Author Contributions

Conceptualization, J.N.; methodology, J.N.; investigation, Ł.N.; data curation, Ł.N.; writing—original draft preparation, Ł.N.; writing—review and editing, J.N.; visualization, Ł.N.; supervision, J.N. All authors have read and agreed to the published version of the manuscript.

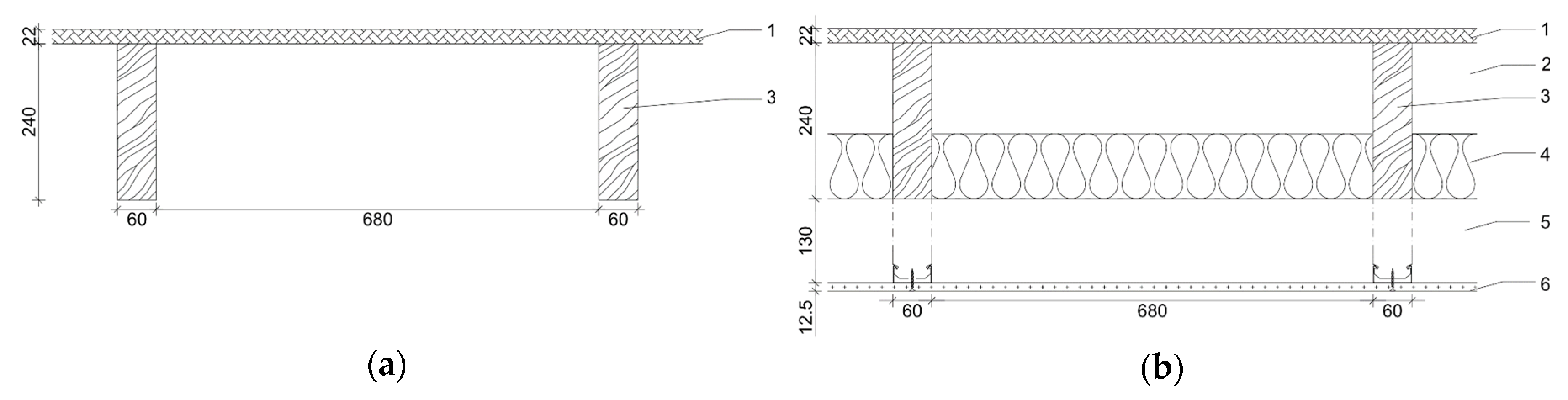

Figure 1.

Cross-sections of model 1a (a) and 1b (b) of the wooden frame floor. 1–OSB board, 2–air gap, 3–wooden joints, 4–mineral wool ρ = 12 kg/m3, 5–air gap, 6–plaster board.

Figure 1.

Cross-sections of model 1a (a) and 1b (b) of the wooden frame floor. 1–OSB board, 2–air gap, 3–wooden joints, 4–mineral wool ρ = 12 kg/m3, 5–air gap, 6–plaster board.

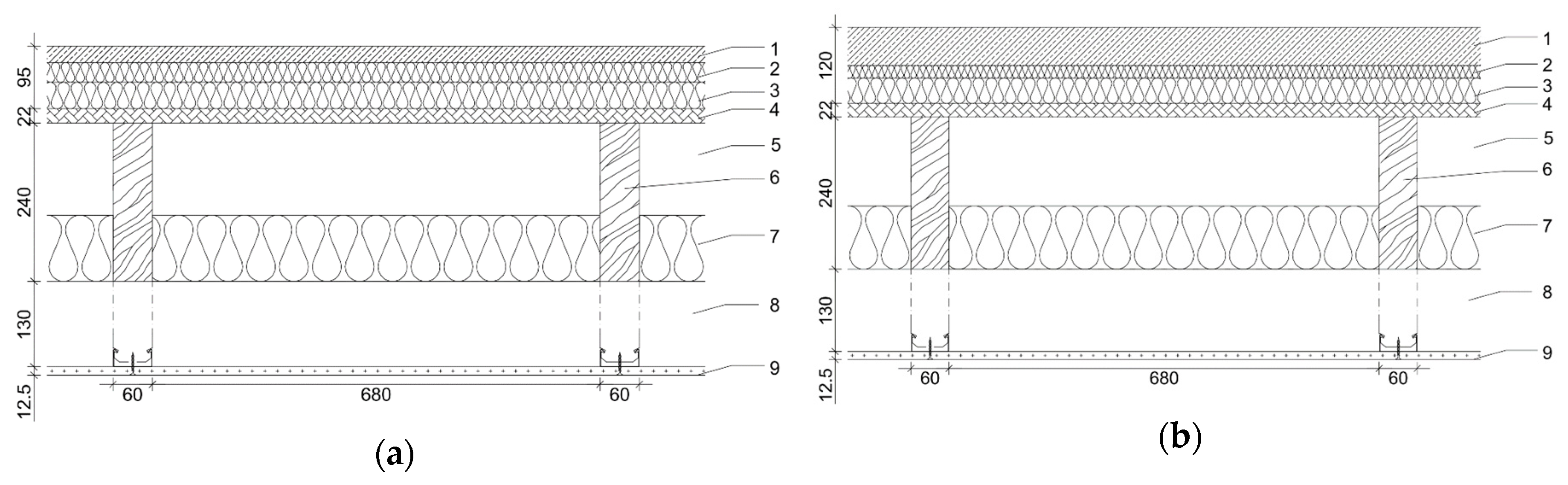

Figure 2.

