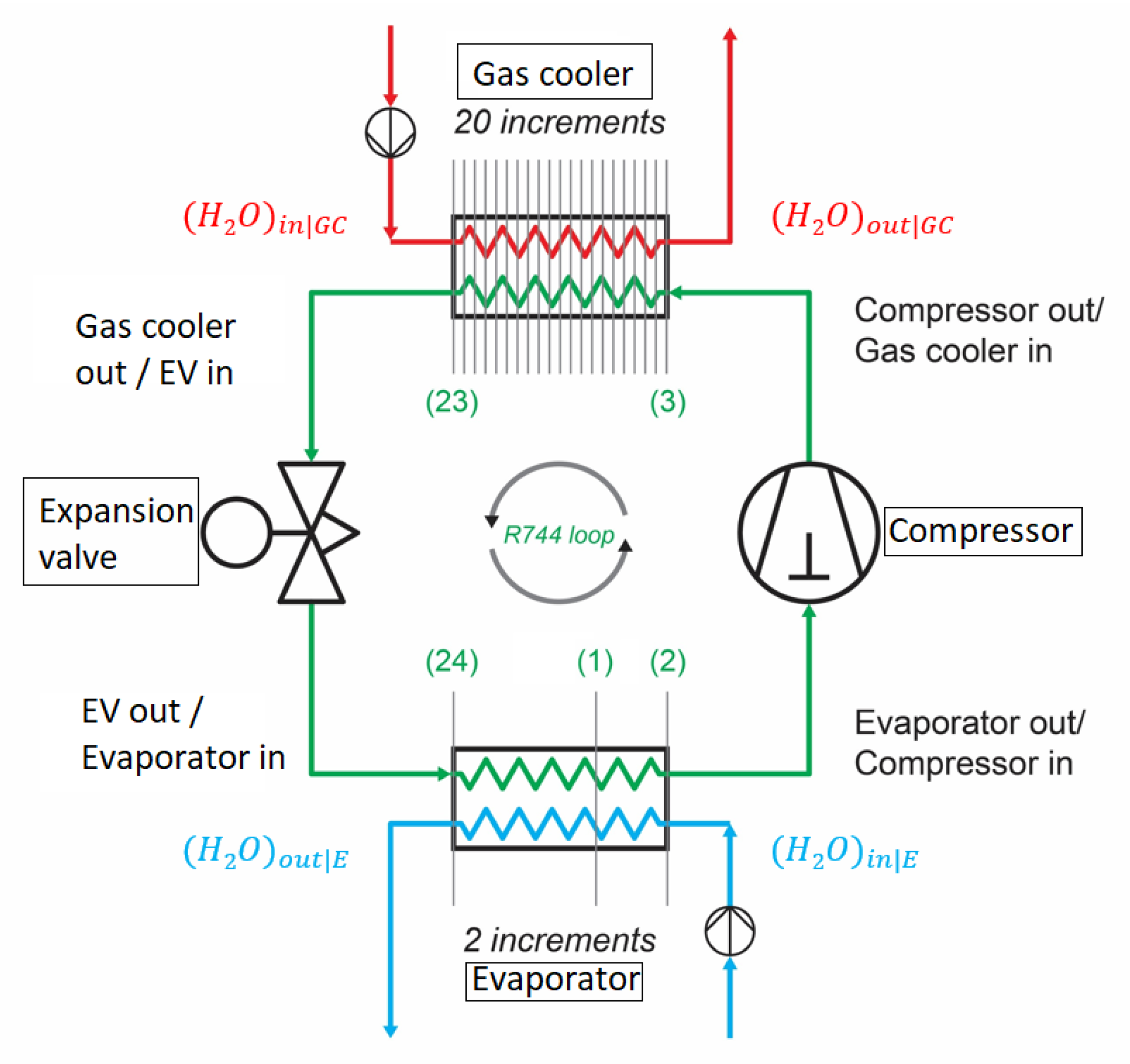

The way in which each component in the heat pump system is represented using control volume (CV) regions is discussed in this section. The specific methodology used to solve for the key driving parameters present in the derived component-specific conservation and characteristic equations is also discussed. The modeling discussion proceeds in the chronological order of evaporator first, compressor second, gas cooler third and concludes with the modeling of the electronic expansion valve component.

Appendix A.1. Evaporator

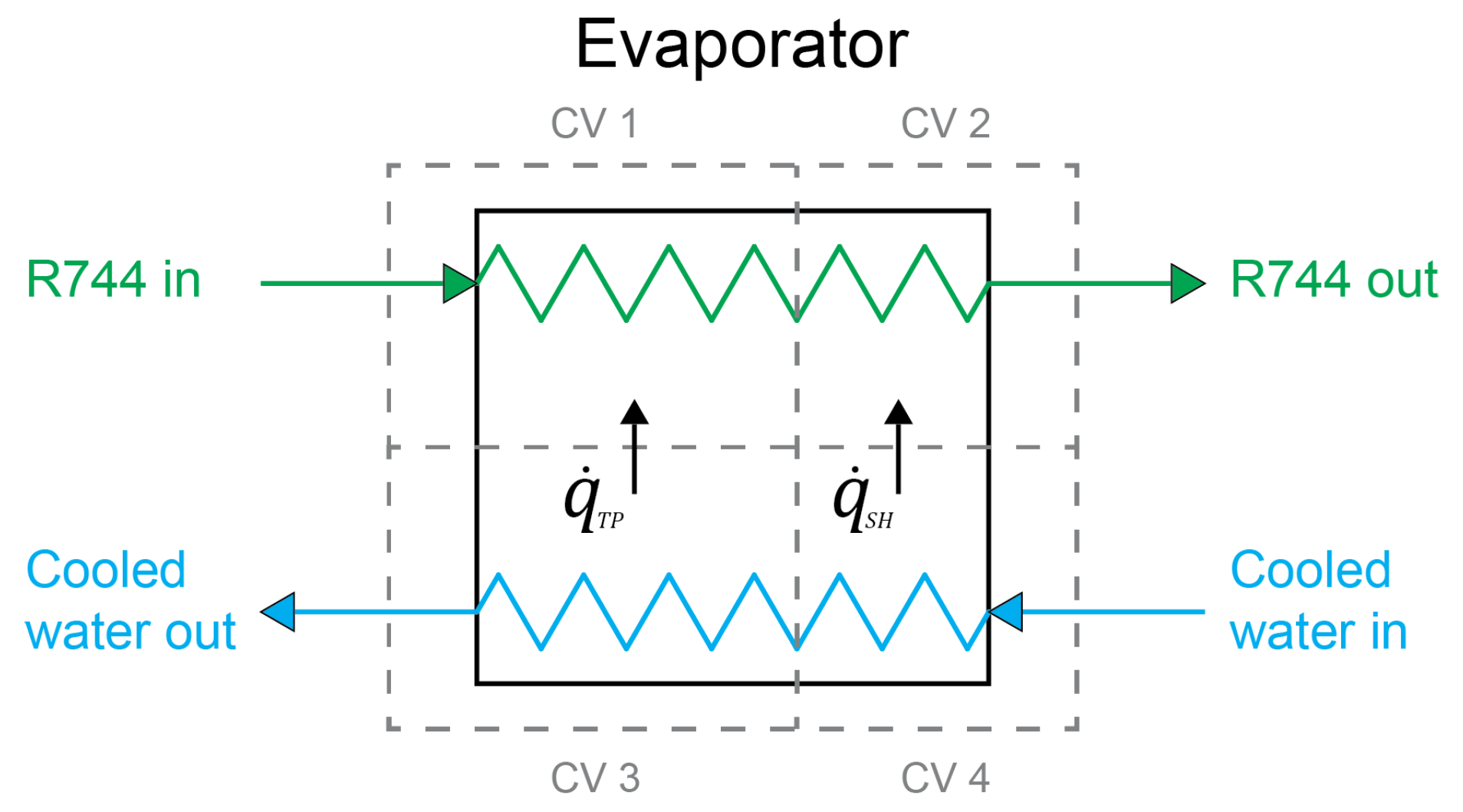

The evaporator component is divided into two CVs on the refrigerant side and two corresponding CVs on the cooled water side, as illustrated in

Figure A1.

Figure A1.

Evaporator component divided into four control volume regions.

Figure A1.

Evaporator component divided into four control volume regions.

It is assumed that the mass flow rate, temperature, and pressure are known at the inlet of the R744 side of the evaporator. The amount of superheating is also known at the outlet of the evaporator component and is controlled by the EV orifice opening percentage. It is also assumed that the water side of the evaporator, the volumetric flow rate delivered by the pump, the inlet temperature, and the pressure of the water are known. The conservation of mass balance for the R744 side of the evaporator is given by:

The conservation of mass for the water side of the evaporator is described by:

The conservation of momentum for the R744 side of the evaporator is as follows:

The total pressure drop,

, that the R744 undergoes along the length of the evaporator is the sum of the total pressure drop that occurs in the evaporator’s two-phase region and the total pressure drop that occurs in the preceding superheating region. The total pressure drop that the R744 undergoes in the two-phase region,

, is modeled using the Friedel method [

41].

