The Impact of a Controlled-Release Fertilizer on Greenhouse Gas Emissions and the Efficiency of the Production of Chinese Cabbage

Abstract

1. Introduction

2. Materials and Methods

- (1)

- Formulation of the strategic objective;

- (2)

- Selection of the experience factors (a single-factor experience was selected);

- (3)

- Selection of the plant (Chinese cabbage is a plant of high economic importance and high GHG emission potential due to high levels of fertilization and relatively low nitrogen use;

- (4)

- Selection of the experiment site (geographical boundary of the system); the experiment was conducted in the area with large acreage of Chinese cabbage cultivations;

- (5)

- Selection of agrotechnical treatments (except the experimental factor); the treatments were selected based on the recommendations of the integrated plant production methodology and based on production practices in the research area;

- (6)

- Formulation of the experimental factor levels. The level of nitrogen fertilization and the forms of nitrogen applied in the subsequent experimental facilities were designed based on the following input data:

- (a)

- A control facility is necessary for the assessment of the site potential;

- (b)

- Objects fertilized with 400 and 500 kg of slow-release fertilizers. The amount of fertilization results from the manufacturer’s recommendations in their advertising materials;

- (c)

- Objects fertilized with 600 and 800 kg of slow-release fertilizer and objects fertilized with 300 and 450 kg of ammonium nitrate·ha−1. The level of fertilization was calculated based on the plants’ fertilizing needs, at the estimated site productivity of 65 and 90 t·ha−1. The two estimated levels result from the likelihood of adverse weather conditions during the vegetation period of the plants;

- (d)

- An object fertilized with 600 kg of ammonium nitrate·ha−1. The level of fertilization results from production practices applied in the research area;

- (7)

- Estimation of the system boundary in terms of GHG emission sources. The selection was based on the latest available literature and a risk analysis in the context of the assumed target, in accordance with ISO 31000:2018. These sources are:

- (a)

- GHG emissions related to the applied fertilizers;

- (b)

- GHG emissions related to the plant protection products used;

- (c)

- GHG emissions related to electricity consumption and combustion of fossil fuels;

- (d)

- GHG emissions related to decomposition of crop residues;

- (e)

- GHG emissions related to decomposition of soil organic matter.

- (1)

- Production of fertilizers and agrochemicals used for growing plants;

- (2)

- The farm’s energy consumption for field work;

- (3)

- Soil emissions (direct and indirect) related to fertilizer use;

- (4)

- Emissions from harvesting residue management and from the mineralization of soil organic matter;

- (5)

- Water consumption for irrigation.