Cross-sections of model 1c (a) and 1d (b) of the wooden frame floor. 1–self-leveling screed, 2–mineral wool ρ = 150 kg/m3, 3–mineral wool ρ = 107 kg/m3, 4–OSB board, 5–air gap, 6–wooden joints, 7–mineral wool ρ = 12 kg/m3, 8–air gap, 9–plaster board.

Figure 2.

Cross-sections of model 1c (a) and 1d (b) of the wooden frame floor. 1–self-leveling screed, 2–mineral wool ρ = 150 kg/m3, 3–mineral wool ρ = 107 kg/m3, 4–OSB board, 5–air gap, 6–wooden joints, 7–mineral wool ρ = 12 kg/m3, 8–air gap, 9–plaster board.

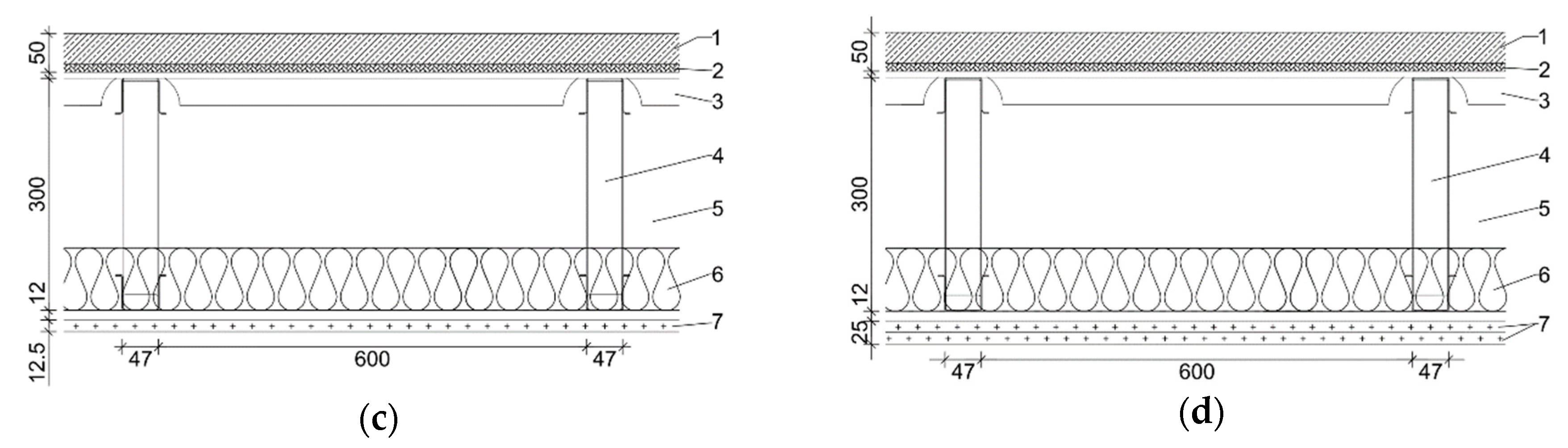

Figure 3.

Cross-sections of model 1e (a) and 1f (b) of the wooden frame floor. 1 – dry screed board, 2 – mineral wool ρ = 150 kg/m3, 3 – expanded clay aggregate, 4 – OSB board, 5 – air gap, 6 – mineral wool ρ = 12 kg/m3, 7 – air gap, 8 – plaster board.

Figure 3.

Cross-sections of model 1e (a) and 1f (b) of the wooden frame floor. 1 – dry screed board, 2 – mineral wool ρ = 150 kg/m3, 3 – expanded clay aggregate, 4 – OSB board, 5 – air gap, 6 – mineral wool ρ = 12 kg/m3, 7 – air gap, 8 – plaster board.

Figure 4.

Basic construction of the wooden floor (model 1a) in a test facility.

Figure 4.

Basic construction of the wooden floor (model 1a) in a test facility.

