Charging and Discharge Currents in Low-Density Polyethylene and its Nanocomposite

Abstract

1. Introduction

2. Materials and Methods

3. Results

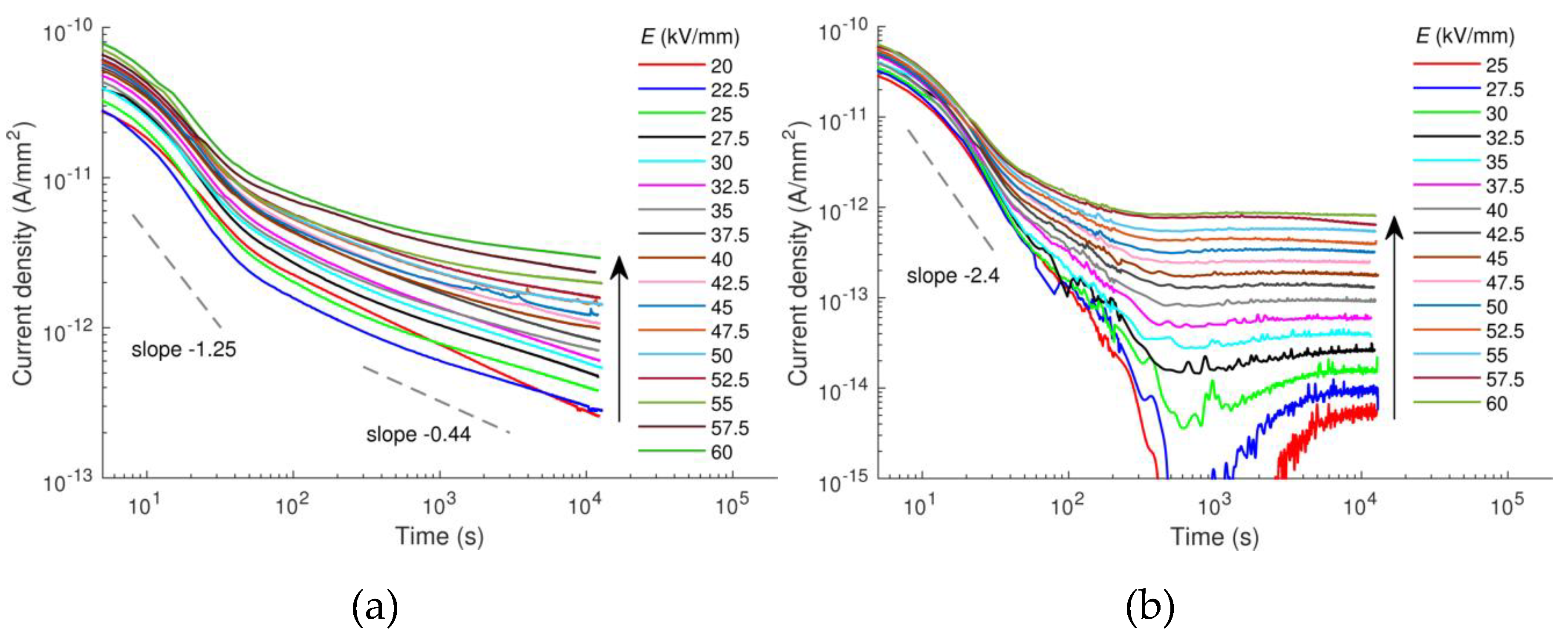

3.1. Charging Currents

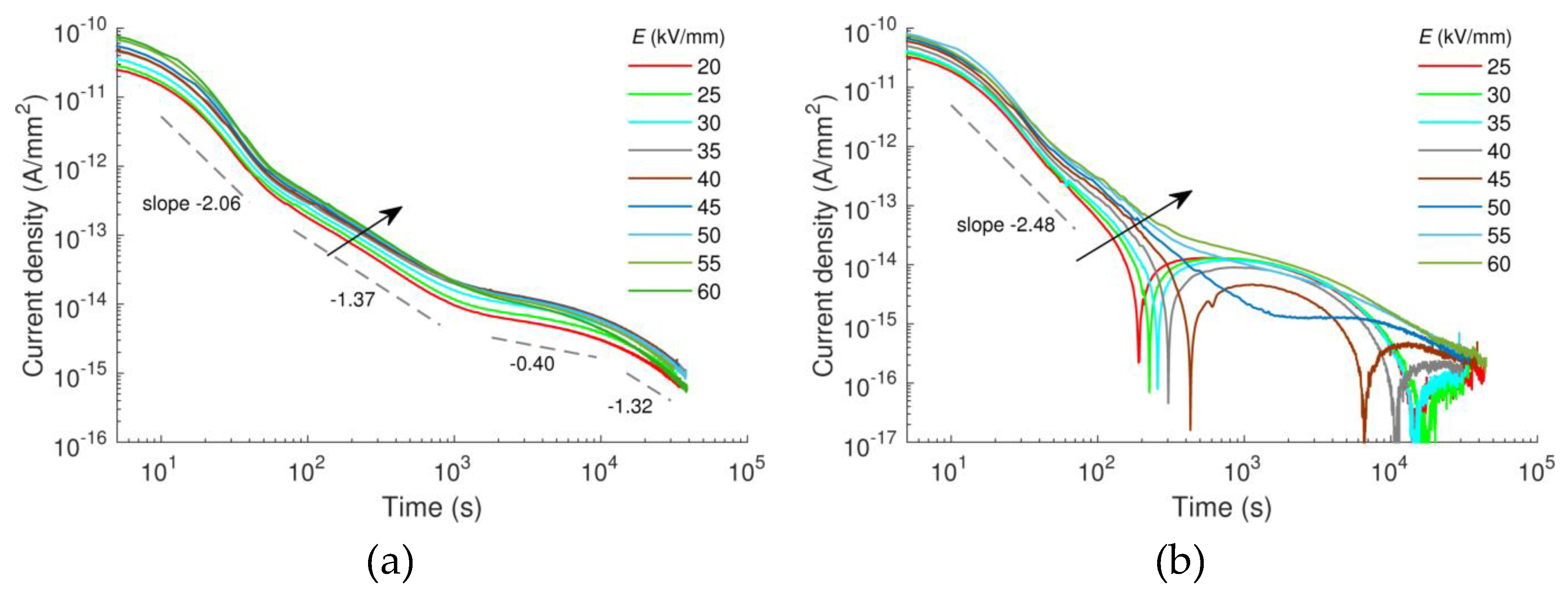

3.1.1. Transient Behavior

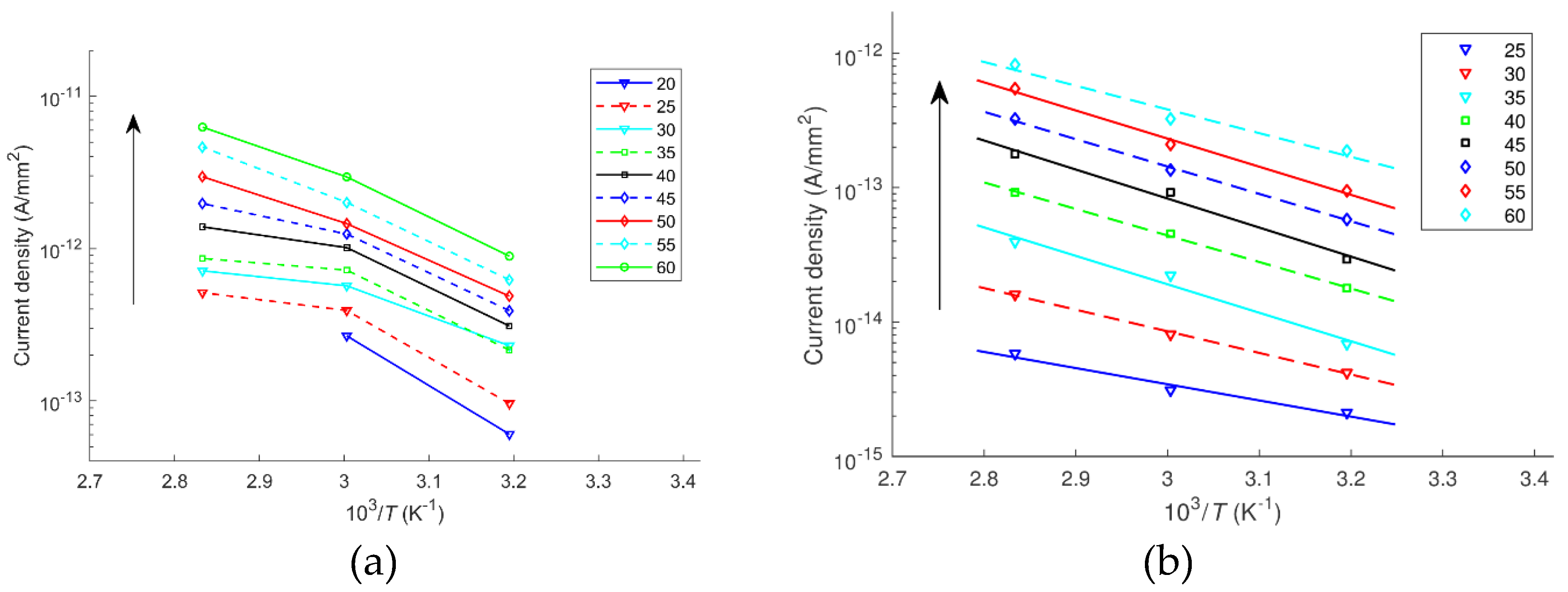

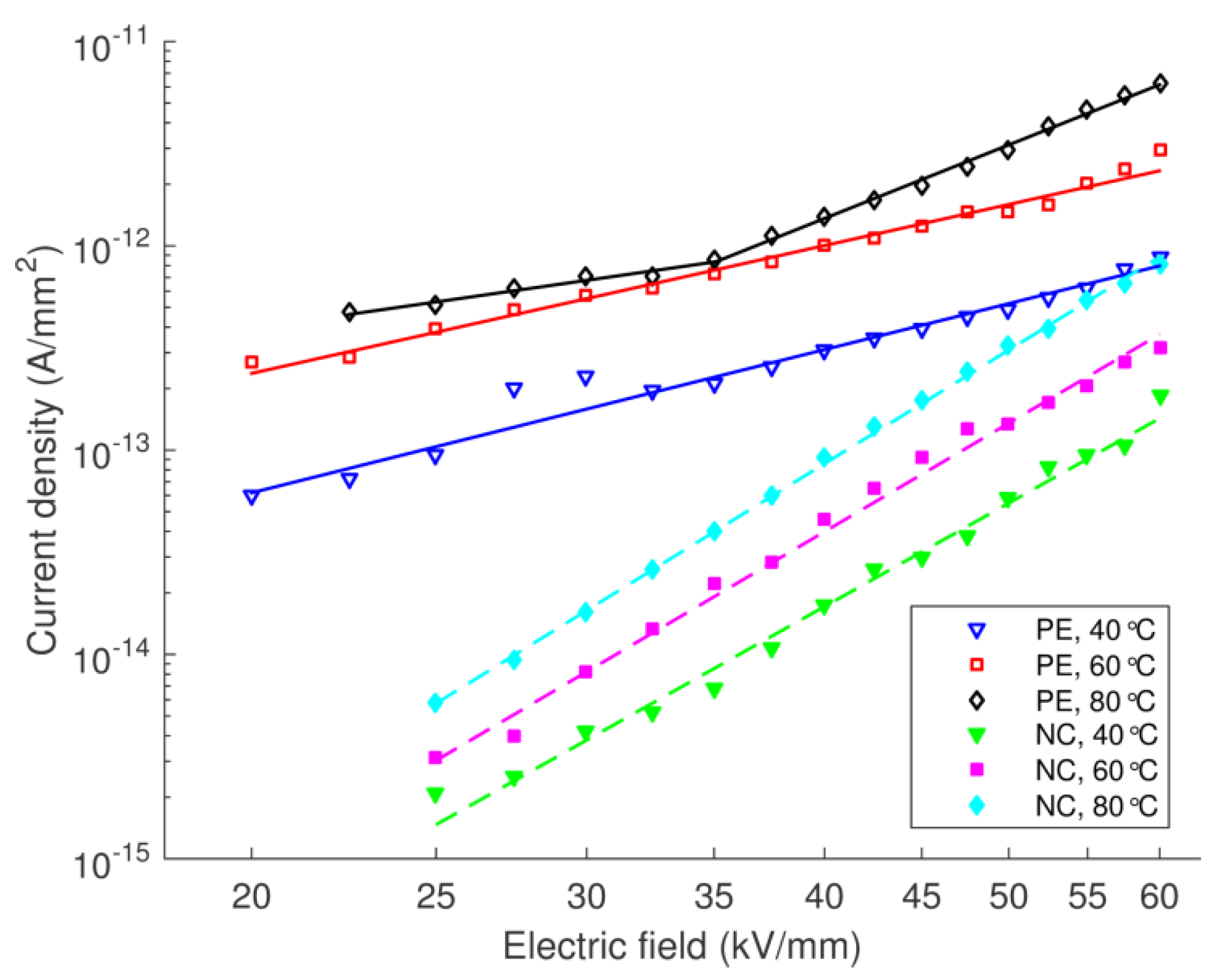

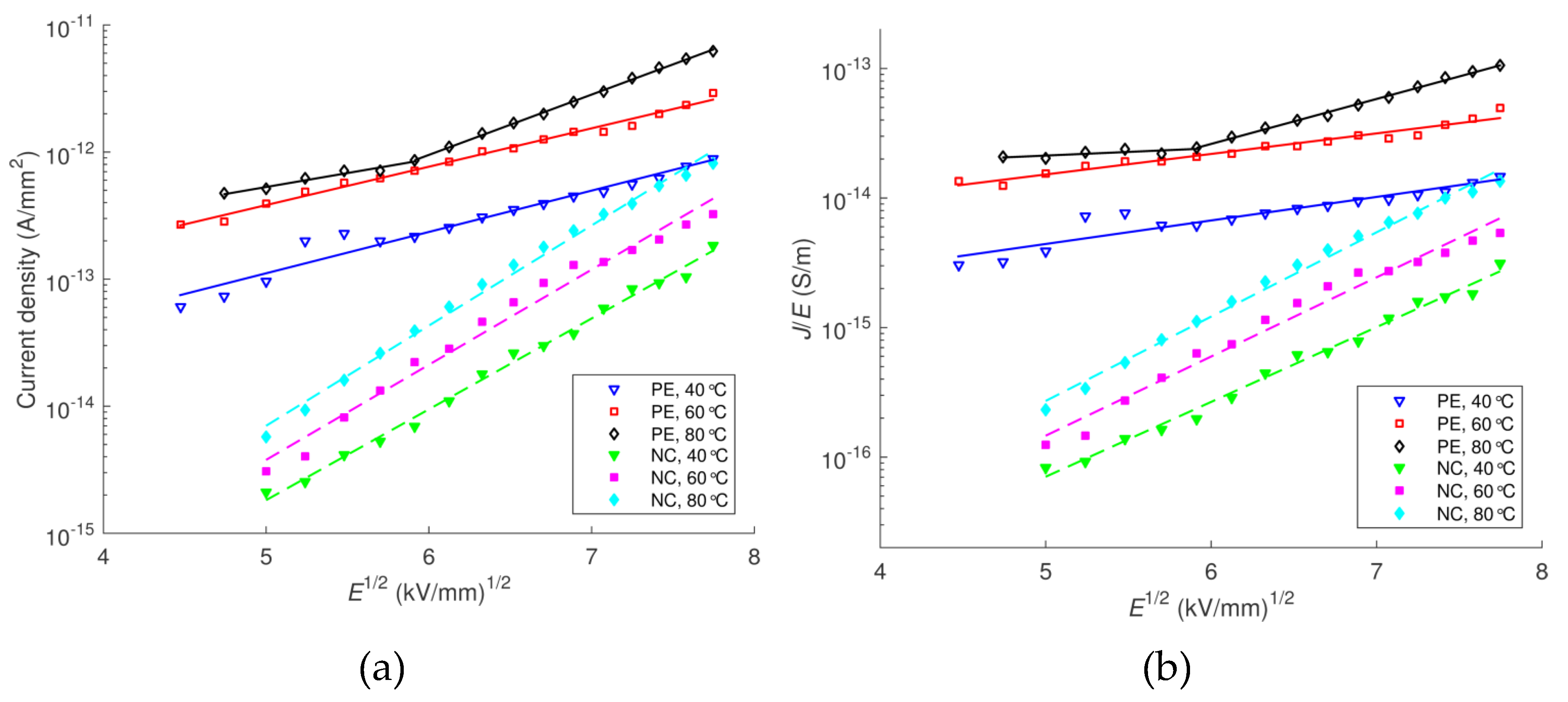

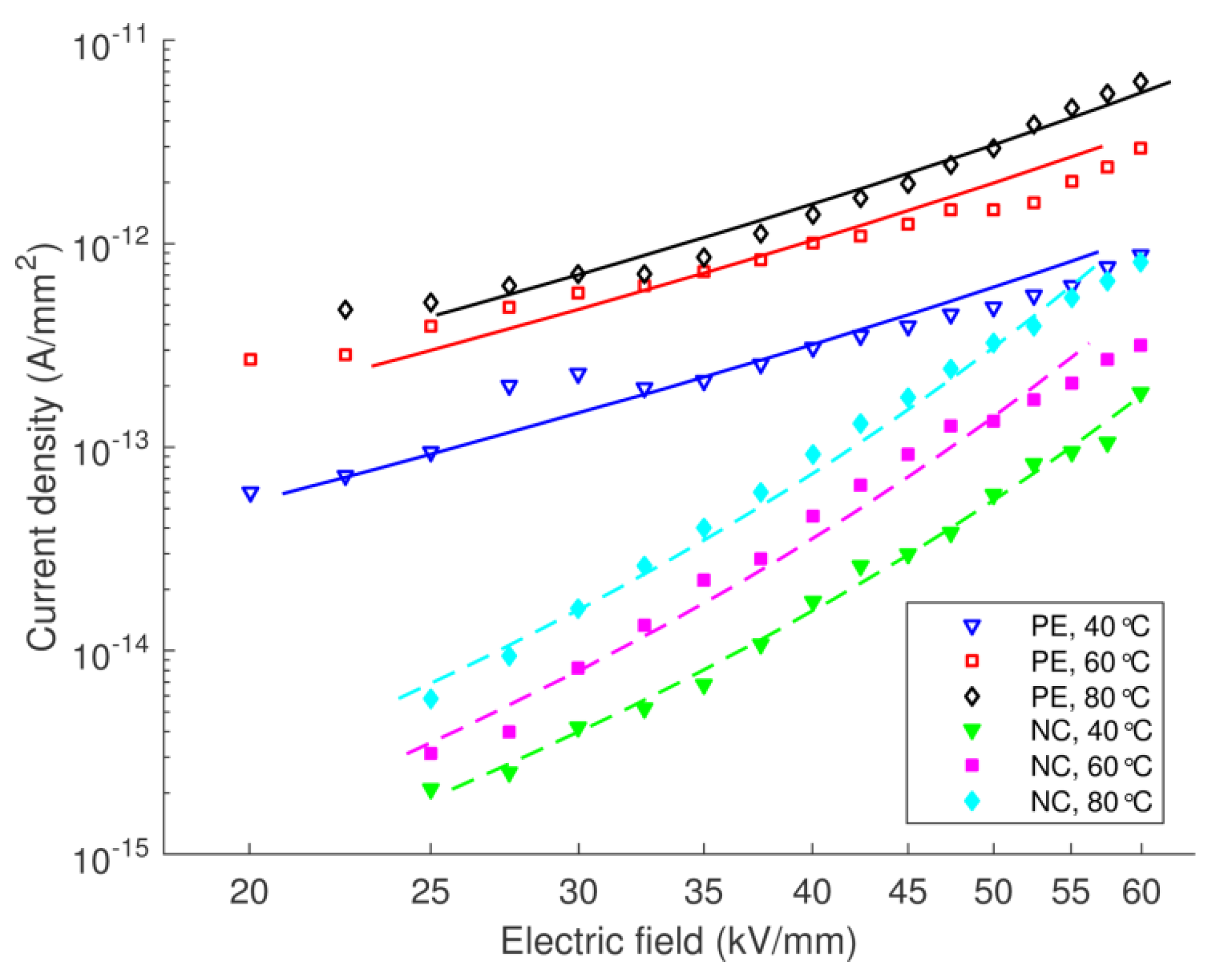

3.1.2. Isochronal Charging Currents

Temperature Dependencies

Field Dependencies

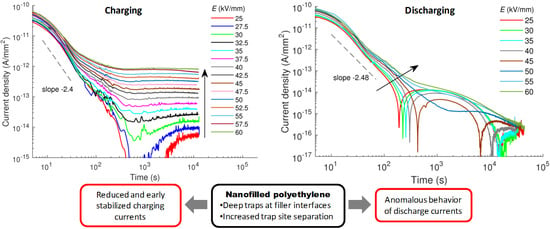

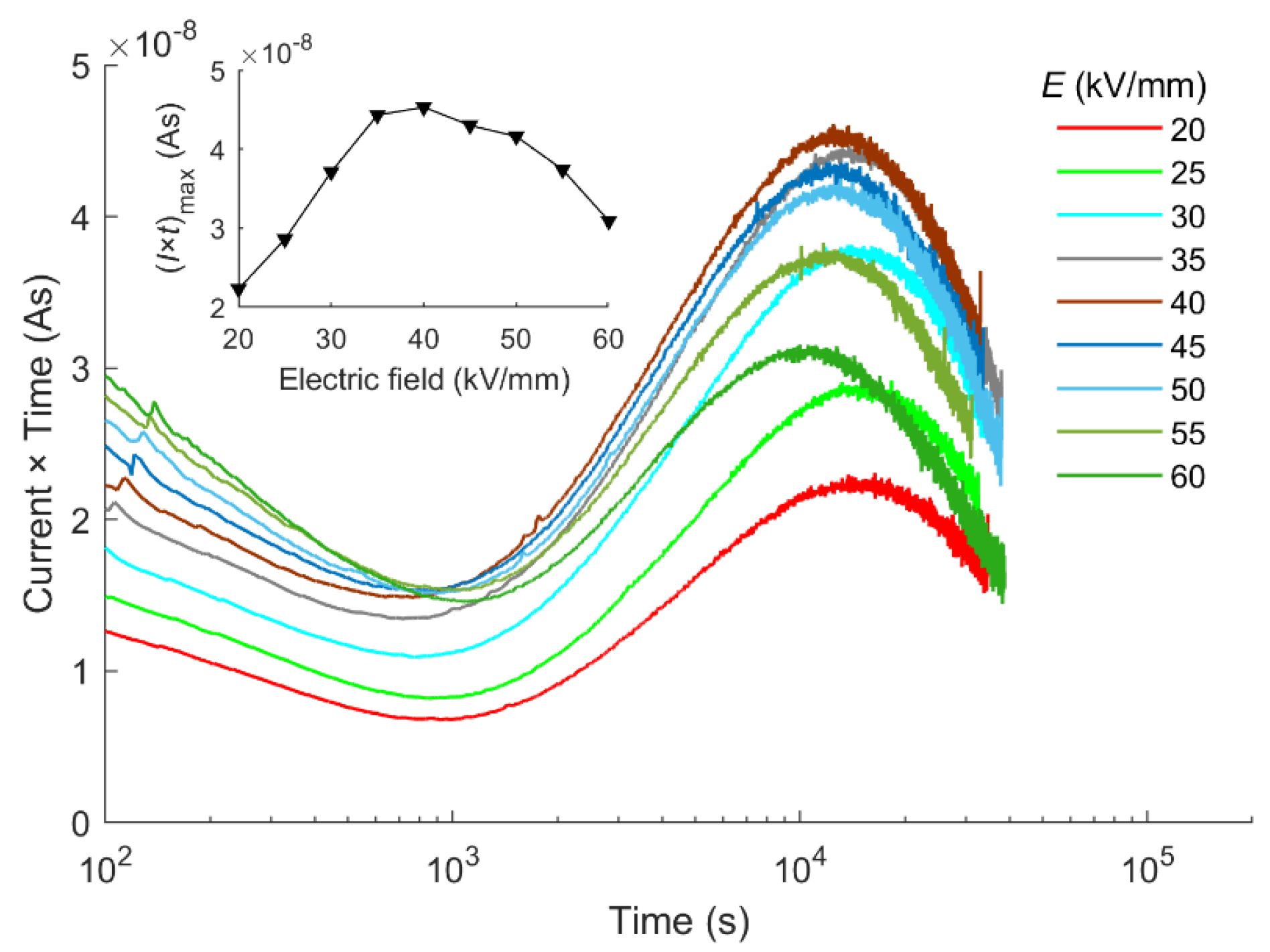

3.2. Discharge Currents

4. Analysis and Discussion

4.1. Isochronal Charging Currents

4.1.1. Possible Conduction Mechanisms

4.1.2. Alternative Conduction Mechanisms

4.2. Anomalous Discharge Currents

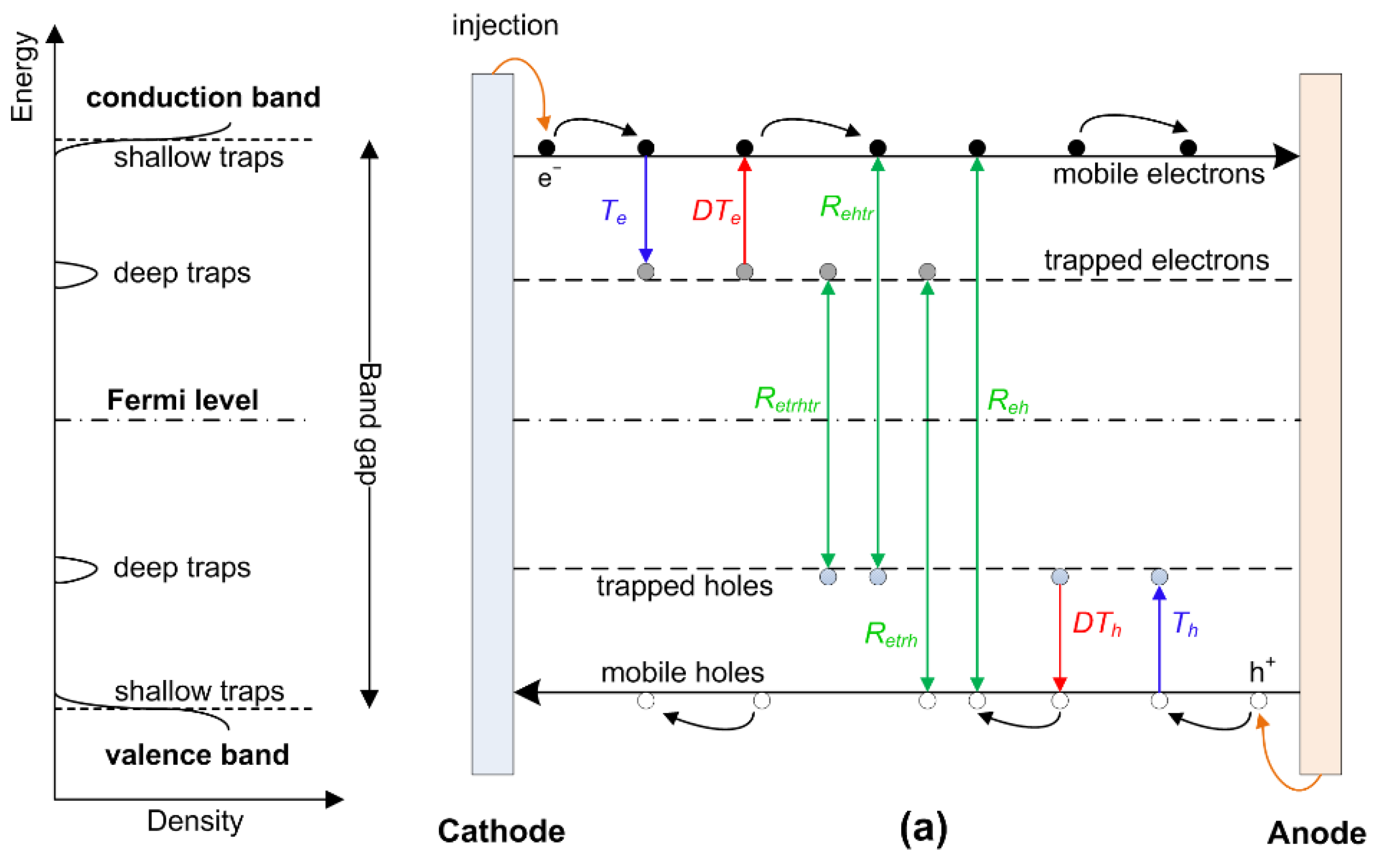

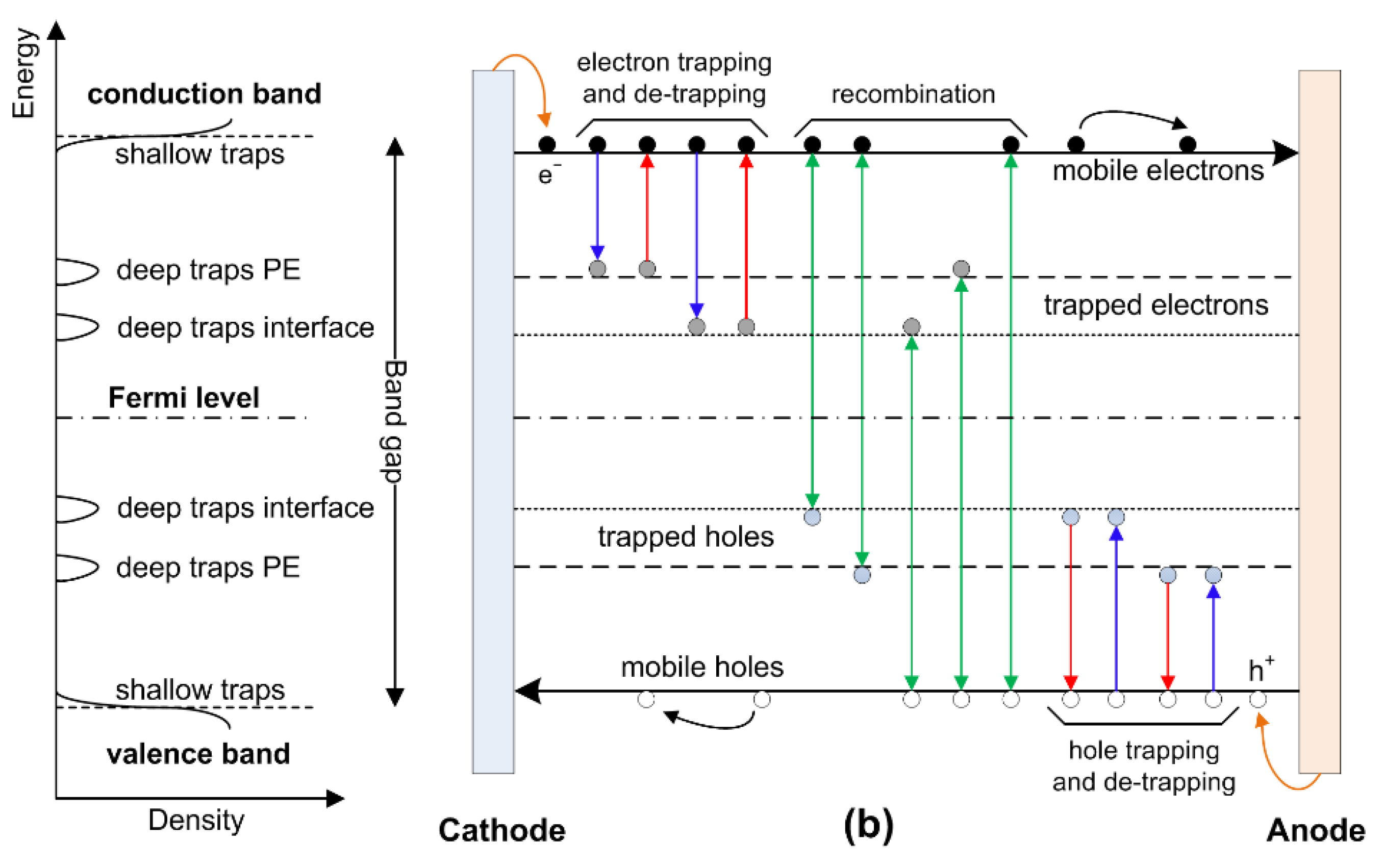

4.2.1. Numerical Model

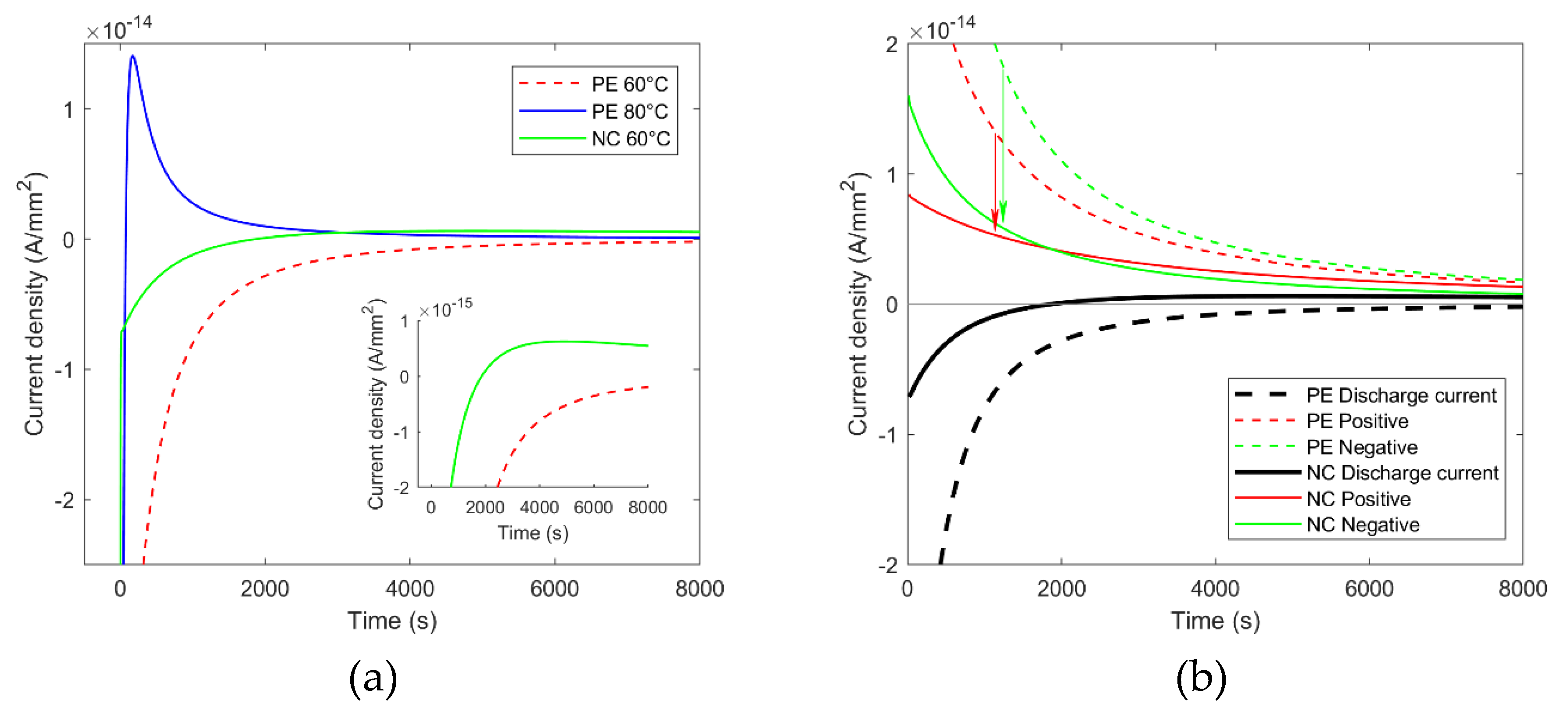

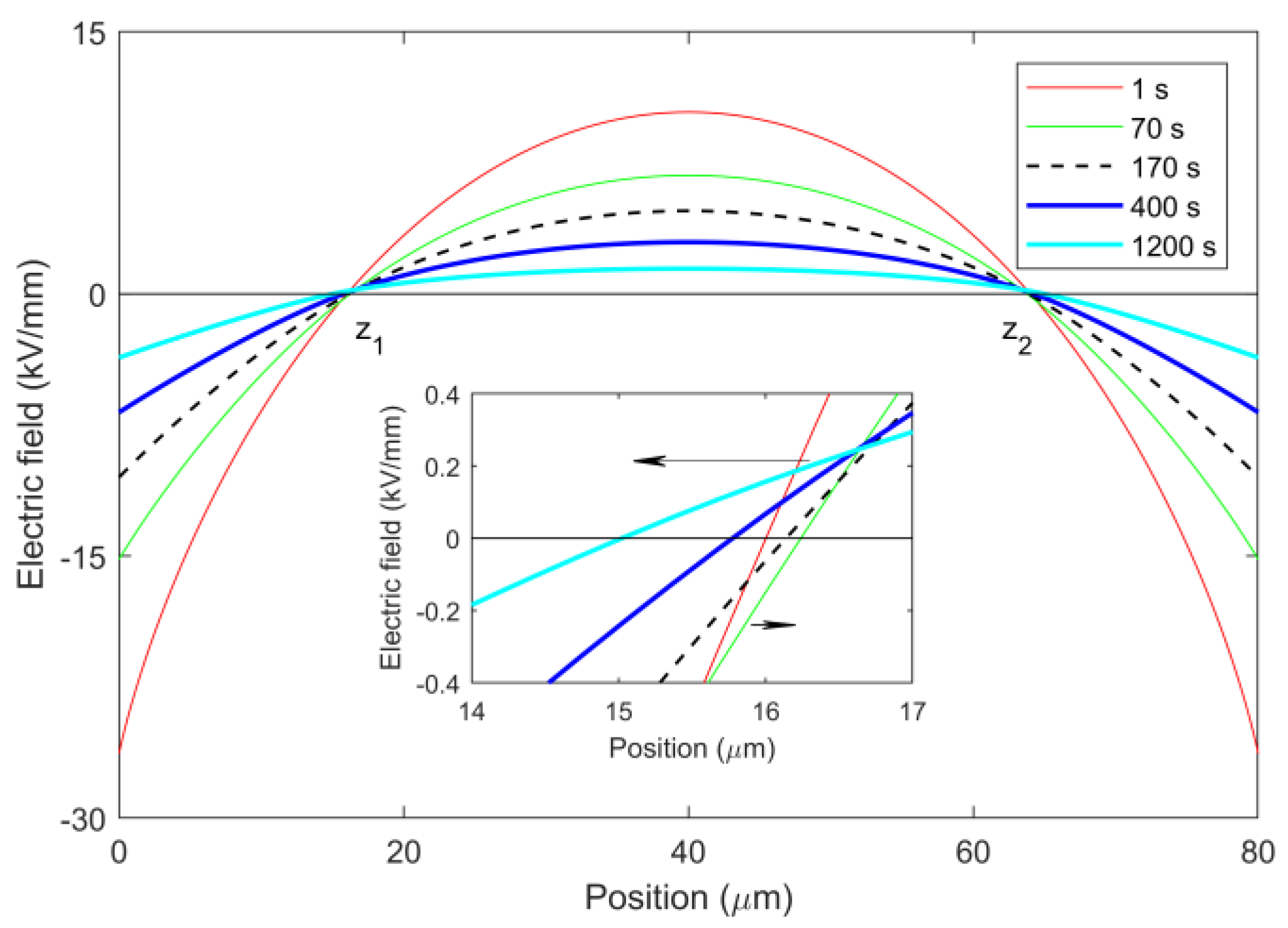

4.2.2. Simulated Results

4.3. Impact of Nanofillers on Electrical Conduction

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hanley, T.L.; Burford, R.P.; Fleming, R.J.; Barber, K.W. A general review of polymeric insulation for use in HVDC cables. IEEE Electr. Insul. Mag. 2003, 19, 13–24. [Google Scholar] [CrossRef]

- Bergelin, P.; Jeroense, M.; Quist, T.; Rapp, H. 640 kV Extruded HVDC Cable System; NKT HV Cables: Lyckeby, Sweden, 2017. [Google Scholar]

- Tanaka, T. Dielectric nanocomposites with insulating properties. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 914–928. [Google Scholar] [CrossRef]

- Roy, M.; Nelson, J.K.; MacCrone, R.K.; Schadler, L.S. Candidate mechanisms controlling the electrical characteristics of silica/XLPE nanodielectrics. J. Mater. Sci. 2007, 42, 3789–3799. [Google Scholar] [CrossRef]

- Murakami, Y.; Nemoto, M.; Okuzumi, S.; Masuda, S.; Nagao, M.; Hozumi, N.; Sekiguchi, Y. DC conduction and electrical breakdown of MgO/LDPE nanocomposite. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 33–39. [Google Scholar] [CrossRef]

- Ishimoto, K.; Kanegae, E.; Ohki, Y.; Tanaka, T.; Sekiguchi, Y.; Murata, Y.; Reddy, C.C. Superiority of dielectric properties of LDPE/MgO nanocomposites over microcomposites. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 1735–1742. [Google Scholar] [CrossRef]

- Wang, W.; Min, D.; Li, S. Understanding the conduction and breakdown properties of polyethylene nanodielectrics: Effect of deep traps. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 564–572. [Google Scholar] [CrossRef]

- Li, S.; Min, D.; Wang, W.; Chen, G. Linking traps to dielectric breakdown through charge dynamics for polymer nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2777–2785. [Google Scholar] [CrossRef]

- Lewis, T.J. Charge transport in polyethylene nano dielectrics. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 497–502. [Google Scholar] [CrossRef]

- Takada, T.; Hayase, Y.; Tanaka, Y.; Okamoto, T. Space charge trapping in electrical potential well caused by permanent and induced dipoles for LDPE/MgO nanocomposite. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 152–160. [Google Scholar] [CrossRef]

