1. Introduction

Various advanced electronic equipment have been applied in military helicopters in order to improve their comprehensive performance. The usage of high-energy electronic equipment has also brought a continuous increase in heat load, which is a huge challenge for the environmental control system (ECS). For the cooling of the electronic equipment, the active methods that require energy or a generator, such as a pump, are widely applied in aircraft and military helicopters, such as an air cycle cooling (ACR) system and a vapor compression refrigeration (VCR) system. However, dissipation of this huge heat load by a conventional ACR system increases the engine bleed air consumption and may have a negative impact on engine performance. Hence, highly efficient heat management technology with a VCR system may be adopted in future helicopters, such as liquid cooling, microchannel cooling, etc.

Sarafraz and Arjomandi pointed out that microchannel heat exchanging systems are relatively new instruments and can transfer significant amounts of heat in a small space, and they investigated the thermal performance and pressure drop of a microchannel heat sink at high-temperatures [

1]. Compared to the embedded high thermal conductivity at the same thermal conductivity ratio, Dadsetani et al. pointed out that the hybrid method can reduce the maximum disk temperature up to 90% [

2]. Some advanced efficient heat transfer technologies for electronic equipment have been studied [

3,

4,

5,

6]. Moreover, the corresponding control research should be carried out for the VCR system.

Deymi-Dashtebayaz et al. [

7] investigated the impact of various refrigerants on the efficiency of the geothermal heat pump operation. The critical parameters such as coefficient of performance (COP), exergy efficiency and exergy destruction for various components were calculated and investigated.

Michalak pointed out that high-performance military aircraft should use a VCR system instead of a direct air refrigeration system [

8]. He conducted experiments with two control strategies for a vapor loop system. The experimental results showed that their method could control electronic expansion valve (EEV) opening very well. Military aircraft and helicopters can gain improved performance and efficiency through the aircraft thermal management systems by the incorporation of VCR systems in place of standard air loop systems [

9,

10,

11,

12,

13]. The VCR system has been applied in civil areas. However, in the aviation field, the heat loads often are large and time-varying. In addition, the heat sink often varies with the flight height over a short period [

14,

15,

16,

17].