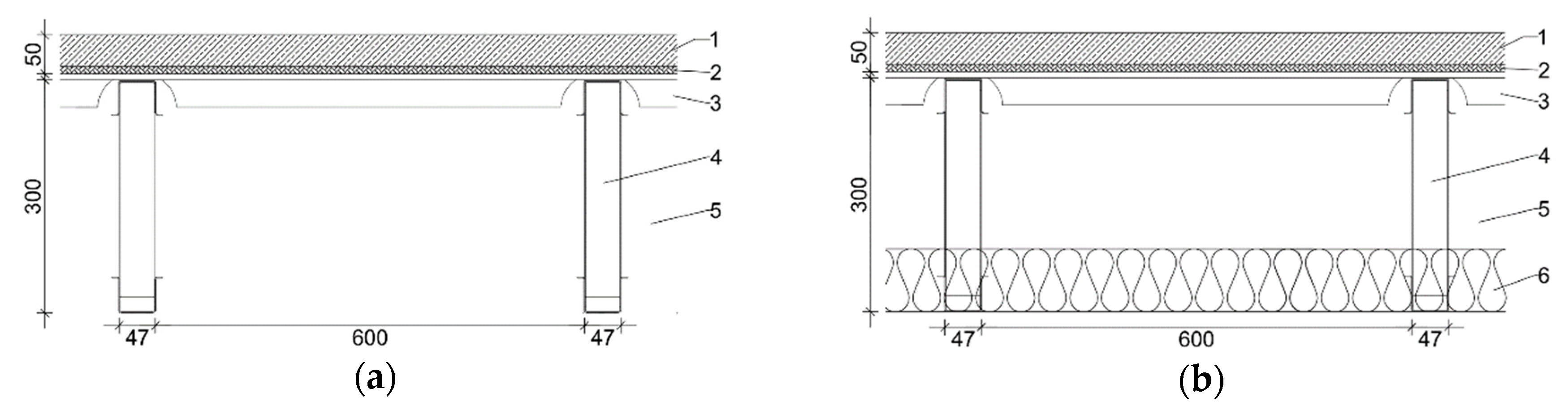

Figure 5.

Cross-sections of a metal frame floor: (a) Basic construction (model 2a); (b) Construction filled with a glass wool (model 2b); (c) Construction with a single plasterboard (model 2c); (d) Construction with a double plasterboard. 1 – concrete slab, 2 – wood-fiber insulating board, 3 – profiled sheet, 4 – steel trusses, 5 – air gap, 6 – glass wool ρ = 12 kg/m3, 7 – plasterboard.

Figure 5.

Cross-sections of a metal frame floor: (a) Basic construction (model 2a); (b) Construction filled with a glass wool (model 2b); (c) Construction with a single plasterboard (model 2c); (d) Construction with a double plasterboard. 1 – concrete slab, 2 – wood-fiber insulating board, 3 – profiled sheet, 4 – steel trusses, 5 – air gap, 6 – glass wool ρ = 12 kg/m3, 7 – plasterboard.

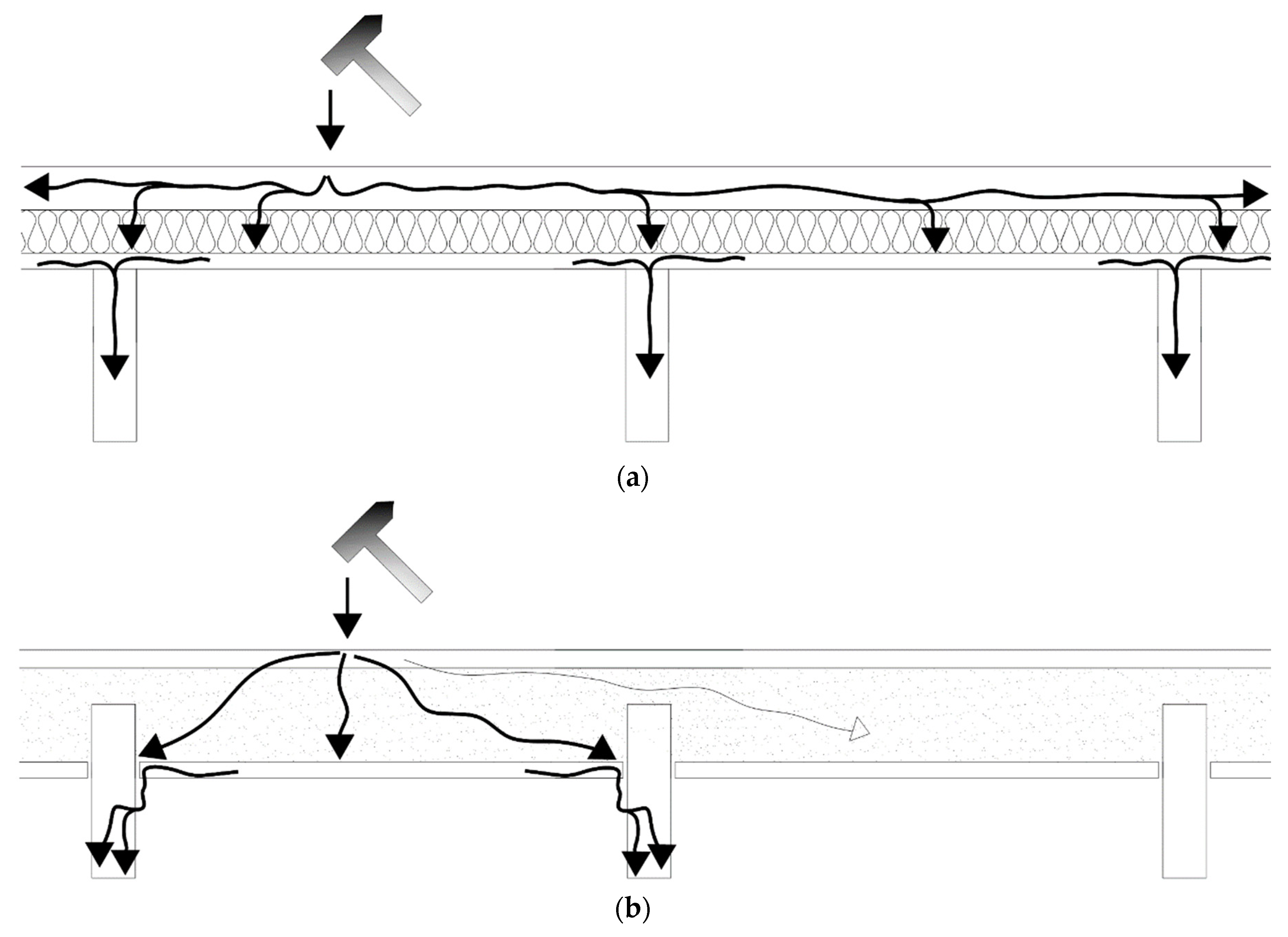

Figure 6.