In the Friedel method the total lengthwise two-phase pressure drop,

, is a function of the pressure drop that would occur in the two-phase region if the whole pipe was filled with only a liquid,

, multiplied by the squared two-phase Friedel multiplier,

. The superscript

refers to a two-phase working fluid. The Friedel method is expressed mathematically as:

The R744 liquid-based pressure drop is expressed as:

where

is the liquid-based friction factor,

is the length of the two-phase region in the evaporator,

is hydraulic diameter of the homogeneous R744 flow,

is the mass velocity of the two-phase R744 mixture, and

is the liquid-based bulk density in the two-phase region. The liquid-based friction factor is calculated by use of the Blasius correlation [

41,

42]:

where

is the bulk dimensionless liquid-based Reynolds number in the two-phase region. The mass velocity of the R744 two-phase flow is simply the total R744 mass flow through the evaporator divided by the free flow area of the inner evaporator tube:

After the liquid-based pressure drop has been determined; the two-phase Friedel multiplier is required to calculate the total two-phase pressure drop with relation to the liquid-based pressure drop in the two-phase region. The Friedel multiplier is expressed as a function of five dimensionless parameters as:

The first dimensionless parameter is defined as:

where

is the bulk quality dryness fraction of the two-phase region and

is the bulk vapor-based friction factor. The second dimensionless parameter is defined as:

The third dimensionless parameter is defined as:

The homogeneous Froude number is defined as:

where

g is the local gravitational acceleration at the physical location of the heat pump system and

is the bulk homogeneous density of the two-phase flow in the two-phase region. The liquid-based Weber number is defined as:

where

is the surface tension at the bulk conditions in the two-phase flow region.

The superheat region follows the two-phase region in the evaporator. The total pressure drop that occurs in the superheat region is expressed as:

The Darcy friction factor for the superheat region is determined using the built-in EES

MoodyChart function as follows:

The total pressure drop on the R744 side of the evaporator is then the sum of the total pressure in the two-phase region and the total pressure drop in the superheat region:

The length of the two-phase region added to the length of the superheating region must equate to the total length of the tube in the evaporator component:

The focus of the simulation is on the modeling of the refrigerant side of the heat pump system. The total pressure drop on the water side of the evaporator is assumed to be negligible. Under this assumption the conservation of momentum for the water side of the evaporator is simply:

The conservation of energy for the R744 side of the evaporator is:

The total heat absorbed by the R744 during the evaporation process is equal to the total heat absorbed in the two-phase region and in the superheat region within the evaporator:

The total enthalpy at the start of the superheat region can easily be calculated when the total pressure drop in the two-phase region is known. The total enthalpy at the start of the superheat region may thus be calculated in EES

as follows:

Once the total enthalpy at the start of the superheat region is known, the heat transfer in the two-phase region can be calculated by performing an energy balance for CV 1 as in

Figure A1. The result is:

Since the amount of superheat at the outlet of the evaporator component is controlled by the EEV operation, the heat transfer in the superheat region is calculated from the single-phase relation:

The heat absorbed by the R744 during the evaporation process is supplied from the cooled water stream. The conservation of energy for the water side of the evaporator is thus given by:

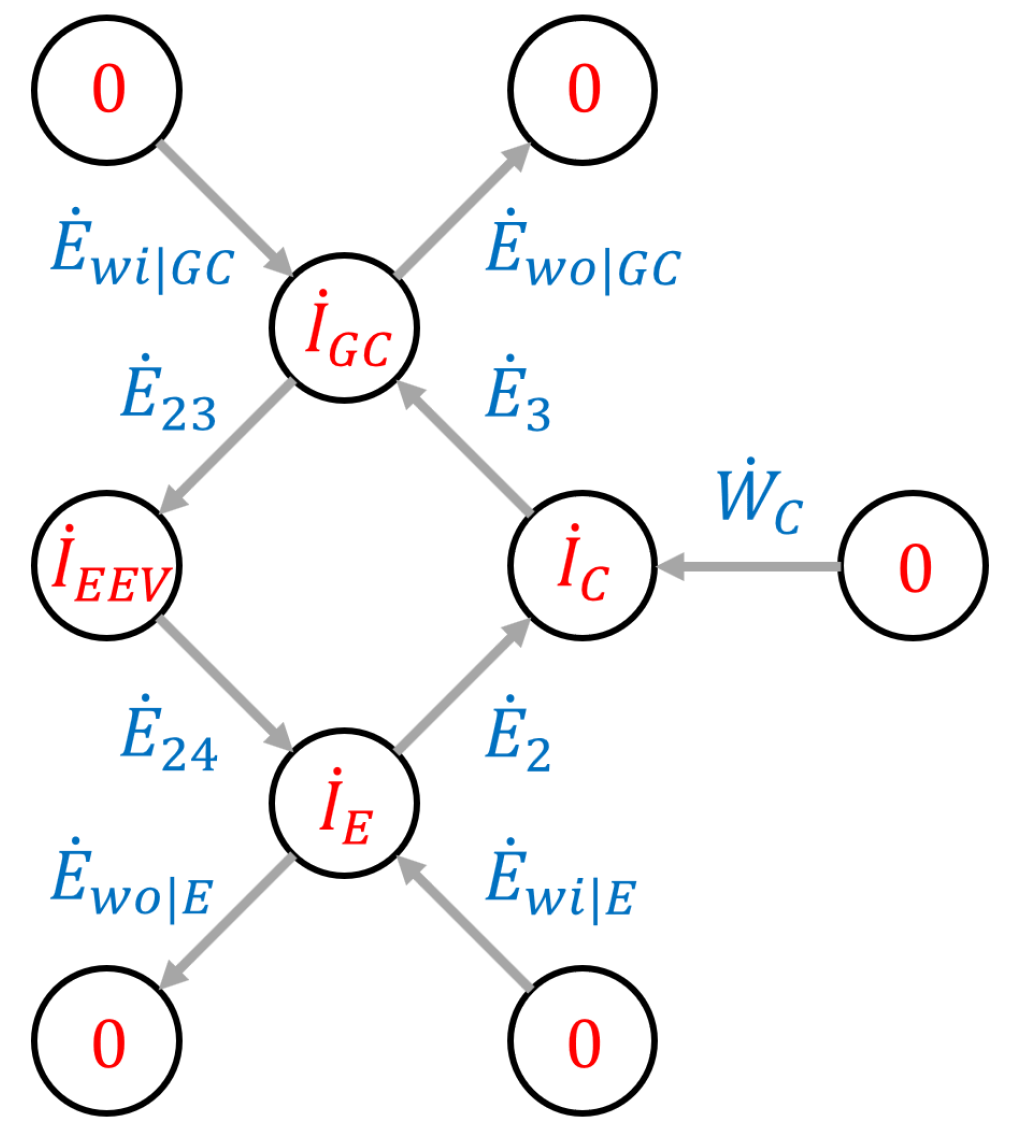

The exergy analysis of the evaporator is performed over the entire evaporator component. The exergy analysis thus considers all four CV regions that encapsulate the evaporator interactions simultaneously. The exergy balance over the entire evaporator is thus given by:

Appendix A.2. Compressor

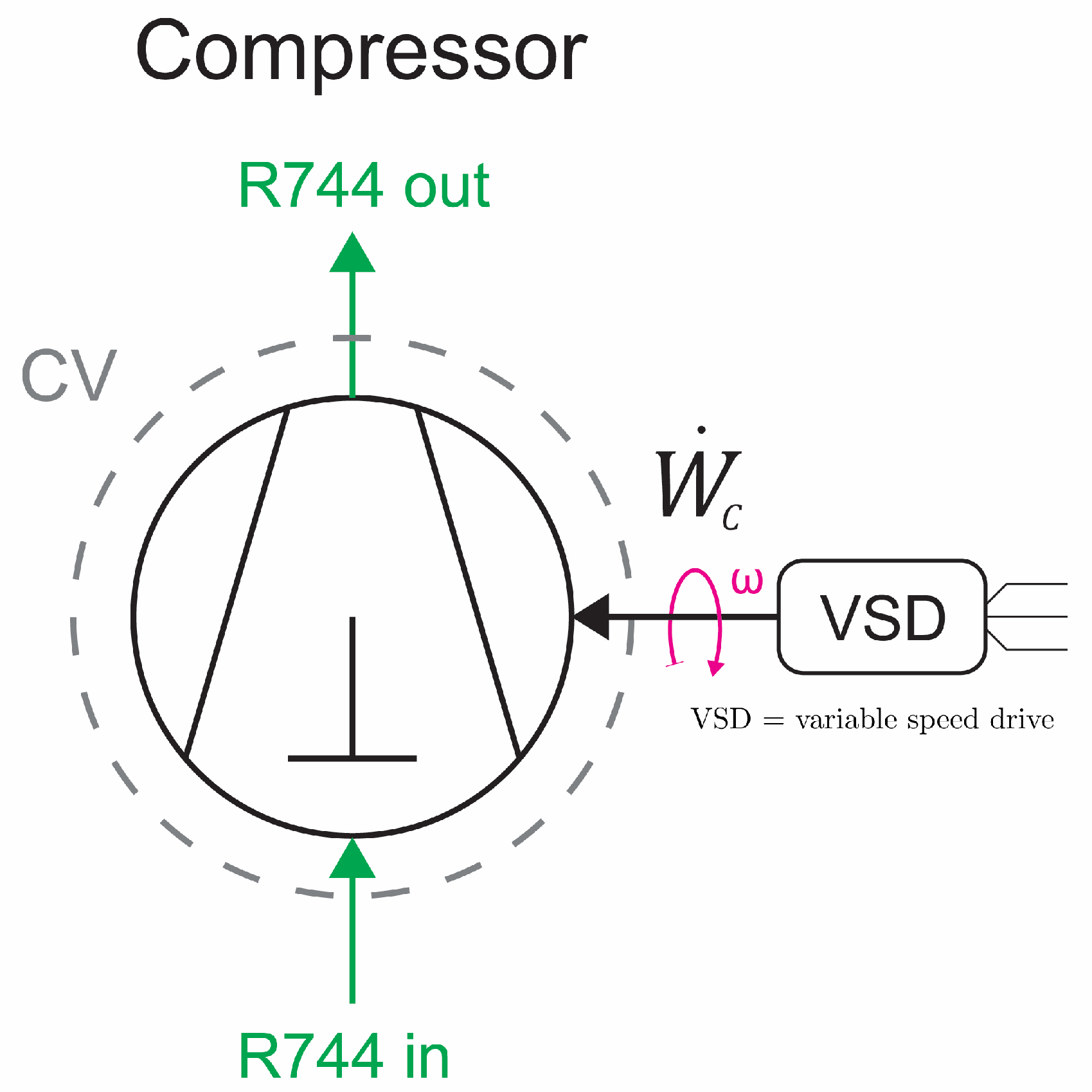

The compressor component is represented using one CV. The compressor component with its CV indicated as illustrated in

Figure A2.

Figure A2.

Compressor component with its CV.

Figure A2.

Compressor component with its CV.

The compressor only has carbon dioxide as its interacting fluid with the conservation of mass for the compressor component given by:

The discharge pressure of the R744 after compression is defined by the compressor’s ratio of pressure:

The conservation of energy for the compressor is given by:

where

is the power absorbed by the compressor during the compression of the carbon dioxide gas. The compressor power drawn is the key parameter required to solve for the output flow energy delivered by the compressor. The compressor power drawn is calculated from the compressor’s isentropic efficiency:

where

is the power the compressor would draw in an ideal imaginary isentropic compression process between the same inlet and outlet thermo-physical conditions and

is the isentropic efficiency of the compressor with a value in the range of zero to one. The ratio of pressure across the compressor will be expressed as a function of the isentropic efficiency of the compressor at various operating conditions.

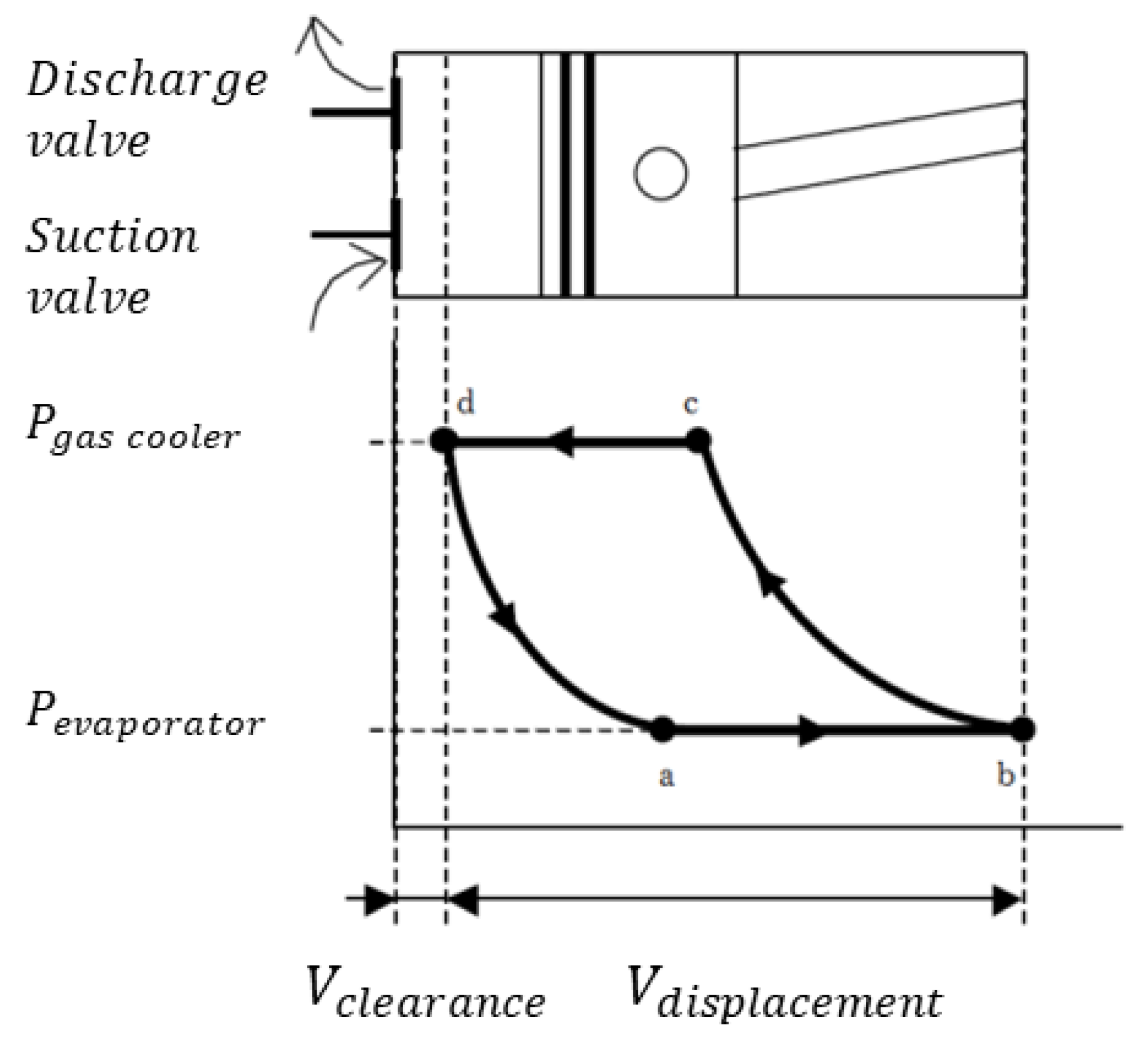

Figure A3 illustrates the pressure-volume behavior of the refrigerant through the compression process inside the compression chamber of a reciprocating compressor.

Four different stages are defined in the cyclic up-and-down movement performed by the compressor’s pistons. At point,

a in

Figure A3, the suction valve opens during the movement of the piston and low-pressure refrigerant flows into the compression chamber. The piston continues to move and draw in refrigerant until it reaches its bottom dead center (BDC) as indicated by point

b in

Figure A3. At point

b the suction valve closes and the piston starts moving in the opposite direction, compressing the refrigerant. The compression action is illustrated in

Figure A3 by the curved line that connects point

b and

c. At point

c the refrigerant reaches a high enough pressure to open the compression chamber’s discharge valve. The refrigerant is pushed out of the compression chamber by the motion of the piston as it moves from point

c to its top dead center (TDC) as indicated by point

d. The discharge valve closes after the piston has reached point

d. The pressure inside the compression chamber is lowered from point

d to

a as the piston moves from its TDC back towards its BDC. After the piston reaches point

a, the process starts anew.

Figure A3.

P-V behavior of the refrigerant inside a reciprocating compressor’s piston chamber.

Figure A3.

P-V behavior of the refrigerant inside a reciprocating compressor’s piston chamber.