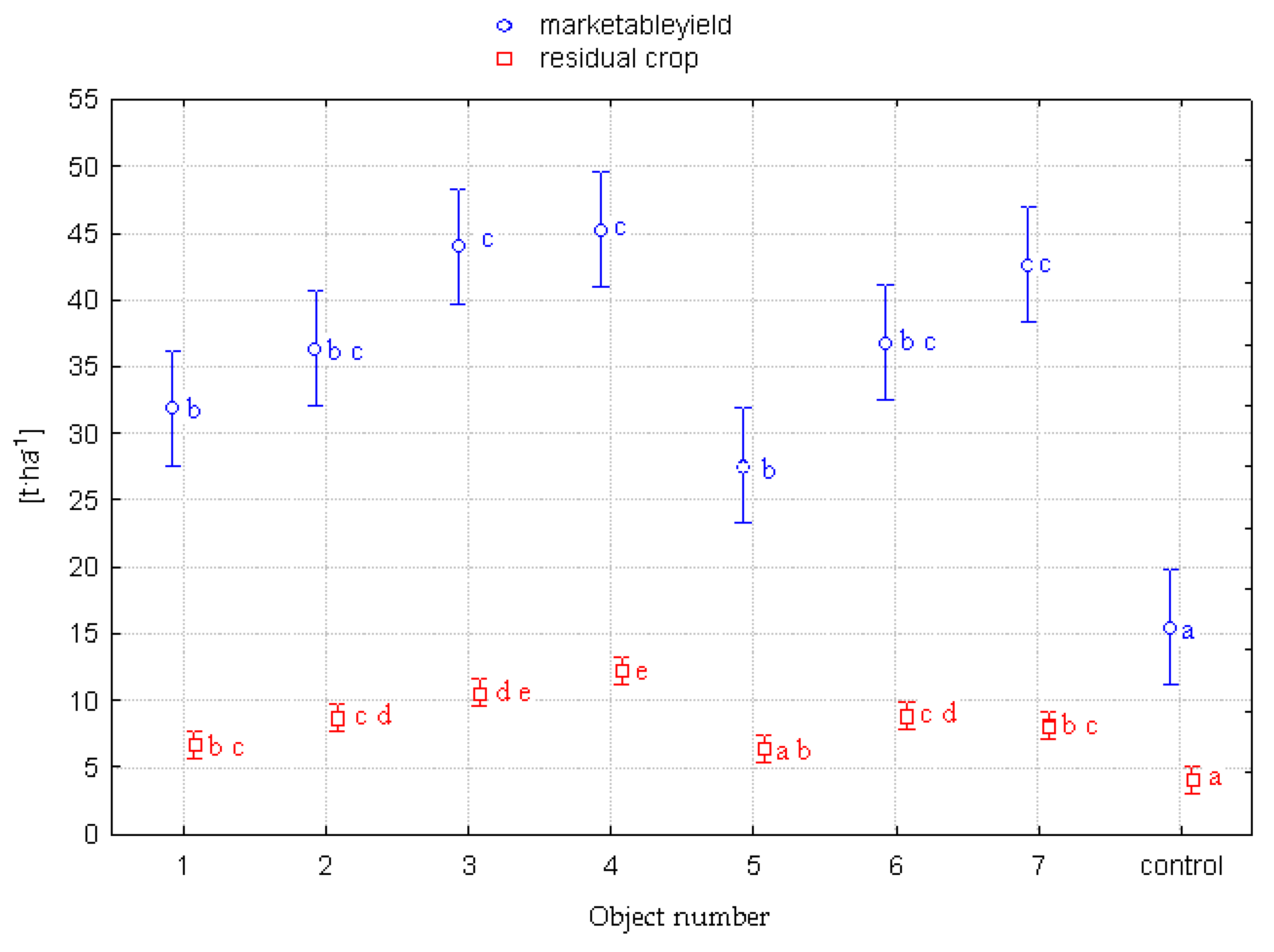

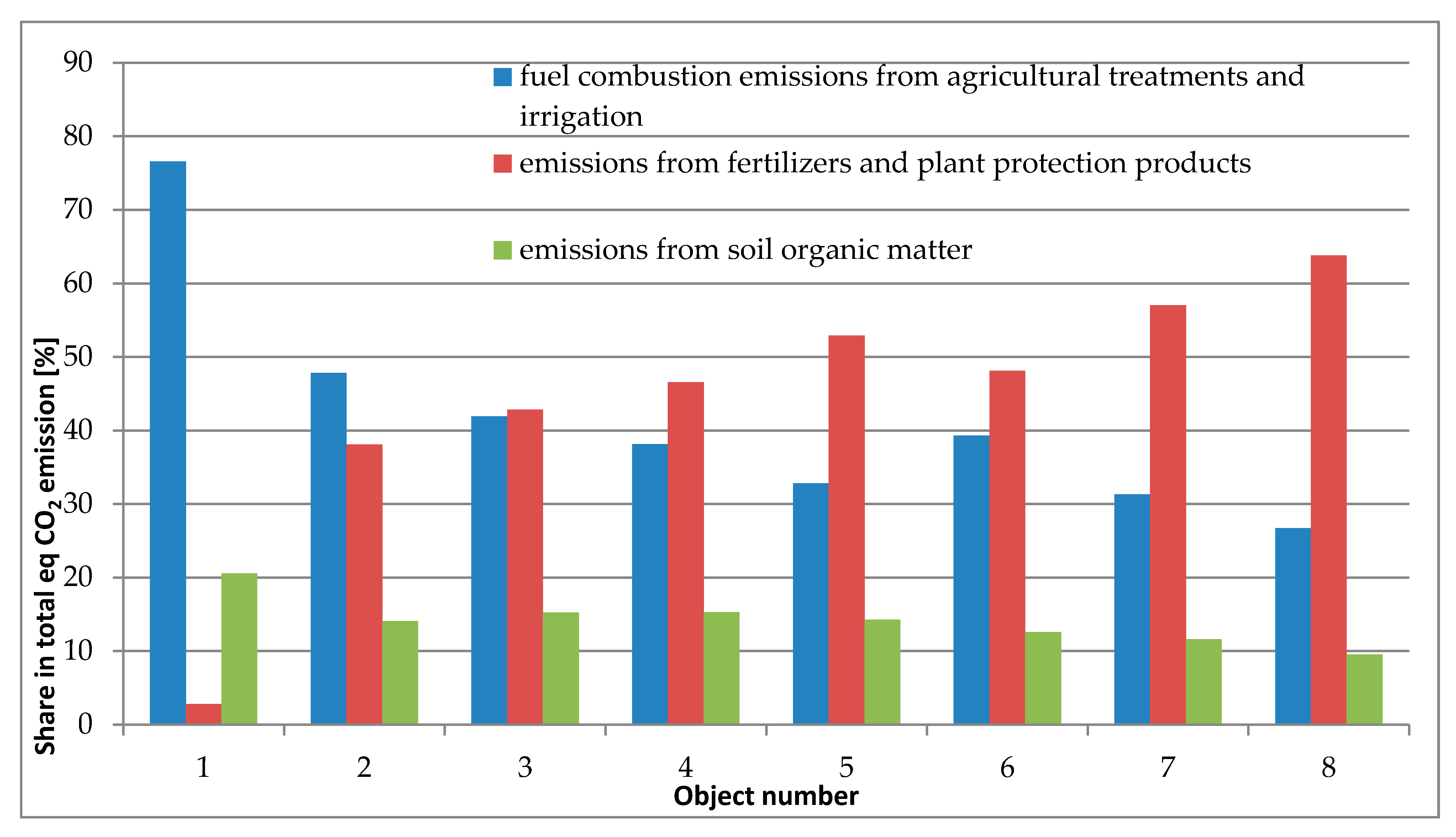

3. Results

- Agricultural treatments and irrigation;

- Production and use of fertilizers;

- Greenhouse gas emissions from soil result from decomposition of harvesting residue and soil organic matter.

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cupiał, M.; Szeląg-Sikora, A.; Niemiec, M. Optimisation of the machinery park with the use of OTR-7 software in context of sustainable agriculture. Agric. Agric. Sci. Procedia 2015, 7, 64–69. [Google Scholar] [CrossRef]

- Szeląg-Sikora, A.; Niemiec, M.; Sikora, J.; Chowaniak, M. Possibilities of Designating Swards of Grasses and Small-Seed Legumes From Selected Organic Farms in Poland for Feed. In Proceedings of the IX International Scientific Symposium Farm Machinery and Processes Management in Sustainable Agriculture, Lublin, Poland, 22–24 November 2017; pp. 365–370. [Google Scholar]

- Li, L.; Wu, W.; Giller, P.; O’Halloran, J.; Liang, L.; Peng, P.; Zhao, G. Life Cycle Assessment of a Highly Diverse Vegetable. Multi-Cropping System in Fengqiu County, China. Sustainability 2018, 10, 983. [Google Scholar] [CrossRef]

- Kocira, S.; Kuboń, M.; Sporysz, M. Impact of information on organic product packagings on the consumers decision concerning their purchase. In Proceedings of the 17th International Multidisciplinary Scientific GeoConference (SGEM 2017), Albena, Bulgaria, 29 June–5 July 2017; Volume 17, pp. 499–506. [Google Scholar]