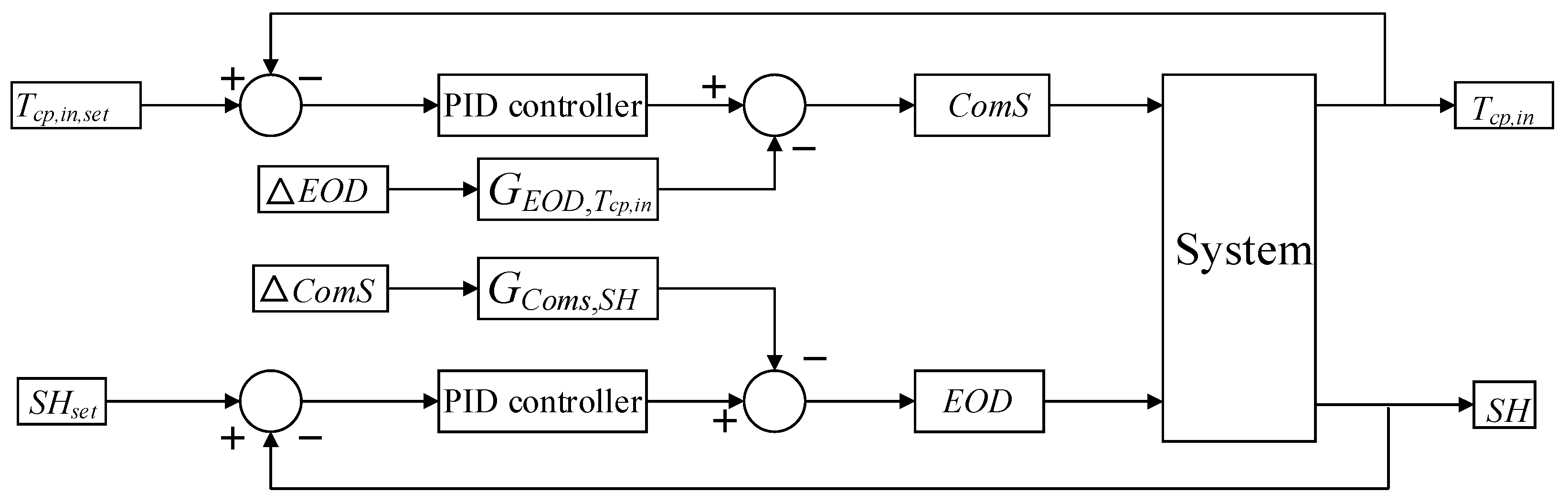

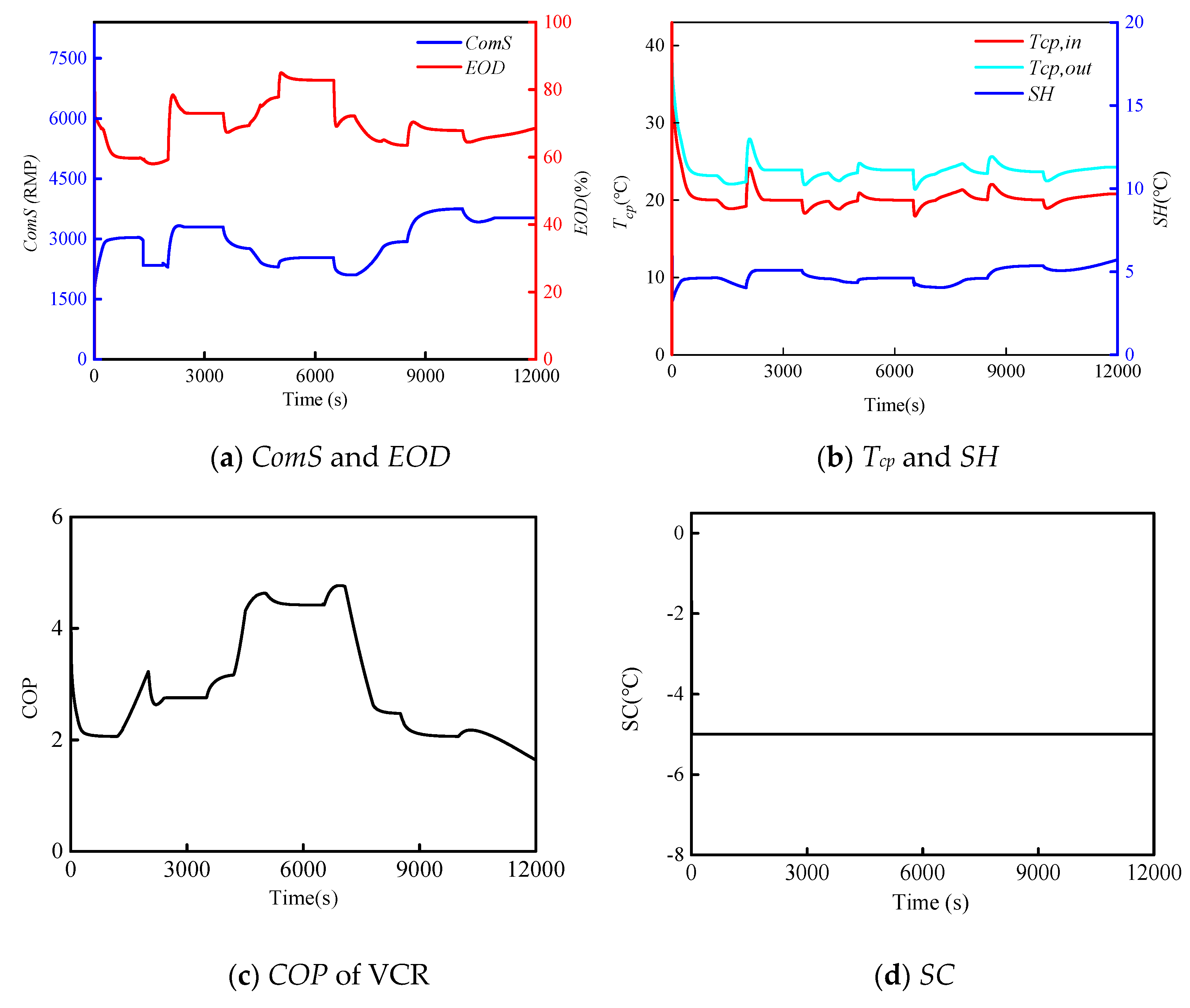

A dual single input–single output (SISO) control strategy was developed by Marcinichen based on the proportion integration feedback method [

18]. It used a variable opening expansion valve and a variable speed compressor to adjust refrigerant valve position and compressor speed, respectively. Correspondingly, its refrigerant flow rate and evaporator superheat had to be adjusted by a variable speed compressor and a variable opening expansion valve, respectively. The SISO control strategy can control evaporator superheating and cooling capacity in good working states.

Rasmussen and Alleyne created a control-oriented model that balanced simplicity with accuracy and developed a gain-scheduled multiple input – multiple output (MIMO) feedback control strategy for a refrigeration and air-conditioning system [

19,

20]. Their results demonstrated that the gain-scheduled approach extended advantages over the entire operating system compared to linear control techniques. Elliott and Rasmussen proposed a cascaded control scheme only requiring evaporator pressure and temperature as measured values, and only handling the opening of the expansion valve with cascaded control [

21]. Their control method had better performance than the complex non-linear or gain-scheduled controllers.

It is well known that the heat exchangers used in VCR typically operate with multiple and non-linear fluid phases [

22,

23,

24,

25]. In order to cope with inherent complexity and nonlinearity in VCR systems, Li et al. dealt with an empirical dynamic model based on experimental data and presented a decoupling control of the VCR [

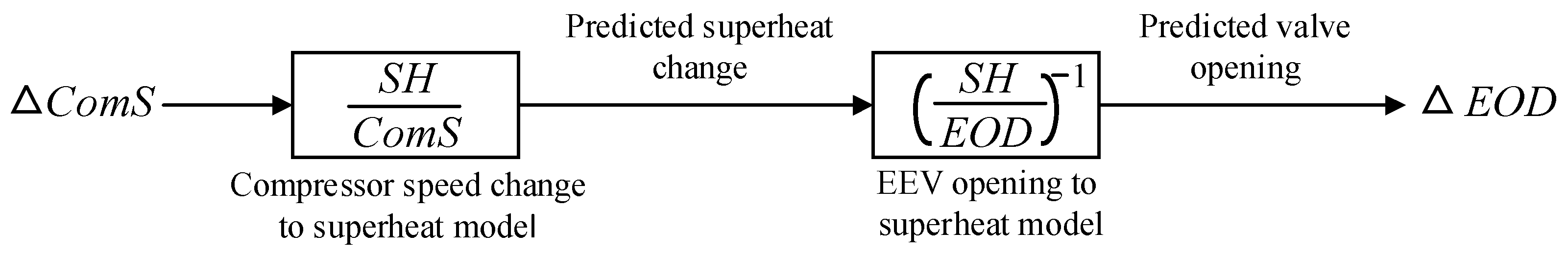

22]. Their experiment and simulation results indicated that the proposed model could describe the actual system. On the basis of the empirical model, Li designed a PI controller scheme with a decoupling model to manage the thermal capacity and superheating independently [

26]. Their works are both effective and exhibit high performance.

