Open-Source Implementation and Validation of a 3D Inverse Design Method for Francis Turbine Runners

Abstract

1. Introduction

2. Inverse Design Method Implementation

2.1. Method Overview

- The available head H, discharge Q, rotational speed , and number of blades B;

- The meridional channel geometry: hub, shroud, leading edge and trailing edge curves;

- The camber surface angle f, also termed blade wrap angle, along the blade leading edge;

- The blade thickness distribution normal to the camber surface;

- The blade loading distribution .

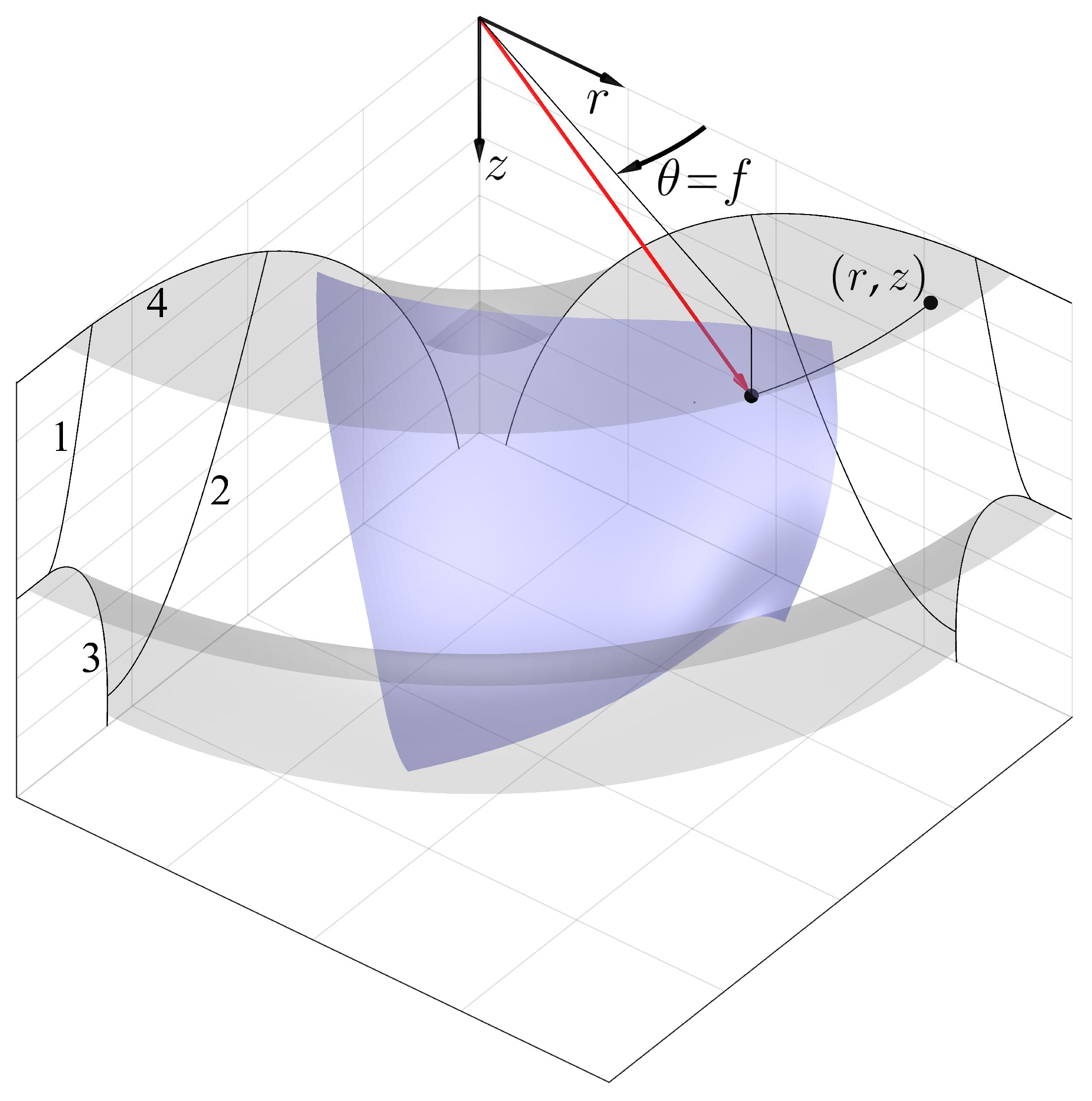

2.2. Governing Equations in Cylindrical Coordinates

2.2.1. Mean Flow

2.2.2. Periodic Flow

2.2.3. Blade Camber Surface

2.2.4. Calculation of the Pressure

2.3. Governing Equations in Non-Orthogonal Curvilinear Coordinates

2.3.1. Mean Flow

2.3.2. Periodic Flow

2.3.3. Blade Camber Surface

2.4. Additional Implementation Details

2.4.1. Algorithm Overview

2.4.2. Meridional Channel Geometry Generation

| Algorithm 1: Implemented inverse design method. |

| read user inputs |

| generate meridional channel geometry |

| generate finite difference mesh |

| initialize fields and constant integration parameters: f, , , , , , |

| while camber surface angle f has not converged do |

|

| end |