- Schmidt Rivera, X.C.; Bacenetti, J.; Fusi, A.; Niero, M. The influence of fertiliser and pesticide emissions model on life cycle assessment of agricultural products: The case of Danish and Italian barley. Sci. Total Environ. 2017, 592, 745–757. [Google Scholar] [CrossRef]

- Szeląg-Sikora, A.; Sikora, J.; Niemiec, M.; Gródek-Szostak, Z.; Kapusta-Duch, J.; Kuboń, M.; Komorowska, M.; Karcz, J. Impact of Integrated and Conventional Plant Production on Selected Soil Parameters in Carrot Production. Sustainability 2019, 11, 5612. [Google Scholar] [CrossRef]

- Niemiec, M.; Komorowska, M.; Szeląg-Sikora, A.; Sikora, J.; Kuboń, M.; Gródek-Szostak, Z.; Kapusta-Duch, J. Risk Assessment for Social Practices in Small Vegetable farms in Poland as a Tool for the Optimization of Quality Management Systems. Sustainability 2019, 11, 1913. [Google Scholar] [CrossRef]

- Kasprzak, K.; Wojtunik-Kulesza, K.; Oniszczuk, T.; Kuboń, M.; Oniszczuk, A. Secondary Metabolites, Dietary Fiber and Conjugated Fatty Acids as Functional Food Ingredients against Overweight and Obesity. Natl. Prod. Commun. 2018, 13, 1073–1082. [Google Scholar] [CrossRef]

- Gródek-Szostak, Z.; Szeląg-Sikora, A.; Sikora, J.; Korenko, M. Prerequisites for the cooperation between enterprises and business supportinstitutions for technological development. In Business and Non-Profit Organizations Facing Increased Competition and Growing Customers’ Demand; Nowy Sacz Business School–National Louis University: Nowy Sącz, Poland, 2017; Volume 16, pp. 427–439. [Google Scholar]

- Goglio, P.; Smith, W.N.; Grant, B.B.; Desjardins, R.L.; McConkey, B.G.; Campbell, C.A.; Nemecek, T. Accounting for soil carbon changes in agricultural life cycle assessment (LCA): A review. J. Clean. Prod. 2015, 104, 23–30. [Google Scholar] [CrossRef]

- Audsley, E.; Stacey, K.; Parsons, D.J.; Williams, A.G. Estimation of the Greenhouse Gas Emissions from Agricultural Pesticide Manufacture and Use; Cranfield University: Cranfield, Bedford, 2009. [Google Scholar]

- Eggleston, H.S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies RIP: Hayama, Japan, 2009. [Google Scholar]

- Tubiello, F.N.; Salvatore, M.; Rossi, S.; Ferrara, A.; Fitton, N.; Smith, P. The FAOSTAT database of greenhouse gas emissions from agriculture. Environ. Res. Lett. 2013, 8, 015009. [Google Scholar] [CrossRef]

- Lan, K.; Yao, Y. Integrating Life Cycle Assessment and Agent-Based Modeling: A Dynamic Modeling Framework for Sustainable Agricultural Systems. J. Clean. Prod. 2019, 238, 117853. [Google Scholar] [CrossRef]

- Forster, P.; Ramaswamy, V.; Artaxo, P.; Berntsen, T.; Betts, R.; Fahey, D.W.; Haywood, J.; Lean, J.; Lowe, D.C.; Myhre, G.; et al. Changes in Atmospheric Constituents and in Radiative Forcing. In Climate Change 2007: The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Solomon, S., Qin, D., Manning, M., Chen, Z., Marquis, M., Averyt, K.B., Tignor, M., Miller, H.L., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2007; p. 212. [Google Scholar]

- Kapusta-Duch, J.; Szeląg-Sikora, A.; Sikora, J.; Niemiec, M.; Gródek-Szostak, Z.; Kuboń, M.; Leszczyńska, T.; Borczak, B. Health-Promoting Properties of Fresh and Processed Purple Cauliflower. Sustainability 2019, 11, 4008. [Google Scholar] [CrossRef]

