Water-Energy-Nutrients Synergies in the Agrifood Sector: A Circular Economy Framework

Abstract

1. Introduction

- How has CE been practically integrated into the agricultural and livestock sectors in terms of bio-based production (e.g., energy, fertilizers) and water reuse?

- Which are the actual benefits of the proposed CE solutions for the agrifood industry in terms of sustainability?

- Which are the interrelations within the water-energy-nutrients nexus?

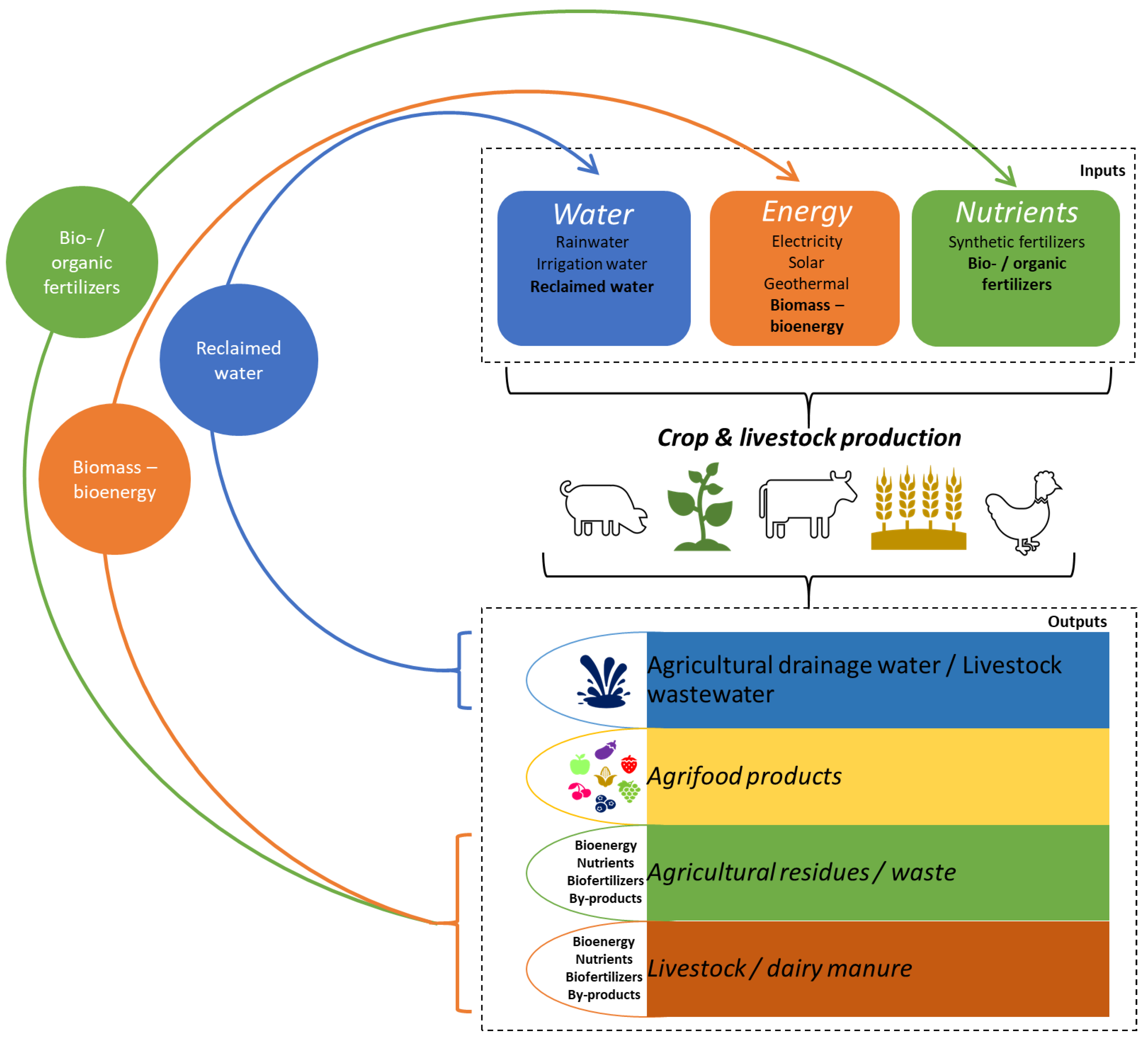

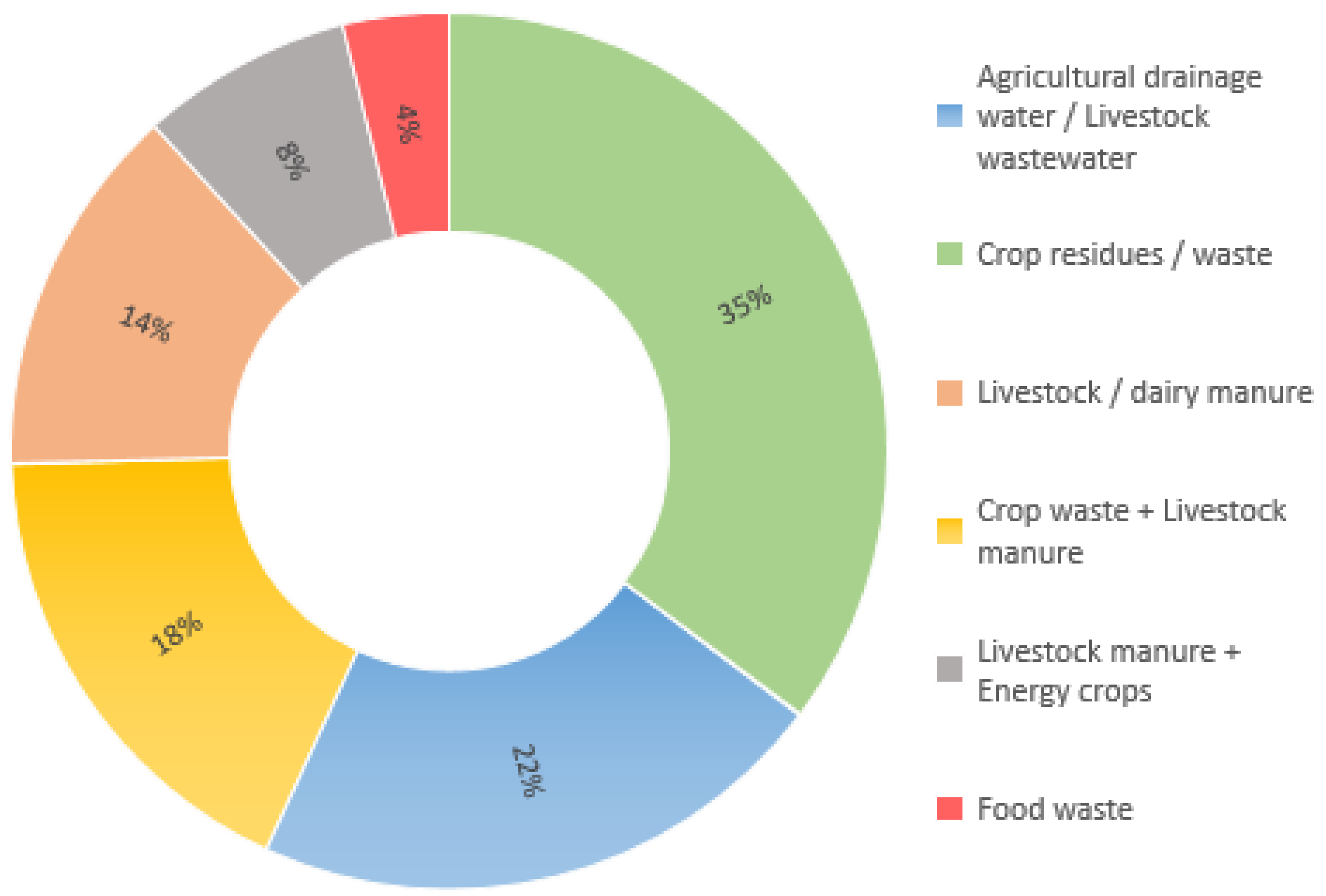

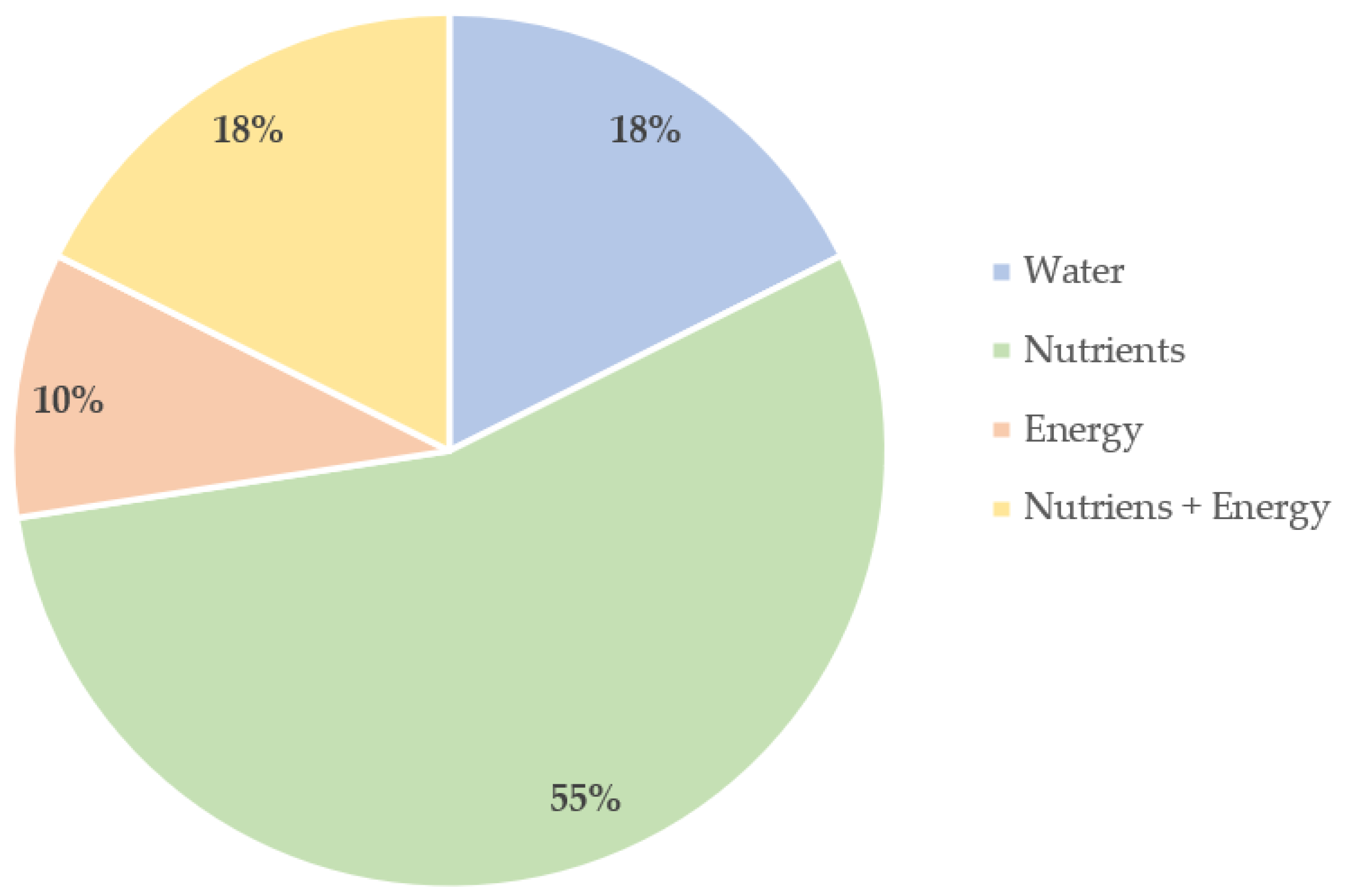

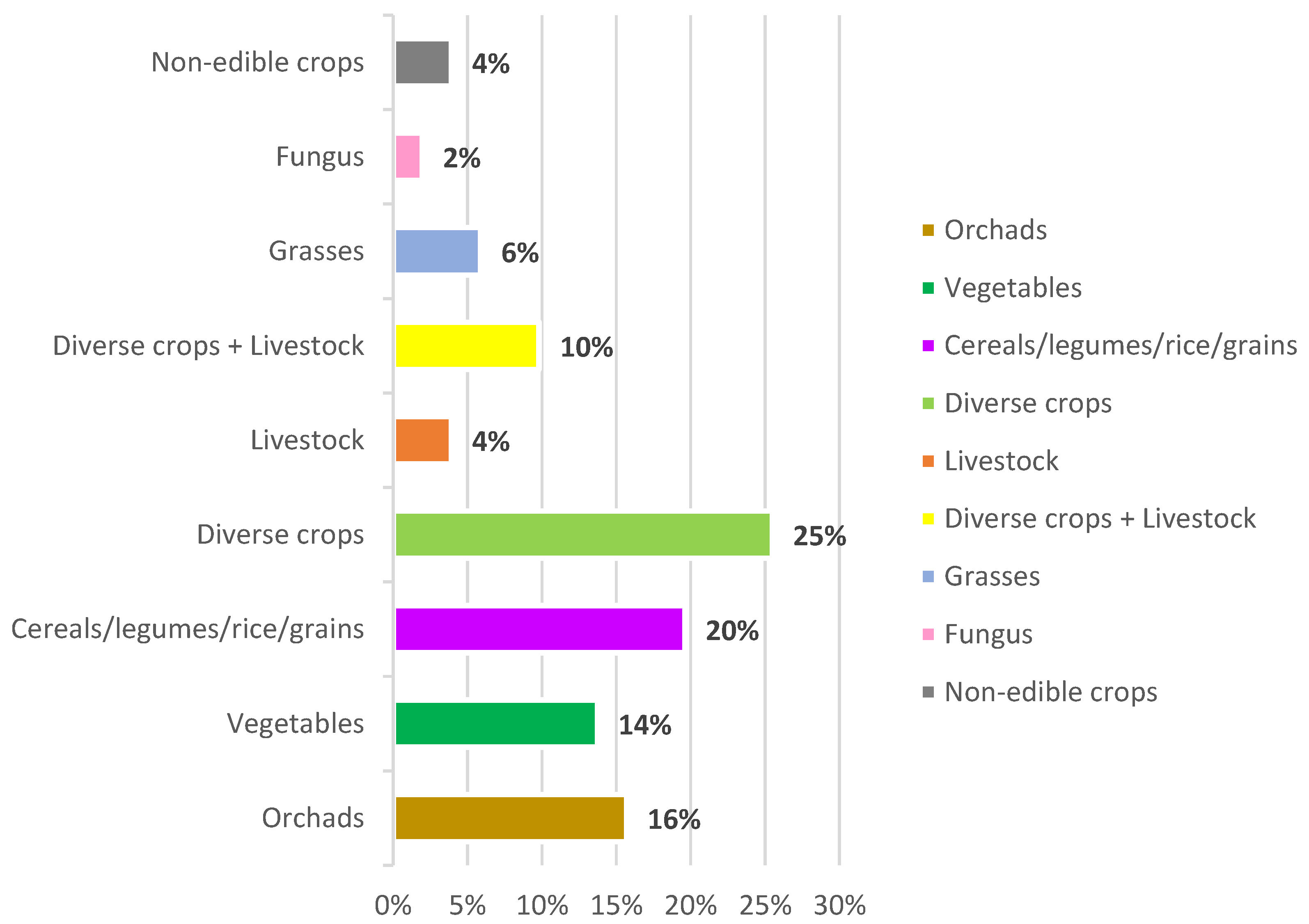

2. System Mapping