The expression to determine the specific work required per piston to compress the refrigerant from the evaporating pressure to the gas cooler pressure is given by:

where

is the average heat capacity ratio between the compressor’s discharge and suction side,

is the specific volume of the refrigerant at point

b in

Figure A3, and

is the pressure ratio over the compressor during steady-state operation. The total specific work required by the compressor during steady operation is then the specific work required per piston times the number of pistons that compress the refrigerant:

where

is the number of compression cylinders that compress the refrigerant at any given instance during steady-state compressor operation.

The isentropic efficiency of the compressor may thus be simulated by taking the theoretical specific isentropic work required by the compressor at the same operating conditions and dividing it by the calculated actual specific work required by the compressor:

The accuracy of (

A32) can be improved by including two constants into the equation that were determined from test bench data. The improved equation for the isentropic efficiency of the compressor is given by:

where

and

. The isentropic efficiency of the compressor is assumed to be known in this study and its value is used as an input parameter in the simulation of the heat pump system. This approach may be used to implicitly determine the ratio of pressure over the compressor when the isentropic efficiency of the compressor is known, as is evident from inspection of (

A30).

The exergy balance for the compressor is given by:

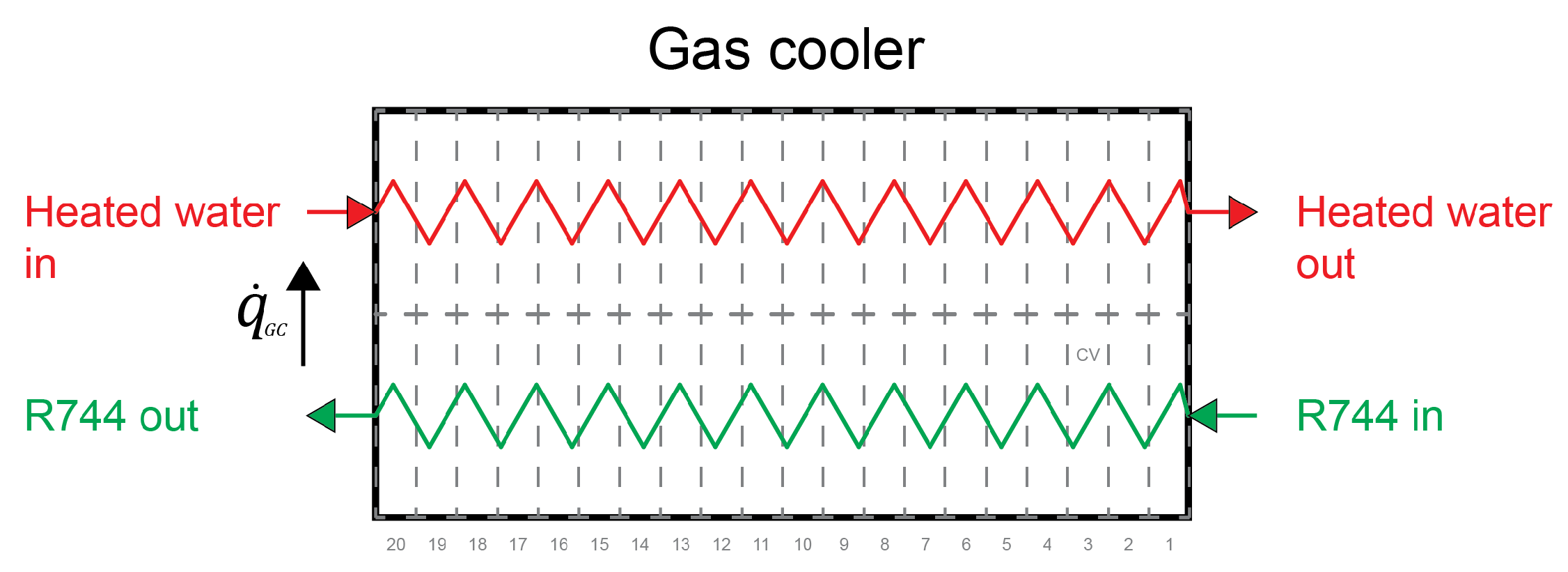

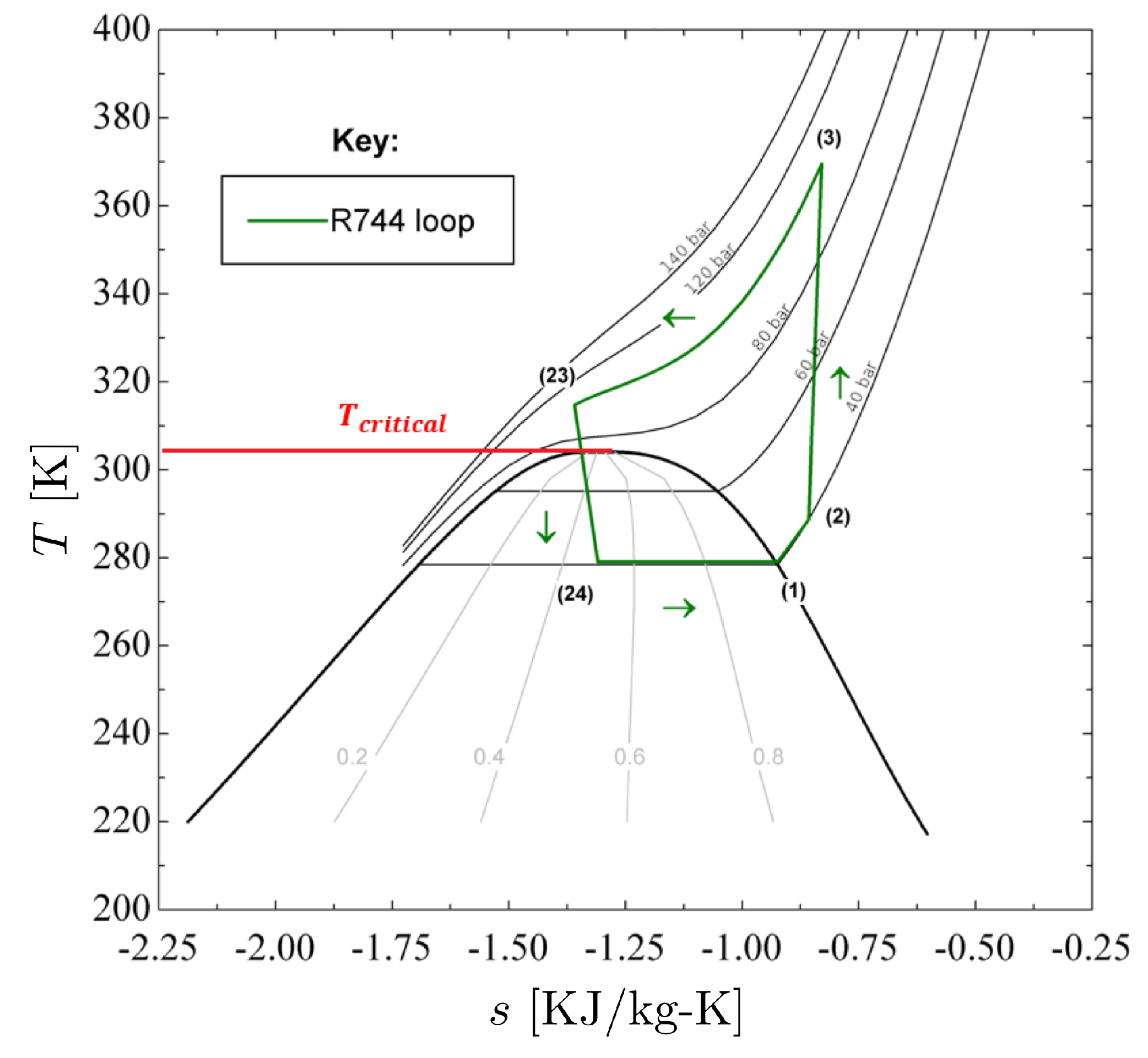

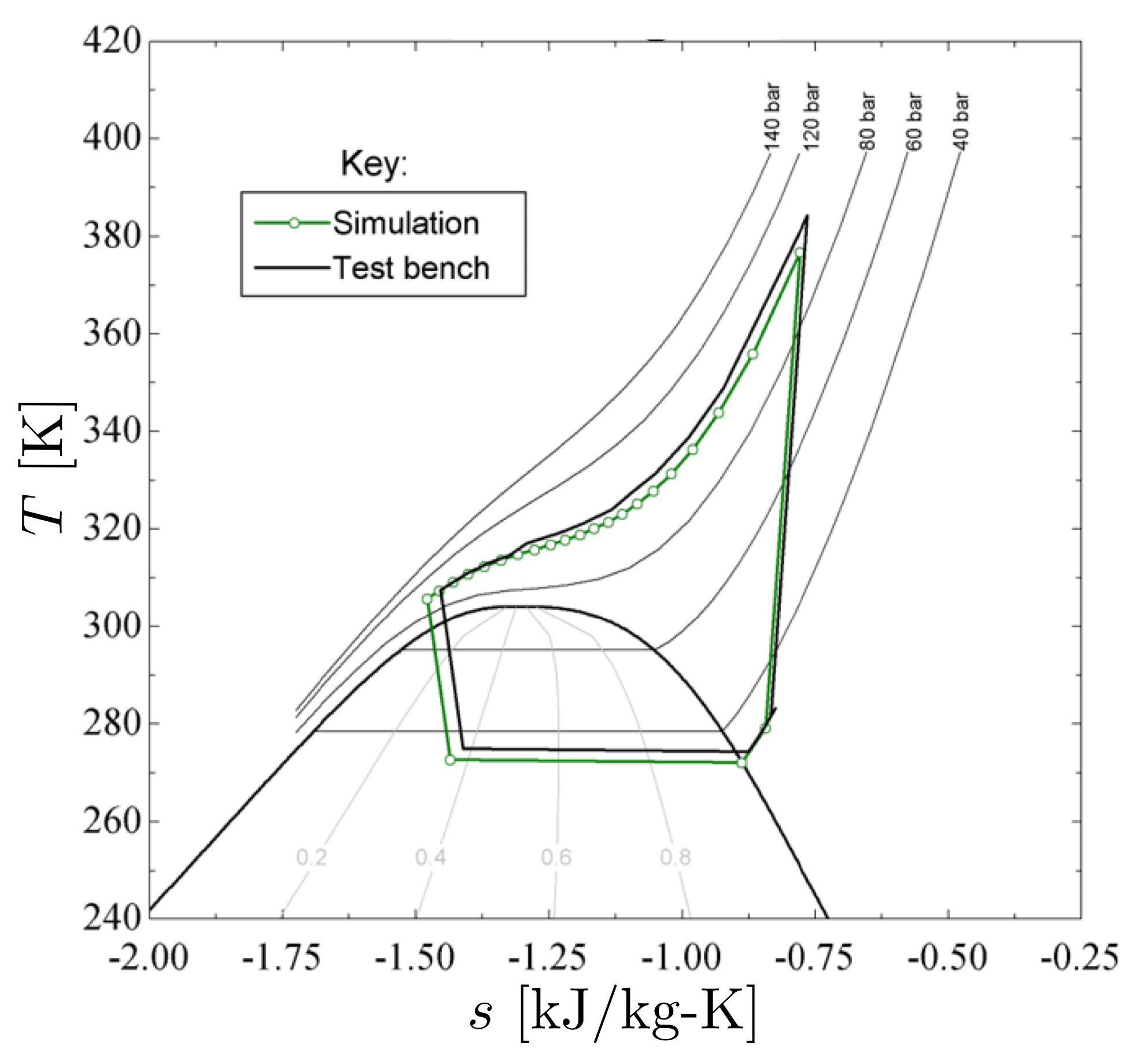

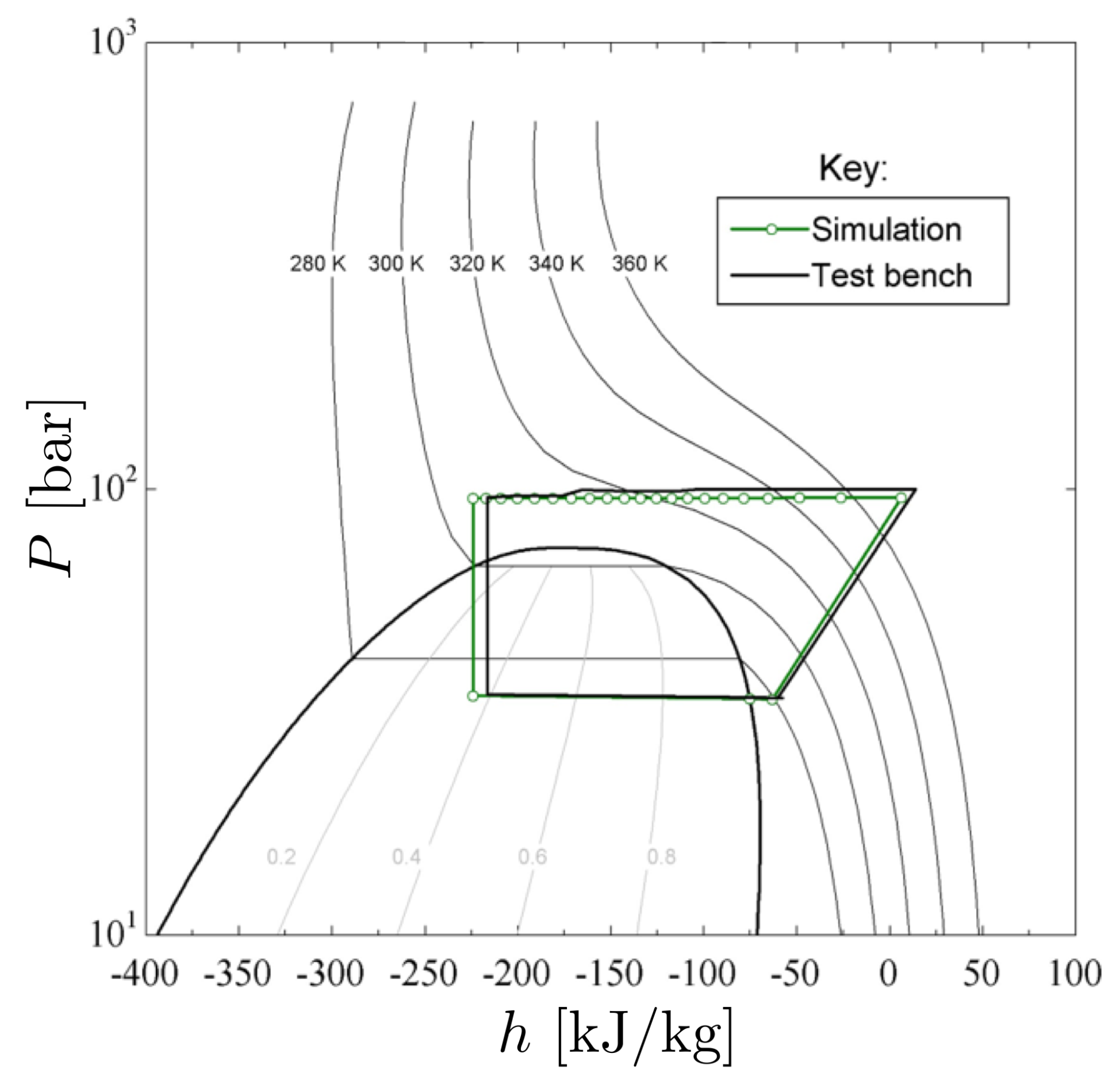

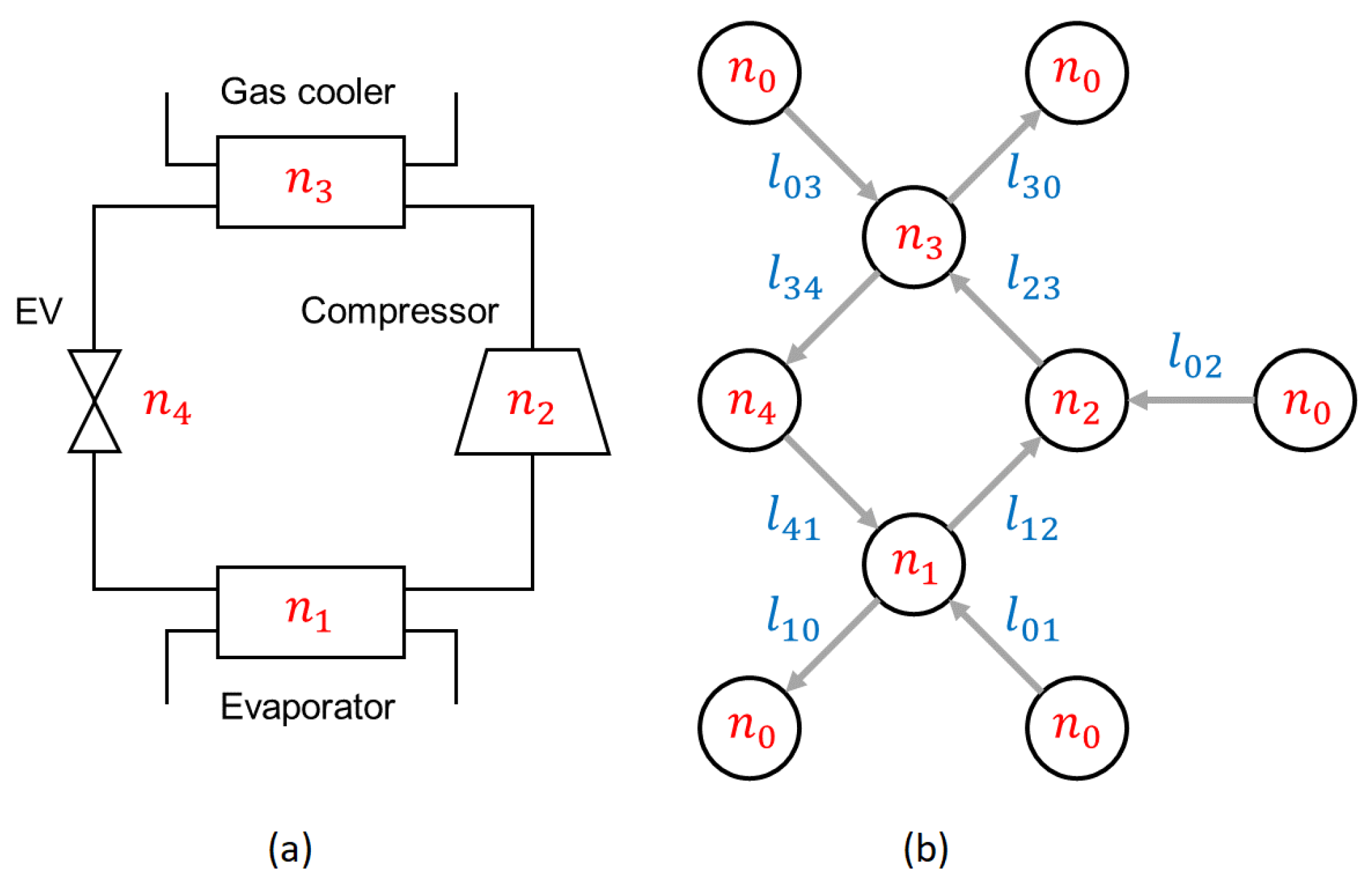

Appendix A.3. Gas Cooler

The gas cooler is divided into 20 control volumes on the refrigerant side and 20 corresponding control volumes on the heated water side. This was done to accurately calculate the heat transfer in the gas cooler component using the

-NTU method. The segmentation is also beneficial when plotting the supercritical heat rejection curve of the refrigerant on a T-s diagram. The gas cooler component with its control volume regions is illustrated in

Figure A4.

Figure A4.

Gas cooler component divided into control volume regions.

Figure A4.

Gas cooler component divided into control volume regions.

It is assumed that the mass flow rate, temperature, and pressure are known at the inlet of the R744 side of the gas cooler. It is also assumed that the volumetric flow rate, inlet temperature and pressure are known on the water side. The conservation of mass balance on the R744 side of the gas cooler is given by:

The conservation of mass balance on the water side of the gas cooler is:

The density of the water,

, [kg/m

] and

the volumetric flow rate of the heated water through the gas cooler has a unit [m

/s]. The conservation of momentum for the R744 side of the gas cooler is