- Bacenetti, J.; Lovarelli, D.; Fiala, M. Mechanisation of organic fertiliser spreading, choice of fertiliser and harvesting residue management as solutions for maize environmental impact mitigation. Eur. J. Agron. 2016, 79, 107–118. [Google Scholar] [CrossRef]

- Liang, L.; Lal, R.; Ridoutt, B.G.; Du, Z.L.; Wang, D.P.; Wang, L.Y.; Wu, W.L.; Zhao, G.S. Life cycle assessment of China’s agroecosystems. Ecol. Indic. 2018, 88, 341–350. [Google Scholar] [CrossRef]

- Nemecek, T.; Dubois, D.; Huguenin-Elie, O.; Gaillard, G. Life cycle assessment of Swiss farming systems: I. Integrated and organic farming. Agric. Syst. 2011, 104, 217–232. [Google Scholar] [CrossRef]

- De Luca, G.; Strkalj, N.; Manz, S. Nanoscale design of polarization in ultrathin ferroelectric heterostructures. Nat. Commun. 2017, 8, 1419. [Google Scholar] [CrossRef] [PubMed]

- Devapriya, P.; Ferrell, W.; Geismar, N. Integrated production and distribution scheduling with a perishable product. Eur. J. Oper. Res. 2017, 259, 906–916. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons, Inc.: New York, NY, USA, 2001. [Google Scholar]

- ISO 31000:2018. Risk management; ISO: Geneva, Switzerland, 2018. [Google Scholar]

- ILCD. General Giude for Lifr Cycle Assessment Detailed Guidance; JRC European Commision, Publications Office of the European Union: Luxembourg, 2010; p. 394. [Google Scholar]

- Kool, A.; Marinussen, M.; Blonk, H. LCI Data for the Calculation Tool Feedprint for Greenhouse Gas Emissions of Feed Production and Utilization GHG Emissions of N, P and K Fertilizer Production; Blonk Consultants: Gouda, The Netherlands, 2016; Available online: https://www.blonkconsultants.nl/wp-content/uploads/2016/06/fertilizer_production-D03.pdf (accessed on 26 March 2020).

- IPCC. Guidelines for National Greenhouse Gas Inventories, Volume 4: Agriculture, Forestry and Other Land Use; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2006. [Google Scholar]

- Novoa, R.; Tejeda, H. Evaluation of the N2O emissions from N in plant residues as affected by environmental and management factors. Nutr. Cycl. Agroecosyst. 2006, 75, 29–46. [Google Scholar] [CrossRef]

- EPA Unated States Environmental Protection Agency. Greenhouse Gas Inventory Guidance Direct Emissions from Mobile Combustion Sources; U.S. EPA Center for Corporate Climate Leadership—GHG Inventory Guidance: Washington, DC, USA, 2016; p. 27.

- Wang, J.; Rothausen, S.; Conway, D.; Zhang, L.; Xiong, W.; Holman, I.P.; Li, Y. China’s water–energy nexus: Greenhouse-gas emissions from groundwater use for agriculture. Environ. Res. Lett. 2012, 7, 1–10. [Google Scholar] [CrossRef]

- FAO. Global database of GHG emissions related to feed crops: Methodology. In Version 1. Livestock Environmental Assessment and Performance Partnership; FAO: Rome, Italy, 2017. [Google Scholar]

- Niemiec, M. Efficiency of slow-acting fertilizer in the integrated cultivation of Chinese cabbage. Ecol. Chem. Eng. A 2014, 21, 333–346. [Google Scholar]

- Niemiec, M.; Cupiał, M.; Szeląg-Sikora, A. Evaluation of the Efficiency of Celeriac Fertilization with the Use of Slow-acting Fertilizers. Agric. Agric. Sci. Procedia 2015, 7, 177–183. [Google Scholar] [CrossRef]