3. Resource Management Framework

3.1. Water Resources

3.2. Energy Resources

3.3. Nutrients

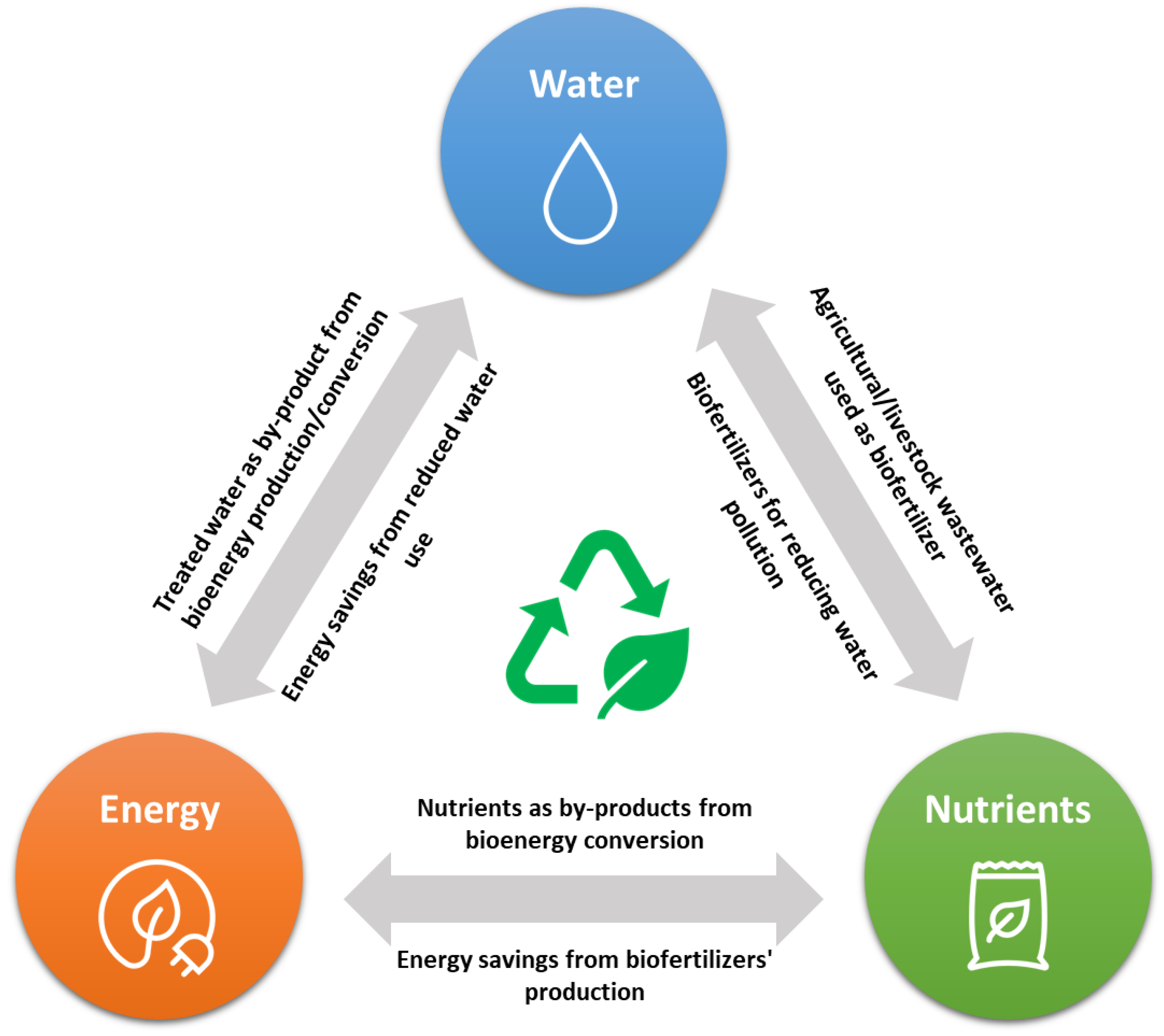

3.4. Water-Energy-Nutrients Nexus

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United Nations. World Population Prospects 2019: Highlights; United Nations: New York, NY, USA, 2019. [Google Scholar]