where

is the total pressure drop of the R744 along the length of the gas cooler. The total pressure drop is a function of flow channel friction, the total coil length, the hydraulic diameter, and the thermo-physical properties of R744 as it flows through the gas cooler. The total pressure drop on the R744 side of the gas cooler is equal to the sum of the pressure drop over each segment on the refrigerant side. The pressure drop per increment on the refrigerant side is given by:

where

is the friction factor correlation by Wang et al. [

43] for the prediction of supercritical carbon dioxide pressure drop in the turbulent flow regime,

is the length of the increment,

is the hydraulic diameter,

is the bulk density per increment, and

is the bulk velocity per increment. The friction factor correlation by Wang et al. is given by:

The parameter

is the surface roughness of the inner gas cooler tube material and

is the dimensionless bulk Reynolds number of the R744 per increment. The correlation by Wang et al. has a valid Reynolds number range of:

. The pressure drop on the water side of the gas cooler is assumed to be negligible. Under this assumption the conservation of momentum equation for the entire water side of the gas cooler is given by:

The conservation of energy for the R744 side of the gas cooler is:

The energy extracted from the R744 side of the gas cooler during the cooling process is absorbed by the heated water side. The conservation of energy for the water side of the gas cooler is described by:

where

is the total heat transfer that takes place from the R744 to the water stream. The total heat transfer is the sum of the heat transfer per increment on the R744 side of the gas cooler. The heat transfer per increment will be solved by using the

-NTU method. The heat transfer per increment is given by:

where

is the maximum theoretical heat transfer possible per increment and

is the effectiveness of the gas cooler in transferring heat per increment in the range of 0.1. The maximum heat transfer per increment is given by:

where

is the minimum heat capacity rate between the two interacting fluid streams and

is the temperature difference between the R744 and water, at their respective inlets, per increment. The effectiveness per increment for a counter-flow tube-in-tube type of heat exchanger is defined by Bergman et al. [

44] as:

where NTU is the dimensionless number of transfer units per segment of the gas cooler and

is the dimensionless capacity ratio of the interacting fluids. Equation (

A45) is valid for all possible values of the capacity ratio that are smaller than one. The capacity ratio is expressed as the ratio of the minimum to maximum heat capacity rates of the interacting heat exchanger fluids per increment:

where

is the bulk specific heat capacity at constant pressure per increment for a given fluid stream. The number of transfer units per gas cooler increment is given by:

where

U is the overall heat transfer coefficient per gas cooler increment and