- Hoang, A.T.; Pallon, L.; Liu, D.; Serdyuk, Y.V.; Gubanski, S.M.; Gedde, U.W. Charge transport in LDPE nanocomposites. Part I—Experimental approach. Polymers 2016, 8, 87. [Google Scholar] [CrossRef]

- Hoang, A.T.; Serdyuk, Y.V.; Gubanski, S.M. Charge transport in LDPE nanocomposites. Part II—Computational approach. Polymers 2016, 8, 103. [Google Scholar] [CrossRef] [PubMed]

- Adamec, V.; Calderwood, J.H. On the determination of electrical conductivity in polyethylene. J. Phys. D Appl. Phys. 1981, 14, 1487–1494. [Google Scholar] [CrossRef]

- Adamec, V.; Calderwood, J.H. Electrical conduction and polarisation phenomena in polymeric dielectrics at low fields. J. Phys. D Appl. Phys. 1978, 11, 781–800. [Google Scholar] [CrossRef]

- Viertel, J.; Petersson, L.; Friberg, A.; Dominguez, G.; Tornkvist, C. Electrode influence on DC conductivity measurements of low density polyethylene. In Proceedings of the IEEE International Conference on Solid Dielectrics, Bologna, Italy, 30 June–4 July 2013; pp. 1048–1051. [Google Scholar]

- Simmons, J.G.; Tam, M.C. Theory of isothermal currents and the direct determination of trap parameters in semiconductors and isulators containing arbitrary trap distributions. Phys. Rev. B 1973, 7, 3706–3713. [Google Scholar] [CrossRef]

- Baudoin, F.; Roy, S.L.; Teyssedre, G.; Laurent, C. Bipolar charge transport model with trapping and recombination: An analysis of the current versus applied electric field characteristic in steady state conditions. J. Phys. D Appl. Phys. 2008, 41, 025306. [Google Scholar] [CrossRef]

- Mizutani, T.; Suzuoki, Y.; Ieda, M. Thermally stimulated currents in polyethylene and ethylene-vinyl-acetate copolymers. J. Appl. Phys. 1977, 48, 2408–2413. [Google Scholar] [CrossRef]

- Pelissou, S.; St-Onge, H.; Wertheimer, M.R. Electrical conduction of polyethylene below and above its melting point. IEEE Trans. Electr. Insul. 1988, 23, 325–333. [Google Scholar] [CrossRef]

- Kitani, I.; Arii, K. Anomalous discharge current in polyethylene (PE), ethylene-vinyl-acetate copolymer (EVA) and PE-EVA laminated films. Jpn. J. Appl. Phys. 1985, 24, 285–288. [Google Scholar] [CrossRef]

- Mark, P.; Helfrich, W. Space-charge-limited currents in organic crystals. J. Appl. Phys. 1962, 33, 205–215. [Google Scholar] [CrossRef]