- Benos, L.; Bechar, A.; Bochtis, D. Safety and ergonomics in human-robot interactive agricultural operations. Biosyst. Eng. 2020, 200, 55–72. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy; Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Velenturf, A.P.M.; Archer, S.A.; Gomes, H.I.; Christgen, B.; Lag-Brotons, A.J.; Purnell, P. Circular economy and the matter of integrated resources. Sci. Total Environ. 2019, 689, 963–969. [Google Scholar] [CrossRef] [PubMed]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission: The European Green Deal. COM(2019) 640 Final 2019; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. A New Circular Economy Action Plan for a Cleaner and more Competitive Europe COM/2020/98 Final; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- D’Amato, D.; Droste, N.; Allen, B.; Kettunen, M.; Lähtinen, K.; Korhonen, J.; Leskinen, P.; Matthies, B.D.; Toppinen, A. Green, circular, bio economy: A comparative analysis of sustainability avenues. J. Clean. Prod. 2017, 168, 716–734. [Google Scholar] [CrossRef]

- Millar, N.; McLaughlin, E.; Börger, T. The Circular Economy: Swings and Roundabouts? Ecol. Econ. 2019, 158, 11–19. [Google Scholar] [CrossRef]

- FAO. The State of the World’s Land and Water Resources for Food and Agriculture (SOLAW)—Managing Systems at Risk; FAO: Roma, Italy, 2011; ISBN 978-92-5-106614-0. [Google Scholar]

- FAO. FAO Energy-Smart Food at FAO—An Overview; FAO: Roma, Italy, 2012. [Google Scholar]

- Lampridi, M.; Kateris, D.; Sørensen, C.G.; Bochtis, D. Energy footprint of mechanized agricultural operations. Energies 2020, 13, 769. [Google Scholar] [CrossRef]

- Lampridi, M.G.; Sørensen, C.G.; Bochtis, D. Agricultural sustainability: A review of concepts and methods. Sustainability 2019, 11, 5120. [Google Scholar] [CrossRef]

- Valin, H.; Sands, R.D.; van der Mensbrugghe, D.; Nelson, G.C.; Ahammad, H.; Blanc, E.; Bodirsky, B.; Fujimori, S.; Hasegawa, T.; Havlik, P.; et al. The future of food demand: Understanding differences in global economic models. Agric. Econ. 2014, 45, 51–67. [Google Scholar] [CrossRef]

- EMF. Cities and Circular Economy for Food; Ellen MacArthur Foundation: Cowes, UK, 2018. [Google Scholar]

- Del Borghi, A.; Moreschi, L.; Gallo, M. Circular economy approach to reduce water–energy–food nexus. Curr. Opin. Environ. Sci. Health 2020, 13, 23–28. [Google Scholar] [CrossRef]

- European Environment Agency. The Circular Economy and the Bioeconomy—Partners in Sustainability; Publications Office of the European Union: Luxembourg, 2018; ISBN 9789292139742. [Google Scholar]

- Caudet, L.; von Hammerstein-Gesmold, V. A New Bioeconomy Strategy for a Sustainable Europe; European Commision Press Release; European Commision: Brussels, Belgium, 2018. [Google Scholar]

- European Commission. Innovating for Sustainable Growth: A Bioeconomy for Europetee of the Regions Innovating for Sustainable Growth: A Bioeconomy for Europe; European Commission: Brussels, Belgium, 2012. [Google Scholar]

- Gurria, P.; Ronzon, T.; Tamosiunas, S.; Lopez, R.; Condado, S.G.; Guillen, J.; Cazzanigam, N.; Jonsson, R.; Banja, M.; Fiore, G.; et al. Biomass Flows in the European Union: The Sankey Biomass Diagram—Towards a Cross-Set Integration of Biomass; Publications Office of the European Union: Luxembourg, 2017. [Google Scholar]

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Cortés-García, F.J.; Camacho-Ferre, F. Agricultural waste: Review of the evolution, approaches and perspectives on alternative uses. Glob. Ecol. Conserv. 2020, 22, e00902. [Google Scholar] [CrossRef]

- Mohan, S.V.; Chiranjeevi, P.; Dahiya, S.; Kumar, A.N. Waste derived bioeconomy in India: A perspective. New Biotechnol. 2018, 40, 60–69. [Google Scholar]

- Caruso, M.C.; Braghieri, A.; Capece, A.; Napolitano, F.; Romano, P.; Galgano, F.; Altieri, G.; Genovese, F. Recent updates on the use of agro-food waste for biogas production. Appl. Sci. 2019, 9, 1217. [Google Scholar] [CrossRef]

- Donner, M.; Gohier, R.; de Vries, H. A new circular business model typology for creating value from agro-waste. Sci. Total Environ. 2020, 716, 137065. [Google Scholar] [CrossRef]

- Bos, H.L.; Broeze, J. Circular bio-based production systems in the context of current biomass and fossil demand. Biofuels Bioprod. Biorefining 2020, 14, 187–197. [Google Scholar] [CrossRef]

- Wang, Y.; Serventi, L. Sustainability of dairy and soy processing: A review on wastewater recycling. J. Clean. Prod. 2019, 237. [Google Scholar] [CrossRef]

- Aivazidou, E.; Tsolakis, N.; Iakovou, E.; Vlachos, D. The emerging role of water footprint in supply chain management: A critical literature synthesis and a hierarchical decision-making framework. J. Clean. Prod. 2016, 137, 1018–1037. [Google Scholar] [CrossRef]

- Woods, J.; Williams, A.; Hughes, J.K.; Black, M.; Murphy, R. Energy and the food system. Philos. Trans. R. Soc. B Biol. Sci. 2010, 365, 2991–3006. [Google Scholar] [CrossRef] [PubMed]

- Dungait, J.A.J.; Cardenas, L.M.; Blackwell, M.S.A.; Wu, L.; Withers, P.J.A.; Chadwick, D.R.; Bol, R.; Murray, P.J.; Macdonald, A.J.; Whitmore, A.P.; et al. Advances in the understanding of nutrient dynamics and management in UK agriculture. Sci. Total Environ. 2012, 434, 39–50. [Google Scholar] [CrossRef] [PubMed]

- Gupta, R.; Tyagi, N.K.; Abrol, I. Rainwater Management and Indian Agriculture: A Call for a Shift in Focus from Blue to Green Water. Agric. Res. 2020, 1–15. [Google Scholar] [CrossRef]