- Gródek-Szostak, Z.; Malik, G.; Kajrunajtys, D.; Szeląg-Sikora, A.; Sikora, J.; Kuboń, M.; Niemiec, M.; Kapusta-Duch, J. Modeling the Dependency between Extreme Prices of Selected Agricultural Products on the Derivatives Market Using the Linkage Function. Sustainability 2019, 11, 4144. [Google Scholar] [CrossRef]

- Cupiał, M.; Szeląg-Sikora, A.; Niemiec, M. Farm Machinery and Processes Management in Sustainable Agriculture Location: 7th International Scientific Symposium: Symposium proceedings, Gembloux, Belgium November, 25–27, 2015. Agric. Agric. Sci. Procedia 2015, 7, 64–69. [Google Scholar]

- Sikora, J.; Niemiec, M.; Szeląg-Sikora, A.; Kuboń, M.; Olech, E.; Marczuk, A. Zgazowanie odpadów z przemysłowego przetwórstwa karpia. Przem. Chem. 2017, 96, 2275–2278. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, J.; Tian, G. 2016. The potential of fertilizer management for reducing nitrous oxide emissions in the cleaner production of bamboo in China. J. Clean. Prod. 2016, 112, 2536–2544. [Google Scholar] [CrossRef]

- Liang, J.-F.; An, J.; Gao, J.-Q.; Zhang, X.-Y.; Song, M.-H.; Yu, F.-H. Interactive effects of biochar and AMF on plant growth and greenhouse gas emissions from wetland microcosms. Geoderma 2019, 346, 11–17. [Google Scholar] [CrossRef]

- Niemiec, M.; Komorowska, M.; Mudryk, K.; Jewiarz, M.; Sikora, J.; Szeląg-Sikora, A.; Rozkosz, A. Evaluation of the Fertilizing Potential of Products Based on Torrefied Biomass and Valorized with Mineral Additives. Renewable Energy Sources: Engineering, Technology, Innovation; Springer: Cham, Switherland, 2020; pp. 267–275. [Google Scholar]

- Xiao, Y.; Peng, F.; Zhang, Y.; Wang, J.; Zhuge, Y.; Zhanga, S.; Gaoa, H. Effect of bag-controlled release fertilizer on nitrogen loss, greenhouse gas emissions, and nitrogen applied amount in peach production. J. Clean. Prod. 2019, 234, 258–274. [Google Scholar] [CrossRef]

- Garg, A.; Kazunari, K.; Pulles, T. IPCC Guidelines for National Greenhouse Gas Inventories. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/pdf/2_Volume2/V2_1_Ch1_Introduction.pdf (accessed on 26 March 2020).

- ISO 14040. Environmental Management-Life Cycle Assessment-Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Zhang, X.; Bol, R.; Rahn, C.; Xiao, G.; Meng, F.; Wu, W. Agricultural sustainable intensification improved nitrogen use efficiency and maintained high crop yield during 1980–2014 in Northern China. Sci. Total Environ. 2017, 596–597, 61–68. [Google Scholar] [CrossRef]

- IFA. Energy Efficiency and CO2 Emissions in Ammonia Production 2008–2009 Summary Report; International Fertilizer Association: Paris, France, 2009. [Google Scholar]

- Tongwane, M.; Mdlambuzi, T.; Moeletsi, M.; Tsubo, M.; Mliswa, V.; Grootboom, L. Greenhouse gas emissions from different crop production and management practices in South Africa. Environ. Dev. 2016, 19, 23–35. [Google Scholar] [CrossRef]

- Jacxsens, L.; Luning, P.A.; Marcelis, W.J.; van Boekel, T.; Rovira, J.; Oses, S.; Kousta, M.; Drosinos, E.; Jasson, V.; Uyttendaele, M. Tools for the performance assessment and improvement of food safety management systems. Trends Food Sci. Technol. 2011, 22 (Suppl. 1), 80–89. [Google Scholar] [CrossRef]