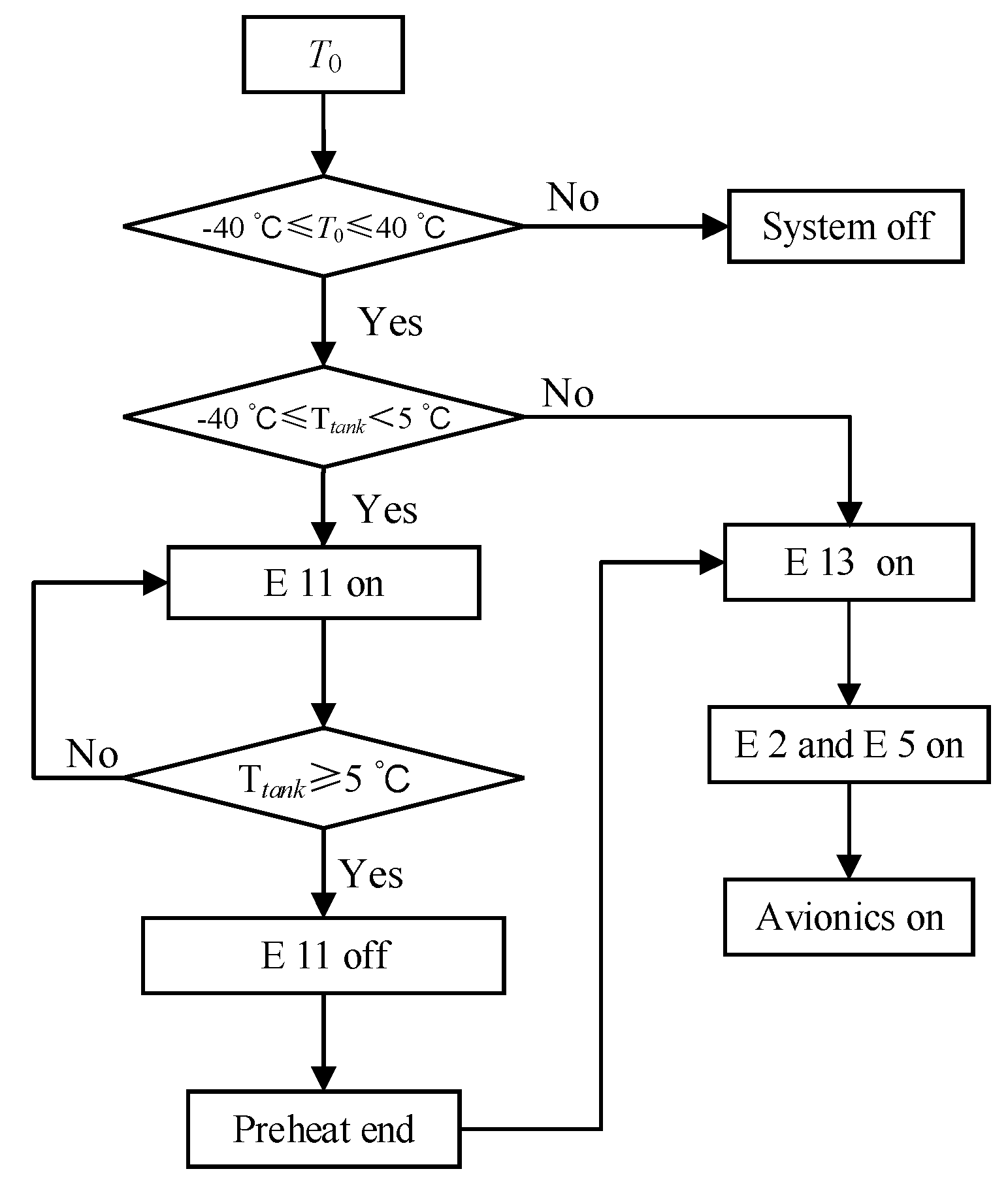

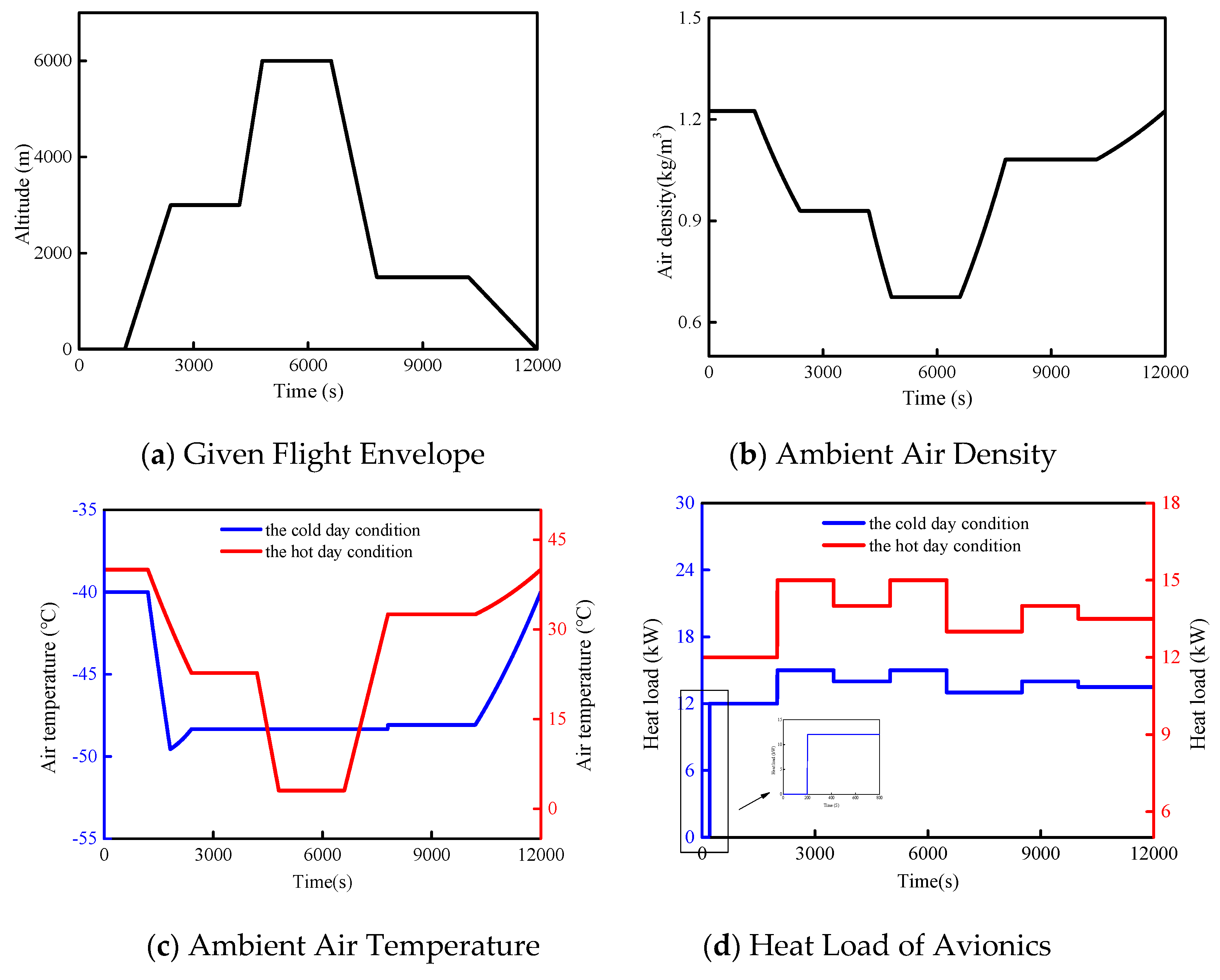

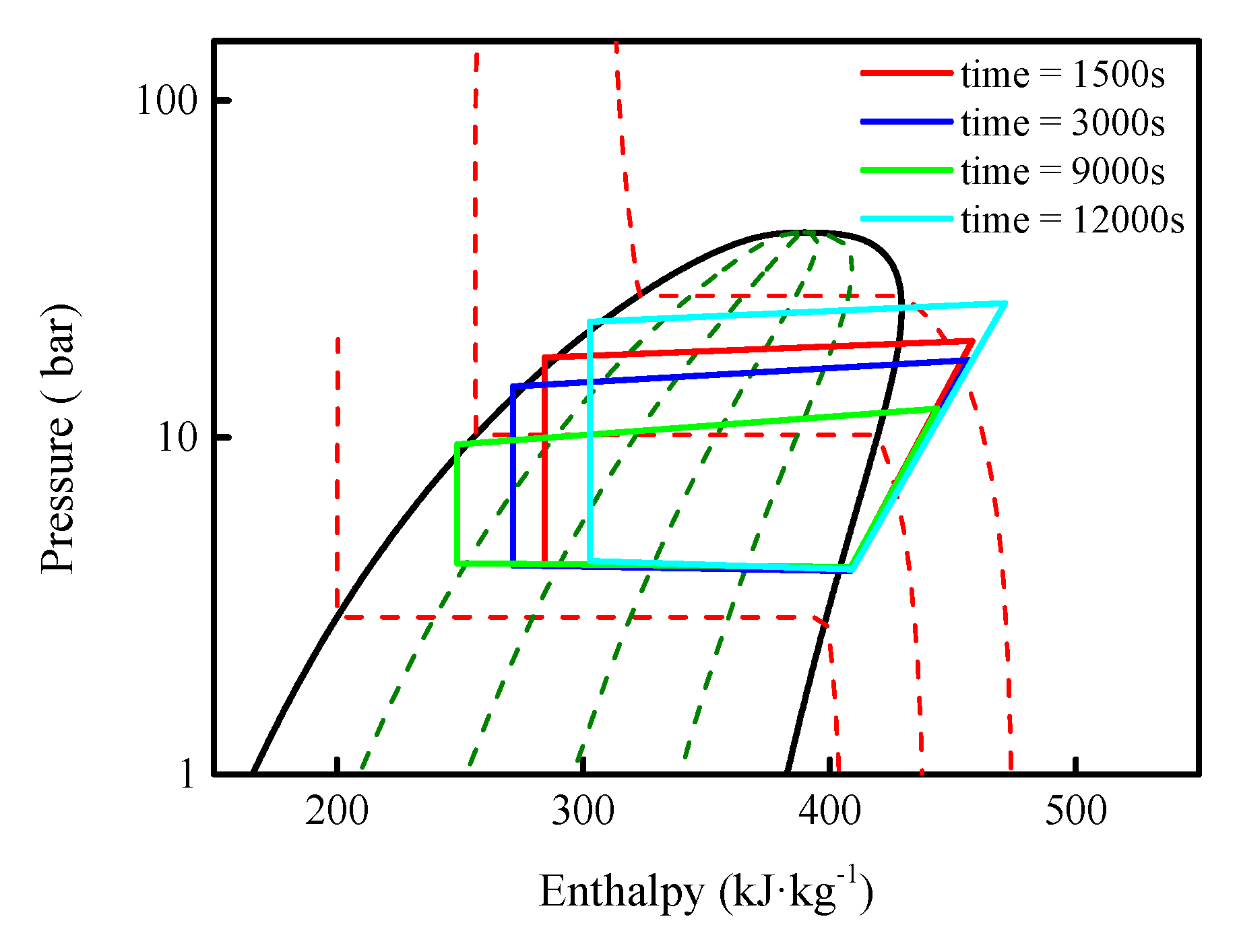

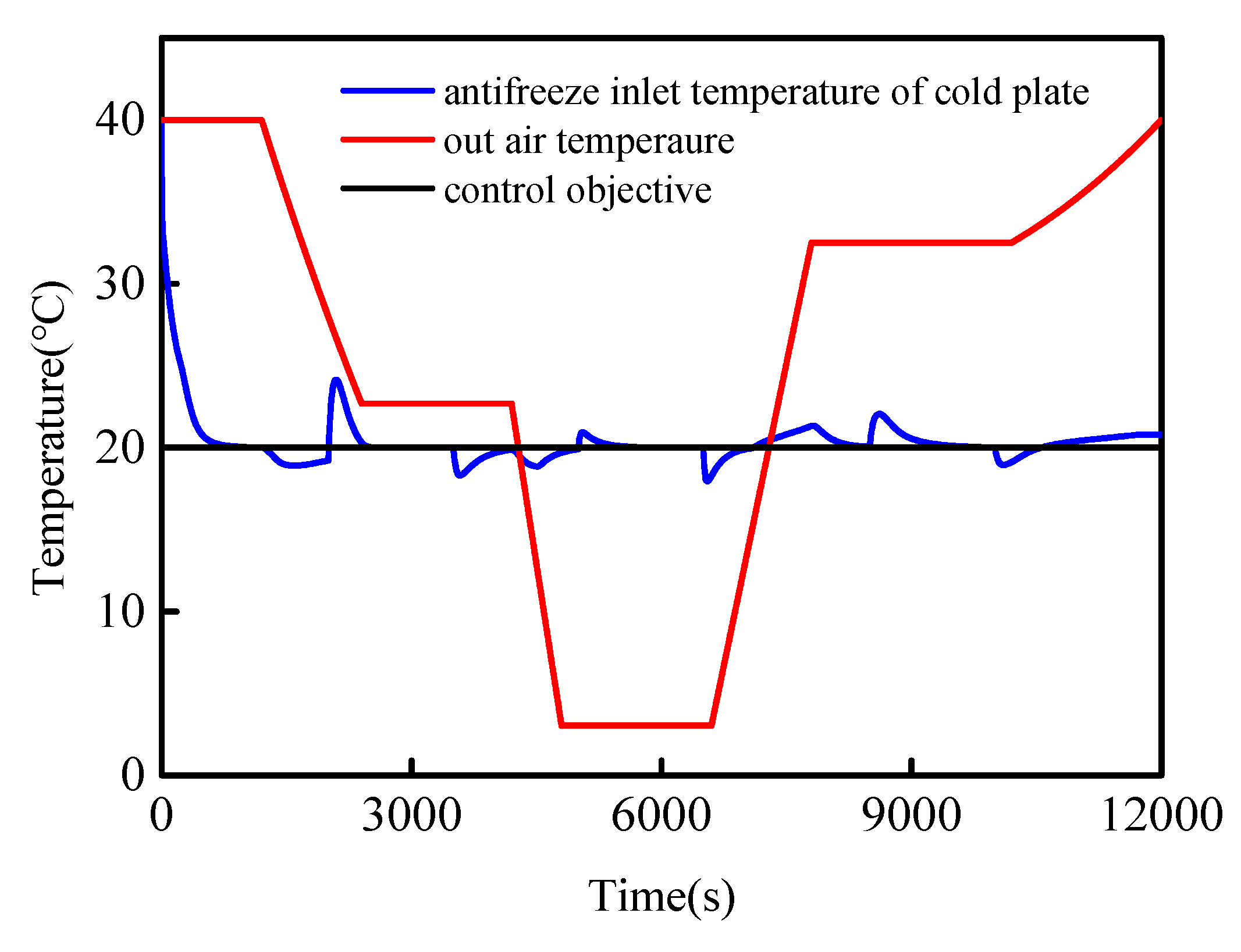

The requirement for future advanced aircraft is the need for precise temperature control of time-varying loads and flight environments. The VCR can offer higher coefficient of performance (COP) and has some advantages in weight, cost and volume than the air loop system. However, there are some challenges for the design of VCR control for advanced helicopters. Firstly, the advanced helicopter requires precise temperature control for rapidly changing heat loads. Secondly, the working environment of advanced helicopters is very extreme, so that the heat sink varies widely in a short period. For example, the air temperature may be over 40 °C on the ground and −20 °C at high altitude in summer. Thirdly, advanced aircraft carry out tasks under various weather conditions, including standard day, cold day and hot day. In extremely cold environment conditions, liquid in the coolant loop should be preheated. All in all, there are some challenges for research of VCR for advanced helicopters.

It has be seen from the previous results that various methods have been studied by many researchers. However, few studies have been conducted on extreme conditions, such as extreme hot weather and extreme cold weather [

27,

28,

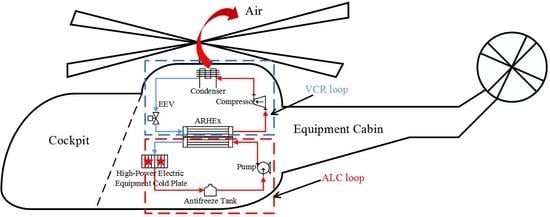

29]. In this paper, a helicopter thermal management system (TMS) based on antifreeze liquid cooling (ALC) and VCR loops is presented. Its control strategy for various weather is further studied in order to ensure the environmental adaptability of the helicopter TMS.