- Garcia-Caparros, P.; Contreras, J.I.; Baeza, R.; Segura, M.L.; Lao, M.T. Integral management of irrigation water in intensive horticultural systems of Almería. Sustainability 2017, 9, 2271. [Google Scholar] [CrossRef]

- Ait-Mouheb, N.; Bahri, A.; Thayer, B.B.; Benyahia, B.; Bourrié, G.; Cherki, B.; Condom, N.; Declercq, R.; Gunes, A.; Héran, M.; et al. The reuse of reclaimed water for irrigation around the Mediterranean Rim: A step towards a more virtuous cycle? Reg. Environ. Chang. 2018. [Google Scholar] [CrossRef]

- Yannopoulos, S.; Giannopoulou, I.; Kaiafa-Saropoulou, M. Investigation of the current situation and prospects for the development of rainwater harvesting as a tool to confront water scarcity worldwide. Water 2019, 11, 2168. [Google Scholar] [CrossRef]

- Arampatzis, G.; Hatzigiannakis, E.; Panagopoulos, A.; Karyoti, A.; Vrouchakis, I.; Karyotis, T. Water scarcity and inputs of nutrients from irrigation in olive groves of Crete Island, Greece. J. Plant Nutr. 2018, 41, 2232–2240. [Google Scholar] [CrossRef]

- Afzaal, H.; Farooque, A.A.; Abbas, F.; Acharya, B.; Esau, T. Precision irrigation strategies for sustainable water budgeting of potato crop in prince Edward Island. Sustainability 2020, 12, 2419. [Google Scholar] [CrossRef]

- Manzardo, A.; Mazzi, A.; Loss, A.; Butler, M.; Williamson, A.; Scipioni, A. Lessons learned from the application of different water footprint approaches to compare different food packaging alternatives. J. Clean. Prod. 2016, 112, 4657–4666. [Google Scholar] [CrossRef]

- Hess, T.; Aldaya, M.; Fawell, J.; Franceschini, H.; Ober, E.; Schaub, R.; Schulze-Aurich, J. Understanding the impact of crop and food production on the water environment-using sugar as a model. J. Sci. Food Agric. 2014, 94, 2–8. [Google Scholar] [CrossRef] [PubMed]

- Pedrero, F.; Grattan, S.R.; Ben-Gal, A.; Vivaldi, G.A. Opportunities for expanding the use of wastewaters for irrigation of olives. Agric. Water Manag. 2020, 241, 106333. [Google Scholar] [CrossRef]

- Deh-Haghi, Z.; Bagheri, A.; Fotourehchi, Z.; Damalas, C.A. Farmers’ acceptance and willingness to pay for using treated wastewater in crop irrigation: A survey in western Iran. Agric. Water Manag. 2020, 239, 106262. [Google Scholar] [CrossRef]

- Mohtar, R.H.; Daher, B. Water, Energy, and Food: The Ultimate Nexus. In Encyclopedia of Agricultural, Food, and Biological Engineering, 2nd ed.; Informa UK Limited: London, UK, 2010. [Google Scholar]

- Dimitrijević, A.; Gavrilović, M.; Ivanović, S.; Mileusnić, Z.; Miodragović, R.; Todorović, S. Energy use and economic analysis of fertilizer use in wheat and sugar beet production in Serbia. Energies 2020, 13, 2631. [Google Scholar] [CrossRef]

- Kyriakarakos, G.; Balafoutis, A.T.; Bochtis, D. Proposing a paradigm shift in rural electrification investments in Sub-Saharan Africa through Agriculture. Sustainability 2020, 12, 3096. [Google Scholar] [CrossRef]

- Oakleaf, J.R.; Kennedy, C.M.; Baruch-Mordo, S.; Gerber, J.S.; West, P.C.; Johnson, J.A.; Kiesecker, J. Mapping global development potential for renewable energy, fossil fuels, mining and agriculture sectors. Sci. Data 2019, 6, 1–17. [Google Scholar] [CrossRef]

- Yates, D.; Meldrum, J.; Averyt, K. The influence of future electricity mix alternatives on southwestern US water resources. Environ. Res. Lett. 2013, 8, 045005. [Google Scholar] [CrossRef]

- Aroonsrimorakot, S.; Laiphrakpam, M. Application of solar energy technology in agricultural farming for sustainable development: A review article. Int. J. Agric. Technol. 2019. [Google Scholar] [CrossRef][Green Version]

- Rahnama, M.; Kazemi, N.; Godarzi, B.; Taki, M. Geothermal energy for heating and cooling in agricultural greenhouses. Agric. Eng. Int. CIGR J. 2018, 20, 97–107. [Google Scholar]

- Fabrizio, E. Energy reduction measures in agricultural greenhouses heating: Envelope, systems and solar energy collection. Energy Build. 2012, 53, 57–63. [Google Scholar] [CrossRef]

- Vlachokostas, C.; Achillas, C.; Agnantiaris, I.; Michailidou, A.V.; Pallas, C.; Feleki, E.; Moussiopoulos, N. Decision support system to implement units of alternative biowaste treatment for producing bioenergy and boosting local bioeconomy. Energies 2020, 13, 2306. [Google Scholar] [CrossRef]

- da Silva Romero, C.W.; Berni, M.D.; Figueiredo, G.K.D.A.; Franco, T.T.; Lamparelli, R.A.C. Assessment of agricultural biomass residues to replace fossil fuel and hydroelectric power energy: A spatial approach. Energy Sci. Eng. 2019, 7, 2287–2305. [Google Scholar] [CrossRef] [PubMed]

- Rodias, E.; Berruto, R.; Bochtis, D.; Sopegno, A.; Busato, P. Green, yellow, and woody biomass supply-chain management: A review. Energies 2019, 12, 3020. [Google Scholar] [CrossRef]

- Allesina, G.; Pedrazzi, S.; Allegretti, F.; Morselli, N.; Puglia, M.; Santunione, G.; Tartarini, P. Gasification of cotton crop residues for combined power and biochar production in Mozambique. Appl. Therm. Eng. 2018, 139, 387–394. [Google Scholar] [CrossRef]

- Ruiz, H.A.; Martínez, A.; Vermerris, W. Bioenergy Potential, Energy Crops, and Biofuel Production in Mexico. Bioenergy Res. 2016, 9, 981–984. [Google Scholar] [CrossRef]

- Sopegno, A.; Rodias, E.; Bochtis, D.; Busato, P.; Berruto, R.; Boero, V.; Sørensen, C. Model for energy analysis of Miscanthus production and transportation. Energies 2016, 9, 392. [Google Scholar] [CrossRef]