- ISO. TS-EN ISO 14067 Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification and Communication; International Organization for Standardization: Geneva, Switzerland, 2013. [Google Scholar]

- Wójcicki, Z. Methodology of examining energy consumption of agricultural production. Problemy Inżynierii Rolniczej 2015, 23, 17–29. [Google Scholar]

- Niemiec, M.; Komorowska, M.; Szeląg-Sikora, A.; Sikora, J.; Kuzminova, N. Content of Ba, B, Sr and As in water and fish larvae of the genus Atherinidae, L. sampled in three bays in the Sevastopol coastal area. J. Elem. 2018, 23, 1009–1020. [Google Scholar] [CrossRef]

- Goglio, P.; Williams, A.G.; Balta-Ozkan, N.; Harris, N.R.P.; Williamson, P.; Balta-Ozkan, N.; Huisingh, D.; Zhang, Z.; Tavoni, M. Advances and challenges of life cycle assessment (LCA) of greenhouse gas removal technologies to fight climate changes. J. Clean. Prod. 2020, 244, 118896. [Google Scholar] [CrossRef]

- Kuźnia, M.; Wojciech, J.; Łyko, P.; Sikora, J. Analysis of the combustion products of biogas produced from organic municipal waste. J. Power Technol. 2015, 95, 158–165. [Google Scholar]

- Niemiec, M.; Chowaniak, M.; Sikora, J.; Szeląg-Sikora, A.; Gródek-Szostak, Z.; Komorowska, M. Selected Properties of Soils for Long-Term Use in Organic Farming. Sustainability 2020, 12, 2509. [Google Scholar] [CrossRef]

- Sikora, J.; Niemiec, M.; Tabak, M.; Gródek-Szostak, Z.; Szeląg-Sikora, A.; Kuboń, M.; Komorowska, M. Assessment of the Efficiency of Nitrogen Slow-Release Fertilizers in Integrated Production of Carrot Depending on Fertilization Strategy. Sustainability 2020, 12, 1982. [Google Scholar] [CrossRef]

- Kuboń, M.; Niemiec, M.; Tabak, M.; Komorowska, M.; Gródek-Szostak, Z. Ocena zasobności gleby w przyswajalne związki siarki z wykorzystaniem ekstrahentów o zróżnicowanej zdolności ekstrakcji. Przem. Chem. 2020, 99, 581–584. [Google Scholar] [CrossRef]

- Sikora, J.; Niemiec, M.; Szeląg-Sikora, A.; Gródek-Szostak, Z.; Kuboń, M.; Komorowska, M. The Effect of the Addition of a Fat Emulsifier on the Amount and Quality of the Obtained Biogas. Energies 2020, 13, 1825. [Google Scholar] [CrossRef]

| pH in H2O | pH in KCl | [%] | mg·kg−1 | |||||

|---|---|---|---|---|---|---|---|---|

| N in Total | C Organic | N Mineral | P | K | Mg | Ca | ||

| 7.01 | 6.65 | 0.16 | 1.41 | 56.65 | 147.8 | 359.5 | 199.4 | 850 |

| Object Number | Slow-Release Fertilizer | Ammonium Nitrate | Triple Superphosphate | Potassium Salt | N | P2O5 | K2O |