is the heat transfer surface area per increment. It is assumed that there is no possibility of fouling build-up on the R744 side of the gas cooler while it is possible for the water side to foul. Furthermore, it is also assumed that the gas cooler is well insulated on the outside of the outer tube such that there is no possibility of heat loss to the environment. Under these assumptions the product of the overall heat transfer coefficient with the heat transfer surface area per gas cooler increment may be expressed in terms of thermal resistance as [

45]:

The first term in (

A48) is the total thermal resistance per gas cooler increment, the second term is the convection thermal resistance on the R744 side and the third term is the conduction thermal resistance per increment. The fourth term is the fouling resistance on the heated water side and the fifth term is the convection resistance of the heated water side on the gas cooler.

The Dittus-Boelter correlation [

46] is used to solve for the convection coefficient,

, on both the R744 and the water side of the gas cooler. Although correlations exist that can predict the convection coefficient of supercritical R744 with higher accuracies such as those investigated by Venter [

47], the study by van Eldik et al. [

38] showed that the Dittus-Boelter correlation shows an excellent fit (for larger diameter tubes) with experimental data over a wider range of Reynolds number values. The study by [

38] also concluded that the Dittus-Boelter correlation remains relatively stable when used to calculate convection coefficients based on thermo-physical conditions in the pseudo-critical region of carbon dioxide. The convection coefficient per gas cooler increment while implementing the Dittus-Boelter correlation is expressed as:

where

is a correlation factor specifically fitted to the specific test bench system to further increase the accuracy of the Dittus-Boelter correlation,

is the bulk conduction heat transfer coefficient of the fluid,

is the bulk dimensionless Prandtl number of the fluid per gas cooler increment and

n is a power set to 0.3 if the fluid considered is cooled or set to 0.4 if the fluid is heated. The CF factor for the experimental data used in this study is 2.294 [-]. The

factor is included to make the prediction of heat transfer values associated with the test bench system as accurate as possible. The CF factor reported here is only valid for this study. The CF factor used here is an average of all the individual factors determined by setting the simulation results equal to the experimental results. The CF factor is thus a form of direct numerical fitting of the simulation to the test bench results. The exergy analysis of the gas cooler is done over the entire component. The exergy balance over the entire gas cooler is given:

Appendix A.4. Expansion Valve

The EV component is represented with one CV. The EV component with its CV is illustrated in

Figure A5.

Figure A5.

EV component with its CV region.

Figure A5.

EV component with its CV region.