- Rodias, E.; Berruto, R.; Bochtis, D.; Busato, P.; Sopegno, A. A computational tool for comparative energy cost analysis of multiple-crop production systems. Energies 2017, 10, 831. [Google Scholar] [CrossRef]

- Rodias, E.C.; Lampridi, M.; Sopegno, A.; Berruto, R.; Banias, G.; Bochtis, D.D.; Busato, P. Optimal energy performance on allocating energy crops. Biosyst. Eng. 2019, 181, 11–27. [Google Scholar] [CrossRef]

- Paschalidou, A.; Tsatiris, M.; Kitikidou, K. Energy crops for biofuel production or for food?—SWOT analysis (case study: Greece). Renew. Energy 2016, 93, 636–647. [Google Scholar] [CrossRef]

- Bochtis, D.; Benos, L.; Lampridi, M.; Marinoudi, V.; Pearson, S.; Sørensen, C.G. Agricultural workforce crisis in light of the COVID-19 pandemic. Sustainability 2020, 12, 8212. [Google Scholar] [CrossRef]

- Toop, T.A.; Ward, S.; Oldfield, T.; Hull, M.; Kirby, M.E.; Theodorou, M.K. AgroCycle—Developing a circular economy in agriculture. Energy Procedia 2017, 123, 76–80. [Google Scholar] [CrossRef]

- Angelopoulou, T.; Balafoutis, A.; Zalidis, G.; Bochtis, D. From laboratory to proximal sensing spectroscopy for soil organic carbon estimation-A review. Sustainability 2020, 12, 443. [Google Scholar] [CrossRef]

- Kizito, S.; Luo, H.; Lu, J.; Bah, H.; Dong, R.; Wu, S. Role of nutrient-enriched biochar as a soil amendment during maize growth: Exploring practical alternatives to recycle agricultural residuals and to reduce chemical fertilizer demand. Sustainability 2019, 11, 3211. [Google Scholar] [CrossRef]

- Vaneeckhaute, C.; Styles, D.; Prade, T.; Adams, P.; Thelin, G.; Rodhe, L.; Gunnarsson, I.; D’Hertefeldt, T. Closing nutrient loops through decentralized anaerobic digestion of organic residues in agricultural regions: A multi-dimensional sustainability assessment. Resour. Conserv. Recycl. 2018, 136, 110–117. [Google Scholar] [CrossRef]

- Li, R.; Tao, R.; Ling, N.; Chu, G. Chemical, organic and bio-fertilizer management practices effect on soil physicochemical property and antagonistic bacteria abundance of a cotton field: Implications for soil biological quality. Soil Tillage Res. 2017, 167, 30–38. [Google Scholar] [CrossRef]

- Savci, S. An Agricultural Pollutant: Chemical Fertilizer. Int. J. Environ. Sci. Dev. 2012, 73–80. [Google Scholar] [CrossRef]

- Lee, J. Effect of application methods of organic fertilizer on growth, soil chemical properties and microbial densities in organic bulb onion production. Sci. Hortic. 2010, 124, 299–305. [Google Scholar] [CrossRef]

- Htwe, A.Z.; Moh, S.M.; Moe, K.; Yamakawa, T. Biofertilizer production for agronomic application and evaluation of its symbiotic effectiveness in soybeans. Agronomy 2019, 9, 162. [Google Scholar] [CrossRef]

- Jefferies, D.; Muñoz, I.; Hodges, J.; King, V.J.; Aldaya, M.; Ercin, A.E.; Milà I Canals, L.; Hoekstra, A.Y. Water footprint and life cycle assessment as approaches to assess potential impacts of products on water consumption. Key learning points from pilot studies on tea and margarine. J. Clean. Prod. 2012, 33, 155–166. [Google Scholar] [CrossRef]

- Wang, E.; Attard, S.; Linton, A.; McGlinchey, M.; Xiang, W.; Philippa, B.; Everingham, Y. Development of a closed-loop irrigation system for sugarcane farms using the Internet of Things. Comput. Electron. Agric. 2020, 172, 105376. [Google Scholar] [CrossRef]

- Nahar, J.; Liu, S.; Mao, Y.; Liu, J.; Shah, S.L. Closed-Loop Scheduling and Control for Precision Irrigation †. Ind. Eng. Chem. Res. 2019, 58, 11485–11497. [Google Scholar] [CrossRef]

- Goap, A.; Sharma, D.; Shukla, A.K.; Rama Krishna, C. An IoT based smart irrigation management system using Machine learning and open source technologies. Comput. Electron. Agric. 2018, 155, 41–49. [Google Scholar] [CrossRef]

- Adeyemi, O.; Grove, I.; Peets, S.; Domun, Y.; Norton, T. Dynamic neural network modelling of soil moisture content for predictive irrigation scheduling. Sensors 2018, 18, 3408. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, C.I.; De Ruiz Galarreta, V.A.; Kruse, E.E. Analysis of water footprint of potato production in the pampean region of Argentina. J. Clean. Prod. 2015, 90, 91–96. [Google Scholar] [CrossRef]

- Magdich, S.; Rouina, B.B.; Ammar, E. Olive Mill Wastewater Agronomic Valorization by its Spreading in Olive Grove. Waste Biomass Valorization 2020, 11, 1359–1372. [Google Scholar] [CrossRef]

- Rosa, D.M.; Sampaio, S.C.; Pereira, P.A.M.; Mauli, M.M.; Reis, R.R. Dos swine wastewater: Impacts on soil, plant, and leachate. Eng. Agric. 2017, 37, 928–939. [Google Scholar]

- Hussain, M.I.; Muscolo, A.; Farooq, M.; Ahmad, W. Sustainable use and management of non-conventional water resources for rehabilitation of marginal lands in arid and semiarid environments. Agric. Water Manag. 2019, 221, 462–476. [Google Scholar] [CrossRef]

- Brînzan, O.; Dragoi, M.; Bociort, D.; Tigan, E.; Mateoc-Sîrb, N.; Lungu, M. A market-based economic instrument to better use water in agriculture. Sustainability 2020, 12, 1473. [Google Scholar] [CrossRef]

- Allam, A.; Tawfik, A.; Yoshimura, C.; Fleifle, A. Simulation-based optimization framework for reuse of agricultural drainage water in irrigation. J. Environ. Manag. 2016, 172, 82–96. [Google Scholar] [CrossRef]

- Ashu, A.; Lee, S.I. Reuse of agriculture drainage water in a mixed land-use watershed. Agronomy 2019, 9, 6. [Google Scholar] [CrossRef]

- Lavrnić, S.; Zapater-Pereyra, M.; Mancini, M.L. Water Scarcity and Wastewater Reuse Standards in Southern Europe: Focus on Agriculture. Water. Air. Soil Pollut. 2017, 228, 251. [Google Scholar] [CrossRef]