|---|---|---|---|---|---|---|---|

| kg of fertilizer·ha−1 | kg of component·ha−1 | ||||||

| control | 0 | - | - | - | - | - | - |

| 1 | 400 | - | 89 | 177 | 72 | 60 | 150 |

| 2 | 500 | - | 76 | 158 | 90 | 60 | 150 |

| 3 | 600 | - | 65 | 140 | 108 | 60 | 150 |

| 4 | 800 | - | 43 | 103 | 144 | 60 | 150 |

| 5 | - | 300 | 130 | 250 | 100 | 60 | 150 |

| 6 | - | 450 | 130 | 250 | 150 | 60 | 150 |

| 7 | - | 600 | 130 | 250 | 200 | 60 | 150 |

| Type of Agricultural Treatment | Diesel Use | Energy Use | CO2 Emission |

|---|---|---|---|

| [dm3] | [MJ] | [kg] | |

| Ploughing | 57.0 | 2299.0 | 220.2 |

| Mineral fertilization, one time | 5.1 | 206.9 | 19.71 |

| Cultivation with an aggregate | 30.8 | 1241.5 | 119.0 |

| Mechanical planting | 154.0 | 6207.4 | 595.1 |

| Application of plant protection products, four times | 24.8 | 517.3 | 95.83 |

| Mechanical weeding, one time | 19.2 | 775.9 | 74.19 |

| Total | 1325.8 | 53,458.0 | 1124.0 |

| Irrigation [KWh] | 194.7 | 179.7 | |

| Total | 1303.7 |

| Object Number | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| control | 1323.4 | 353.1a * | ||||

| 2 | 592 | 72.29 | 664.29 | 48.75 | 1323.4 | 384.3a |

| 3 | 740 | 64.00 | 804.00 | 48.75 | 1323.4 | 474.0b |

| 4 | 888 | 56.34 | 944.34 | 48.75 | 1323.4 | 521.1bc |

| 5 | 1184 | 40.70 | 1224.70 | 48.75 | 1323.4 | 563.9c |

| 6 | 502.3 | 502.28 | 48.75 | 1303.7 | 412.8a | |

| 7 | 901.8 | 901.78 | 48.75 | 1303.7 | 476.9b | |

| 8 | 1301.3 | 1301.28 | 48.75 | 1303.7 | 458.1bc |

| Object Number | G | H | I | J | K |

|---|---|---|---|---|---|

| equivalent of CO2∙ha−1 | equivalent of CO2∙ha−1 | ||||

| control | 14.5 | ||||

| 1 | 1.13 | 0.04 | 330.4 | 11.33 | 18.9 |

| 2 | 1.41 | 0.30 | 413.0 | 87.81 | 31.5 |

| 3 | 1.70 | 0.44 | 495.6 | 128.02 | 38.2 |

| 4 | 2.26 | 0.68 | 660.8 | 197.77 | 44.2 |

| 5 | 1.57 | 0.64 | 458.9 | 187.85 | 22.9 |

| 6 | 2.36 | 1.15 | 688.3 | 334.51 | 31.9 |

| 7 | 3.14 | 1.53 | 917.7 | 448.01 | 29.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sikora, J.; Niemiec, M.; Szeląg-Sikora, A.; Gródek-Szostak, Z.; Kuboń, M.; Komorowska, M. The Impact of a Controlled-Release Fertilizer on Greenhouse Gas Emissions and the Efficiency of the Production of Chinese Cabbage. Energies 2020, 13, 2063. https://doi.org/10.3390/en13082063

Sikora J, Niemiec M, Szeląg-Sikora A, Gródek-Szostak Z, Kuboń M, Komorowska M. The Impact of a Controlled-Release Fertilizer on Greenhouse Gas Emissions and the Efficiency of the Production of Chinese Cabbage. Energies. 2020; 13(8):2063. https://doi.org/10.3390/en13082063

Chicago/Turabian StyleSikora, Jakub, Marcin Niemiec, Anna Szeląg-Sikora, Zofia Gródek-Szostak, Maciej Kuboń, and Monika Komorowska. 2020. "The Impact of a Controlled-Release Fertilizer on Greenhouse Gas Emissions and the Efficiency of the Production of Chinese Cabbage" Energies 13, no. 8: 2063. https://doi.org/10.3390/en13082063

APA StyleSikora, J., Niemiec, M., Szeląg-Sikora, A., Gródek-Szostak, Z., Kuboń, M., & Komorowska, M. (2020). The Impact of a Controlled-Release Fertilizer on Greenhouse Gas Emissions and the Efficiency of the Production of Chinese Cabbage. Energies, 13(8), 2063. https://doi.org/10.3390/en13082063