| output runner geometry and flow fields |

2.4.3. Discretization and Numerical Methods

3. Characterization and Validation of the Inverse Method Implementation

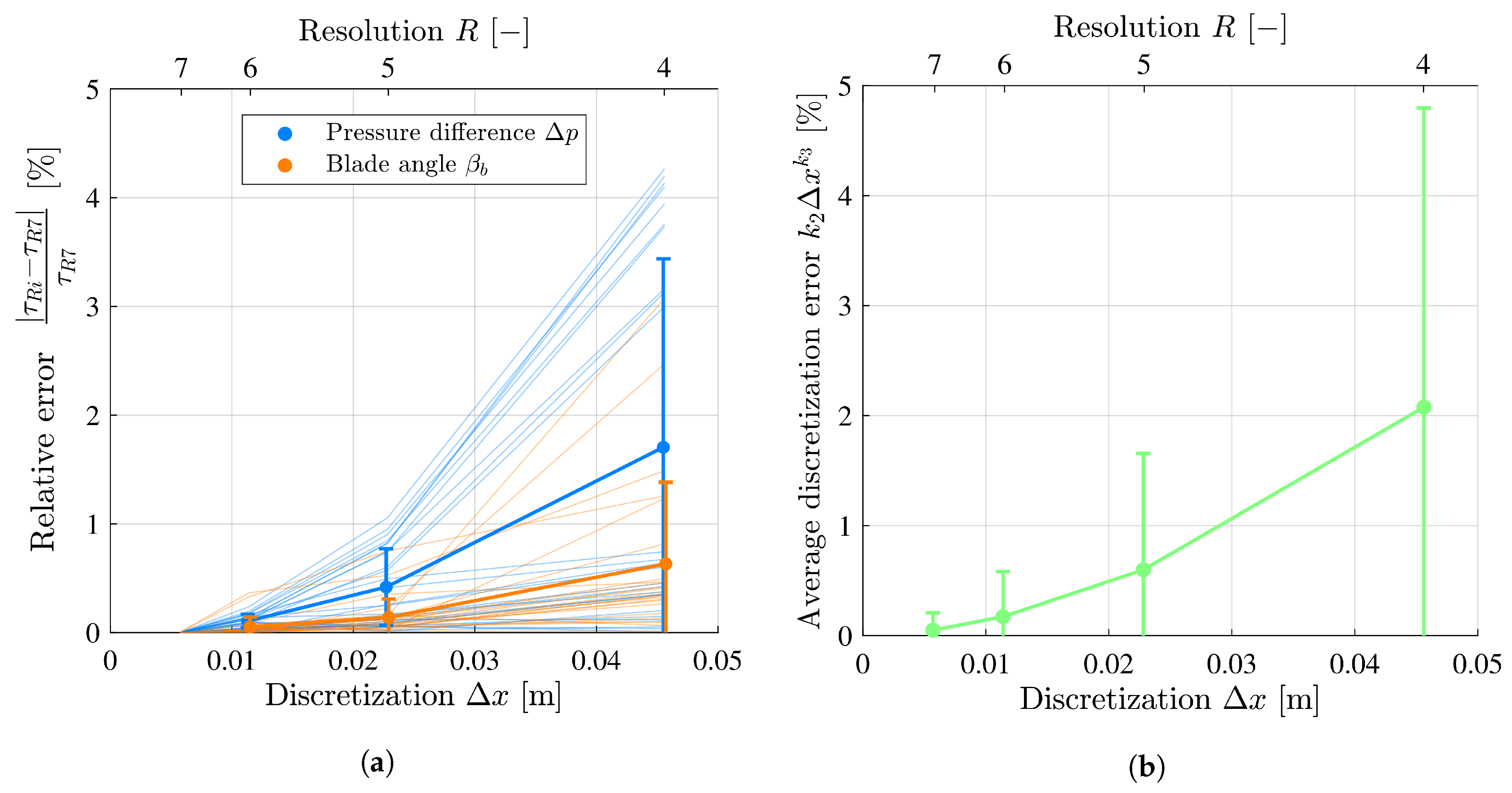

3.1. Convergence Analyses

3.2. Implementation Validation

3.2.1. Qualitative Validation

3.2.2. Quantitative Validation

4. Discussion and Outlook

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- REN21. Renewables 2018 Global Status Report; Technical Report; Renewable Energy Policy Network for the 21st Century (REN21) Secretariat: Paris, France, 2018. [Google Scholar]

- Tan, C.S.; Hawthorne, W.R.; McCune, J.E.; Wang, C. Theory of blade design for large deflections: Part II—Annular cascades. ASME J. Eng. Gas Turbines Power 1984, 106, 354–365. [Google Scholar] [CrossRef]

- Borges, J.E. A three-dimensional inverse design method for turbomachinery: Part I—Theory. J. Turbomach. 1990, 112, 346–354. [Google Scholar] [CrossRef]

- Borges, J.E. A three-dimensional inverse design method for turbomachinery: Part II—Experimental Verification. J. Turbomach. 1990, 112, 355–361. [Google Scholar] [CrossRef]

- Zangeneh, M. A compressible three-dimensional design method for radial and mixed flow turbomachinery blades. Int. J. Numer. Methods Fluids 1991, 13, 599–624. [Google Scholar] [CrossRef]