- Papageorgiou, K.; Singh, P.K.; Papageorgiou, E.; Chudasama, H.; Bochtis, D.; Stamoulis, G. Fuzzy cognitive map-based sustainable socio-economic development planning for rural communities. Sustainability 2020, 12, 305. [Google Scholar] [CrossRef]

- Tsolakis, N.K.; Keramydas, C.A.; Toka, A.K.; Aidonis, D.A.; Iakovou, E.T. Agrifood supply chain management: A comprehensive hierarchical decision-making framework and a critical taxonomy. Biosyst. Eng. 2014, 120, 47–64. [Google Scholar] [CrossRef]

- Aidonis, D.; Folinas, D.; Achillas, C.; Triantafyllou, D.; Malindretos, G. Multi-criteria evaluation of sustainable supply chains in the agrifood sector. Int. J. Sustain. Agric. Manag. Inform. 2015, 1, 106. [Google Scholar] [CrossRef]

- Roghanian, E.; Cheraghalipour, A. Addressing a set of meta-heuristics to solve a multi-objective model for closed-loop citrus supply chain considering CO2 emissions. J. Clean. Prod. 2019, 239, 118081. [Google Scholar] [CrossRef]

- Hoehn, D.; Margallo, M.; Laso, J.; García-Herrero, I.; Bala, A.; Fullana-i-Palmer, P.; Irabien, A.; Aldaco, R. Energy embedded in food loss management and in the production of uneaten food: Seeking a sustainable pathway. Energies 2019, 12, 767. [Google Scholar] [CrossRef]

- Montoro, S.B.; Lucas, J.; Santos, D.F.L.; Costa, M.S.S.M. Anaerobic co-digestion of sweet potato and dairy cattle manure: A technical and economic evaluation for energy and biofertilizer production. J. Clean. Prod. 2019, 226, 1082–1091. [Google Scholar] [CrossRef]

- Blades, L.; Morgan, K.; Douglas, R.; Glover, S.; De Rosa, M.; Cromie, T.; Smyth, B. Circular Biogas-Based Economy in a Rural Agricultural Setting. Energy Procedia 2017, 123, 89–96. [Google Scholar] [CrossRef]

- Yu, O.Y.; Ferrell, J.; Kim, H.Y.; Houser, J. NEXUS: Integrated sustainable energy for enhancing farm productivity. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Shanghai, China, 21–24 August 2018. [Google Scholar]

- Zabaniotou, A.; Rovas, D.; Libutti, A.; Monteleone, M. Boosting circular economy and closing the loop in agriculture: Case study of a small-scale pyrolysis-biochar based system integrated in an olive farm in symbiosis with an olive mill. Environ. Dev. 2015, 14, 22–36. [Google Scholar] [CrossRef]

- Muradin, M.; Joachimiak-Lechman, K.; Foltynowicz, Z. Evaluation of eco-efficiency of two alternative agricultural biogas plants. Appl. Sci. 2018, 8, 2083. [Google Scholar] [CrossRef]

- Fan, W.; Zhang, P.; Xu, Z.; Wei, H.; Lu, N.; Wang, X.; Weng, B.; Chen, Z.; Wu, F.; Dong, X. Life cycle environmental impact assessment of circular agriculture: A case study in Fuqing, China. Sustainability 2018, 10, 1810. [Google Scholar] [CrossRef]

- Jun, H.; Xiang, H. Development of circular economy is a fundamental way to achieve agriculture sustainable development in China. Energy Procedia 2011, 5, 1530–1534. [Google Scholar] [CrossRef]

- Hidalgo, D.; Corona, F.; Martín-Marroquín, J.M. Nutrient recycling: From waste to crop. Biomass Convers. Biorefinery 2020, 1–11. [Google Scholar] [CrossRef]

- Molina-Moreno, V.; Leyva-Díaz, J.C.; Llorens-Montes, F.J.; Cortés-García, F.J. Design of indicators of circular economy as instruments for the evaluation of sustainability and efficiency in wastewater from pig farming industry. Water 2017, 9, 653. [Google Scholar] [CrossRef]

- Tsai, W.T. Regulatory promotion and benefit analysis of biogas-power and biogas-digestate from anaerobic digestion in taiwan’s livestock industry. Fermentation 2018, 4, 57. [Google Scholar] [CrossRef]

- Rodias, E.C.; Sopegno, A.; Berruto, R.; Bochtis, D.D.; Cavallo, E.; Busato, P. A combined simulation and linear programming method for scheduling organic fertiliser application. Biosyst. Eng. 2019, 178, 233–243. [Google Scholar] [CrossRef]

- Morgano, M.T.; Bergfeldt, B.; Leibold, H.; Richter, F.; Stapf, D. Intermediate pyrolysis of agricultural waste: A decentral approach towards circular economy. Chem. Eng. Trans. 2018, 65, 649–654. [Google Scholar]

- Balawejder, M.; Matlok, N.; Gorzelany, J.; Pieniazek, M.; Antos, P.; Witek, G.; Szostek, M. Foliar fertilizer based on calcined bones, boron and molybdenum-a study on the development and potential effects on maize grain production. Sustainability 2019, 11, 5287. [Google Scholar] [CrossRef]

- Montemayor, E.; Bonmatí, A.; Torrellas, M.; Camps, F.; Ortiz, C.; Domingo, F.; Riau, V.; Antón, A. Environmental accounting of closed-loop maize production scenarios: Manure as fertilizer and inclusion of catch crops. Resour. Conserv. Recycl. 2019, 146, 395–404. [Google Scholar] [CrossRef]

- Bechara, E.; Papafilippaki, A.; Doupis, G.; Sofo, A.; Koubouris, G. Nutrient dynamics, soil properties and microbiological aspects in an irrigated olive orchard managed with five different management systems involving soil tillage, cover crops and compost. J. Water Clim. Chang. 2018, 9, 736–747. [Google Scholar] [CrossRef]

- Ferreira, I.Q.; Rodrigues, M.Â.; Claro, A.M.; Arrobas, M. Management of Nitrogen-Rich Legume Cover Crops as Mulch in Traditional Olive Orchards. Commun. Soil Sci. Plant Anal. 2015, 46, 1881–1894. [Google Scholar] [CrossRef]

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Plaza-Úbeda, J.A.; Camacho-Ferre, F. The management of agricultural waste biomass in the framework of circular economy and bioeconomy: An opportunity for greenhouse agriculture in Southeast Spain. Agronomy 2020, 10, 489. [Google Scholar] [CrossRef]