The EV has only carbon dioxide as its interacting fluid. The conservation of mass for the R744 flowing through the EV component is given by:

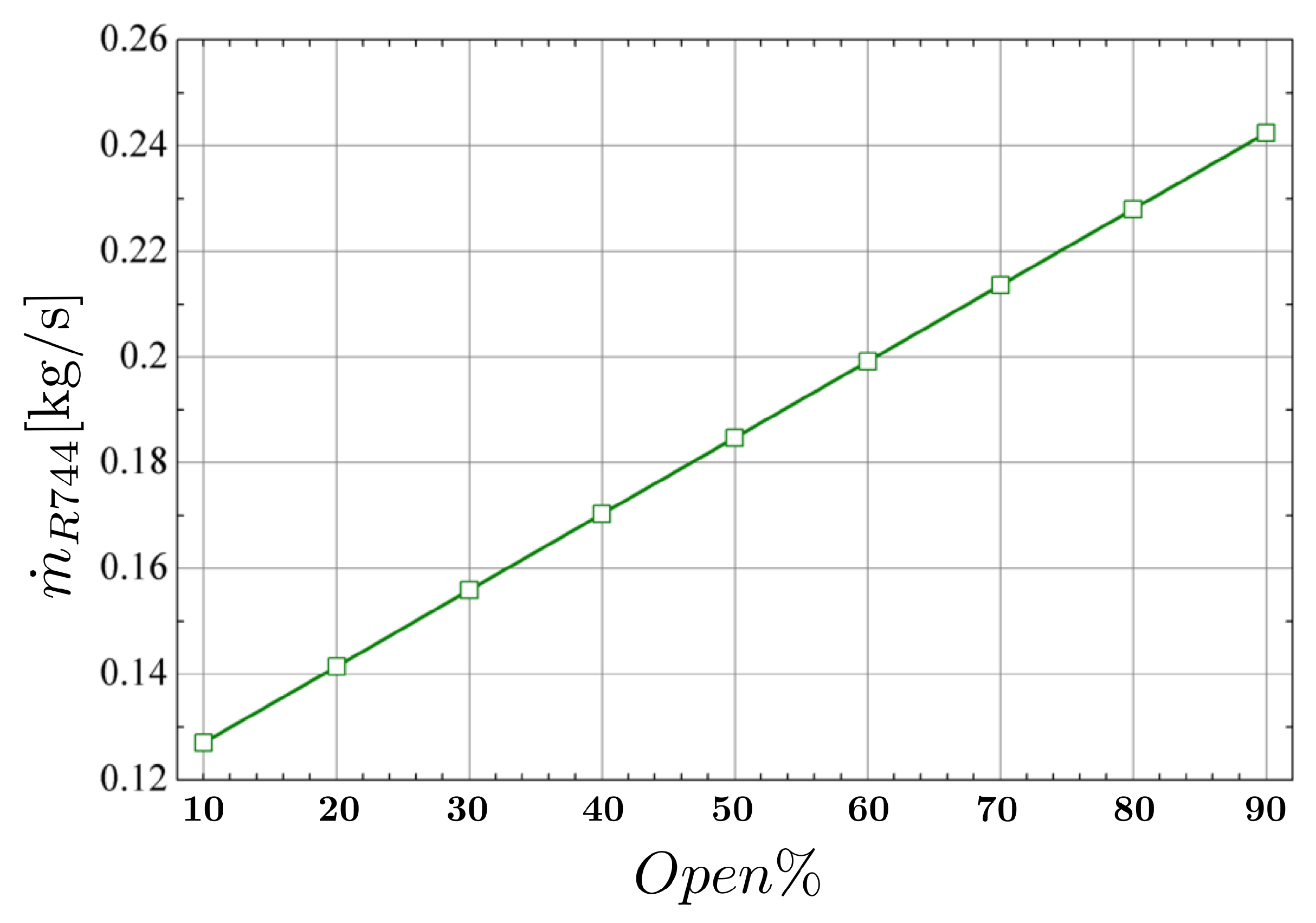

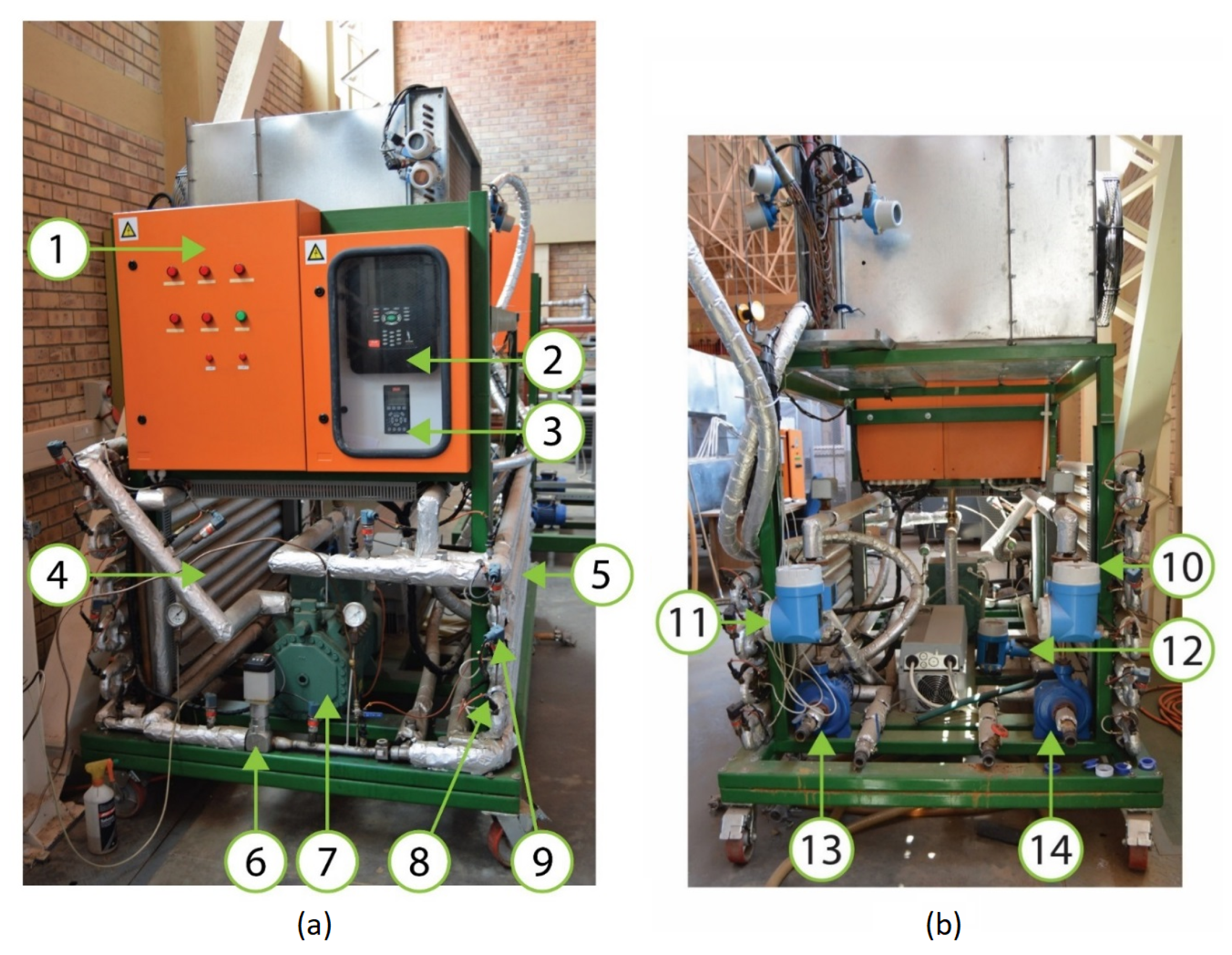

The EV controls the mass flow rate of the refrigerant through the entire heat pump system. The BITZER

TM Software v6.7.0 utility [

48] may be used to find the recommended mass flow rate for the BITZER

TM type 4JTC-15K (40P) compressor operating at specific working points. The amount of refrigerant that was loaded into the heat pump test bench was done by an operator. The mass flow rate of the refrigerant at various locations throughout the heat pump system may thus not match the mass flow rate recommended by the BITZER

TM Software utility. A better approach is a linear regression fit of the refrigerant mass flow as a function of the EV orifice opening percentage for the actual test bench. The built-in EES

® [

23] linear regression utility was used to fit the mass flow rate of the refrigerant to the experimental data generated from the heat pump test bench. The fitted linear relation of mass flow as a function of the EV orifice opening is illustrated in

Figure A6.

From

Figure A6 it should be noted that a decrease in the flow restricting orifice opening area percentage leads to an increase in the mass flow rate of the refrigerant through the entire heat pump system. The specific linear equation that describes the relationship between the refrigerant mass flow rate and EV orifice opening of the line displayed in

Figure A6 is:

Figure A6.

Refrigerant mass flow rate as a function of EV opening.

Figure A6.

Refrigerant mass flow rate as a function of EV opening.