3. Mathematical Model

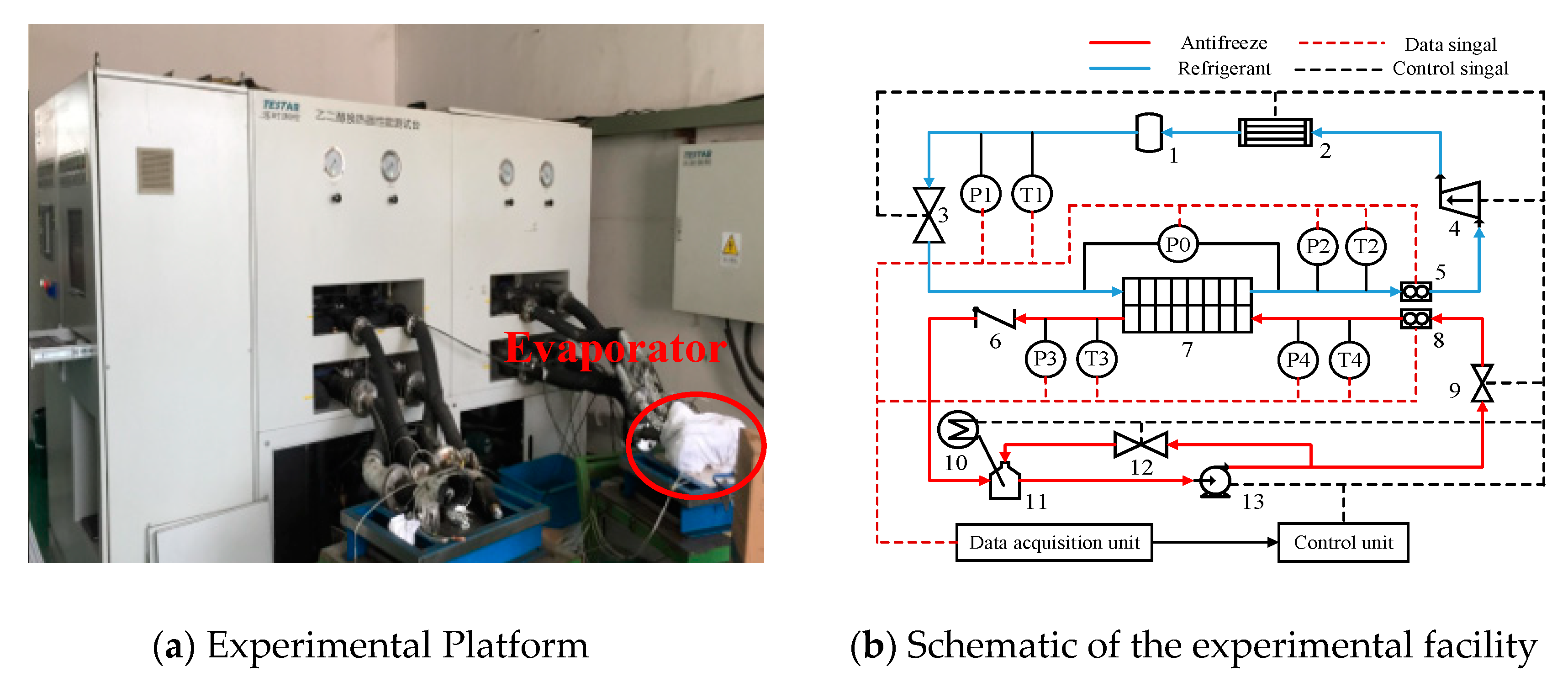

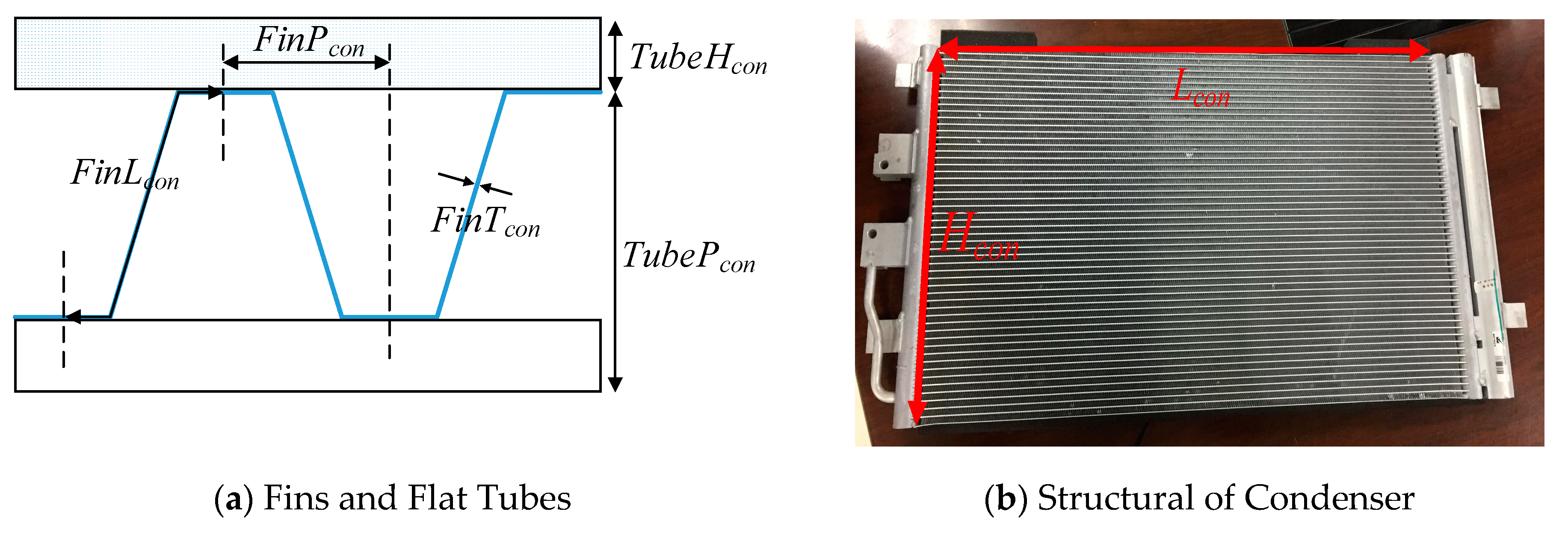

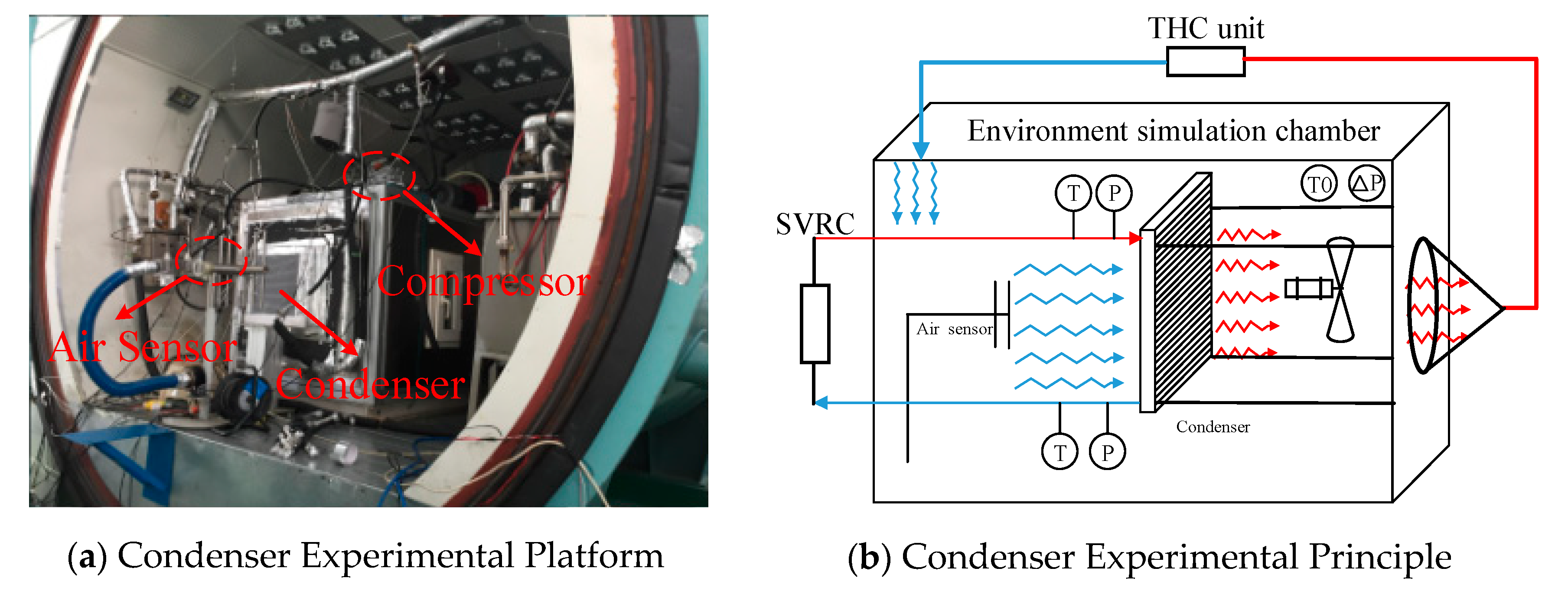

In the helicopter TMS, the condenser is a parallel flow air-cooled heat exchanger, and the evaporator is a plate-fin antifreeze-R134a heat exchanger.

The fundamental assumptions [

32,

33] for homogeneous flow model are as follows:

No slip between the two phases;

Thermodynamic equilibrium between the phases;

No non-condensable gas in the phase transformation process of refrigerant;

One-dimensional steady-state flow of the flow of the refrigerant in the flat tube.