- Zhu, B.; Wang, X.; Tan, L.; Zhou, D.; Zhao, Y.; Cao, S. Optimization design of a reversible pump-turbine runner with high efficiency and stability. Renew. Energy 2015, 81, 366–376. [Google Scholar] [CrossRef]

- Zhu, B.; Tan, L.; Wang, X.; Ma, Z. Investigation on flow characteristics of pump-turbine runners with large blade lean. ASME J. Fluids Eng. 2018, 140, 031101. [Google Scholar] [CrossRef]

- Daneshkah, K.; Zangeneh, M. Parametric design of a Francis turbine runner by means of a three-dimensional inverse design method. IOP Conf. Ser. Earth Environ. Sci. 2010, 12, 012058. [Google Scholar] [CrossRef]

- Wang, P.; Vera-Morales, M.; Vollmer, M.; Zangeneh, M.; Zhu, B.; Ma, Z. Optimisation of a pump-as-turbine runner using a 3D inverse design methodology. IOP Conf. Ser. Earth Environ. Sci. 2019, 240, 042005. [Google Scholar] [CrossRef]

- Yang, W.; Liu, B.; Xiao, R. Three-Dimensional Inverse Design Method for Hydraulic Machinery. Energies 2019, 12, 3210. [Google Scholar] [CrossRef]

- Batchelor, G.K. An Introduction to Fluid Dynamics; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar] [CrossRef]

- Rishav, R. NURBS Curve. MATLAB Central File Exchange. 2018. Available online: https://www.mathworks.com/matlabcentral/fileexchange/67009-nurbs-curve (accessed on 1 February 2020).

