the d-q Axes Currents. Energies, 14(1), 192. https://doi.org/10.3390/en14010192