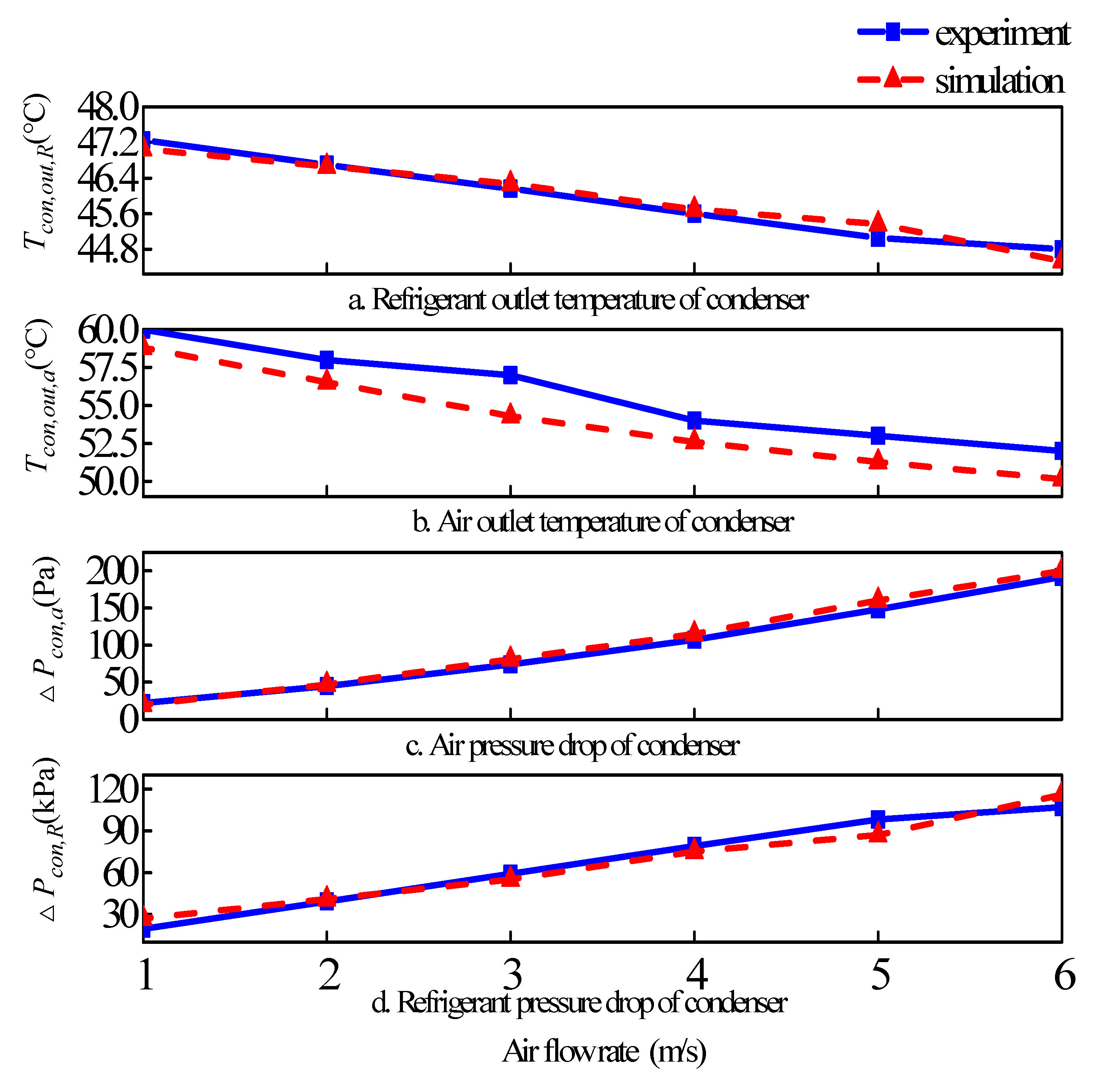

The steady-state experimental correction of evaporator and condenser was carried out using the homogeneous flow model. A homogenous flow model was validated by experimental results for an evaporator [

34]. About 92% of deviations between predicted and tested pressure drops were within ±20%.

The components of the TMS mainly include a antifreeze–refrigerant heat exchanger (ARHEx), an air-R134a heat exchanger, an expansion valve and a compressor. These calculation models are established in this section.