- Ott, C. Non-Linearly Spaced Vector Generator. MATLAB Central File Exchange. 2017. Available online: https://www.mathworks.com/matlabcentral/fileexchange/64831-non-linearly-spaced-vector-generator (accessed on 1 February 2020).

- Kumpulainen, P. Tight Subplot. MATLAB Central File Exchange. 2016. Available online: https://www.mathworks.com/matlabcentral/fileexchange/27991-tight_subplot-nh-nw-gap-marg_h-marg_w (accessed on 1 February 2020).

- Bovet, T. Contribution à l’étude du tracé d’aubage d’une turbine à réaction du type Francis; Technical Report; Informations Techniques Charmilles: Geneva, Switzerland, 1963; Available online: https://infoscience.epfl.ch/record/149853/ (accessed on 1 February 2020).

- Vivier, L. Turbines hydrauliques et leur régulation: Théorie, construction, utilisation; Albin Michel: Paris, France, 1966. [Google Scholar]

- Henry, P. Turbomachines hydrauliques: Choix illustré de réalisations marquantes; Presses Polytechniques et Universitaires Romandes: Lausanne, Switzerland, 1992. [Google Scholar]

- Ferziger, J.; Perić, M. Computational Methods for Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 1996. [Google Scholar] [CrossRef]

- Mössinger, P.; Jester-Zürker, R.; Jung, A. Investigation of different simulation approaches on a high-head Francis turbine and comparison with model test data: Francis-99. J. Phys. Conf. Ser. 2015, 579, 012005. [Google Scholar] [CrossRef]

- Lenarcic, M.; Eichhorn, M.; Schoder, S.J.; Bauer, C. Numerical investigation of a high head Francis turbine under steady operating conditions using foam-extend. J. Phys. Conf. Ser. 2015, 579, 012008. [Google Scholar] [CrossRef]

- Casartelli, E.; Mangani, L.; Ryan, O.; Del Rio, A. Performance prediction of the high head Francis-99 turbine for steady operation points. J. Phys. Conf. Ser. 2017, 782, 012007. [Google Scholar] [CrossRef]

- Dewan, Y.; Custer, C.; Ivashchenko, A. Simulation of the Francis-99 hydro turbine during steady and transient operation. J. Phys. Conf. Ser. 2017, 782, 012003. [Google Scholar] [CrossRef]

- Leguizamón, S.; Ségoufin, C.; Hai-Trieu, P.; Avellan, F. On the efficiency alteration mechanisms due to cavitation in Kaplan turbines. ASME J. Fluids Eng. 2017, 139, 061301. [Google Scholar] [CrossRef]

| Resolution level R | 4 | 5 | 6 | 7 | [−] |

| Number of nodes in spanwise direction: | 17 | 33 | 65 | 129 | [−] |

| Representative discretization error | [%] | ||||

| Time to solution | 0.051 | 0.154 | 1.06 | 13.4 | [min] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leguizamón, S.; Avellan, F. Open-Source Implementation and Validation of a 3D Inverse Design Method for Francis Turbine Runners. Energies 2020, 13, 2020. https://doi.org/10.3390/en13082020

Leguizamón S, Avellan F. Open-Source Implementation and Validation of a 3D Inverse Design Method for Francis Turbine Runners. Energies. 2020; 13(8):2020. https://doi.org/10.3390/en13082020

Chicago/Turabian StyleLeguizamón, Sebastián, and François Avellan. 2020. "Open-Source Implementation and Validation of a 3D Inverse Design Method for Francis Turbine Runners" Energies 13, no. 8: 2020. https://doi.org/10.3390/en13082020

APA StyleLeguizamón, S., & Avellan, F. (2020). Open-Source Implementation and Validation of a 3D Inverse Design Method for Francis Turbine Runners. Energies, 13(8), 2020. https://doi.org/10.3390/en13082020