- Alobwede, E.; Leake, J.R.; Pandhal, J. Circular economy fertilization: Testing micro and macro algal species as soil improvers and nutrient sources for crop production in greenhouse and field conditions. Geoderma 2019, 334, 113–123. [Google Scholar] [CrossRef]

- Liu, H.; Ou, X.; Yuan, J.; Yan, X. Experience of producing natural gas from corn straw in China. Resour. Conserv. Recycl. 2018, 135, 216–224. [Google Scholar] [CrossRef]

- Manniello, C.; Statuto, D.; Di Pasquale, A.; Giuratrabocchetti, G.; Picuno, P. Planning the flows of residual biomass produced by wineries for the preservation of the rural landscape. Sustainability 2020, 12, 847. [Google Scholar] [CrossRef]

- Petropoulos, S.; Fernandes, Â.; Stojković, D.; Pereira, C.; Taofiq, O.; Di Gioia, F.; Tzortzakis, N.; Soković, M.; Barros, L.; Ferreira, I.C.F.R. Cotton and cardoon byproducts as potential growing media components for Cichorium spinosum L. commercial cultivation. J. Clean. Prod. 2019, 240, 118254. [Google Scholar] [CrossRef]

- Casson Moreno, V.; Iervolino, G.; Tugnoli, A.; Cozzani, V. Techno-economic and environmental sustainability of biomass waste conversion based on thermocatalytic reforming. Waste Manag. 2020, 101, 106–115. [Google Scholar] [CrossRef]

- Vaskalis, I.; Skoulou, V.; Stavropoulos, G.; Zabaniotou, A. Towards circular economy solutions for the management of rice processing residues to bioenergy via gasification. Sustainability 2019, 11, 6433. [Google Scholar] [CrossRef]

- Kadoglidou, K.; Kalaitzidis, A.; Stavrakoudis, D.; Mygdalia, A.; Katsantonis, D. A novel compost for rice cultivation developed by rice industrial by-products to serve circular economy. Agronomy 2019, 9, 553. [Google Scholar] [CrossRef]

- Antoniou, N.; Monlau, F.; Sambusiti, C.; Ficara, E.; Barakat, A.; Zabaniotou, A. Contribution to Circular Economy options of mixed agricultural wastes management: Coupling anaerobic digestion with gasification for enhanced energy and material recovery. J. Clean. Prod. 2019, 209, 505–514. [Google Scholar] [CrossRef]

- Zied, D.C.; Pardo-Giménez, A.; de Oliveira, G.A.; Carrasco, J.; Zeraik, M.L. Study of Waste Products as Supplements in the Production and Quality of Pleurotus ostreatus var. Florida. Indian J. Microbiol. 2019, 59, 328–335. [Google Scholar] [CrossRef] [PubMed]

- Aziz, S.; Yaseen, L.; Jamal, A.; Farooq, U.; Qureshi, Z.; Tauseef, I.; Haleem, S.K.; Ali, M.I. Fabrication of biochar from organic wastes and its effect on wheat growth and soil microflora. Pol. J. Environ. Stud. 2020, 29, 1069–1076. [Google Scholar] [CrossRef]

- Mosquera-Losada, M.R.; Amador-García, A.; Rigueiro-Rodríguez, A.; Ferreiro-Domínguez, N. Circular economy: Using lime stabilized bio-waste based fertilisers to improve soil fertility in acidic grasslands. Catena 2019, 179, 119–128. [Google Scholar] [CrossRef]

- Kuisma, M.; Kahiluoto, H. Biotic resource loss beyond food waste: Agriculture leaks worst. Resour. Conserv. Recycl. 2017, 124, 129–140. [Google Scholar] [CrossRef]

- Diacono, M.; Persiani, A.; Testani, E.; Montemurro, F.; Ciaccia, C. Recycling agricultural wastes and by-products in organic farming: Biofertilizer production, yield performance and carbon footprint analysis. Sustainability 2019, 11, 3824. [Google Scholar] [CrossRef]

- Loh, S.K.; Lai, M.E.; Ngatiman, M. Vegetative growth enhancement of organic fertilizer from anaerobically-treated palm oil mill effluent (POME) supplemented with chicken manure in food-energy-water nexus challenge. Food Bioprod. Process. 2019, 117, 95–104. [Google Scholar] [CrossRef]

- Xu, Z.; Fan, W.; Dong, X.; Wang, X.C.; Liu, Y.; Xue, H.; Klemeš, J.J. Analysis of the functional orientation of agricultural systems from the perspective of resource circulation. J. Clean. Prod. 2020, 258, 120642. [Google Scholar] [CrossRef]

- Cheong, J.C.; Lee, J.T.E.; Lim, J.W.; Song, S.; Tan, J.K.N.; Chiam, Z.Y.; Yap, K.Y.; Lim, E.Y.; Zhang, J.; Tan, H.T.W.; et al. Closing the food waste loop: Food waste anaerobic digestate as fertilizer for the cultivation of the leafy vegetable, xiao bai cai (Brassica rapa). Sci. Total Environ. 2020, 715, 136789. [Google Scholar] [CrossRef]

- Krishnan, R.; Agarwal, R.; Bajada, C.; Arshinder, K. Redesigning a food supply chain for environmental sustainability—An analysis of resource use and recovery. J. Clean. Prod. 2020, 242, 118374. [Google Scholar] [CrossRef]

- Zhu, Q.; Jia, R.; Lin, X. Building sustainable circular agriculture in China: Economic viability and entrepreneurship. Manag. Decis. 2019, 57, 1108–1122. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodias, E.; Aivazidou, E.; Achillas, C.; Aidonis, D.; Bochtis, D. Water-Energy-Nutrients Synergies in the Agrifood Sector: A Circular Economy Framework. Energies 2021, 14, 159. https://doi.org/10.3390/en14010159

Rodias E, Aivazidou E, Achillas C, Aidonis D, Bochtis D. Water-Energy-Nutrients Synergies in the Agrifood Sector: A Circular Economy Framework. Energies. 2021; 14(1):159. https://doi.org/10.3390/en14010159

Chicago/Turabian StyleRodias, Efthymios, Eirini Aivazidou, Charisios Achillas, Dimitrios Aidonis, and Dionysis Bochtis. 2021. "Water-Energy-Nutrients Synergies in the Agrifood Sector: A Circular Economy Framework" Energies 14, no. 1: 159. https://doi.org/10.3390/en14010159

APA StyleRodias, E., Aivazidou, E., Achillas, C., Aidonis, D., & Bochtis, D. (2021). Water-Energy-Nutrients Synergies in the Agrifood Sector: A Circular Economy Framework. Energies, 14(1), 159. https://doi.org/10.3390/en14010159