Vertical cross-section of the test facility.

Figure 6.

Vertical cross-section of the test facility.

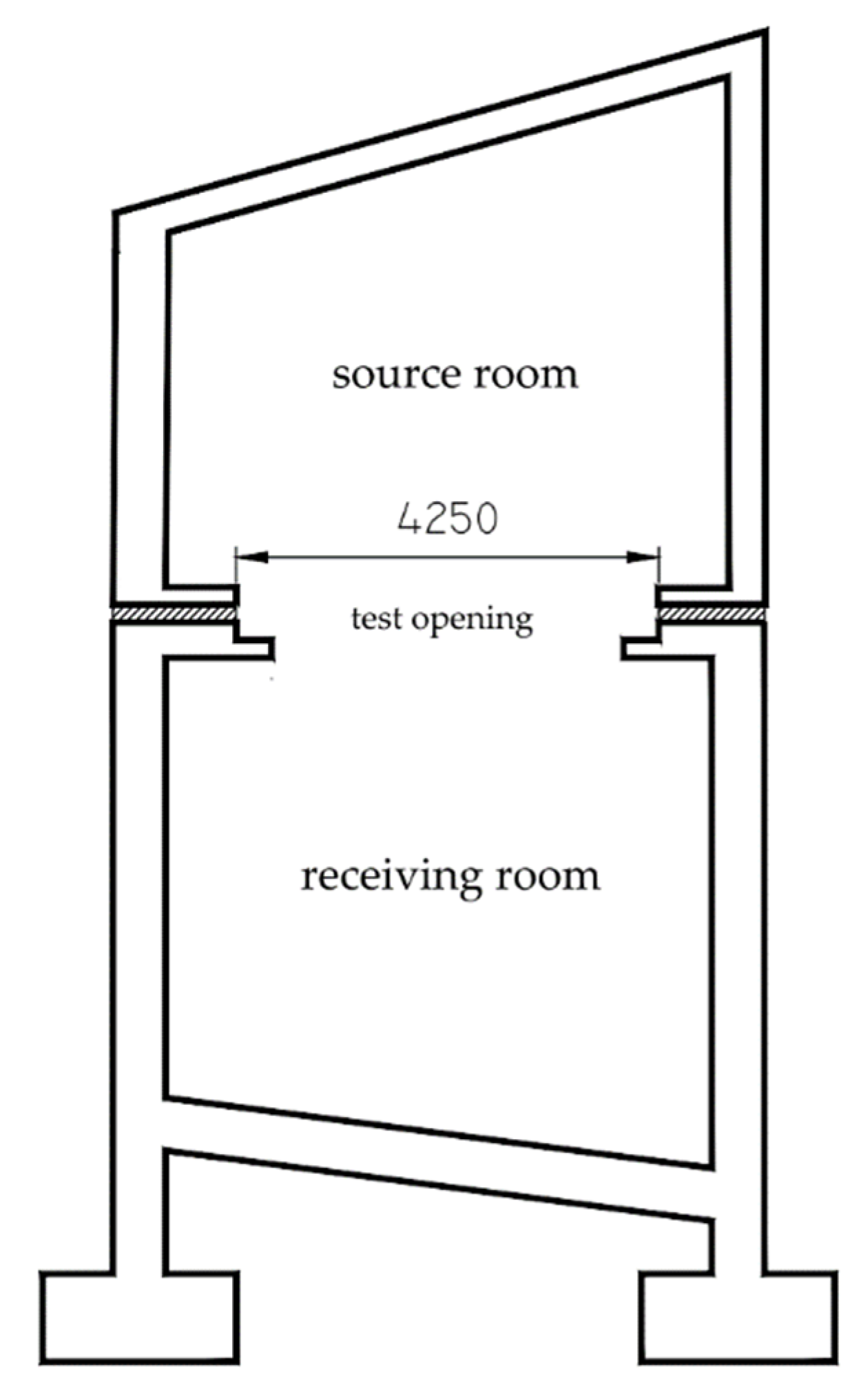

Figure 7.

Airborne (a) and impact (b) sound insulation test results of the wooden floor (models 1a and 1b).

Figure 7.

Airborne (a) and impact (b) sound insulation test results of the wooden floor (models 1a and 1b).