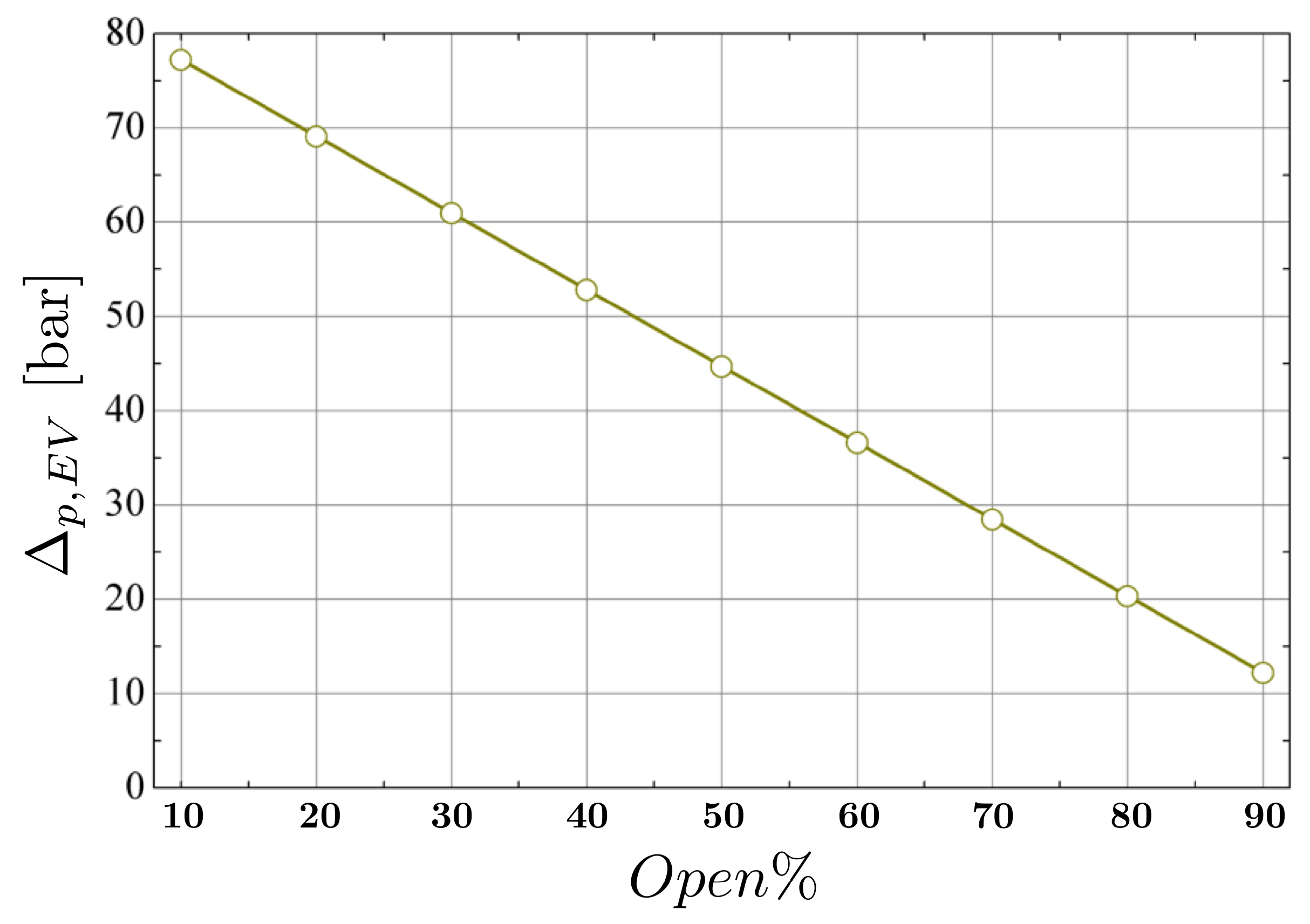

The conservation of momentum for the R744 that undergoes throttling as it passes through the EV is given by:

Since the physical dimensions of the internal EV mechanisms are not readily available, a new method is required to predict the total pressure drop over the EV component. The static pressure drop over the EV is modeled as an inverse linearly proportional function of the opening percentage of the expansion valve orifice area. The suggested inverse linearly proportional graph of the static pressure drop over the EV as a function of the opening percentage of the expansion valve orifice is illustrated in

Figure A7.

Figure A7.

Static pressure drop over EV vs EV orifice opening.

Figure A7.

Static pressure drop over EV vs EV orifice opening.

From

Figure A7 it should be noted that the static pressure drop over the expansion valve orifice tends to zero as the valve orifice is increasingly opened. This trend is suited because when the EEV orifice is 100% open it will not offer any resistance to the flow of the refrigerant and the induced pressure drop on the refrigerant will thus be zero. The specific linear equation that describes the line displayed in

Figure A7 is:

Once the static pressure drop over the EV is known, it can easily be converted to total pressure drop by adding the kinetic energy component of total pressure to the static pressure drop value. The throttling of the R744 through the EV is assumed to be an isenthalpic process. Under this assumption the conservation of energy for the EV is simply:

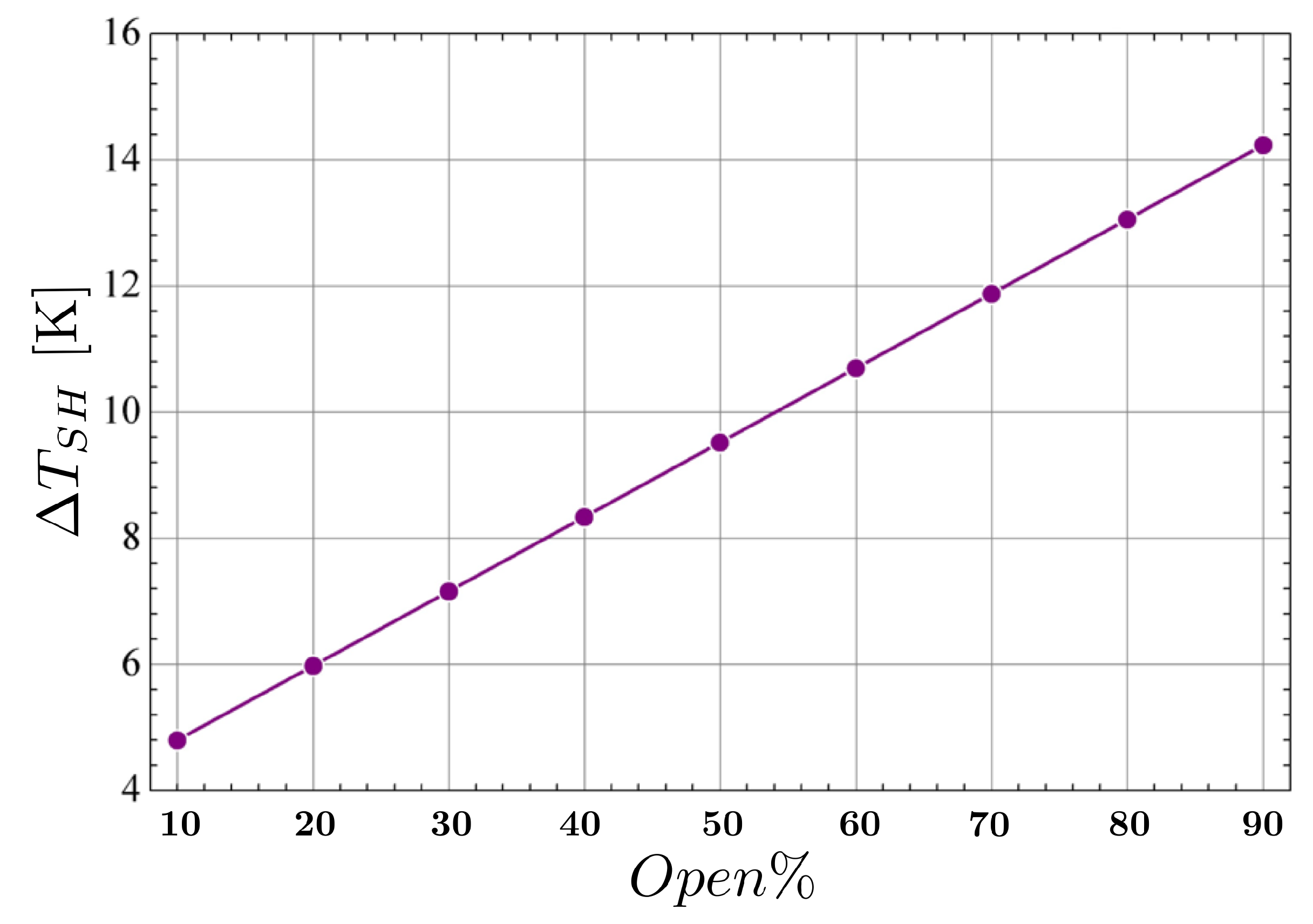

Another important cycle parameter controlled by the EV is the amount of superheating that takes place in the evaporator. A linear equation is also used to describe the amount of superheating as a function of the EV orifice opening. The linear relationship between the amount of evaporator superheating and the EV orifice opening is shown in

Figure A8.

Figure A8.

Amount of superheating in evaporator vs EV orifice opening.

Figure A8.

Amount of superheating in evaporator vs EV orifice opening.

The specific linear equation that describes the line displayed in

Figure A8 is:

The exergy balance over the EV is performed over the entire EV CV region. The exergy balance for the EV is given by: