Research on Modeling of a Micro Variable-Pitch Turboprop Engine Based on Rig Test Data

Abstract

1. Introduction

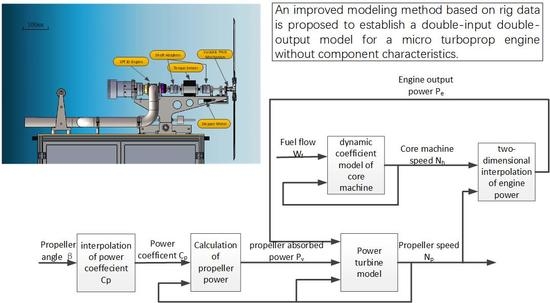

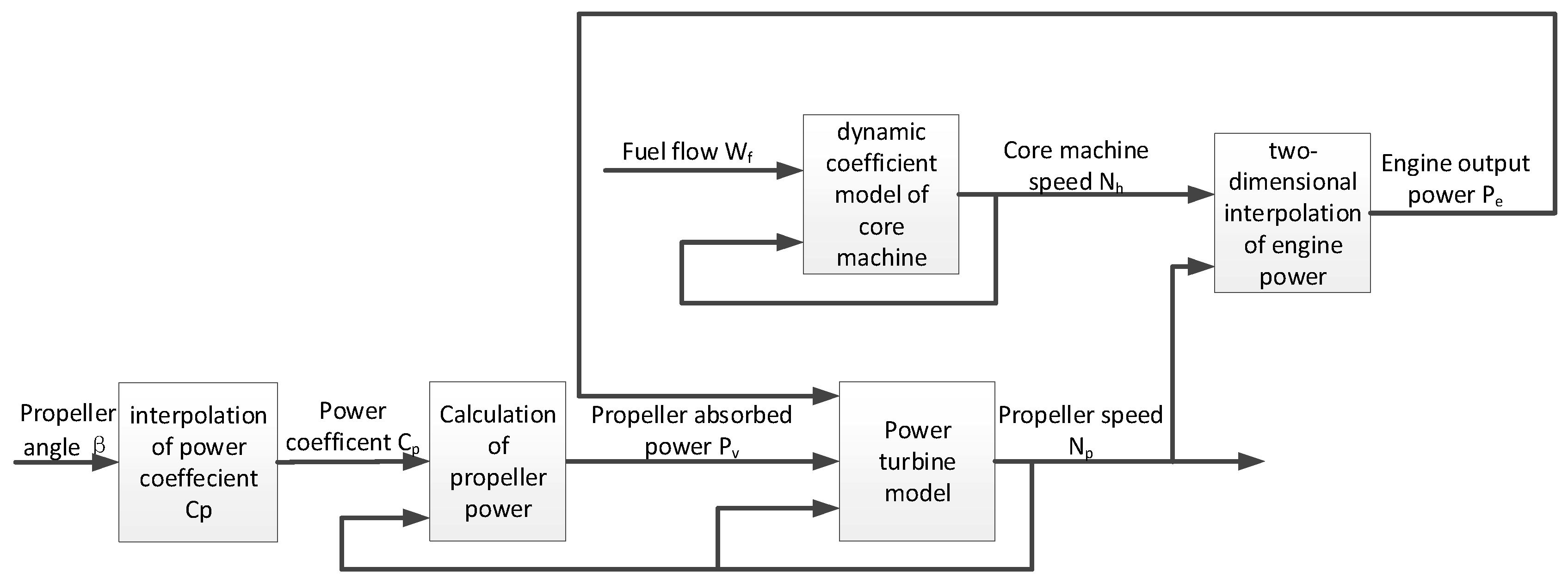

2. Overall Design of the Model

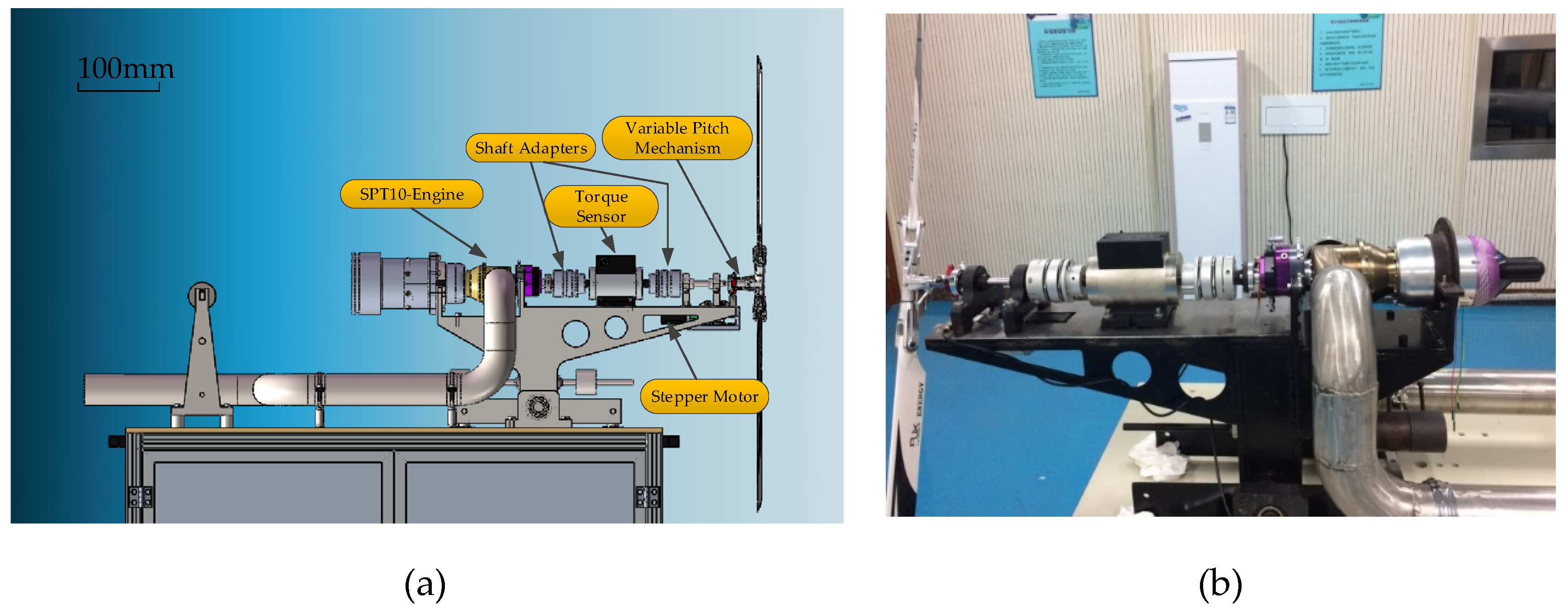

3. Design of the Rig Test Bench and Test Program

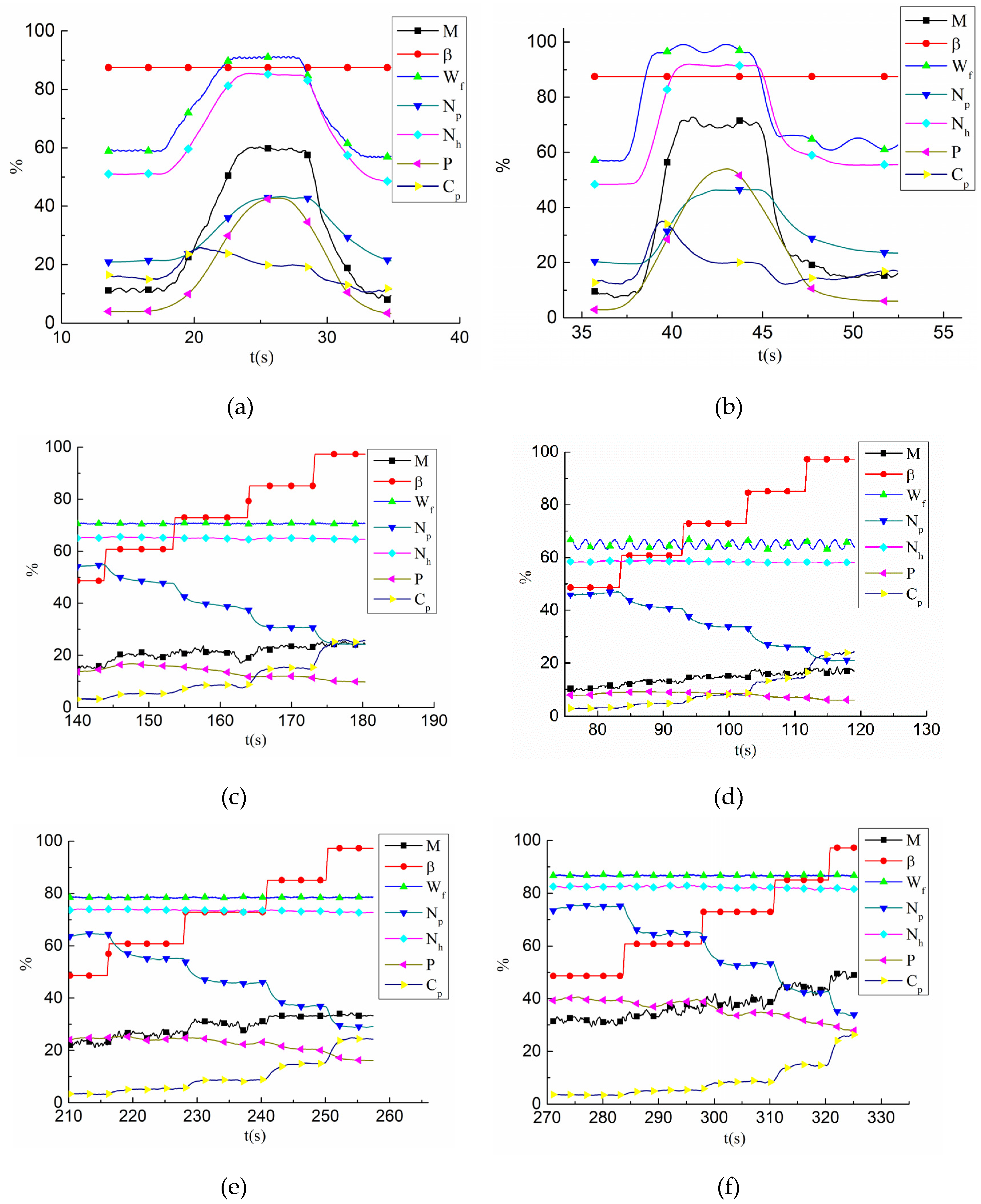

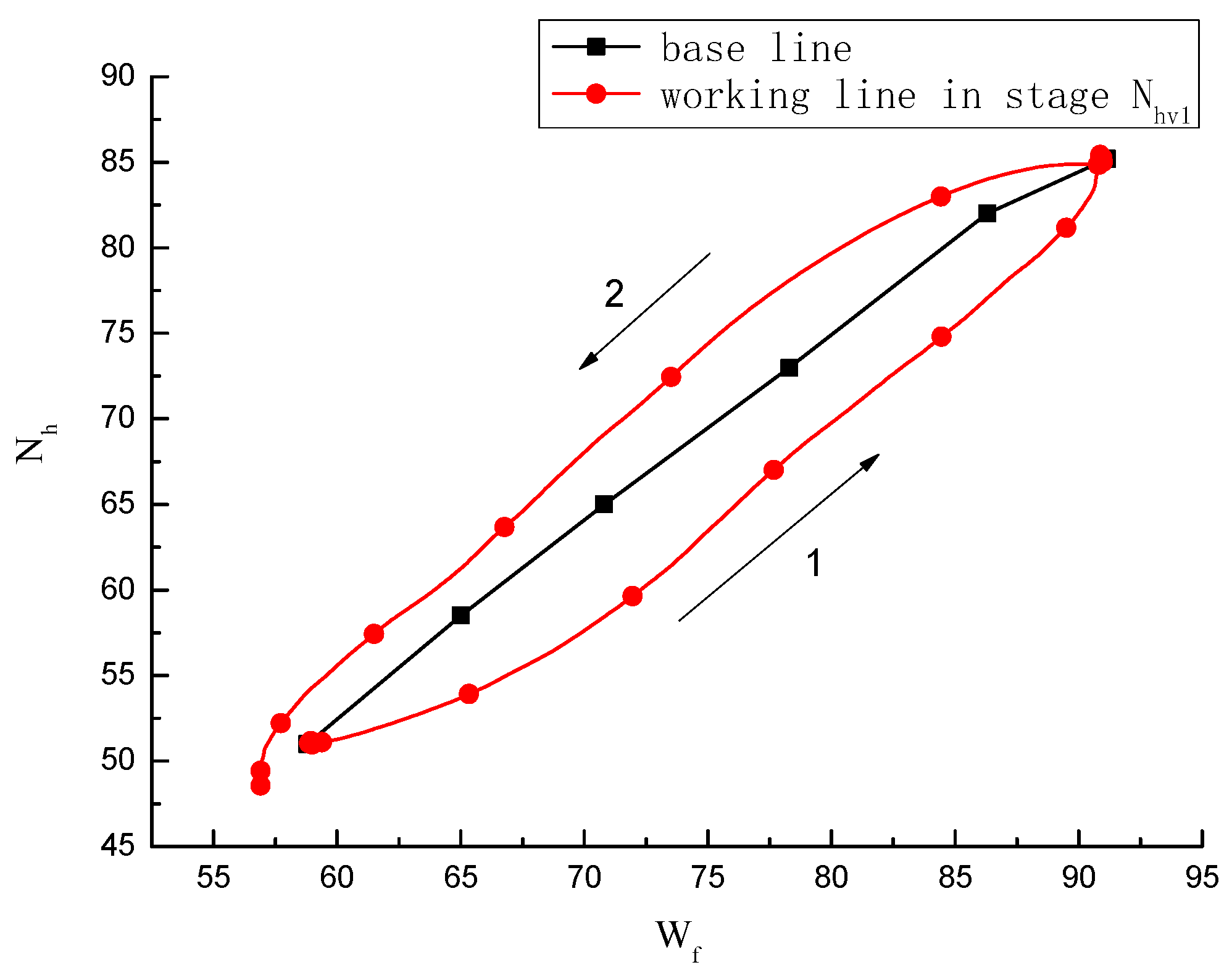

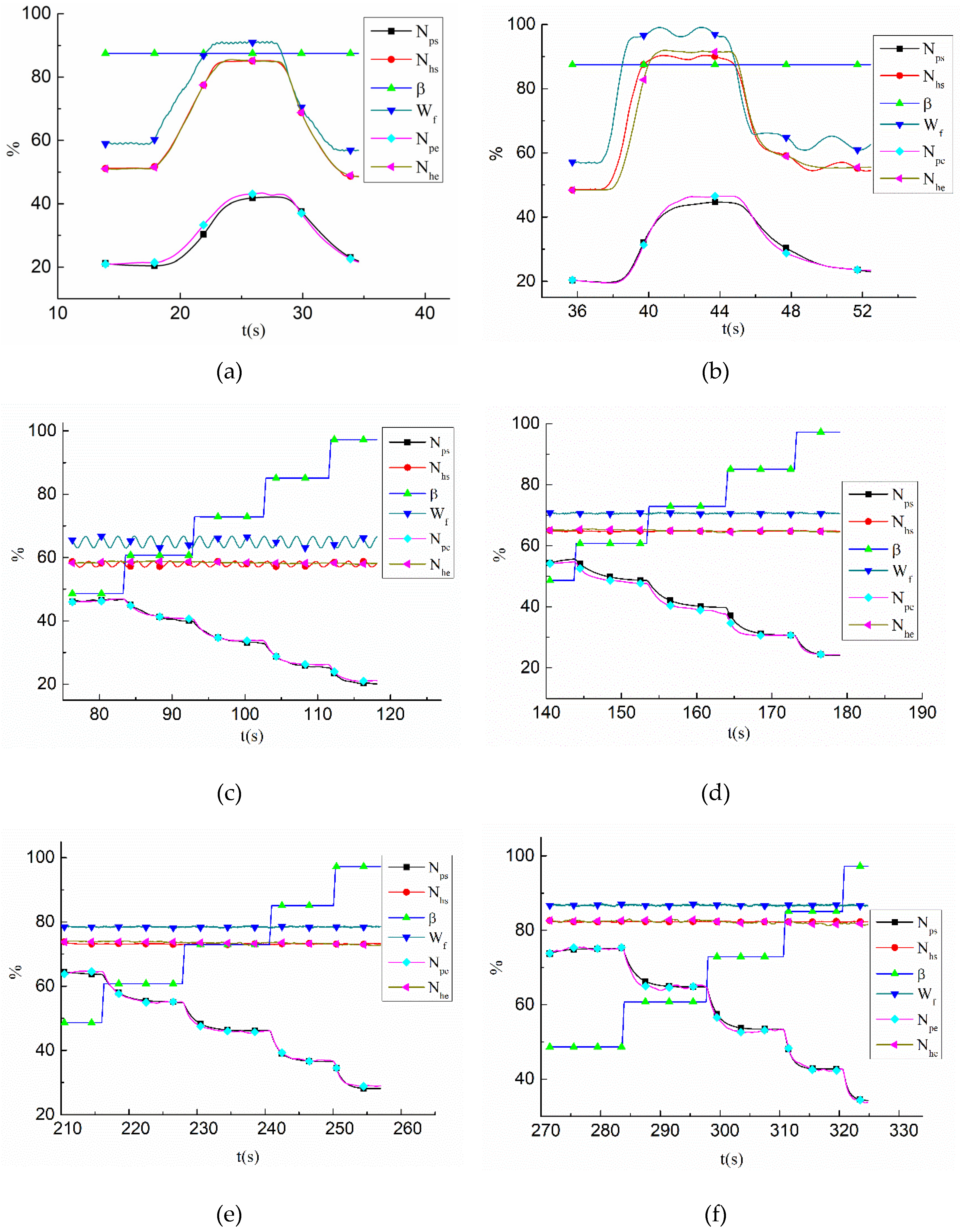

- The first part of the test consisted of 2 stages. For the convenience of expression, they were expressed as stage and stage . In this part, remained unchanged, and was adjusted by changing . In order to verify the reproducibility of the model, two tests were performed at this mode, called and , respectively. The change rates of the fuel flow were different in the two stages. First, the power lever angle was changed to the maximum state within 2 to 5 s from the idle state. For safety, the maximum test state was defined as the state with a core speed of 56,000 r/min, and the propeller speed was 1500 r/min in the maximum state. After the engine speed was stabilized, the throttle was moved back to the idle state.

- The other part of the test consisted of 4 stages, expressed as stage , and . In this part, in order to obtain the characteristic parameters of the variable pitches, tests were carried out at 4 core speeds. The selected speeds were , and they were higher than that in an idle state. was set at one of the 5 selected degrees at each operating node, they were . When carrying out the experiments, remained unchanged after was maintained at 4 selected speed, respectively. changed between the 5 selected degrees in turn. did not switch to the next degree until stayed stable for some time.