3.1. Evaporator

3.1.1. R134a Side of the Evaporator

The transient thermal equation of the R134a is established in Equation (6), and the average temperature of the R134a can be calculated by the following equation [

35].

where

meva,R and

cv are the mass (kg) and specific heat of the R134a (J/(kg·°C)), respectively;

Teva,R,in and 1/

Eeva,R are the temperatures of the inner wall (°C) and the thermal resistance of the convection between the inner wall and the R134a inside the evaporator (W/°C), respectively;

and

are the mass flow rates at the inlet and outlet of the evaporator, respectively, in kg/s; and

heva,R,out and

heva,R,in are, respectively, the enthalpy values at the outlet and inlet of the R134a in J/kg.

In the R134a side of the evaporator, the heat transfer between the refrigerant and the wall of the heat exchanger can be calculated by the following equation:

where

keva,R is the heat transfer gain coefficient;

heva,R is the convective heat exchange coefficient between the refrigerant and the wall of heat exchange in W/(m

2·°C);

Aeva,R is the heat exchange area in m

2;

Teva,R is the refrigerant temperature in °C;

Teva,wall is the wall temperature in °C.

The Nusselt number of the refrigerant in laminar flow is 3.66, while the Nusselt number in turbulent flow is calculated according to the Gnielinski correlation as follows:

where

f is the friction coefficient;

λref is the thermal conductivity of refrigerant in W/(m·°C);

D is the hydraulic diameter in m.

where

ε is surface absolute roughness.

There are two processes of evaporation in the convective heat exchange between the refrigerant and the wall of heat exchanger when the flow pattern of refrigerant is two-phase flow [

36]. The heat exchange coefficient of refrigerant is calculated by the following correlation [

37]:

The convective boiling contribution is as follows:

The convective boiling coefficient

kcb is calculated by the following formula:

where

is the Martinelli parameter;

Gas is the gas mass fraction;

is the vapor density in kg/m

3;

is the liquid density in kg/m

3;

is the vapor dynamic viscosity in N·s/m

2;

is the liquid dynamic viscosity in N·s/m

2.

The nucleate boiling coefficient,

knb, is calculated by the following formula:

The nucleate boiling contribution,

heva2, refers to reference [

38].

3.1.2. Antifreeze Side of the Evaporator

In the antifreeze side of the evaporator, the heat transfer between the antifreeze and the wall of heat exchanger can be calculated by the following equation:

where

keva,A is the heat transfer gain coefficient;

heva,A is the convective heat exchange coefficient between the antifreeze and the wall of heat exchange in W(m

2·°C);

Aeva,A is the heat exchange area in m

2;

Teva,A is the antifreeze temperature in °C;

Teva,wall is the wall temperature in °C;

ηeva,fin is fin efficiency.

3.2. Condenser

3.2.1. R134a Side of the Condenser

The transient thermal equation of the R134a is established in Equation (17), and the average temperature of the R134a can be calculated by the following equation:

where

mcon,R and

cv are the mass (kg) and specific heat of the R134a J/(kg·°C), respectively;

Tcon,a,in and 1/

Econ,a are the temperatures of the inner wall (°C) and the thermal resistance of the convection between the inner wall and the R134a inside the condenser (W/°C), respectively;

and

are the mass flow rates at the inlet and outlet of the condenser, respectively, in kg/s; and

hcon,R,out and

hcon,R,in are, respectively, the enthalpy values at the outlet and inlet of the R134a in J/kg.

In the refrigerant side of the condenser, the fluid refrigerant enters as superheated vapor and exits as sub-cooled liquid. The space-averaged and time varying values of the refrigerant thermodynamic properties are computed as the properties of a liquid–vapor mixture with constant time and space-averaged values [

39]. The calculation formula of single-phase refrigerant can refer to the calculation formula in the evaporator.

The convective heat exchange coefficient of the condensation process is calculated by the Cavallini and Zecchin correlation [

37].

where

x is the dryness;

ρl and

ρv are the density values of refrigerant in liquid and gas, respectively, in kg/m

3;

μl and

μv are the kinetic viscosity values of refrigerant in liquid and gas, respectively, in N.s/m

2; and

Gv is the mass flux in kg/(m

2s).

3.2.2. Air Side of the Condenser

Some assumptions are made to simplify the model: (1) The air-side temperature and velocity are uniform; (2) The parameters of air do not change with time at each point; (3) The effects of heat conduction and radiation are ignored.

The heat transfer between the air and the wall of heat exchanger is calculated as follows:

where Φ

con,a is the heat flux in kW;

kcon,a is the heat transfer gain coefficient;

ηcon,fin is fin efficiency;

hcon,a is the heat transfer coefficient in kW/(m

2·°C);

Acon,a is the heat exchange area in m

2;

Tcon,a is the air temperature in °C;

Tcon,wall is the wall temperature in °C;

is the mass flow rate in kg/s; and

Lvap is the latent heat of vaporization of water in m.

3.3. Expansion Valve

In the expansion valve, the refrigerant undergoes an isenthalpic process. It enters as subcooled liquid and exits as a liquid–vapor mixture. Its mass flow is as follows:

where

is the mass flow of the refrigerant in kg/s;

Aeev is the expansion orifice area in m

2;

keev is the gain coefficient;

ρ is the density of the refrigerant in kg/m

3;

is the inlet pressure of EEV in kPa; and

is the outlet pressure of EEV in kPa.