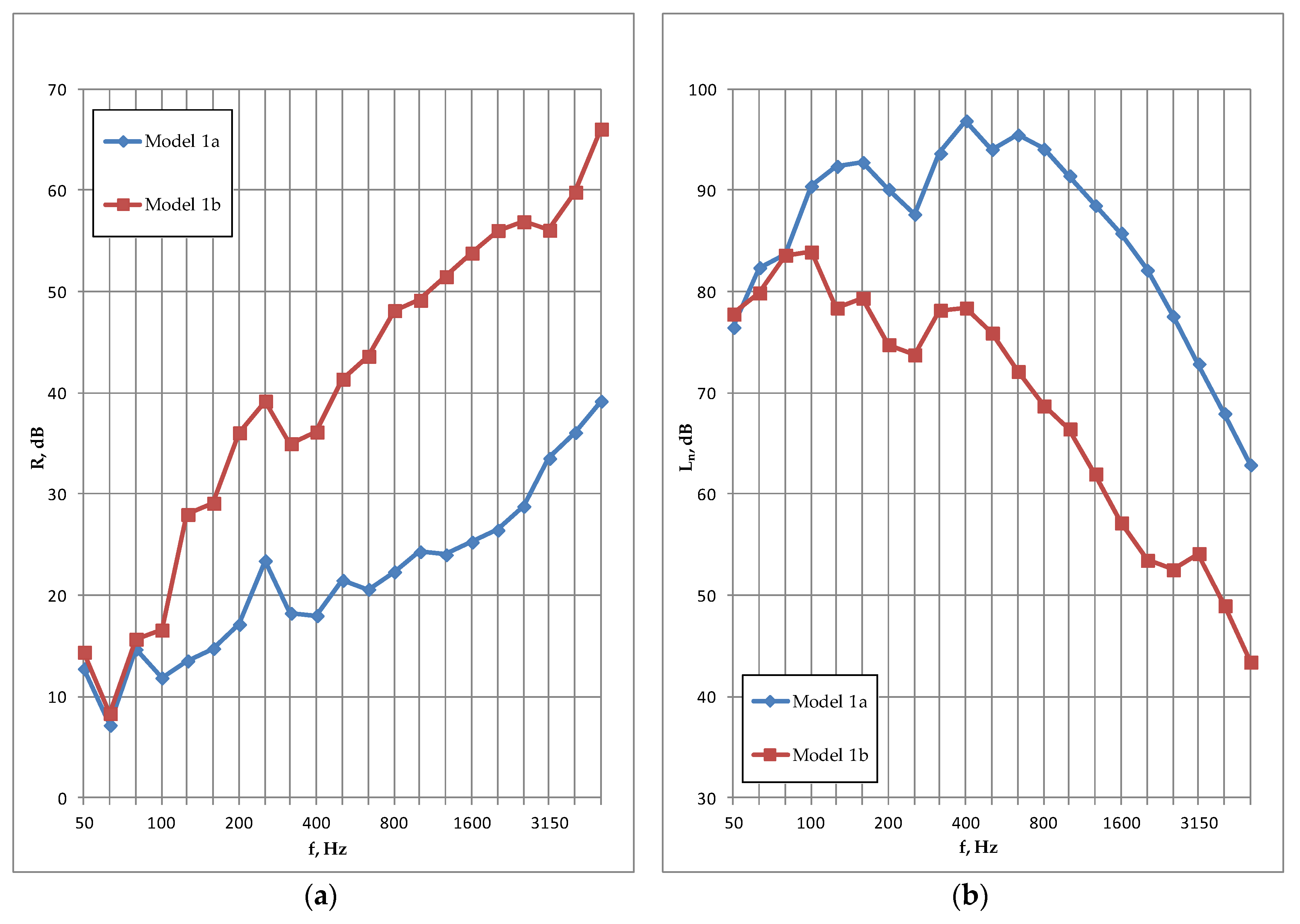

Figure 8.

Airborne (a) and impact (b) sound insulation test results of models 1c and 1d of the wooden floor compared to the basic construction (model 1b).

Figure 8.

Airborne (a) and impact (b) sound insulation test results of models 1c and 1d of the wooden floor compared to the basic construction (model 1b).