4. Processing and Analysis of Test Data

- When remained unchanged, barely changed with the variation of . As shown in Figure 3c–f, the test results of basically remained the same, when only was changed.

- was merely correlated with . Neither nor had any influence on it. As shown in Table 1, when remained unchanged, did not vary with . As shown in Figure 3c,d, and in test stage were different from those in test stage as in the two stages were different. However, there were no significant differences in in the two stages when was set to the same value.

5. Modeling Based on Rig Data by the Improved Dynamic Coefficient Method

5.1. Model Structure of the Micro Variable-Pitch Turboprop Engine

5.2. Steady State Model of the Core Engine

5.3. Dynamic Model of the Core Engine

5.4. The Dynamic Model of the Propeller Speed

6. Model Simulation Results

7. Discussion

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Fuel flow | |

| Propeller pitch angle | |

| Core machine speed | |

| Propeller speed | |

| Shaft torque | |

| Propeller absorbed power | |

| Power coefficient of propeller | |

| Propeller advance ratio | |

| Axial velocity of propeller | |

| Radius of propeller | |

| K | Dynamic coefficient |

| Power turbine output power | |

| Propeller absorbed power | |

| Inertia moment |

| MGTE | Micro gas turbine engine |

| UCAV | Unmanned combat air vehicle |

References

- Nascimento, M.A.R.; Rodrigues, L.; Santos, E.; Gomes, E.E.B.; Dias, F.L.G.; Velásques, E.I.G.; Carrillo, R.A.M. Micro gas turbine engine: A review. In Progress in Gas Turbine Performance; Ernesto, B., Ed.; BoD–Books on Demand: Norderstedt, Germany, 2013; pp. 107–141. [Google Scholar]

- Xiao, G.; Yang, T.; Liu, H.; Ni, D.; Ferrari, M.L.; Li, M.; Luo, Z.; Cen, K.; Ni, M. Recuperators for micro gas turbines: A review. Appl. Energy 2017, 197, 83–99. [Google Scholar] [CrossRef]

- Iki, N.; Kurata, O.; Matsunuma, T.; Inoue, T.; Suzuki, M.; Tsujimura, T.; Furutani, H. Micro gas turbine firing kerosene and ammonia. In Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition, Montreal, QC, Canada, 15–19 June 2015. [Google Scholar]

- Sychenkov, V.; Limanskii, A.; Yousef, W.; Ankudimov, V.; Jafari, S.S. Micro Gas Turbine Engine for Unmanned Aerial Vehicles. Russian Aeronaut. 2019, 62, 651–660. [Google Scholar] [CrossRef]

- Cao, Y.; Huang, X.; Sheng, L.; Wang, Z. A flight experimental platform for synchrophasing control based on a small propeller UAV. Sci. China Technol. Sci. 2018, 61, 1915–1924. [Google Scholar] [CrossRef]

- Topal, A.; Turan, O.; Uslu, S. Design, manufacturing and rig test of a small turbojet engine combustor with airblast atomizer. Int. J. Mater. Mech. Manuf. 2015, 3, 97–100. [Google Scholar] [CrossRef]

- Zhao, X.; Huang, X.; Zhang, T.; Wang, Y. Integrated speed/synchrophasing control of turboprop engine. Aeronaut. J. 2018, 122, 1038–1050. [Google Scholar] [CrossRef]

- Zaccaria, V.; Ferrari, M.L.; Kyprianidis, K. Adaptive Control of Microgas Turbine for Engine Degradation Compensation. J. Eng. Gas Turbines Power 2020, 142. [Google Scholar] [CrossRef]

- Jaw, L.C.; Mattingly, J.D. Aircraft Engine Controls: Design, System Analysis, and Health Monitoring; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2009. [Google Scholar]