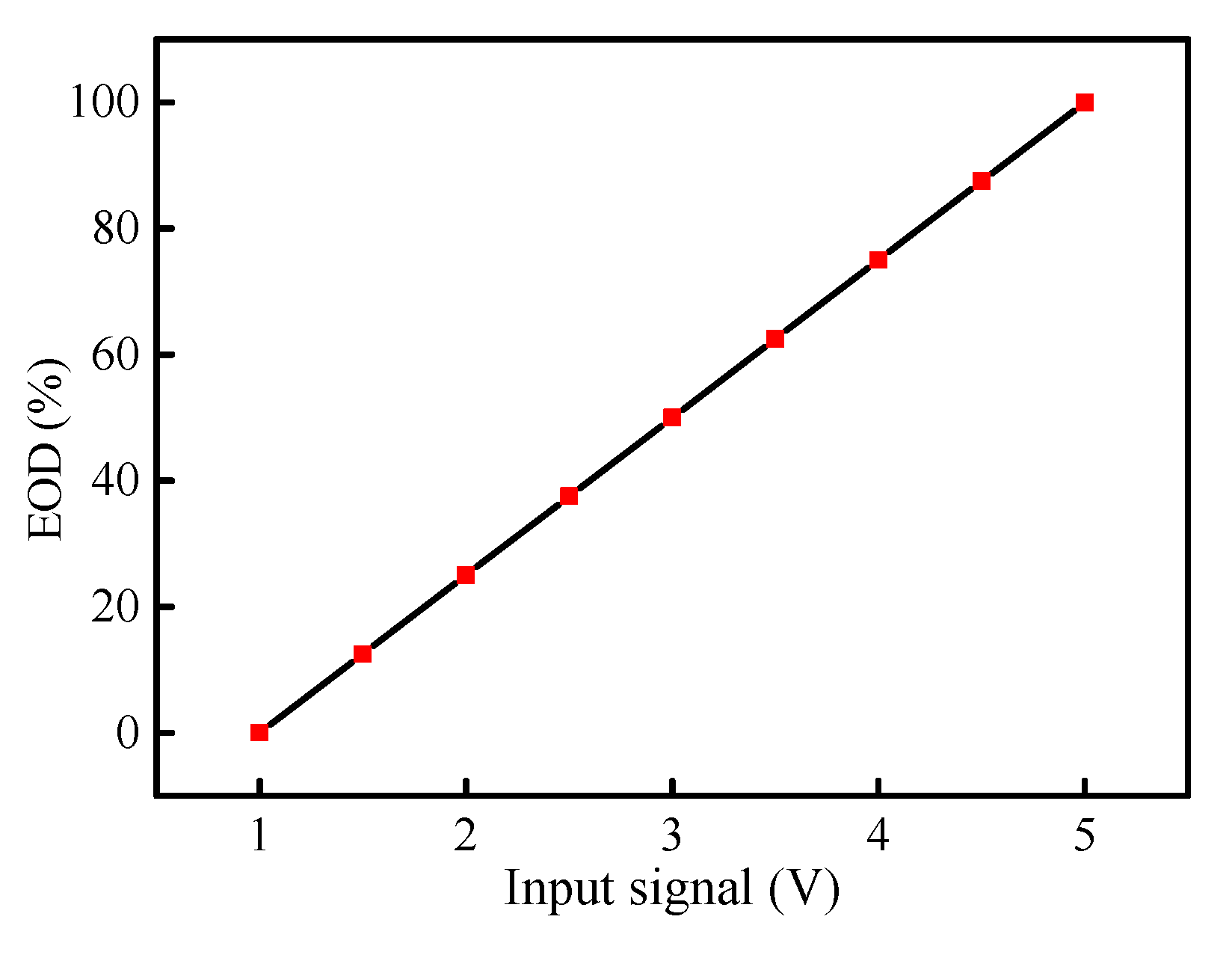

As shown in

Figure 6, according to the relationship between the input signal of the stepping motor and

EOD, a simulation model was established for the EX5-type expansion valve of Emerson. Its range of cooling capacity was from 4 kW to 39 kW for R134a refrigerant.

3.4. Compressor

Mass flow and energy change across the compressor is determined by experimentally identified volumetric and isentropic efficiencies (

ηcom,v and

ηcom,s). In the compressor, the fluid is assumed as a quasi-steady adiabat polytropic compression process. The displacement of compressor is constant, and its mass flow rate is calculated by the following formula:

where

ComS is the speed of compressor in rpm;

ρR is the vapor density of compressor inlet in kg/m

3;

Vm is the volume in m

2; and

ηcom,v is the volumetric efficiency of the compressor.

The compressor power can be calculated by the following formula:

where

Tup is the upstream temperature in °C;

Tdown is the downstream temperature in °C;

π is the pressure ratio;

ηis is the adiabatic efficiency; and

cp is the specific heat in J/(kgK).

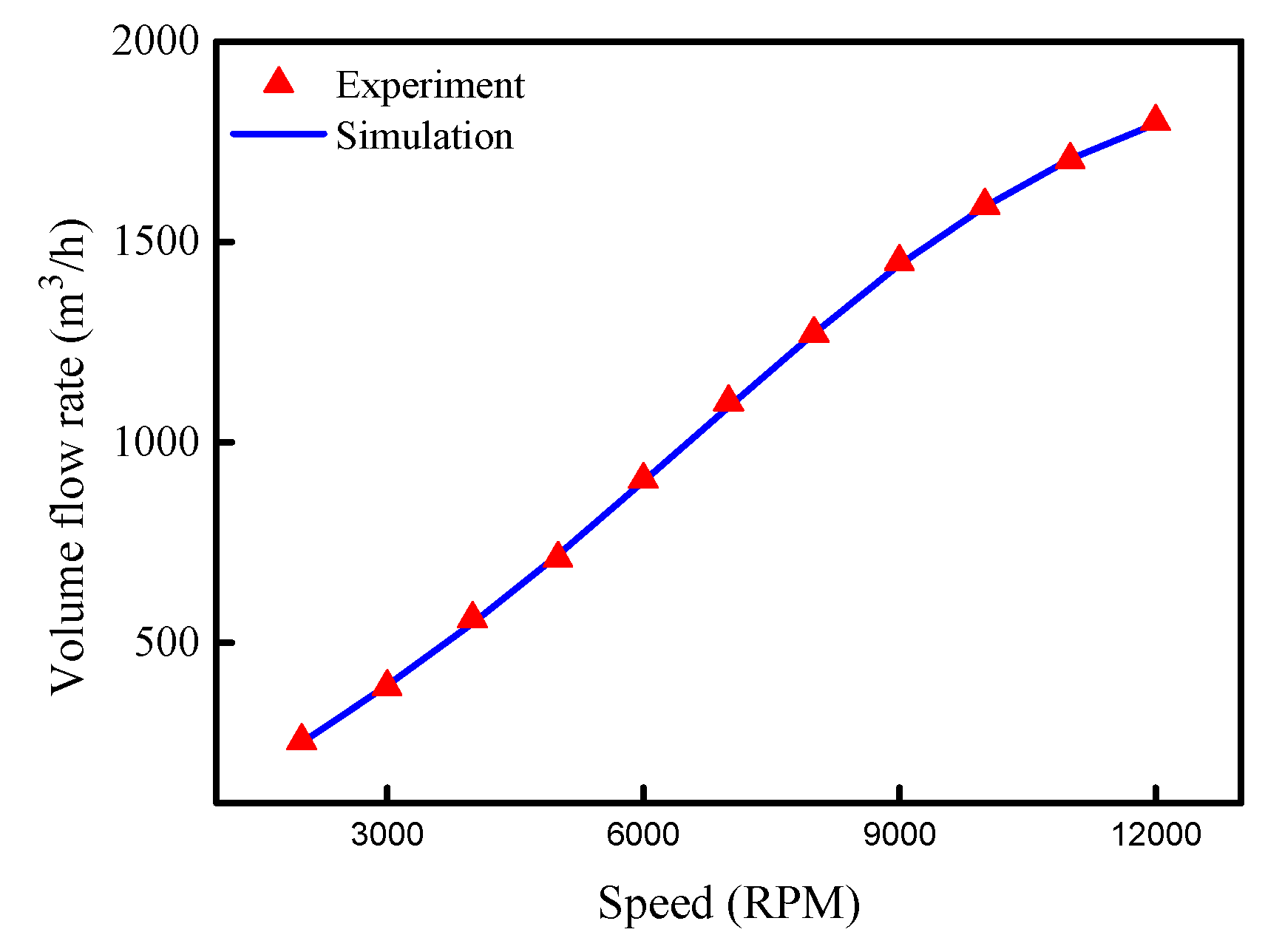

Based on the experimental data, the relationship between rotational speed and volume flow rate is fitted as follows:

Figure 7 illustrates the relationship of the compressor speed and the corresponding volume flow rate.