- Boudou, L.; Guastavino, J. Influence of temperature on low-density polyethylene films through conduction measurement. J. Phys. D Appl. Phys. 2002, 35, 1555–1561. [Google Scholar] [CrossRef]

- Taylor, D.M.; Lewis, T.J. Electrical conduction in polyethylene terephthalate and polyethylene films. J. Phys. D Appl. Phys. 1971, 4, 1346–1357. [Google Scholar] [CrossRef]

- Ieda, M.; Sawa, G.; Kato, S. A consideration of Poole–Frenkel effect on electric conduction in insulators. J. Appl. Phys. 1971, 42, 3737–3740. [Google Scholar] [CrossRef]

- Adamec, V.; Calderwood, J.H. Electrical conduction in dielectrics at high fields. J. Phys. D Appl. Phys. 1975, 8, 551–560. [Google Scholar] [CrossRef]

- Nath, R.; Kaura, T.; Perlman, M.M. Steady-state conduction in linear low-density polyethylene with Poole-lowered trap depth. IEEE Trans. Electr. Insul. 1990, 25, 419–425. [Google Scholar] [CrossRef]

- Kitani, I.; Tsuji, Y.; Arii, K. Analysis of anomalous discharge current in low-density polyethylene. Jpn. J. Appl. Phys. 1984, 23, 855–860. [Google Scholar] [CrossRef]

- Le Roy, S.; Teyssedre, G.; Laurent, C.; Montanari, G.C.; Palmieri, F. Description of charge transport in polyethylene using a fluid model with a constant mobility: Fitting model and experiments. J. Phys. D Appl. Phys. 2006, 39, 1427–1436. [Google Scholar] [CrossRef]

- Lindmayer, J. Current transients in insulators. J. Appl. Phys. 1965, 36, 196–201. [Google Scholar] [CrossRef]

- Hoang, A.T.; Nguyen, Q.D.; Wirges, W.; Gerhard, R.; Serdyuk, Y.V.; Gubanski, S.M. Open-circuit thermally stimulated currents in LDPE/Al2O3 nanocomposite. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Toronto, ON, Canada, 16–19 October 2016; pp. 611–614. [Google Scholar]

- Ishimoto, K.; Tanaka, T.; Ohki, Y.; Sekiguchi, Y.; Murata, Y. Thermally stimulated current in low-density polyethylene/MgO nanocomposite. On the mechanism of its superior dielectric properties. Electr. Eng. Jpn. 2011, 176, 1–7. [Google Scholar] [CrossRef]

| Material | Test temperature, °C | Peak time tp, s | Trap energy, eV |

|---|---|---|---|

| LDPE | 40 | – | – |

| 60 | (1–1.5) × 104 | 1.10 | |

| 80 | (5–6) × 102 | 1.09 | |

| LDPE/Al2O3 3 wt% nanocomposite | 40 | – | – |

| 60 | (2–3) × 104 | 1.14 | |

| 80 | (2–3) × 103 | 1.14 |

| Material | Test temperature, °C | Electric field for ADC appearance, kV/mm | ADC peak, A/mm2 | ADC time peak, s |

|---|---|---|---|---|

| LDPE | 40 | – | – | – |

| 60 | – | – | – | |

| 80 | 20–60 | (2.1–5.6) × 10−14 | 170–230 | |

| LDPE/Al2O3 3 wt% nanocomposite | 40 | – | – | – |

| 60 | 25–35 | (2.5–6.0) × 10−16 | 4350–5830 | |

| 80 | 25–47.5 | (0.1–1.3) × 10−14 | 580–1370 |

| Conduction Model | Calculated Parameters | LDPE | LDPE/Al2O3 3 wt% | ||||

|---|---|---|---|---|---|---|---|

| 40 °C | 60 °C | 80 °C | 40 °C | 60 °C | 80 °C | ||

| J ∝ Em | m | 2.33 | 2.08 | 1.34/3.72 | 5.23 | 5.49 | 5.75 |

| Schottky | εr | 3.52 | 3.60 | 6.05/1.30 | 0.73 | 0.59 | 0.47 |

| Poole–Frenkel | εr | 11.3 | 13.1 | 91.7/2.43 | 1.12 | 0.88 | 0.69 |

| Material | LDPE | LDPE/Al2O3 3 wt% | ||||

|---|---|---|---|---|---|---|

| Temperature, °C | 40 | 60 | 80 | 40 | 60 | 80 |

| λ, nm | 1.41 | 1.51 | 1.76 | 5.17 | 6.30 | 6.99 |

| µθ0, m2V−1s−1 | 3.14 × 10−16 | 1.01 × 10−15 | 1.42 × 10−15 | 1.64 × 10−18 | 2.31 × 10−18 | 4.07 × 10−18 |

| Material | λ, nm | Reference |

|---|---|---|

| LLDPE | 2.8 | Nath et al. [26] |

| LDPE | 2–3 | Boudou and Guatavino [22] |

| Parameter | Unit | Temperature, °C | |

|---|---|---|---|

| 60 | 80 | ||

| Schottky injection barrier, φ | eV | 1.16 | |

| Effective mobility, µ | m2V−1s−1 | 5 × 10−14 | 1.5 × 10−13 |

| Trapping coefficient, ttr | s−1 | 0.1 | 0.2 |

| Deep trap density, Ntr | m−3 | 6.25 × 1020 | |

| De-trapping barrier height, φtr | eV | 1.0 | |

| Recombination coefficients, | |||

| reh, rehtr, retrh | m3s−1 | 8 × 10−22 | |

| retrhtr | 0 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoang, A.T.; Serdyuk, Y.V.; Gubanski, S.M. Charging and Discharge Currents in Low-Density Polyethylene and its Nanocomposite. Energies 2020, 13, 1518. https://doi.org/10.3390/en13061518

Hoang AT, Serdyuk YV, Gubanski SM. Charging and Discharge Currents in Low-Density Polyethylene and its Nanocomposite. Energies. 2020; 13(6):1518. https://doi.org/10.3390/en13061518

Chicago/Turabian StyleHoang, Anh T., Yuriy V. Serdyuk, and Stanislaw M. Gubanski. 2020. "Charging and Discharge Currents in Low-Density Polyethylene and its Nanocomposite" Energies 13, no. 6: 1518. https://doi.org/10.3390/en13061518

APA StyleHoang, A. T., Serdyuk, Y. V., & Gubanski, S. M. (2020). Charging and Discharge Currents in Low-Density Polyethylene and its Nanocomposite. Energies, 13(6), 1518. https://doi.org/10.3390/en13061518