- Chipperfield, A.; Fleming, P.; Betteridge, H. Multi-Objective Evolutionary Algorithms in Gas Turbine Aero-Engine Control. In Fusion of Neural Networks, Fuzzy Systems and Genetic Algorithms; CRC Press: Boca Raton, FL, USA, 2020; pp. 295–320. [Google Scholar]

- Jie, B.; Shuai, L.; Wei, W. An integrated controller design for a small aero-engine. In Proceedings of the 2019 Chinese Control And Decision Conference (CCDC), Nanchang, China, 3–5 June 2019; pp. 3129–3133. [Google Scholar]

- Pakmehr, M.; Fitzgerald, N.; Paduano, J.; Feron, E.; Behbahani, A. Dynamic modeling of a turboshaft engine driving a variable pitch propeller: A decentralized approach. In Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, San Diego, CA, USA, 31 July 2011–03 August 2011; p. 6149. [Google Scholar]

- Pakmehr, M.; Fitzgerald, N.; Feron, E.; Paduano, J.; Behbahani, A. Physics-based dynamic modeling of a turboshaft engine driving a variable pitch propeller. J. Propuls. Power 2016, 32, 646–658. [Google Scholar] [CrossRef]

- Reed, J.A.; Afjeh, A.A. Computational simulation of gas turbines: Part 1—Foundations of component-based models. J. Eng. Gas Turbines Power 2000, 122, 366–376. [Google Scholar] [CrossRef]

- Reed, J.A.; Afjeh, A.A. Computational Simulation of Gas Turbines: Part II—Extensible Domain Framework. In Proceedings of the ASME 1999 International Gas Turbine and Aeroengine Congress and Exhibition, Indianapolis, IN, USA, 7–10 June 1999. [Google Scholar]

- Xu, X.; Zhang, T.; Sheng, H. Research on MTE Real-time Modeling Based on Dynamic Coefficient Method. China Mech. Eng. 2015, 26, 243–247. [Google Scholar]

- Zhou, W.-x.; Huang, J.-q.; Huang, K.-m. Real-time simulation system for aeroengine based on simplified model. J. Nanjing Univ. Aeronaut. Astronaut. 2005, 2, 251–255. [Google Scholar]

- Xing, Y.D.; Huang, J.Q.; Feng, L.U.; Yao, W.R. Research on Simplified Real-time Model of Turboshaft Engine. Aeroengine 2012, 38, 15–18. [Google Scholar]

- MacIsaac, B.; Langton, R. Gas Turbine Propulsion Systems; John Wiley & Sons: 111 River Street, Hoboken, NJ, USA, 2011; Volume 49. [Google Scholar]

| Stage | |||||

|---|---|---|---|---|---|

| 3.08 | 4.62 | 8.06 | 14.00 | 23.96 | |

| 3.21 | 5.15 | 8.41 | 15.31 | 24.97 | |

| 3.45 | 5.00 | 8.782 | 14.74 | 24.51 | |

| 3.45 | 4.87 | 8.44 | 15.01 | 25.73 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Huang, X.; Xia, T. Research on Modeling of a Micro Variable-Pitch Turboprop Engine Based on Rig Test Data. Energies 2020, 13, 1768. https://doi.org/10.3390/en13071768

Zhao X, Huang X, Xia T. Research on Modeling of a Micro Variable-Pitch Turboprop Engine Based on Rig Test Data. Energies. 2020; 13(7):1768. https://doi.org/10.3390/en13071768

Chicago/Turabian StyleZhao, Xiaochun, Xianghua Huang, and Tianqian Xia. 2020. "Research on Modeling of a Micro Variable-Pitch Turboprop Engine Based on Rig Test Data" Energies 13, no. 7: 1768. https://doi.org/10.3390/en13071768

APA StyleZhao, X., Huang, X., & Xia, T. (2020). Research on Modeling of a Micro Variable-Pitch Turboprop Engine Based on Rig Test Data. Energies, 13(7), 1768. https://doi.org/10.3390/en13071768