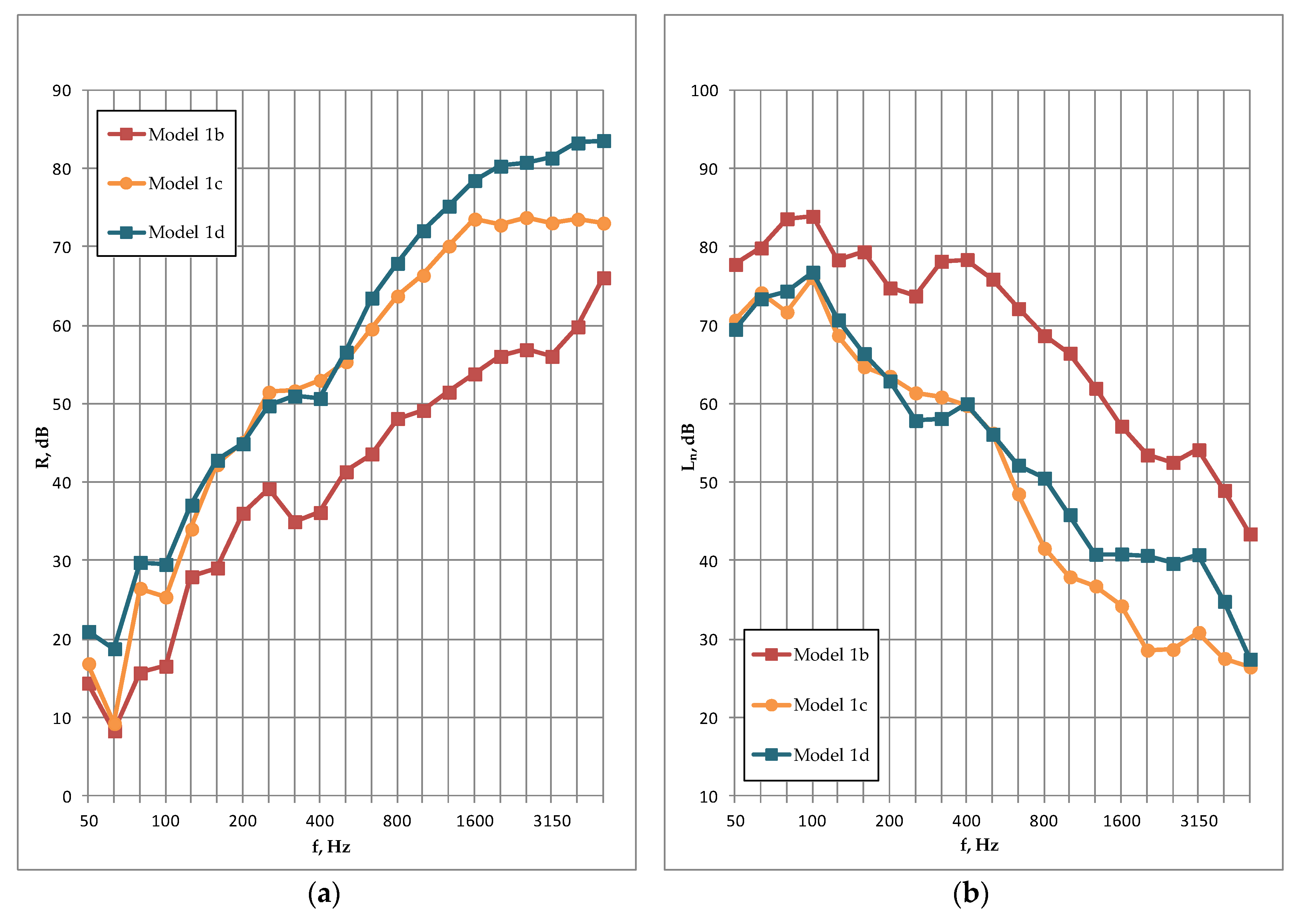

Figure 9.

Structural paths of sound transmission in the case of: (a) Heavy floating floor with a concrete slab on the top; (b) Lightweight floating floor built with dry-screed boards and expanded clay aggregate.

Figure 9.

Structural paths of sound transmission in the case of: (a) Heavy floating floor with a concrete slab on the top; (b) Lightweight floating floor built with dry-screed boards and expanded clay aggregate.

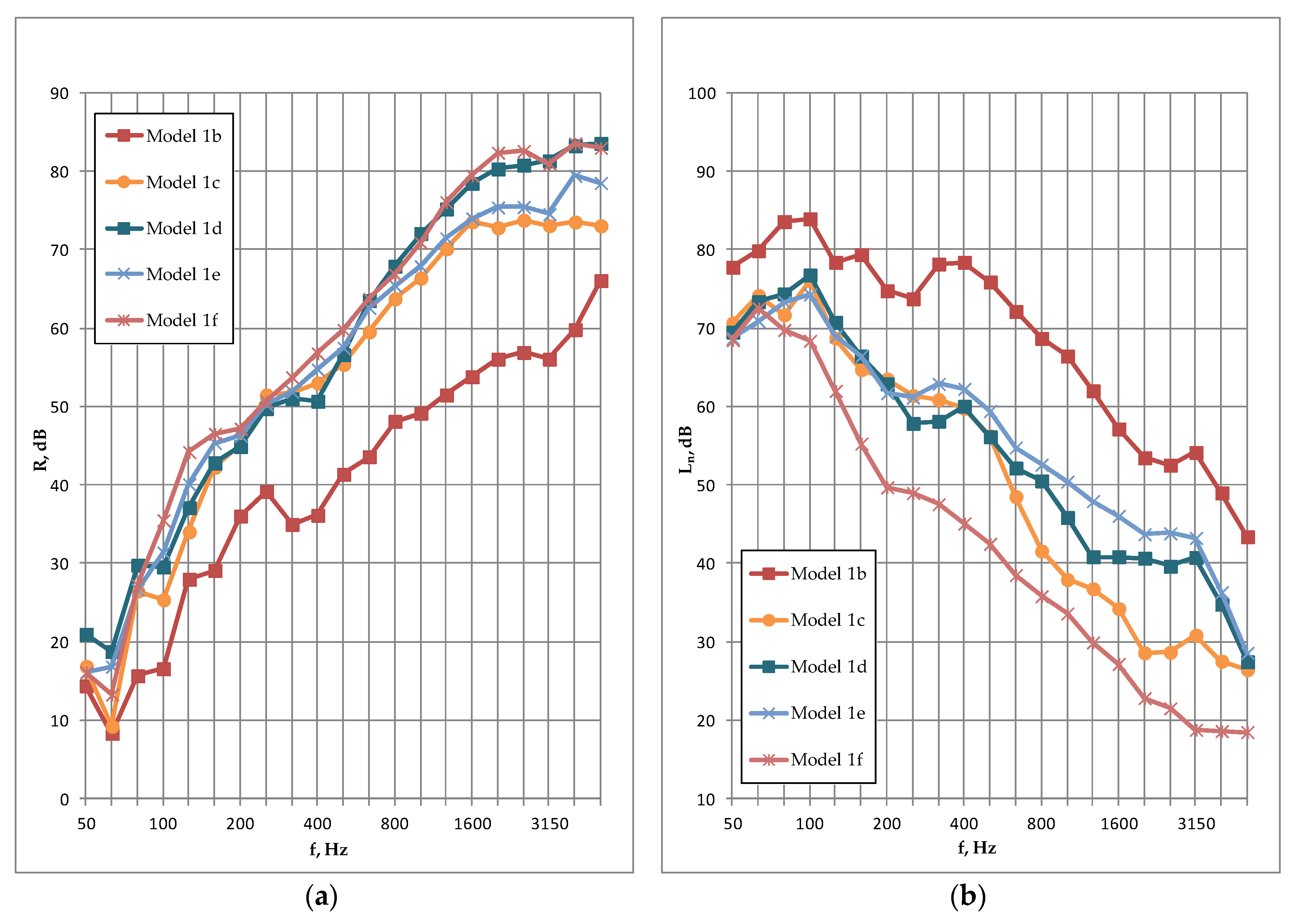

Figure 10.

Airborne (a) and impact (b) sound insulation test results of all models of the wooden floor compared to the basic construction (model 1b).

Figure 10.

Airborne (a) and impact (b) sound insulation test results of all models of the wooden floor compared to the basic construction (model 1b).

Figure 11.

Airborne (a) and impact (b) sound insulation test results of a metal frame floor.

Figure 11.

Airborne (a) and impact (b) sound insulation test results of a metal frame floor.

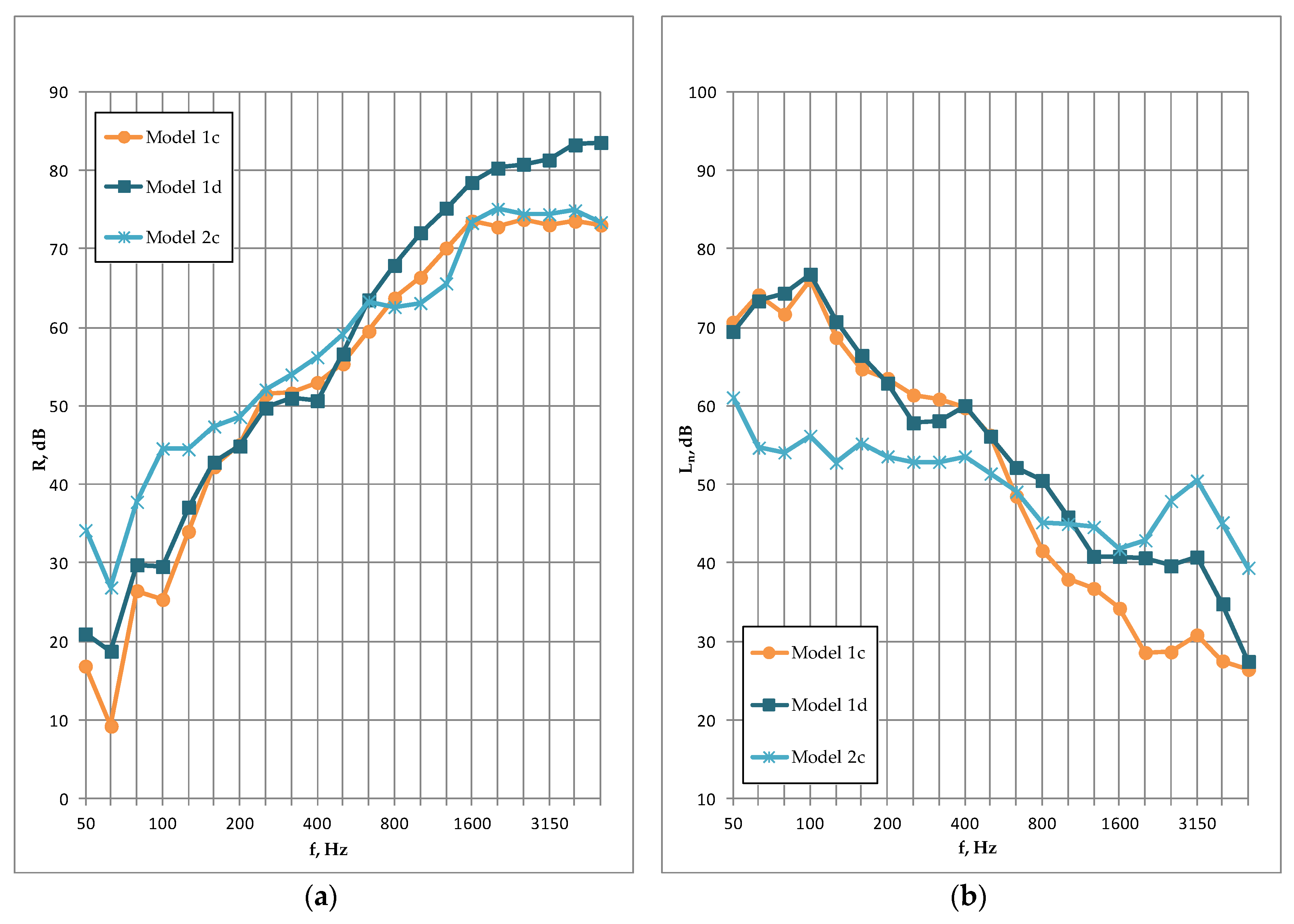

Figure 12.

Airborne (a) and impact (b) sound insulation test results of both floor structures.

Figure 12.

Airborne (a) and impact (b) sound insulation test results of both floor structures.

Table 1.

Specification of the wood frame floors (models 1a–d).

Table 1.

Specification of the wood frame floors (models 1a–d).

| Layers (from top to bottom) | Model 1a | Model 1b | Model 1c | Model 1d |

|---|

| Self-leveling screed, mm | – | – | 25 | 60 |

| Polyethylene film, mm | – | – | 0.5 | 0.5 |

| Mineral wool (2) (150 kg/m3), mm | – | – | 30 | 20 |

| Mineral wool (3) (107 kg/m3), mm | – | – | 40 | 40 |

| OSB board, mm | 22 | 22 | 22 | 22 |

| Ceiling cavity, mm | 240 | 140 | 140 | 140 |

| Mineral wool (7) (12 kg/m3), mm | – | 100 | 100 | 100 |

| Air plenum, mm | – | 130 | 130 | 130 |

| Plasterboard, mm | – | 12.5 | 12.5 | 12.5 |

Table 2.

Specification of the wood frame floors (models 1e–f).

Table 2.

Specification of the wood frame floors (models 1e–f).

| Layers (from top to bottom) | Model 1e | Model 1f |

|---|

| Dry screed-board, mm | 22 | 22 |

| Mineral wool (2) (150 kg/m3), mm | – | 20 |

| Expanded clay aggregate, mm | 130 | 130 |

| OSB board, mm | 22 | 22 |

| Ceiling cavity, mm | 38 | 38 |

| Mineral wool (6) (12 kg/m3), mm | 100 | 100 |

| Air plenum, mm | 130 | 130 |

| Plasterboard, mm | 12.5 | 12.5 |

Table 3.

Specification of the metal frame floors (models 2a–d).

Table 3.

Specification of the metal frame floors (models 2a–d).

| Layers (from Top to Bottom) | Model 2a | Model 2b | Model 2c | Model 2d |

|---|

| Concrete slab, mm | 40 | 40 | 40 | 40 |

| Wood-fiber insulating board, mm | 10 | 10 | 10 | 10 |

| Profiled sheet, mm | 1.3 | 1.3 | 1.3 | 1.3 |

| Ceiling cavity, mm | 300 | 200 | 200 | 200 |

| Mineral wool (12 kg/m3), mm | – | 100 | 100 | 100 |

| Air plenum, mm | – | – | 12 | 12 |

| Plasterboard, mm | – | – | 12.5 | 2 × 12.5 |

Table 4.

Specification of the resilient materials used in all floating floors.

Table 4.

Specification of the resilient materials used in all floating floors.

| Floor Model | Thickness, mm | Dynamic Stiffness, MN/m3 |

|---|

| Model 1c, Mineral wool (2) | 30 | 11 |

| Model 1c, Mineral wool (3) | 40 | 39 |

| Model 1d, Mineral wool (2) | 20 | 13 |

| Model 1d, Mineral wool (3) | 40 | 39 |

| Model 1f, Mineral wool (2) | 20 | 13 |

| Models 2a–d, Wood fiber (2) | 10 | 70 |

Table 5.

Single-number quantities of wooden frame floors.

Table 5.

Single-number quantities of wooden frame floors.

| Index | Model 1a | Model 1b | Model 1c | Model 1d | Model 1e | Model 1f |

|---|

| Rw, dB | 24 | 44 | 57 | 58 | 59 | 61 |

| C, dB | −1 | −2 | −5 | −3 | −2 | −1 |

| C50−5000, dB | 0 | −4 | −12 | −6 | −8 | −12 |

| Ln,w, dB | 92 | 73 | 59 | 60 | 60 | 50 |

| CI, dB | −3 | 0 | 4 | 3 | 2 | 5 |

| CI,50-3150, dB | −3 | 2 | 6 | 6 | 4 | 11 |

Table 6.

Single-number quantities of a metal frame floor.

Table 6.

Single-number quantities of a metal frame floor.

| Index | Model 2a | Model 2b | Model 2c | Model 2d |

|---|

| Rw, dB | 42 | 49 | 62 | 63 |

| C, dB | −2 | −2 | −1 | −2 |

| C50−5000, dB | −1 | −1 | −3 | −4 |

| Ln,w, dB | 81 | 70 | 53 | 49 |

| CI, dB | −7 | −3 | −4 | −5 |

| CI,50−3150, dB | −7 | −3 | −2 | −3 |

Table 7.

Single-number quantities of the selected floor structures.

Table 7.

Single-number quantities of the selected floor structures.

| Index | Model 1c | Model 1d | Model 2c |

|---|

| Rw, dB | 57 | 58 | 62 |

| C, dB | −5 | −3 | −1 |

| C50−5000, dB | −12 | −6 | −3 |

| Ln,w, dB | 59 | 60 | 53 |

| CI, dB | 4 | 3 | −4 |

| CI,50−3150, dB | 6 | 6 | −2 |